engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 323 of 1146

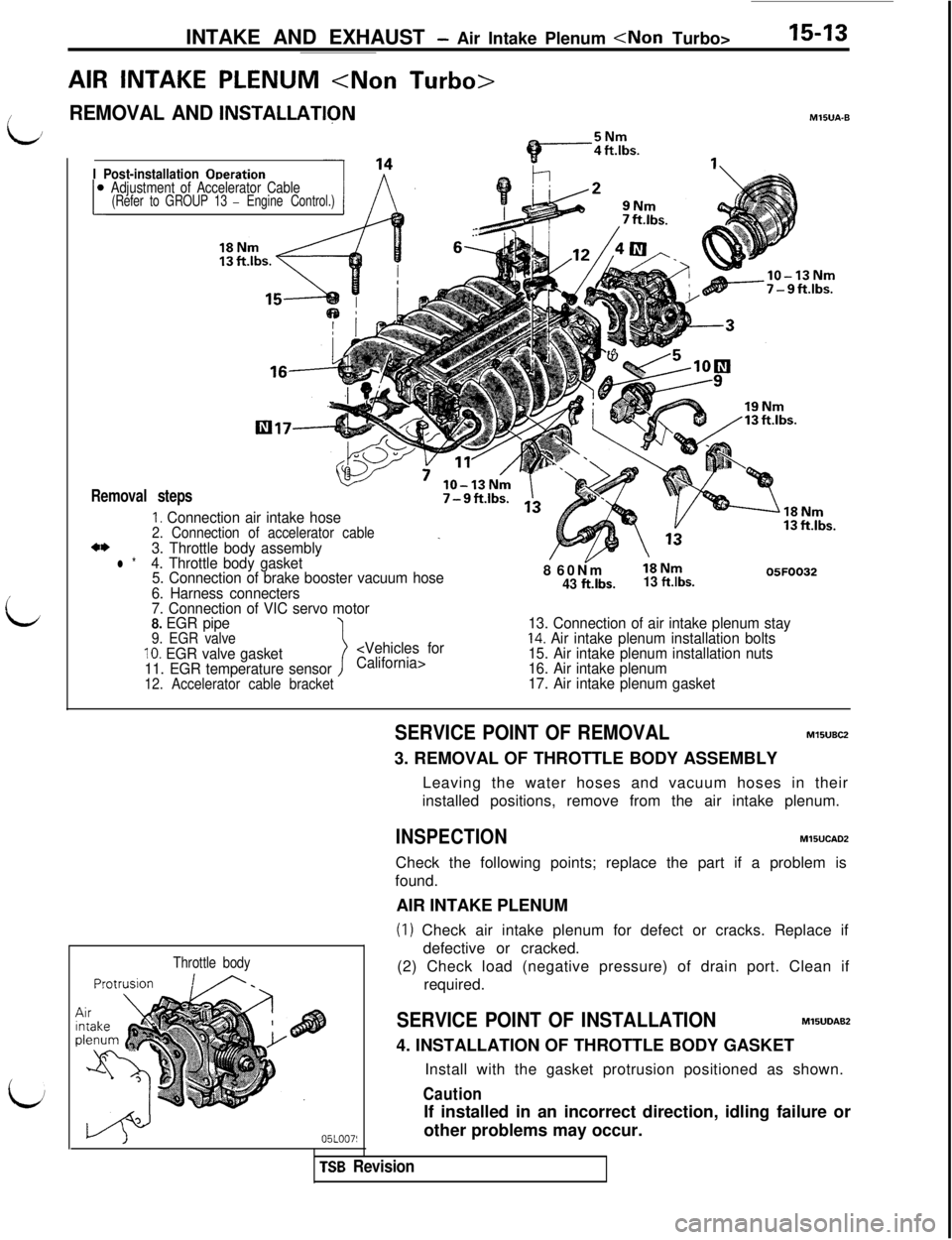

INTAKE AND EXHAUST - Air Intake Plenum

AIR INTAKE PLENUM

/REMOVAL AND INSTALLATIQNMlWA-B

L/

i

I Post-installation ODeration

Adjustment of Accelerator Cable

(Refer to GROUP 13 - Engine Control.)

Removal steps7-9ft.lbs.

I. Connection air intake hose2. Connection of accelerator cable_*I)3. Throttle body assemblyl *4. Throttle body gasket

5. Connection of brake booster vacuum hose

6. Harness connecters8 60Nm;6Nm05FOO32

43 ft.lbs.13 ft.lbs.

7. Connection of VIC servo motor

8. EGR pipe

9. EGR valve

11. EGR temperature sensor

12. Accelerator cable bracket

13. Connection of air intake plenum stay14. Air intake plenum installation bolts

15. Air intake plenum installation nuts

16. Air intake plenum

17. Air intake plenum gasket

Throttle body

SERVICE POINT OF REMOVALM15UBC23. REMOVAL OF THROTTLE BODY ASSEMBLY

Leaving the water hoses and vacuum hoses in their

installed positions, remove from the air intake plenum.

INSPECTIONM15UCAD2

Check the following points; replace the part if a problem is

found.

AIR INTAKE PLENUM

(1) Check air intake plenum for defect or cracks. Replace if

defective or cracked.

(2) Check load (negative pressure) of drain port. Clean if

required.

SERVICE POINT OF INSTALLATIONMl5UDAB2

4. INSTALLATION OF THROTTLE BODY GASKET

Install with the gasket protrusion positioned as shown.

CautionIf installed in an incorrect direction, idling failure or

other problems may occur.

TSB Revision

Page 324 of 1146

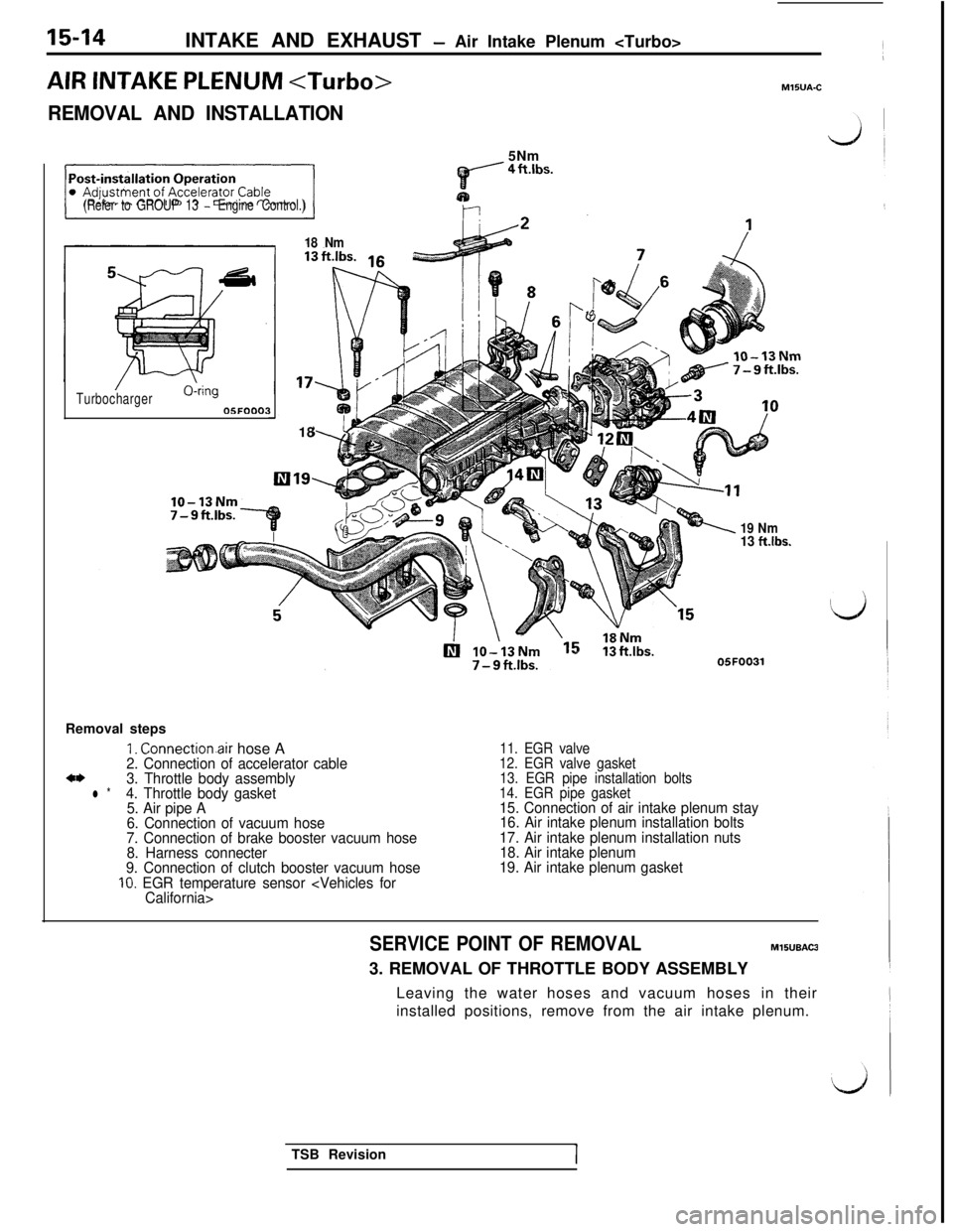

15-14INTAKE AND EXHAUST - Air Intake Plenum

AIR INTAKE PLENUM

REMOVAL AND INSTALLATION

(Refer to GROUP 13 - Engine Control.)

/TurbochargerO&gOSFOOOS5Nm

L

18 Nm18

19 Nm13 ft.lbs.

-05FOO31Removal steps

I. Connection.air hose A2. Connection of accelerator cablea*3. Throttle body assemblyl *4. Throttle body gasket

5. Air pipe A

6. Connection of vacuum hose

7. Connection of brake booster vacuum hose

8. Harness connecter

9. Connection of clutch booster vacuum hose

10. EGR temperature sensor

11. EGR valve

12. EGR valve gasket

13. EGR pipe installation bolts

14. EGR pipe gasket

15. Connection of air intake plenum stay

16. Air intake plenum installation bolts

17. Air intake plenum installation nuts

18. Air intake plenum

19. Air intake plenum gasket

SERVICE POINT OF REMOVALM15UBAU3. REMOVAL OF THROTTLE BODY ASSEMBLY

Leaving the water hoses and vacuum hoses in their

installed positions, remove from the air intake plenum.

TSB Revision

Page 326 of 1146

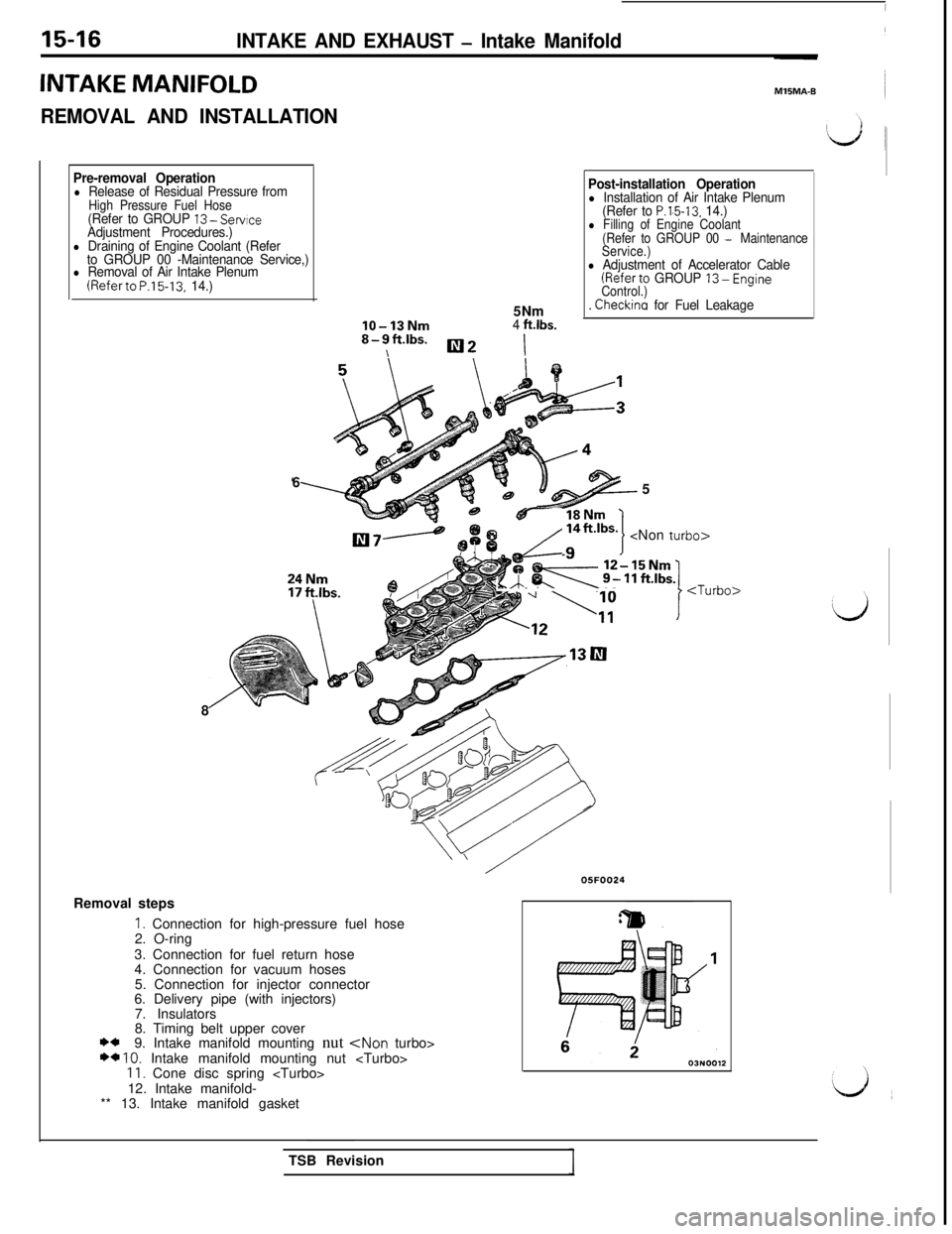

15-16INTAKE AND EXHAUST - Intake Manifold

INTAKE MANIFOLD

REMOVAL AND INSTALLATION

Pre-removal Operationl Release of Residual Pressure fromHigh Pressure Fuel Hose(Refer to GROUP 13-ServiceAdjustment Procedures.)l Draining of Engine Coolant (Refer

to GROUP 00 -Maintenance Service,)

l Removal of Air Intake Plenum(Referto P.15-13, 14.)5Nm

lo-13Nm4 ft.lbs.8-9ftJbs. w2\I

Post-installation Operationl Installation of Air Intake Plenum

(Refer to P.1.5-13. 14.)l Filling of Engine Coolant

(Refer to GROUP 00 - Maintenance

Service.)

l Adjustment of Accelerator Cable(Referto GROUP 13-EngineControl.). Checkina for Fuel Leakage6

5

2 :‘;bs.)

gp,.qgs ~-zt!EJ8OSFOO24

Removal steps

I. Connection for high-pressure fuel hose

2. O-ring

3. Connection for fuel return hose

4. Connection for vacuum hoses

5. Connection for injector connector

6. Delivery pipe (with injectors)

7. Insulators

8. Timing belt upper cover

I)*9. Intake manifold mounting nut

12. Intake manifold-

** 13. Intake manifold gasket

TSB Revision

Page 328 of 1146

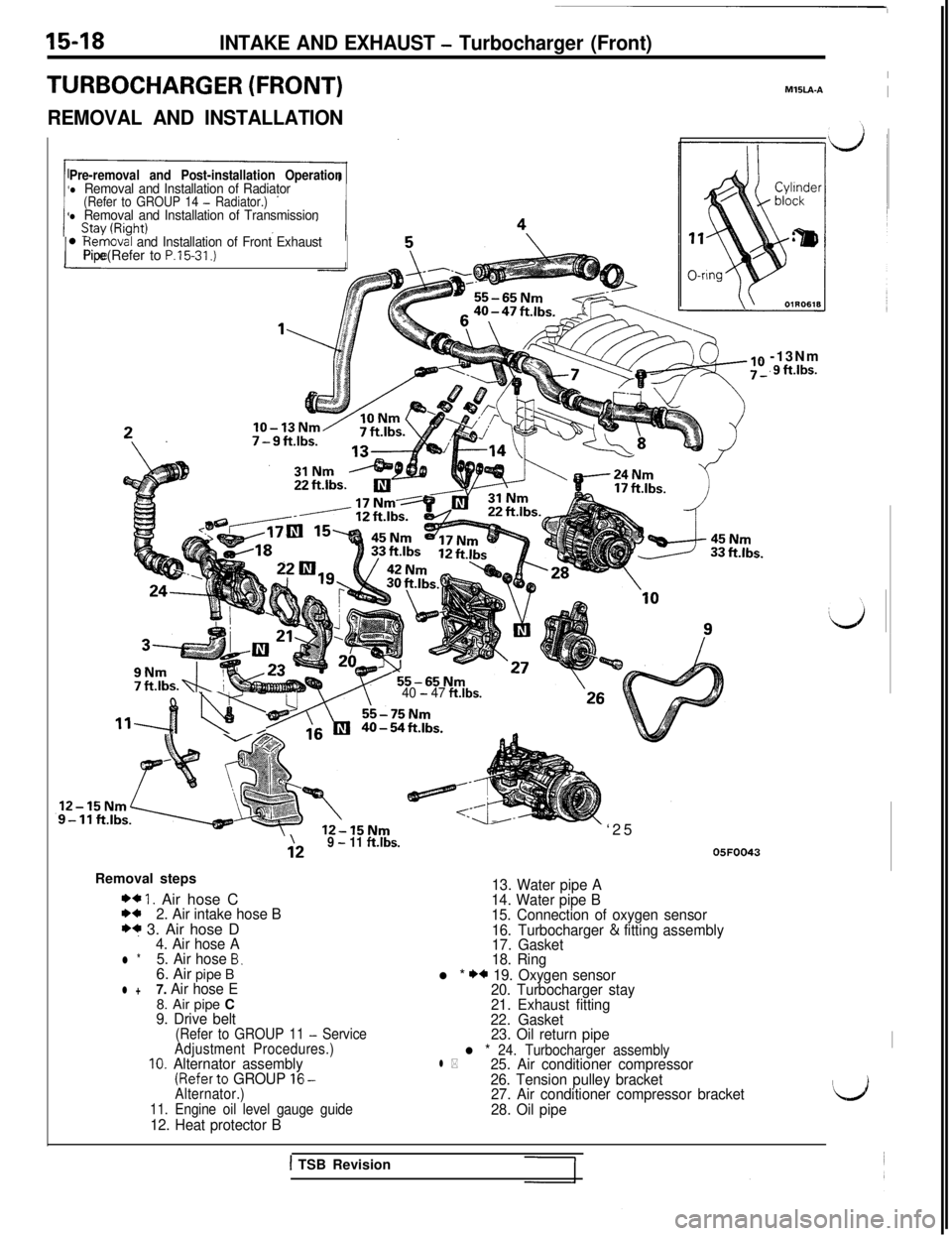

15-18INTAKE AND EXHAUST - Turbocharger (Front)

TURBOCHARGER (FRONT)

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operationl Removal and Installation of Radiator(Refer to GROUP 14 - Radiator.)l Removal and Installation of Transmission

l Rerr

IPipeioval and Installation of Front Exhaust(Refer to P.15-31.)

lJl QG!?

IMlSLA-AI

40 - 47 ft.lbs.

1\29 - 11 ft.lbs.Removal steps

** 1. Air hose C*+2. Air intake hose B*+ 3. Air hose D4. Air hose Al *5. Air hose B.6. Air pipe B

l +7. Air hose E8. Air pipe C

9. Drive belt(Refer to GROUP 11 - Service

Adjustment Procedures.)

10. Alternator assembly(Referto GROUP 16-Alternator.)

11. Engine oil level gauge guide

12. Heat protector B-13Nm

‘9 ft.lbs.

-‘25

05FOO43

13. Water pipe A

14. Water pipe B

15. Connection of oxygen sensor

16. Turbocharger

& fitting assembly

17. Gasket

18. Ring

l * ** 19. Oxygen sensor

20. Turbocharger stay

21. Exhaust fitting

22. Gasket

23. Oil return pipe

l * 24. Turbocharger assemblyl *25. Air conditioner compressor

26. Tension pulley bracket

27. Air conditioner compressor bracket

28. Oil pipe

I

LJ

1 TSB Revision

Page 329 of 1146

INTAKE AND EXHAUST - Turbocharger (Front)15-19

05FOO2(

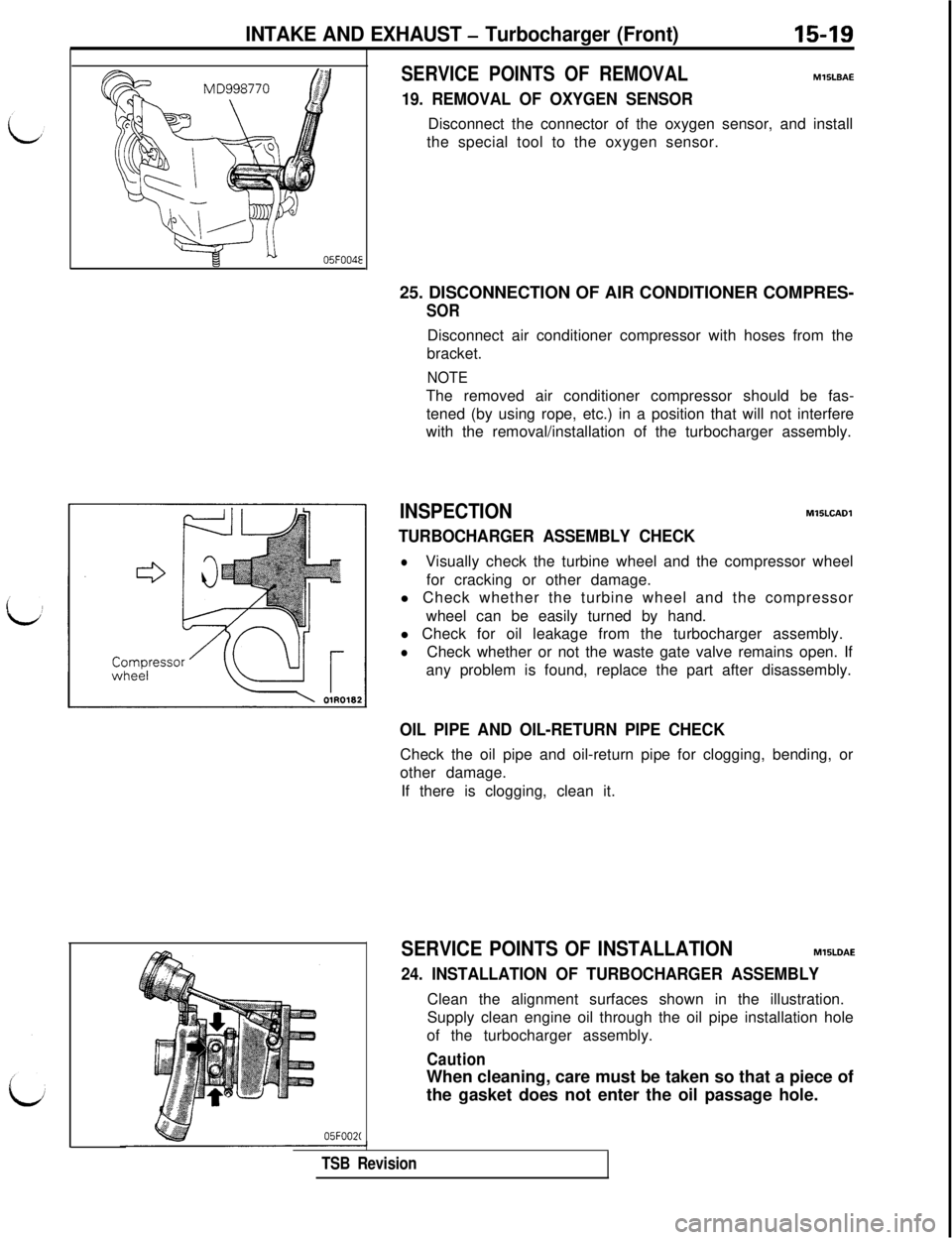

SERVICE POINTS OF REMOVALM15LBAE

19. REMOVAL OF OXYGEN SENSORDisconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

25. DISCONNECTION OF AIR CONDITIONER COMPRES-

SORDisconnect air conditioner compressor with hoses from the

bracket.

NOTEThe removed air conditioner compressor should be fas-

tened (by using rope, etc.) in a position that will not interfere

with the removal/installation of the turbocharger assembly.

INSPECTION

TURBOCHARGER ASSEMBLY CHECKMlSLCADl

lVisually check the turbine wheel and the compressor wheel

for cracking or other damage.

l Check whether the turbine wheel and the compressor

wheel can be easily turned by hand.

l Check for oil leakage from the turbocharger assembly.

lCheck whether or not the waste gate valve remains open. If

any problem is found, replace the part after disassembly.

OIL PIPE AND OIL-RETURN PIPE CHECKCheck the oil pipe and oil-return pipe for clogging, bending, or

other damage.

If there is clogging, clean it.

SERVICE POINTS OF INSTALLATIONMllLDAE

24. INSTALLATION OF TURBOCHARGER ASSEMBLYClean the alignment surfaces shown in the illustration.

Supply clean engine oil through the oil pipe installation hole

of the turbocharger assembly.

CautionWhen cleaning, care must be taken so that a piece of

the gasket does not enter the oil passage hole.

TSB Revision

Page 331 of 1146

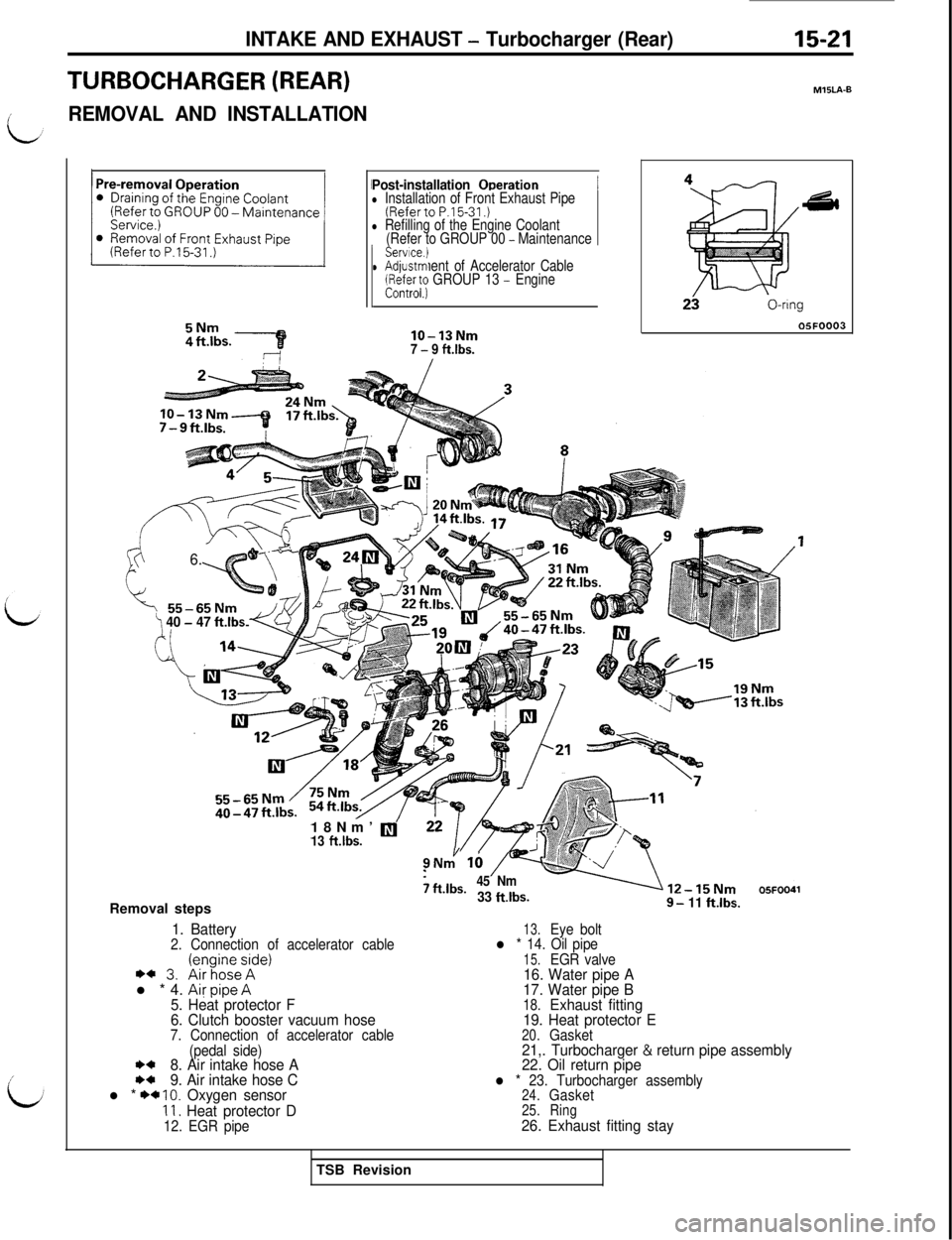

INTAKE AND EXHAUST - Turbocharger (Rear)15-21

TURBOCHARGER (REAR)

iREMOVAL AND INSTALLATION

/

id

Post-installation ODerationIl Installation of Front Exhaust Pipe(Referto P.15-31.)l Refilling of the Engine Coolant

(Refer to GROUP 00 - Maintenance

l Adjustment of Accelerator Cable1~~~~o~~ GROUP 13 - Engine

lo-13Nm7 - 9 ft.lbs.

6.

7 55-65Nmb

5 40 - 47 ft.lbs.i18Nm’

d13 ft.lbs.

MlSLA-B

0-nng

05FOOO3Removal steps

1. Battery2. Connection of accelerator cable

** 3, pg,t;eye)l * 4.

AirpipeA5. Heat protector F

6. Clutch booster vacuum hose

7. Connection of accelerator cable

(pedal side)

I)+8. Air intake hose AO+9. Air intake hose Cl * I)* 10. Oxygen sensor

11. Heat protector D12. EGR pipe

9Nmv 10 //--!

-7 ft.lbs.45 Nm33 ft.lbs.LIZ-15NmOSFOO419- 11 ft.lbs.

13.Eye boltl * 14. Oil pipe15.EGR valve16. Water pipe A

17. Water pipe B

18.Exhaust fitting

19. Heat protector E

20.Gasket21,. Turbocharger & return pipe assembly

22. Oil return pipe

l * 23. Turbocharger assembly24.Gasket25.Ring26. Exhaust fitting stayTSB Revision

Page 332 of 1146

INTAKE AND EXHAUST - Turbocharger (Rear)

0

Comrxessorwheel \u ~i, rOlR0182

I05FOO19

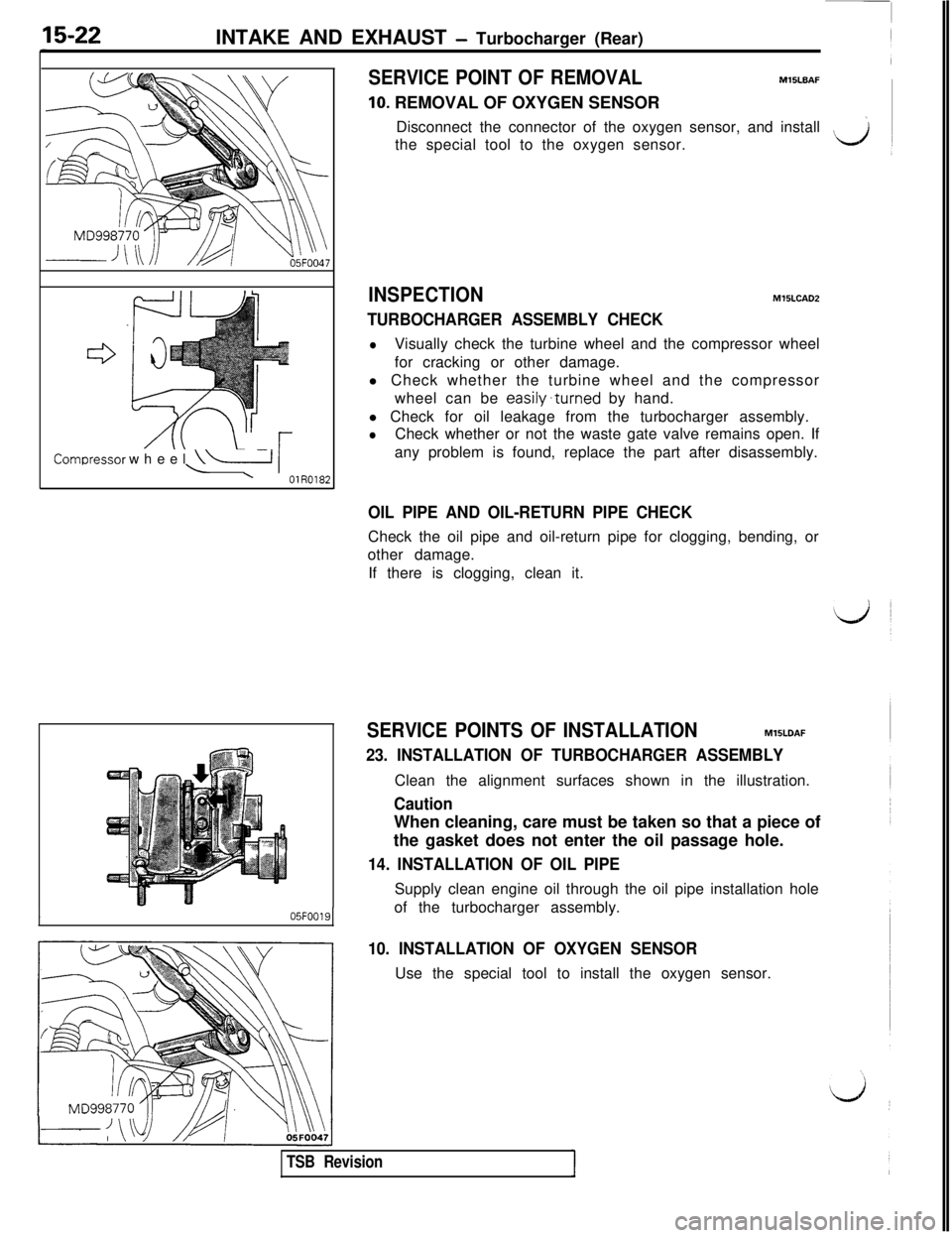

SERVICE POINT OF REMOVALM15LBAF

10. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

’the special tool to the oxygen sensor.

d,

INSPECTION

TURBOCHARGER ASSEMBLY CHECK

M15LCADZ

lVisually check the turbine wheel and the compressor wheel

for cracking or other damage.

l Check whether the turbine wheel and the compressor

wheel can be

easily.turned by hand.

l Check for oil leakage from the turbocharger assembly.

lCheck whether or not the waste gate valve remains open. If

any problem is found, replace the part after disassembly.

OIL PIPE AND OIL-RETURN PIPE CHECKCheck the oil pipe and oil-return pipe for clogging, bending, or

other damage.

If there is clogging, clean it.

SERVICE POINTS OF INSTALLATIONMlBLDAF

23. INSTALLATION OF TURBOCHARGER ASSEMBLYClean the alignment surfaces shown in the illustration.

CautionWhen cleaning, care must be taken so that a piece of

the gasket does not enter the oil passage hole.

14. INSTALLATION OF OIL PIPESupply clean engine oil through the oil pipe installation hole

of the turbocharger assembly.

10. INSTALLATION OF OXYGEN SENSORUse the special tool to install the oxygen sensor.

TSB Revision

Page 335 of 1146

INTAKE AND EXHAUST - Turbocharger

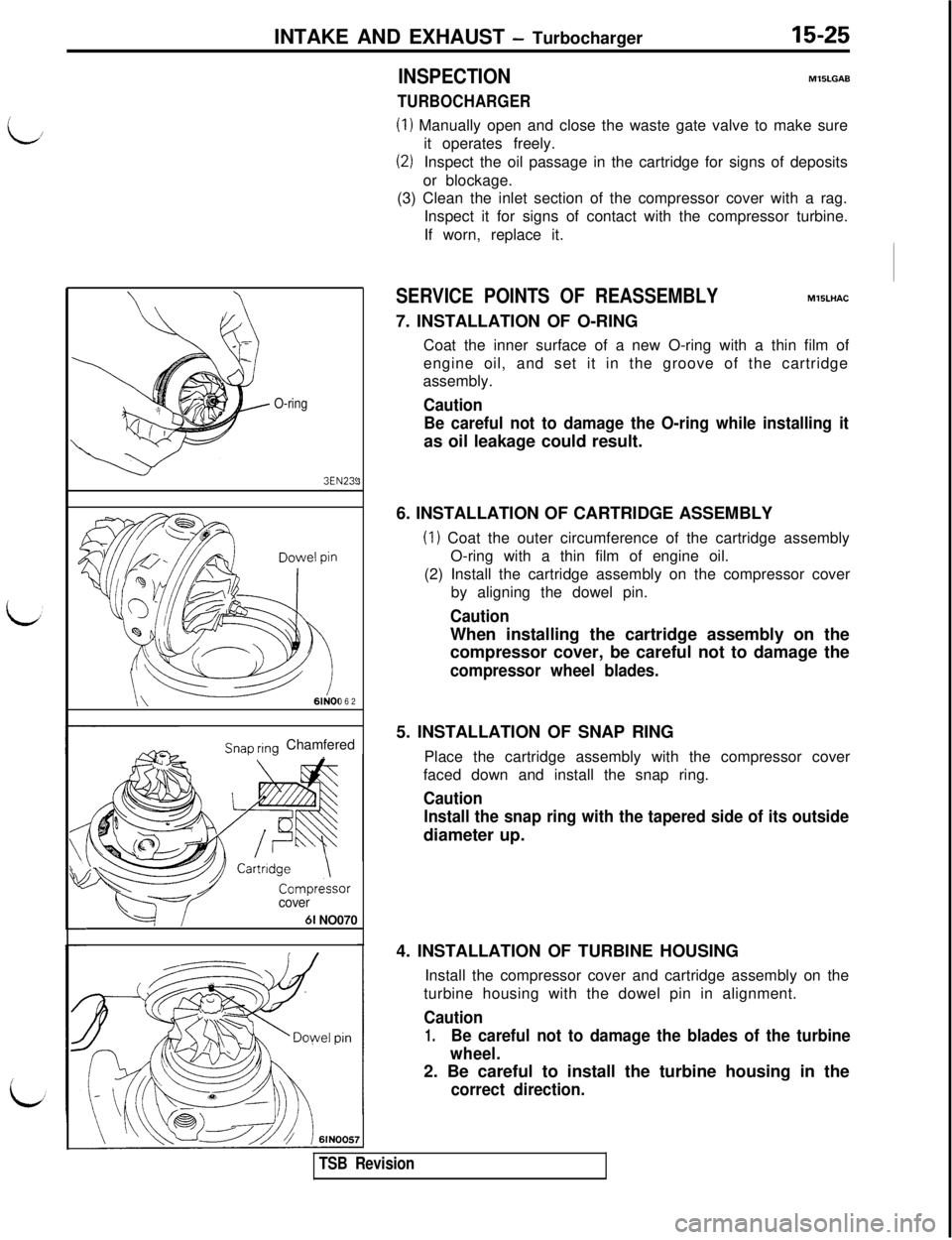

INSPECTION

TURBOCHARGER

15-25MllLGAB

(I) Manually open and close the waste gate valve to make sure

it operates freely.

(2)Inspect the oil passage in the cartridge for signs of deposits

or blockage.

(3) Clean the inlet section of the compressor cover with a rag.

Inspect it for signs of contact with the compressor turbine.

If worn, replace it.

L/

O-ring

3EN23C3062

snap ring Chamfered

.

v cartr~d~om,,ir

,jFcover

WI61 NO070

SERVICE POINTS OF REASSEMBLYM15LHAC7. INSTALLATION OF O-RING

Coat the inner surface of a new O-ring with a thin film of

engine oil, and set it in the groove of the cartridge

assembly.

Caution

Be careful not to damage the O-ring while installing itas oil leakage could result.

6. INSTALLATION OF CARTRIDGE ASSEMBLY

(1) Coat the outer circumference of the cartridge assembly

O-ring with a thin film of engine oil.

(2) Install the cartridge assembly on the compressor cover

by aligning the dowel pin.

CautionWhen installing the cartridge assembly on the

compressor cover, be careful not to damage the

compressor wheel blades.5. INSTALLATION OF SNAP RING

Place the cartridge assembly with the compressor cover

faced down and install the snap ring.

Caution

Install the snap ring with the tapered side of its outsidediameter up.

TSB Revision4. INSTALLATION OF TURBINE HOUSING

Install the compressor cover and cartridge assembly on the

turbine housing with the dowel pin in alignment.

Caution

1.Be careful not to damage the blades of the turbine

wheel.2. Be careful to install the turbine housing in the

correct direction.

Page 345 of 1146

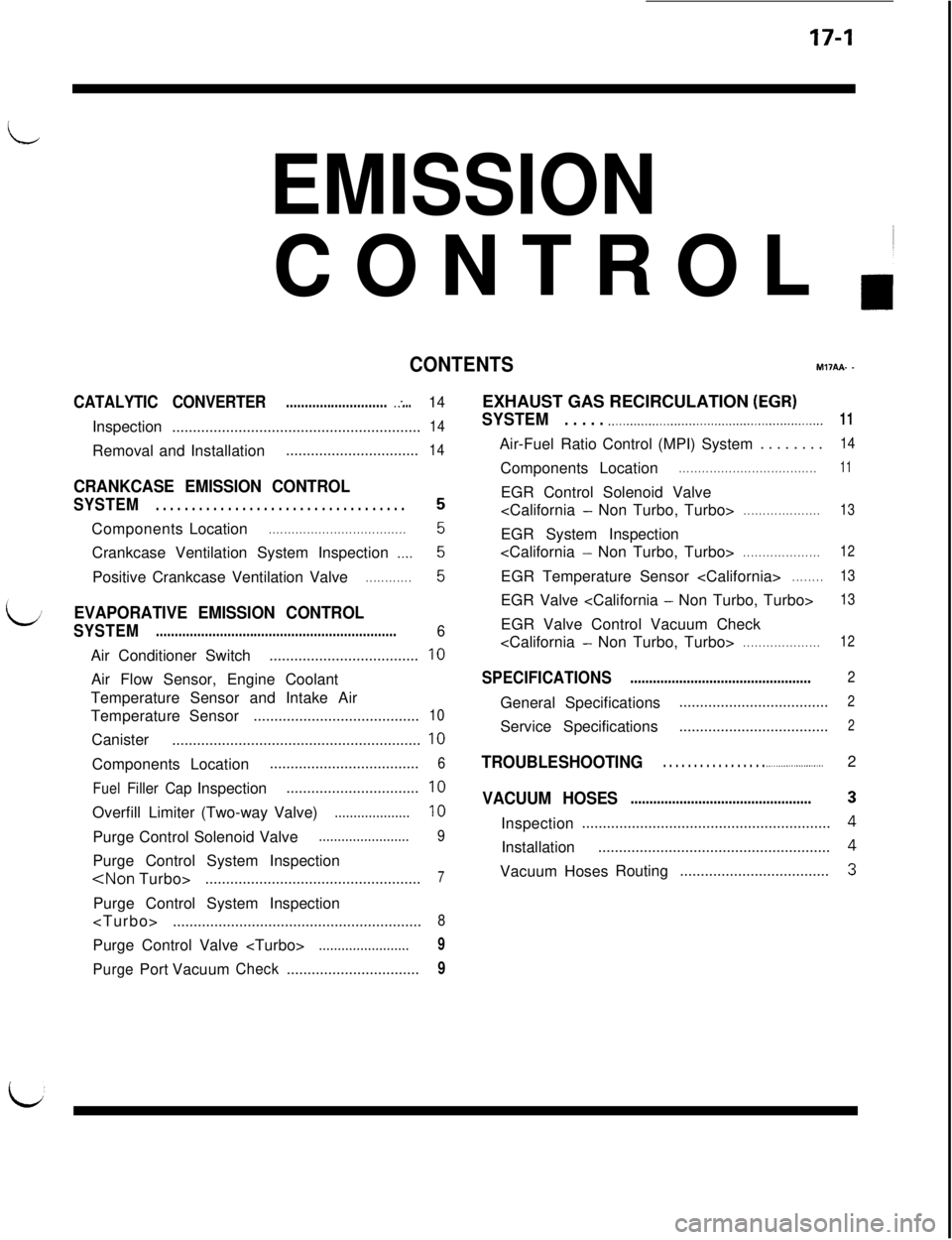

17-1

EMISSIONCONTROL

.~

CATALYTIC CONVERTER............................:...Inspection

............................................................Removal and Installation

................................

CONTENTSM17.U. -

CRANKCASE EMISSION CONTROL

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ComponentsLocation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Crankcase Ventilation System Inspection

._..Positive Crankcase Ventilation Valve

. . . . . . . . . . . .

EVAPORATIVE EMISSION CONTROL

SYSTEM................................................................Air Conditioner Switch

....................................Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor

........................................Canister

............................................................Components Location

....................................

FuelFiller CapInspection................................OverfillLimiter (Two-way Valve)

....................Purge Control Solenoid Valve

........................Purge Control System Inspection

............................................................Purge Control Valve

........................

PurgePort VacuumCheck................................14

14

14

6

10

10

10

6

10

10

9

7

8

9

9EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM. . . . . ..____._.._........__........_____.........................Air-FuelRatio Control (MPI) System. . . . . . . .

Components Location

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .EGR Control Solenoid Valve

. . . . . . . .EGR Valve

EGR Valve Control Vacuum Check

SPECIFICATIONS................................................General Specifications

....................................Service Specifications

....................................

TROUBLESHOOTING. . . . . . . . . . . . . . . . . ..______...............

VACUUM HOSES................................................Inspection

............................................................Installation

........................................................VacuumHosesRouting

....................................

11

14

11

13

12

13

13

12

2

2

22

Page 346 of 1146

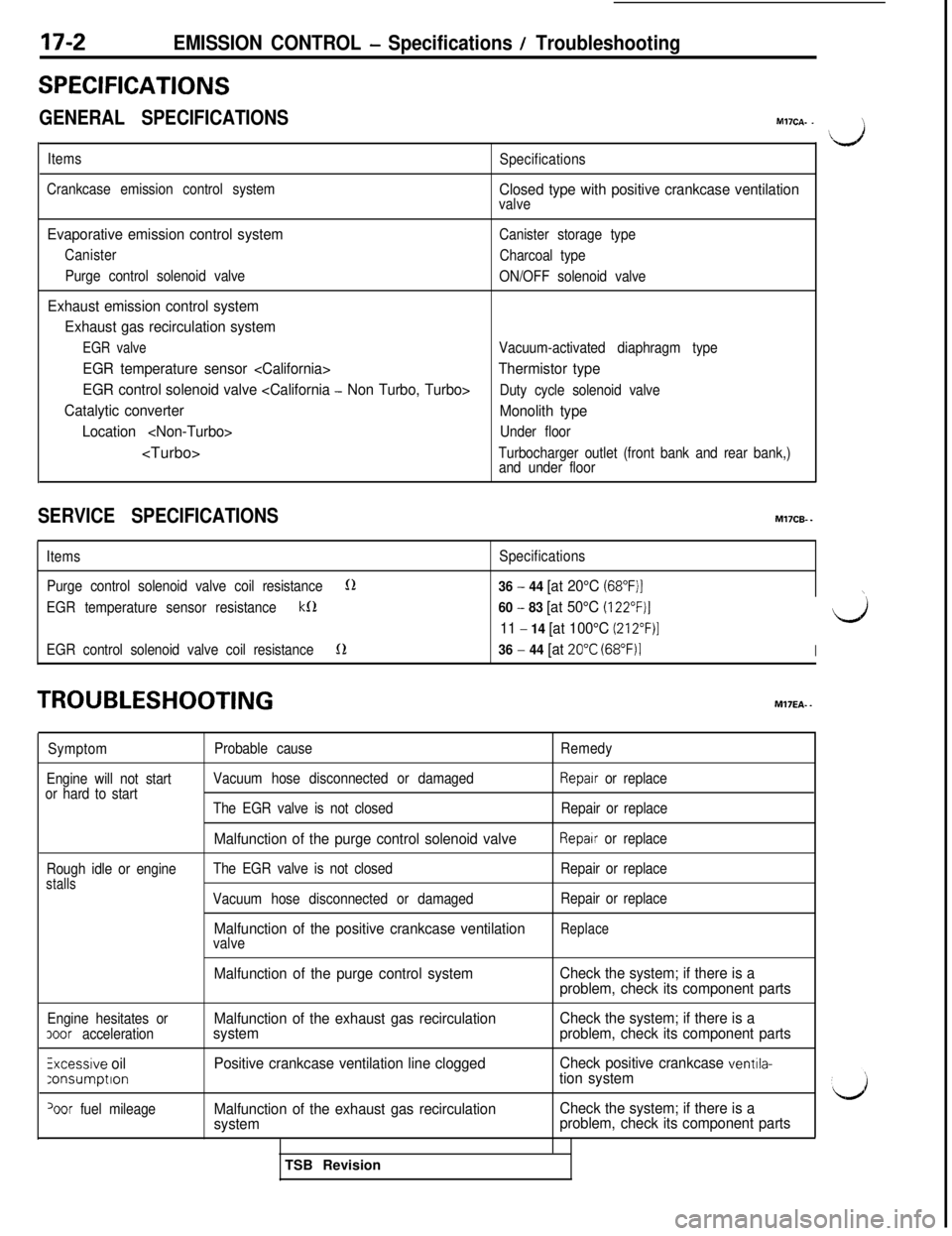

17-2EMISSION CONTROL - Specifications / Troubleshooting

SPECIFICATIONS

GENERAL SPECIFICATIONSMl’ICA- -\

Items

Crankcase emission control systemSpecifications

Closed type with positive crankcase ventilationvalve

Evaporative emission control systemCanister storage type

Canister

Charcoal type

Purge control solenoid valve

ON/OFF solenoid valve

Exhaust emission control system

Exhaust gas recirculation system

EGR valveVacuum-activated diaphragm type

EGR temperature sensor

EGR control solenoid valve

Catalytic converter

Monolith type

Location

Under floor

Turbocharger outlet (front bank and rear bank,)

and under floor

SERVICE SPECIFICATIONSMl7CB-.

ItemsSpecifications

Purge control solenoid valve coil resistance

036 - 44 [at 20°C (68”F)I\

EGR temperature sensor resistancekfl60 - 83 [at 50°C (I 22”F)]

11 - 14 [at 100°C (212”F)l

EGR control solenoid valve coil resistance1236 - 44 [at 20°C (68”F)lI

TROUBLESHOOTING

Symptom

Engine will not start

or hard to start

Rough idle or engine

stalls

Probable cause

Vacuum hose disconnected or damaged

The EGR valve is not closed

Malfunction of the purge control solenoid valve

The EGR valve is not closed

Vacuum hose disconnected or damaged

Malfunction of the positive crankcase ventilationvalveRemedy

Repair or replace

Repair or replace

Repair or replace

Repair or replace

Repair or replace

Replace

Malfunction of the purge control systemCheck the system; if there is a

problem, check its component parts

Engine hesitates or3oor acceleration

Zxcessive oil:onsumptron

Malfunction of the exhaust gas recirculation

system

Positive crankcase ventilation line cloggedCheck the system; if there is a

problem, check its component parts

Check positive crankcase

ventila-tion system

Ioor fuel mileageMalfunction of the exhaust gas recirculation

systemTSB RevisionCheck the system; if there is a

problem, check its component parts

d