steering MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 76 of 1146

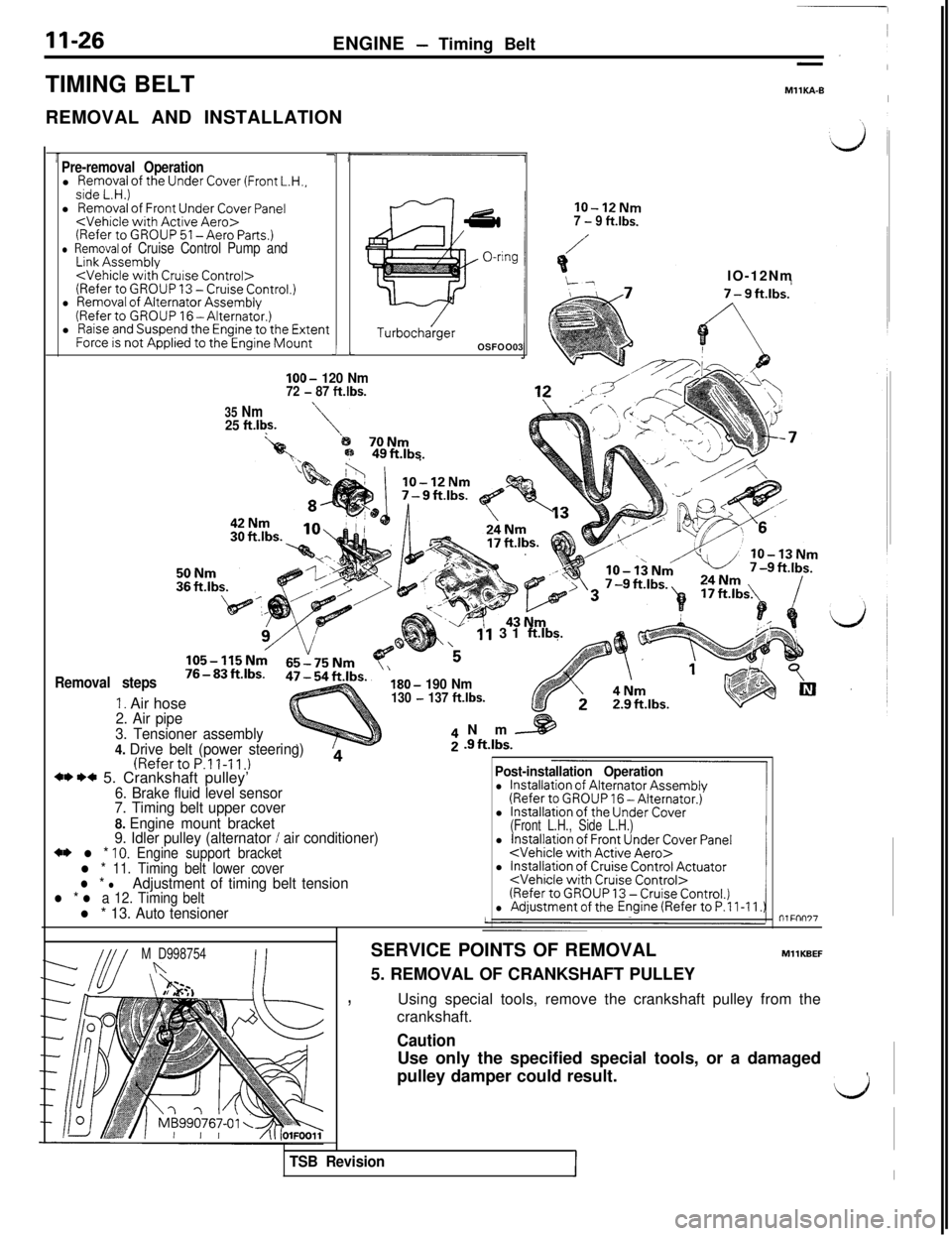

11-26ENGINE - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

MllKA-BI

Pre-removal Operationl Removal of the Under Cover (Front L.H.,side L.H.)l Removal of Front Under Cover Panel

l Raise and Suspend the Engine to the ExtentForce is not Applied to the Engine Mounti LIOO-

120 Nm72 - 87 ft.lbs.

35 Nm25 ft.l$.

TurbochargerOSFOO03

lo-12Nm7 - 9 ft.lbs.

Removal steps

1. Air hose

11 31 ftlbs.

‘5IO-12Nm

B;p 49ftJbs.

\

180- 190 Nm130 - 137 ft.lbs.

2. Air pipe

3. Tensioner assembly

4. Drive belt (power steering)

(RefertoP.ll-11.)4** I)* 5. Crankshaft pulley’6. Brake fluid level sensor

7. Timing belt upper cover

8. Engine mount bracket

9. Idler pulley (alternator

/ air conditioner)+* l * 10. Engine support bracketl * 11. Timing belt lower coverl * lAdjustment of timing belt tensionl * l a 12. Timing beltl * 13. Auto tensionerNm

[email protected].

Post-installation Operation

l Installation of Alternator Assembly(Refer to GROUP 16 -Alternator.)

l Installation of the Under Cover(Front L.H., Side L.H.)l Installation of Front Under Cover Panel

l Installation of Cruise Control Actuator

M D998754nSERVICE POINTS OF REMOVAL

5. REMOVAL OF CRANKSHAFT PULLEYMllKBEF

,Using special tools, remove the crankshaft pulley from the

crankshaft.

TSB RevisionII

CautionUse only the specified special tools, or a damaged

pulley damper could result.

,

LJ

Page 108 of 1146

13-2

Boost Meter

Components Location........................................................36

Crank Angle Sensor

............................................................72Detonation Sensor................................................................84EGR Control Solenoid Valve

EGR Temperature Sensor

Fuel Pump Operation Check................................................137Fuel Pump Relay No. 2........................................................53Fuel Pump Resistor............................................................53

Idle Position Switch............................................................68Idle Speed Control Servo (Stepper Motor Type)............1 IOIgnition Coil and Power Transistor....................................115Ignition Switch-ST and Inhibitor Switch ................76Ignition Switch-ST

Injectors

94

Oxygen Sensor

Power Steering Oil Pressure Switch................................80Power Supply and Ignition Switch-IG................................41

Purge Control Solenord Valve............................................1 19Release of Residual Pressure from High

Pressure Fuel Hose............................................................137Throttle Position Sensor....................................................65Top Dead Center Sensor....................................................70Variable Induction Control Servo (DC Motor)

SERVICE ADJUSTMENT PROCEDURES............................31

Adjustment of Fixed SAS....................................................35Adjustment of Idle Position Switch and

Throttle Position Sensor (TPS)............................................33Basic Idle Speed Adjustment............................................31Throttle Body (Throttle Valve Area) Cleaning....................33

SPECIAL TOOLS........................................................................8

SPECIFICATIONS

....................................................................6

General Specifications........................................................6Sealant....................................................................................7Service Specifications........................................................7

THROlTLE BODY....................................................................143

TROUBLESHOOTING............................................................9

Check Chart Classified by Problem Symptoms................16Circuit Diagram....................................................................18Engine Warning Light (Malfunction Indicator Light)........11Explanation and Cautions about Harness Check............10Explanation of Troubleshooting Procedures....................9Fuel Tank and Fuel Line........................................................30

Problem Symptoms Table (For Your Information)............17Self-diagnosis........................................................................12)

I

Page 123 of 1146

FUEL SYSTEM - Troubleshootina13-17

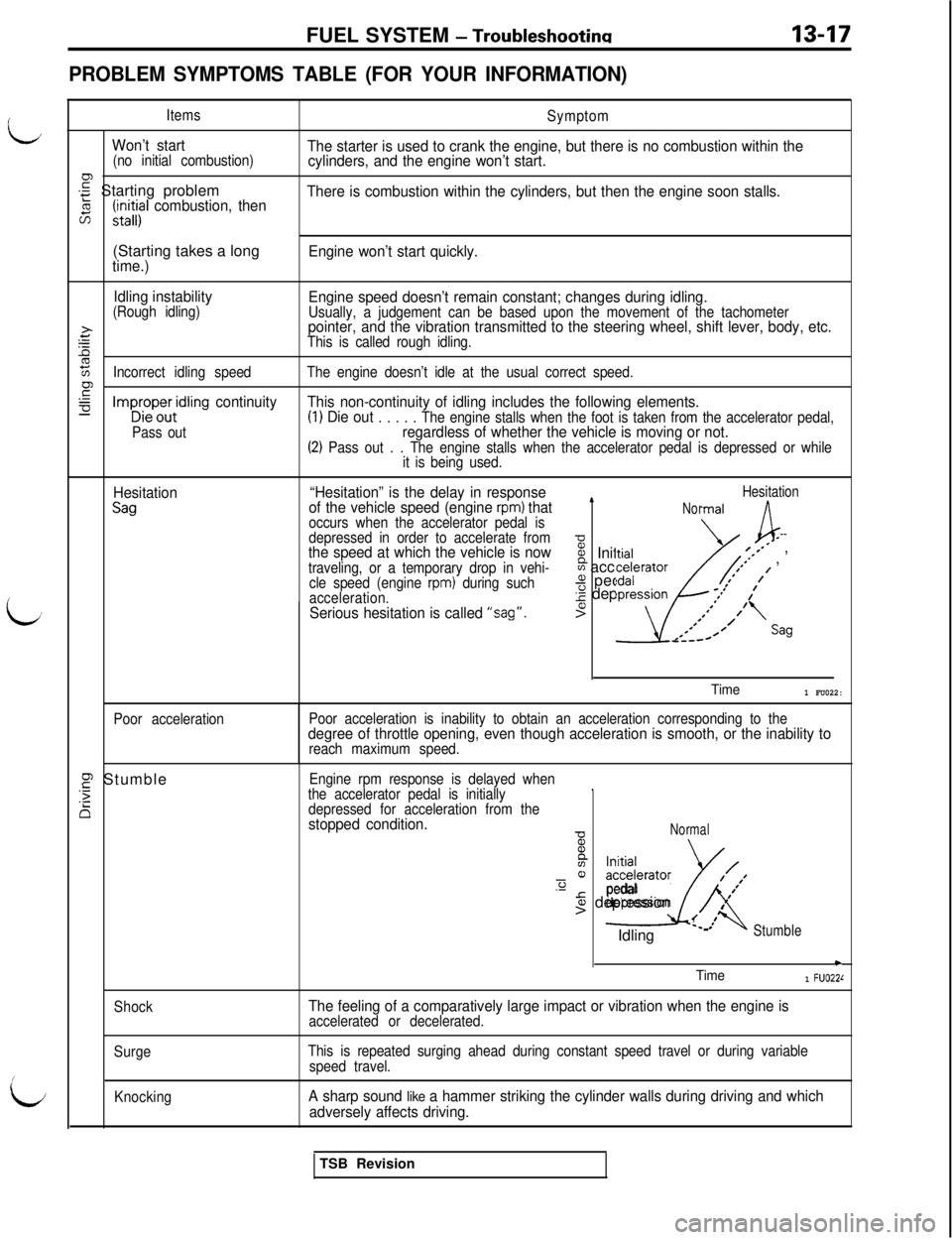

PROBLEM SYMPTOMS TABLE (FOR YOUR INFORMATION)

I;

L

/

L/

Items

Won’t start(no initial combustion)-g Starting problem

2(i;il;i combustion, then

Symptom

The starter is used to crank the engine, but there is no combustion within the

cylinders, and the engine won’t start.

There is combustion within the cylinders, but then the engine soon stalls.(Starting takes a long

time.)Engine won’t start quickly.

Idling instability

(Rough idling)Engine speed doesn’t remain constant; changes during idling.Usually, a judgement can be based upon the movement of the tachometer

>.rpointer, and the vibration transmitted to the steering wheel, shift lever, body, etc.

EThis is called rough idling.

s0

Incorrect idling speedThe engine doesn’t idle at the usual correct speed.

F.-=e-ImpDr;p;ertidling continuityThis non-continuity of idling includes the following elements.(1) Die outPass out. . . . . The engine stalls when the foot is taken from the accelerator pedal,regardless of whether the vehicle is moving or not.(2) Pass out . . The engine stalls when the accelerator pedal is depressed or while

it is being used.

Hesitation

Sag

“Hesitation” is the delay in responseHesitation

of the vehicle speed (engine rpm) thatLNormaloccurs when the accelerator pedal is

depressed in order to accelerate from---

the speed at which the vehicle is nowx\a,r- ,

traveling, or a temporary drop in vehi-g Initialv) accelerator**’ ,8’ /cle speed (engine rpm) during such+ pedal/,’ /

’

acceleration.2 depression

Serious hesitation is called “sag”.2

1“*’.’

/’ ,’I&L-e**’Ii Sag

Poor acceleration

Time1 FU022:

Poor acceleration is inability to obtain an acceleration corresponding to thedegree of throttle opening, even though acceleration is smooth, or the inability toreach maximum speed.

0, Stumble.F

‘iIn

Engine rpm response is delayed when

the accelerator pedal is initially.

depressed for acceleration from thestopped condition.

$Normal

x

:Initial

3acceleratorI//

c

-7

pedal2 depression,#’,

4,/Idling *--’Stumble

Shock

cTime1 FUO22L

The feeling of a comparatively large impact or vibration when the engine isaccelerated or decelerated.

SurgeThis is repeated surging ahead during constant speed travel or during variable

speed travel.

Knocking

A sharp sound like a hammer striking the cylinder walls during driving and which

adversely affects driving.TSB Revision

Page 135 of 1146

![MITSUBISHI 3000GT 1991 Owners Manual FUEL SYSTEM - Troubleshooting13-29

ENGINE

CONTROL

RELAYF

1 7=2

c----IIIIIIII2,(2Io FUEL

) SE

PRESSURE

SOLENOID

VALVE

IfII

I

I

I

I

J

]i#&B,D i

A-20

1

WASTE

GATE

SOLENOIDVALVE

/

7 EGRi ~XE~~OID

I

; A-21 MITSUBISHI 3000GT 1991 Owners Manual FUEL SYSTEM - Troubleshooting13-29

ENGINE

CONTROL

RELAYF

1 7=2

c----IIIIIIII2,(2Io FUEL

) SE

PRESSURE

SOLENOID

VALVE

IfII

I

I

I

I

J

]i#&B,D i

A-20

1

WASTE

GATE

SOLENOIDVALVE

/

7 EGRi ~XE~~OID

I

; A-21](/img/19/57085/w960_57085-134.png)

FUEL SYSTEM - Troubleshooting13-29

ENGINE

CONTROL

RELAYF

1 7=2

c----IIIIIIII2,(2Io FUEL

) SE

PRESSURE

SOLENOID

VALVE

IfII

I

I

I

I

J

]i#&B,D i

A-20

1

WASTE

GATE

SOLENOIDVALVE

/

7 EGRi ~XE~~OID

I

; A-21

L

1 A-70

j A-72

f ENGINEj jXICI$ROL

I

-------13s

3.------

s

10

/\1

>

J

c

”-_-

1 A-18

3P

~;~E&DIAGNOSIS #Fjhl;;ON

CONNECTORADJUSTMENT

EFfq&@gCONNECTOR

d

Efpggggg]

I B-OS

ENGINE

COOLANT

Q&;EEATURE ,,'I/\FOR AIR)/@ICONDITIONEROFF --xOlJ

POWER STEERING;tK;BESSURETSB Revision

Page 137 of 1146

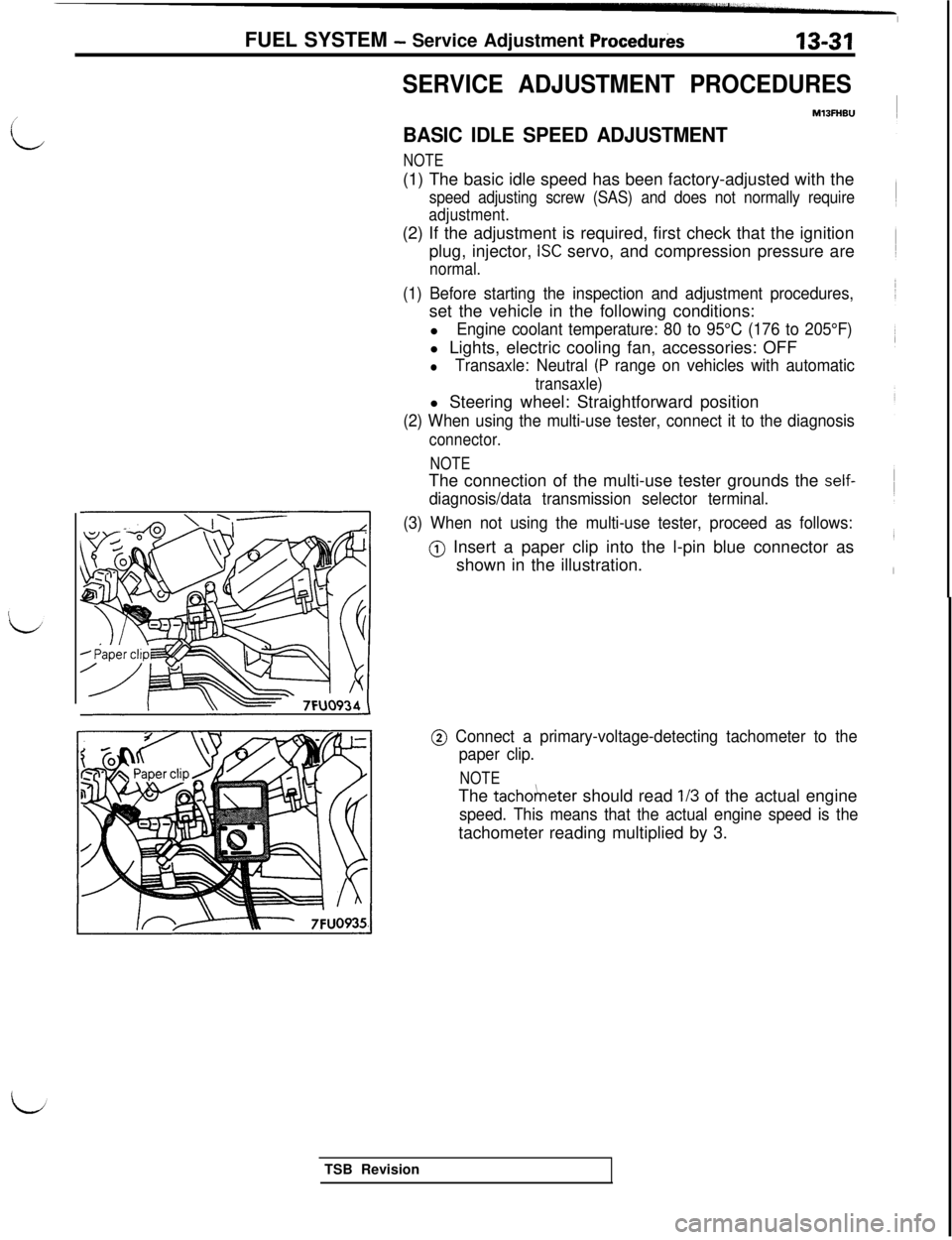

SERVICE ADJUSTMENT PROCEDURES

MlBFHSU

BASIC IDLE SPEED ADJUSTMENT

NOTE(1) The basic idle speed has been factory-adjusted with the

speed adjusting screw (SAS) and does not normally require

adjustment.(2) If the adjustment is required, first check that the ignition

plug, injector,

ISC servo, and compression pressure are

normal.

(1) Before starting the inspection and adjustment procedures,set the vehicle in the following conditions:

l

Engine coolant temperature: 80 to 95°C (176 to 205°F)l Lights, electric cooling fan, accessories: OFF

lTransaxle: Neutral (P range on vehicles with automatic

transaxle)l Steering wheel: Straightforward position

(2) When using the multi-use tester, connect it to the diagnosis

connector.

NOTEThe connection of the multi-use tester grounds the

self-

diagnosis/data transmission selector terminal.

(3) When not using the multi-use tester, proceed as follows:

@) Insert a paper clip into the l-pin blue connector as

shown in the illustration. FUEL SYSTEM

- Service Adjustment Procedurks13-31

i

@ Connect a primary-voltage-detecting tachometer to the

paper clip.

NOTEThe

tacho/neter should read l/3 of the actual engine

speed. This means that the actual engine speed is thetachometer reading multiplied by 3.

TSB Revision

Page 161 of 1146

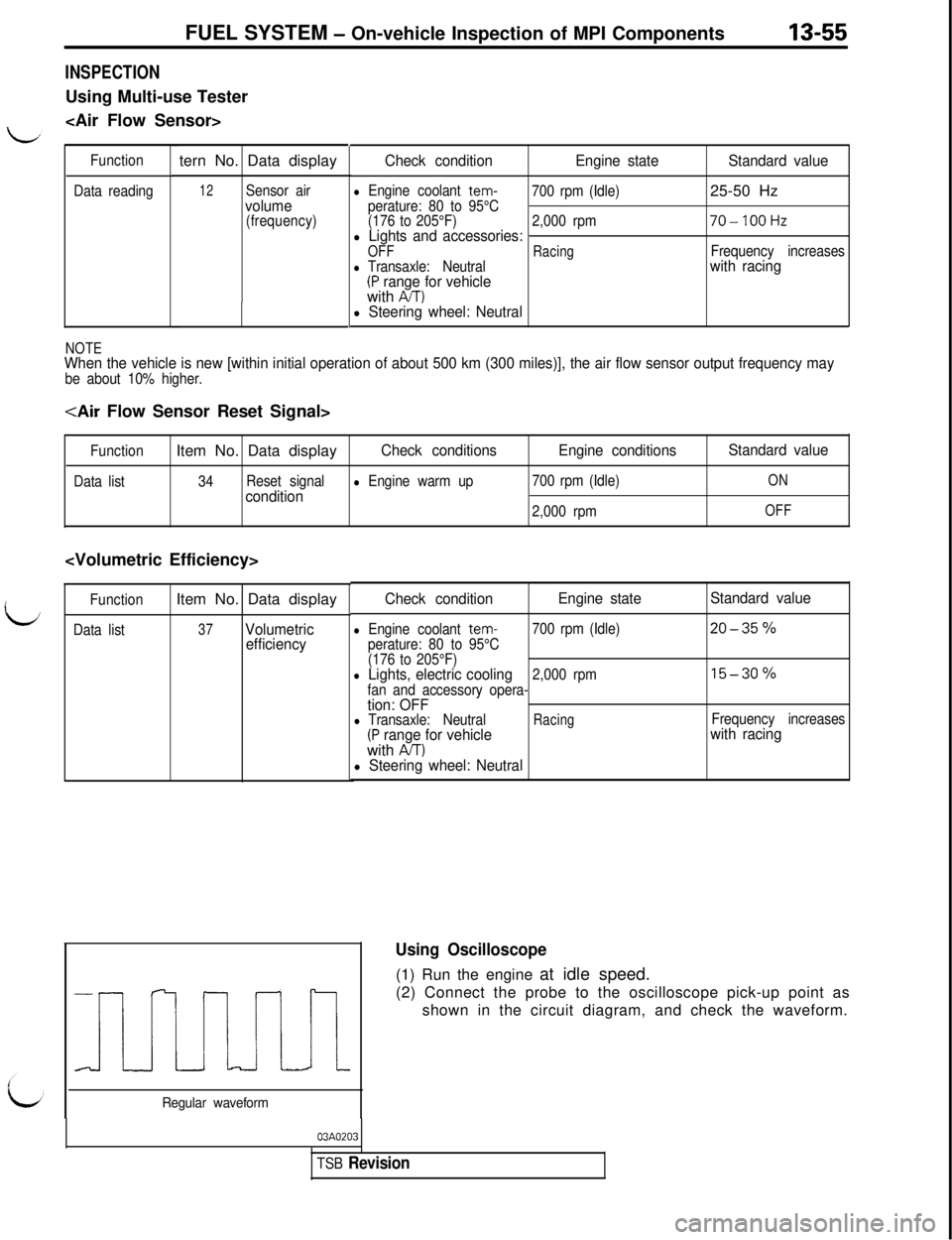

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-55

INSPECTIONUsing Multi-use Tester

Function

Data readingtern No. Data display

12Sensor airvolume(frequency)

Check conditionEngine stateStandard value

l Engine coolant tem-

700 rpm (Idle)25-50 Hzperature: 80 to 95°C

(176 to 205°F)2,000 rpm70-IOOHzl Lights and accessories:OFFRacingFrequency increasesl Transaxle: Neutralwith racing(P range for vehiclewith AIT)l Steering wheel: Neutral

NOTEWhen the vehicle is new [within initial operation of about 500 km (300 miles)], the air flow sensor output frequency maybe about 10% higher.

Function

Data listItem No. Data displayCheck conditionsEngine conditionsStandard value

34Reset signall Engine warm up700 rpm (Idle)ON

condition2,000 rpmOFF

L;

FunctionItem No. Data display

Data list37Volumetric

efficiencyCheck conditionEngine stateStandard valuel Engine coolant tem-700 rpm (Idle)20-35%

perature: 80 to 95°C

(176 to 205°F)

l Lights, electric cooling2,000 rpm15-30%

fan and accessory opera-tion: OFFl Transaxle: NeutralRacingFrequency increases

(P range for vehiclewith racingwith &T)

l Steering wheel: Neutral

Using Oscilloscope(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Regular waveform

03A0203

TSB Revision

Page 186 of 1146

13-80FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

POWER STEERING OIL PRESSURE SWITCHMlOYQAA

B

$-

Engine control unit

'107

@ Harness side

connector

ml-

Power steering oil

Pressure switch

7FUO536700-2.000 1.500-2.000(100-284) (213-284)Pressure [kPa (psi)]

0, l.oIu

OPERATIONl

The power steering oil pressure switch converts presence/absence of power steering load into low/high

voltage and inputs it to the engine control unit, which then controls the idle speed control servo based on

this signal.l The battery voltage in the engine control unit is applied through a resistor to the power steering oil

pressure switch. Steering operation causes the power steering oil pressure to increase, turning the

switch on. As a result, continuity is produced between the battery voltage applied and ground. This

causes the power steering oil pressure terminal voltage to go from high to low.

TSB Revision

Page 187 of 1146

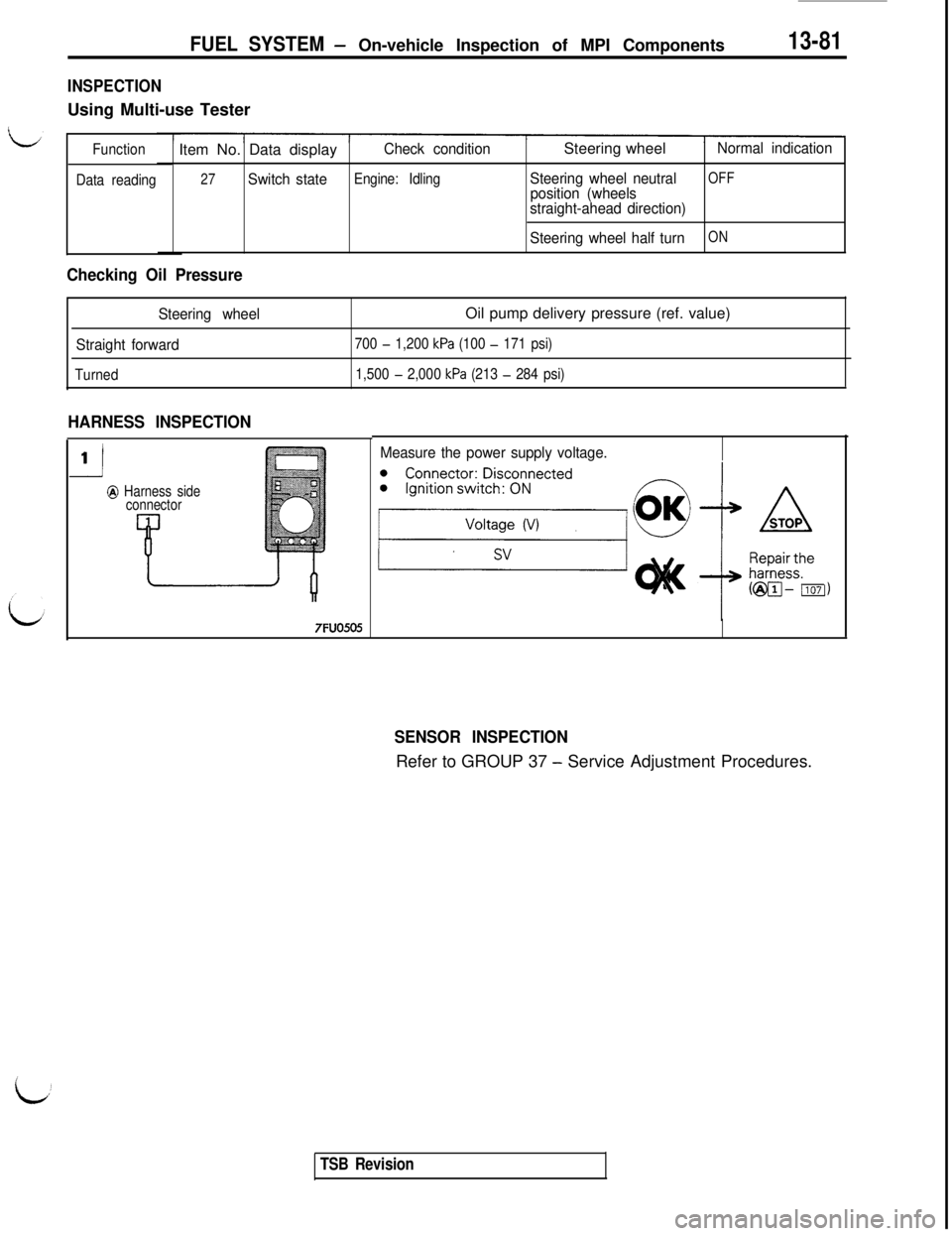

FUEL SYSTEM- On-vehicle Inspection of MPI Components13-81

INSPECTIONUsing Multi-use Tester

Function

Data readingItem No. Data displayCheck conditionSteering wheelNormal indication

27Switch stateEngine: IdlingSteering wheel neutralOFFposition (wheels

straight-ahead direction)

Steering wheel half turn

ON

Checking Oil Pressure

Steering wheelOil pump delivery pressure (ref. value)

Straight forward700 - 1,200 kPa (100 - 171 psi)

Turned1,500

- 2,000 kPa (213 - 284 psi)

HARNESS INSPECTION

i1

@ Harness side

connector

Measure the power supply voltage.

SENSOR INSPECTIONRefer to GROUP 37

- Service Adjustment Procedures.

TSB Revision

Page 208 of 1146

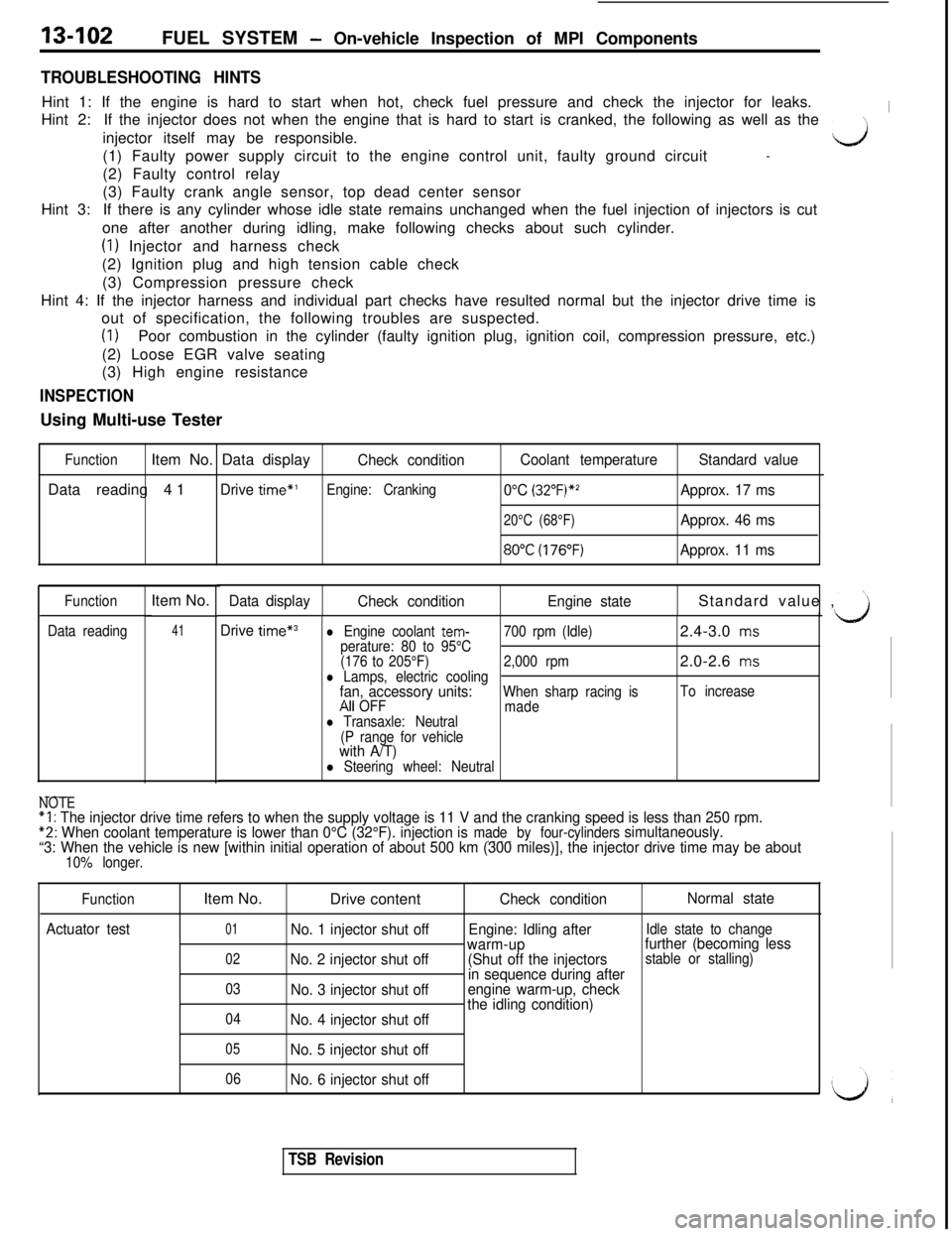

13-102FUEL SYSTEM - On-vehicle Inspection of MPI Components

TROUBLESHOOTING HINTSHint 1: If the engine is hard to start when hot, check fuel pressure and check the injector for leaks.

Hint 2:If the injector does not when the engine that is hard to start is cranked, the following as well as the

Iinjector itself may be responsible.

(1) Faulty power supply circuit to the engine control unit, faulty ground circuit

\-J

-(2) Faulty control relay

Hint 3:(3) Faulty crank angle sensor, top dead center sensor

If there is any cylinder whose idle state remains unchanged when the fuel injection of injectors is cut

one after another during idling, make following checks about such cylinder.

(1) Injector and harness check

(2) Ignition plug and high tension cable check

(3) Compression pressure check

Hint 4: If the injector harness and individual part checks have resulted normal but the injector drive time is

out of specification, the following troubles are suspected.

(1)Poor combustion in the cylinder (faulty ignition plug, ignition coil, compression pressure, etc.)

(2) Loose EGR valve seating

(3) High engine resistance

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionCoolant temperatureStandard valueData reading 41

Drive time”’Engine: Cranking0°C (32”F)*zApprox. 17 ms

20°C (68°F)Approx. 46 ms

8O"C(176"F)Approx. 11 ms

Function

Data readingItem No.Data display

41Drive time*3l Engine coolant tem-perature: 80 to 95°C700 rpm (Idle)2.4-3.0 ms

(176 to 205°F)2,000 rpm2.0-2.6

msl Lamps, electric coolingfan, accessory units:When sharp racing isTo increaseAll OFF

madel Transaxle: Neutral

(P range for vehicle

with A/T)l Steering wheel: Neutral

Check conditionEngine stateStandard value ,

.---NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.*2: When coolant temperature is lower than 0°C (32°F). injection ismade by four-cylinders.---simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive content

Check conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to change

02No. 2 injector shut offwarm-up

(Shut off the injectorsfurther (becoming less

in sequence during afterstable or stalling)

03

No. 3 injector shut offengine warm-up, check

04No. 4 injector shut offthe idling condition)

05No. 5 injector shut off

06No. 6 injector shut off

TSB Revision

Page 212 of 1146

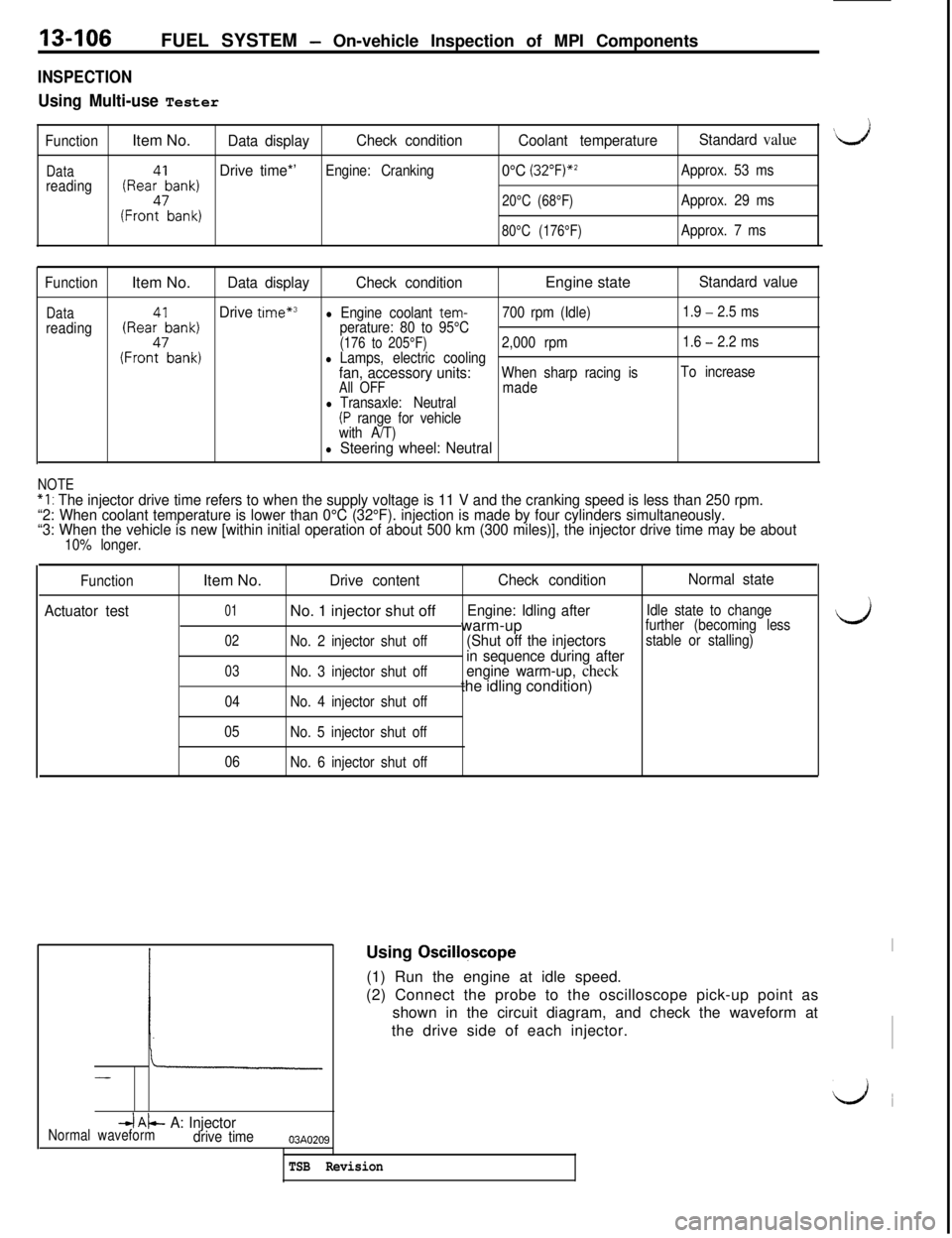

13-106FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

FunctionItem No.Data displayCheck conditionCoolant temperatureStandard value‘L,,,J

DataDrive time*’0°C (32’F)*’readingiRea:bankiEngine: CrankingApprox. 53 ms

(FronT7bank)20°C (68°F)

Approx. 29 ms

80°C (176°F)Approx. 7 ms

FunctionItem No.

Data displayCheck conditionEngine stateStandard value

Datareading(Reaebank)Drive time*3l Engine coolant tem-700 rpm (Idle)1.9 - 2.5 ms

perature: 80 to 95°C

(Front7banki(176 to 205°F)2,000 rpm1.6 - 2.2 ms

l Lamps, electric coolingfan, accessory units:To increase

All OFFWhen sharp racing is

made

l Transaxle: Neutral(P range for vehicle

with A/T)

l Steering wheel: Neutral

NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

“2: When coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive contentCheck conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to changewarm-upfurther (becoming less

02No. 2 injector shut off(Shut off the injectorsstable or stalling)

03in sequence during afterNo. 3 injector shut offengine warm-up, checkthe idling condition)

04No. 4 injector shut off

05

No. 5 injector shut off

06

No. 6 injector shut off

\,iUsing

OscillqscopeI(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.~

-

LJ

4 AL A: InjectorNormal waveformdrive time03A0209

TSB Revision