ABS MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 600 of 1146

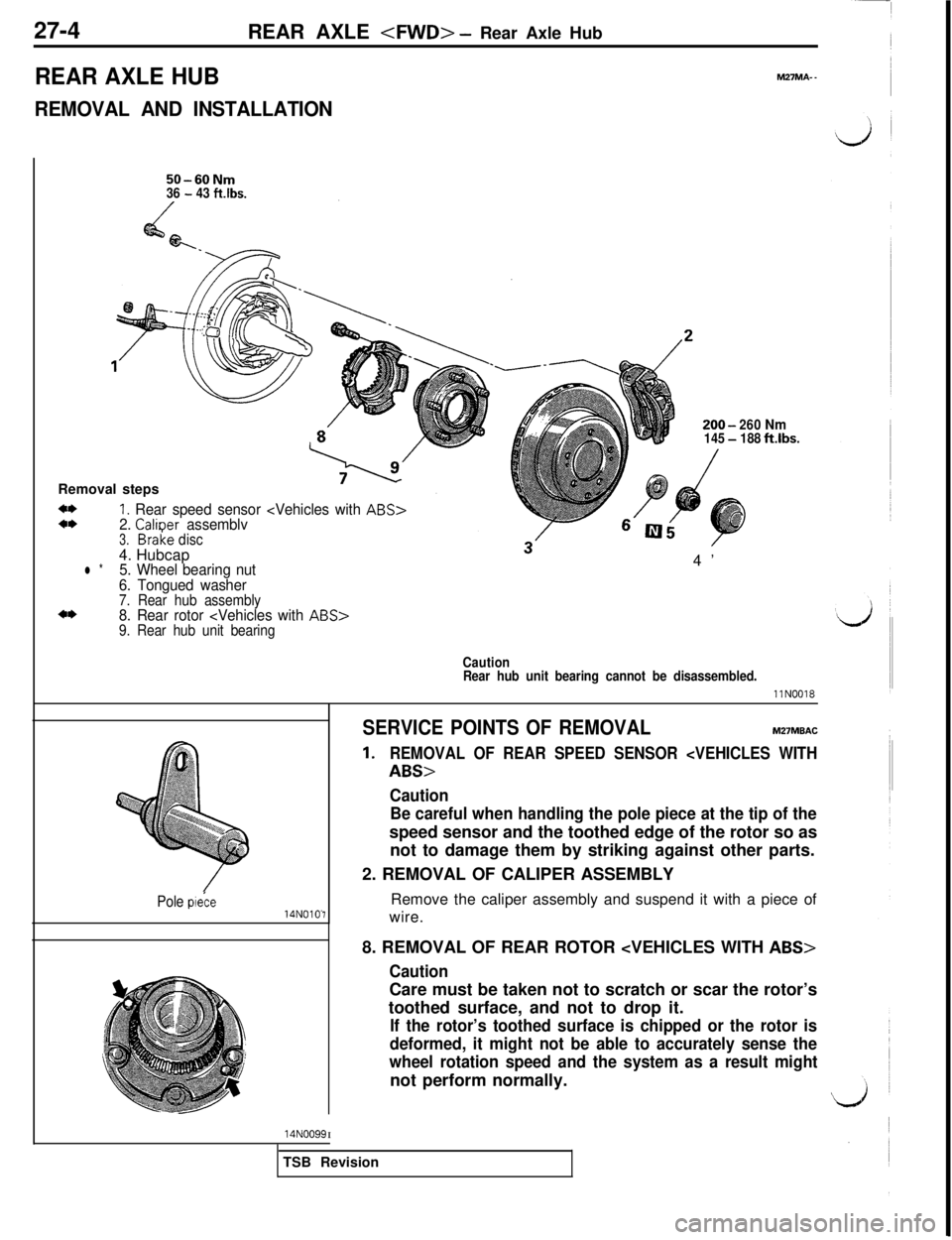

27-4

REAR AXLE

REAR AXLE HUB

REMOVAL AND INSTALLATION

M27MA- -

50-60Nm36 - 43 ftlbs.

200-260Nm145-188ftibs.Removal steps

4*4*1. Rear speed sensor

l *5. Wheel bearing nut4’6. Tongued washer7. Rear hub assembly4*8. Rear rotor

Caution

Rear hub unit bearing cannot be disassembled.

llN0018

Pole p&e14NOlO-7

SERVICE POINTS OF REMOVALM27MBAC

1.REMOVAL OF REAR SPEED SENSOR

Caution

Be careful when handling the pole piece at the tip of thespeed sensor and the toothed edge of the rotor so as

not to damage them by striking against other parts.

2. REMOVAL OF CALIPER ASSEMBLY

Remove the caliper assembly and suspend it with a piece of

wire.

8. REMOVAL OF REAR ROTOR

CautionCare must be taken not to scratch or scar the rotor’s

toothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result mightnot perform normally.

14NOO99ITSB Revision

Page 652 of 1146

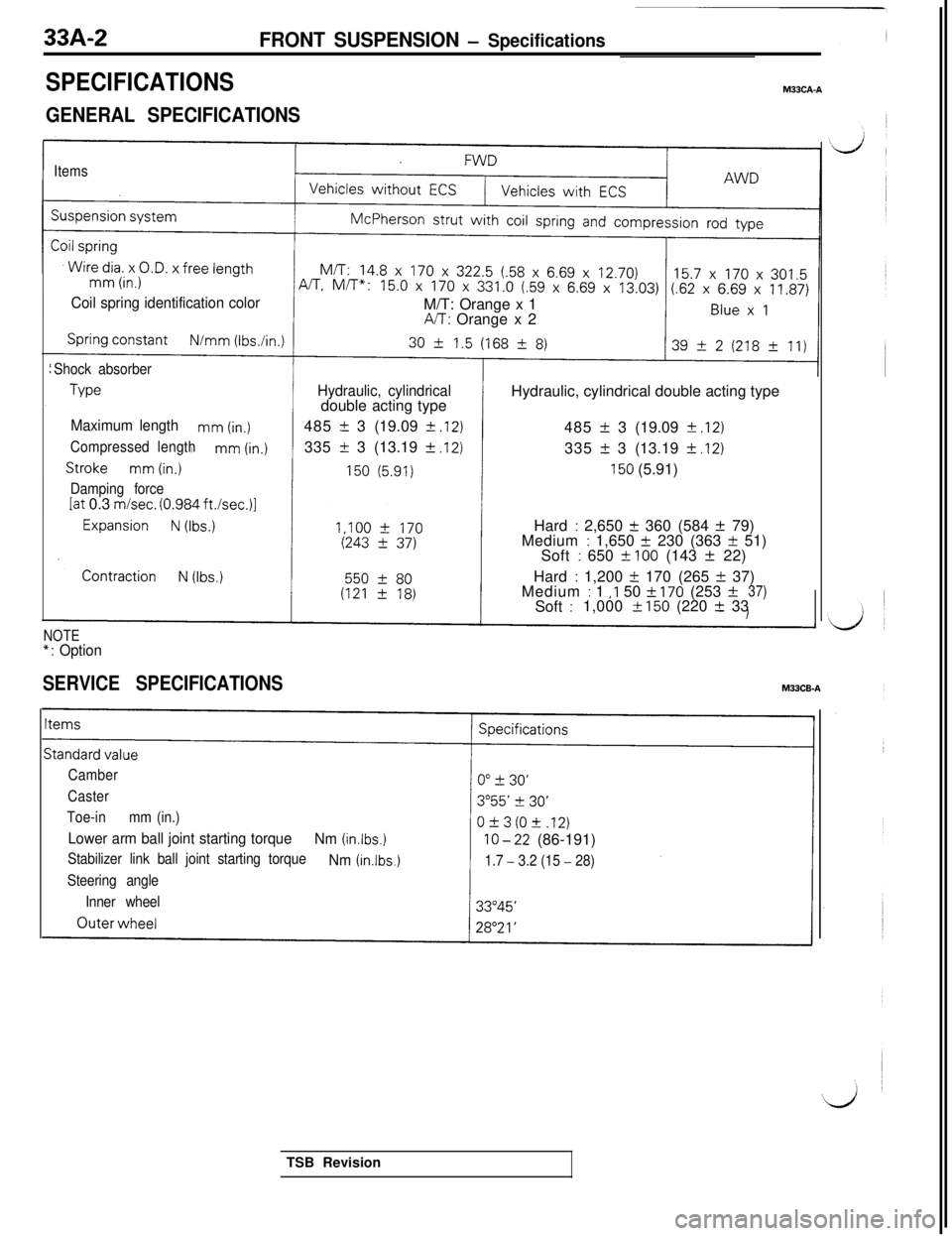

33A-2FRONT SUSPENSION - Specifications

SPECIFICATIONSM33CA-A

GENERAL SPECIFICATIONS

Items

Coil spring identification colorM/T: Orange x 1

ATT: Orange x 2

Shock absorber

Type

Maximum length

Compressed length

Damping force

[at 0.3 m/set. (0.984 ft./set.)]

Hydraulic, cylindricaldouble acting type

485 + 3 (19.09

f .12)335

I 3 (13.19 + .12)Hydraulic, cylindrical double acting type

485

k 3 (19.09 + .12)335 2 3 (13.19 +

.12)

150 (5.91)

NOTE*: OptionHard

: 2,650 + 360 (584 + 79)

Medium : 1,650 t 230 (363 ?I 51)

Soft : 650 f 100 (143 + 22)

Hard

: 1,200 + 170 (265 * 37)

Medium : 1 ,I 50 k 170 (253 +37)Soft :1,000 z!z 150 (220 + 33

SERVICE SPECIFICATIONSM33CB-A

Camber

Caster

Toe-inmm (in.)

Lower arm ball joint starting torque

Nm (in.lbs.)IO-22 (86-191)

Stabilizer link ball joint starting torqueNm (in.lbs.)1.7 - 3.2 (15 - 28)

Steering angle

Inner wheelTSB Revision

Page 653 of 1146

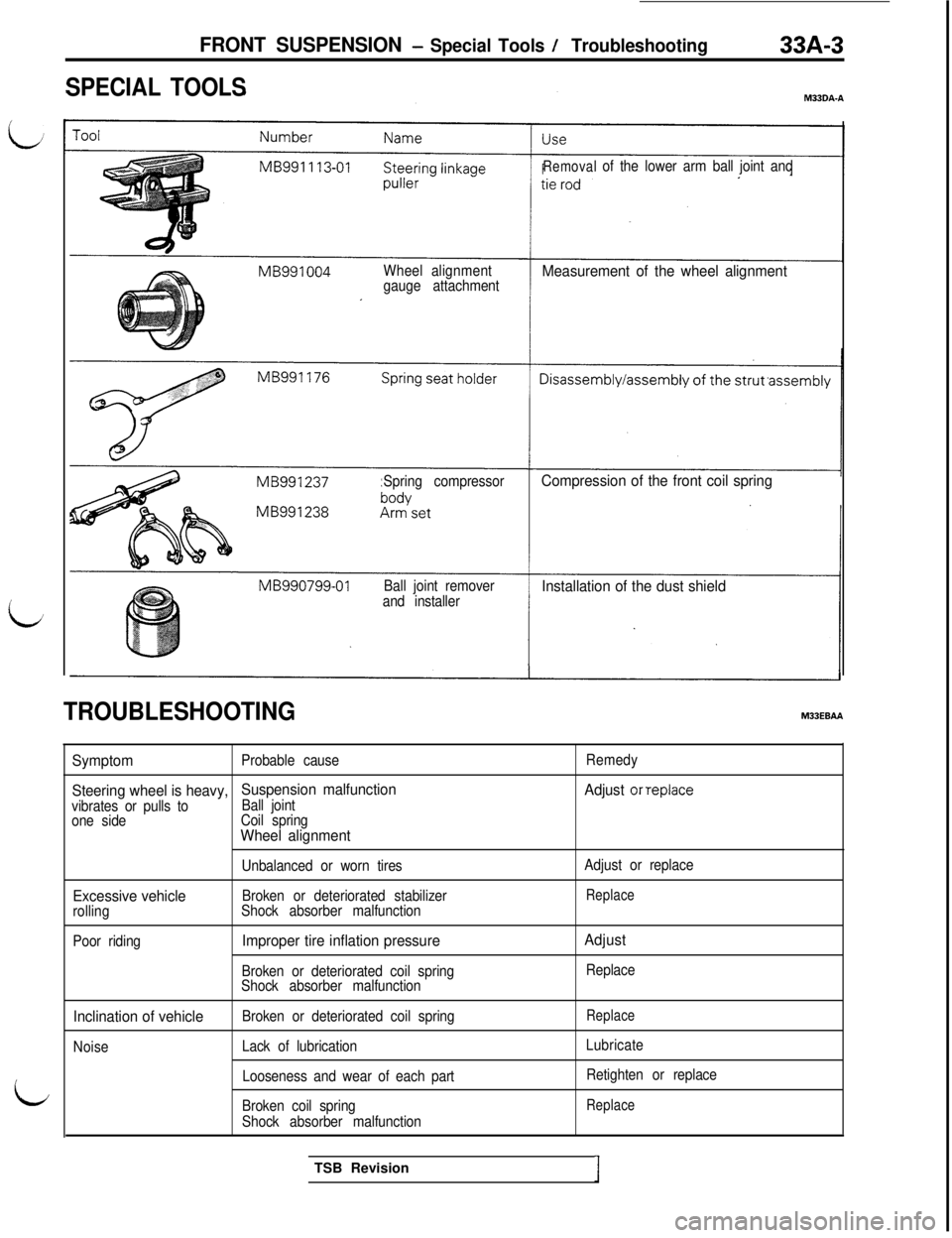

FRONT SUSPENSION - Special Tools / Troubleshooting

SPECIAL TOOLS

L

L

Removalof the lower arm ball joint and

Wheel alignment

gauge attachment

Measurement of the wheel alignment

Spring compressorCompression of the front coil spring

MB990799-01Ball joint remover

and installerInstallation of the dust shield

TROUBLESHOOTINGM33EBAA

SymptomProbable causeRemedy

Steering wheel is heavy,Suspension malfunctionvibrates or pulls toBall joint

Adjust orreplace

one sideCoil springWheel alignment

Unbalanced or worn tiresAdjust or replace

Excessive vehicleBroken or deteriorated stabilizer

rollingShock absorber malfunctionReplace

Poor ridingImproper tire inflation pressureAdjust

Broken or deteriorated coil spring

Shock absorber malfunctionReplace

Inclination of vehicleBroken or deteriorated coil springReplace

NoiseLack of lubricationLubricate

Looseness and wear of each partRetighten or replace

Broken coil spring

Shock absorber malfunction

ReplaceTSB Revision

I

Page 655 of 1146

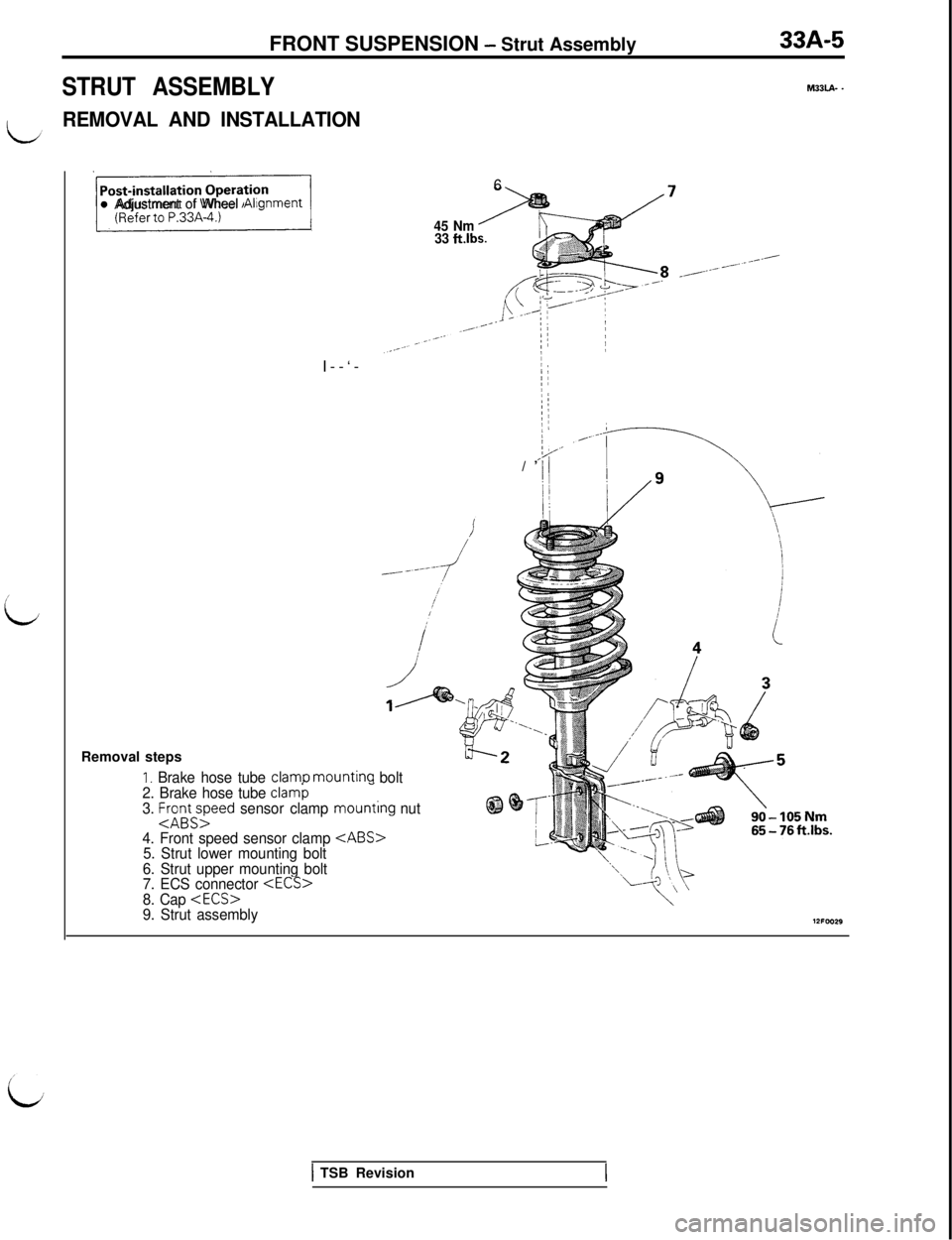

FRONT SUSPENSION - Strut Assembly33A-5

STRUT ASSEMBLY

IREMOVAL AND INSTALLATION

‘=Il Adjustment of Wheel Alignment

M33lA- *

6

45 Nm

2

33 ft.lbs.4!

AI$

c3liI7 // ;I jI ’II ;/ ~I: /I /j j

1

-r11Ii /’ I--‘-

Removal steps

1. Brake hose tube clamo mountina bolt

2. Brake hose tube clam;-,3. Fr;;tSs;eed sensor clamp mountmg nut

4. Front speed sensor clamp

tABS>5. Strut lower mounting bolt

6. Strut upper mounting bolt

7. ECS connector

8. Cap

9. Strut assembly

1 TSB Revision

Page 657 of 1146

FRONT SUSPENSION - Strut Assembly33A-7

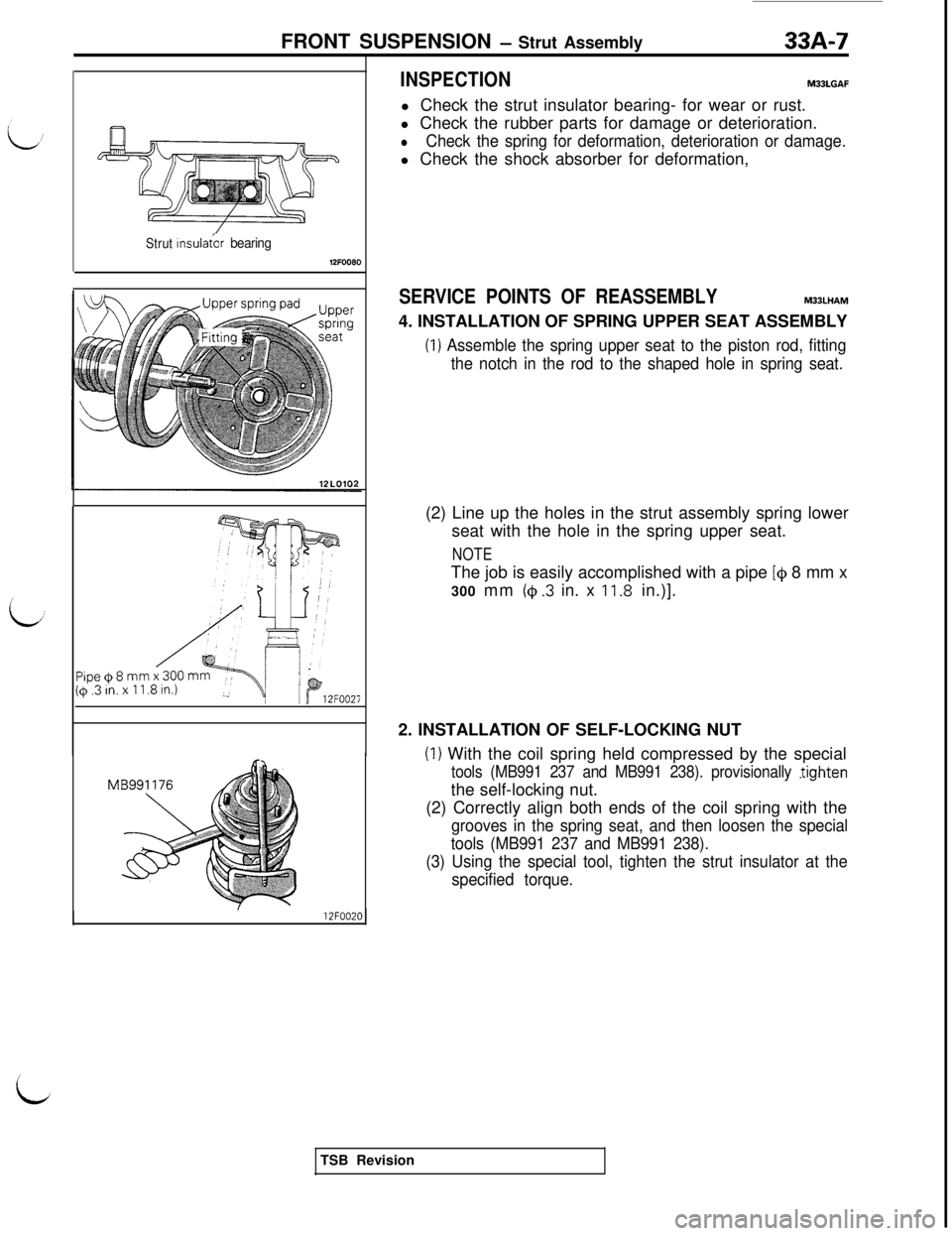

INSPECTIONM33LGAFl Check the strut insulator bearing- for wear or rust.

l Check the rubber parts for damage or deterioration.

lCheck the spring for deformation, deterioration or damage.l Check the shock absorber for deformation,

Strutmsulatkx bearing

12FOO80

SERVICE POINTS OF REASSEMBLYM33UlAM

4. INSTALLATION OF SPRING UPPER SEAT ASSEMBLY

(1) Assemble the spring upper seat to the piston rod, fitting

the notch in the rod to the shaped hole in spring seat.(2) Line up the holes in the strut assembly spring lower

seat with the hole in the spring upper seat.

NOTEThe job is easily accomplished with a pipe

[$I 8 mm x

300 mm

(4 .3 in. x 11.8 in.)].

2. INSTALLATION OF SELF-LOCKING NUT

(1) With the coil spring held compressed by the special

tools (MB991 237 and MB991 238). provisionally .tightenthe self-locking nut.

(2) Correctly align both ends of the coil spring with the

grooves in the spring seat, and then loosen the special

tools (MB991 237 and MB991 238).

(3) Using the special tool, tighten the strut insulator at the

specified torque.12FOO20

iTSB Revision

Page 664 of 1146

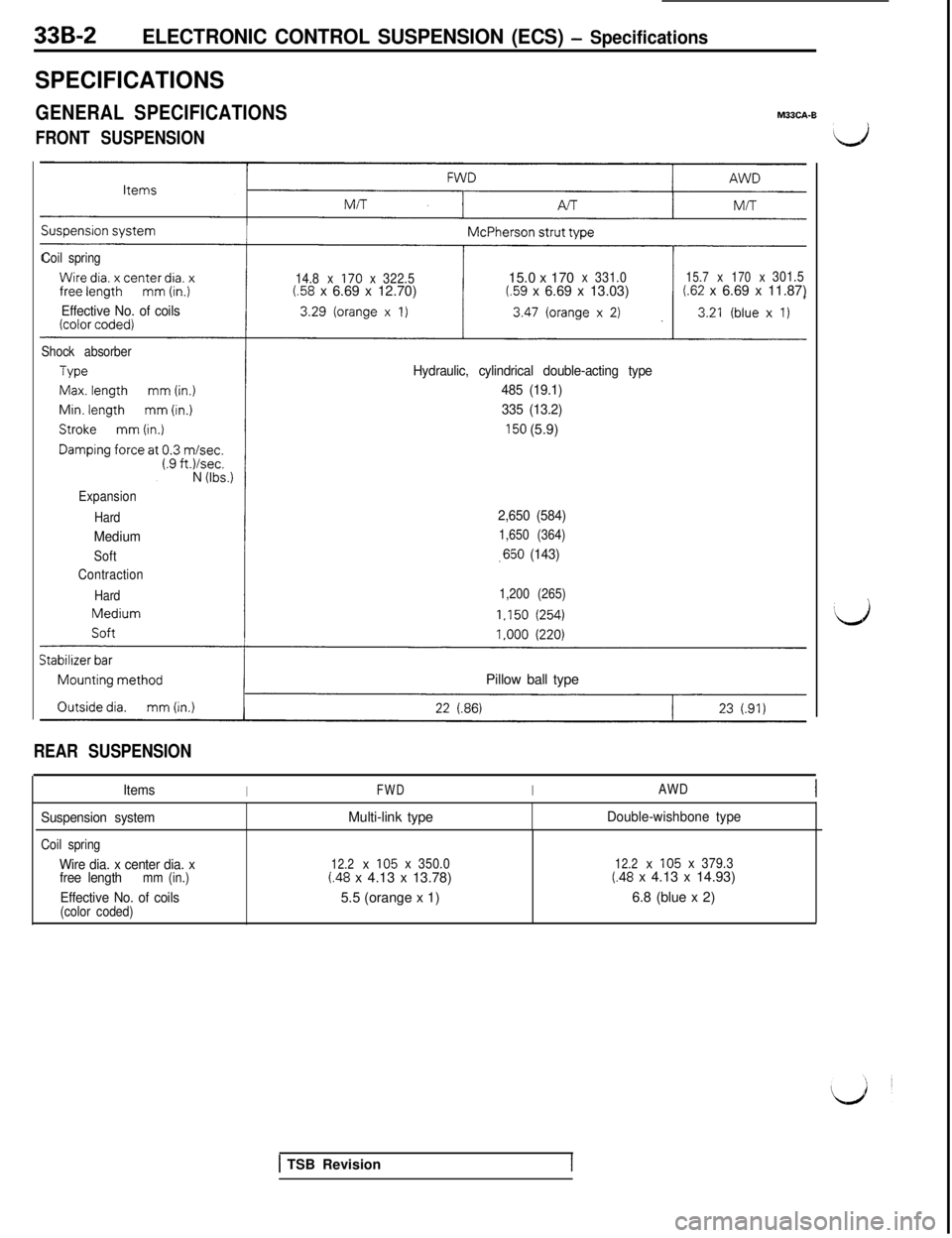

33B-2ELECTRONIC CONTROL SUSPENSION (ECS) - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

FRONT SUSPENSION

M33CA-B

Coil spring

Effective No. of coils

14.8x170x322.515.0 x 170x331.015.7x170x301.5(.58 x 6.69 x 12.70)(.59 x 6.69 x 13.03)(.62 x 6.69 x 11.87)

Shock absorber

TypeHydraulic, cylindrical double-acting type

485 (19.1)

335 (13.2)

150 (5.9)

Expansion

Hard

Medium

Soft

Contraction

Hard

2,650 (584)

1,650 (364)

.650 (143)

1,200 (265)Pillow ball type

REAR SUSPENSION

ItemsIFWDIAWDI

Suspension systemMulti-link typeDouble-wishbone type

Coil spring

Wire dia. x center dia. x

free lengthmm (in.)

Effective No. of coils(color coded)

12.2x105x350.0(48 x 4.13 x 13.78)

5.5 (orange x 1)12.2x105x379.3(48 x 4.13 x 14.93)

6.8 (blue x 2)

1 TSB Revision

Page 665 of 1146

L

I

iJ

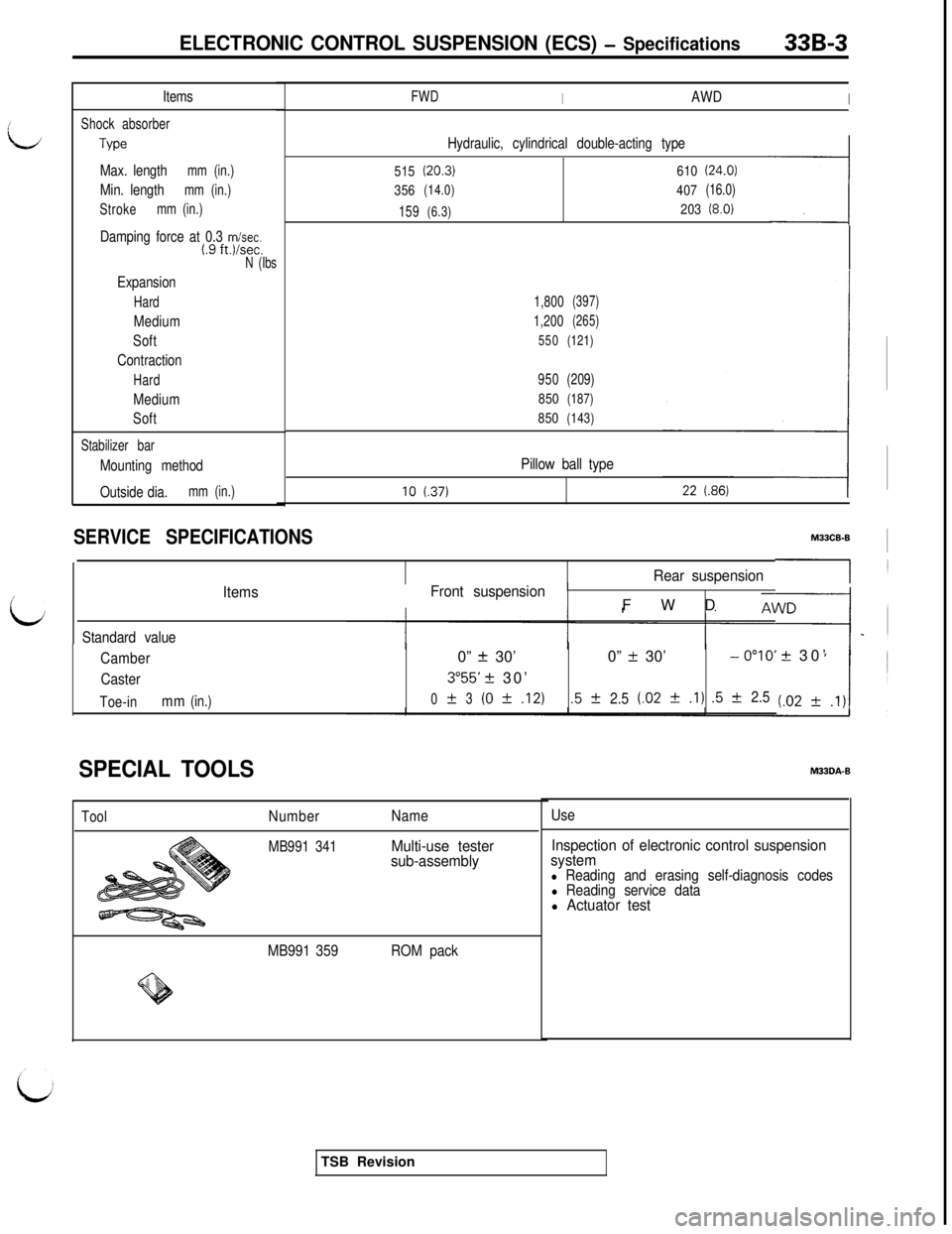

ELECTRONIC CONTROL SUSPENSION (ECS) - Specifications33B-3

Items

Shock absorber

Type

Max. lengthmm (in.)

Min. lengthmm (in.)

Strokemm (in.)

Damping force at 0.3 m/seeI.9 ft.)/sec.N (Ibs

Expansion

Hard

Medium

Soft

Contraction

Hard

Medium

Soft

Stabilizer bar

Mounting method

Outside dia.

mm (in.)FWD

IAWDI

Hydraulic, cylindrical double-acting type

515(20.3)610(24.0)

356(14.0)407(16.0)

159

(6.3)203(8.0)

1,800(397)

1,200(265)

550(121)

950(209)

850(187)

850(143)

10 (.37)

Pillow ball type

M33CB-B~SERVICE SPECIFICATIONS

Rear suspension1'FWDItemsFront suspension

Standard value

Camber0” + 30’0”

k 30’- O”10’ Ik 30’

Caster3”55’ t 30’

Toe-inmm(in.)0+3(0f.12).522.5(.02+.I).5k2.5

SPECIAL TOOLS

ToolNumber

MB991 341

Name

Multi-use tester

sub-assembly

MB991 359ROM packM33DA-B

Use

Inspection of electronic control suspension

system

l Reading and erasing self-diagnosis codesl Reading service datal Actuator testTSB Revision

Page 670 of 1146

33B-8ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting

III

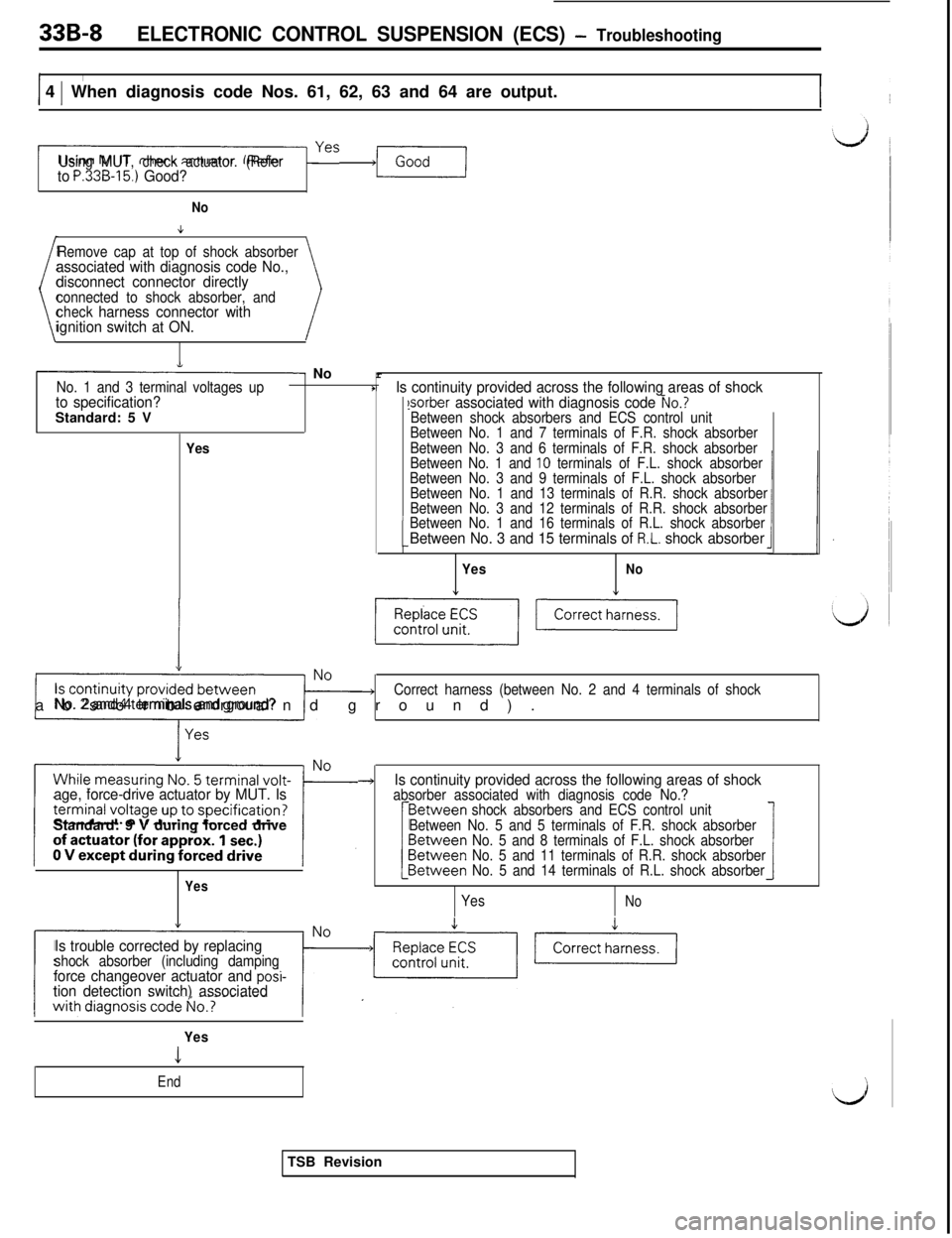

1 4 1 When diagnosis code Nos. 61, 62, 63 and 64 are output.

(-yesUsing MUT, check actuator. (Referto P.33B-15.) Good?

No

Remove cap at top of shock absorber

associated with diagnosis code No.,

disconnect connector directly

connected to shock absorber, and

checkharness connector with

ignition switch at ON.r

~...- NoNo. 1 and 3 terminal voltages upto specification?Standard: 5 V

YesIs continuity provided across the following areas of shock

Lsorber associated with diagnosis code No.?Between shock absorbers and ECS control unit

Between No. 1 and 7 terminals of F.R. shock absorber

Between No. 3 and 6 terminals of F.R. shock absorber

Between No. 1 and

10 terminals of F.L. shock absorber

Between No. 3 and 9 terminals of F.L. shock absorber

Between No. 1 and 13 terminals of R.R. shock absorber

Between No. 3 and 12 terminals of R.R. shock absorber

Between No. 1 and 16 terminals of R.L. shock absorber

Between No. 3 and 15 terminals of R.L. shock absorber1

YesNo

””

Is continuity provided between

rTi”’

Correct harness (between No. 2 and 4 terminals of shockabsorber and ground).No. 2 and 4 terminals and ground?

age, force-drive actuator by MUT. IsStandard: 9 V during forced drive

Yes

+Is continuity provided across the following areas of shockabsorber associated with diagnosis code No.?

shock absorbers and ECS control unit

Between No. 5 and 5 terminals of F.R. shock absorber

No. 5 and 8 terminals of F.L. shock absorber

No. 5 and 11 terminals of R.R. shock absorber

No. 5 and 14 terminals of R.L. shock absorber

I

YesNo

Is trouble corrected by replacingshock absorber (including dampingforce changeover actuator and POSI-tion detection switch) associated

Yes

1

EndTSB Revision

Page 675 of 1146

![MITSUBISHI 3000GT 1991 User Guide Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defect MITSUBISHI 3000GT 1991 User Guide Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defect](/img/19/57085/w960_57085-674.png)

Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defective*l Ride controls (pinching and bouncingcontrol, bad road detection control) sl:op.

21Steering angularvelocity sensor open-circuited*

l Anti-roll control stops.

24Vehicle speed sensor*nn open-crrcurtedl Steering stability controls (anti-roll, high

speed sensitive controls) and attitude

controls (anti-dive, anti-squat) stop.l Shock absorber damping force fixed

F. L. damping forcefl-~-~-j 11c$i;z;;Fr actuator

R. R. damping force

I /

64 j-jMJ-~-~-~ ~t$ec~Z$rn&ftYrrZ& /

NOTE(1)Control stop, warning indication and fixed damping force return to normal when the ignition switch is set to OFF.

When any of the problems marked* occurs, if no subsequent problem occurs (for example, when the problem IStransient) normal operation will be restored even if the ignition switch is not set to OFF.(2)Even if control stop warning indication and fixed damping force return to normal as described above, the

self-diagnosis code’is stored in the memory in the ECS control unrt.

(3)The self-diagnosis code can be force-cleared by use of the MUT or by stopping the power supply to the ECS controlunit. In addition

it is automatically cleared if the ON/OFF control of the ignition swatch is repeated 60 times after the

self-diagnosis code has been output, provided that no new self-diagnosis code is output during the period.TSB Revision

Page 677 of 1146

I,

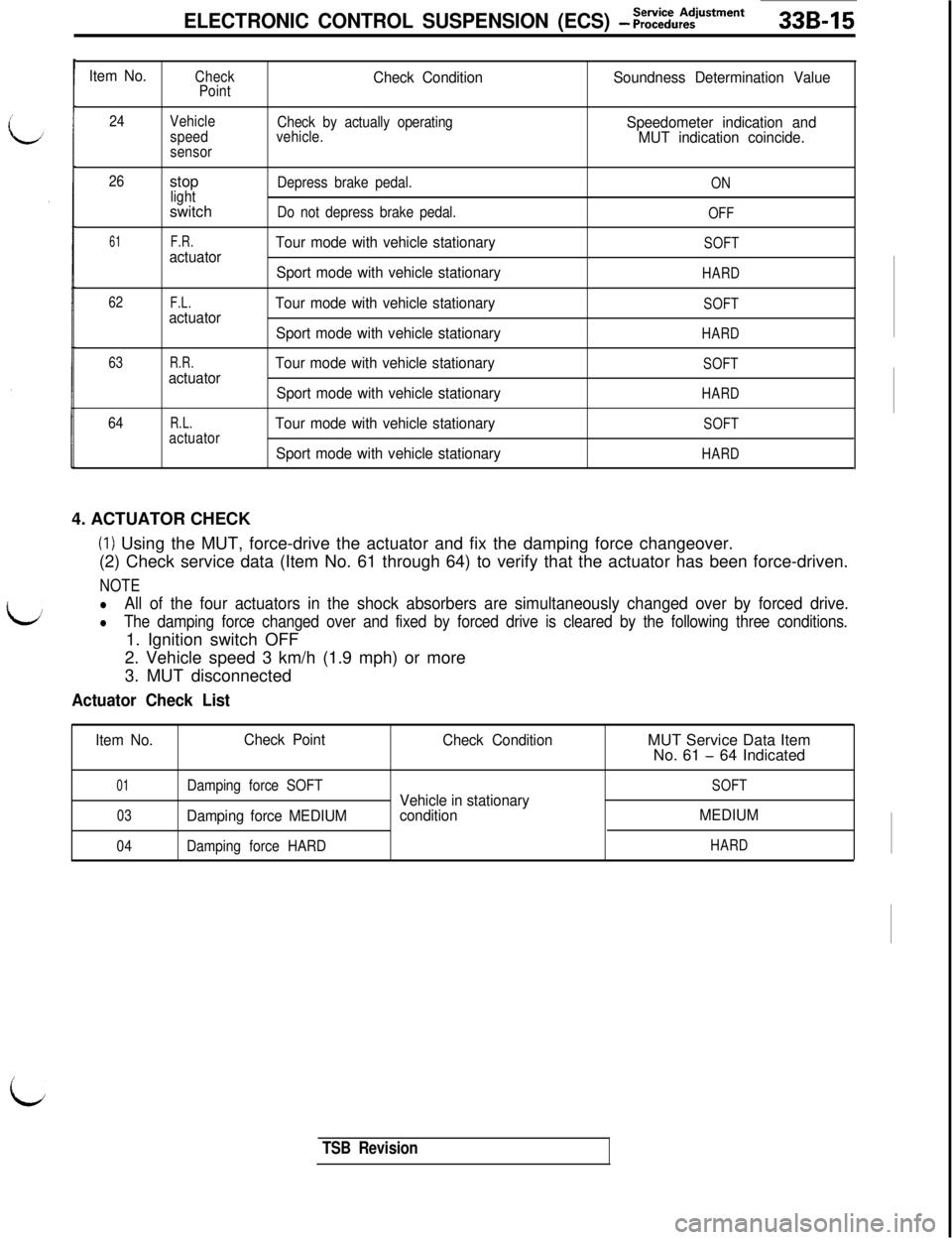

ELECTRONIC CONTROL SUSPENSION (ECS) - ;;~i%:~ustment339-15

Item No.Check

PointCheck ConditionSoundness Determination Value

24

Check by actually operating

vehicle.Speedometer indication and

MUT indication coincide.

26

61

62

63

64Vehicle

speed

sensorstop

lightswitch

F.R.actuator

F.L.actuator

R.R.actuator

R.L.actuatorDepress brake pedal.

ON

Do not depress brake pedal.OFF

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD4. ACTUATOR CHECK

(I) Using the MUT, force-drive the actuator and fix the damping force changeover.

(2) Check service data (Item No. 61 through 64) to verify that the actuator has been force-driven.

NOTE

lAll of the four actuators in the shock absorbers are simultaneously changed over by forced drive.

lThe damping force changed over and fixed by forced drive is cleared by the following three conditions.1. Ignition switch OFF

2. Vehicle speed 3 km/h (1.9 mph) or more

3. MUT disconnected

Actuator Check List

Item No.Check Point

Check ConditionMUT Service Data Item

No. 61 - 64 Indicated

01Damping force SOFT

03Damping force MEDIUM

04Damping force HARD

Vehicle in stationary

conditionSOFT

MEDIUM

HARD

i

TSB Revision