ECU MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 170 of 1146

13-64FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

7FUO670

Apply sealant

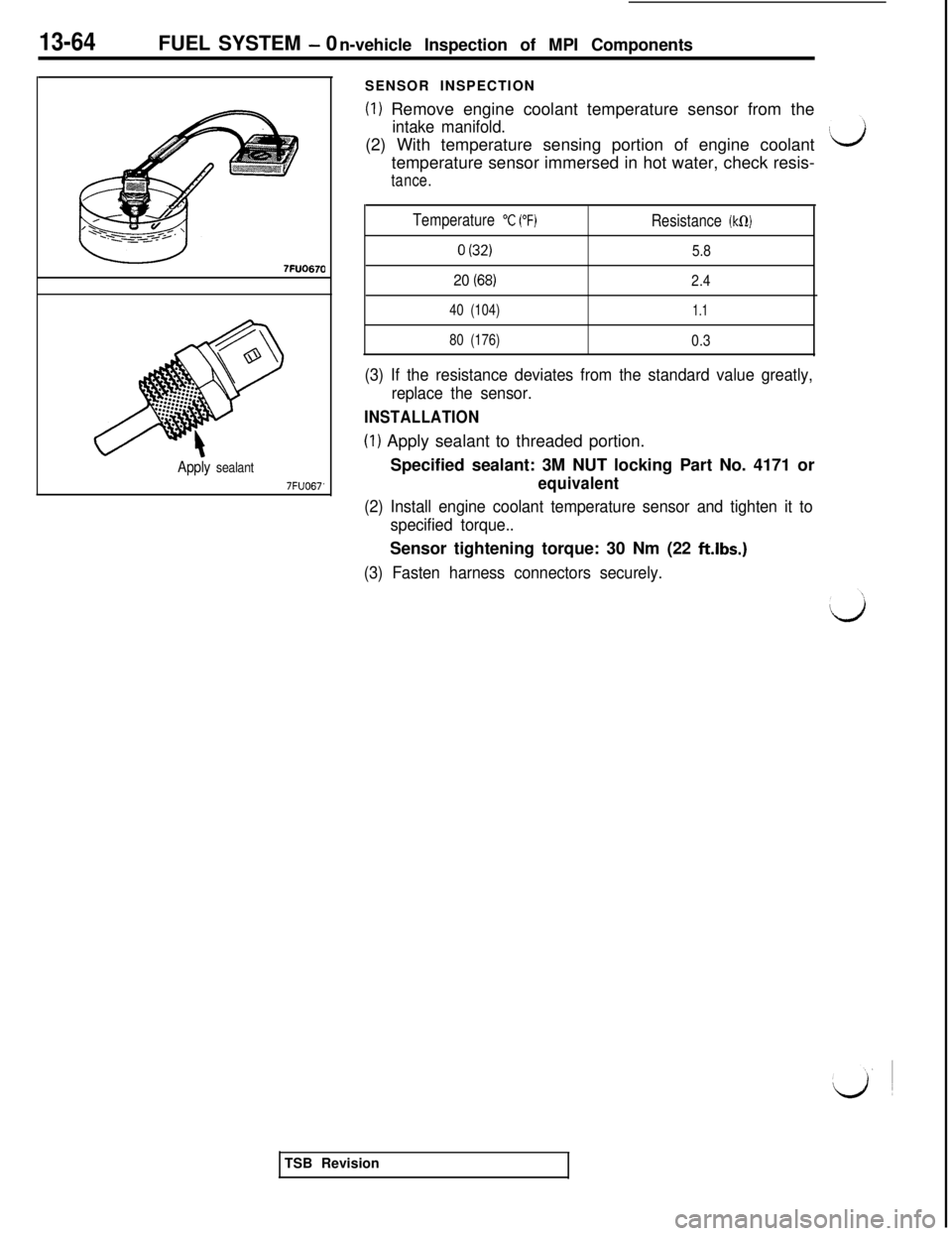

7FUO67’SENSOR INSPECTION

(1) Remove engine coolant temperature sensor from the

intake manifold.(2) With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check resis-

tance.

Temperature

“C (“F)Resistance (kCI)

0 (32)5.8

20 (68)2.4

40 (104)1.1

80 (176)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

INSTALLATION

(1) Apply sealant to threaded portion.

Specified sealant: 3M NUT locking Part No. 4171 or

equivalent

(2) Install engine coolant temperature sensor and tighten it to

specified torque..Sensor tightening torque: 30 Nm (22

ft.lbs.)

(3) Fasten harness connectors securely.TSB Revision

Page 239 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

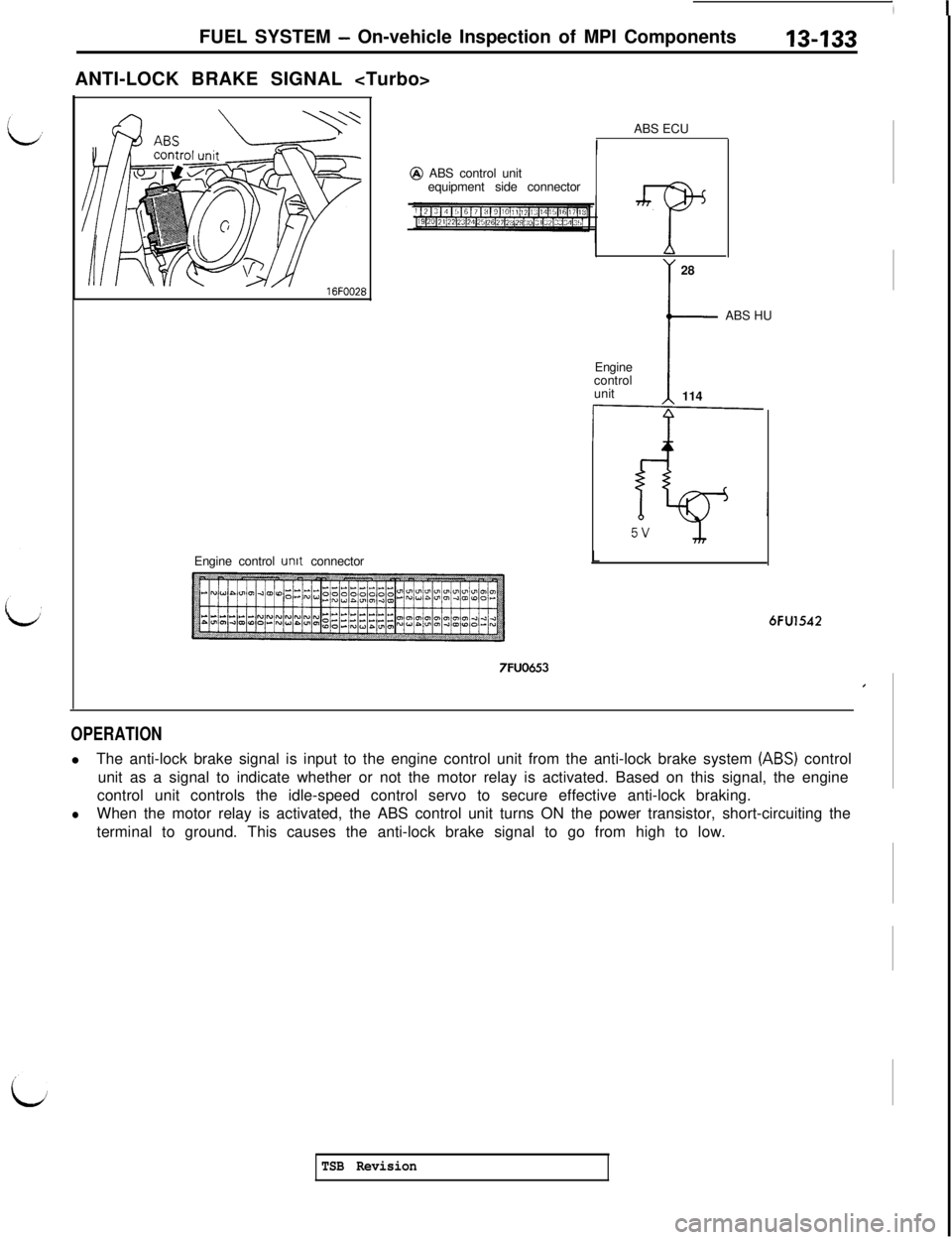

ANTI-LOCK BRAKE SIGNAL

Engine control

unit connectorABS ECU@ ABS control unit

equipment side connector

A28

tABS HU

Engine

control

unit

114

/L6FU1542

7FUO653,

OPERATIONlThe anti-lock brake signal is input to the engine control unit from the anti-lock brake system

(ABS) control

unit as a signal to indicate whether or not the motor relay is activated. Based on this signal, the engine

control unit controls the idle-speed control servo to secure effective anti-lock braking.

lWhen the motor relay is activated, the ABS control unit turns ON the power transistor, short-circuiting the

terminal to ground. This causes the anti-lock brake signal to go from high to low.

TSB Revision

Page 253 of 1146

FUEL SYSTEM - Fuel Tank13-147

Rubber hose

ngn

03FOOl

9

OSFOOB

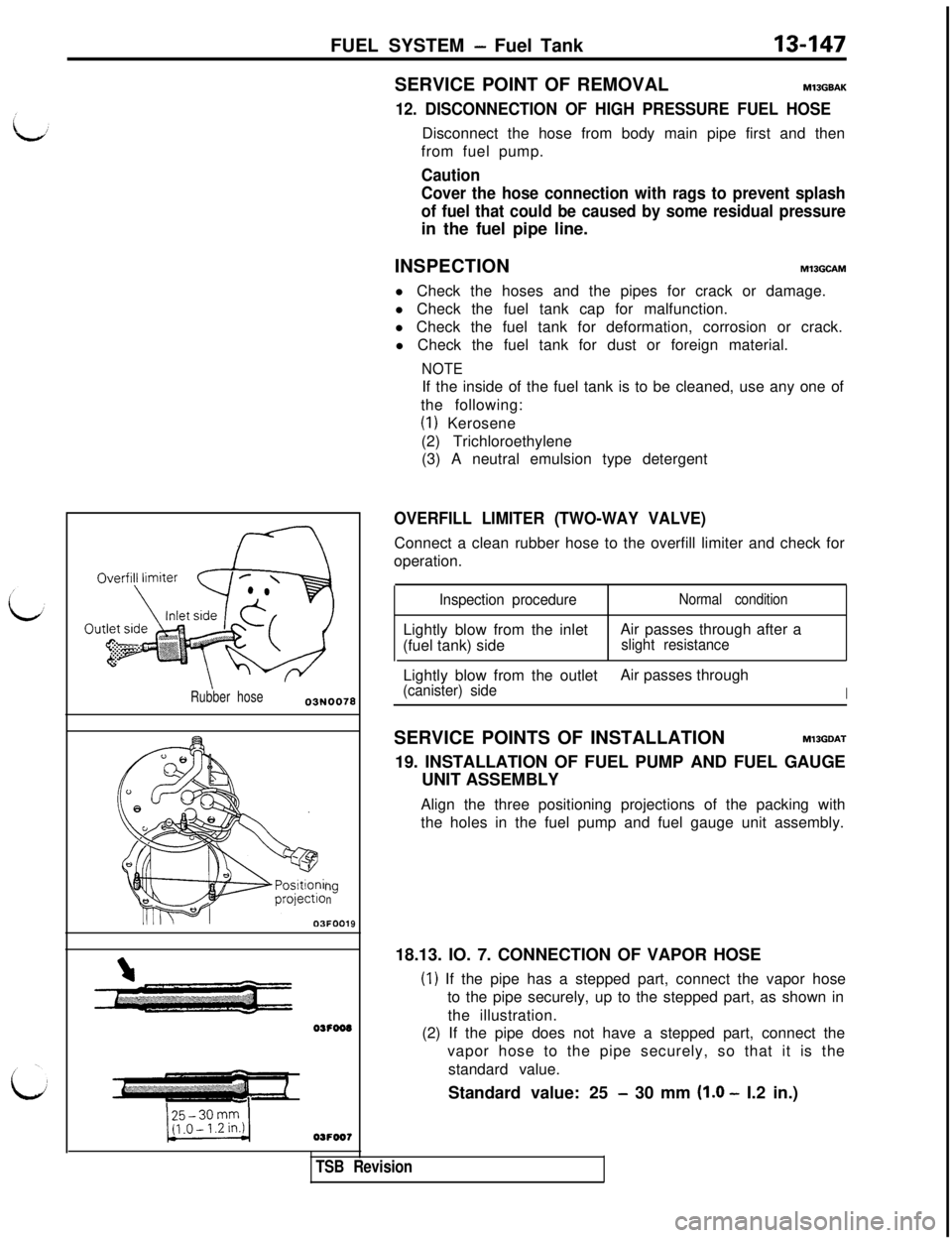

05FOO7SERVICE POINT OF REMOVAL

MlBGBAK

12. DISCONNECTION OF HIGH PRESSURE FUEL HOSEDisconnect the hose from body main pipe first and then

from fuel pump.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

INSPECTION

MlBGCAMl Check the hoses and the pipes for crack or damage.

l Check the fuel tank cap for malfunction.

l Check the fuel tank for deformation, corrosion or crack.

l Check the fuel tank for dust or foreign material.

NOTEIf the inside of the fuel tank is to be cleaned, use any one of

the following:

(1) Kerosene

(2) Trichloroethylene

(3) A neutral emulsion type detergent

OVERFILL LIMITER (TWO-WAY VALVE)Connect a clean rubber hose to the overfill limiter and check for

operation.

Inspection procedureLightly blow from the inlet

(fuel tank) sideNormal conditionAir passes through after a

slight resistanceLightly blow from the outletAir passes through

(canister) sideISERVICE POINTS OF INSTALLATION

MlSGDAT19. INSTALLATION OF FUEL PUMP AND FUEL GAUGE

UNIT ASSEMBLY

Align the three positioning projections of the packing with

the holes in the fuel pump and fuel gauge unit assembly.

TSB Revision18.13. IO. 7. CONNECTION OF VAPOR HOSE

(1) If the pipe has a stepped part, connect the vapor hose

to the pipe securely, up to the stepped part, as shown in

the illustration.

(2) If the pipe does not have a stepped part, connect the

vapor hose to the pipe securely, so that it is the

standard value.

Standard value: 25

- 30 mm (1.0 - I.2 in.)

Page 254 of 1146

13-148FUEL SYSTEM - Fuel Tank

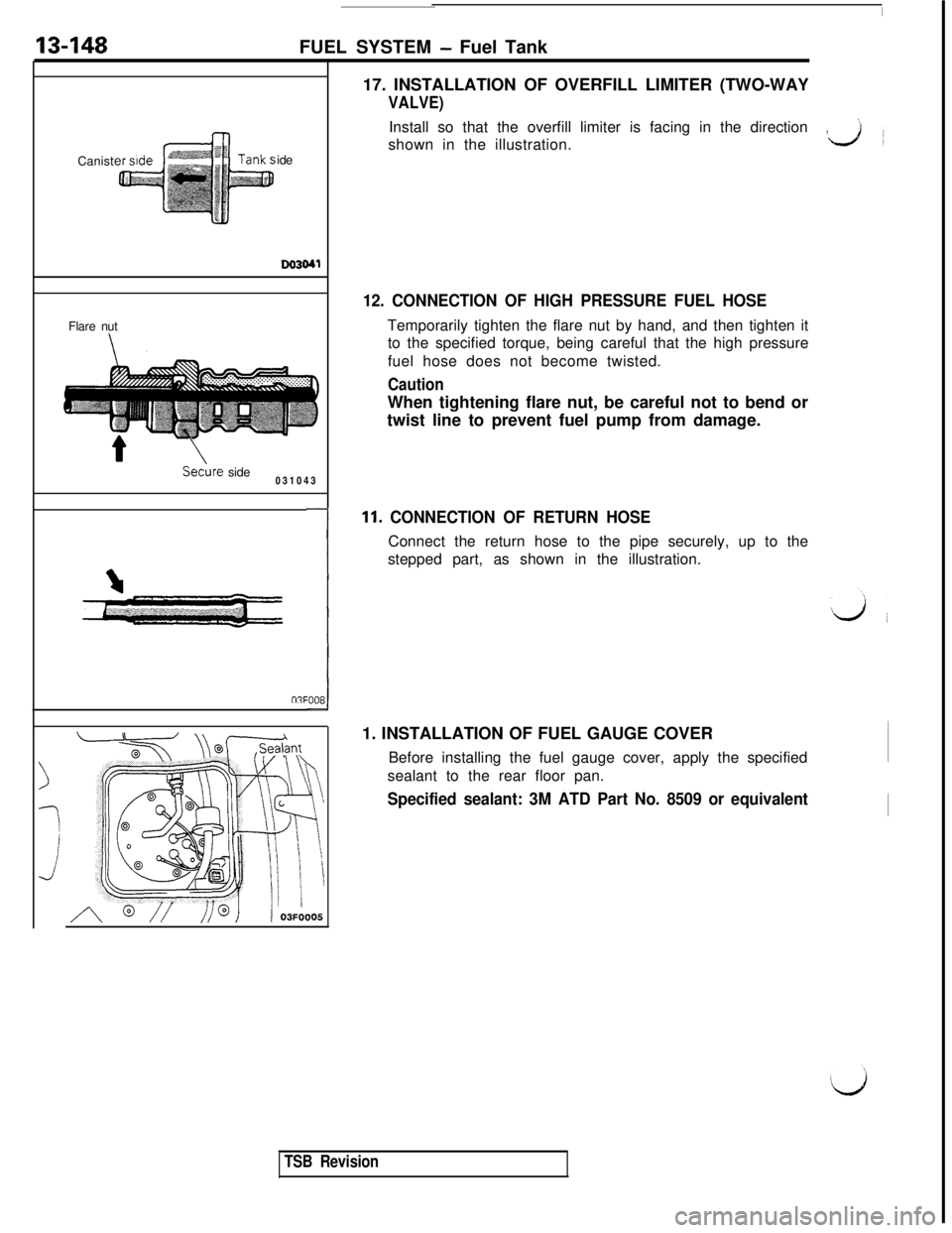

Canistide

Do3041Flare nut

Se&e side

0310430%

e:00817. INSTALLATION OF OVERFILL LIMITER (TWO-WAY

VALVE)Install so that the overfill limiter is facing in the direction

’,~

shown in the illustration.L.&l

12. CONNECTION OF HIGH PRESSURE FUEL HOSETemporarily tighten the flare nut by hand, and then tighten it

to the specified torque, being careful that the high pressure

fuel hose does not become twisted.

CautionWhen tightening flare nut, be careful not to bend or

twist line to prevent fuel pump from damage.

11. CONNECTION OF RETURN HOSEConnect the return hose to the pipe securely, up to the

stepped part, as shown in the illustration.

1. INSTALLATION OF FUEL GAUGE COVER

Before installing the fuel gauge cover, apply the specified

sealant to the rear floor pan.

Specified sealant: 3M ATD Part No. 8509 or equivalent

TSB Revision

Page 256 of 1146

13-150FUEL SYSTEMFuel Pump and Fuel Gauge Unit Assembly- and Overfill Limiter (Two-Way Valve)

Rubber hose

9Flare nut

Secure side

03Yo43Camst

ide

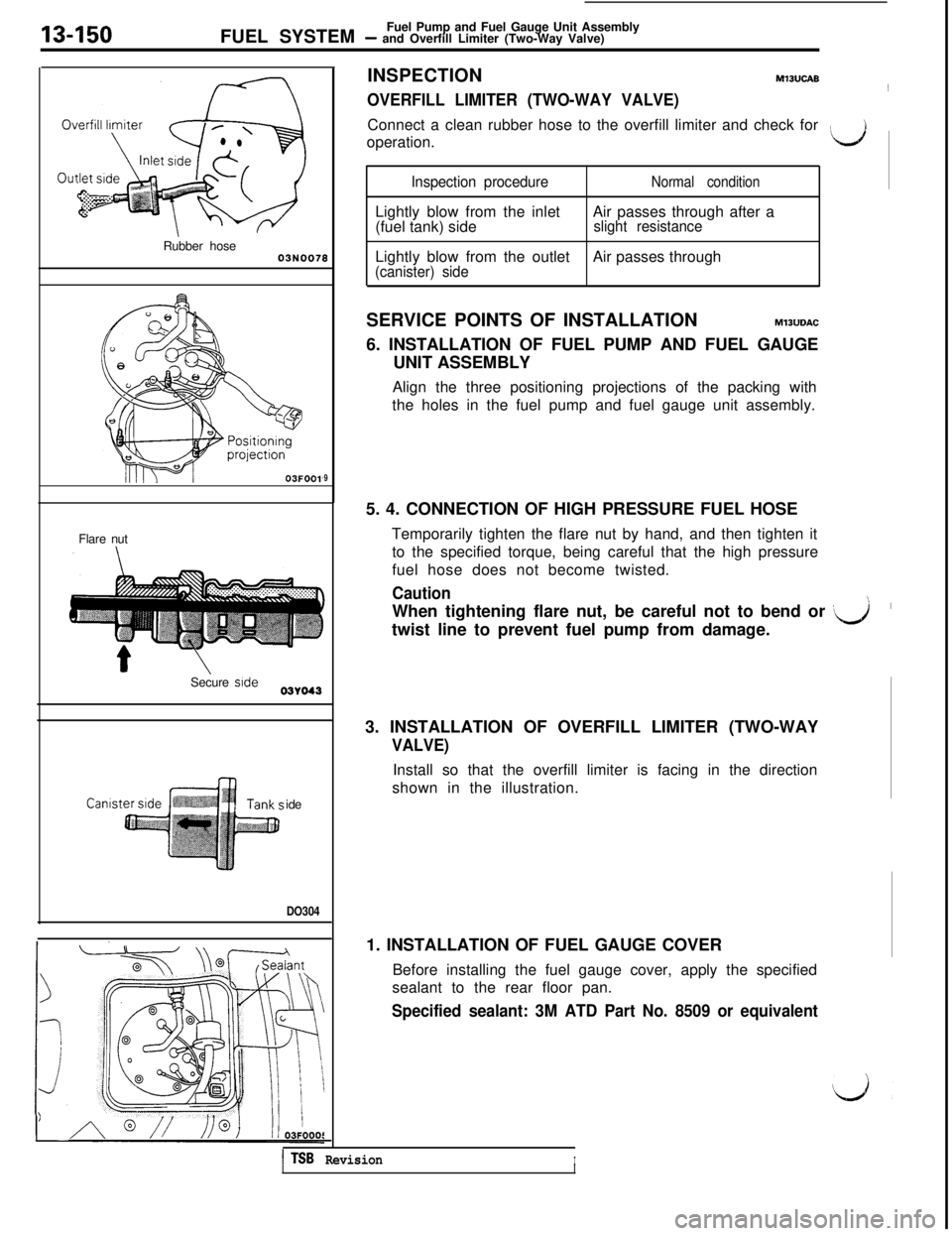

DO304INSPECTION

MlBUCAB

OVERFILL LIMITER (TWO-WAY VALVE)~

Connect a clean rubber hose to the overfill limiter and check for

operation.

‘d

Inspection procedureNormal conditionLightly blow from the inlet

(fuel tank) sideAir passes through after a

slight resistanceLightly blow from the outlet

(canister) sideAir passes through

SERVICE POINTS OF INSTALLATION

M13UDAC6. INSTALLATION OF FUEL PUMP AND FUEL GAUGE

UNIT ASSEMBLY

Align the three positioning projections of the packing with

the holes in the fuel pump and fuel gauge unit assembly.

5. 4. CONNECTION OF HIGH PRESSURE FUEL HOSE

Temporarily tighten the flare nut by hand, and then tighten it

to the specified torque, being careful that the high pressure

fuel hose does not become twisted.

CautionWhen tightening flare nut, be careful not to bend or

[J’twist line to prevent fuel pump from damage.\3. INSTALLATION OF OVERFILL LIMITER (TWO-WAY

VALVE)Install so that the overfill limiter is facing in the direction

shown in the illustration.

1. INSTALLATION OF FUEL GAUGE COVER

Before installing the fuel gauge cover, apply the specified

sealant to the rear floor pan.

Specified sealant: 3M ATD Part No. 8509 or equivalent

1 TSB RevisionIII

Page 258 of 1146

13-152FUEL SYSTEM- Fuel Line and Vapor Line

03FOO3

05FOO735 Nm7r; ft

Ihr-k” ._..I_.

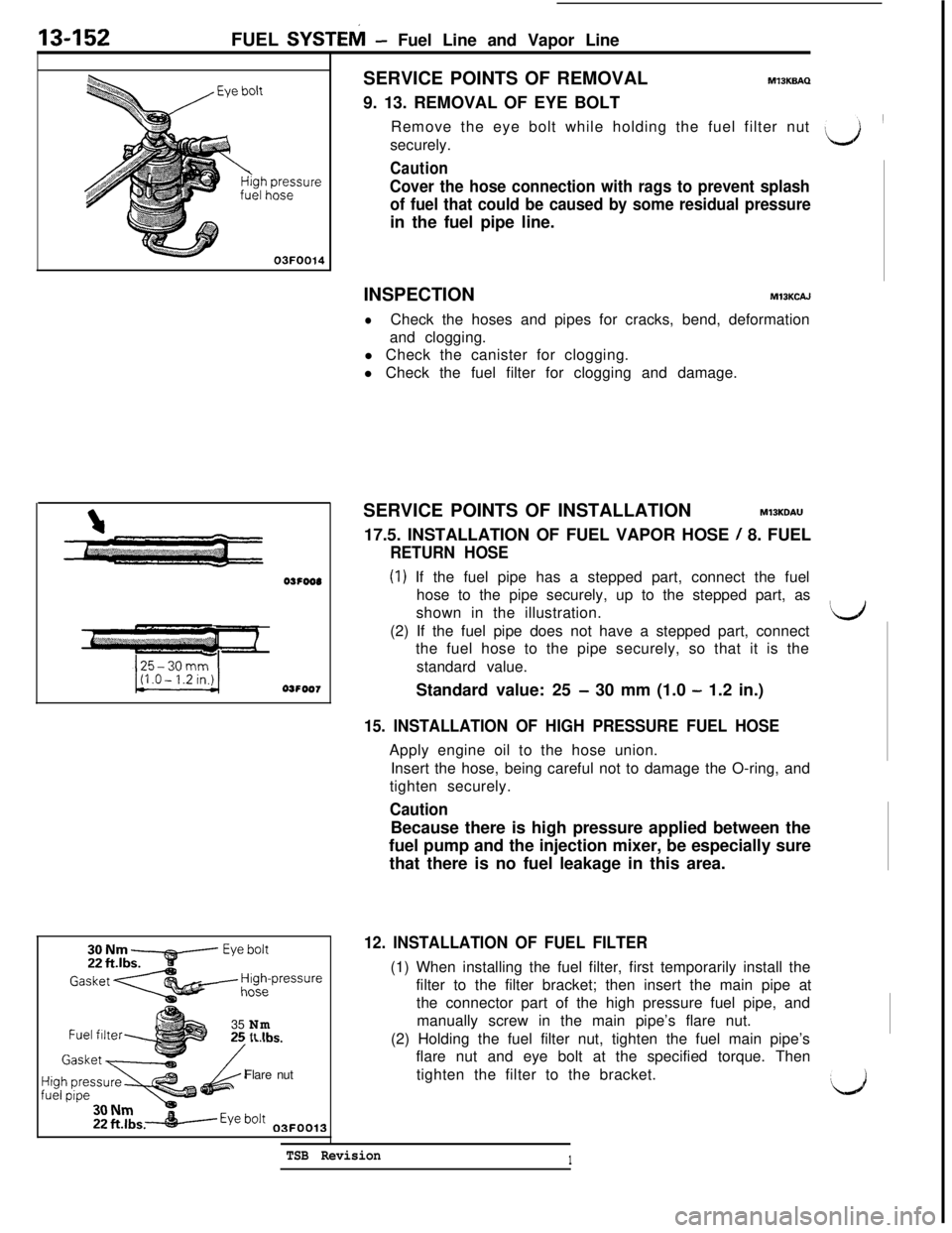

@dFlare nut,xSERVICE POINTS OF REMOVAL

MlBKBAQ9. 13. REMOVAL OF EYE BOLT

Remove the eye bolt while holding the fuel filter nut

\securely.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

INSPECTION

MIBKCAJ

lCheck the hoses and pipes for cracks, bend, deformation

and clogging.

l Check the canister for clogging.

l Check the fuel filter for clogging and damage.

SERVICE POINTS OF INSTALLATION

MlSKDAU17.5. INSTALLATION OF FUEL VAPOR HOSE

/ 8. FUEL

RETURN HOSE

(1) If the fuel pipe has a stepped part, connect the fuel

hose to the pipe securely, up to the stepped part, as

shown in the illustration.

Iti(2) If the fuel pipe does not have a stepped part, connect

the fuel hose to the pipe securely, so that it is the

standard value.

Standard value: 25

- 30 mm (1.0 - 1.2 in.)

15. INSTALLATION OF HIGH PRESSURE FUEL HOSEApply engine oil to the hose union.

Insert the hose, being careful not to damage the O-ring, and

tighten securely.

CautionBecause there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

12. INSTALLATION OF FUEL FILTER(1) When installing the fuel filter, first temporarily install the

filter to the filter bracket; then insert the main pipe at

the connector part of the high pressure fuel pipe, and

manually screw in the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

TSB Revision1

‘d

Page 259 of 1146

FUEL SYSTEM - Fuel Filter13453

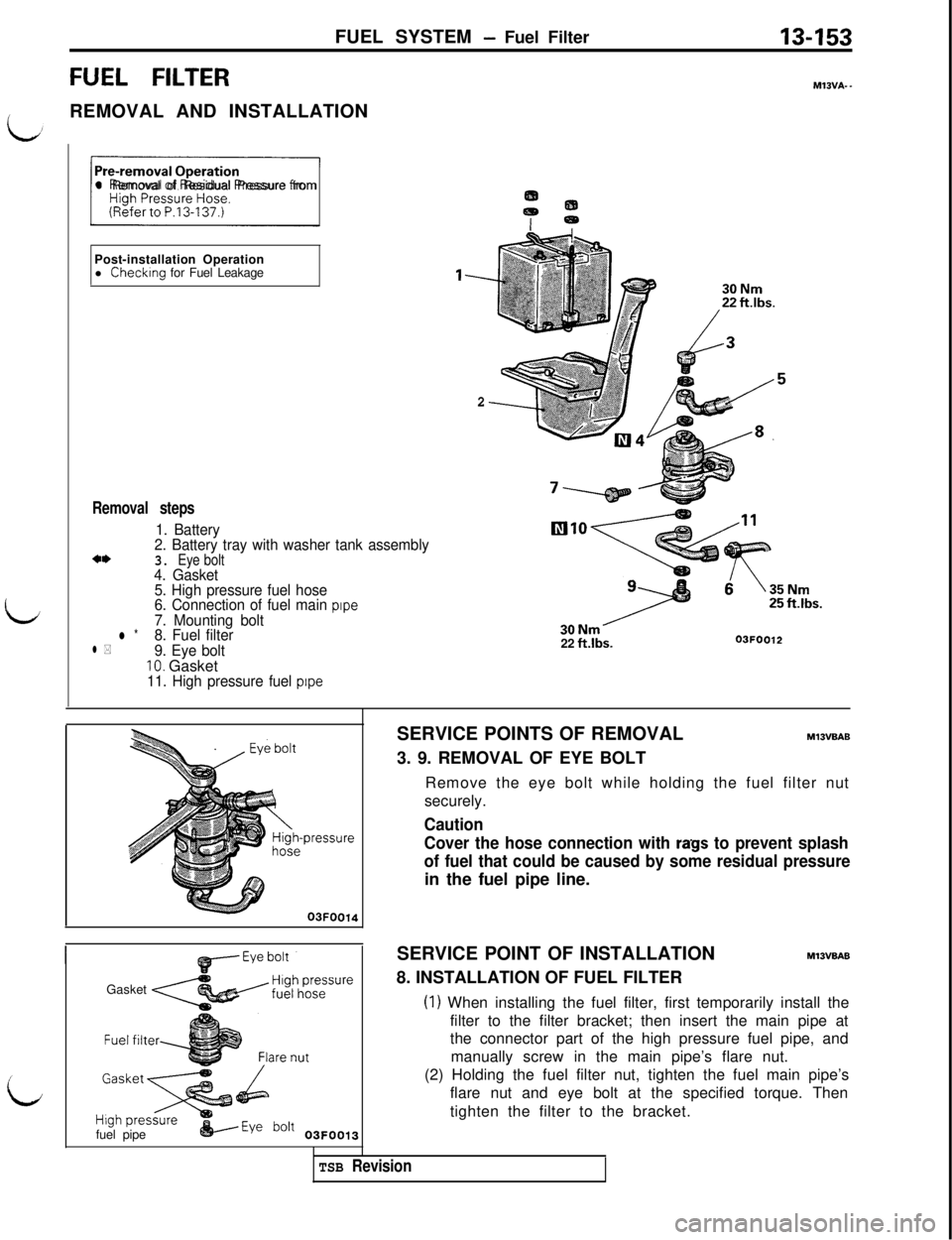

FUEL FILTERM13VA-.

/REMOVAL AND INSTALLATION

i&J

L

/Il Removal of Residual Pressure from

Post-installation Operation

l Checking for Fuel Leakage

Removal steps

1. Battery

2. Battery tray with washer tank assembly

3. Eye bolt4. Gasket

5. High pressure fuel hose

6. Connection of fuel main

pipe7. Mounting boltl *8. Fuel filterl *9. Eye bolt10. Gasket11. High pressure fuel pipe

l---

222 ft.lbs.03FOO12

Gasket

fuel pipe

&----Eye bo’t 03FOO13SERVICE POINTS OF REMOVAL

MlSVBAB3. 9. REMOVAL OF EYE BOLT

Remove the eye bolt while holding the fuel filter nut

securely.

Caution

Cover the hose connection with

rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

SERVICE POINT OF INSTALLATION

M13VBAB8. INSTALLATION OF FUEL FILTER

(1) When installing the fuel filter, first temporarily install the

filter to the filter bracket; then insert the main pipe at

the connector part of the high pressure fuel pipe, and

manually screw in the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

TSB Revision

Page 262 of 1146

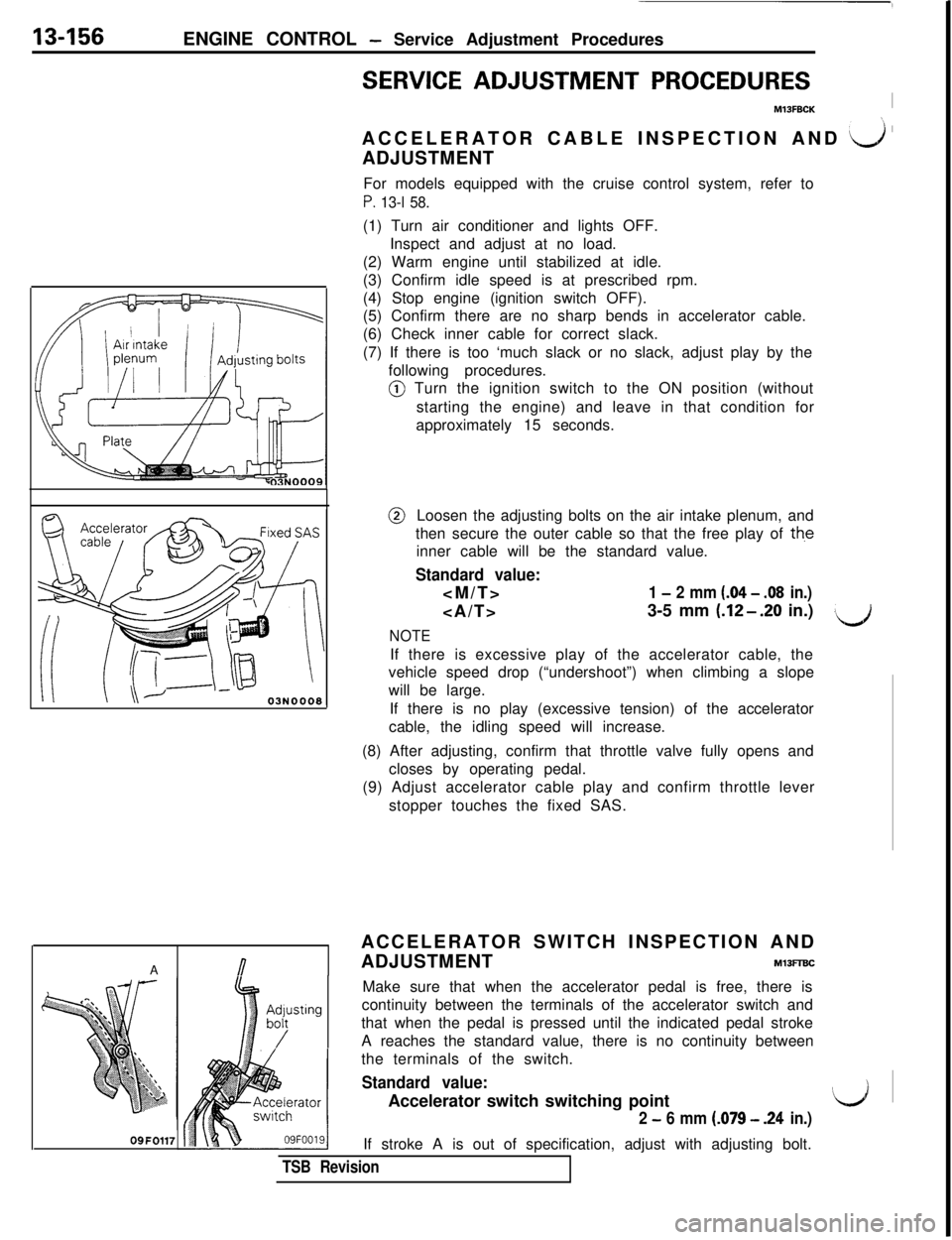

13-156ENGINE CONTROL - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

M13FBCKIACCELERATOR CABLE INSPECTION AND

a ’ADJUSTMENT

For models equipped with the cruise control system, refer to

P. 13-l 58.(1) Turn air conditioner and lights OFF.

Inspect and adjust at no load.

(2) Warm engine until stabilized at idle.

(3) Confirm idle speed is at prescribed rpm.

(4) Stop engine (ignition switch OFF).

(5) Confirm there are no sharp bends in accelerator cable.

(6) Check inner cable for correct slack.

(7) If there is too ‘much slack or no slack, adjust play by the

following procedures.@ Turn the ignition switch to the ON position (without

starting the engine) and leave in that condition for

approximately 15 seconds.@Loosen the adjusting bolts on the air intake plenum, and

then secure the outer cable so that the free play of

th,einner cable will be the standard value.

Standard value:

1 - 2 mm (.04 - .08 in.)3-5 mm

(.12-.20 in.)

NOTE

\JIf there is excessive play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a slope

will be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

(8) After adjusting, confirm that throttle valve fully opens and

closes by operating pedal.

(9) Adjust accelerator cable play and confirm throttle lever

stopper touches the fixed SAS.

ACCELERATOR SWITCH INSPECTION AND

A

nADJUSTMENTMlBFlBC

09FO117Make sure that when the accelerator pedal is free, there is

;$ustingcontinuity between the terminals of the accelerator switch and

/that when the pedal is pressed until the indicated pedal stroke

A reaches the standard value, there is no continuity between

the terminals of the switch.

Standard value:Accelerator switch switching point

2 - 6 mm (.079 - .24 in.)If stroke A is out of specification, adjust with adjusting bolt.

TSB Revision

\

‘LJ ~

Page 267 of 1146

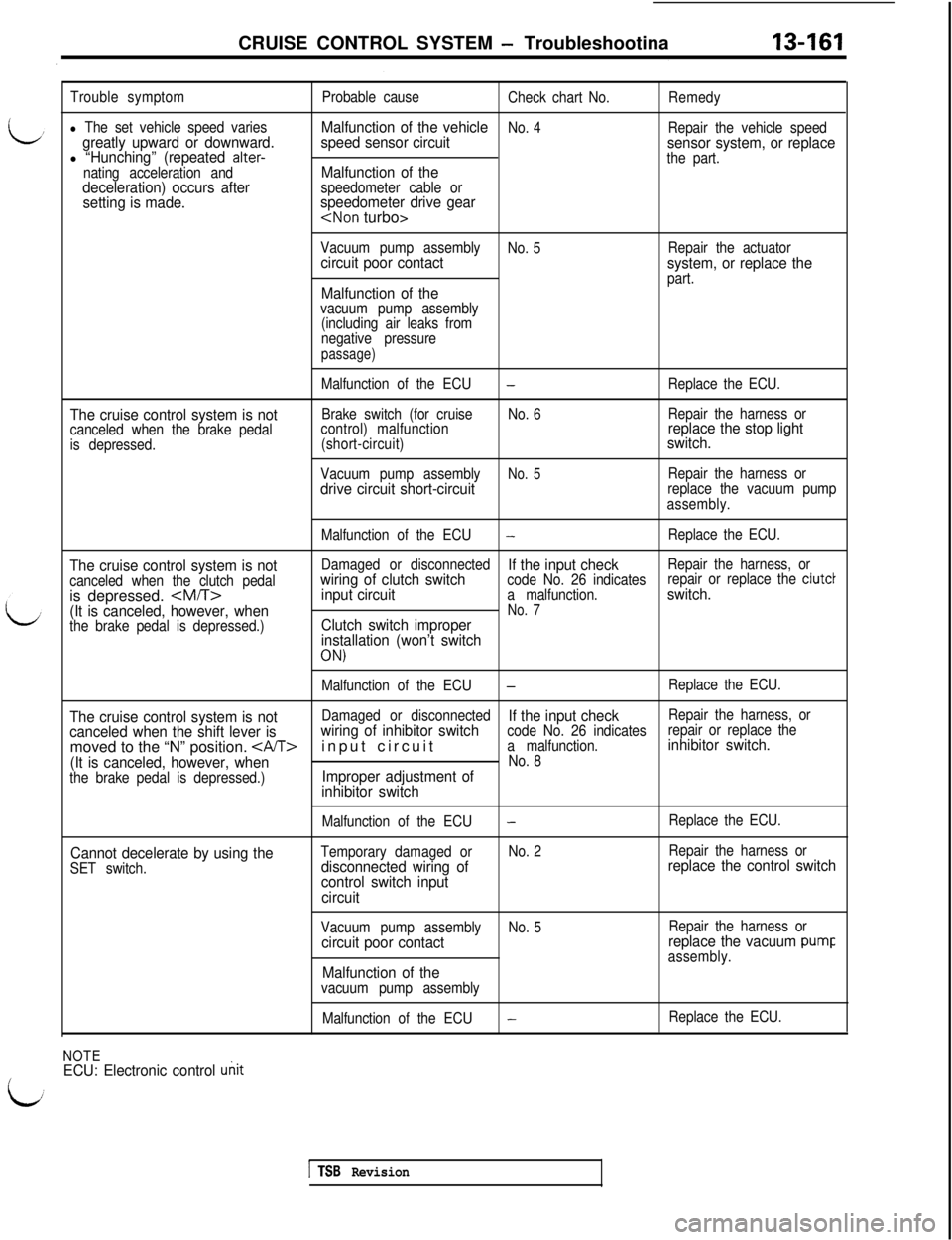

CRUISE CONTROL SYSTEM - Troubleshootina13461

Trouble symptom

l The set vehicle speed variesgreatly upward or downward.l “Hunching” (repeated alter-

nating acceleration and

deceleration) occurs after

setting is made.

Probable cause

Check chart No.Remedy

Malfunction of the vehicleNo. 4Repair the vehicle speedspeed sensor circuit

sensor system, or replacethe part.Malfunction of thespeedometer cable orspeedometer drive gear

Vacuum pump assembly

No. 5Repair the actuatorcircuit poor contact

system, or replace thepart.Malfunction of thevacuum pump assembly

(including air leaks from

negative pressure

passage)

The cruise control system is notcanceled when the brake pedal

is depressed.Malfunction of the ECU

-Replace the ECU.

Brake switch (for cruiseNo. 6Repair the harness or

control) malfunction

replace the stop light

(short-circuit)switch.

Vacuum pump assemblyNo. 5Repair the harness ordrive circuit short-circuitreplace the vacuum pump

assembly.

The cruise control system is notcanceled when the clutch pedalis depressed.

-Replace the ECU.

Damaged or disconnected

If the input checkRepair the harness, orwiring of clutch switchcode No. 26 indicatesrepair or replace the clutch

input circuita malfunction.switch.No. 7Clutch switch improper

installation (won’t switch

ON)

Malfunction of the ECU-Replace the ECU.

The cruise control system is notDamaged or disconnectedIf the input checkRepair the harness, or

canceled when the shift lever iswiring of inhibitor switchcode No. 26 indicatesrepair or replace themoved to the “N” position.

input circuita malfunction.inhibitor switch.

(It is canceled, however, when

No. 8

the brake pedal is depressed.)Improper adjustment of

inhibitor switch

Cannot decelerate by using the

SET switch.Malfunction of the ECU

Temporary damaged ordisconnected wiring of

control switch input

circuit

-

No. 2Replace the ECU.

Repair the harness orreplace the control switch

Vacuum pump assemblyNo. 5Repair the harness orcircuit poor contactreplace the vacuum puml:assembly.

Malfunction of thevacuum pump assembly

Malfunction of the ECU

-Replace the ECU.

NOTEECU: Electronic control unit

1 TSB Revision

Page 268 of 1146

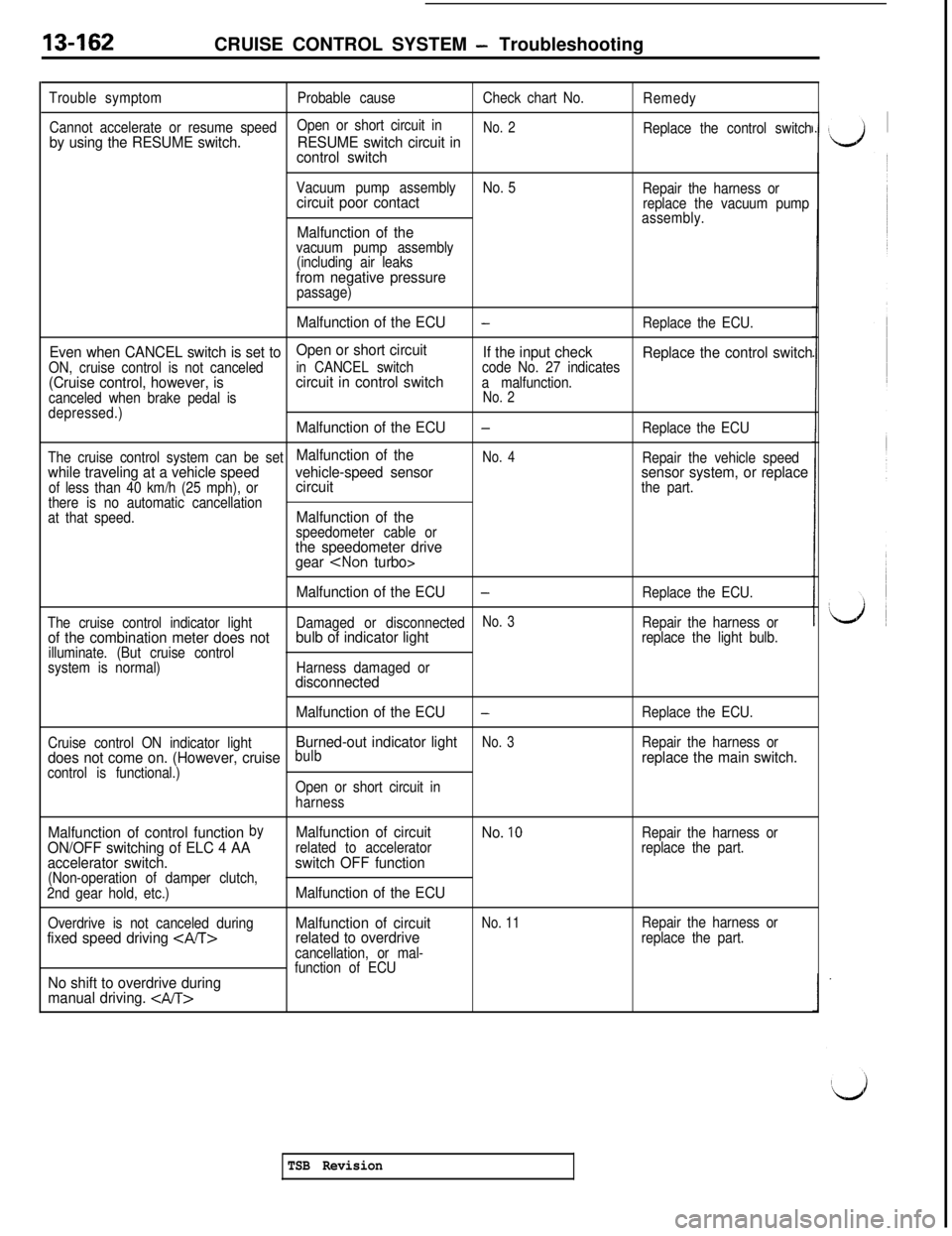

13-162CRUISE CONTROL SYSTEM - Troubleshooting

Trouble symptomProbable causeCheck chart No.

Remedy

Cannot accelerate or resume speedOpen or short circuit in

No. 2by using the RESUME switch.RESUME switch circuit inReplace the control switch

control switch

Vacuum pump assemblyNo. 5circuit poor contactRepair the harness or

replace the vacuum pump

Malfunction of thevacuum pump assembly

(including air leaks

from negative pressurepassage)assembly.

Malfunction of the ECU-Replace the ECU.

Even when CANCEL switch is set toON, cruise control is not canceled

Open or short circuit

in CANCEL switchIf the input check

Replace the control switch

(Cruise control, however, iscode No. 27 indicatescircuit in control switch

canceled when brake pedal isa malfunction.

depressed.)No. 2

Malfunction of the ECU-Replace the ECU

The cruise control system can be set

Malfunction of theNo. 4while traveling at a vehicle speedvehicle-speed sensorRepair the vehicle speed

of less than 40 km/h (25 mph), or

circuitsensor system, or replace

there is no automatic cancellationthe part.

at that speed.Malfunction of thespeedometer cable orthe speedometer drive

gear

Malfunction of the ECU

-Replace the ECU.

The cruise control indicator light

No. 3

of the combination meter does notDamaged or disconnectedbulb of indicator lightRepair the harness or

illuminate. (But cruise controlreplace the light bulb.

system is normal)Harness damaged or

disconnected

Malfunction of the ECU

-Replace the ECU.

Cruise control ON indicator light

No. 3

does not come on. (However, cruiseBurned-out indicator lightbulbRepair the harness or

control is functional.)replace the main switch.

Open or short circuit in

harness

Malfunction of control functionby

ON/OFF switching of ELC 4 AA

accelerator switch.

(Non-operation of damper clutch,

2nd gear hold, etc.)

Overdrive is not canceled during

fixed speed driving

No shift to overdrive during

manual driving.

Malfunction of circuitrelated to acceleratorswitch OFF function

Malfunction of the ECU

Malfunction of circuit

related to overdrive

cancellation, or mal-

function of ECU

No. IO

No. 11Repair the harness or

replace the part.

Repair the harness or

replace the part.

TSB Revision