wheel alignment MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 654 of 1146

33A-4FRONT SUSPENSION - Service Adjustment Procedures

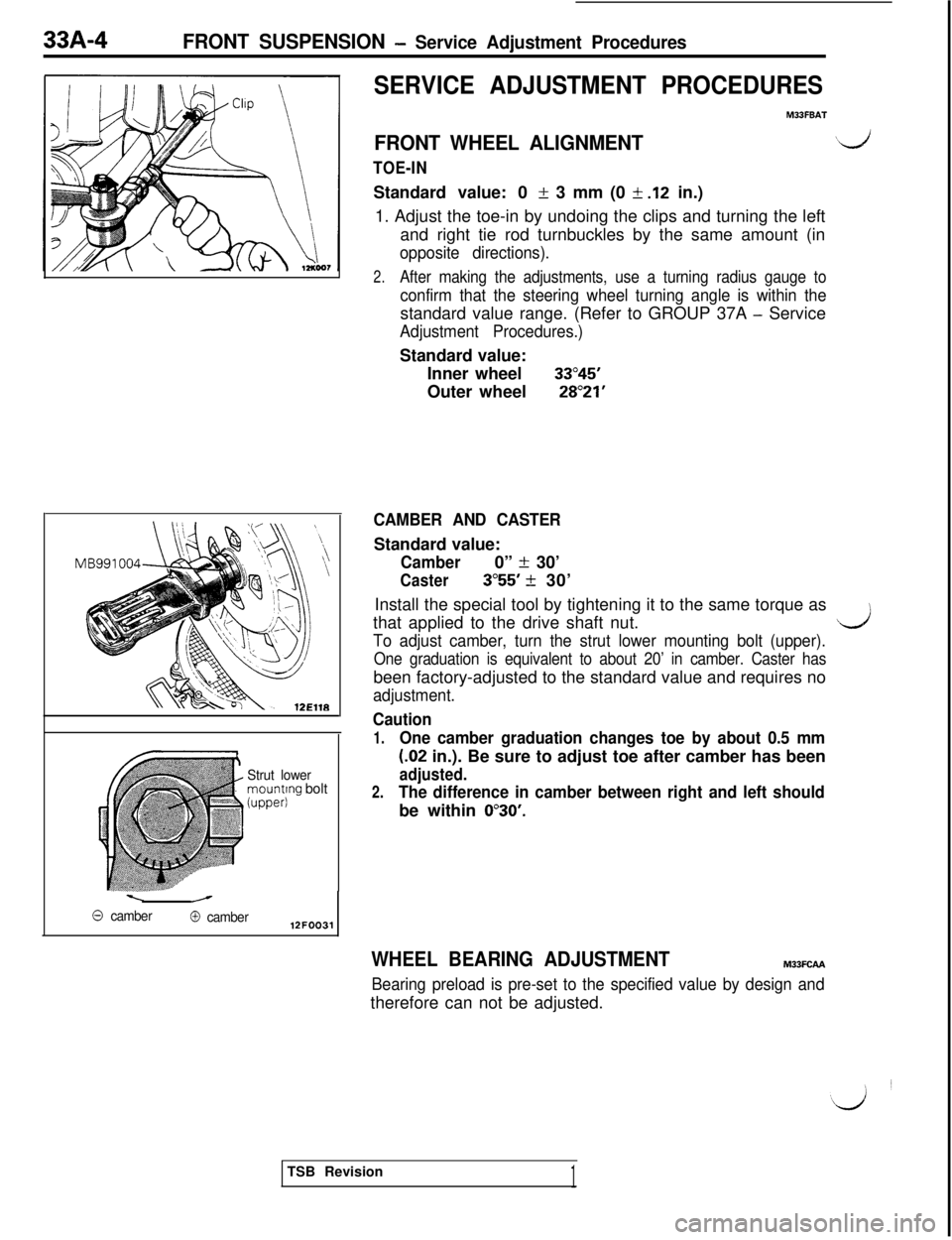

Strut lowermounting bolt(upper)

\/

0 camber@ camber12FOO31

SERVICE ADJUSTMENT PROCEDURES

M33FBAT

FRONT WHEEL ALIGNMENT‘d

TOE-INStandard value: 0 2 3 mm (0 +

.12 in.)

1. Adjust the toe-in by undoing the clips and turning the left

and right tie rod turnbuckles by the same amount (in

opposite directions).

2.After making the adjustments, use a turning radius gauge to

confirm that the steering wheel turning angle is within thestandard value range. (Refer to GROUP 37A

- Service

Adjustment Procedures.)Standard value:

Inner wheel

33”45’Outer wheel

28”21’

CAMBER AND CASTERStandard value:

Camber0” IL 30’

Caster3”55’ IL 30’

Install the special tool by tightening it to the same torque as

that applied to the drive shaft nut.

a

To adjust camber, turn the strut lower mounting bolt (upper).

One graduation is equivalent to about 20’ in camber. Caster hasbeen factory-adjusted to the standard value and requires no

adjustment.

Caution

1.One camber graduation changes toe by about 0.5 mm

(.02 in.). Be sure to adjust toe after camber has been

adjusted.

2.The difference in camber between right and left shouldbe within

O”30’.

WHEEL BEARING ADJUSTMENTM33FCAA

Bearing preload is pre-set to the specified value by design andtherefore can not be adjusted.

TSB Revision

1

Page 655 of 1146

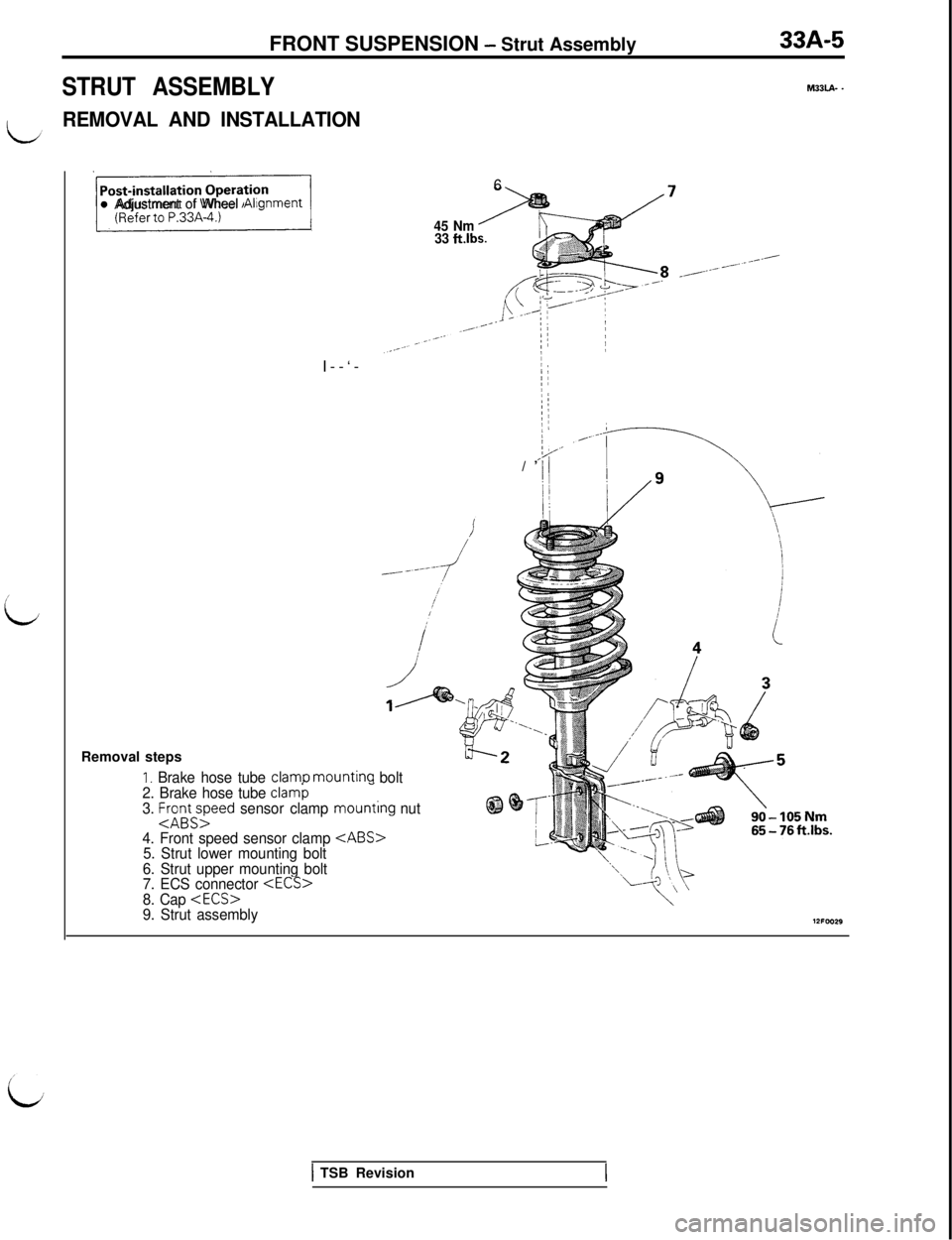

FRONT SUSPENSION - Strut Assembly33A-5

STRUT ASSEMBLY

IREMOVAL AND INSTALLATION

‘=Il Adjustment of Wheel Alignment

M33lA- *

6

45 Nm

2

33 ft.lbs.4!

AI$

c3liI7 // ;I jI ’II ;/ ~I: /I /j j

1

-r11Ii /’ I--‘-

Removal steps

1. Brake hose tube clamo mountina bolt

2. Brake hose tube clam;-,3. Fr;;tSs;eed sensor clamp mountmg nut

4. Front speed sensor clamp

tABS>5. Strut lower mounting bolt

6. Strut upper mounting bolt

7. ECS connector

8. Cap

9. Strut assembly

1 TSB Revision

Page 687 of 1146

id

REAR

SUSPE,NSlON

CONTENTSM34AA-.

REAR SUSPENSION ASSEMBLY. . . . . . . . . .._..24

SERVICE ADJUSTMENT PROCEDURES. .

23

Rear Wheel Alignment Inspection. . . . . . . . . .23

SHOCK ABSORBER ASSEMBLY. . . . . . . . . . . . .33

SPECIAL TOOLS .

.._____......_..................._.................20SPECIFICATIONS

.__............................................. 19

General Specifications. . . . . . . . . . . . . . . . . . . .19

/

id

Service Specifications.._............................... 19

STABILIZER BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34TRAILING ARM

.._........_._...................................... 30

TROUBLESHOOTING

_....................................... 22

UPPER AND LOWER ARM. . . . . . . . . . . . . . . . . . . ..t..........27

REAR AXLE HUB................................................

17

REAR SUSPENSION ASSEMBLY....................7

SERVICE ADJUSTMENT PROCEDURES........5

Rear Hub Rotary-sliding Resistance

(Torque) Inspection................................................

6

Rear Wheel Alignment Inspection....................

5

Wheel Bearing End Play Inspection....................6

SHOCK ABSORBER ASSEMBLY....................13

SPECIAL TOOLS....................................................

3

SPECIFICATIONS................................................2

,General Specifications....................................2

Service Specifications....................................2

STABILIZER BAR................................................15

TRAILING ARM....................................................11ITROUBLESHOOTING

4........................................UPPER ARM, LOWER ARM AND

ASSIST LINK91........................................................

iI

Page 691 of 1146

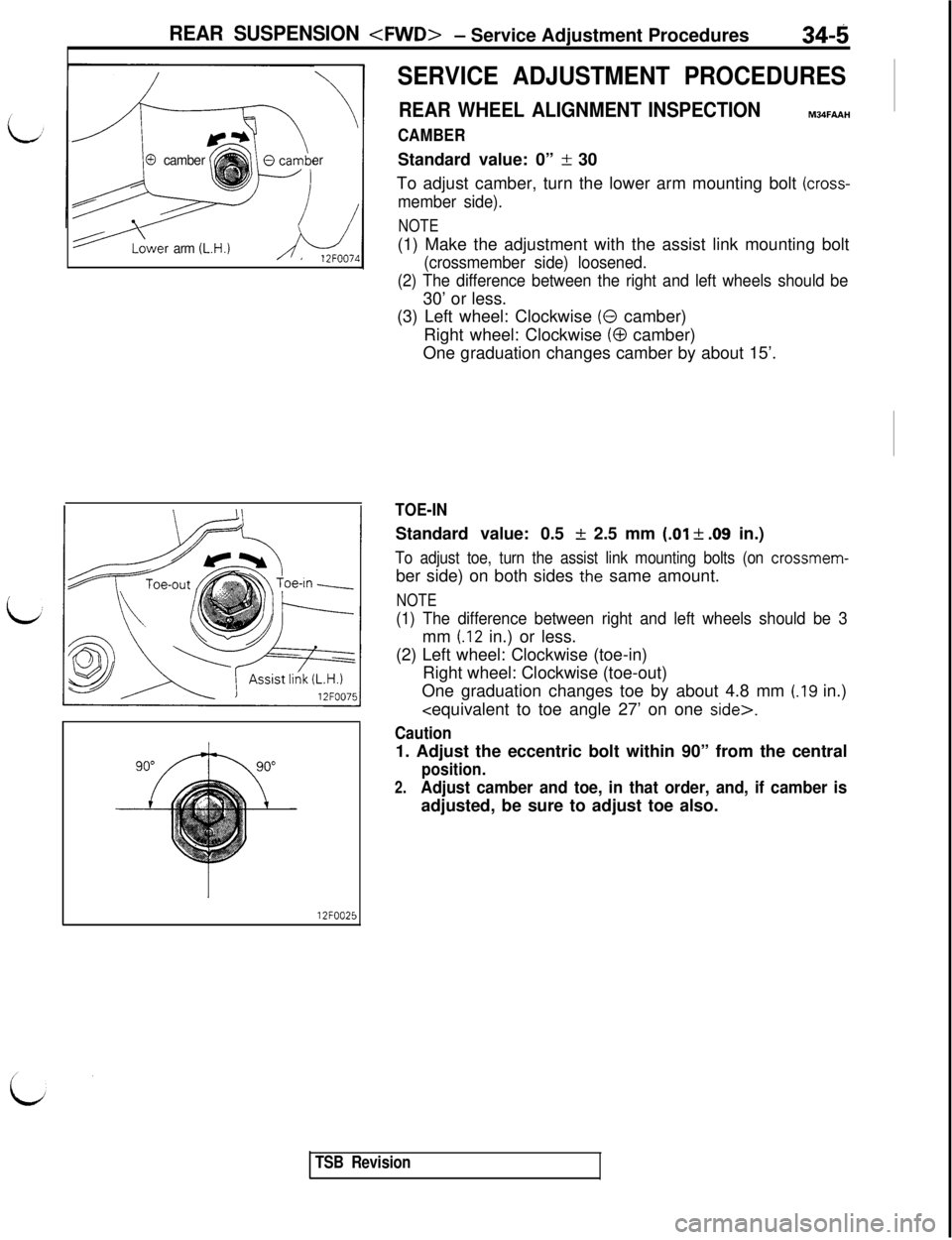

REAR SUSPENSION

0 camber

“\

er

ewer arm (L.H.)A-L!?., ’ cLr”“l‘412F002E

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONM34FAAH

CAMBERStandard value: 0” + 30

To adjust camber, turn the lower arm mounting bolt

(cross-

member side).

NOTE(1) Make the adjustment with the assist link mounting bolt

(crossmember side) loosened.

(2) The difference between the right and left wheels should be30’ or less.

(3) Left wheel: Clockwise

(0 camber)

Right wheel: Clockwise

(0 camber)

One graduation changes camber by about 15’.

TOE-INStandard value: 0.5

-+ 2.5 mm (.Ol + .09 in.)

To adjust toe, turn the assist link mounting bolts (on crossmem-ber side) on both sides

t,he same amount.

NOTE

(1) The difference between right and left wheels should be 3mm (.I2 in.) or less.

(2) Left wheel: Clockwise (toe-in)

Right wheel: Clockwise (toe-out)

One graduation changes toe by about 4.8 mm

(.19 in.)

Caution1. Adjust the eccentric bolt within 90” from the central

position.

2.Adjust camber and toe, in that order, and, if camber isadjusted, be sure to adjust toe also.

TSB Revision

Page 693 of 1146

REAR SUSPENSION

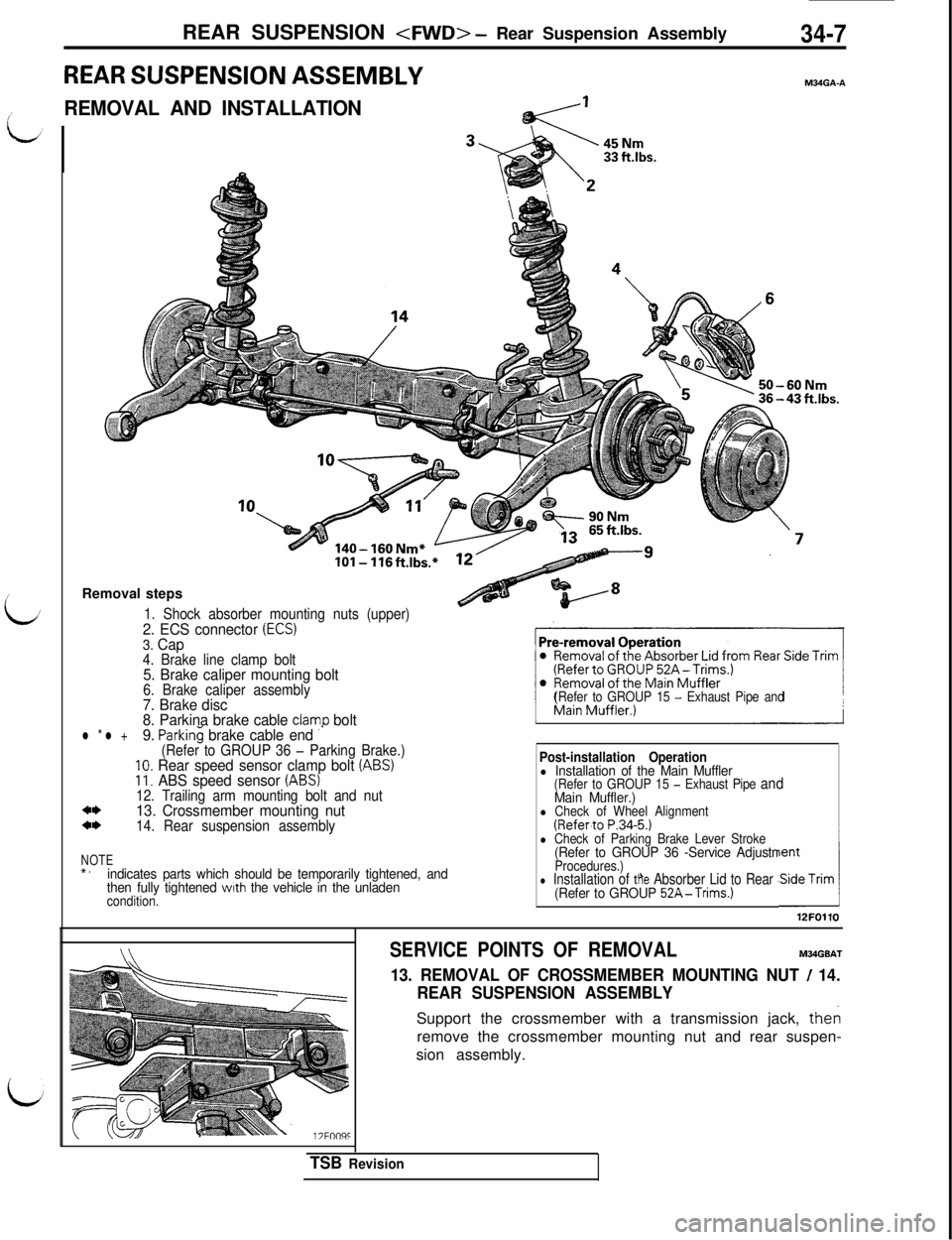

REAR SUSPENSION ASSEMBLYM34GA-A

L/

REMOVAL AND INSTALLATION

140- 160 Nm*IOI- 116ftlbs.

Removal steps

1. Shock absorber mounting nuts (upper)2. ECS connector (ECS)3. Cap4. Brake line clamp bolt5. Brake caliper mounting bolt6. Brake caliper assembly7. Brake disc

8. Parkina brake cable clamo bolt

(Refer to GROUP 15 - Exhaust Pipe and

l * l +9. ParkinG brake cable end ”(Refer to GROUP 36 - Parking Brake.)10. Rear speed sensor clamp bolt (ABS)11. ABS speed sensor (ABS)12. Trailing arm mounting bolt and nut*I)13. Crossmember mounting nut*I)14. Rear suspension assembly

NOTE*.indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladencondition.

Post-installation Operationl Installation of the Main Muffler(Refer to GROUP 15 - Exhaust Pipe andMain Muffler.)l Check of Wheel Alignment(Refer.to P.34-5.)l Check of Parking Brake Lever Stroke(Refer to GROUP 36 -Service AdjustmentProcedures.)l Installation of the Absorber Lid to Rear Side Trim(Refer to GROUP 52A-Trims.)A12FOllO

SERVICE POINTS OF REMOVALM34GBAT

13. REMOVAL OF CROSSMEMBER MOUNTING NUT / 14.

REAR SUSPENSION ASSEMBLYSupport the crossmember with a transmission jack, then

remove the crossmember mounting nut and rear suspen-

sion assembly.

TSB Revision

Page 695 of 1146

REAR SUSPENSION

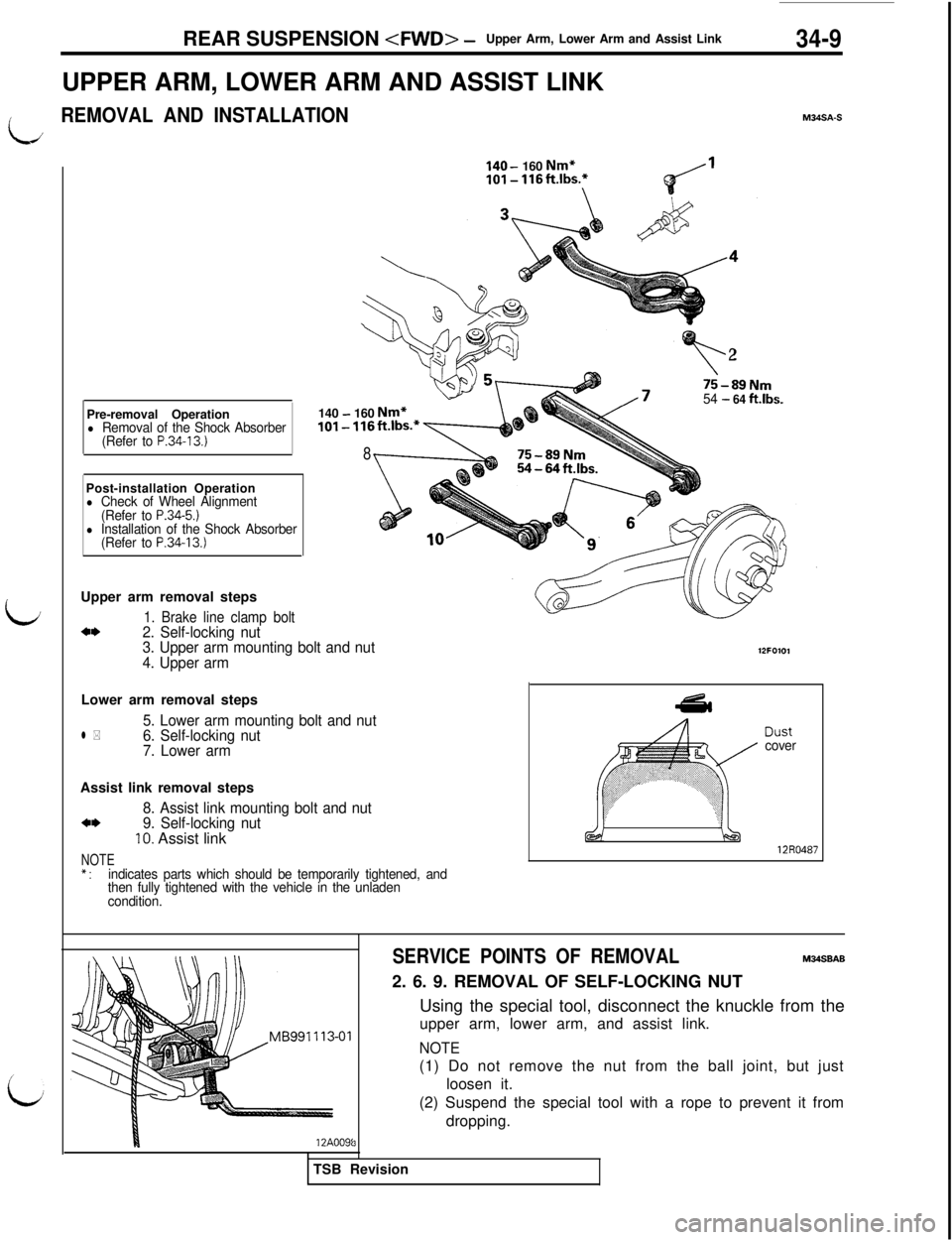

iREMOVAL AND INSTALLATION

LPre-removal Operation

l Removal of the Shock Absorber

(Refer to P.34-13.)Post-installation Operation

l Check of Wheel Alignment

(Refer to P.34-5.)l Installation of the Shock Absorber

(Refer to P.34-13.)Upper arm removal steps

1. Brake line clamp bolta*2. Self-locking nut

140- 160 Nm*IOl-116ft.lbs.”\

\

2

/7

75-89Nm54 - 64 ft.lbs.

140 - 160 Nm*101 - 116ft.lbs.*

8

3. Upper arm mounting bolt and nut

4. Upper armLower arm removal steps

5. Lower arm mounting bolt and nutl *6. Self-locking nut

7. Lower armAssist link removal steps

8. Assist link mounting bolt and nut4*9. Self-locking nut10. Assist link

NOTE*:indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladen

condition.

M34SA-S

Dustcover

rz412R0487

12A009$3TSB Revision

SERVICE POINTS OF REMOVALMSBAB2. 6. 9. REMOVAL OF SELF-LOCKING NUT

Using the special tool, disconnect the knuckle from the

upper arm, lower arm, and assist link.

NOTE(1) Do not remove the nut from the ball joint, but just

loosen it.

(2) Suspend the special tool with a rope to prevent it from

dropping.

Page 697 of 1146

REAR SUSPENSION

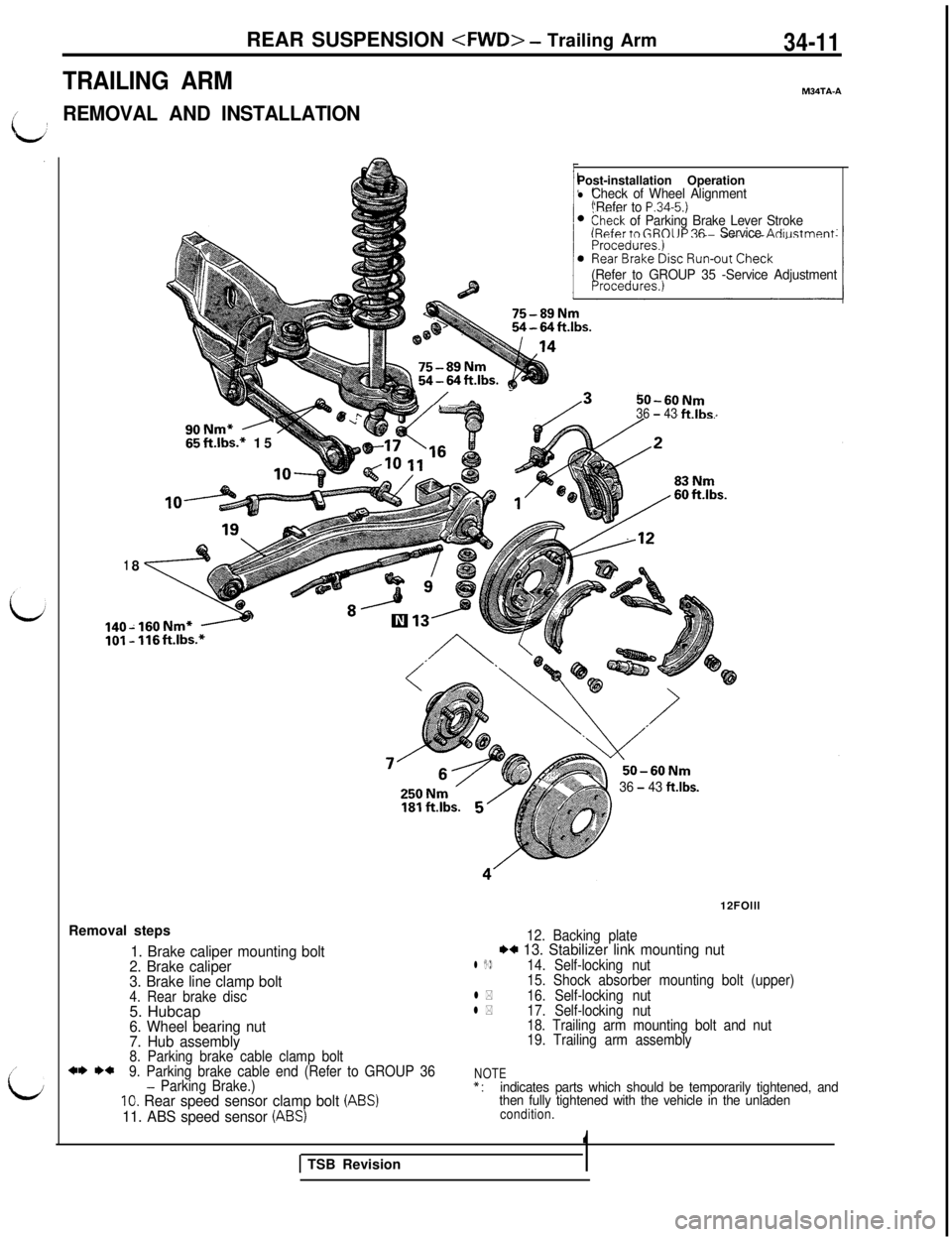

TRAILING ARMM34TA-A

t’REMOVAL AND INSTALLATION

,’

i;

18

90Nm* A65ft.lbs.* 15Post-installation Operation

lCheck of Wheel Alignment

‘Refer to P.34-5.)>heck of Parking Brake Lever Stroke(Refer tn GROIJP 36 - Service Adiustment

r/A -50-60Nm36 - 43ftlbs.

(Refer to GROUP 35 -Service Adjustment

-160Nm* -- 116ft.lbs.*Removal steps

1. Brake caliper mounting bolt

2. Brake caliper

3. Brake line clamp bolt

4. Rear brake disc5. Hubcap

6. Wheel bearing nut

7. Hub assembly

8. Parking brake cable clamp bolt*I) I)*9. Parking brake cable end (Refer to GROUP 36- Parking Brake.)IO. Rear speed sensor clamp bolt (ABS)

11. ABS speed sensor (ABS)

36 - 43 ftlbs.12FOlll

12. Backing plateI)+ 13. Stabilizer link mounting nutl I)14. Self-locking nut

15. Shock absorber mounting bolt (upper)

l *16. Self-locking nutl *17. Self-locking nut

18. Trailing arm mounting bolt and nut

19. Trailing arm assembly

NOTE*:indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladen

condition.

1 TSB Revision1

Page 709 of 1146

REAR SUSPENSION

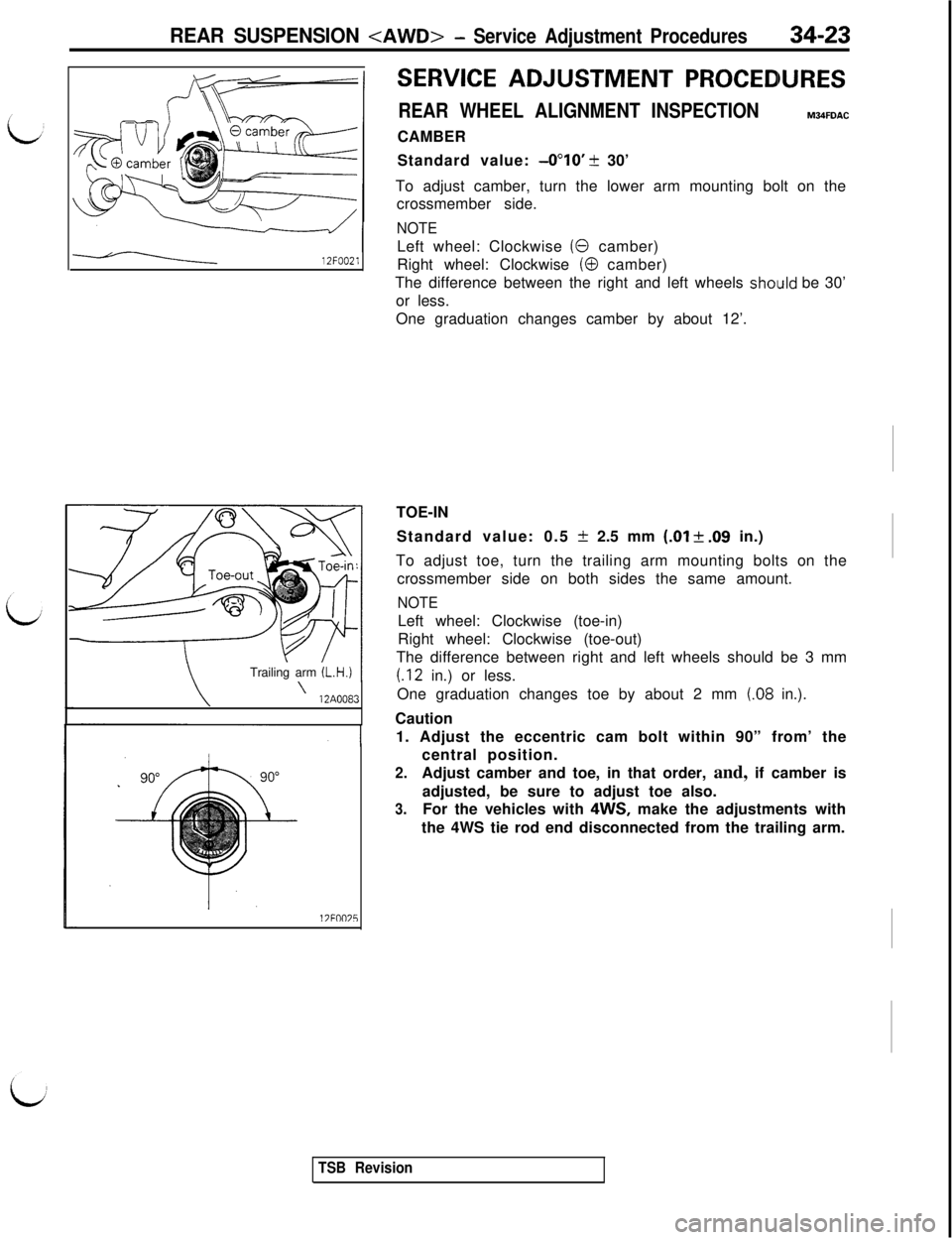

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONM34FDACCAMBER

Standard value:

-0”lO’ + 30’

To adjust camber, turn the lower arm mounting bolt on the

crossmember side.

NOTE

12FOO21Left wheel: Clockwise (0 camber)

Right wheel: Clockwise

(0 camber)

The difference between the right and left wheels

shoiuld be 30’

or less.

One graduation changes camber by about 12’.

\Trailing arm (L.H.)

\\12A0083

17FllO75TOE-IN

Standard value: 0.5

-t 2.5 mm (.Ol + .09 in.)

To adjust toe, turn the trailing arm mounting bolts on the

crossmember side on both sides the same amount.

NOTELeft wheel: Clockwise (toe-in)

Right wheel: Clockwise (toe-out)

The difference between right and left wheels should be 3 mm

(.12 in.) or less.

One graduation changes toe by about 2 mm

(.08 in.).

Caution

1. Adjust the eccentric cam bolt within 90” from’ the

central position.

2.Adjust camber and toe, in that order, and, if camber is

adjusted, be sure to adjust toe also.

3.For the vehicles with 4WS, make the adjustments with

the 4WS tie rod end disconnected from the trailing arm.

TSB Revision

Page 710 of 1146

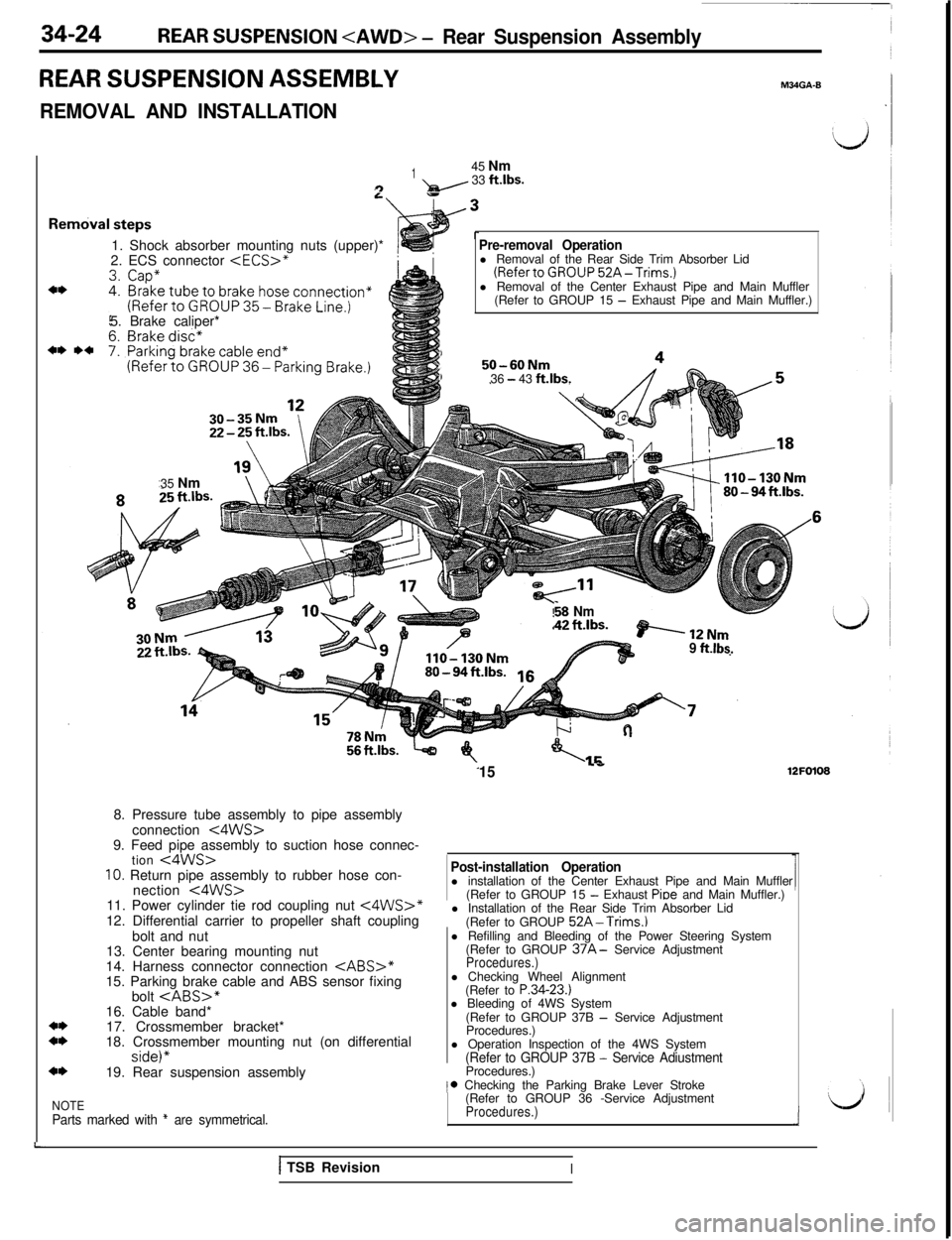

34-24REAR SUSPENSION

REAR SUSPENSION ASSEMBLY

REMOVAL AND INSTALLATION

M34GA-B

L

Rel

145 Nm9- 33 ftlbs.

1. Shock absorber mounting nuts (upper)*

2. ECS connector

(RefertoGROUP52A-Trims.)l Removal of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pipe and Main Muffler.)

5. Brake caliper*

1,50-60NmI36 - 43 ft.lbs.35 Nm

$8 Nm“?C,ILc. ashwez I,..“=.BP’----12Nm9 ftlbs.

15..e12FO1088. Pressure tube assembly to pipe assembly

connection

<4WS>9. Feed pipe assembly to suction hose connec-

tion

<4WS>10. Return pipe assembly to rubber hose con-

nection t4WS>11. Power cylinder tie rod coupling nut <4WS>*12. Differential carrier to propeller shaft coupling

bolt and nut

Post-installation Operationl installation of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pioe and Main Muffler.)

l Installation of the Rear Side Trim Absorber Lid

(Refer to GROUP

52A-Trims.)13. Center bearing mounting nut

14. Harness connector connection

CABS>*15. Parking brake cable and ABS sensor fixingl Refilling and Bleeding of the Power Steering System

(Refer to GROUP

37A- Service AdjustmentProcedures.)bolt

17. Crossmember bracket*

18. Crossmember mounting nut (on differential

side)”19. Rear suspension assemblyl Checking Wheel Alignment

(Refer to P.34-23.)

l Bleeding of 4WS System

(Refer to GROUP 37B

- Service Adjustment

Procedures.)

l Operation Inspection of the 4WS System

(Refer to GROUP 37B - Service AdiustmentProcedures.)

NOTEParts marked with * are symmetrical.

,* Checking the Parking Brake Lever Stroke

(Refer to GROUP 36 -Service Adjustment

Procedures.)i

1 TSB RevisionI

Page 716 of 1146

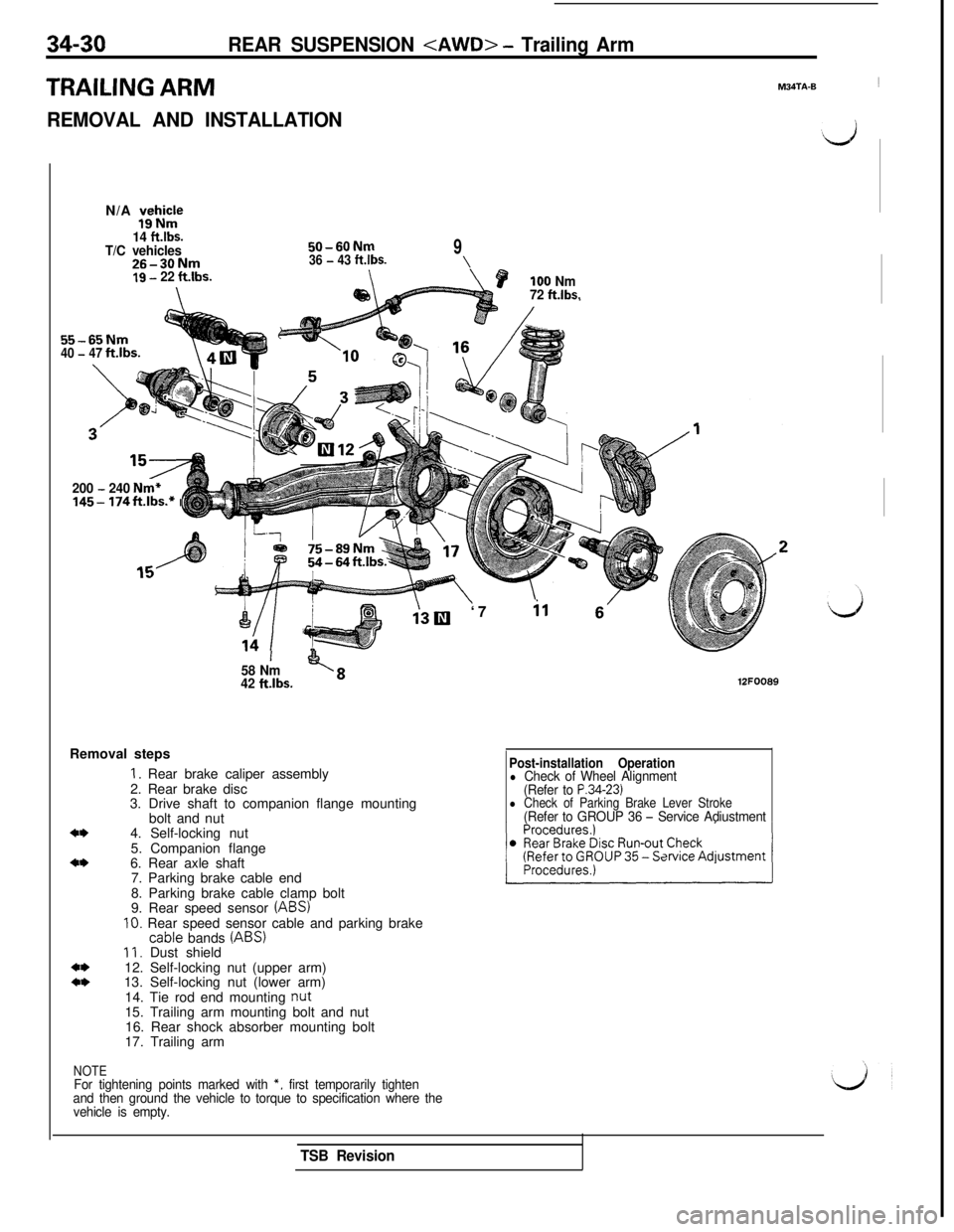

34-30REAR SUSPENSION

TRAILING ARMM34TA-B1

REMOVAL AND INSTALLATIONN/A

$icJ

14 ft.lbs.T/C vehicles26-30Nm

50-60Nm936 - 43 ftlbs.\19 - 22 ft.lbs.

55-65Nm40 - 47ft.lbs.

200

- 240 Nm*145- 174ft.lbs.* I

P100 Nm

72 ft.lbs.

58 Nm’ <842 ft.lbs.Removal steps

*I)

*I)

+*+*

1. Rear brake caliper assembly

2. Rear brake disc

3. Drive shaft to companion flange mounting

bolt and nut

4. Self-locking nut

5. Companion flange

6. Rear axle shaft

7. Parking brake cable end

8. Parking brake cable clamp bolt

9. Rear speed sensor

(ABS)IO. Rear speed sensor cable and parking brake

cable bands (ABS)II. Dust shield

12. Self-locking nut (upper arm)

13. Self-locking nut (lower arm)

14. Tie rod end mounting

nut15. Trailing arm mounting bolt and nut

16. Rear shock absorber mounting bolt

17. Trailing arm

NOTEFor tightening points marked with *, first temporarily tighten

and then ground the vehicle to torque to specification where the

vehicle is empty.‘7

il 6’

12FOO89

Post-installation Operationl Check of Wheel Alignment

(Refer to P.34-23)l Check of Parking Brake Lever Stroke(Refer to GROUP 36 - Service Adiustment

TSB Revision