engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 304 of 1146

14-10COOLING - Radiator

r-----I

113

EY

4 :

2 :

i.-.-..i

0312161908

Ionnector04FOOO8

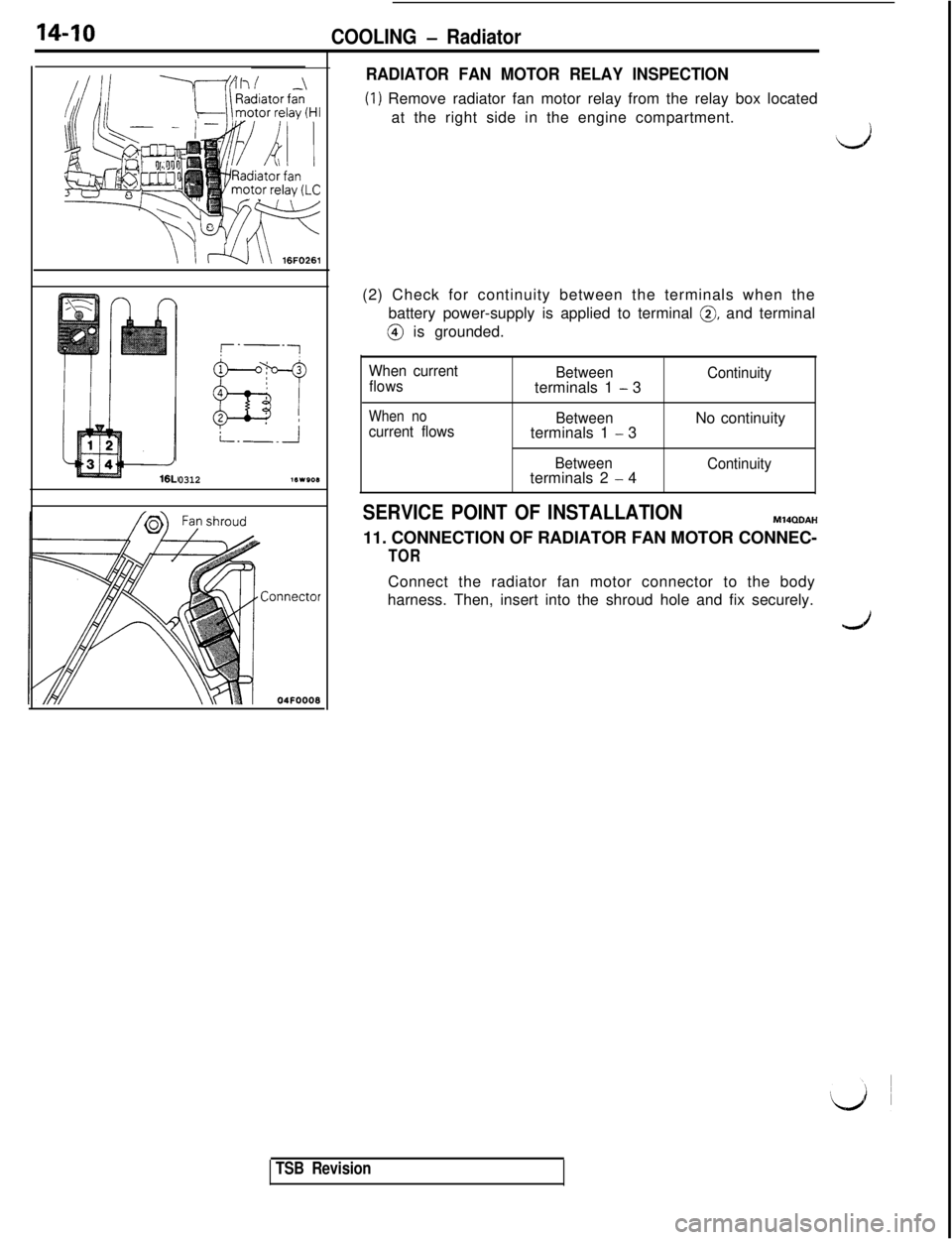

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor relay from the relay box located

at the right side in the engine compartment.

Ll(2) Check for continuity between the terminals when the

battery power-supply is applied to terminal

0, and terminal@ is grounded.

When current

flowsBetweenterminals 1

- 3Continuity

When nocurrent flowsBetweenterminals 1 - 3No continuity

Betweenterminals 2 - 4Continuity

SERVICE POINT OF INSTALLATIONM14QDAH

11. CONNECTION OF RADIATOR FAN MOTOR CONNEC-

TORConnect the radiator fan motor connector to the body

harness. Then, insert into the shroud hole and fix securely.

TSB Revision

Page 307 of 1146

COOLING - Water Pump, Water Pipe and Water Hose

WATER PUMP, WATER PIPE AND WATER HOSE

14-13

M14MB-B

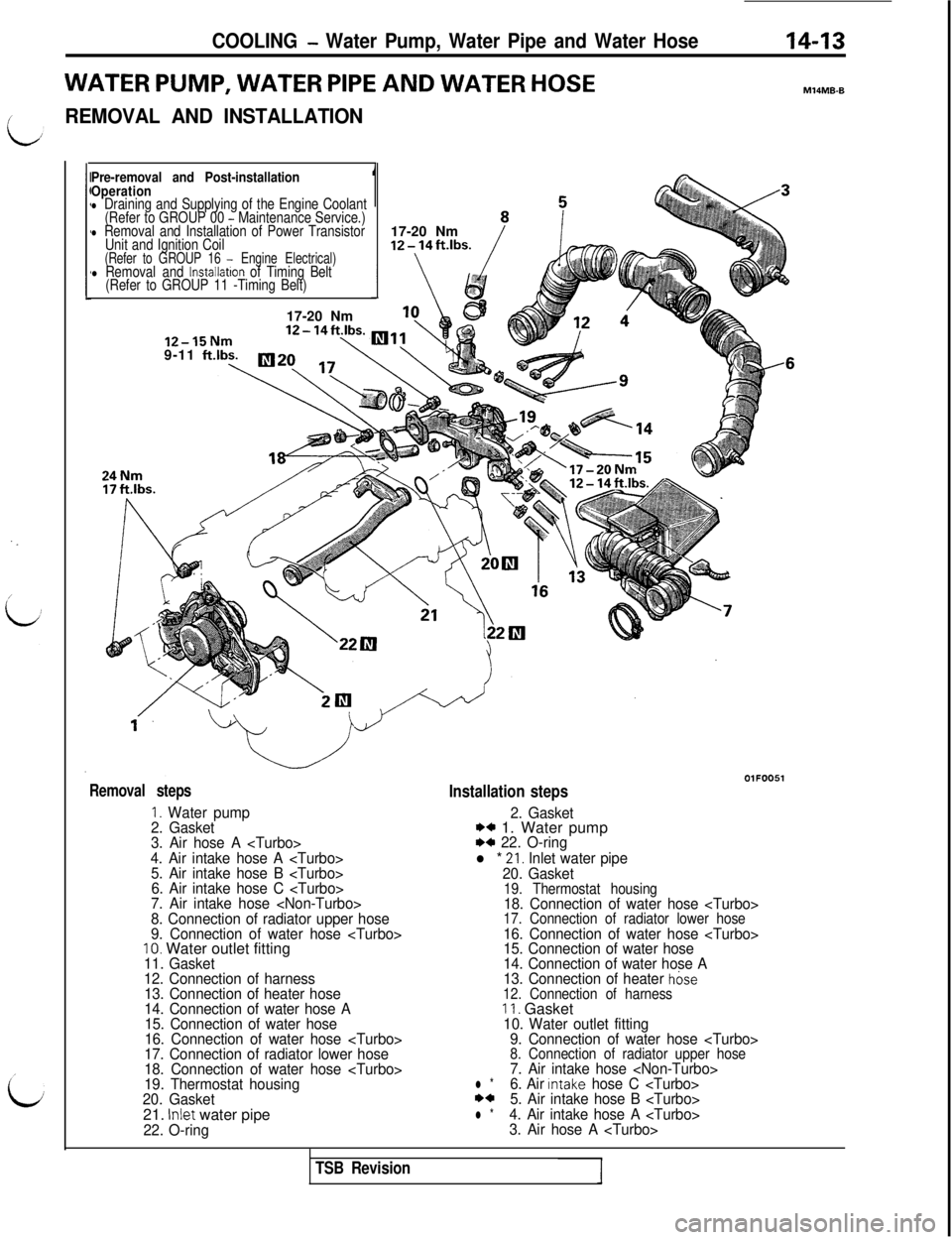

/REMOVAL AND INSTALLATION

Pre-removal and Post-installation

Operation

l Draining and Supplying of the Engine Coolant

(Refer to GROUP 00 - Maintenance Service.)l Removal and Installation of Power Transistor

Unit and Ignition Coil

(Refer to GROUP 16 - Engine Electrical)l Removal and lnstallatlon of Timing Belt

(Refer to GROUP 11 -Timing Belt)17-20 Nm17-20 Nm

12-14ft.lbs.

1

12-15Nm9-11 ft.1bs.q

Removal steps

1. Water pump

2. Gasket

3. Air hose A

4. Air intake hose A

5. Air intake hose B

6. Air intake hose C

7. Air intake hose

8. Connection of radiator upper hose

9. Connection of water hose

IO. Water outlet fitting11. Gasket

12. Connection of harness

13. Connection of heater hose

14. Connection of water hose A

15. Connection of water hose

16. Connection of water hose

17. Connection of radiator lower hose

18. Connection of water hose

19. Thermostat housing

20. Gasket21.

Her water pipe22. O-ringOlFOO51

Installation steps

2. Gasket** 1. Water pumpI)+ 22. O-ring

l * 21. Inlet water pipe

20. Gasket

19. Thermostat housing18. Connection of water hose

15. Connection of water hose

14. Connection of water hose A

13. Connection of heater h&e

12. Connection of harness11. Gasket10. Water outlet fitting

9. Connection of water hose

8. Connection of radiator upper hose7. Air intake hose

3. Air hose A

TSB Revision

Page 308 of 1146

COOLING - Water Pump, Water Pipe and Water Hose

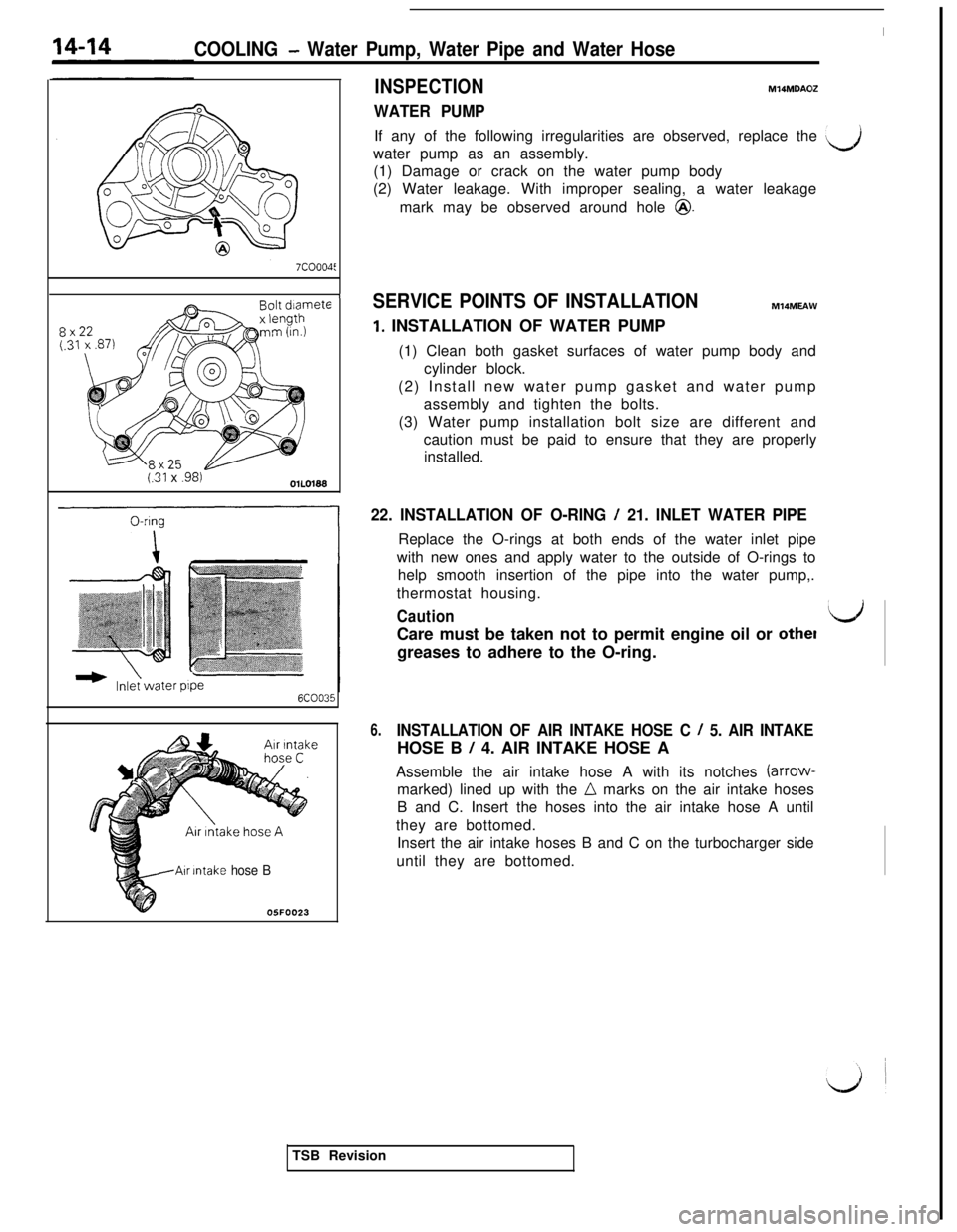

INSPECTION

WATER PUMP

I

MIQMDAOZIf any of the following irregularities are observed, replace the

LJwater pump as an assembly.

(1) Damage or crack on the water pump body

(2) Water leakage. With improper sealing, a water leakage

mark may be observed around hole

@.

,

(.31 x .98)OlLO188

6COO35

Air intake hose BOSFOO23

SERVICE POINTS OF INSTALLATION

1. INSTALLATION OF WATER PUMPM14MEAW

(1) Clean both gasket surfaces of water pump body and

cylinder block.

(2) Install new water pump gasket and water pump

assembly and tighten the bolts.

(3) Water pump installation bolt size are different and

caution must be paid to ensure that they are properly

installed.

22. INSTALLATION OF O-RING / 21. INLET WATER PIPEReplace the O-rings at both ends of the water inlet pipe

with new ones and apply water to the outside of O-rings to

help smooth insertion of the pipe into the water pump,.

thermostat housing.

CautionLJCare must be taken not to permit engine oil or

othergreases to adhere to the O-ring.

6.INSTALLATION OF AIR INTAKE HOSE C / 5. AIR INTAKEHOSE B

/ 4. AIR INTAKE HOSE A

Assemble the air intake hose A with its notches (arrow-

marked) lined up with the

D marks on the air intake hoses

B and C. Insert the hoses into the air intake hose A until

they are bottomed.

Insert the air intake hoses B and C on the turbocharger side

until they are bottomed.

TSB Revision

Page 309 of 1146

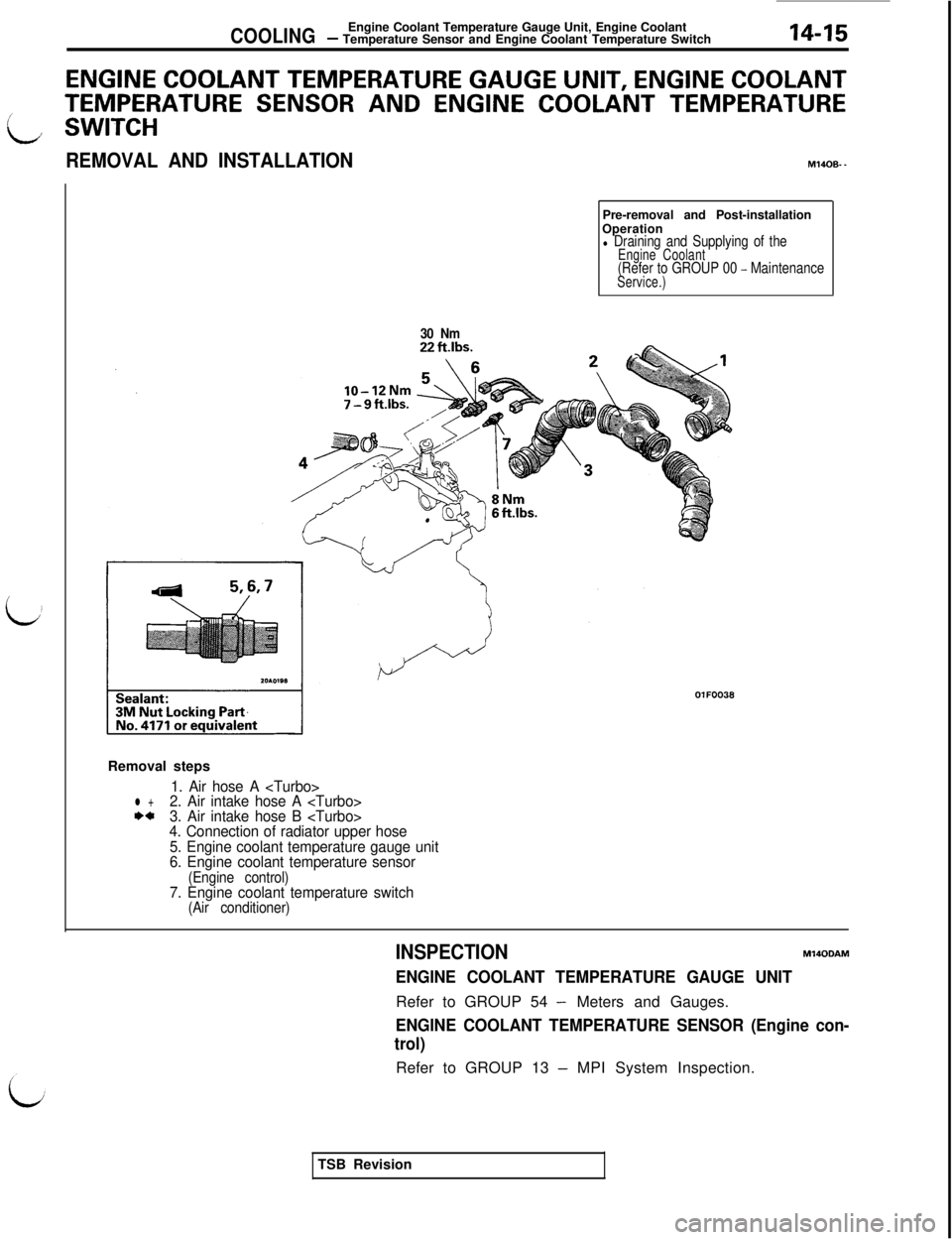

COOLINGEngine Coolant Temperature Gauge Unit, Engine Coolant- Temperature Sensor and Engine Coolant Temperature Switch14-15

ENGINE COOLANT TEMPERATURE GAUGE UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE COOLANT TEMPERATURE

L,SWITCH

REMOVAL AND INSTALLATIONM140B. -Pre-removal and Post-installation

Operation

l Draining and Supplying of theEngine Coolant(Refer to GROUP 00 - MaintenanceService.)

30 NmOlFOO38

Removal steps

1. Air hose A

4. Connection of radiator upper hose

5. Engine coolant temperature gauge unit

6. Engine coolant temperature sensor

(Engine control)7. Engine coolant temperature switch(Air conditioner)

INSPECTIONM140DAM

ENGINE COOLANT TEMPERATURE GAUGE UNITRefer to GROUP 54

- Meters and Gauges.

ENGINE COOLANT TEMPERATURE SENSOR (Engine con-

trol)Refer to GROUP 13

- MPI System Inspection.

TSB Revision

Page 310 of 1146

14-16

I

COOLINGEngine Coolant Temperature Gauge Unit, Engine Coolant- Temperature Sensor and Engine Coolant Temperature SwitchI

Air Intake hose B

05FOO2:

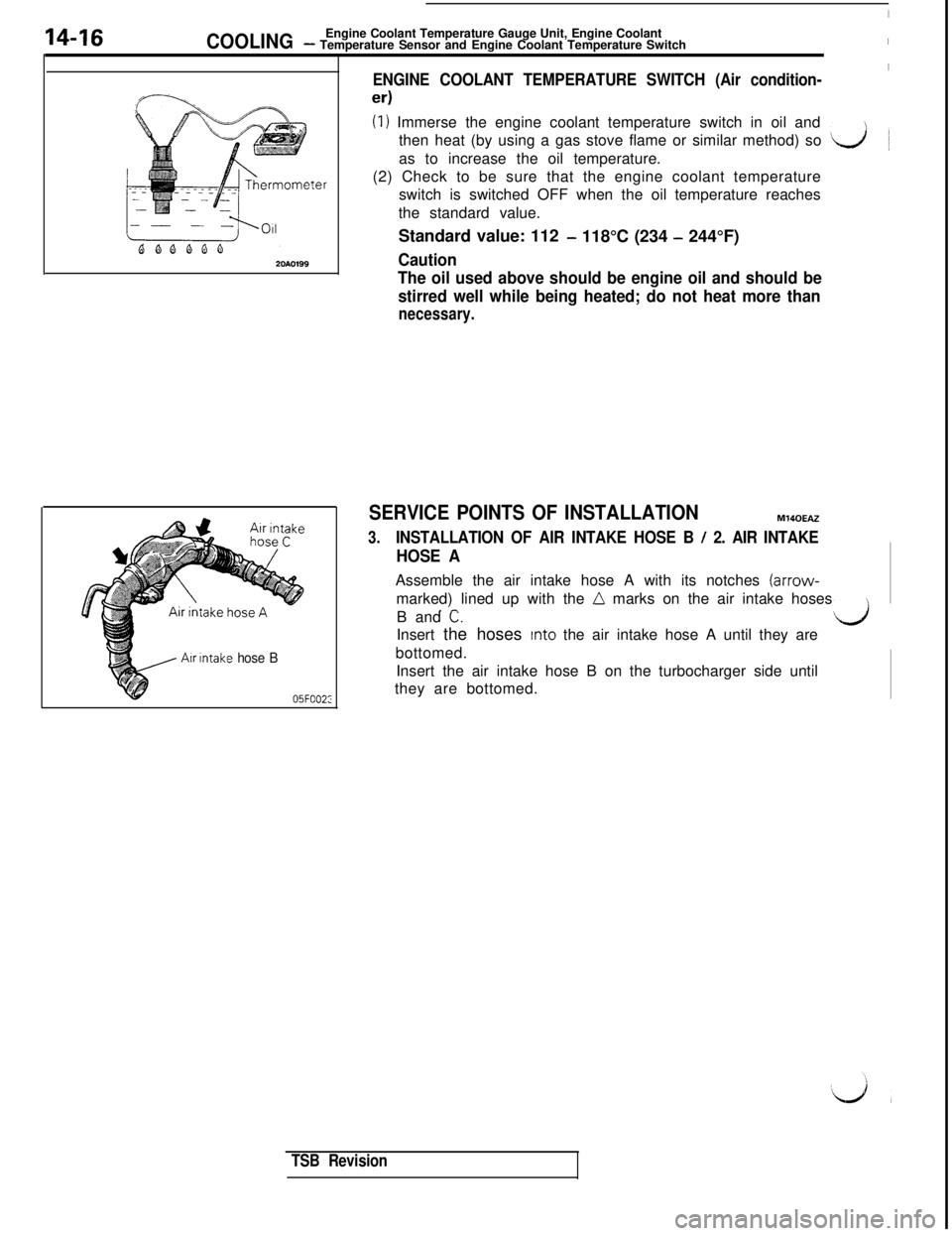

ENGINE COOLANT TEMPERATURE SWITCH (Air condition-I

4

(1) Immerse the engine coolant temperature switch in oil and

then heat (by using a gas stove flame or similar method) so

as to increase the oil temperature.

L.2~(2) Check to be sure that the engine coolant temperature

switch is switched OFF when the oil temperature reaches

the standard value.

Standard value: 112

- 118°C (234 - 244°F)

Caution

The oil used above should be engine oil and should be

stirred well while being heated; do not heat more than

necessary.

SERVICE POINTS OF INSTALLATIONM140EAz

3.INSTALLATION OF AIR INTAKE HOSE B / 2. AIR INTAKE

HOSE AB and L. Assemble the air intake hose A with its notches (arrow-

marked) lined up with the

n marks on the air intake hoses

. -dInsert the hoses Into the air intake hose A until they are

bottomed.

Insert the air intake hose B on the turbocharger side until

they are bottomed.

TSB Revision

Page 315 of 1146

INTAKE AND EXHAUST -Troubleshooting (Active Exhaust.System)15-5

ACTIVE EXHAUST SYSTEM CIRCUIT CHECK

5= i C-82

-i

@g

0J/S1%

‘I

‘6 c-71

3

1

+RHEOSTATmACTUATOR

1::ASSEMBLYF-29

&$jq

ACTlYEFXoQBIlBZ"NIT

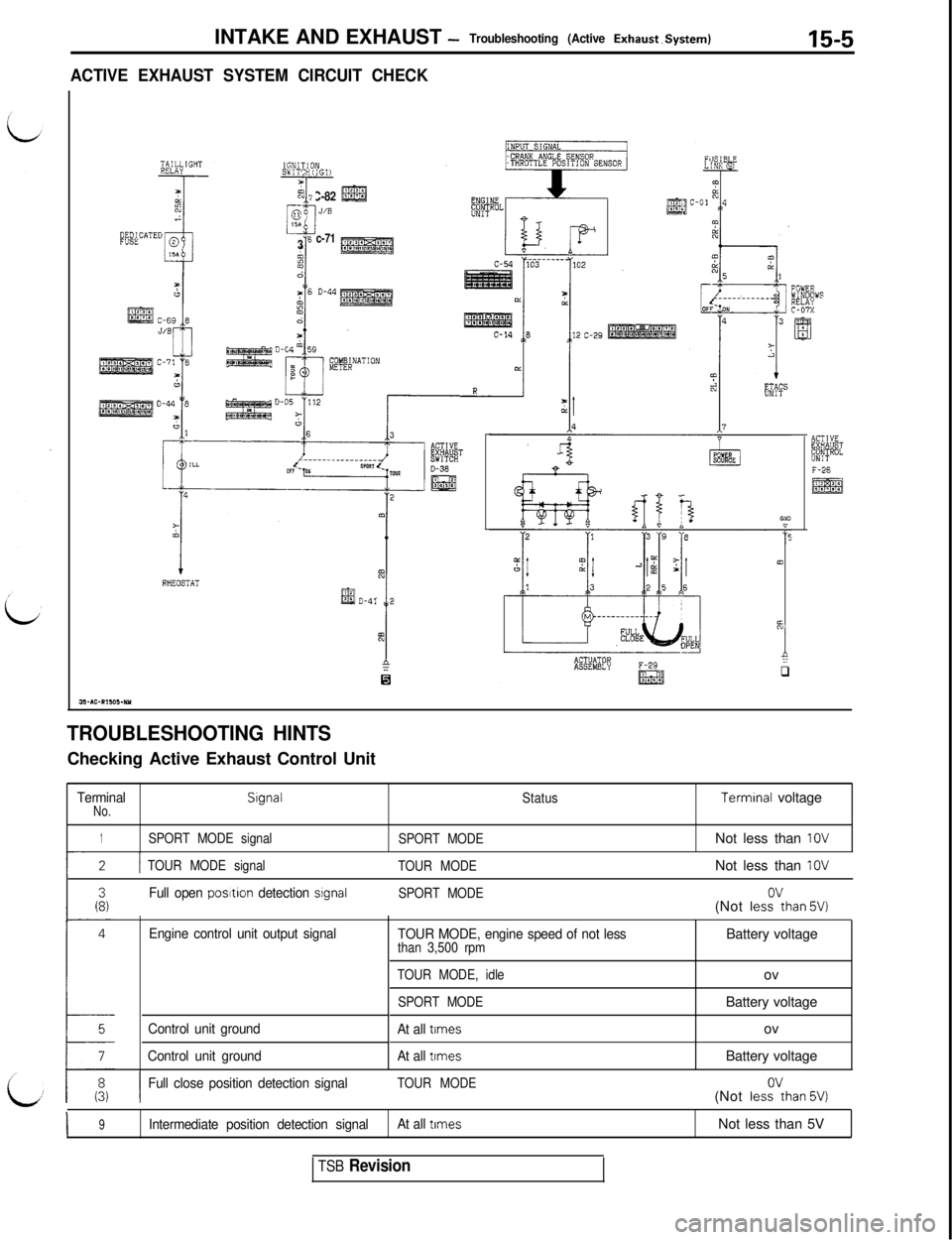

TROUBLESHOOTING HINTSChecking Active Exhaust Control Unit

TerminalNo.Signal

StatusTerminal voltage

1SPORT MODE signal

SPORT MODENot less than IOV

I-2 TTOUR MODE signal

TOUR MODENot less than IOV

Full open posrtion detection srgnalSPORT MODE(Not lesi’than 5V)

Engine control unit output signal

Control unit ground

Control unit groundTOUR MODE, engine speed of not lessthan 3,500 rpm

TOUR MODE, idle

SPORT MODE

At all times

At all

trmesBattery voltage

ov

Battery voltage

ov

Battery voltage

IFull close position detection signalTOUR MODE(Not lesk?than 5V)

I9Intermediate position detection signalAt all timesNot less than 5V

TSB Revision

Page 316 of 1146

15-6INTAKE AND EXHAUST - Service Adjustment Procedures

Variable rnductiorcontrol servoconnectors

6FU1277

Open

Close

71 NO105

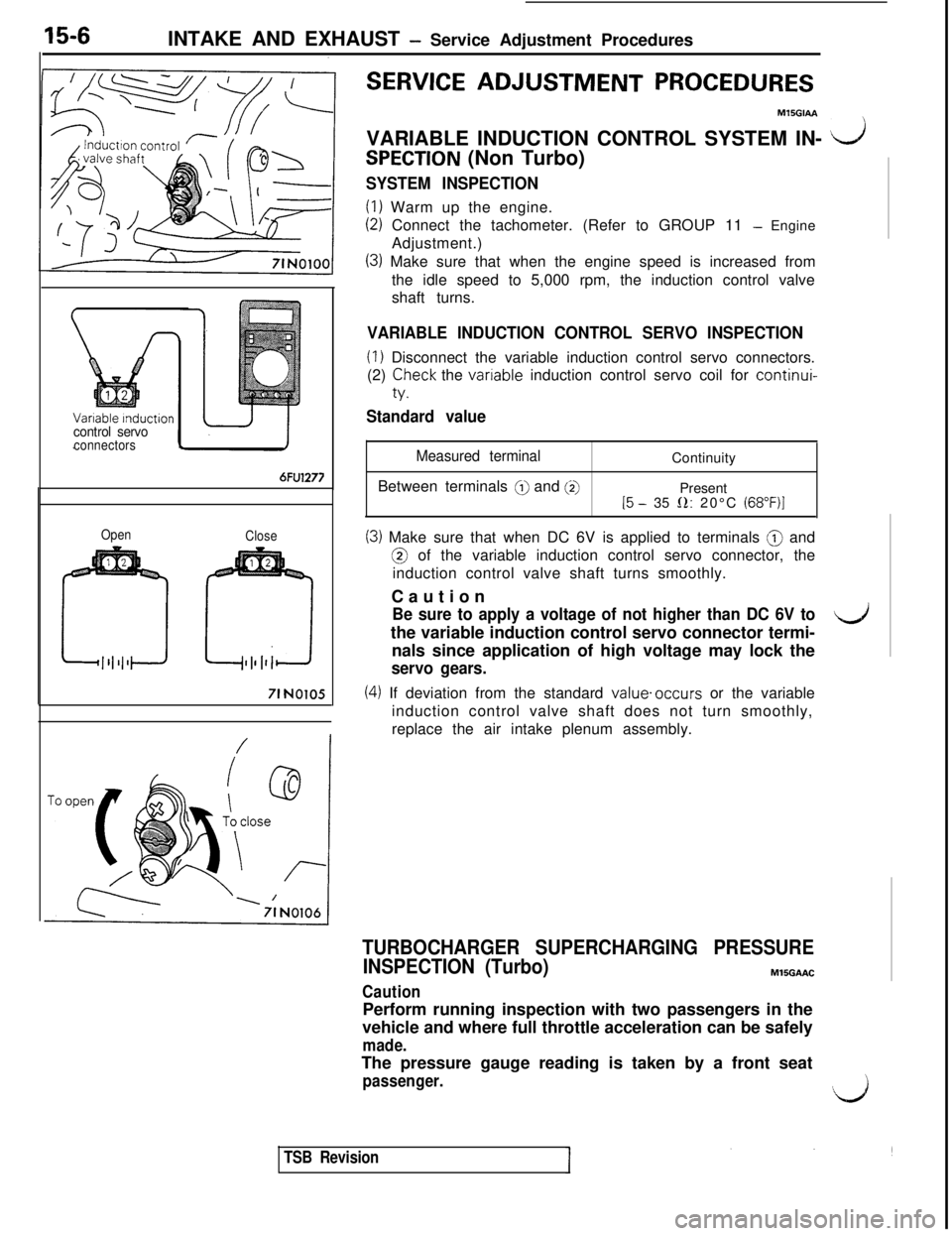

SERVICE ADJUSTMENT PROCEDURESMlSGlAA

VARIABLE INDUCTION CONTROL SYSTEM IN-

d

SPECTION (Non Turbo)

SYSTEM INSPECTION

(1) Warm up the engine.

(2) Connect the tachometer. (Refer to GROUP 11 - Engine

Adjustment.)

(3) Make sure that when the engine speed is increased from

the idle speed to 5,000 rpm, the induction control valve

shaft turns.

VARIABLE INDUCTION CONTROL SERVO INSPECTION

(1) Disconnect the variable induction control servo connectors.

(2)

Teck the vanable induction control servo coil for continui-

Standard value

Measured terminalBetween terminals

@ and @]Continuity

Present

15 - 35 0: 20°C (68”F)I

(3) Make sure that when DC 6V is applied to terminals @ and@ of the variable induction control servo connector, the

induction control valve shaft turns smoothly.

Caution

Be sure to apply a voltage of not higher than DC 6V tothe variable induction control servo connector termi-4nals since application of high voltage may lock the

servo gears.

(4) If deviation from the standard value.occurs or the variable

induction control valve shaft does not turn smoothly,

replace the air intake plenum assembly.

TURBOCHARGER SUPERCHARGING PRESSURE

INSPECTION (Turbo)MlSGAAC

CautionPerform running inspection with two passengers in the

vehicle and where full throttle acceleration can be safely

made.The pressure gauge reading is taken by a front seat

passenger.‘,k,i

TSB Revision

Page 317 of 1146

INTAKE AND EXHAUST - Service Adiustment Procedures15-7

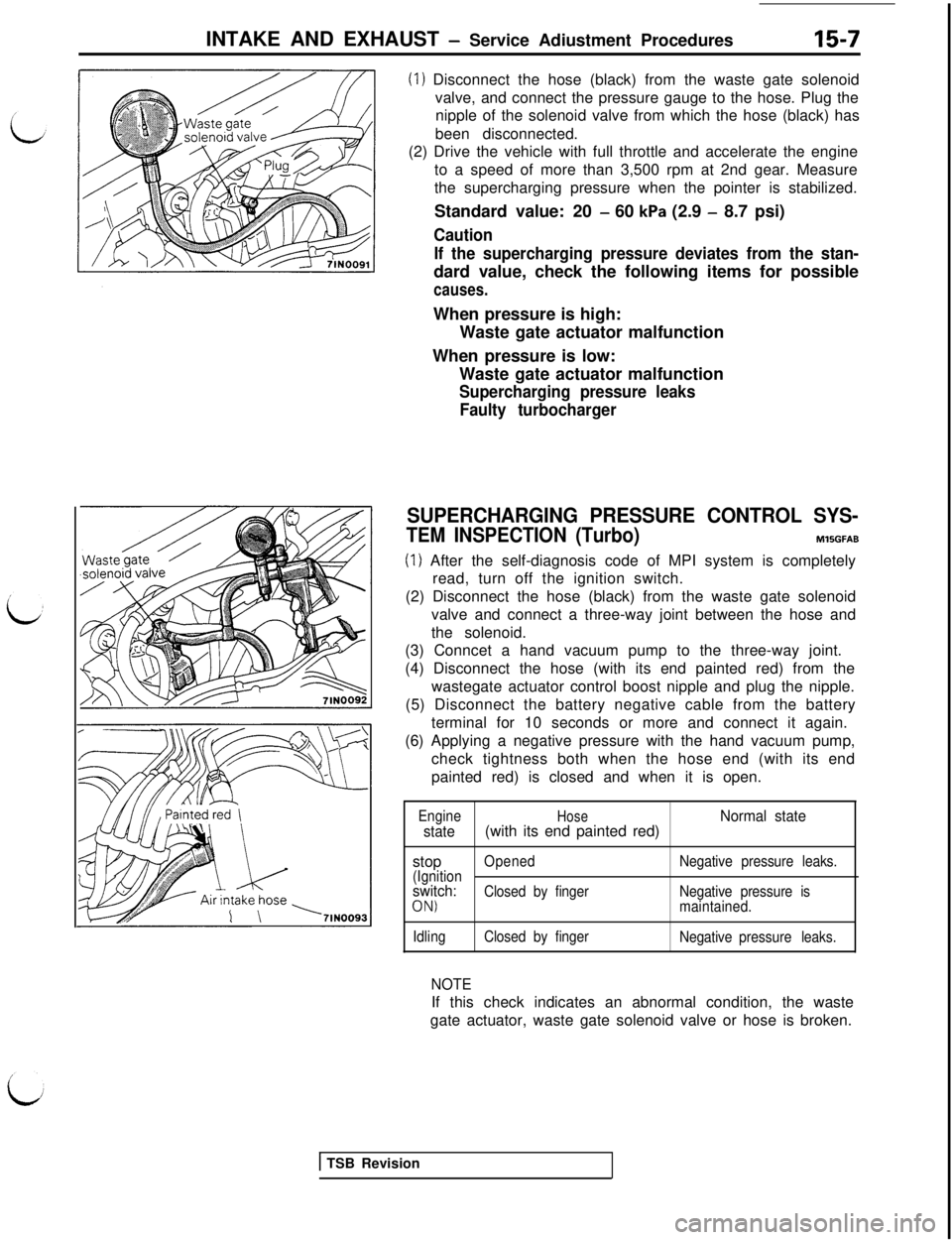

(1) Disconnect the hose (black) from the waste gate solenoid

valve, and connect the pressure gauge to the hose. Plug the

nipple of the solenoid valve from which the hose (black) has

been disconnected.

(2) Drive the vehicle with full throttle and accelerate the engine

to a speed of more than 3,500 rpm at 2nd gear. Measure

the supercharging pressure when the pointer is stabilized.

Standard value: 20

- 60 kPa (2.9 - 8.7 psi)

Caution

If the supercharging pressure deviates from the stan-dard value, check the following items for possible

causes.When pressure is high:

Waste gate actuator malfunction

When pressure is low:

Waste gate actuator malfunction

Supercharging pressure leaks

Faulty turbocharger

SUPERCHARGING PRESSURE CONTROL SYS-

TEM INSPECTION (Turbo)MlSGFAB

(1) After the self-diagnosis code of MPI system is completely

read, turn off the ignition switch.

(2) Disconnect the hose (black) from the waste gate solenoid

valve and connect a three-way joint between the hose and

the solenoid.

(3) Conncet a hand vacuum pump to the three-way joint.

(4) Disconnect the hose (with its end painted red) from the

wastegate actuator control boost nipple and plug the nipple.

(5) Disconnect the battery negative cable from the battery

terminal for 10 seconds or more and connect it again.

(6) Applying a negative pressure with the hand vacuum pump,

check tightness both when the hose end (with its end

painted red) is closed and when it is open.

EngineHoseNormal state

state(with its end painted red)

stop

OpenedNegative pressure leaks.

(Ignition

switch:Closed by fingerNegative pressure is

ON)maintained.

IdlingClosed by finger

Negative pressure leaks.

NOTEIf this check indicates an abnormal condition, the waste

gate actuator, waste gate solenoid valve or hose is broken.

1 TSB Revision

Page 321 of 1146

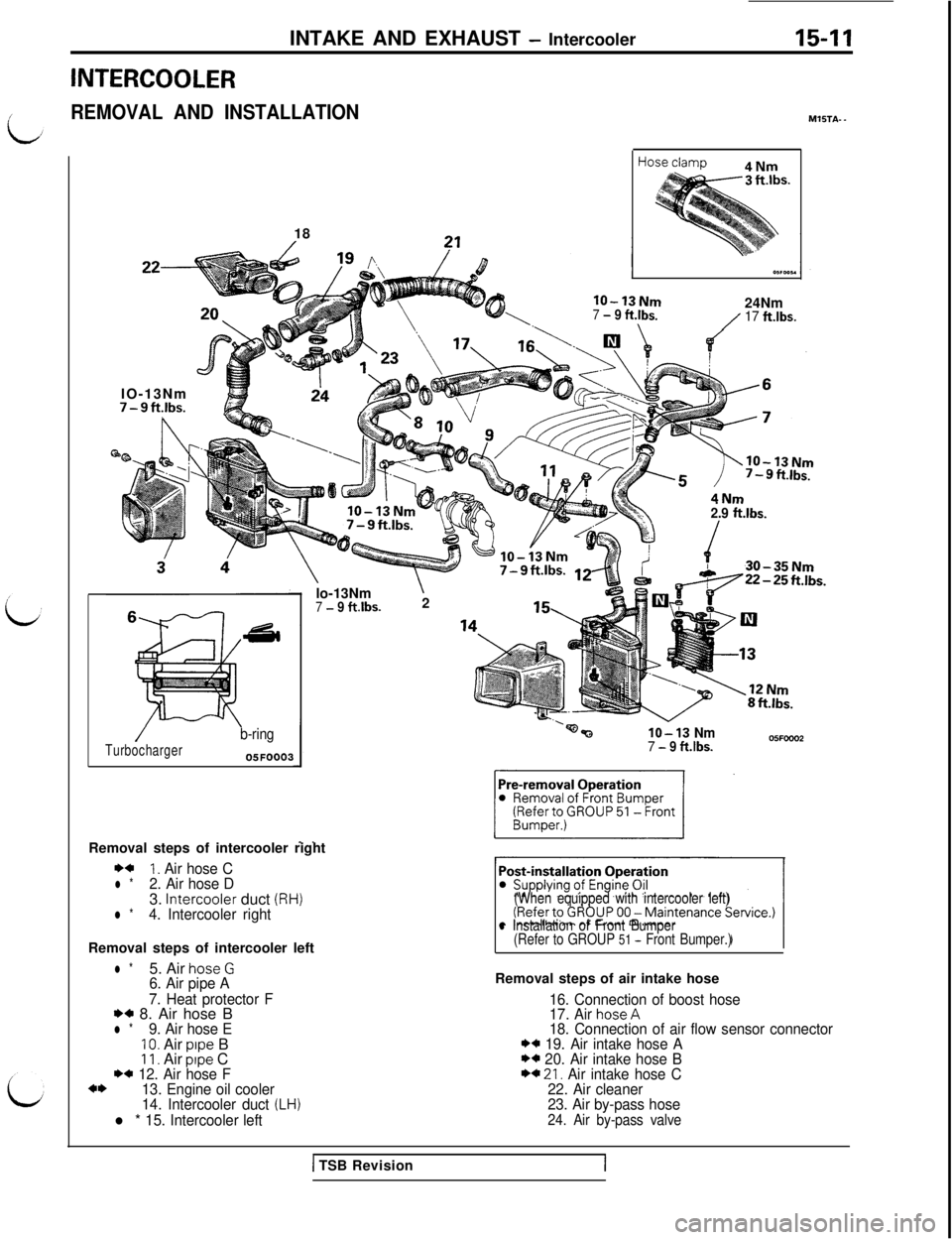

INTAKE AND EXHAUST - Intercooler

INTERCOOLER

/REMOVAL AND INSTALLATION18

/?1IO-13Nm

7-9ftJbs.

/Turbocharger

b-ring

05FOOO3MlSTA-

-

I

lo-13Nm7 - 9 ft.lbs.

OSPDOU24Nm

/ 17 ft.lbs.

ANm

7-.9 ft.lbs.

. .-...2.9 ft.lbs.lo-13Nm

’7 - 9 ft.lbs.2

_ .

Removal steps of intercooler right

**I. Air hose Cl *2. Air hose D3. Intercooler duct (RH)l *4. Intercooler rightRemoval steps of intercooler left

l *5. Air hoseG

6. Air pipe A

7. Heat protector F

I)* 8. Air hose Bl *9. Air hose E10. Air pipe BII. Air pope C** 12. Air hose F*I)13. Engine oil cooler

14. Intercooler duct (LH)

l * 15. Intercooler left

lo-13 Nm7 - 9 ft.lbs.OSFOC.02

(When equipped with intercooler left)

l Installation of Front Bumper

(Refer to GROUP 51 - Front Bumper.)Removal steps of air intake hose

16. Connection of boost hose

17. Air hoseA

18. Connection of air flow sensor connector

I)* 19. Air intake hose A** 20. Air intake hose B*a 21. Air intake hose C

22. Air cleaner

23. Air by-pass hose

24. Air by-pass valve

1 TSB Revision

Page 322 of 1146

15-12INTAKE AND EXHAUST - lntercooier

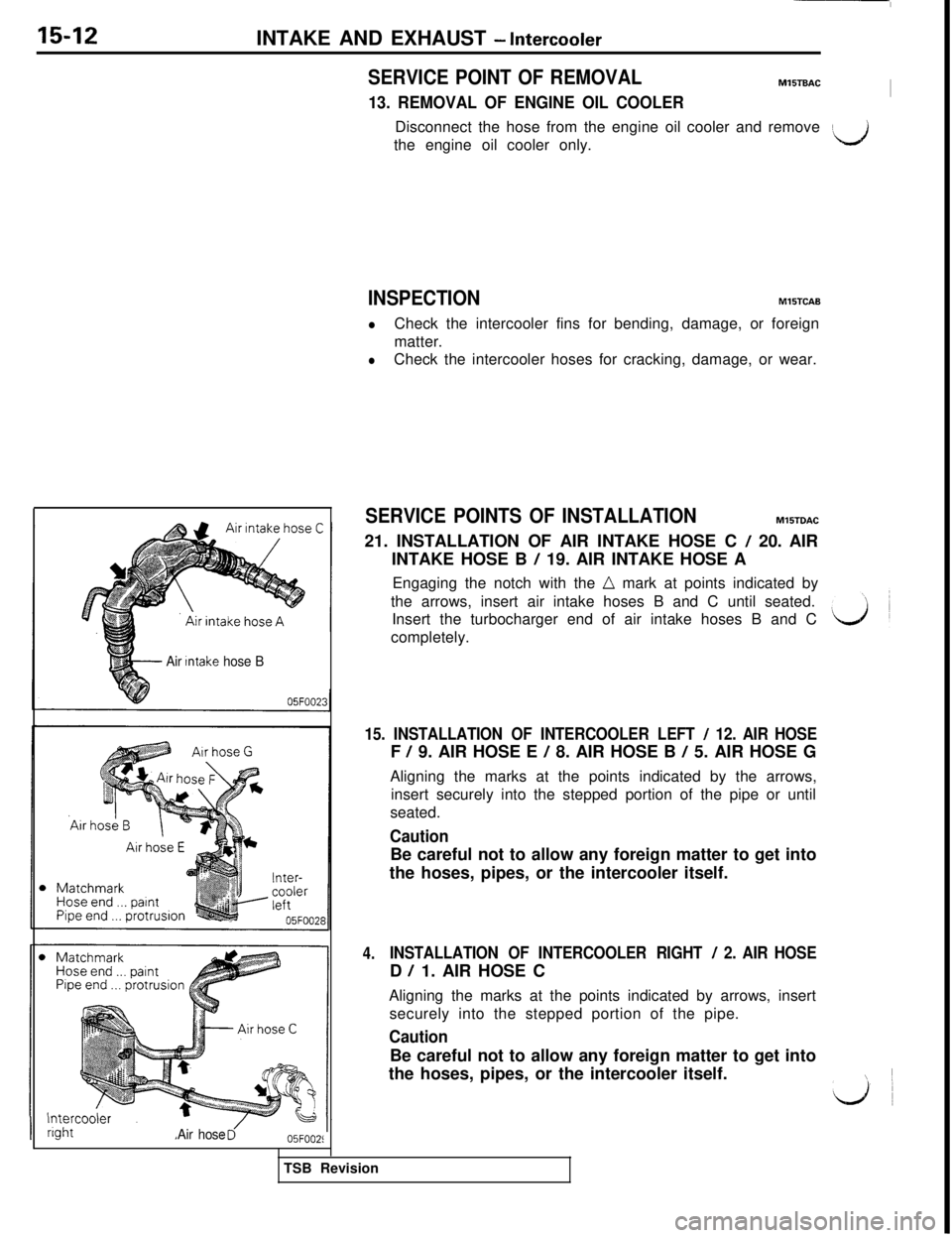

SERVICE POINT OF REMOVALMlSTSAC

13. REMOVAL OF ENGINE OIL COOLERIDisconnect the hose from the engine oil cooler and remove

the engine oil cooler only.

IL)

INSPECTIONMISTCAB

lCheck the intercooler fins for bending, damage, or foreign

matter.

lCheck the intercooler hoses for cracking, damage, or wear.

Air Intake hose B

Air hose

05FOO21

SERVICE POINTS OF INSTALLATIONMlSTDAC

21. INSTALLATION OF AIR INTAKE HOSE C

/ 20. AIR

INTAKE HOSE B

/ 19. AIR INTAKE HOSE A

Engaging the notch with the

n mark at points indicated by

the arrows, insert air intake hoses B and C until seated.

Insert the turbocharger end of air intake hoses B and C

completely.

15. INSTALLATION OF INTERCOOLER LEFT / 12. AIR HOSEF

/ 9. AIR HOSE E / 8. AIR HOSE B / 5. AIR HOSE G

Aligning the marks at the points indicated by the arrows,

insert securely into the stepped portion of the pipe or until

seated.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

4.INSTALLATION OF INTERCOOLER RIGHT / 2. AIR HOSED

/ 1. AIR HOSE C

Aligning the marks at the points indicated by arrows, insert

securely into the stepped portion of the pipe.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

1 ~

LJ~TSB Revision