ECU MITSUBISHI 3000GT 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 304 of 1146

14-10COOLING - Radiator

r-----I

113

EY

4 :

2 :

i.-.-..i

0312161908

Ionnector04FOOO8

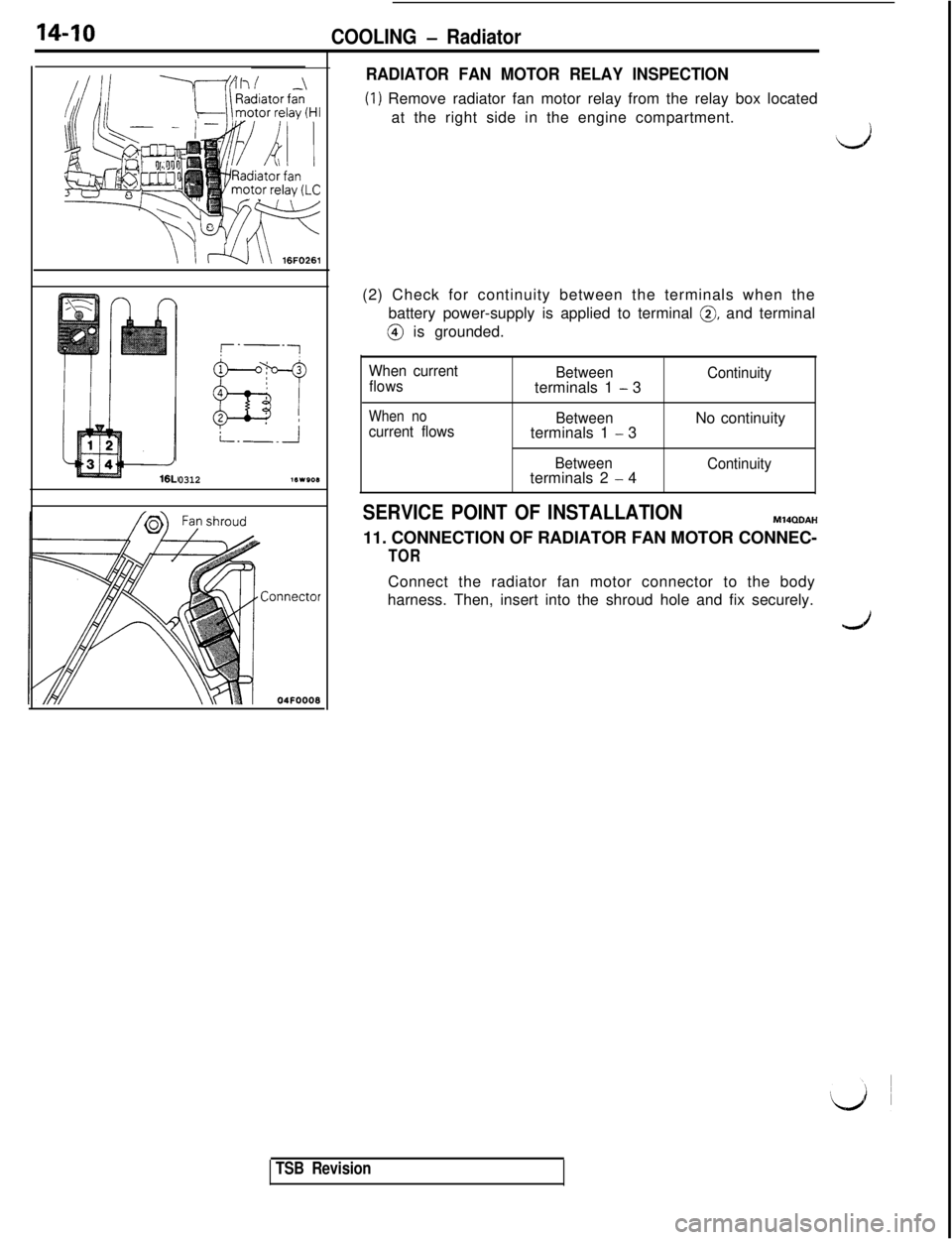

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor relay from the relay box located

at the right side in the engine compartment.

Ll(2) Check for continuity between the terminals when the

battery power-supply is applied to terminal

0, and terminal@ is grounded.

When current

flowsBetweenterminals 1

- 3Continuity

When nocurrent flowsBetweenterminals 1 - 3No continuity

Betweenterminals 2 - 4Continuity

SERVICE POINT OF INSTALLATIONM14QDAH

11. CONNECTION OF RADIATOR FAN MOTOR CONNEC-

TORConnect the radiator fan motor connector to the body

harness. Then, insert into the shroud hole and fix securely.

TSB Revision

Page 322 of 1146

15-12INTAKE AND EXHAUST - lntercooier

SERVICE POINT OF REMOVALMlSTSAC

13. REMOVAL OF ENGINE OIL COOLERIDisconnect the hose from the engine oil cooler and remove

the engine oil cooler only.

IL)

INSPECTIONMISTCAB

lCheck the intercooler fins for bending, damage, or foreign

matter.

lCheck the intercooler hoses for cracking, damage, or wear.

Air Intake hose B

Air hose

05FOO21

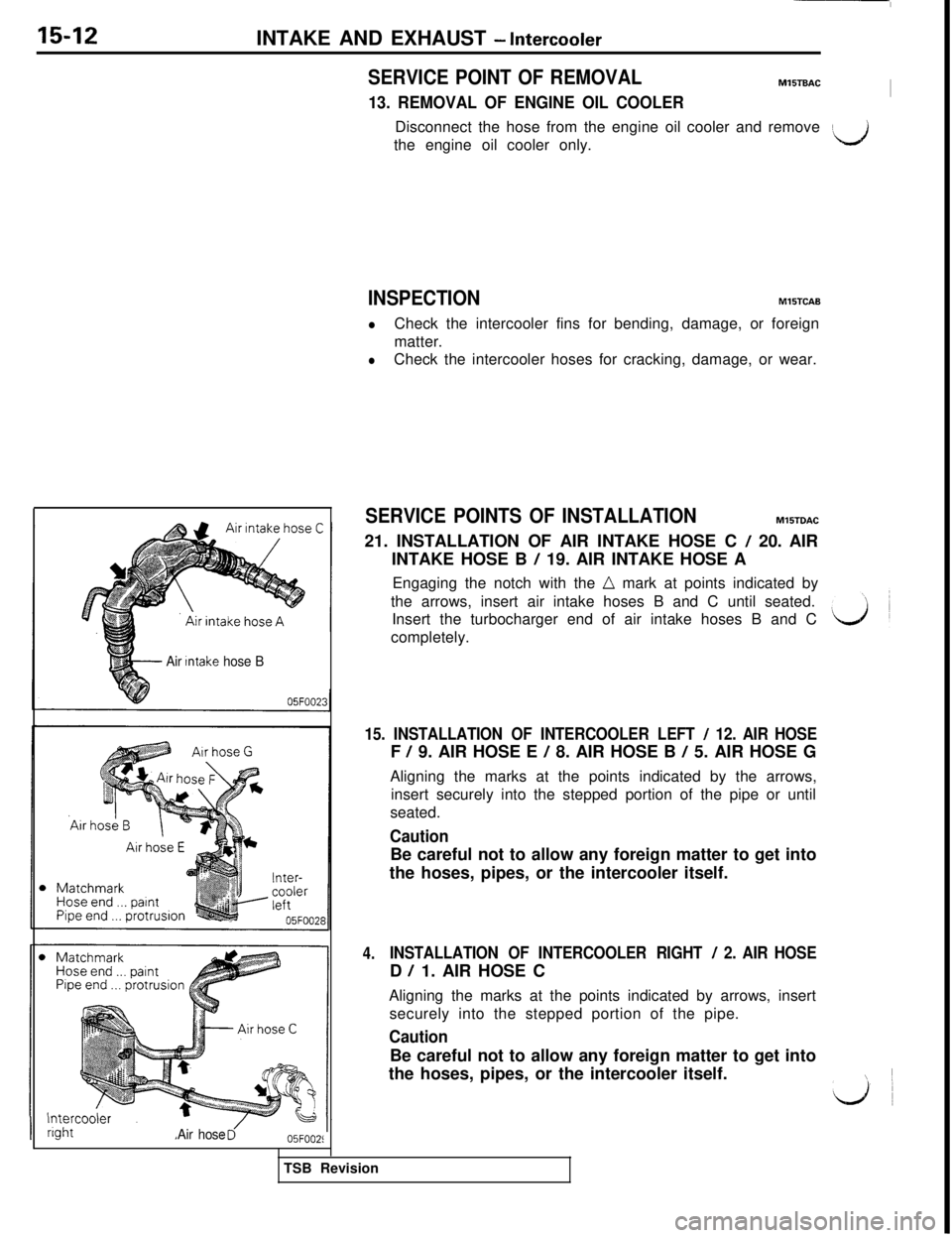

SERVICE POINTS OF INSTALLATIONMlSTDAC

21. INSTALLATION OF AIR INTAKE HOSE C

/ 20. AIR

INTAKE HOSE B

/ 19. AIR INTAKE HOSE A

Engaging the notch with the

n mark at points indicated by

the arrows, insert air intake hoses B and C until seated.

Insert the turbocharger end of air intake hoses B and C

completely.

15. INSTALLATION OF INTERCOOLER LEFT / 12. AIR HOSEF

/ 9. AIR HOSE E / 8. AIR HOSE B / 5. AIR HOSE G

Aligning the marks at the points indicated by the arrows,

insert securely into the stepped portion of the pipe or until

seated.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

4.INSTALLATION OF INTERCOOLER RIGHT / 2. AIR HOSED

/ 1. AIR HOSE C

Aligning the marks at the points indicated by arrows, insert

securely into the stepped portion of the pipe.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

1 ~

LJ~TSB Revision

Page 330 of 1146

15-20INTAKE AND EXHAUST - Turbocharger (Front)

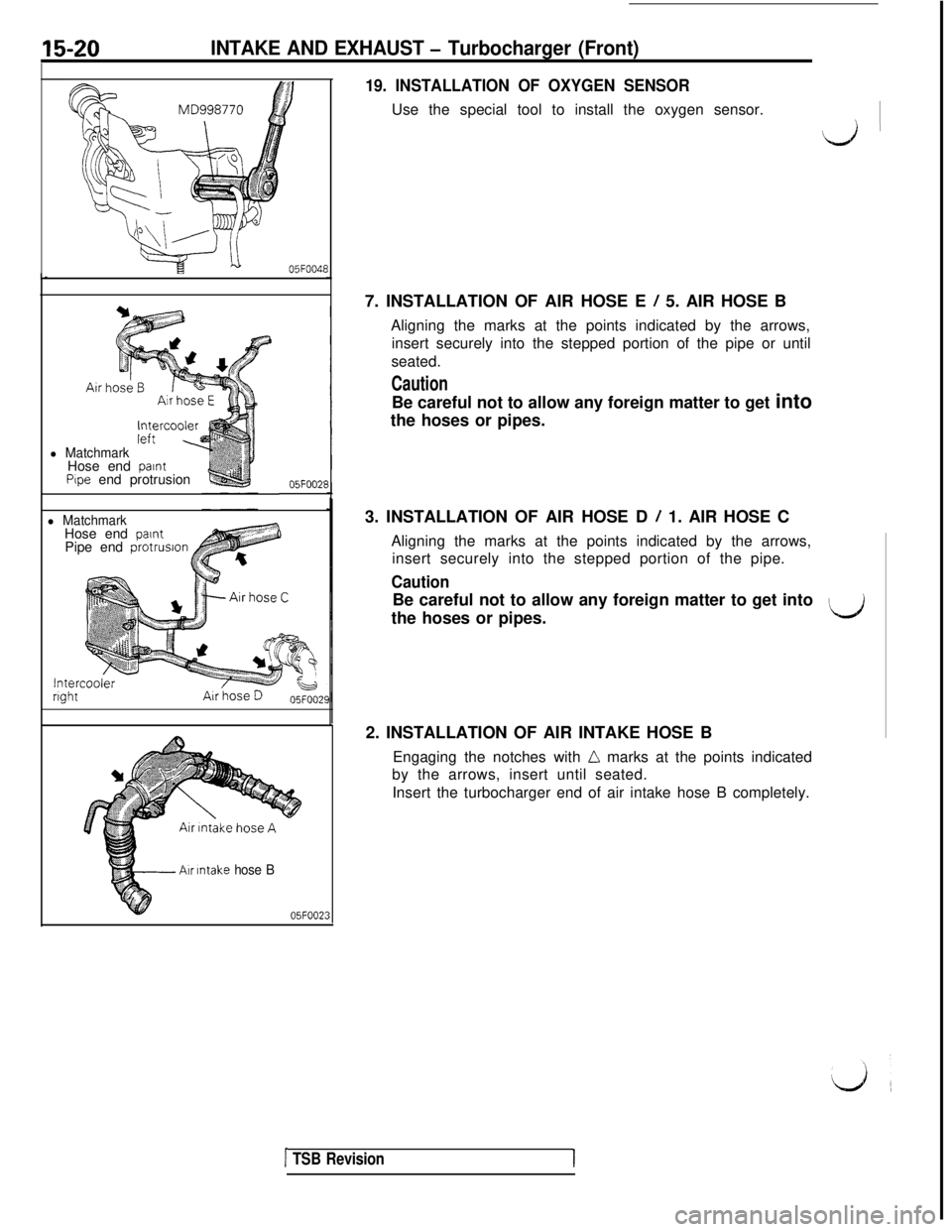

19. INSTALLATION OF OXYGEN SENSORUse the special tool to install the oxygen sensor.

I;,iI-

i=x---b05F004E

l MatchmarkHose end paintPipe end protrusion05F002F

l MatchmarkHose end paintPipe end protrusion

Intercoolerright

J

Air Intake hose B

05FOO237. INSTALLATION OF AIR HOSE E

/ 5. AIR HOSE B

Aligning the marks at the points indicated by the arrows,

insert securely into the stepped portion of the pipe or until

seated.

CautionBe careful not to allow any foreign matter to get into

the hoses or pipes.

3. INSTALLATION OF AIR HOSE D

/ 1. AIR HOSE C

Aligning the marks at the points indicated by the arrows,

insert securely into the stepped portion of the pipe.

CautionBe careful not to allow any foreign matter to get into

the hoses or pipes.

LJ2. INSTALLATION OF AIR INTAKE HOSE B

Engaging the notches with

LL marks at the points indicated

by the arrows, insert until seated.

Insert the turbocharger end of air intake hose B completely.

[ TSB RevisionI

Page 333 of 1146

INTAKE AND EXHAUST - Turbocharger (Rear)15-23

Air intake hose A

Air intake hose BHose end

paint

3

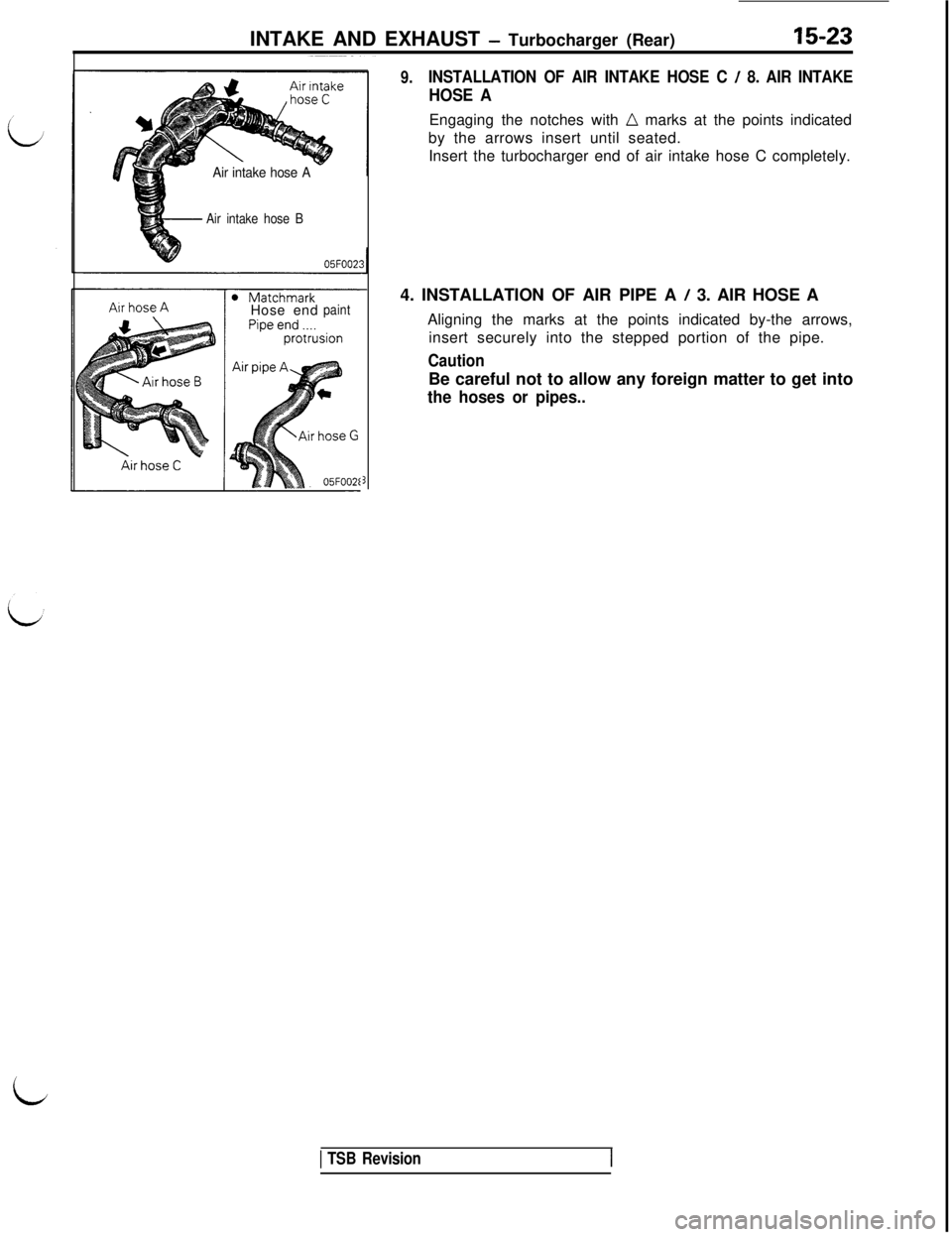

9.INSTALLATION OF AIR INTAKE HOSE C / 8. AIR INTAKE

HOSE AEngaging the notches with

n marks at the points indicated

by the arrows insert until seated.

Insert the turbocharger end of air intake hose C completely.

4. INSTALLATION OF AIR PIPE A

/ 3. AIR HOSE A

Aligning the marks at the points indicated by-the arrows,

insert securely into the stepped portion of the pipe.

CautionBe careful not to allow any foreign matter to get into

the hoses or pipes..

1 TSB Revision

id

Page 363 of 1146

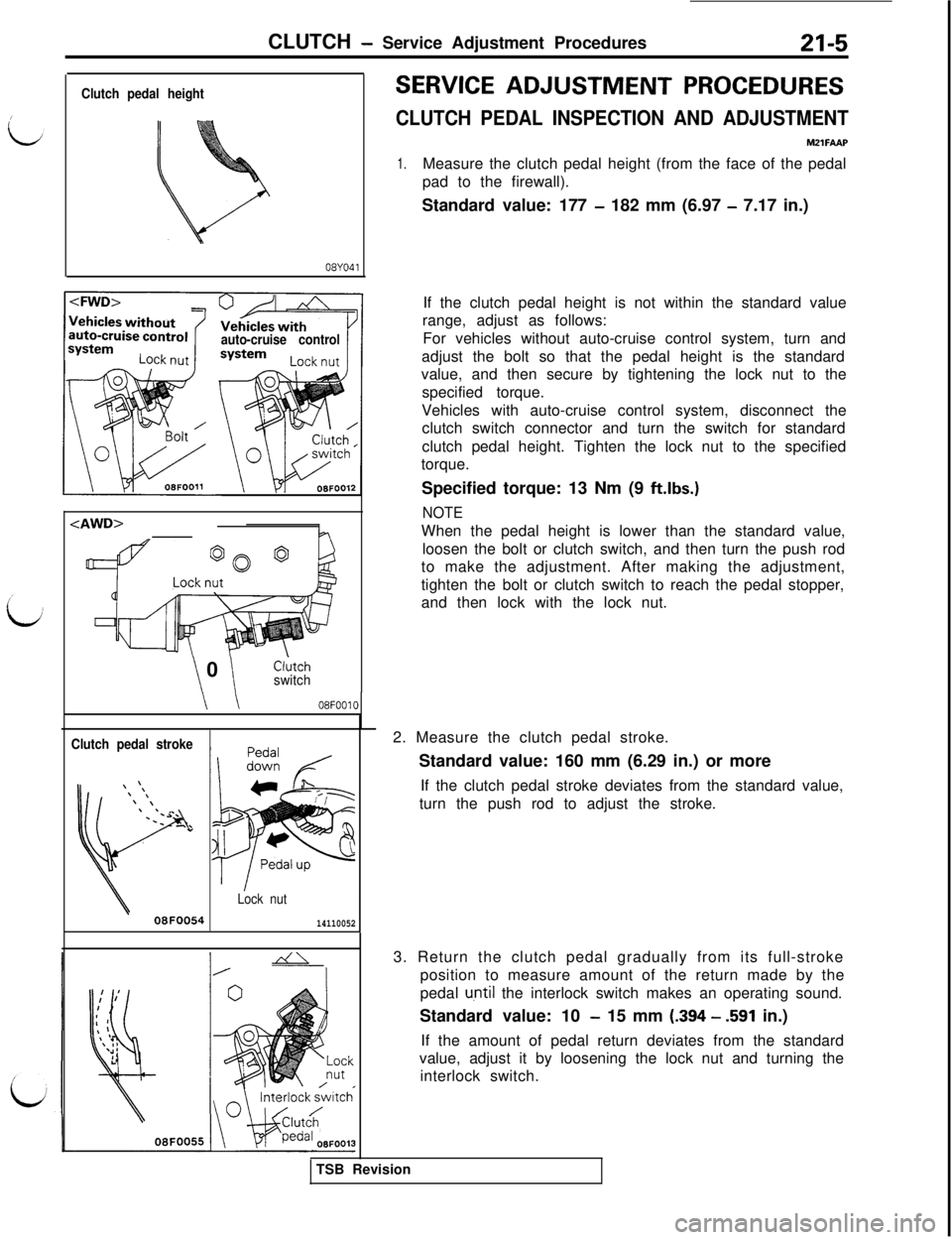

CLUTCH - Service Adjustment Procedures21-5

Clutch pedal height

08YO41

auto-cruise control

\ \ 0Cl;tchswitch

\ \08F0010

Clutch pedal stroke

Lock nut

08F005414110052

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTMENTMZlFAAP

1.Measure the clutch pedal height (from the face of the pedal

pad to the firewall).

Standard value: 177

- 182 mm (6.97 - 7.17 in.)

If the clutch pedal height is not within the standard value

range, adjust as follows:

For vehicles without auto-cruise control system, turn and

adjust the bolt so that the pedal height is the standard

value, and then secure by tightening the lock nut to the

specified torque.

Vehicles with auto-cruise control system, disconnect the

clutch switch connector and turn the switch for standard

clutch pedal height. Tighten the lock nut to the specified

torque.

Specified torque: 13 Nm (9

ft.lbs.)

NOTEWhen the pedal height is lower than the standard value,

loosen the bolt or clutch switch, and then turn the push rod

to make the adjustment. After making the adjustment,

tighten the bolt or clutch switch to reach the pedal stopper,

and then lock with the lock nut.

2. Measure the clutch pedal stroke.

Standard value: 160 mm (6.29 in.) or more

If the clutch pedal stroke deviates from the standard value,

turn the push rod to adjust the stroke.

3. Return the clutch pedal gradually from its full-stroke

position to measure amount of the return made by the

pedal

u,ntil the interlock switch makes an operating sound.

Standard value: 10

- 15 mm (.394 - .591 in.)

If the amount of pedal return deviates from the standard

value, adjust it by loosening the lock nut and turning the

interlock switch.

TSB Revision

Page 370 of 1146

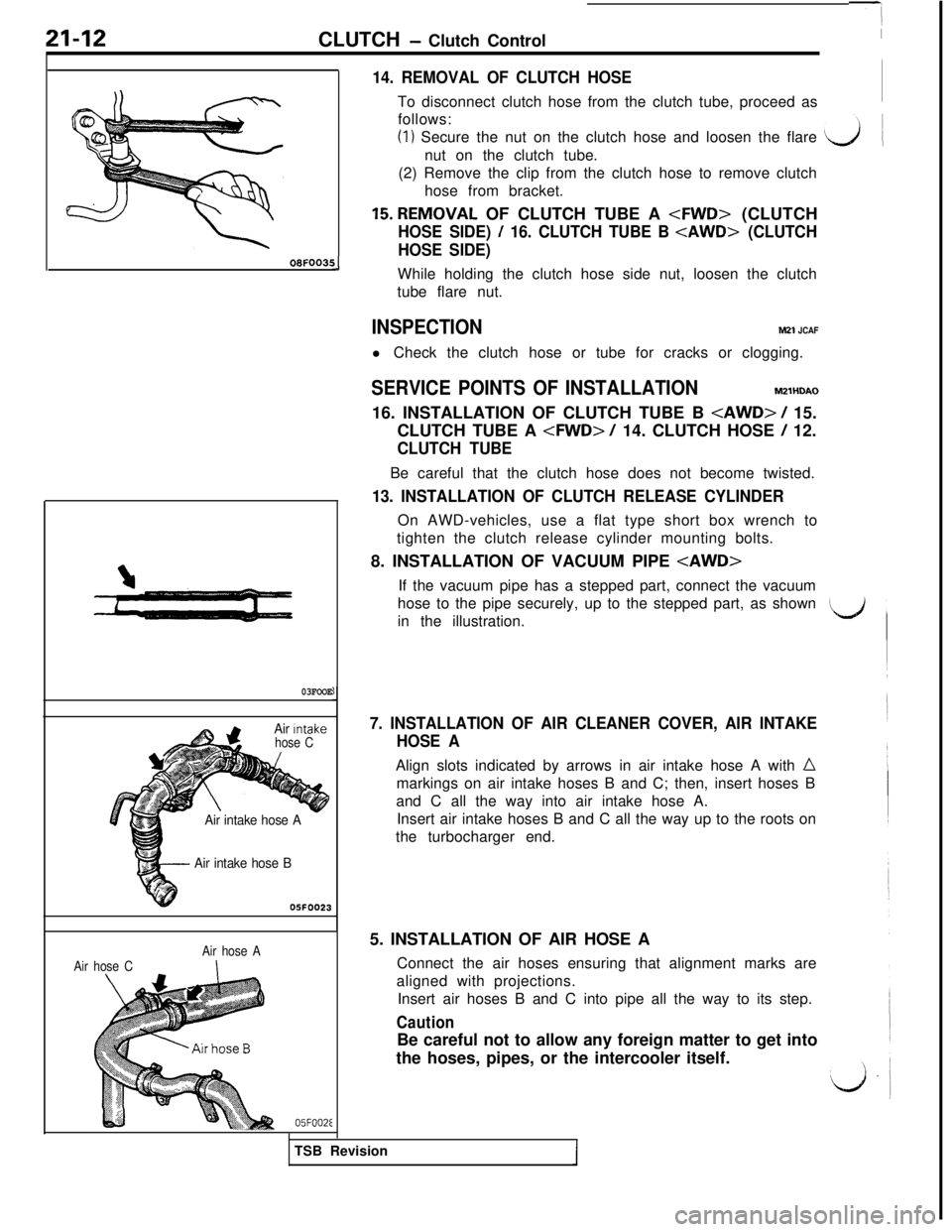

21-12CLUTCH - Clutch ControlOBFOOBf

!J

03FOOE

- Air intake hose B05FOO23

Air Intake

hose C

aAir intake hose A

Air hose CAir hose AI

05FOOZE

14. REMOVAL OF CLUTCH HOSETo disconnect clutch hose from the clutch tube, proceed as

follows:

(I) Secure the nut on the clutch hose and loosen the flare

nut on the clutch tube.

(2) Remove the clip from the clutch hose to remove clutch

hose from bracket.

15.REMOVAL OF CLUTCH TUBE A

HOSE SIDE) / 16. CLUTCH TUBE B

HOSE SIDE)While holding the clutch hose side nut, loosen the clutch

tube flare nut.

INSPECTIONM21 JCAFl Check the clutch hose or tube for cracks or clogging.

SERVICE POINTS OF INSTALLATIONM2lHDAO

16. INSTALLATION OF CLUTCH TUBE B

CLUTCH TUBE A

CLUTCH TUBEBe careful that the clutch hose does not become twisted.

13. INSTALLATION OF CLUTCH RELEASE CYLINDEROn AWD-vehicles, use a flat type short box wrench to

tighten the clutch release cylinder mounting bolts.

8. INSTALLATION OF VACUUM PIPE

hose to the pipe securely, up to the stepped part, as shown

in the illustration.

7. INSTALLATION OF AIR CLEANER COVER, AIR INTAKE

HOSE AAlign slots indicated by arrows in air intake hose A with

nmarkings on air intake hoses B and C; then, insert hoses B

and C all the way into air intake hose A.

Insert air intake hoses B and C all the way up to the roots on

the turbocharger end.

5. INSTALLATION OF AIR HOSE A

Connect the air hoses ensuring that alignment marks are

aligned with projections.

Insert air hoses B and C into pipe all the way to its step.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

TSB Revision

Page 389 of 1146

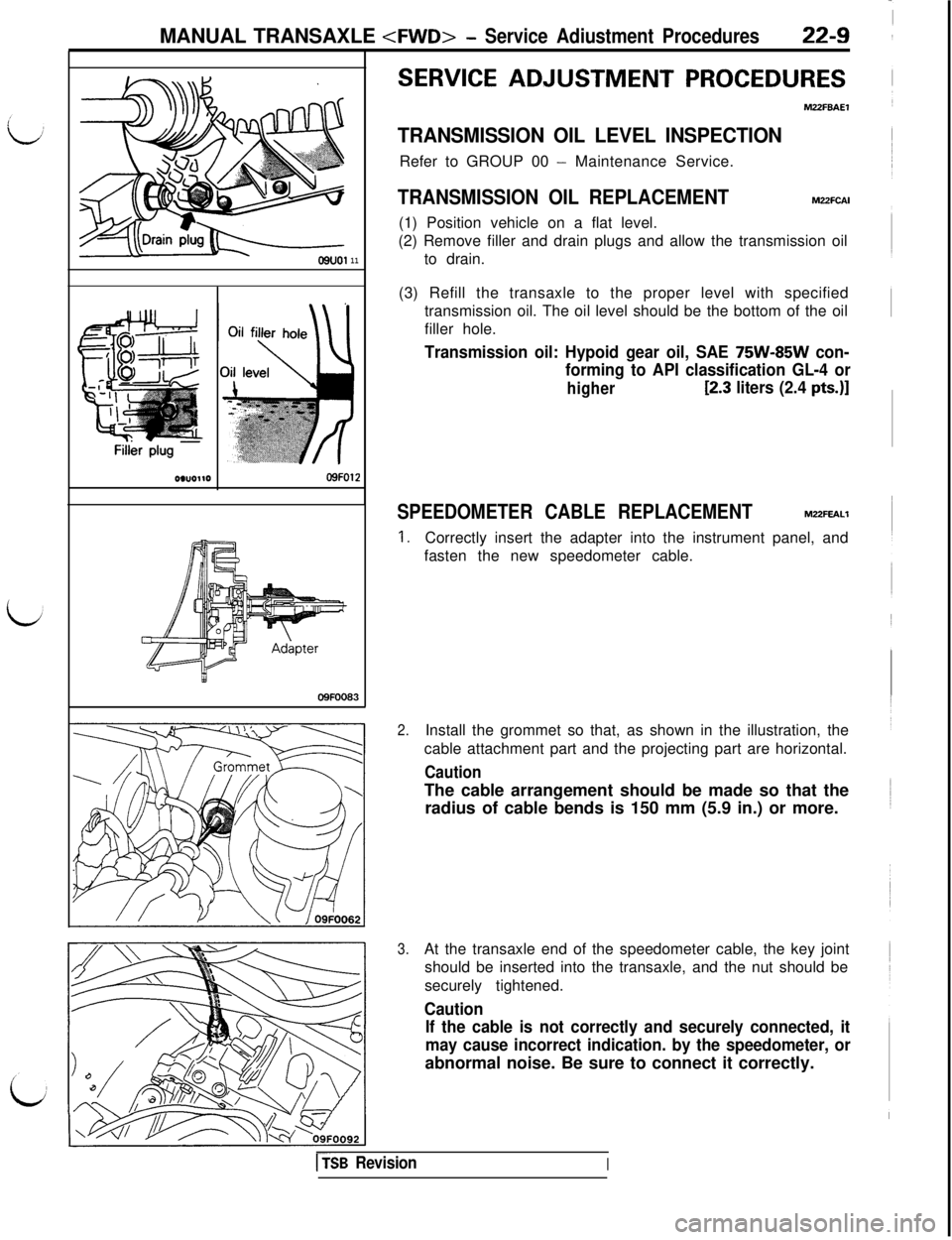

MANUAL TRANSAXLE

110*u011009FO12

SERVICE ADJUSTMENT PROCEDURES

MZZFBAEl

TRANSMISSION OIL LEVEL INSPECTIONRefer to GROUP 00

- Maintenance Service.

TRANSMISSION OIL REPLACEMENTM22FCAI(1) Position vehicle on a flat level.

(2) Remove filler and drain plugs and allow the transmission oil

to drain.

(3) Refill the transaxle to the proper level with specified

transmission oil. The oil level should be the bottom of the oil

filler hole.

Transmission oil: Hypoid gear oil, SAE 75W-85W con-

forming to API classification GL-4 or

higherC2.3 liters (2.4 pts.)]

SPEEDOMETER CABLE REPLACEMENTMUFEALl

1.Correctly insert the adapter into the instrument panel, and

fasten the new speedometer cable.

2.Install the grommet so that, as shown in the illustration, the

cable attachment part and the projecting part are horizontal.

CautionThe cable arrangement should be made so that the

radius of cable bends is 150 mm (5.9 in.) or more.

3.At the transaxle end of the speedometer cable, the key joint

should be inserted into the transaxle, and the nut should be

securely tightened.

Caution

If the cable is not correctly and securely connected, it

may cause incorrect indication. by the speedometer, orabnormal noise. Be sure to connect it correctly.

DSB RevisionI

Page 395 of 1146

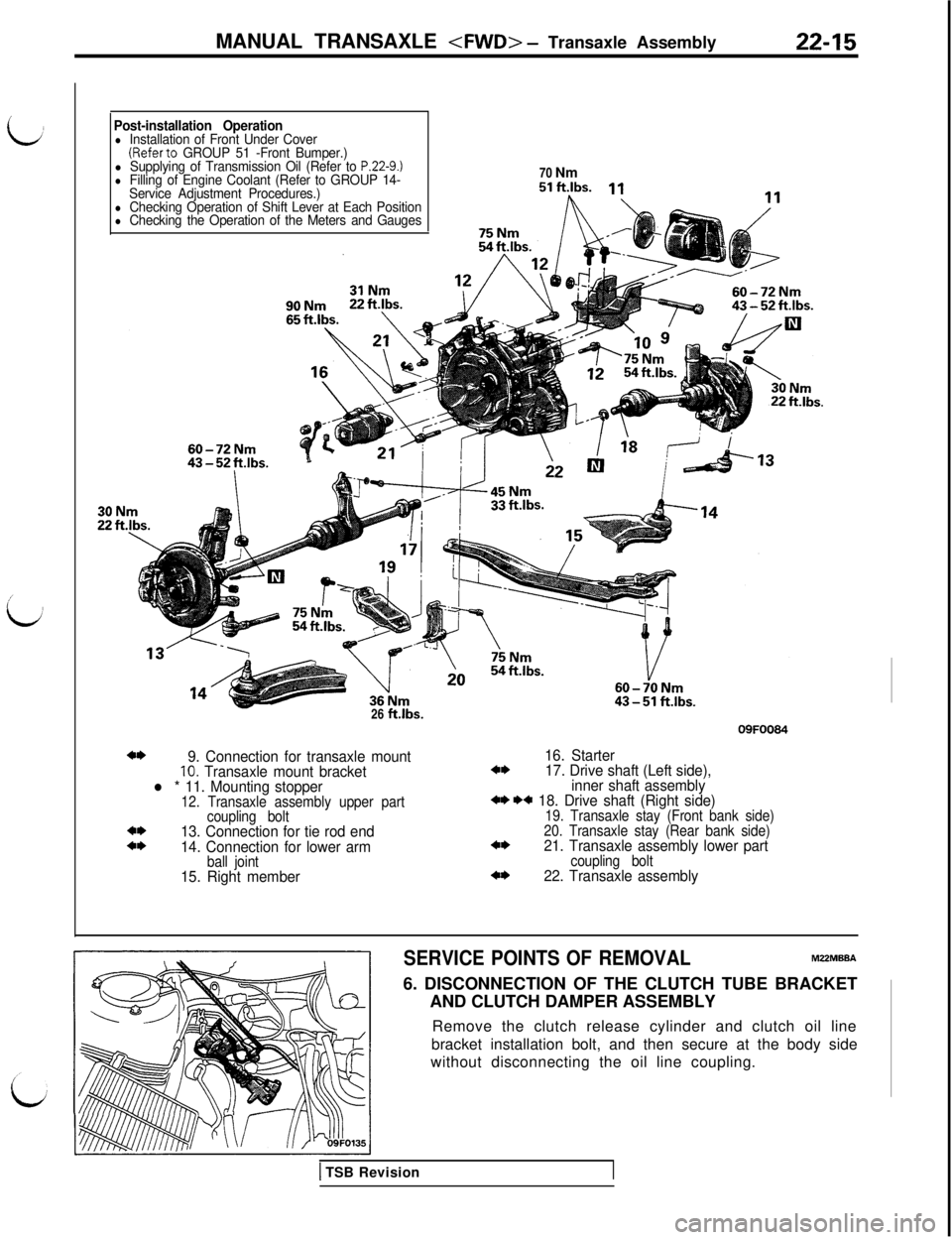

MANUAL TRANSAXLE

idPost-installation Operationl Installation of Front Under Cover(Referto GROUP 51 -Front Bumper.)l Supplying of Transmission Oil (Refer to P.22-9.)l Filling of Engine Coolant (Refer to GROUP 14-

Service Adjustment Procedures.)70 Nm

l Checking Operation of Shift Lever at Each Positionl Checking the Operation of the Meters and Gauges26

ft.lbs.09FOO84

4*9. Connection for transaxle mount16. Starter10. Transaxle mount bracket4*17. Drive shaft (Left side),

l * 11. Mounting stopperinner shaft assembly12. Transaxle assembly upper part+* ** 18. Drive shaft (Right side)

coupling bolt19. Transaxle stay (Front bank side)4*13. Connection for tie rod end20. Transaxle stay (Rear bank side)4*14. Connection for lower arm4*21. Transaxle assembly lower part

ball jointcoupling bolt15. Right member4*22. Transaxle assembly

SERVICE POINTS OF REMOVALMZZMBBA6. DISCONNECTION OF THE CLUTCH TUBE BRACKET

AND CLUTCH DAMPER ASSEMBLY

Remove the clutch release cylinder and clutch oil line

bracket installation bolt, and then secure at the body side

without disconnecting the oil line coupling.

1 TSB Revision

Page 435 of 1146

MANUAL TRANSAXLE

03FOO

Air‘mtakehose A Air intake

hose C

Air intake hose B05FOO2:

Air hose A

05FOOZE

8

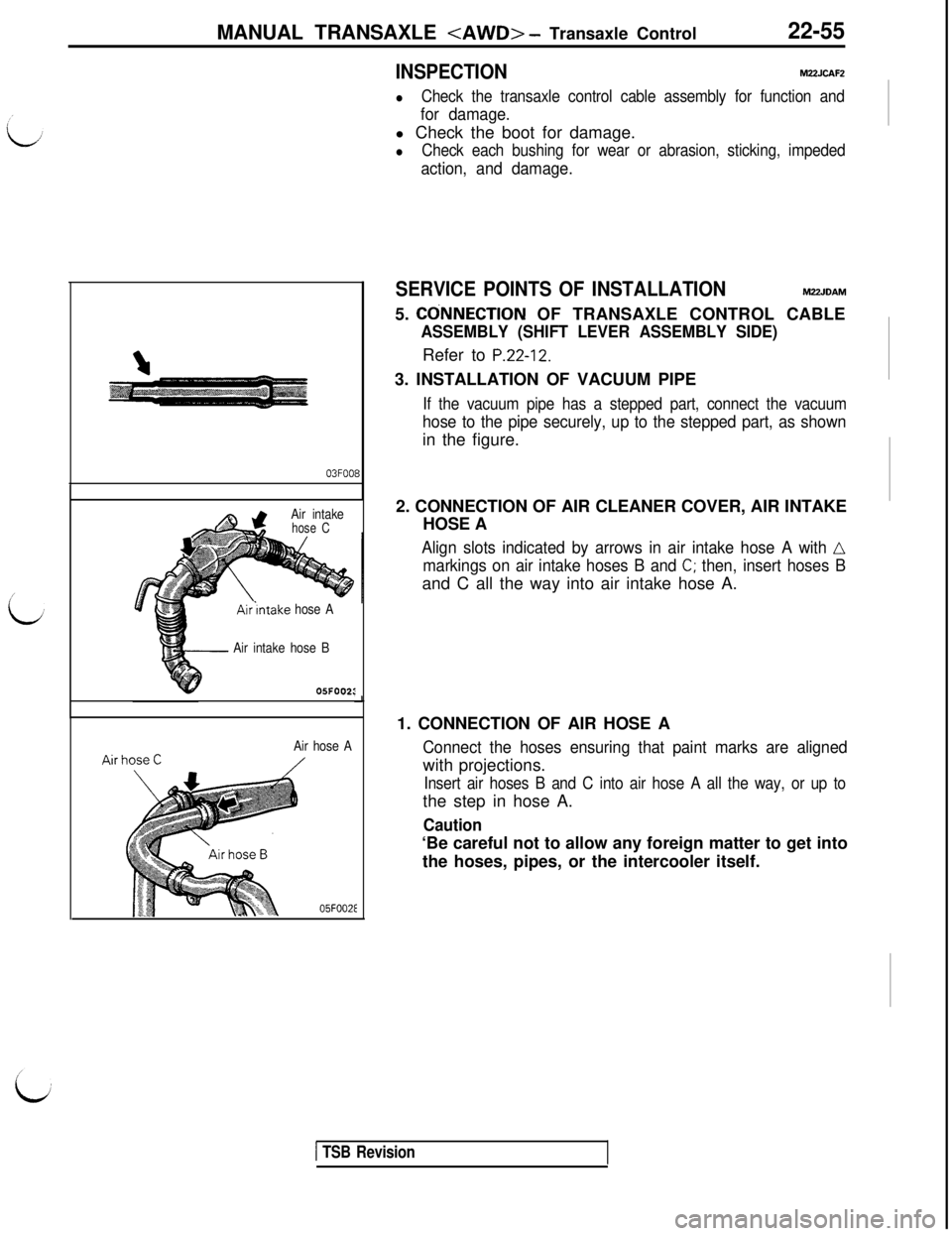

INSPECTIONM22JCAFZ

lCheck the transaxle control cable assembly for function and

for damage.l Check the boot for damage.

lCheck each bushing for wear or abrasion, sticking, impeded

action, and damage.

SERVICE POINTS OF INSTALLATIONM22JDAM5.

CdNNECTlON OF TRANSAXLE CONTROL CABLE

ASSEMBLY (SHIFT LEVER ASSEMBLY SIDE)Refer to

P.22-12.3. INSTALLATION OF VACUUM PIPE

If the vacuum pipe has a stepped part, connect the vacuum

hose to the pipe securely, up to the stepped part, as shownin the figure.

2. CONNECTION OF AIR CLEANER COVER, AIR INTAKE

HOSE A

Align slots indicated by arrows in air intake hose A with n

markings on air intake hoses B and C; then, insert hoses Band C all the way into air intake hose A.

1. CONNECTION OF AIR HOSE A

Connect the hoses ensuring that paint marks are alignedwith projections.

Insert air hoses B and C into air hose A all the way, or up tothe step in hose A.

Caution‘Be careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

1 TSB Revision

Page 438 of 1146

22-58

MANUAL TRANSAXLE

SERVICE POINTS OF REMOVALMPMBBB11. REMOVAL OF CLUTCH RELEASE CYLINDER

/ 12.

CONNECTION OF TRANSAXLE MOUNT

Refer to

PZ-15.‘L-J

18. DISCONNECTION OF TIE ROD END / 19. LOWER ARM

BALL JOINTRefer to

P.22-16.

23. REMOVAL OF DRIVE SHAFT (LEFT SIDE), INNER SHAFTASSEMBLY

/ 24. DRIVE SHAFT (RIGHT SIDE) / 27.

TRANSAXLE ASSEMBLY LOWER COUPLING BOLT / 28.

TRANSAXLE ASSEMBLYRefer to

P.22-16.

SERVICE POINTS OF INSTALLATIONM22MDAU24. INSTALLATION OF DRIVE SHAFT (RIGHT SIDE)

/ 15.

MOUNTING STOPPERRefer to

P.22-17.

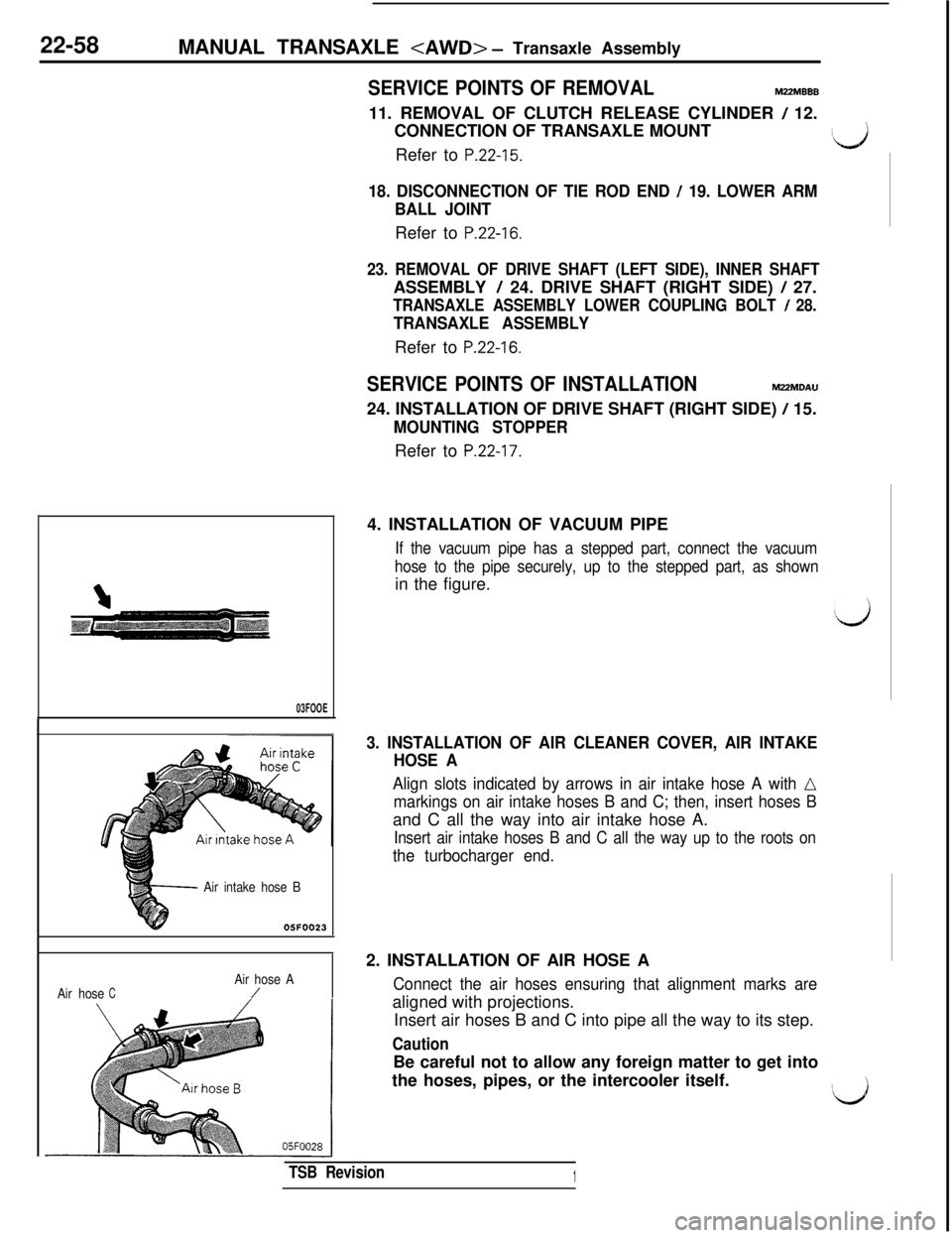

03FOOE

Air intake hose B

05FOO23

Air hose A

Air hoseC/4. INSTALLATION OF VACUUM PIPE

If the vacuum pipe has a stepped part, connect the vacuum

hose to the pipe securely, up to the stepped part, as shownin the figure.

3. INSTALLATION OF AIR CLEANER COVER, AIR INTAKE

HOSE A

Align slots indicated by arrows in air intake hose A with LI

markings on air intake hoses B and C; then, insert hoses Band C all the way into air intake hose A.

Insert air intake hoses B and C all the way up to the roots on

the turbocharger end.2. INSTALLATION OF AIR HOSE A

Connect the air hoses ensuring that alignment marks arealigned with projections.

Insert air hoses B and C into pipe all the way to its step.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

#L.&J

TSB Revision1