engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 270 of 1146

13-164CRUISE CONTROL SYSTEM - Troubleshooting

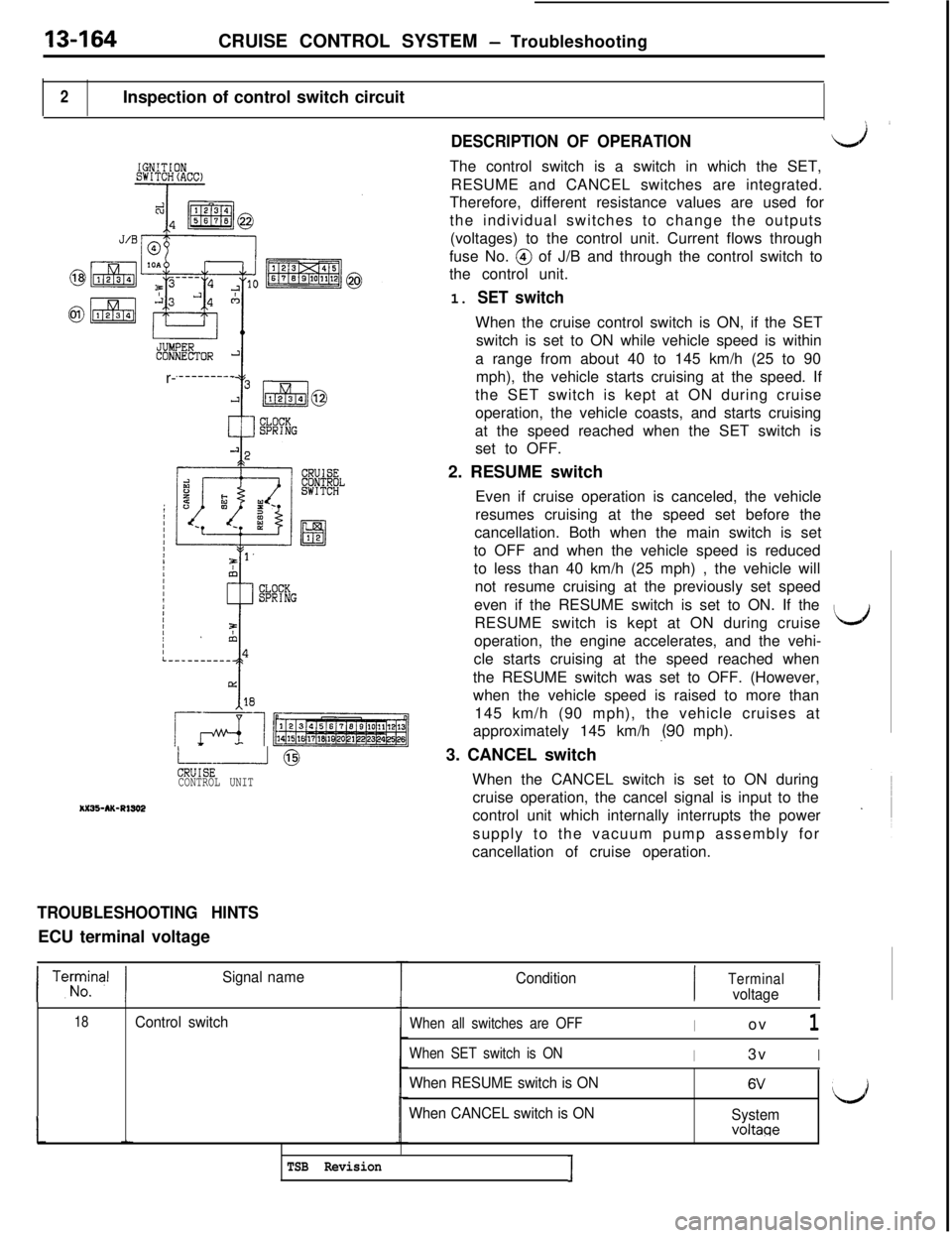

2Inspection of control switch circuit

IGNITIONSWITCHtACC)

*X35-AK-R1302r-

._--------

LE- @CONTROL UNIT

TROUBLESHOOTING HINTSECU terminal voltage

DESCRIPTION OF OPERATIONdThe control switch is a switch in which the SET,

RESUME and CANCEL switches are integrated.

Therefore, different resistance values are used for

the individual switches to change the outputs

(voltages) to the control unit. Current flows through

fuse No. @ of J/B and through the control switch to

the control unit.

1. SET switchWhen the cruise control switch is ON, if the SET

switch is set to ON while vehicle speed is within

a range from about 40 to 145 km/h (25 to 90

mph), the vehicle starts cruising at the speed. If

the SET switch is kept at ON during cruise

operation, the vehicle coasts, and starts cruising

at the speed reached when the SET switch is

set to OFF.

2. RESUME switch

Even if cruise operation is canceled, the vehicle

resumes cruising at the speed set before the

cancellation. Both when the main switch is set

to OFF and when the vehicle speed is reduced

to less than 40 km/h (25 mph) , the vehicle will

not resume cruising at the previously set speed

even if the RESUME switch is set to ON. If the

RESUME switch is kept at ON during cruise

LJoperation, the engine accelerates, and the vehi-

cle starts cruising at the speed reached when

the RESUME switch was set to OFF. (However,

when the vehicle speed is raised to more than

145 km/h (90 mph), the vehicle cruises at

approximately 145 km/h {90 mph).

3. CANCEL switch

When the CANCEL switch is set to ON during

cruise operation, the cancel signal is input to the

control unit which internally interrupts the power

supply to the vacuum pump assembly for

cancellation of cruise operation.

18Control switchSignal name

L

Condition

I

Terminalvoltage1

When all switches are OFFIov1

When SET switch is ONI3vI

When RESUME switch is ON

When CANCEL switch is ON6Vd

Systemvoltage

TSB RevisionJ

Page 275 of 1146

Page 282 of 1146

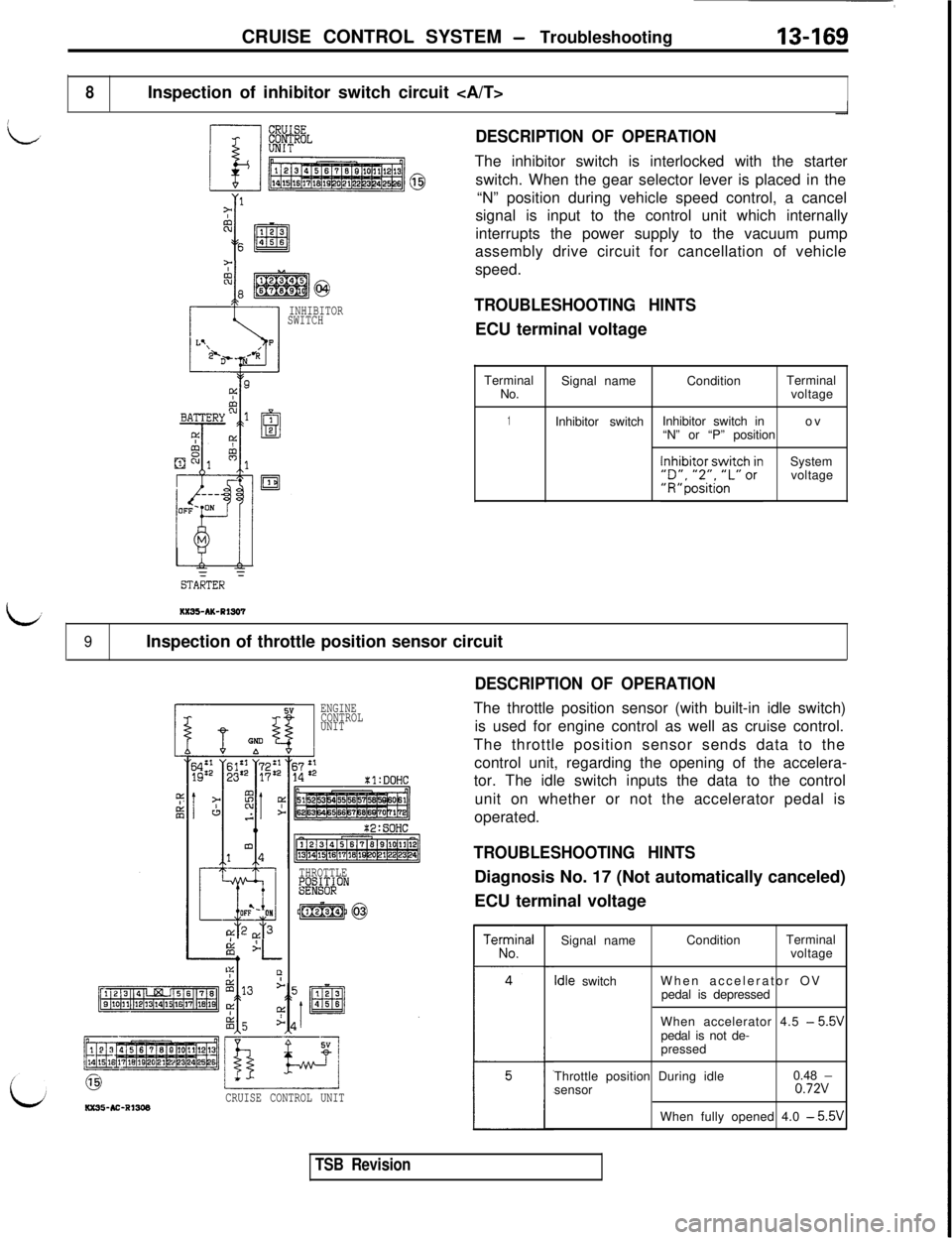

13-176CRUISE CONTROL SYSTEM - Troubleshooting

HARNESS AND COMPONENTS LAYOUT

ENGINE COMPARTMENT

01 Jumper connector

02 Vacuum pump

03 Throttle position sensor04 Inhibitor switch

05

VeTkFo;peed sensor

INSTRUMENT PANEL

AND FLOOR CONSOLE

Combination meter

Main switchEngine front view

03

36FOOO5Engine rear view

16FO175

36FOO17

TSB Revision

Page 284 of 1146

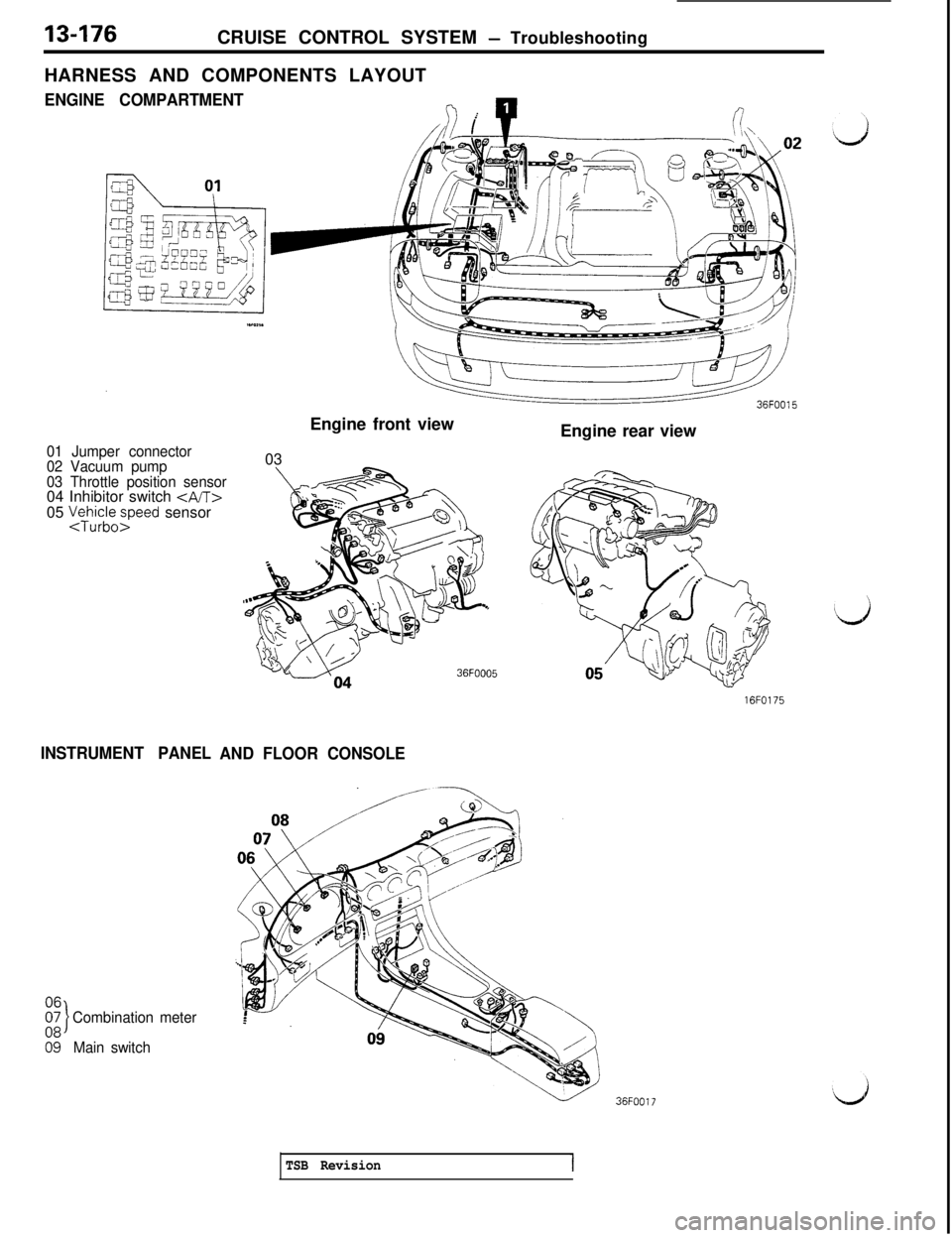

13-I 78CRUISE CONTROL SYSTEM - Service Adjustment ProceduresSERVICE

ADJUSTMENT PROCEDURESCRUISE CONTROL CABLES INSPECTION AND ADJUSTMENT

I

MlSFTCA

‘\J ~

Cruise control actuator

Cruise control assemblyAdjusting nut A

Link B

.

Adillstinn nr~+ R\Cruise control

cable

Adjusting nut C

Accelerator cable

Throttle valve-Link A

07N0004(1) Set the air conditioner, lights and other switches to OFF for

inspection at no load.

(2) Let the engine warm up until it runs at idle.

(3) Check that the idle speed is within the specified range.

(4) Stop the engine and set the ignition switch to OFF.

(5) Check that the accelerator cable, cruise control cable and

throttle cable are routed without sharp bends.

(6) Depress the accelerator pedal to check that the throttle

lever moves smoothly from the fully-closed to fully-opened

position.

(7) Check the free travel state of the inner cables of the

accelerator cable, cruise control cable and throttle cable.

(8) If the inner cables are too loose or have no free travel at all,

check using the following procedure.@ Remove the’ link protector.

@ Loosen the adjusting and lock nuts of the throttle lever

and intermediate links A, B and C to place the throttle

lever and intermediate links A, B and C in the free state.

1 TSB Revision

Page 285 of 1146

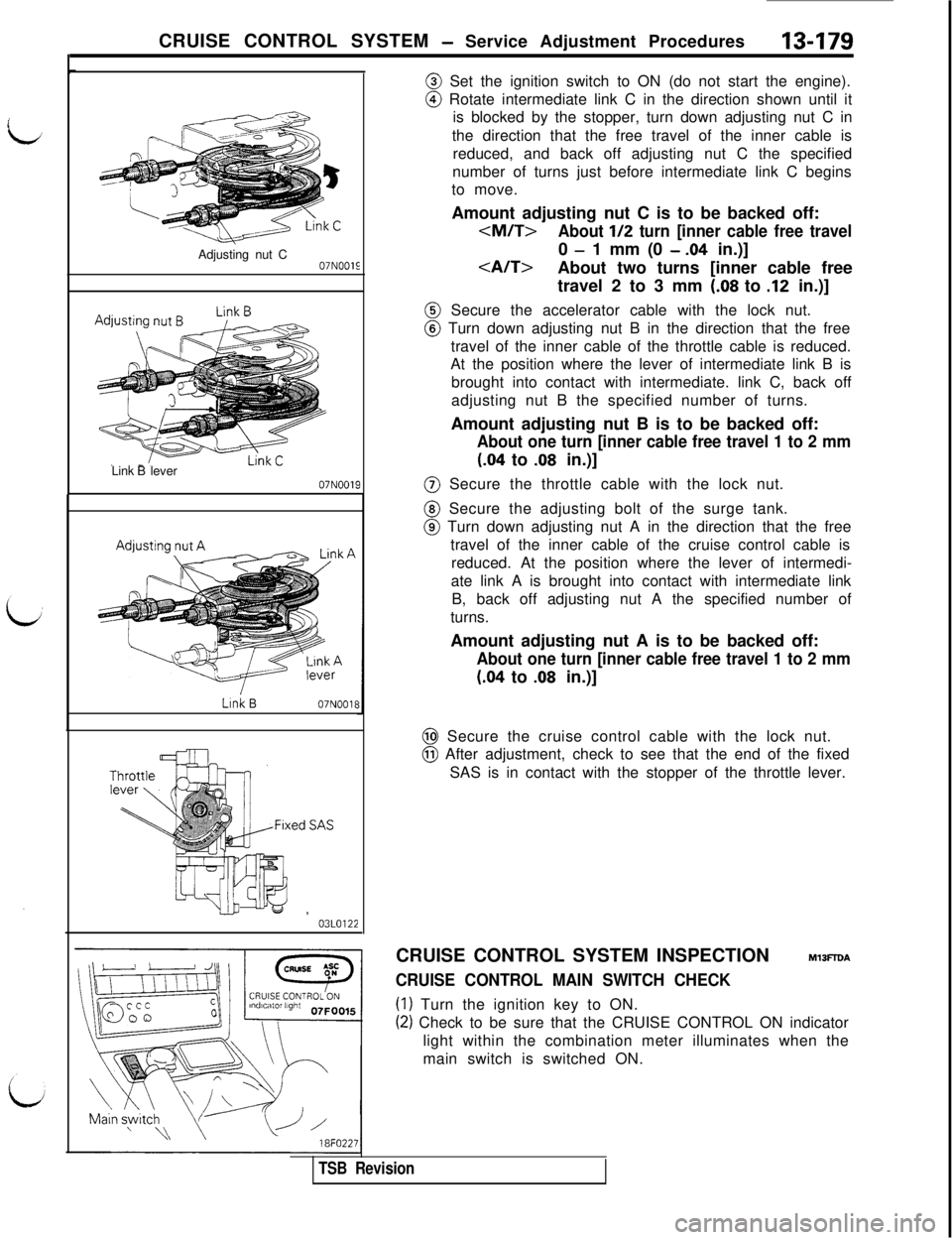

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-179Adjusting nut C

07NOOlELink Blever

07N0019Link

B07NOOlE

y,jj--ww ,03LO122

\\ \18FO2.2'@ Set the ignition switch to ON (do not start the engine).@ Rotate intermediate link C in the direction shown until it

is blocked by the stopper, turn down adjusting nut C in

the direction that the free travel of the inner cable is

reduced, and back off adjusting nut C the specified

number of turns just before intermediate link C begins

to move.

Amount adjusting nut C is to be backed off:

- 1 mm (0 - .04 in.)]

About two turns [inner cable free

travel 2 to 3 mm

(.08 to .12 in.)]@ Secure the accelerator cable with the lock nut.@ Turn down adjusting nut B in the direction that the free

travel of the inner cable of the throttle cable is reduced.

At the position where the lever of intermediate link B is

brought into contact with intermediate. link C, back off

adjusting nut B the specified number of turns.

Amount adjusting nut B is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the throttle cable with the lock nut.@ Secure the adjusting bolt of the surge tank.@ Turn down adjusting nut A in the direction that the free

travel of the inner cable of the cruise control cable is

reduced. At the position where the lever of intermedi-

ate link A is brought into contact with intermediate link

B, back off adjusting nut A the specified number of

turns.

Amount adjusting nut A is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the cruise control cable with the lock nut.@ After adjustment, check to see that the end of the fixed

SAS is in contact with the stopper of the throttle lever.

CRUISE CONTROL SYSTEM INSPECTION

MlBFlDA

CRUISE CONTROL MAIN SWITCH CHECK

(1) Turn the ignition key to ON.

(2) Check to be sure that the CRUISE CONTROL ON indicator

light within the combination meter illuminates when the

main switch is switched ON.

TSB Revision

Page 295 of 1146

COOLINGCONTENTS

M14AA..

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT TEMPERATURESENSOR AND ENGINE COOLANT

TEMPERATURE SWITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.__15

RADIATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SERVICE ADJUSTMENT PROCEDURES . . . . . . . .7Cap Pressure Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.......7Engine Coolant Concentration Test

. . . . . . . . . . . . . . . .‘7

L,Engine Coolant Leak Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . .7Engine Coolant Replacement

. . . . . . . . . . . . . . . . . . . . . . . .7

SPECIFICATIONS. . . . . . . . . . . . .._.................................General Specifications

. ..___....___._...___.__............Lubricant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.................._........Sealant and Adhesive

. . . . . . . . . . . . . . . . .._...........Service Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . .

THERMOSTAT. . . ..__......................_.._...................

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...No Rise in Temperature

Overheat

WATER PUMP, WATER PIPE AND WATER

HOSE. . . . _......_........_ _.._ .._..... . . . . . . . . . . . ._. . . . . . . . . . . . . . . . .

2

2

2

3

2

11

3

13

Page 296 of 1146

14-2COOLING - SDecifications

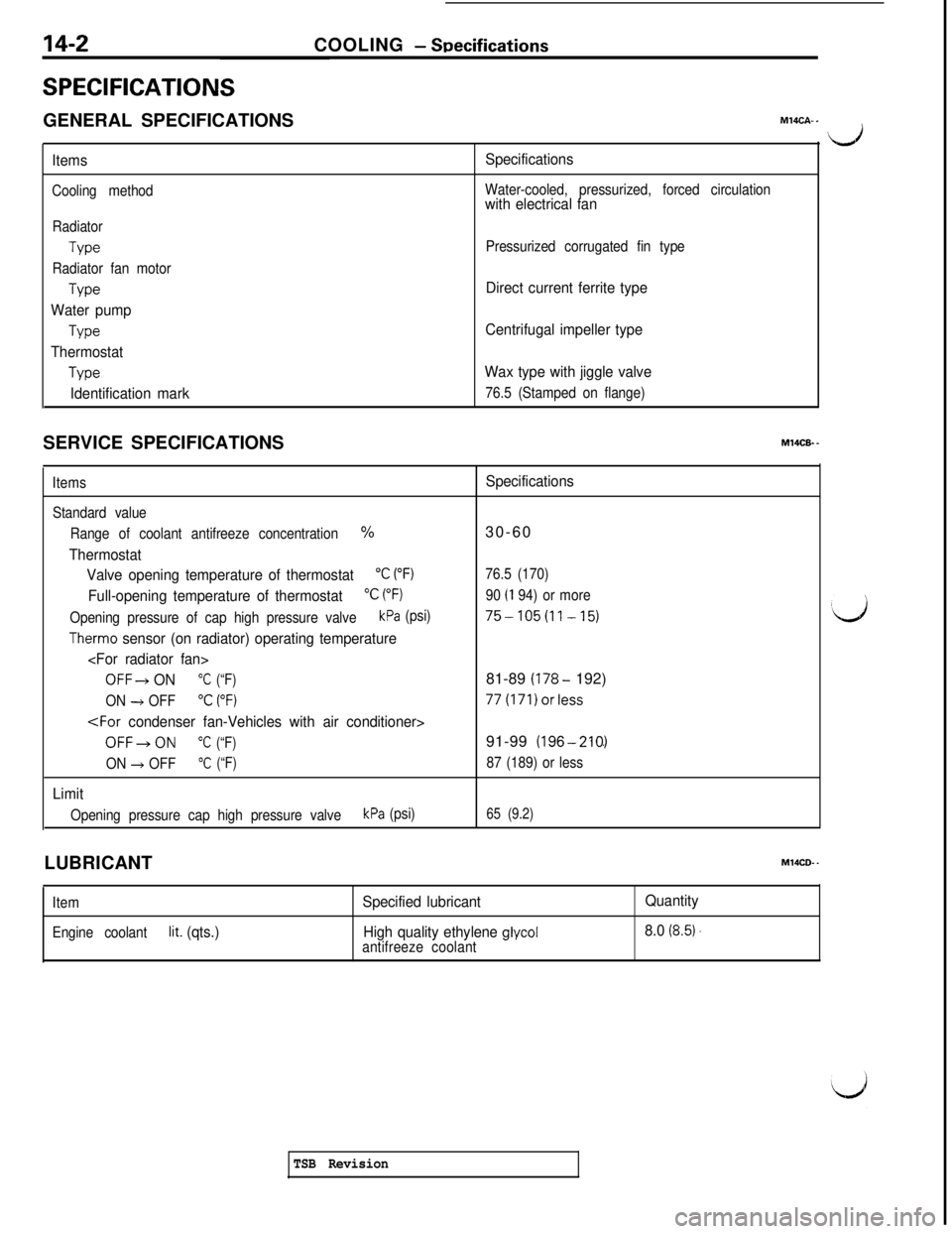

SPECIFICATIONSGENERAL SPECIFICATIONSMMCA..

Items

Cooling method

Radiator

Type

Radiator fan motor

Type

Water pump

Type

Thermostat

Type

Identification markSpecifications

Water-cooled, pressurized, forced circulationwith electrical fan

Pressurized corrugated fin type

Direct current ferrite type

Centrifugal impeller type

Wax type with jiggle valve

76.5 (Stamped on flange)

dSERVICE SPECIFICATIONS

Items

Standard valueSpecifications

Range of coolant antifreeze concentration%30-60

Thermostat

Valve opening temperature of thermostat

“C (“F)

Full-opening temperature of thermostat“C (“F)

Opening pressure of cap high pressure valvekPa (psi)

Therm0 sensor (on radiator) operating temperature

OFF-t ON“C (“F)

ON -+ OFF“C (“F)

OFF-ON“C (“F)

ON + OFF“C (“F)

Limit

76.5 (170)

90

(I 94) or more

75-105(11-15)81-89

(178- 192)77(171)orless

91-99

(196-210.)

87 (189) or less

Opening pressure cap high pressure valve

kPa (psi)65 (9.2)LUBRICANT

MlQCD- -

ItemSpecified lubricantQuantity

Engine coolantlit. (qts.)High quality ethylene glycol8.0 (8.5).

antifreeze coolant

‘d

TSB Revision

Page 297 of 1146

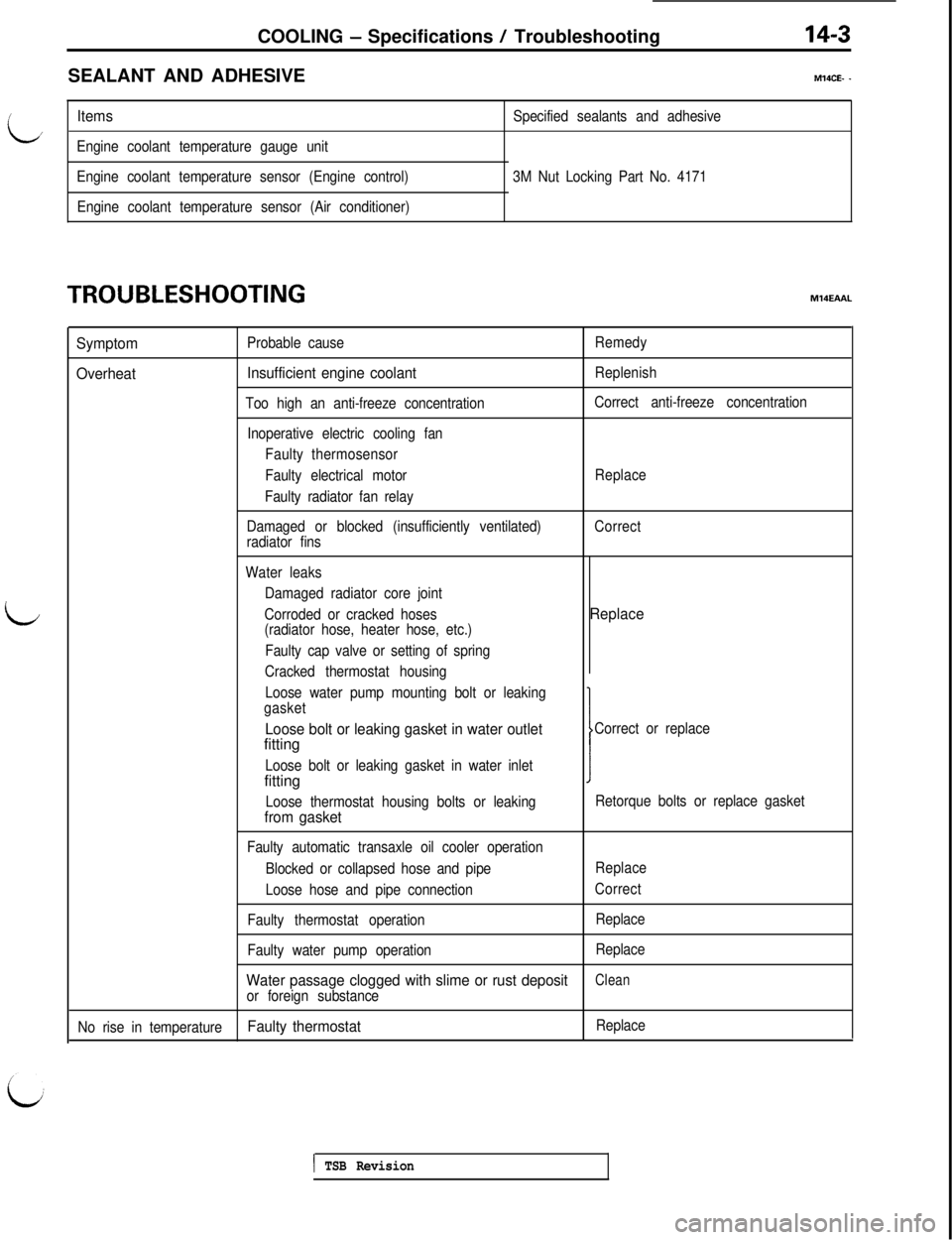

COOLING - Specifications / Troubleshooting

SEALANT AND ADHESIVE14-3

MMCE- -

/

id

ItemsSpecified sealants and adhesive/

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature sensor (Air conditioner)3M Nut Locking Part No. 4171

TROUBLESHOOTING

L

MllEAAL

Symptom

OverheatProbable cause

Insufficient engine coolant

Too high an anti-freeze concentration

Inoperative electric cooling fan

Faulty thermosensor

Faulty electrical motor

Faulty radiator fan relayRemedy

Replenish

Correct anti-freeze concentration

Replace

Damaged or blocked (insufficiently ventilated)

radiator finsCorrect

Water leaks

Damaged radiator core joint

Corroded or cracked hoses

(radiator hose, heater hose, etc.)

Faulty cap valve or setting of spring

Cracked thermostat housing

Loose water pump mounting bolt or leaking

gasket

Replace

Loose bolt or leaking gasket in water outlet

I

Correct or replacefitting

Loose bolt or leaking gasket in water inletfitting

Loose thermostat housing bolts or leakingfrom gasket

Retorque bolts or replace gasket

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipeReplace

Loose hose and pipe connectionCorrect

Faulty thermostat operationReplace

Faulty water pump operationReplace

Water passage clogged with slime or rust depositClean

or foreign substance

No rise in temperature

Faulty thermostatReplace

( TSB Revision

Page 300 of 1146

14-6COOLING - Troubleshooting.TROUBLESHOOTING HINTS

1. Neither the radiator fan nor condenser fan

rotate at all.

l Check fusible link No. 5.

2. Only the condenser fan does not operate.

l Check dedicated fuse No. 8.

3. The radiator fan and condenser fan do not

operate in the low speed mode, but operate

otherwise.

(1) The A/C compressor magnet clutch does not

enter the “ON” state.

l Check whether the output of the auto

compressor control unit is available.

NOTEFor troubleshooting of the air conditioner

control unit, refer to GROUP 55.

(2) The A/C compressor magnet clutch enters

the “ON” state.

l Check the resistor.

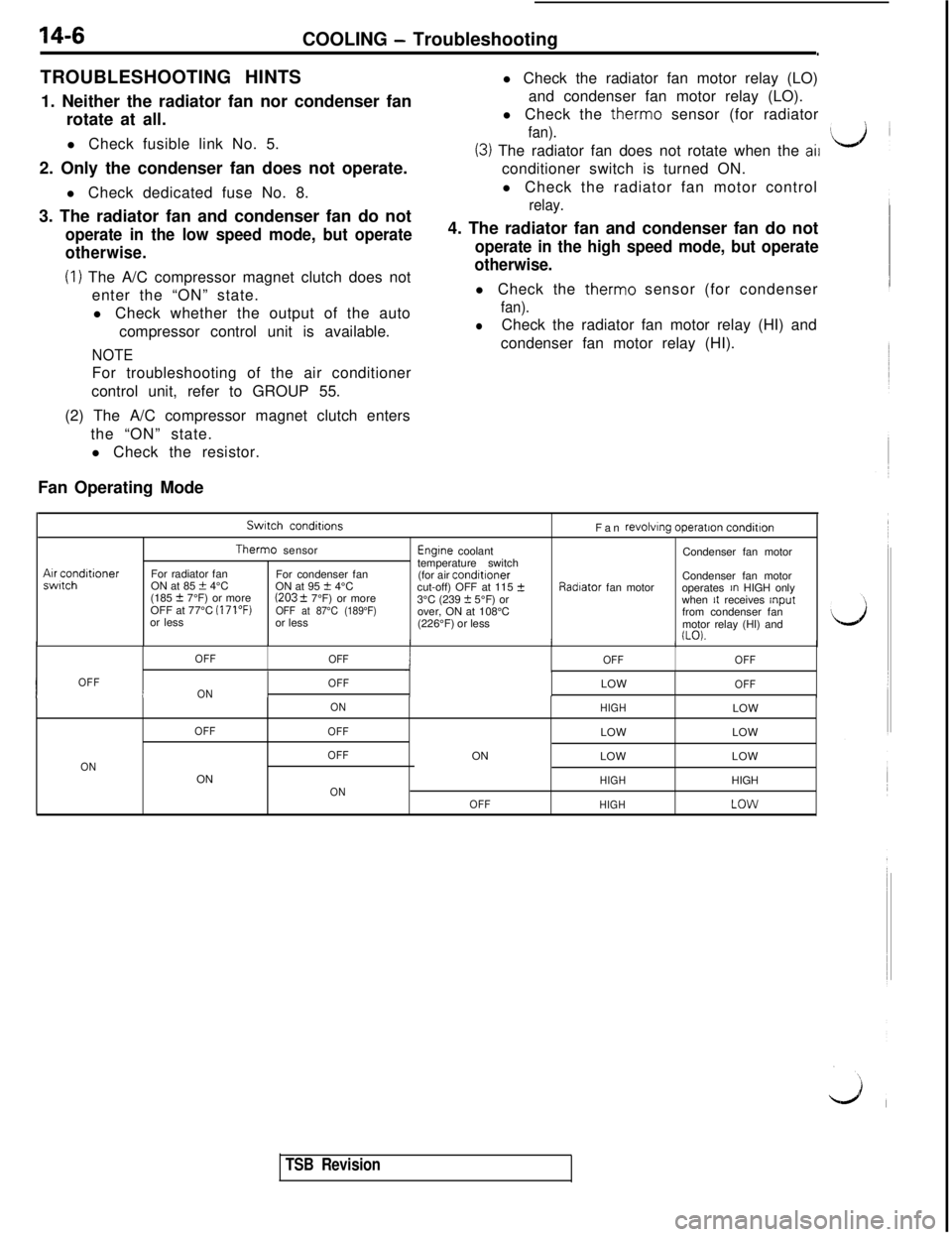

Fan Operating Model Check the radiator fan motor relay (LO)

and condenser fan motor relay (LO).

l Check the therm0 sensor (for radiator

fan).

(3) The radiator fan does not rotate when the ailconditioner switch is turned ON.

l Check the radiator fan motor control

relay.4. The radiator fan and condenser fan do not

operate in the high speed mode, but operate

otherwise.l Check the therm0 sensor (for condenser

fan).

lCheck the radiator fan motor relay (HI) and

condenser fan motor relay (HI).Air

conditionerswitch

Switch conditionsTherm0 sensor

For radiator fan

For condenser fan

ON at 85

k 4°C

ON at 95 t 4°C

(185 f 7°F) or more(203 + 7°F) or more

OFF at 77°C (171°F)

OFF at 87°C (189°F)or less

or lessEngine coolant

temperature switch

(for air conditioner

cut-off) OFF at 115

+3°C (239 2 5°F) or

over, ON at 108°C

(226°F) or lessFan revolving operation

conditionCondenser fan motor

Condenser fan motorRadiator fan motor

operates

In HIGH only

when it receives input

from condenser fan

motor relay (HI) and

U-0).I/I/

OFF

OFF

OFFOFF

IOFFIOFF

ONLOWOFF

ON

HIGHLOW

OFF

OFFLOWLOW

OFF

ONON

LOWLOW

ON

HIGH

ONHIGH

OFF

HIGHLOW

TSB Revision

Page 301 of 1146

COOLING - Service Adiustment Procedures.14-7

SERVICE ADJUSTMENT PROCEDURES

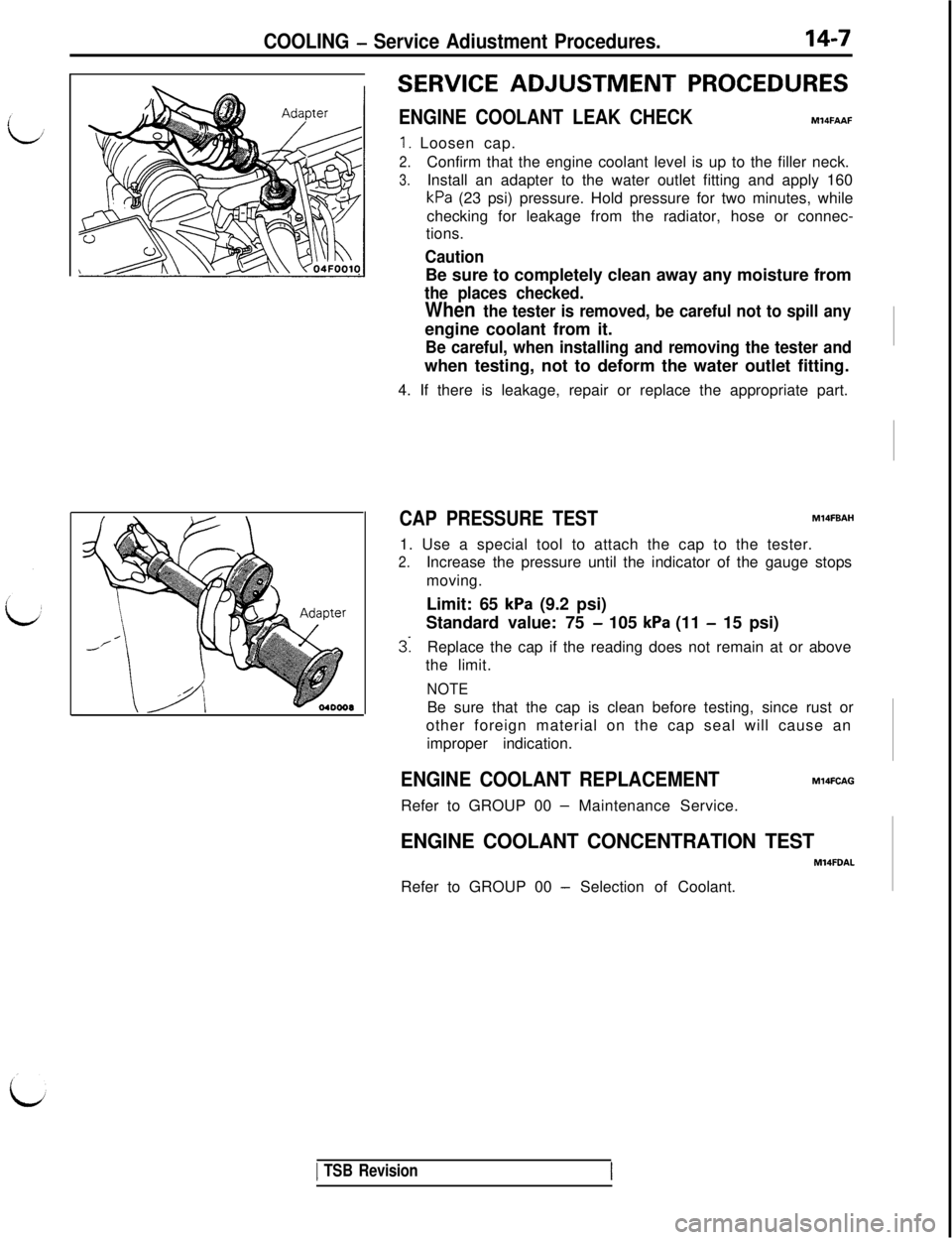

ENGINE COOLANT LEAK CHECKMl4FAAF

1. Loosen cap.

2.Confirm that the engine coolant level is up to the filler neck.

3.Install an adapter to the water outlet fitting and apply 160

kPa (23 psi) pressure. Hold pressure for two minutes, while

checking for leakage from the radiator, hose or connec-

tions.

CautionBe sure to completely clean away any moisture from

the places checked.

When the tester is removed, be careful not to spill anyengine coolant from it.

Be careful, when installing and removing the tester andwhen testing, not to deform the water outlet fitting.

4. If there is leakage, repair or replace the appropriate part.

CAP PRESSURE TESTM14FBAH1. Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gauge stops

moving.

Limit: 65

kPa (9.2 psi)

Standard value: 75

- 105 kPa (11 - 15 psi)

3:Replace the cap if the reading does not remain at or above

the limit.

NOTEBe sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an

improper indication.

ENGINE COOLANT REPLACEMENTM14FCAGRefer to GROUP 00

- Maintenance Service.

ENGINE COOLANT CONCENTRATION TEST

M14FDALRefer to GROUP 00

- Selection of Coolant.

1 TSB Revision