ECU MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 474 of 1146

![MITSUBISHI 3000GT 1991 Workshop Manual 23-22AUTOMATIC TRANSAXLE - Troubleshooting

0”

TM362

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION

1.Drive until the fluid temperature reaches the usual tempera-

ture

[70 - 80°C (160 - 18O”F)].2. MITSUBISHI 3000GT 1991 Workshop Manual 23-22AUTOMATIC TRANSAXLE - Troubleshooting

0”

TM362

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION

1.Drive until the fluid temperature reaches the usual tempera-

ture

[70 - 80°C (160 - 18O”F)].2.](/img/19/57085/w960_57085-473.png)

23-22AUTOMATIC TRANSAXLE - Troubleshooting

0”

TM362

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION

1.Drive until the fluid temperature reaches the usual tempera-

ture

[70 - 80°C (160 - 18O”F)].2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position. This operation is necessary to

be sure that fluid level check is accurate.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the condition

of the fluid.

The transaxle should be overhauled under the following

conditions.

l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

lIf there is a noticeably great amount of metal particles in

the fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transaxle fluid until level

reaches “HOT” range.

Low fluid level can cause a variety of conditions because it

allows pump to take in air along with fluid. Air trapped in

hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and

cause same conditions which occur with low fluid level,

resulting in accelerated deterioration of automatic transaxle

fluid.

dIn either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch, and

servo operation. Foaming can also result in fluid escaping

from transaxle vent where it may be mistaken for a leak.

6. Be sure to examine fluid on dipstick closely.

,CONTROL CABLEWhether control cable is properly adjusted can be confirmed by

checking whether inhibitor switch is performing well.

1. Apply parking brakes and service brakes securely.

2. Place selector lever to “R” range.

3. Set ignition key to “ST” position.

4. Slowly move the selector lever upward until it clicks as it

fits in notch of “P” range. If starter motor operates when

lever makes a click, “P” position is correct.

5.Then slowly move selector lever to “N” range by the same

procedure as in foregoing paragraph. If starter motor

operates when selector lever fits in

“N”, “N” position is

correct.

6. Also check to be sure the vehicle doesn’t begin to move

and the lever doesn’t stop between P-R-N-D.

7. The control cable is properly adjusted if, as described

above, the starter motor starts at both the “P” range and

the “N” range.

TSB Revision

Page 478 of 1146

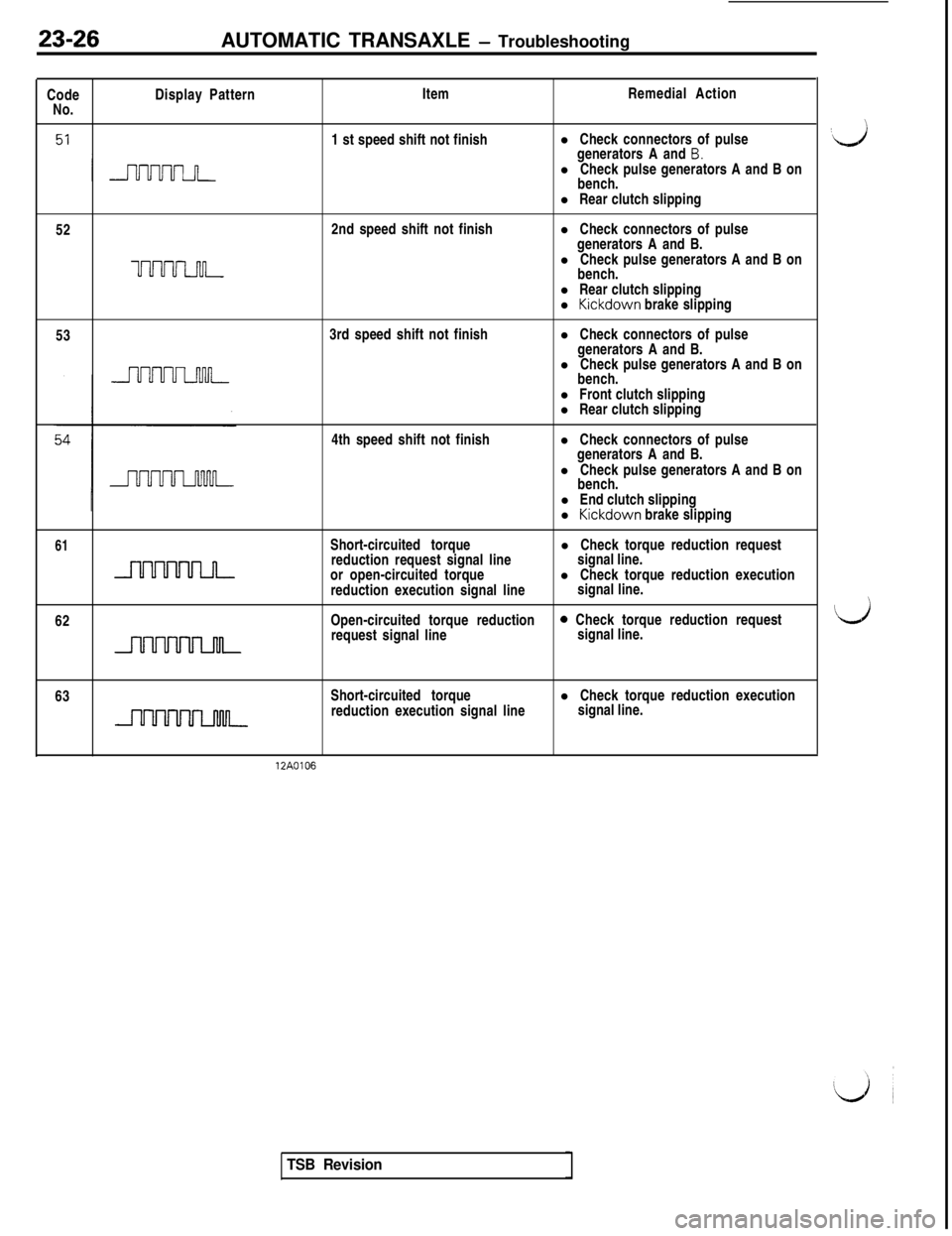

23-26AUTOMATIC TRANSAXLE - Troubleshooting

Code

No.Display PatternItemRemedial Action

1 st speed shift not finishl Check connectors of pulse

generators A and

B.l Check pulse generators A and B on

bench.

l Rear clutch slipping

52

uuuuu-ln-2nd speed shift not finishl Check connectors of pulse

generators A and B.

l Check pulse generators A and B on

bench.

l Rear clutch slipping

533rd speed shift not finishl Kickdown brake slipping

l Check connectors of pulse

generators A and B.

4th speed shift not finishl Check pulse generators A and B on

bench.

l Front clutch slipping

l Rear clutch slipping

l Check connectors of pulse

generators A and B.

l Check pulse generators A and B on

bench.

l End clutch slipping

6162l Kickdown brake slipping

Short-circuited torque

reduction request signal linel Check torque reduction request

or open-circuited torquesignal line.

reduction execution signal linel Check torque reduction execution

signal line.

Open-circuited torque reduction

request signal line0 Check torque reduction request

signal line.

63Short-circuited torque

reduction execution signal linel Check torque reduction execution

signal line.

12A0106

‘J

\J

TSB Revision

Page 487 of 1146

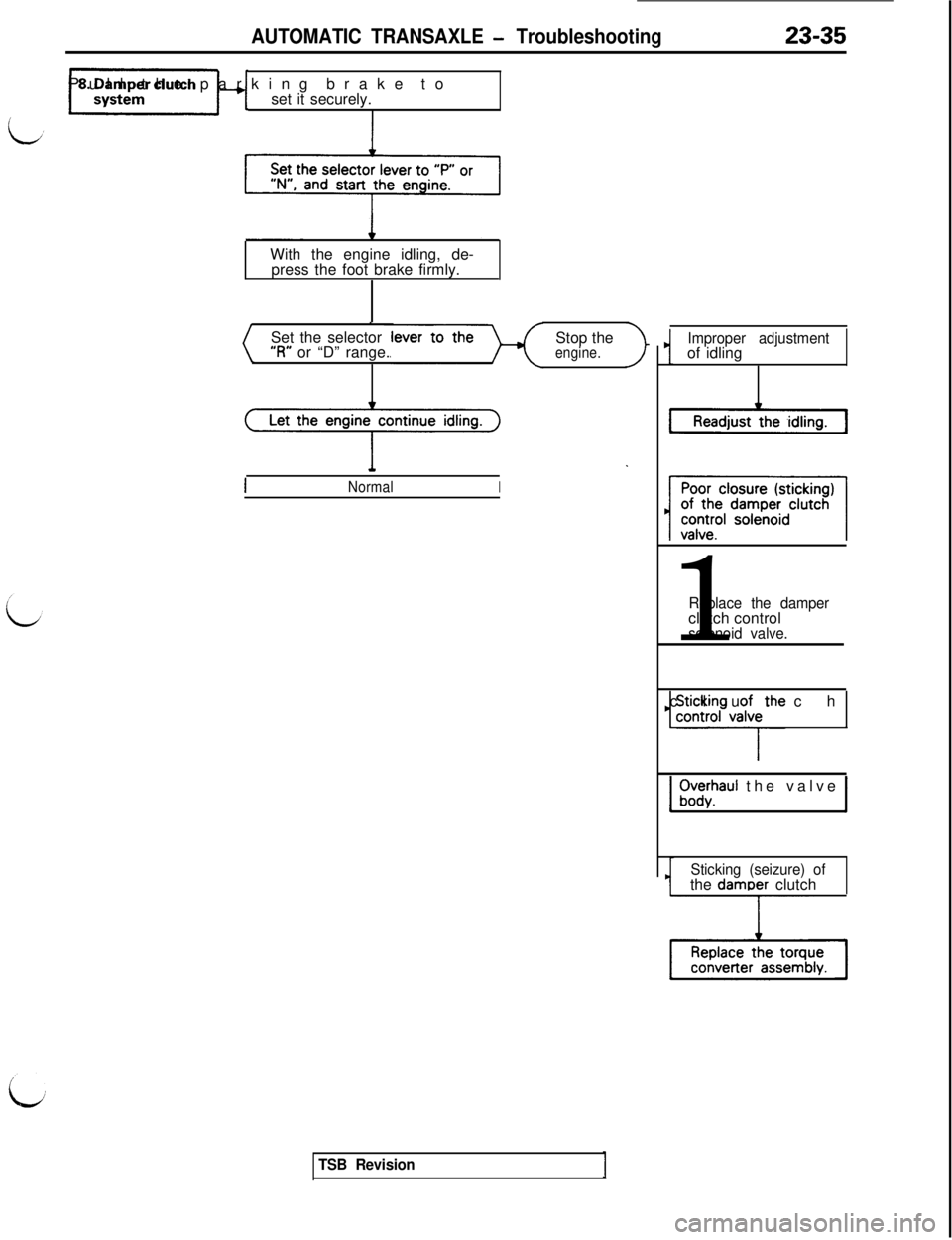

AUTOMATIC TRANSAXLE - Troubleshooting

~I+~Pull the parking brake to

set it securely.

I

23-35With the engine idling, de-

press the foot brake firmly.

.

Set the selector

‘3” or “D” range.Stop theengine.Let the engine continue idling.

c .

INormalI

Improper adjustmentof idling

-Readjust1

Replace the damperclutch control

solenoid valve.

1 9$4nFv;itheclutch 1

1 f;w$aul the valve 1

Sticking (seizure) ofthe damDer clutch

TSB Revision

Page 499 of 1146

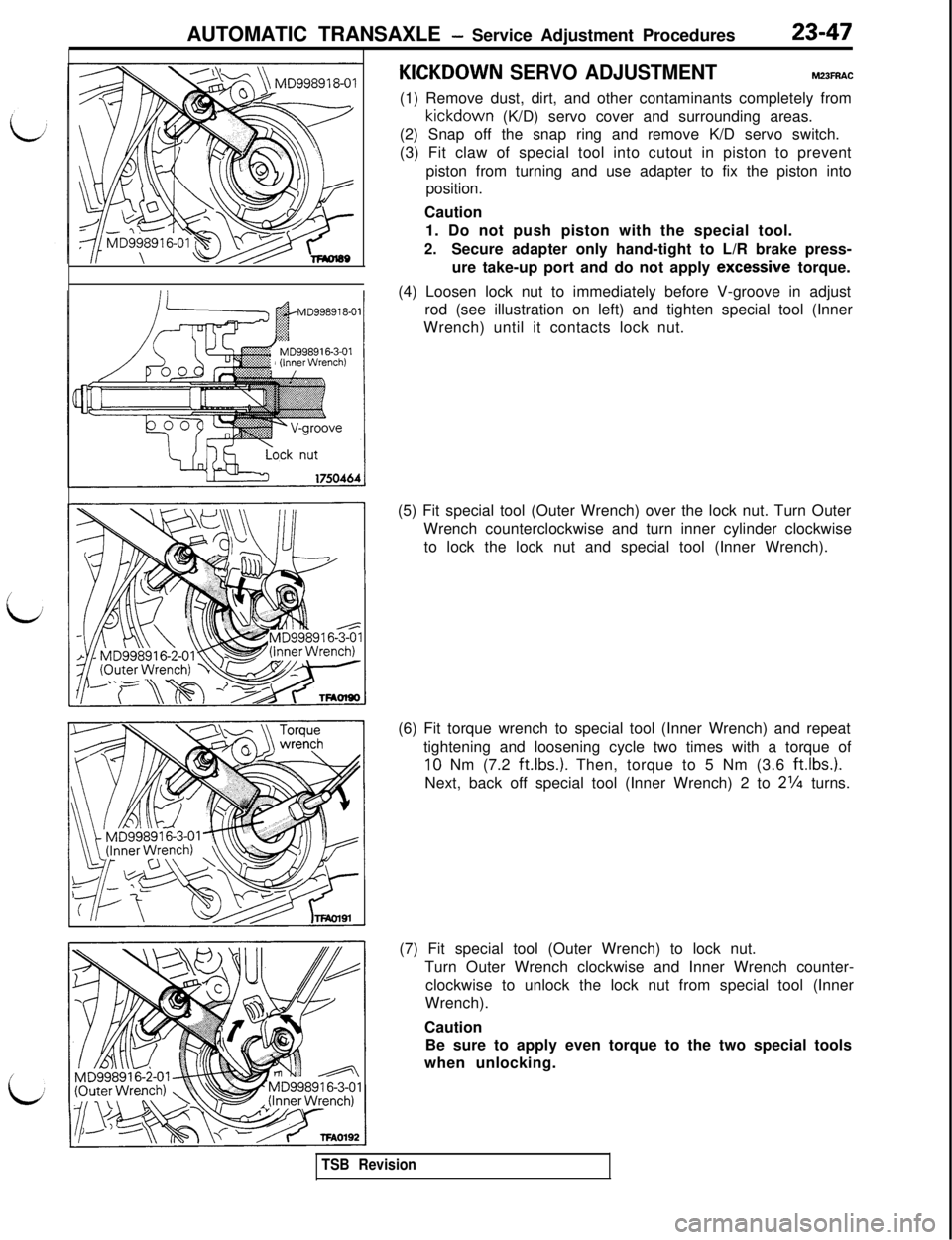

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-47

MD998916-3-01

KICKDOWN SERVO ADJUSTMENTM23FRAC(1) Remove dust, dirt, and other contaminants completely fromkickdown (K/D) servo cover and surrounding areas.

(2) Snap off the snap ring and remove K/D servo switch.

(3) Fit claw of special tool into cutout in piston to prevent

piston from turning and use adapter to fix the piston into

position.

Caution

1. Do not push piston with the special tool.

2.Secure adapter only hand-tight to L/R brake press-

ure take-up port and do not apply

excessiwe torque.

(4) Loosen lock nut to immediately before V-groove in adjust

rod (see illustration on left) and tighten special tool (Inner

Wrench) until it contacts lock nut.

(5) Fit special tool (Outer Wrench) over the lock nut. Turn Outer

Wrench counterclockwise and turn inner cylinder clockwise

to lock the lock nut and special tool (Inner Wrench).

(6) Fit torque wrench to special tool (Inner Wrench) and repeat

tightening and loosening cycle two times with a torque of

10 Nm (7.2 ft.lbs.). Then, torque to 5 Nm (3.6 ftlbs.).Next, back off special tool (Inner Wrench) 2 to

2’/4 turns.

(7) Fit special tool (Outer Wrench) to lock nut.

Turn Outer Wrench clockwise and Inner Wrench counter-

clockwise to unlock the lock nut from special tool (Inner

Wrench).

Caution

Be sure to apply even torque to the two special tools

when unlocking.

TSB Revision

Page 500 of 1146

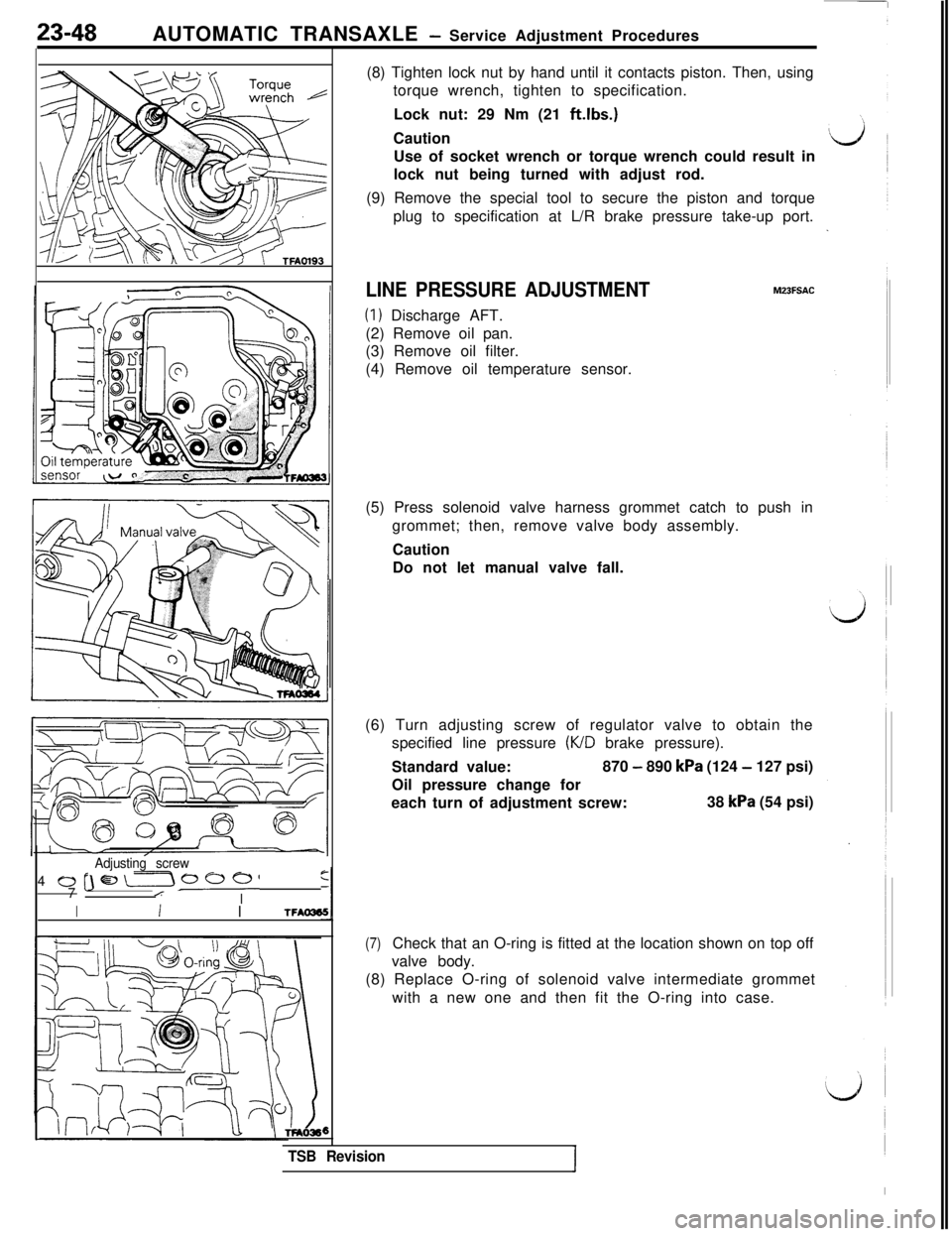

23-48AUTOMATIC TRANSAXLE - Service Adjustment Procedures

Adjusting screw4

or~0\====m00~7/IIIITFAm

c-1

Pi(8) Tighten lock nut by hand until it contacts piston. Then, using

torque wrench, tighten to specification.

Lock nut: 29 Nm (21

ftlbs.)Caution

Use of socket wrench or torque wrench could result in

lock nut being turned with adjust rod.

(9) Remove the special tool to secure the piston and torque

plug to specification at L/R brake pressure take-up port.

LINE PRESSURE ADJUSTMENT

(I) Discharge AFT.

(2) Remove oil pan.

(3) Remove oil filter.

(4) Remove oil temperature sensor.

M23FSAC(5) Press solenoid valve harness grommet catch to push in

grommet; then, remove valve body assembly.

Caution

Do not let manual valve fall.

(6) Turn adjusting screw of regulator valve to obtain the

specified line pressure

(K/D brake pressure).

Standard value:870

- 890 kPa (124 - 127 psi)

Oil pressure change for

each turn of adjustment screw:38

kPa (54 psi)

(7)Check that an O-ring is fitted at the location shown on top off

valve body.

(8) Replace O-ring of solenoid valve intermediate grommet

with a new one and then fit the O-ring into case.6

TSB RevisionI

Page 501 of 1146

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-49

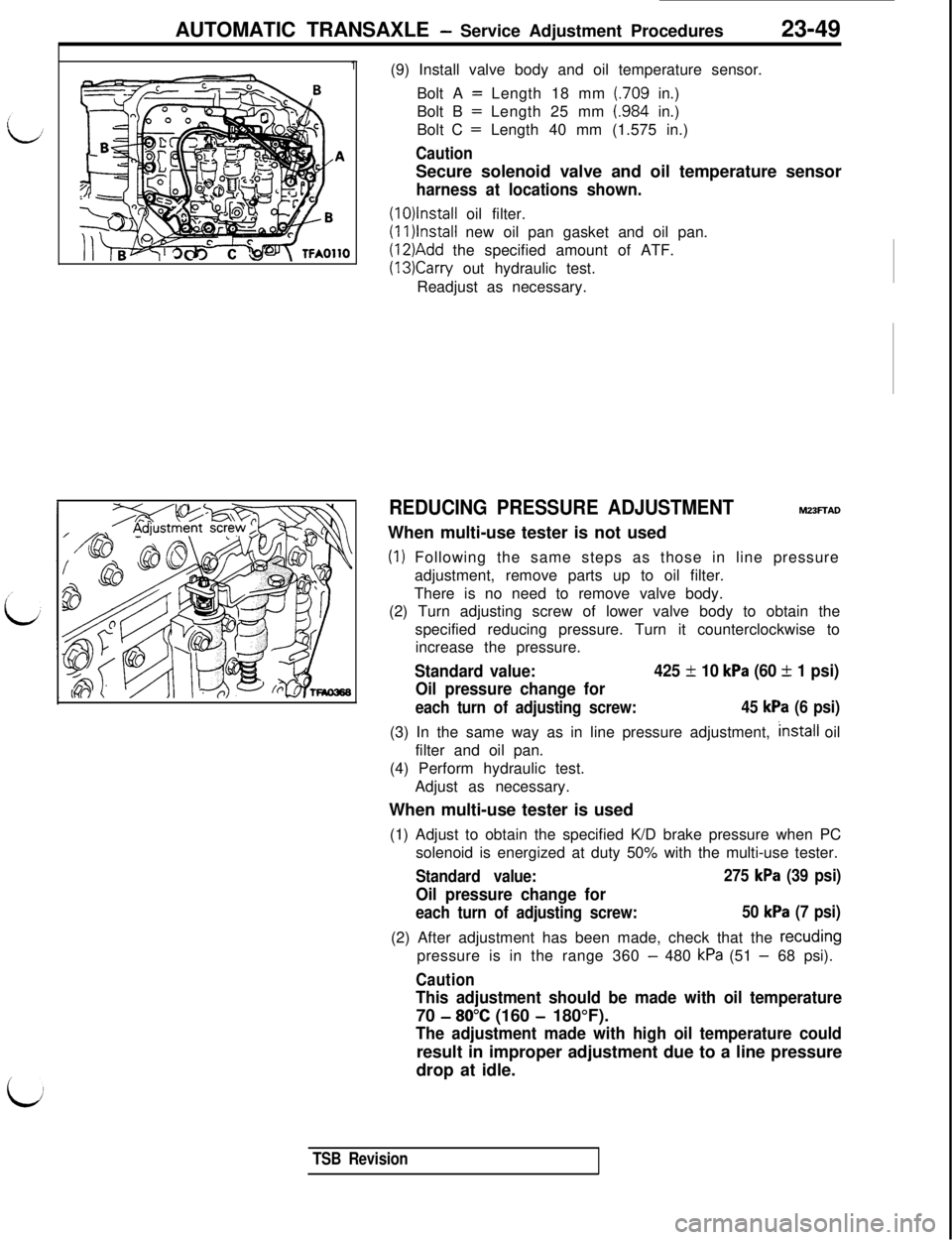

1(9) Install valve body and oil temperature sensor.

Bolt A

= Length 18 mm (.709 in.)

Bolt B

= Length 25 mm (.984 in.)

Bolt C

= Length 40 mm (1.575 in.)

CautionSecure solenoid valve and oil temperature sensor

harness at locations shown.

(1O)lnstall oil filter.(1l)lnstall new oil pan gasket and oil pan.

(12)Add the specified amount of ATF.

(13)Carry out hydraulic test.

Readjust as necessary.

REDUCING PRESSURE ADJUSTMENTh323FfADWhen multi-use tester is not used

(1) Following the same steps as those in line pressure

adjustment, remove parts up to oil filter.

There is no need to remove valve body.

(2) Turn adjusting screw of lower valve body to obtain the

specified reducing pressure. Turn it counterclockwise to

increase the pressure.

Standard value:425 f 10 kPa (60 f 1 psi)

Oil pressure change for

each turn of adjusting screw:45 kPa (6 psi)(3) In the same way as in line pressure adjustment,

/nstall oil

filter and oil pan.

(4) Perform hydraulic test.

Adjust as necessary.

When multi-use tester is used

(1) Adjust to obtain the specified K/D brake pressure when PC

solenoid is energized at duty 50% with the multi-use tester.

Standard value:275 kPa (39 psi)

Oil pressure change for

each turn of adjusting screw:50 kPa (7 psi)(2) After adjustment has been made, check that the recuding

pressure is in the range 360

- 480 kPa (51 - 68 psi).

Caution

This adjustment should be made with oil temperature70

- 80°C (160 - 180°F).

The adjustment made with high oil temperature couldresult in improper adjustment due to a line pressure

drop at idle.

TSB Revision

Page 503 of 1146

AUTOMATIC TRANSAXLE - Service Adiustment Procedures23-51

D9N007SPush button

II

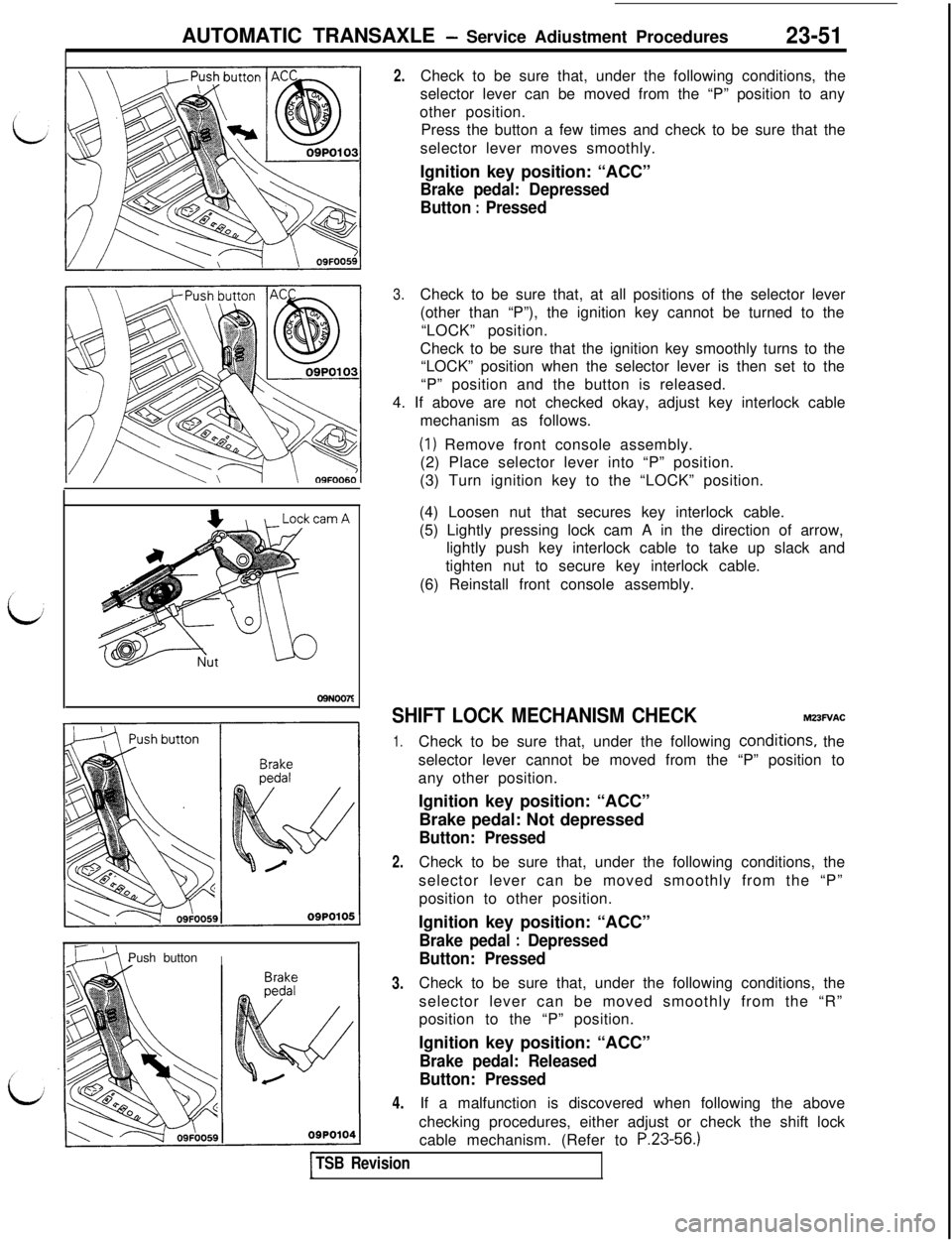

2.Check to be sure that, under the following conditions, the

selector lever can be moved from the “P” position to any

other position.

Press the button a few times and check to be sure that the

selector lever moves smoothly.

Ignition key position: “ACC”

Brake pedal: Depressed

Button

: Pressed

3.Check to be sure that, at all positions of the selector lever

(other than “P”), the ignition key cannot be turned to the

“LOCK” position.

Check to be sure that the ignition key smoothly turns to the

“LOCK” position when the selector lever is then set to the

“P” position and the button is released.

4. If above are not checked okay, adjust key interlock cable

mechanism as follows.

(1) Remove front console assembly.

(2) Place selector lever into “P” position.

(3) Turn ignition key to the “LOCK” position.

(4) Loosen nut that secures key interlock cable.

(5) Lightly pressing lock cam A in the direction of arrow,

lightly push key interlock cable to take up slack and

tighten nut to secure key interlock cable.

(6) Reinstall front console assembly.

SHIFT LOCK MECHANISM CHECKMZ3FVAC

1.

2.

3.

4.Check to be sure that, under the following

condi,tions, the

selector lever cannot be moved from the “P” position to

any other position.

Ignition key position: “ACC”

Brake pedal: Not depressed

Button: PressedCheck to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “P”

position to other position.

Ignition key position: “ACC”

Brake pedal : Depressed

Button: PressedCheck to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “R”

position to the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button: PressedIf a malfunction is discovered when following the above

checking procedures, either adjust or check the shift lock

cable mechanism. (Refer to

P.23-56.)

TSB Revision

Page 504 of 1146

23-52

AUTOMATIC TRANSAXLE - Service Adjustment Procedures

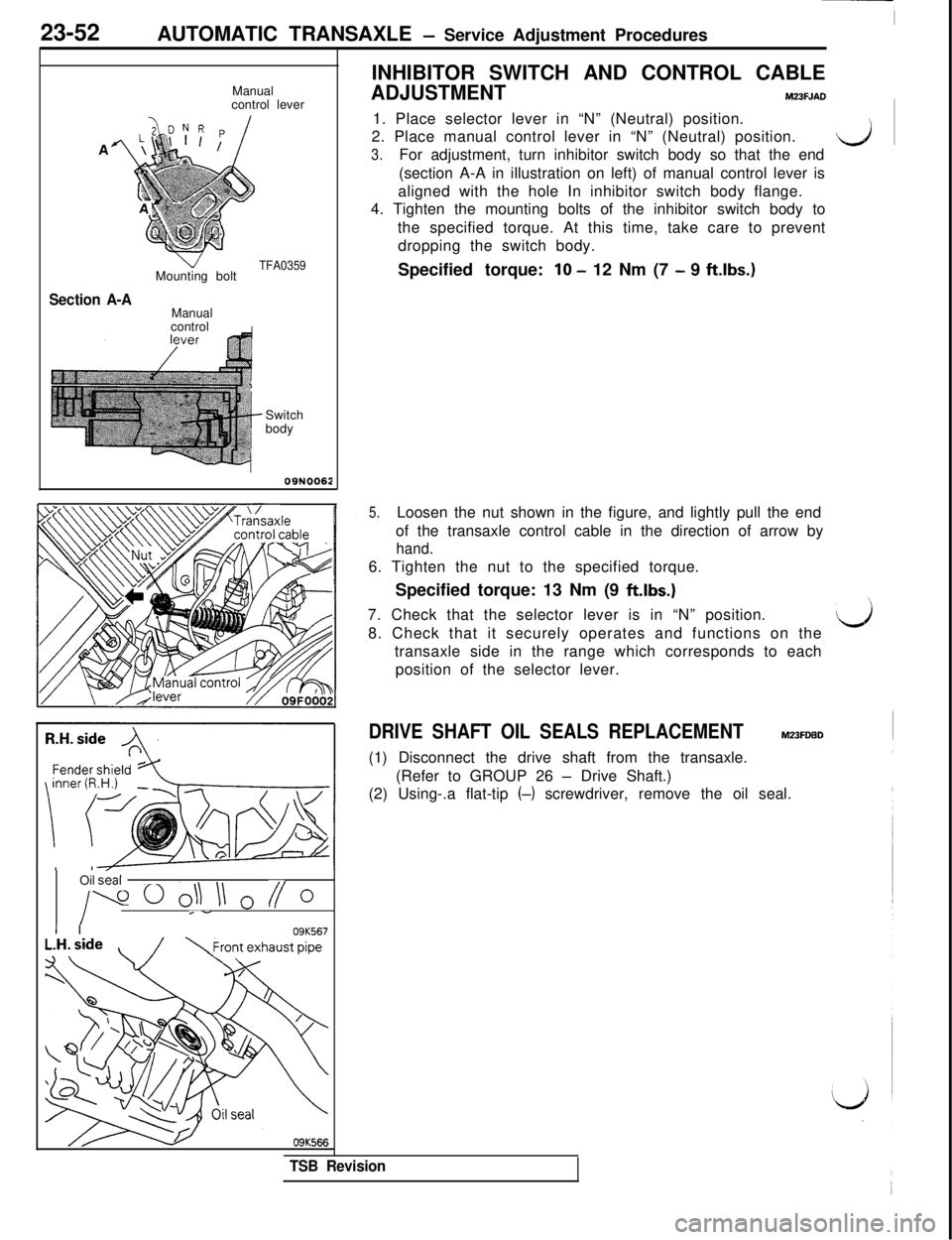

Manual

control leverINHIBITOR SWITCH AND CONTROL CABLE

ADJUSTMENTM23FJADI1. Place selector lever in “N” (Neutral) position.

2. Place manual control lever in “N” (Neutral) position.

d3.For adjustment, turn inhibitor switch body so that the end

(section A-A in illustration on left) of manual control lever is

aligned with the hole In inhibitor switch body flange.

4. Tighten the mounting bolts of the inhibitor switch body to

the specified torque. At this time, take care to prevent

dropping the switch body.

TFA0359Mounting bolt

Section A-AManual

control

ISwitch

body

09N0062Oil

skal

1

v0 o\l II 0 // 0*-

I I09K567

09K566Specified torque:

10 - 12 Nm (7 - 9 ftlbs.)

5.Loosen the nut shown in the figure, and lightly pull the end

of the transaxle control cable in the direction of arrow by

hand.6. Tighten the nut to the specified torque.

Specified torque: 13 Nm (9

ftlbs.)7. Check that the selector lever is in “N” position.

8. Check that it securely operates and functions on the

transaxle side in the range which corresponds to each

position of the selector lever.

d

DRIVE SHAFT OIL SEALS REPLACEMENTM23FLN3D(1) Disconnect the drive shaft from the transaxle.

(Refer to GROUP 26

- Drive Shaft.)

(2) Using-.a flat-tip (-) screwdriver, remove the oil seal.

TSB Revision

Page 505 of 1146

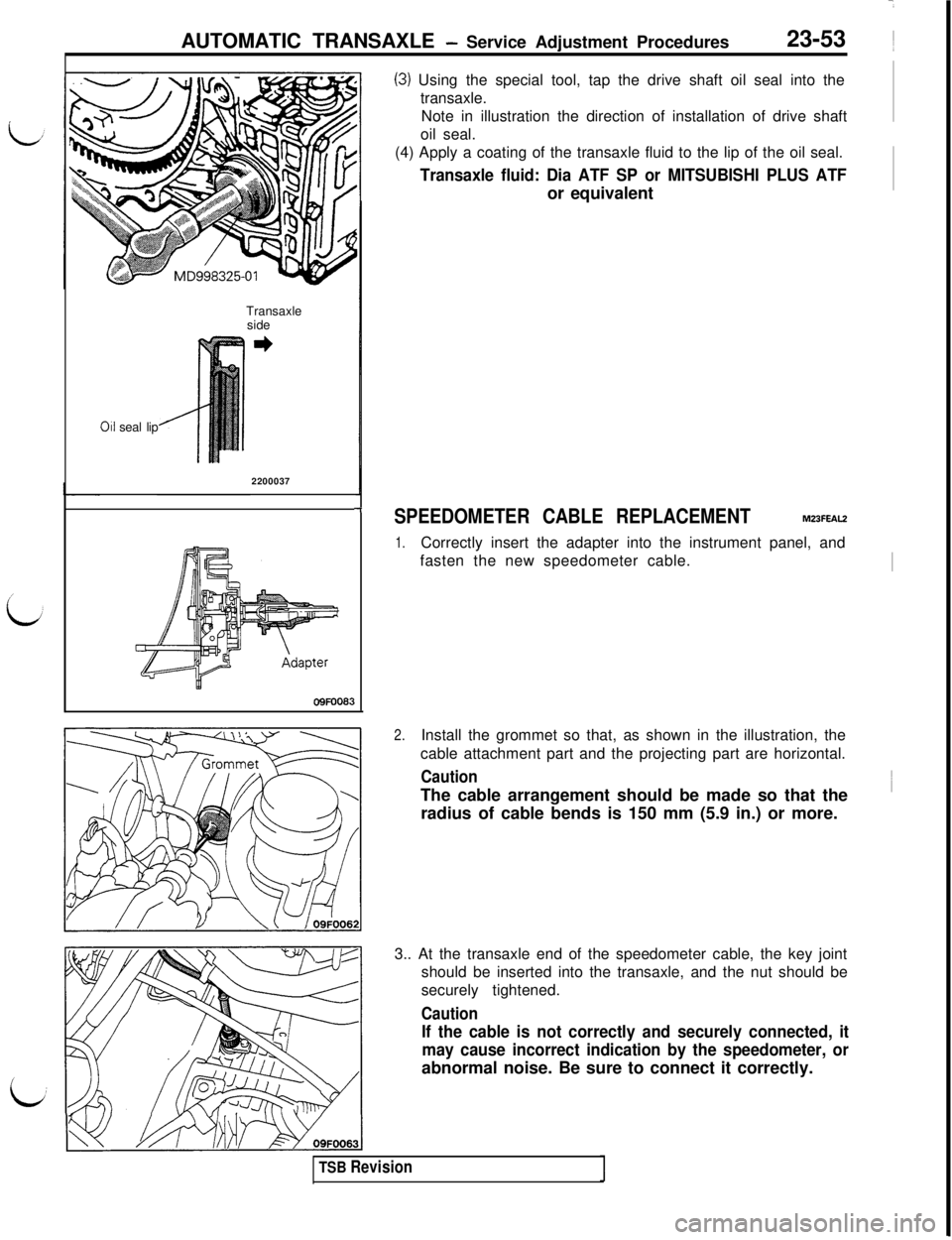

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-53 ~

(3) Using the special tool, tap the drive shaft oil seal into the

transaxle.

Note in illustration the direction of installation of drive shaft

oil seal.

(4) Apply a coating of the transaxle fluid to the lip of the oil seal.

Transaxle fluid: Dia ATF SP or MITSUBISHI PLUS ATFor equivalent

Transaxle

side

011 seal lip

2200037

-fSPEEDOMETER CABLE REPLACEMENTM23FEAL2

1.Correctly insert the adapter into the instrument panel, and

fasten the new speedometer cable.

I

OQFOO83

2.Install the grommet so that, as shown in the illustration, the

cable attachment part and the projecting part are horizontal.

Caution1

The cable arrangement should be made so that the

’radius of cable bends is 150 mm (5.9 in.) or more.

3.. At the transaxle end of the speedometer cable, the key joint

should be inserted into the transaxle, and the nut should be

securely tightened.

Caution

If the cable is not correctly and securely connected, it

may cause incorrect indication by the speedometer, orabnormal noise. Be sure to connect it correctly.

TSB Revision

Page 509 of 1146

AUTOMATIC TRANSAXLE - Transaxle Control23-57

09N0050Was

Nut

09N0049Was

Nut

0910046

I

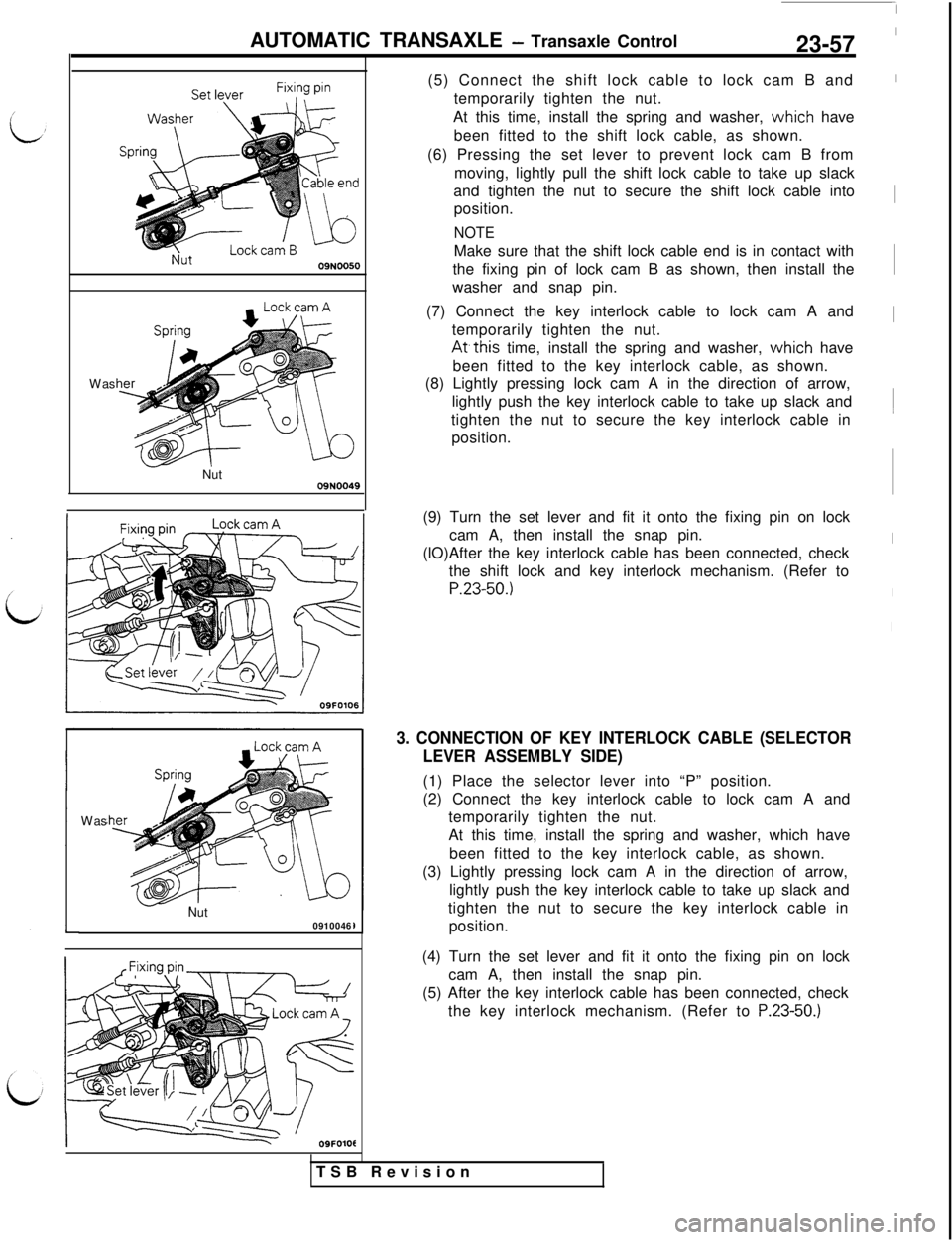

-09FOlOt(5) Connect the shift lock cable to lock cam B and

temporarily tighten the nut.

At this time, install the spring and washer,

vvhich have

been fitted to the shift lock cable, as shown.

(6) Pressing the set lever to prevent lock cam B from

moving, lightly pull the shift lock cable to take up slack

and tighten the nut to secure the shift lock cable into

position.

NOTEMake sure that the shift lock cable end is in contact with

the fixing pin of lock cam B as shown, then install the

washer and snap pin.

(7) Connect the key interlock cable to lock cam A and

temporarily tighten the nut.

At,this time, install the spring and washer, vvhich have

been fitted to the key interlock cable, as shown.

(8) Lightly pressing lock cam A in the direction of arrow,

lightly push the key interlock cable to take up slack and

tighten the nut to secure the key interlock cable in

position.

(9) Turn the set lever and fit it onto the fixing pin on lock

cam A, then install the snap pin.

(lO)After the key interlock cable has been connected, check

the shift lock and key interlock mechanism. (Refer to

P.23-50.)

3. CONNECTION OF KEY INTERLOCK CABLE (SELECTOR

LEVER ASSEMBLY SIDE)(1) Place the selector lever into “P” position.

(2) Connect the key interlock cable to lock cam A and

temporarily tighten the nut.

At this time, install the spring and washer, which have

been fitted to the key interlock cable, as shown.

(3) Lightly pressing lock cam A in the direction of arrow,

lightly push the key interlock cable to take up slack and

tighten the nut to secure the key interlock cable in

position.

(4) Turn the set lever and fit it onto the fixing pin on lock

cam A, then install the snap pin.

(5) After the key interlock cable has been connected, check

the key interlock mechanism. (Refer to

P.23-50.)TSB Revision

-1

I

I

I~

I~

I

I

I