ABS MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 7 of 1146

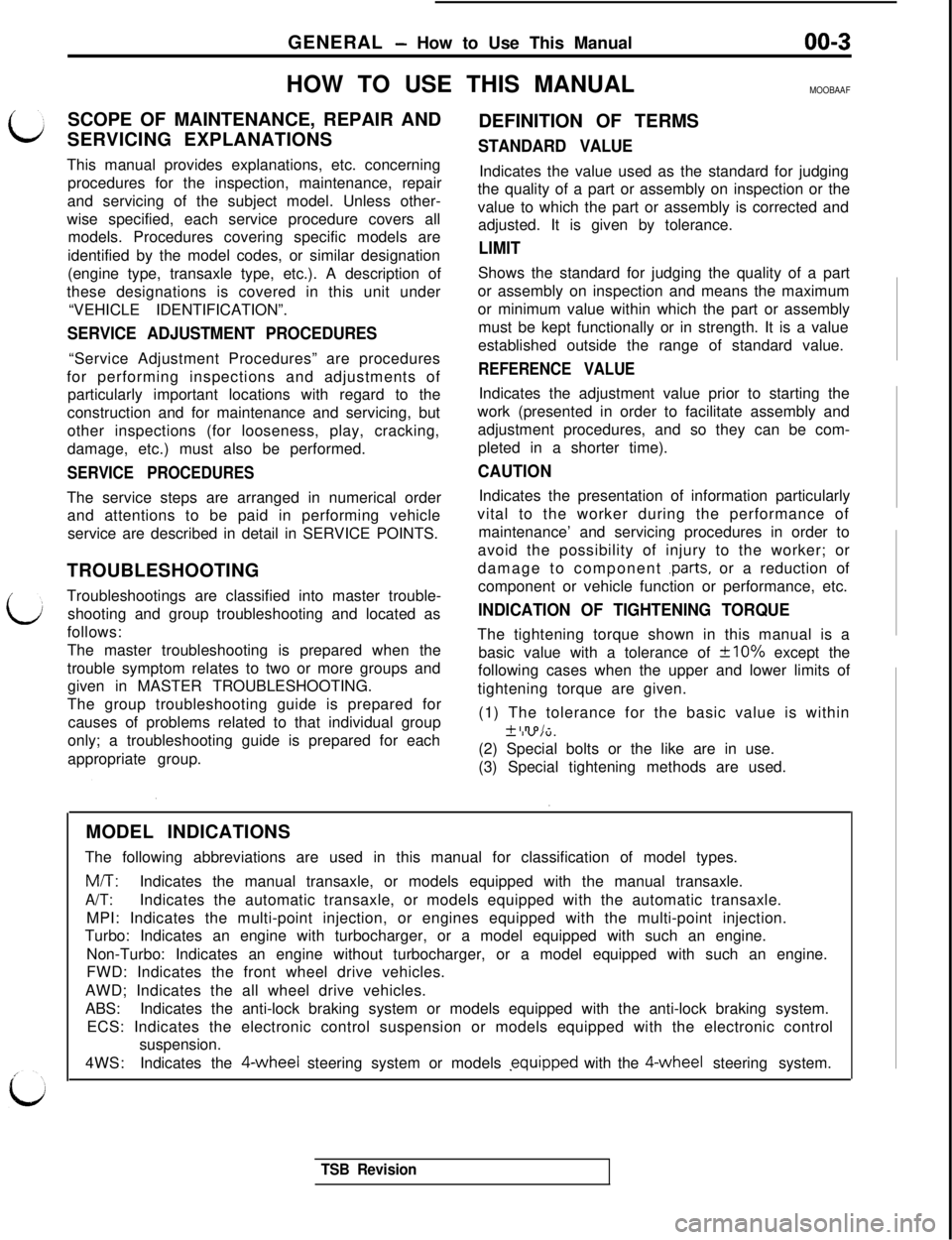

GENERAL - How to Use This Manual00-3HOW TO USE THIS MANUAL

MOOBAAF

c;SCOPE OF MAINTENANCE, REPAIR AND

DEFINITION OF TERMS

SERVICING EXPLANATIONSSTANDARD VALUE

bThis manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the model codes, or similar designation

(engine type, transaxle type, etc.). A description of

these designations is covered in this unit under

“VEHICLE IDENTIFICATION”.

SERVICE ADJUSTMENT PROCEDURES“Service Adjustment Procedures” are procedures

for performing inspections and adjustments of

particularly important locations with regard to the

construction and for maintenance and servicing, but

other inspections (for looseness, play, cracking,

damage, etc.) must also be performed.

SERVICE PROCEDURESThe service steps are arranged in numerical order

and attentions to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

TROUBLESHOOTING

Troubleshootings are classified into master trouble-

shooting and group troubleshooting and located as

follows:

The master troubleshooting is prepared when the

trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for

causes of problems related to that individual groupIndicates the value used as the standard for judging

the quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMITShows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly

must be kept functionally or in strength. It is a value

established outside the range of standard value.

REFERENCE VALUEIndicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTIONIndicates the presentation of information particularly

vital to the worker during the performance of

maintenance’ and servicing procedures in order to

avoid the possibility of injury to the worker; or

damage to component

.parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUEThe tightening torque shown in this manual is a

basic value with a tolerance of

+lO% except the

following cases when the upper and lower limits of

tightening torque are given.

(1) The tolerance for the basic value is within

+ I no/-

only; a troubleshooting guide is prepared for eachI iv,“.appropriate group.(2) Special bolts or the like are in use.

(3) Special tighteningmethods are used.

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.M/T:Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T:Indicates the automatic transaxle, or models equipped with the automatic transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-point injection.

Turbo: Indicates an engine with turbocharger, or a model equipped with such an engine.

Non-Turbo: Indicates an engine without turbocharger, or a model equipped with such an engine.

FWD: Indicates the front wheel drive vehicles.

AWD; Indicates the all wheel drive vehicles.

ABS:Indicates the anti-lock braking system or models equipped with the anti-lock braking system.

ECS: Indicates the electronic control suspension or models equipped with the electronic control

suspension.

4WS:Indicates the 4-wheel steering system or models .equipped with the 4-wheel steering system.

TSB Revision

Page 32 of 1146

00-28GENERAL - Master Troubleshooting

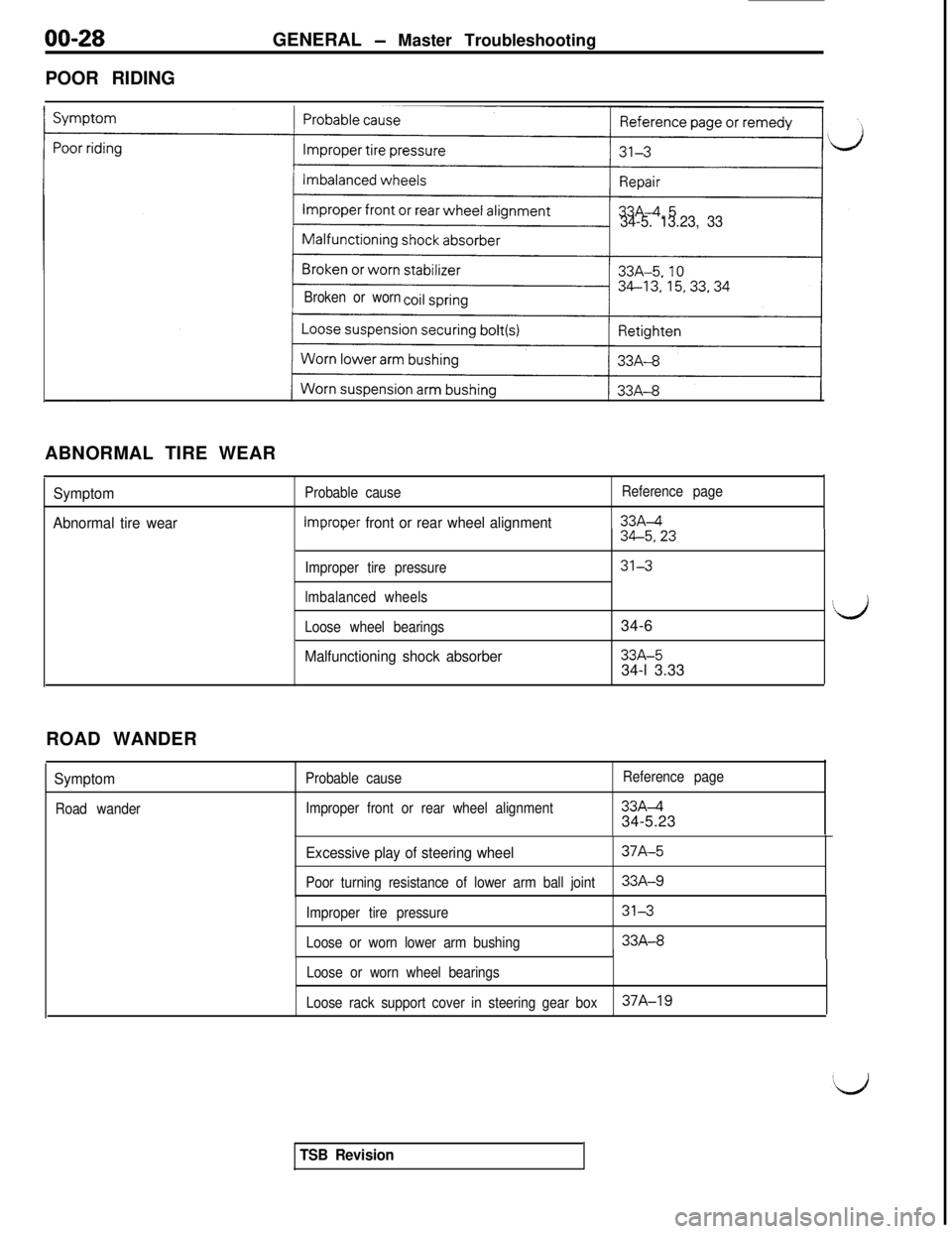

POOR RIDING

34-5. 13.23, 33

Broken or wornABNORMAL TIRE WEAR

Symptom

Abnormal tire wearProbable cause

lmorooer front or rear wheel alignment, ,

Improper tire pressure

lmbalanced wheels

Loose wheel bearings

Malfunctioning shock absorber

Reference page

33Ad34-5,23

31334-6

LJ33A-5

34-l 3.33

ROAD WANDER

Symptom

Road wanderProbable cause

Improper front or rear wheel alignmentReference page33A&34-5.23

Excessive play of steering wheel

Poor turning resistance of lower arm ball joint37A-533A-9

Improper tire pressure

Loose or worn lower arm bushing31333A-8

III

Loose or worn wheel bearings

Loose rack support cover in steering gear box37A-19

TSB Revision

Page 33 of 1146

GENERAL - Master Troubleshootinn

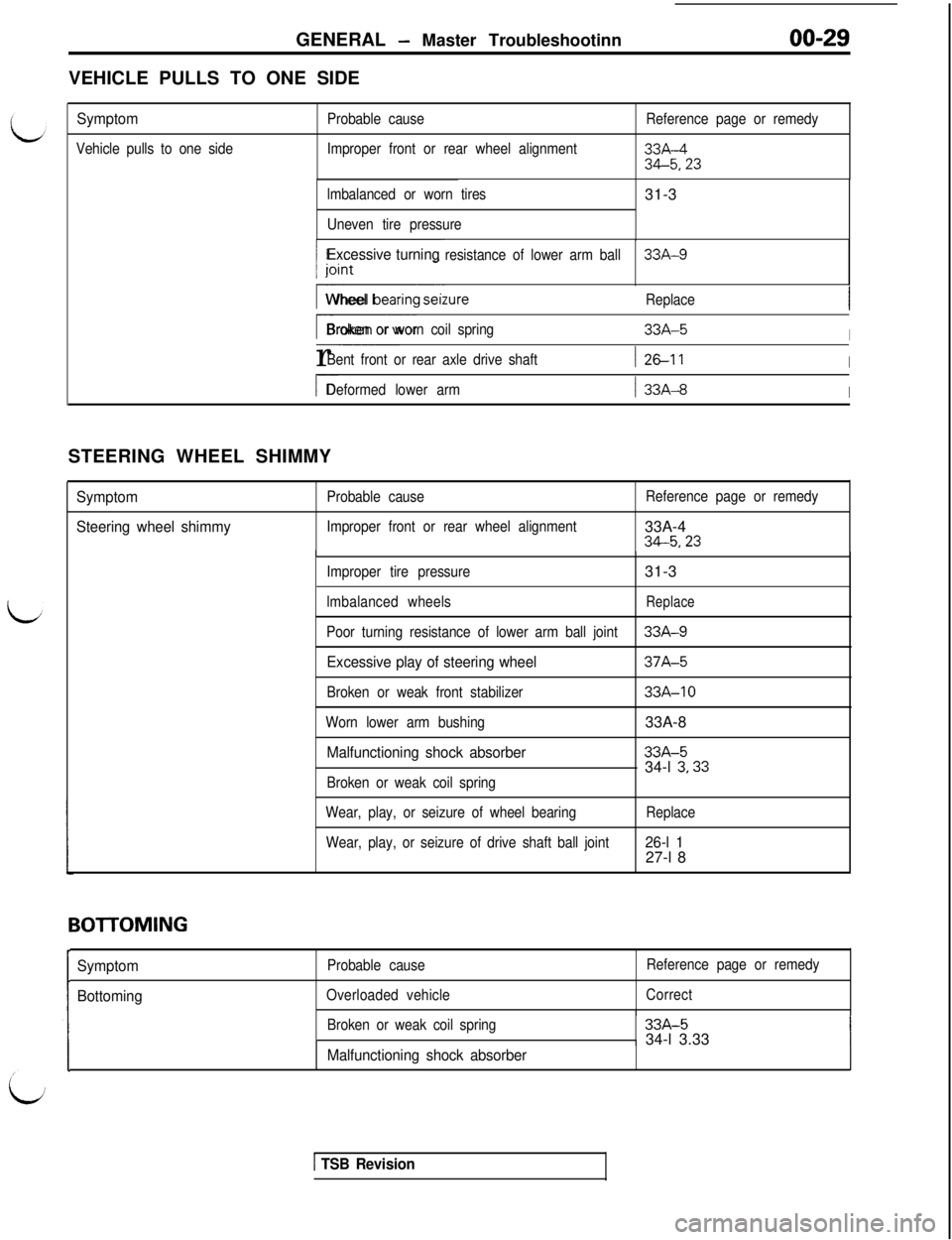

VEHICLE PULLS TO ONE SIDE

Symptom

Vehicle pulls to one sideProbable cause

Improper front or rear wheel alignmentReference page or remedy33A-4

34-5,23

lmbalanced or worn tires

Uneven tire pressure31-3

Excessive turningresistance of lower arm ball33A-9

I--_Wheel beanng serzureReplace

I---Broken or worn coil spring33A-5Ir

~~~~~~Bent front or rear axle drive shaft126-11I

I-Deformed lower arm1 33A-8I

Improper tire pressure31-3

lmbalanced wheelsReplace

Poor turning resistance of lower arm ball joint33A-9

Excessive play of steering wheel37A-5

Broken or weak front stabilizer33A-10

Worn lower arm bushing33A-8

Malfunctioning shock absorber33A-5

34-l 3,33

Broken or weak coil spring

Wear, play, or seizure of wheel bearing

Wear, play, or seizure of drive shaft ball jointReplace

26-l 127-l 8 STEERING WHEEL SHIMMY

SymptomProbable cause

Steering wheel shimmyImproper front or rear wheel alignmentReference page or remedy33A-434-5,23

Boll-OMING

Symptom

BottomingProbable cause

Overloaded vehicleReference page or remedy

Correct

Broken or weak coil spring33A-5

34-l 3.33

IMalfunctioning shock absorber

1 TSB Revision

Page 49 of 1146

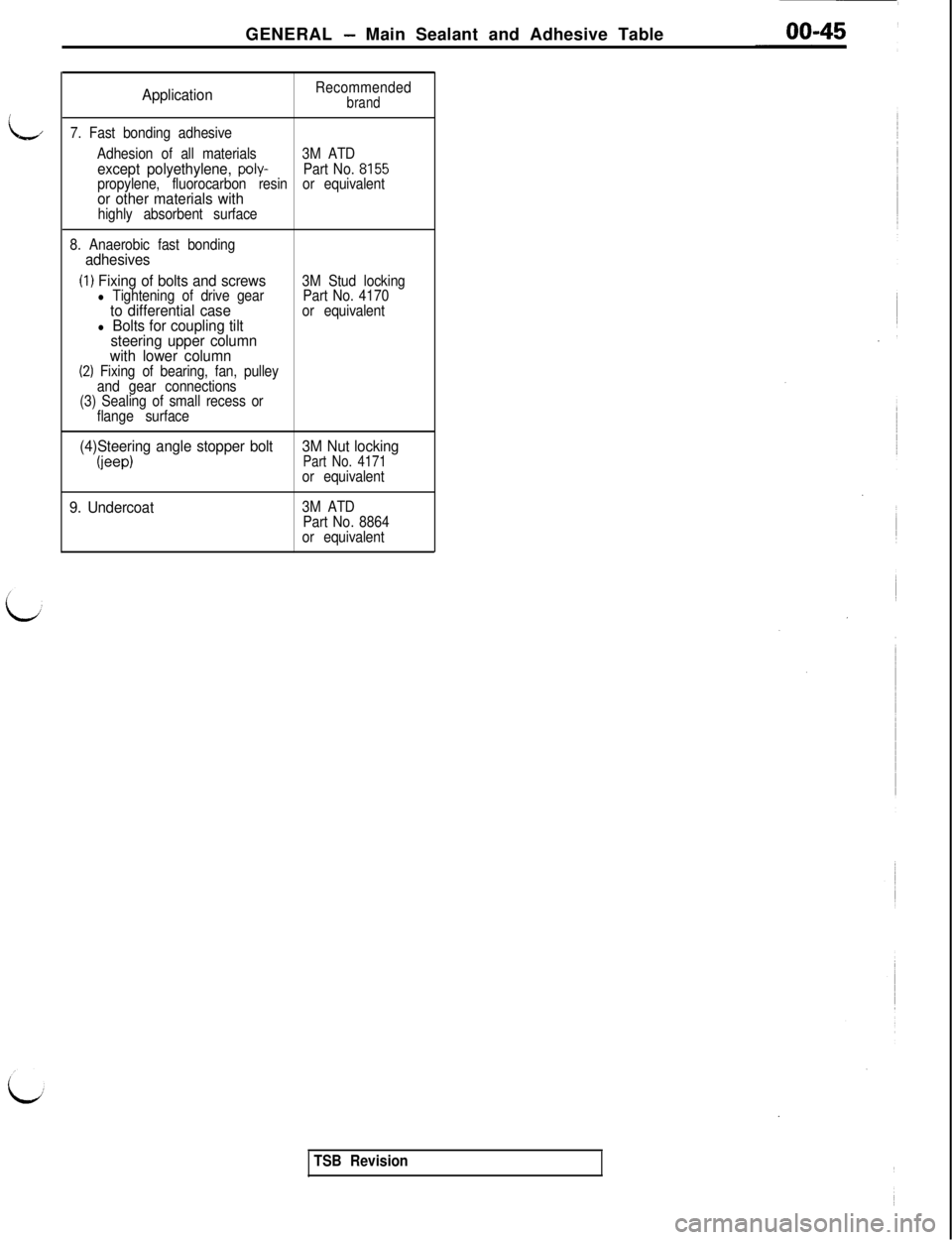

GENERAL - Main Sealant and Adhesive Table

I,i

ApplicationRecommendedbrand

7. Fast bonding adhesive

Adhesion of all materials3M ATD

except polyethylene, poly-Part No. 8155propylene, fluorocarbon resinor equivalentor other materials withhighly absorbent surface

8. Anaerobic fast bonding

adhesives

(I) Fixing of bolts and screws3M Stud lockingl Tightening of drive gearPart No. 4170to differential caseor equivalentl Bolts for coupling tilt

steering upper column

with lower column

(2) Fixing of bearing, fan, pulley

and gear connections

(3) Sealing of small recess or

flange surface

(4)Steering angle stopper bolt

(jeep)

3M Nut lockingPart No. 4171or equivalent

9. Undercoat3M ATD

Part No. 8864

or equivalent

TSB Revision

Page 134 of 1146

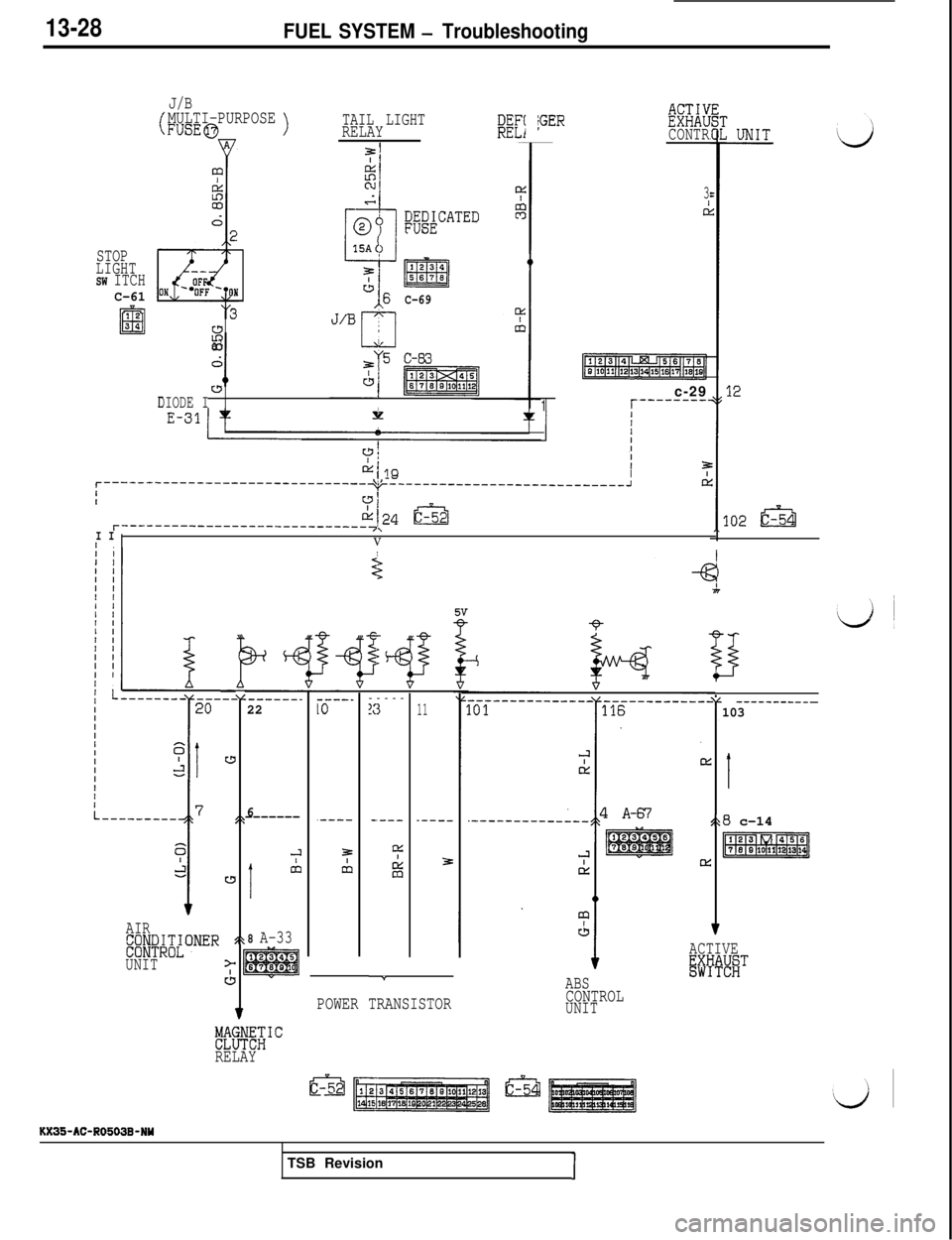

13-28FUEL SYSTEM - Troubleshooting

J/B

(MULTI-PURPOSEFUSE@>TAIL LIGHTRELAYDEF(RELfjGERKixCONTR

m

ONC-69'(3I

if2-

L&ia3

dd

I0_-w1DIODE II

3

d

STOP

LIGHT

SW ITCHC-6112

El34c-29

1r--------'

fII

--__---_-__------___------~~--- \1,--Iy----------------------------Jd

71

z?124 t&r-----------------------------7;I IIV

I---

w

Sk

w,t

>

JI

v

----_10

.----

5

cb-----

3

-.---

!xI

%

:------_22

6-------

J

1

&I

8 A-33

11

.----

3

- -----------

r

103

c

I

128 c-14

pER!Eq?

v

.-----_-_-----_

AIR

E;;F#ONER

UNITACTIVEisiii%!iTc

ABS

CONTROLUNIT

Y

POWER TRANSISTOR

FlffiWRELAYKX35-AC-R0503B-NY

TSB Revision

I

Page 166 of 1146

![MITSUBISHI 3000GT 1991 Service Manual 13-60FUEL SYSTEM - On-vehicle Inspection of MPI Components

BAROMETRIC PRESSURE SENSOR

Barometric

pressure sensor7FUO66

Output voltage (VI

a---l- 760Barometric pressure [mmHg (in.Hg)] (30) EC1551

@ Equ MITSUBISHI 3000GT 1991 Service Manual 13-60FUEL SYSTEM - On-vehicle Inspection of MPI Components

BAROMETRIC PRESSURE SENSOR

Barometric

pressure sensor7FUO66

Output voltage (VI

a---l- 760Barometric pressure [mmHg (in.Hg)] (30) EC1551

@ Equ](/img/19/57085/w960_57085-165.png)

13-60FUEL SYSTEM - On-vehicle Inspection of MPI Components

BAROMETRIC PRESSURE SENSOR

Barometric

pressure sensor7FUO66

Output voltage (VI

a---l- 760Barometric pressure [mmHg (in.Hg)] (30) EC1551

@ Equipment side

M13YHAA2

d

connecror

Air flow sensor

connector

r

Barometric pressure sensor

@ Harness sideconnector

Engine control unit

A6 IA65A\72

7

7F U0664

Engine control unit connector

7FUO653

OPERATIONl The barometric pressure sensor converts the barometric pressure into a voltage and inputs it to the

engine control unit, which then corrects the fuel injection rate, etc. based on the input signal.

lThe 5 V power in the engine control unit is supplied to the barometric pressure sensor. Through the circuitin the sensor, it is grounded in the engine control unit.1

l

The barometric pressure sensor output voltage which is proportional to the barometric pressure (absolutepressure) is supplied to the engine control unit.

d ITSB Revision

Page 186 of 1146

13-80FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

POWER STEERING OIL PRESSURE SWITCHMlOYQAA

B

$-

Engine control unit

'107

@ Harness side

connector

ml-

Power steering oil

Pressure switch

7FUO536700-2.000 1.500-2.000(100-284) (213-284)Pressure [kPa (psi)]

0, l.oIu

OPERATIONl

The power steering oil pressure switch converts presence/absence of power steering load into low/high

voltage and inputs it to the engine control unit, which then controls the idle speed control servo based on

this signal.l The battery voltage in the engine control unit is applied through a resistor to the power steering oil

pressure switch. Steering operation causes the power steering oil pressure to increase, turning the

switch on. As a result, continuity is produced between the battery voltage applied and ground. This

causes the power steering oil pressure terminal voltage to go from high to low.

TSB Revision

Page 239 of 1146

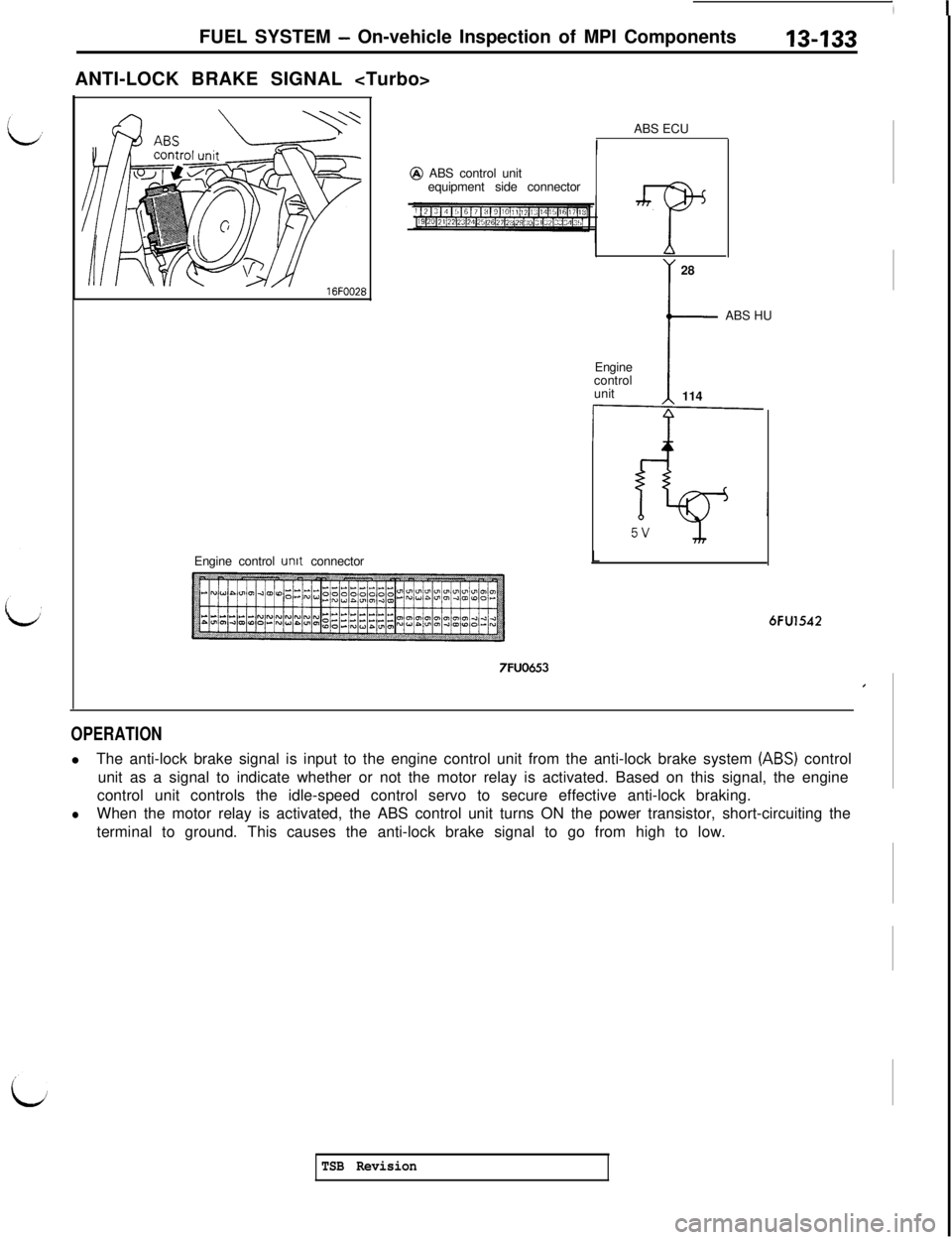

FUEL SYSTEM - On-vehicle Inspection of MPI Components

ANTI-LOCK BRAKE SIGNAL

Engine control

unit connectorABS ECU@ ABS control unit

equipment side connector

A28

tABS HU

Engine

control

unit

114

/L6FU1542

7FUO653,

OPERATIONlThe anti-lock brake signal is input to the engine control unit from the anti-lock brake system

(ABS) control

unit as a signal to indicate whether or not the motor relay is activated. Based on this signal, the engine

control unit controls the idle-speed control servo to secure effective anti-lock braking.

lWhen the motor relay is activated, the ABS control unit turns ON the power transistor, short-circuiting the

terminal to ground. This causes the anti-lock brake signal to go from high to low.

TSB Revision

Page 240 of 1146

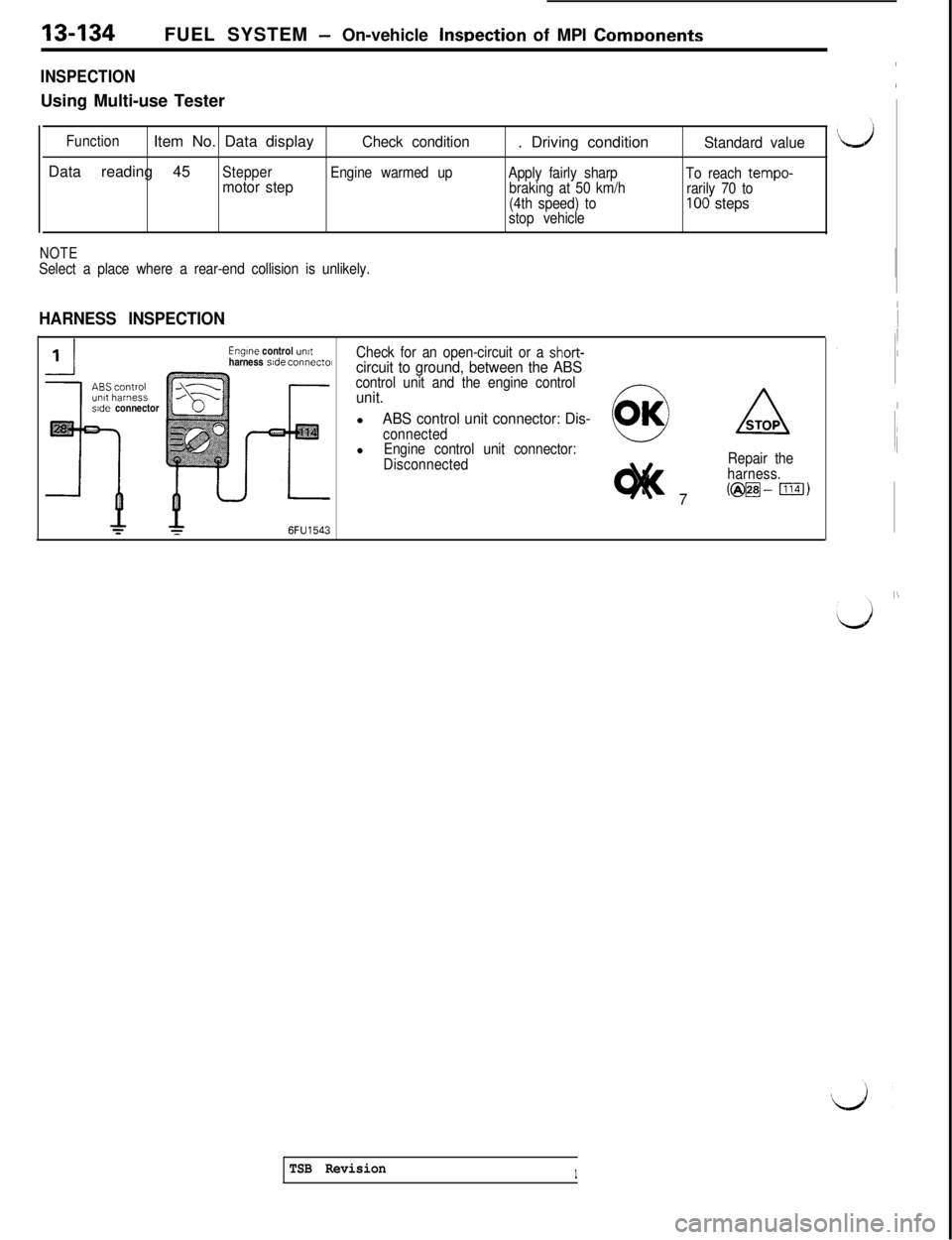

13-134FUEL SYSTEM - On-vehicle InsDection of MPI ComDonents

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck condition. Driving conditionStandard valueData reading 45

Stepper

Engine warmed up

Apply fairly sharp

To reach tempo-motor stepbraking at 50 km/h

rarily 70 to

(4th speed) to100 stepsstop vehicle

NOTESelect a place where a rear-end collision is unlikely.

HARNESS INSPECTION

side connector

Engine control umtharness side connecm

6FU1543

Check for an open-circuit or a short-circuit to ground, between the ABScontrol unit and the engine controlunit.l

ABS control unit connector: Dis-connectedlEngine control unit connector:

Disconnected7Repair the

harness.

(@m-ml)

I

I

I

I

IiI

I

~,

I\

TSB Revision1

Page 585 of 1146

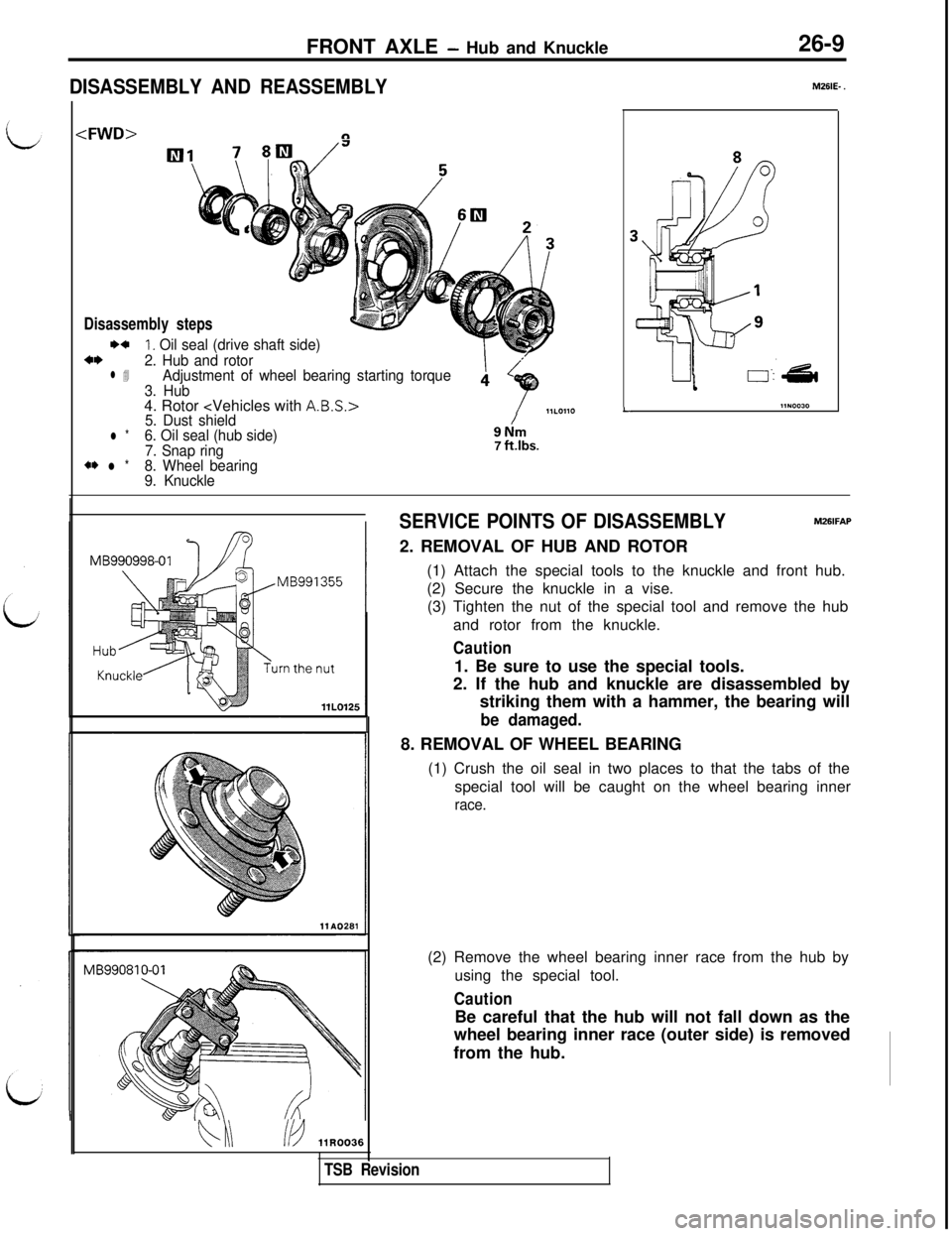

FRONT AXLE - Hub and Knuckle26-9

DISASSEMBLY AND REASSEMBLY

Disassembly stepsI)+

1. Oil seal (drive shaft side)*I)2. Hub and rotorl 4Adjustment of wheel bearing starting torque

3. Hub4. Rotor

5. Dust shieldl *6. Oil seal (hub side)

7. Snap ring

*I) l *8. Wheel bearing

9. Knuckle

/9Nm7 ftlbs.

L

MSIE- .

bi\/b ilR0036

SERVICE POINTS OF DISASSEMBLYM26lFAP2. REMOVAL OF HUB AND ROTOR

(1) Attach the special tools to the knuckle and front hub.

(2) Secure the knuckle in a vise.

(3) Tighten the nut of the special tool and remove the hub

and rotor from the knuckle.

Caution1. Be sure to use the special tools.

2. If the hub and knuckle are disassembled by

striking them with a hammer, the bearing will

be damaged.8. REMOVAL OF WHEEL BEARING

(1) Crush the oil seal in two places to that the tabs of the

special tool will be caught on the wheel bearing inner

race.(2) Remove the wheel bearing inner race from the hub by

using the special tool.

CautionBe careful that the hub will not fall down as the

wheel bearing inner race (outer side) is removed

from the hub.

TSB Revision