wheel alignment MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 844 of 1146

37A-16STEERING - Steering Wheel and Shaft13E;O613FOO5

inyl tape13NOOl;

INSPECTIONM37GGAKl Check the steering shaft for play and round movement.

l Check the joints for play, damage, or rough movement.

l Check the joint bearing for wear and damage.

l Check the dust shield for damage.

SERVICE POINTS OF REASSEMBLYM37GHBE7. INSTALLATION OF STEERING LOCK CYLINDER

/ 6.

STEERING LOCK BRACKET / 5. SPECIAL BOLT

(1) When installing the steering lock cylinder and steering

lock bracket to the column tube, temporarily install the

steering lock in alignment with the column boss.

(2) After checking that the lock works properly, tighten the

special bolts until the head twists off.

CautionThe steering lock bracket and bolts must be re-

placed with new ones when the steering lock

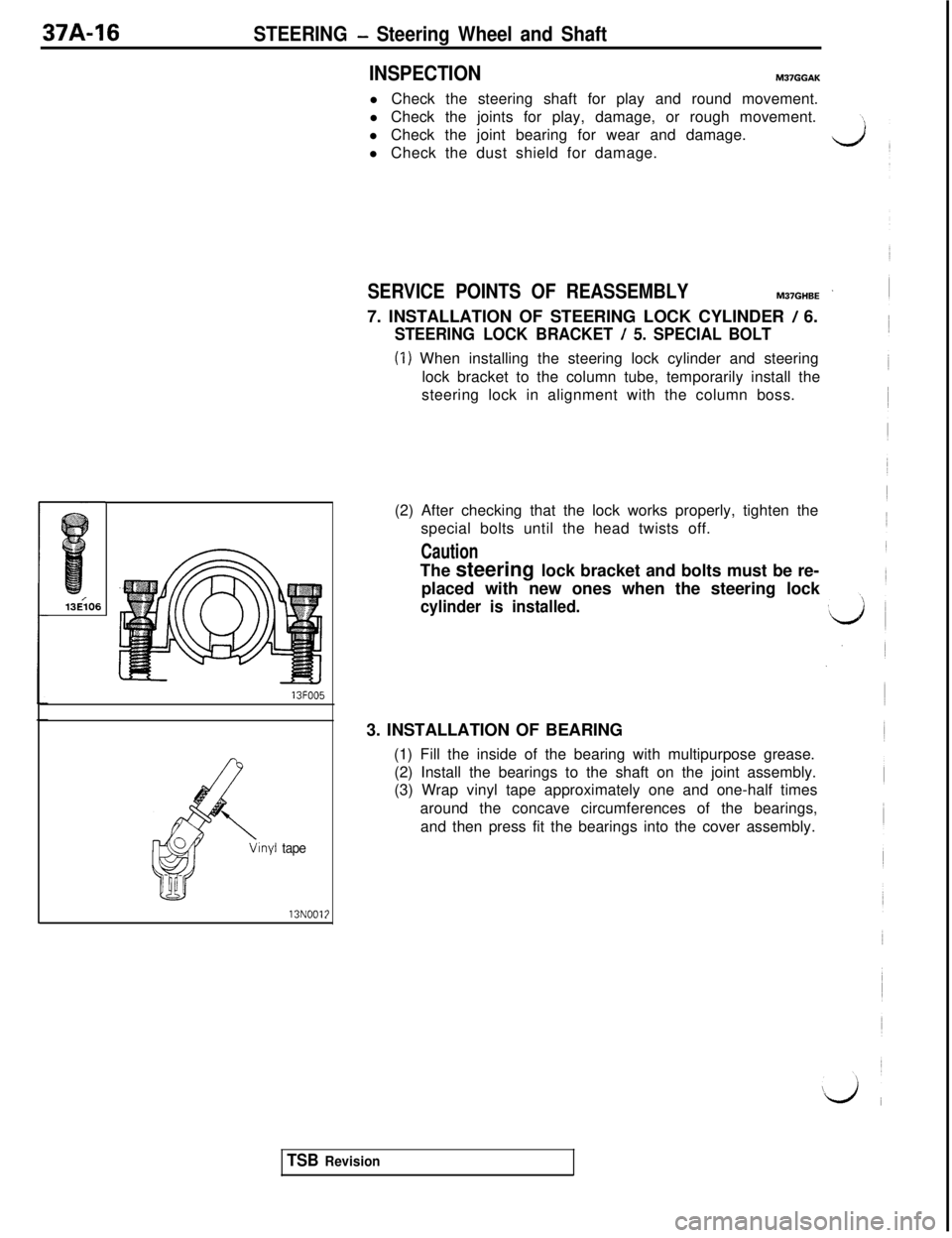

cylinder is installed.3. INSTALLATION OF BEARING

(1) Fill the inside of the bearing with multipurpose grease.

(2) Install the bearings to the shaft on the joint assembly.

(3) Wrap vinyl tape approximately one and one-half times

around the concave circumferences of the bearings,

and then press fit the bearings into the cover assembly.

TSB Revision

Page 845 of 1146

STEERING- Power Steering Gear Box

POWER STEERING GEAR BOX

/REMOVAL AND INSTALLATION37A-17

M37PA- -

i

i/

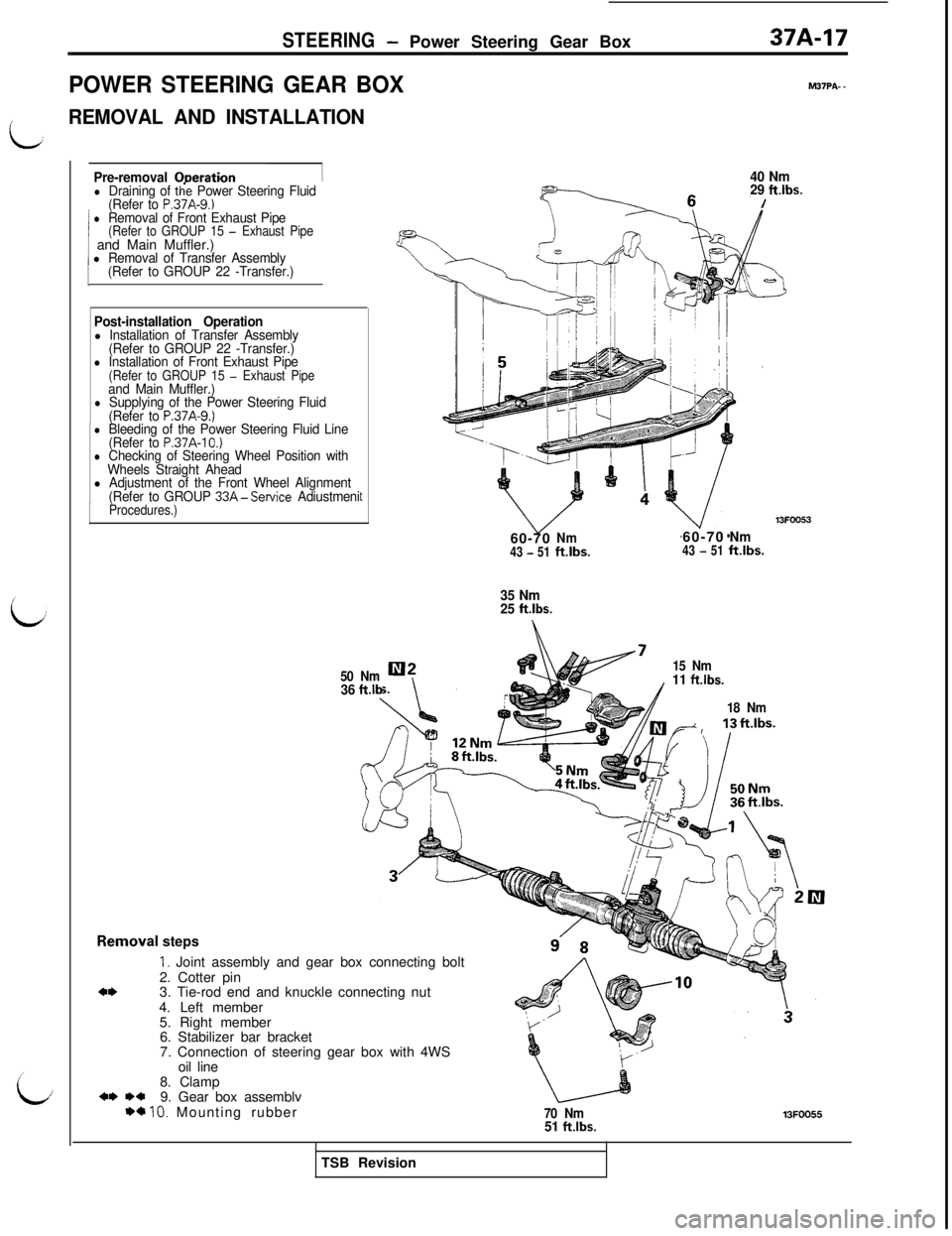

Pre-removal ODerationl Draining of the Power Steering Fluid

(Refer to P.37A-9.)l Removal of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipe1 and Main Muffler.)1l Removal of Transfer Assembly

(Refer to GROUP 22 -Transfer.)

Post-installation Operationl Installation of Transfer Assembly

(Refer to GROUP 22 -Transfer.)

l Installation of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipeand Main Muffler.)l Supplying of the Power Steering Fluid

(Refer to P.37A-9.)l Bleeding of the Power Steering Fluid Line

(Refer to P.37A-IO.)l Checking of Steering Wheel Position with

Wheels Straight Ahead

l Adjustment of the Front Wheel Alignment

(Refer to GROUP 33A-Service AdiustmeniProcedures.)Removt

50 Nm

c40 Nm

29 ftlbs.

/60-70

Nm43 - 51ft.lbs.60-70Nm43 - 51ft.lbs.

36

ft.lb

35 Nm

25 ft.lbs.

15 Nm

11 ftlbs.

18 Nm

lal steps

1. Joint assembly and gear box connecting bolt

2. Cotter pin

3. Tie-rod end and knuckle connecting nut

4. Left member

5. Right member

6. Stabilizer bar bracket

7. Connection of steering gear box with 4WS

oil line

8. Clamp

9. Gear box assemblv

*a 10. Mounting rubber70 Nm51 ftlbs.13FOOE.5TSB Revision

Page 863 of 1146

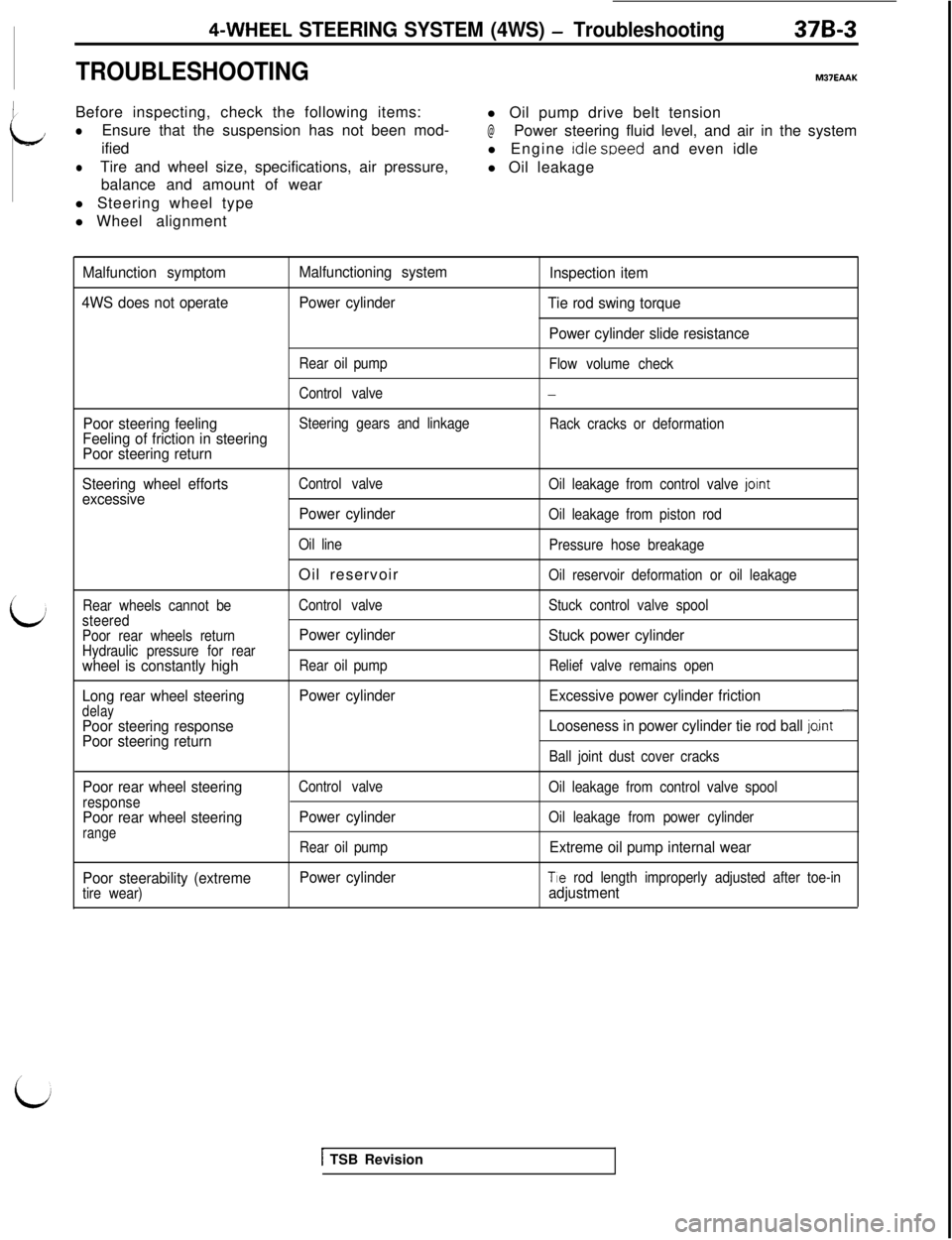

4-WHEEL STEERING SYSTEM (4WS) - Troubleshooting

TROUBLESHOOTING

37B-3

M37EMKBefore inspecting, check the following items:

l Oil pump drive belt tension

lEnsure that the suspension has not been mod-@Power steering fluid level, and air in the system

ified

l Engine

Idle soeed and even idle

lTire and wheel size, specifications, air pressure,

l Oil leakage

balance and amount of wear

l Steering wheel type

l Wheel alignment

Malfunction symptom

4WS does not operateMalfunctioning system

Power cylinderInspection item

Tie rod swing torque

Power cylinder slide resistance

Rear oil pump

Flow volume check

Control valve

-

Poor steering feelingSteering gears and linkage

Rack cracks or deformationFeeling of friction in steering

Poor steering return

Steering wheel efforts

excessive

Control valve

Oil leakage from control valve jornt

Rear wheels cannot be

steered

Poor rear wheels return

Hydraulic pressure for rear

wheel is constantly high

Long rear wheel steering

delayPoor steering response

Poor steering returnPower cylinder

Oil lineOil reservoir

Control valve

Power cylinder

Rear oil pump

Power cylinder

Oil leakage from piston rod

Pressure hose breakage

Oil reservoir deformation or oil leakage

Stuck control valve spool

Stuck power cylinder

Relief valve remains open

Excessive power cylinder friction-

Looseness in power cylinder tie rod ball jo.int

Ball joint dust cover cracks

Poor rear wheel steeringresponsePoor rear wheel steeringrange

Poor steerability (extremetire wear)Control valve

Power cylinder

Rear oil pump

Power cylinder

Oil leakage from control valve spool

Oil leakage from power cylinder

Extreme oil pump internal wear

Tie rod length improperly adjusted after toe-inadjustment

[ TSB Revision

Page 866 of 1146

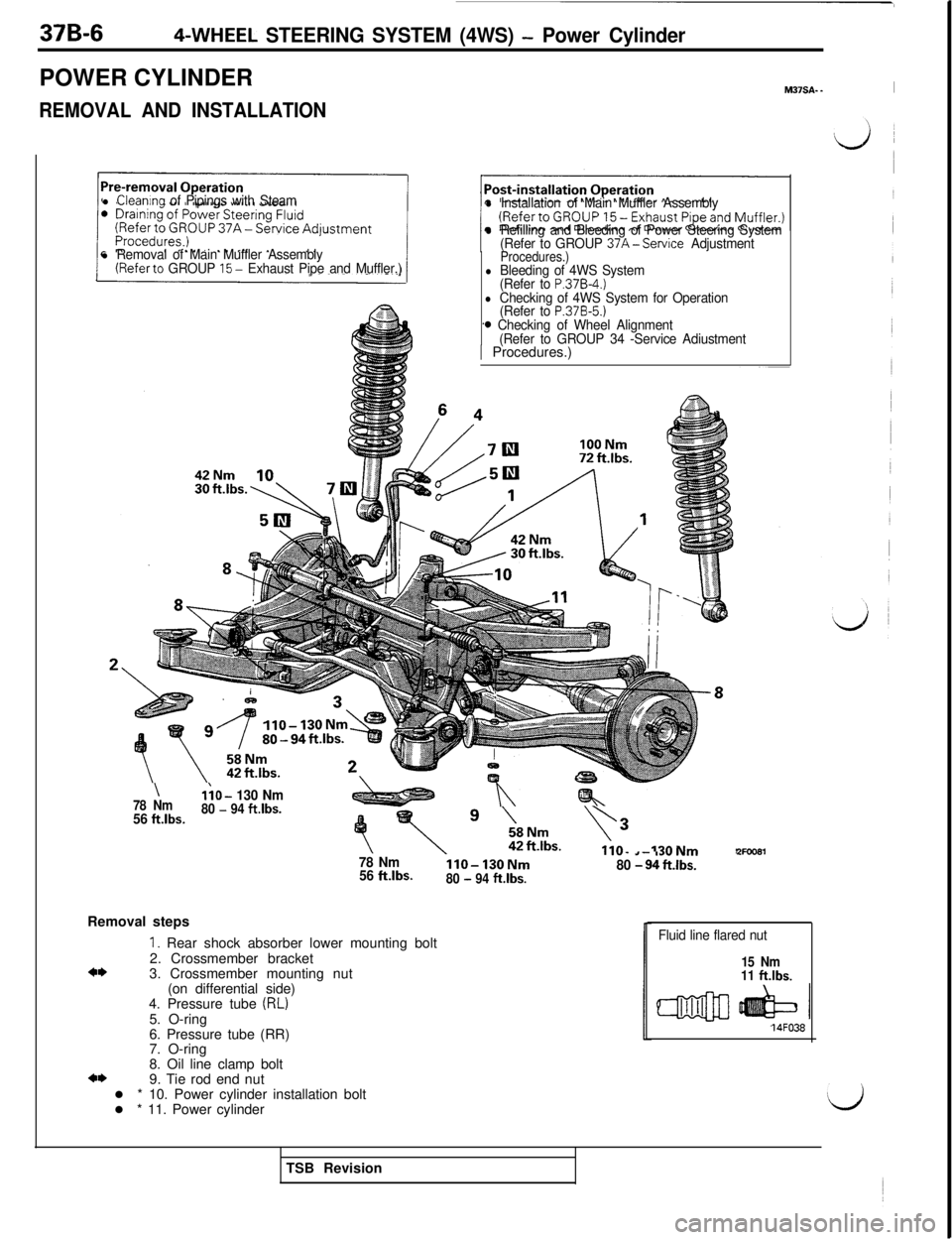

37B-64-WHEEL STEERING SYSTEM (4WS) - Power CylinderPOWER CYLINDER

REMOVAL AND INSTALLATION

M37S&~I

l Cleaning of Pipings with Steam

l Removal of Main Muffler Assembly(Referto GROUP 15- Exhaust Pipe and Muffler.)

Ilo-130Nm

l Installation of Main Muffler Assembly

l Refilling and Bleeding of Power Steering System

(Refer to GROUP 37A-Service Adjustment

\78 Nml;O- 130 Nm

56

ft.lbs.80 - 94 ft.lbs.

Procedures.)l Bleeding of 4WS System

(Refer to P.37B-4.)l Checking of 4WS System for Operation

(Refer to P.37B-5.)‘0 Checking of Wheel Alignment

(Refer to GROUP 34 -Service Adiustment

1 Procedures.)

f @, ’ i%,s. yf ,30Nm,

78 NmIIO-130Nm80 -94 ft.lbs.56 ft.lbs.

80 - 94 ft.lbs.Removal steps

1. Rear shock absorber lower mounting bolt

2. Crossmember bracket

a*3. Crossmember mounting nut

(on differential side)

4. Pressure tube

(RL)5. O-ring

6. Pressure tube (RR)

7. O-ring

8. Oil line clamp bolt

4*9. Tie rod end nut

l * 10. Power cylinder installation bolt

l * 11. Power cylinder

Fluid line flared nut

15 Nm

11 ft.lbs.14FO38

‘dTSB Revision

Page 1065 of 1146

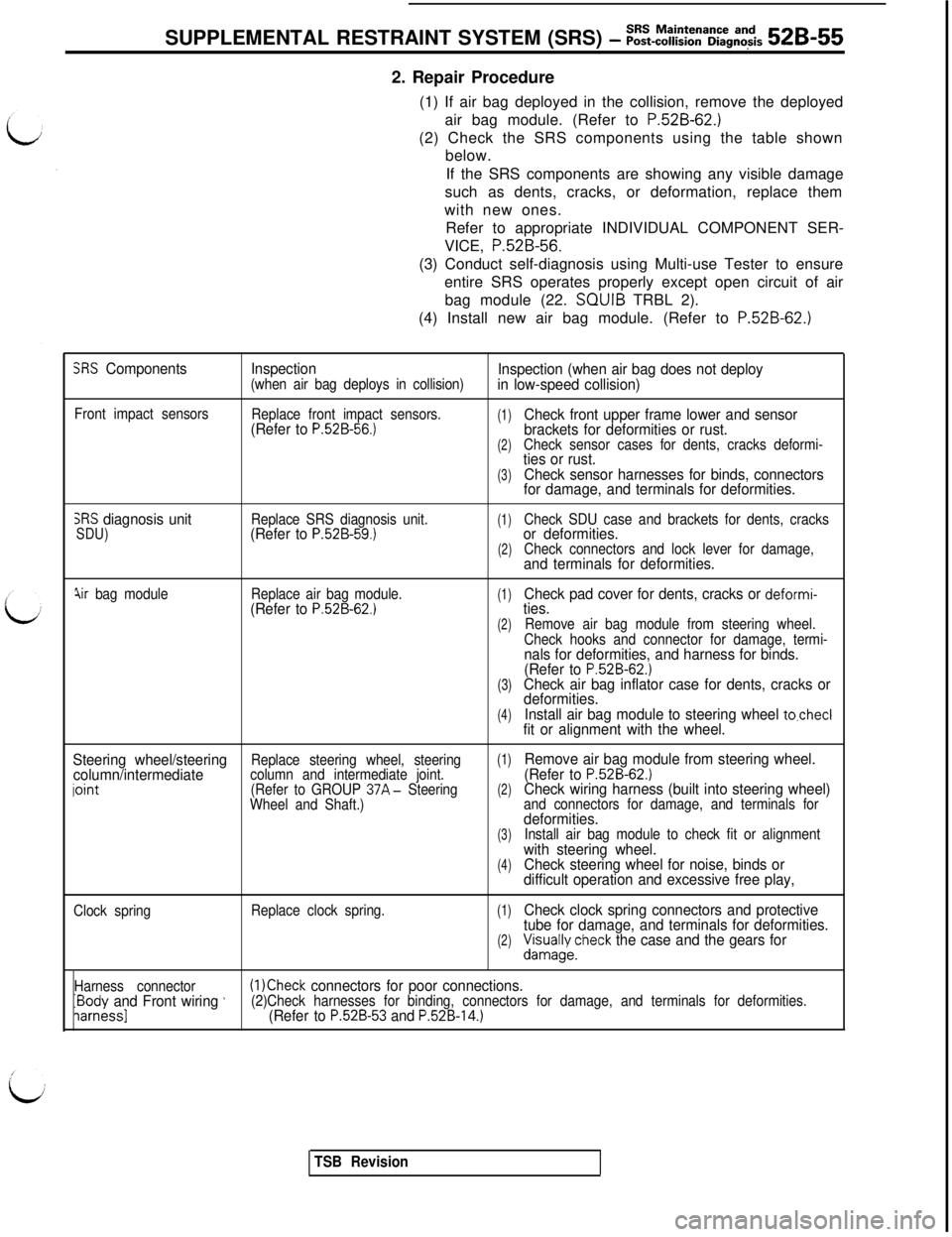

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - ~~~-~~~~~a~~g~~~s 52B-552. Repair Procedure

(1) If air bag deployed in the collision, remove the deployed

air bag module. (Refer to

P.52B-62.)(2) Check the SRS components using the table shown

below.

If the SRS components are showing any visible damage

such as dents, cracks, or deformation, replace them

with new ones.

Refer to appropriate INDIVIDUAL COMPONENT SER-

VICE, P.52B-56.

(3) Conduct self-diagnosis using Multi-use Tester to ensure

entire SRS operates properly except open circuit of air

bag module (22. SQUIB TRBL 2).

(4) Install new air bag module. (Refer to

P.52B-62.)

SRS ComponentsInspection(when air bag deploys in collision)Inspection (when air bag does not deploy

in low-speed collision)

Front impact sensors

Replace front impact sensors.(Refer to P.52B-56.)(1)Check front upper frame lower and sensor

brackets for deformities or rust.

(2)Check sensor cases for dents, cracks deformi-ties or rust.

(3)Check sensor harnesses for binds, connectors

for damage, and terminals for deformities.

SRS diagnosis unitSDU)Replace SRS diagnosis unit.(Refer to P.52B-59.)(1)Check SDU case and brackets for dents, cracksor deformities.(2)Check connectors and lock lever for damage,and terminals for deformities.

jir bag moduleReplace air bag module.(Refer to P.52B-62.)(1)Check pad cover for dents, cracks or deformi-ties.

(2)Remove air bag module from steering wheel.

Check hooks and connector for damage, termi-

nals for deformities, and harness for binds.

(Refer to P.52B-62.)(3)Check air bag inflator case for dents, cracks or

deformities.

(4)Install air bag module to steering wheel to.checlfit or alignment with the wheel.

Steering wheel/steering

(1)column/intermediateReplace steering wheel, steering

iointcolumn and intermediate joint.Remove air bag module from steering wheel.

(Refer to P.52B-62.)(Refer to GROUP 37A- Steering(2)Wheel and Shaft.)Check wiring harness (built into steering wheel)and connectors for damage, and terminals fordeformities.(3)Install air bag module to check fit or alignmentwith steering wheel.(4)Check steering wheel for noise, binds or

difficult operation and excessive free play,

Clock springReplace clock spring.(1)Check clock spring connectors and protective

tube for damage, and terminals for deformities.

(2)&/;yecheck the case and the gears for

Harness connectorIBody and Front wiring ’(1 )Check connectors for poor connections.

iarnessl(2)Check harnesses for binding, connectors for damage, and terminals for deformities.(Refer to P.52B-53 and P.52B-14.)

TSB Revision

Page 1074 of 1146

52B-64Air Eag Module

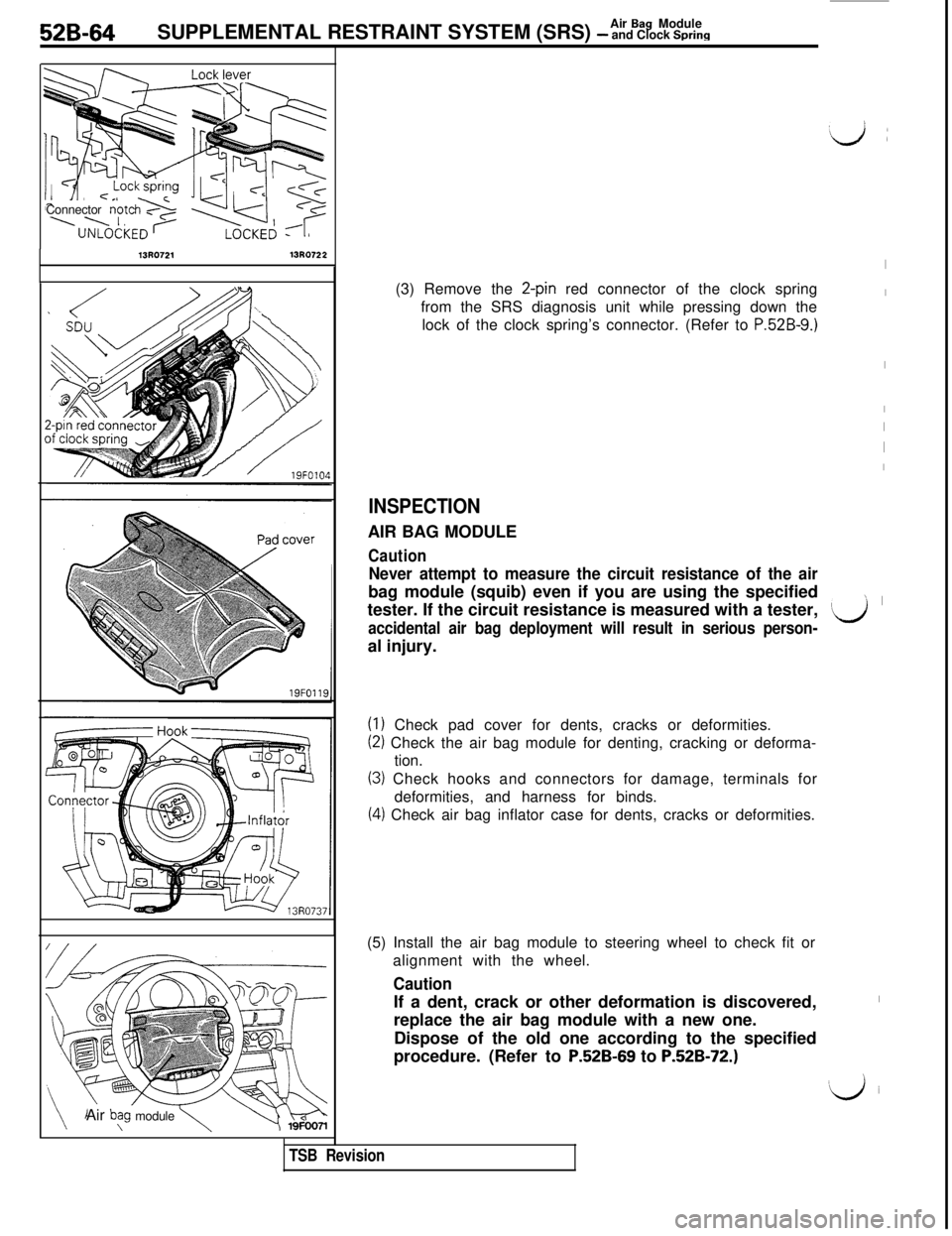

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock SpringConnector note

\\ I,

13R072113R0722

Air

b\“g module \(3) Remove the

2-pin red connector of the clock spring

from the SRS diagnosis unit while pressing down the

lock of the clock spring’s connector. (Refer to

P.52B-9.)

INSPECTIONAIR BAG MODULE

Caution

Never attempt to measure the circuit resistance of the airbag module (squib) even if you are using the specified

tester. If the circuit resistance is measured with a tester,

accidental air bag deployment will result in serious person-al injury.

(1) Check pad cover for dents, cracks or deformities.

(2) Check the air bag module for denting, cracking or deforma-

tion.

(3) Check hooks and connectors for damage, terminals for

deformities, and harness for binds.

(4) Check air bag inflator case for dents, cracks or deformities.

TSB Revision(5) Install the air bag module to steering wheel to check fit or

alignment with the wheel.

CautionIf a dent, crack or other deformation is discovered,

replace the air bag module with a new one.

Dispose of the old one according to the specified

procedure. (Refer to

P52B-69 to P.52B-72.)

I

I

I

I

I

I

I

’ I

‘Lj

I

‘iJ i