ESP MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 700 of 1146

34-14REAR SUSPENSION

12K(u9

‘7

Coil

,’I

seat12A0049

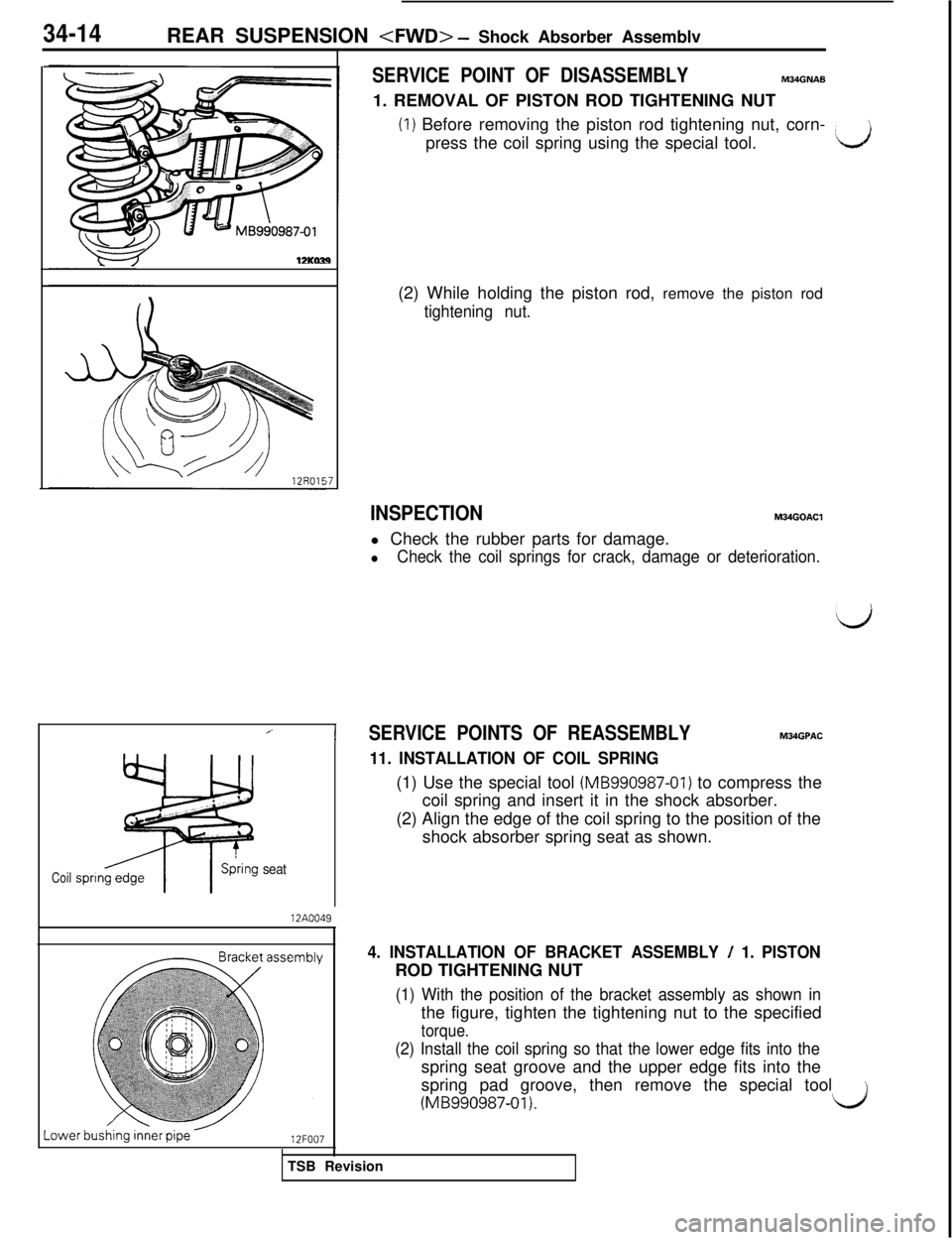

SERVICE POINT OF DISASSEMBLYM34GNAB1. REMOVAL OF PISTON ROD TIGHTENING NUT

(1) Before removing the piston rod tightening nut, corn-

press the coil spring using the special tool.

d(2) While holding the piston rod, remove the piston rod

tightening nut.

INSPECTIONM34GOACl

l Check the rubber parts for damage.

lCheck the coil springs for crack, damage or deterioration.

SERVICE POINTS OF REASSEMBLYM34GPAC

11. INSTALLATION OF COIL SPRING(1) Use the special tool

(MB990987-01) to compress the

coil spring and insert it in the shock absorber.

(2) Align the edge of the coil spring to the position of the

shock absorber spring seat as shown.

4. INSTALLATION OF BRACKET ASSEMBLY / 1. PISTONROD TIGHTENING NUT

(1) With the position of the bracket assembly as shown inthe figure, tighten the tightening nut to the specified

torque.

(2) Install the coil spring so that the lower edge fits into thespring seat groove and the upper edge fits into the

spring pad groove, then remove the special tool

’

(MB990987-01).L/iTSB Revision

Page 723 of 1146

L,

SERVICE

BRAKES

CONTENTSM35AA..

ANTI-LOCK BRAKING SYSTEM TROUBLESHOOTING7Actuator Test Function

. . . . ..___..._____.__................................ I 2, 36Check Using Self Diagnosis Function __._.....,_._.._____........ 11, 28

Diagnosis Code Chart ..,,........,......_..................................,. 1 I, 28

How to Use the Troubleshooting Flow Chart

_____.___......._._.7Method of Clearing Diagnosis Code Memory._.,._...... 12, 30

Particular Phenomena of the Anti-lock Braking System

7Troubleshooting (ABS-AWD) ._______._.._...........................,... 26

Troubleshooting (ABS-FWD) ______.._._........_...........,.....,.....,....8

TroubleshootingMethods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

BRAKE LINE . . . . . . .._.......................................................................71

BRAKEPEDAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

ELECTRONIC CONTROL UNIT (ABS). . . . .._._..___..__._............93/

L

FRONT DISC BRAKE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73G SENSOR (AWD-ABS)’

____.____.___.__._._.................,,......,.....,.... 92

HYDRAULIC UNIT (ABS) .___.._._._._.______.............,...,,..........~ .,_____86

MASTER CYLINDER AND BRAKE BOOSTER ..__.._____.._____67SPECIFICATIONS ._....._.___.....................................

REAR DISC BRAKE . . . . . . .._..._._.___................................................81

SERVICE ADJUSTMENT PROCEDURES..___........45Bleeding48

Brake Booster Operating Inspection.

46

Brake Drum Inside Diameter Check. . .56

BrakeFluidLevelSensor Check.46

Brake Lining and Brake Drum Connection Check56Brake

Linrng Thickness Check............................................Brake Pedal Inspection and Adjustment............................Check Valve Operation Check............................................Front Brake Disc Run-out Check........................................Front Brake Disc Run-out Correction................................Front Disc Brake Pad Check and Replacement................Inspection of Front Brake Disc Thickness........................Inspection of Hydraulic Unit................................................Inspectton of Power Relay....................................................Inspection of Valve Relay and Motor Relay (ABS)............Measurement of Wheel Speed Sensor Output Voltage

Proportioning Valve Function Test

....................................Rear Brake Disc Run-out Check........................................Rear Brake Disc Run-out Correction................................Rear Brake Disc Thickness Check....................................Rear Disc Brake Pad Check and Replacement................Remedy in Case of DischargedBattery............................56

45

46

52

53

48

5258

62

62

57

47

55

55

55

53

62

SPECIAL TOOLS ..__.......___..........................................................General Specifications

........................................................Lubricants............................................................................Sealants and Adhesives........................................................Service Specifications........................................................3

TROUBLESHOOTING............................................................5

WHEEL SPEED SENSOR (ABS)............................................88

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

i

Page 743 of 1146

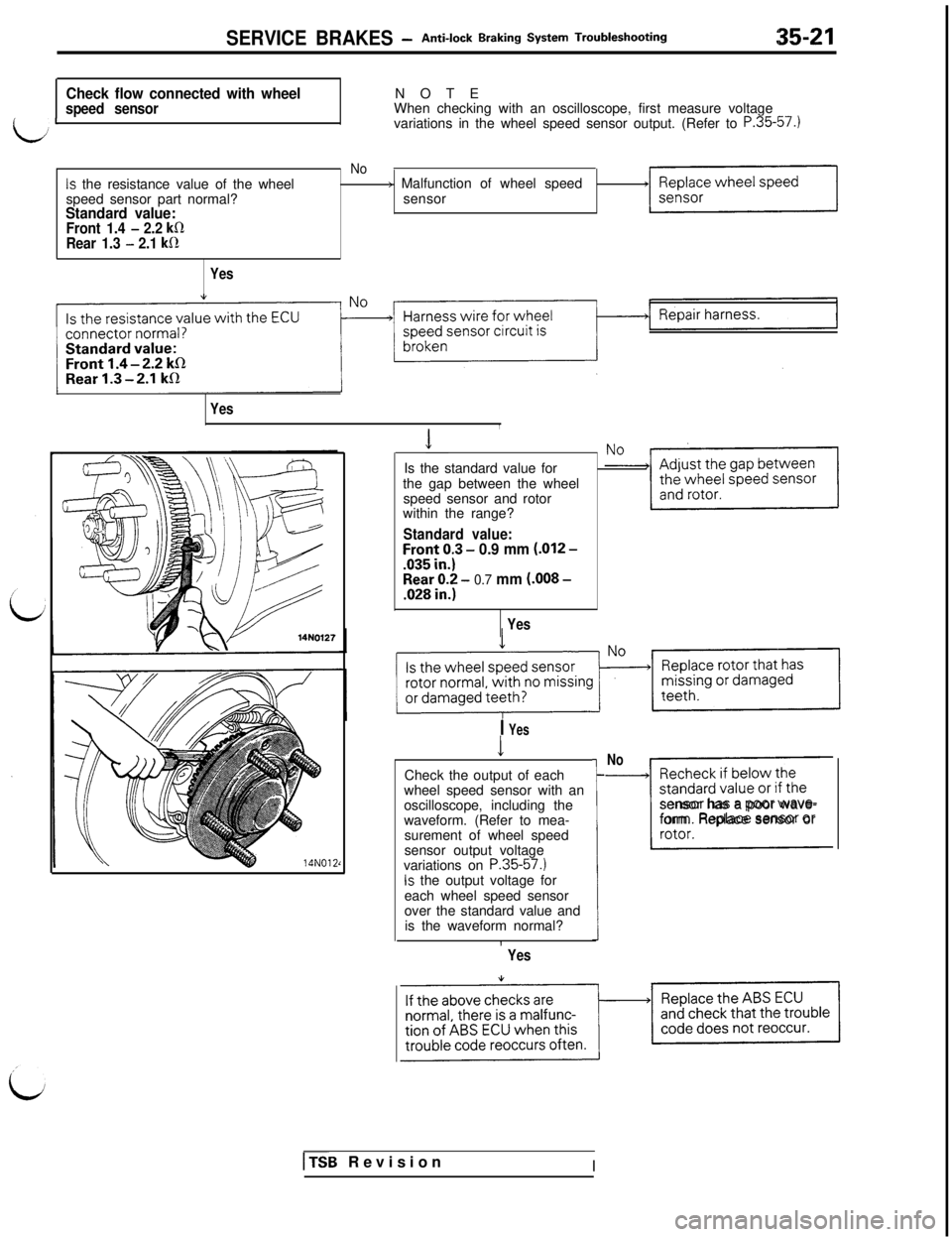

SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-21

Check flow connected with wheelNOTEspeed sensorWhen checking with an oscilloscope, first measure voltage

iivariations in the wheel speed sensor output. (Refer to P.35-57.)

No

Is the resistance value of the wheel

speed sensor part normal?

Standard value:Front 1.4 - 2.2 kRRear 1.3 - 2.1 kSZ

> Malfunction of wheel speed

sensor

Yes

Yes

1

IIs the standard value for

the gap between the wheel

speed sensor and rotor

within the range?

Standard value:;+;;fi3 - 0.9 mm LO12 -

poe288r,$ - 0.7 mm LOO8 -

Yes

I Yes

ICheck the output of each

wheel speed sensor with an

oscilloscope, including the

waveform. (Refer to mea-

surement of wheel speed

sensor output voltage

variations on

P.35-57.)Is the output voltage for

each wheel speed sensor

over the standard value and

is the waveform normal?

:

No-

Lsensor has a poor wave-

form. Replace sensor or

Yes

RB RevisionI

Page 817 of 1146

36-1

PARKING

BRAKES

CONTENTSM36AA-.

PARKINGBRAKE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8SPECIAL TOOLS . .._.._.............................................

PARKING BRAKE LEVER AND PARKINGSPECIFICATIONS................................................

BRAKE CABLE*....................................................5General Specifications....................................

SERVICE ADJUSTMENT PROCEDURES4Lubricants....................................................................Parking Brake Lever Stroke Check4Sealants

andAdhesives....................................................Parking Brake Switch Check

............................4Service Specifications....................................

TROUBLESHOOTING........................................

i

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the SRS inoperative).(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

u

I

Page 829 of 1146

37A-1

STEERING

CONTENTSM37AA-A

POWER STEERING GEAR BOX*....................17Steering Wheel Return to Center

Check................................................................8

POWER STEERING HOSES................................32Tie Rod End Ball Joint Startinq Torque

POWER STEERING OIL PUMP. .._....................28Check. . . . . . . . .._.............................. r . . . . . . . . ..I . . . . . .6Tie Rod End Ball Joint Variation Check

SERVICE ADJUSTMENT PROCEDURES5(Shaft direction)................................................5........

Bleeding............................................................10V-Belt Tension Check........................................8

Fluid Level Check............................................9SPECIAL TOOLS....................................................3Fluid Replacement

............................................9

/

bOil Pressure Switch Check

SPECIFICATIONS2............................12................................................Oil Pump Pressure Test

....................................1 1General Specifications....................................2Stationary Steering Effort Check

....................8Lubricants............................................................3Steering Angle Check

5Sealant and Adhesives....................................3........................................Steering Wheel Centering

6Service Specifications....................................2................................Steering Wheel Free Play Check

....................5STEERING WHEEL AND SHAFT*....................13

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 836 of 1146

37A-8STEERING - Service Adjustment Procedures13FOOO3

13FOOOl

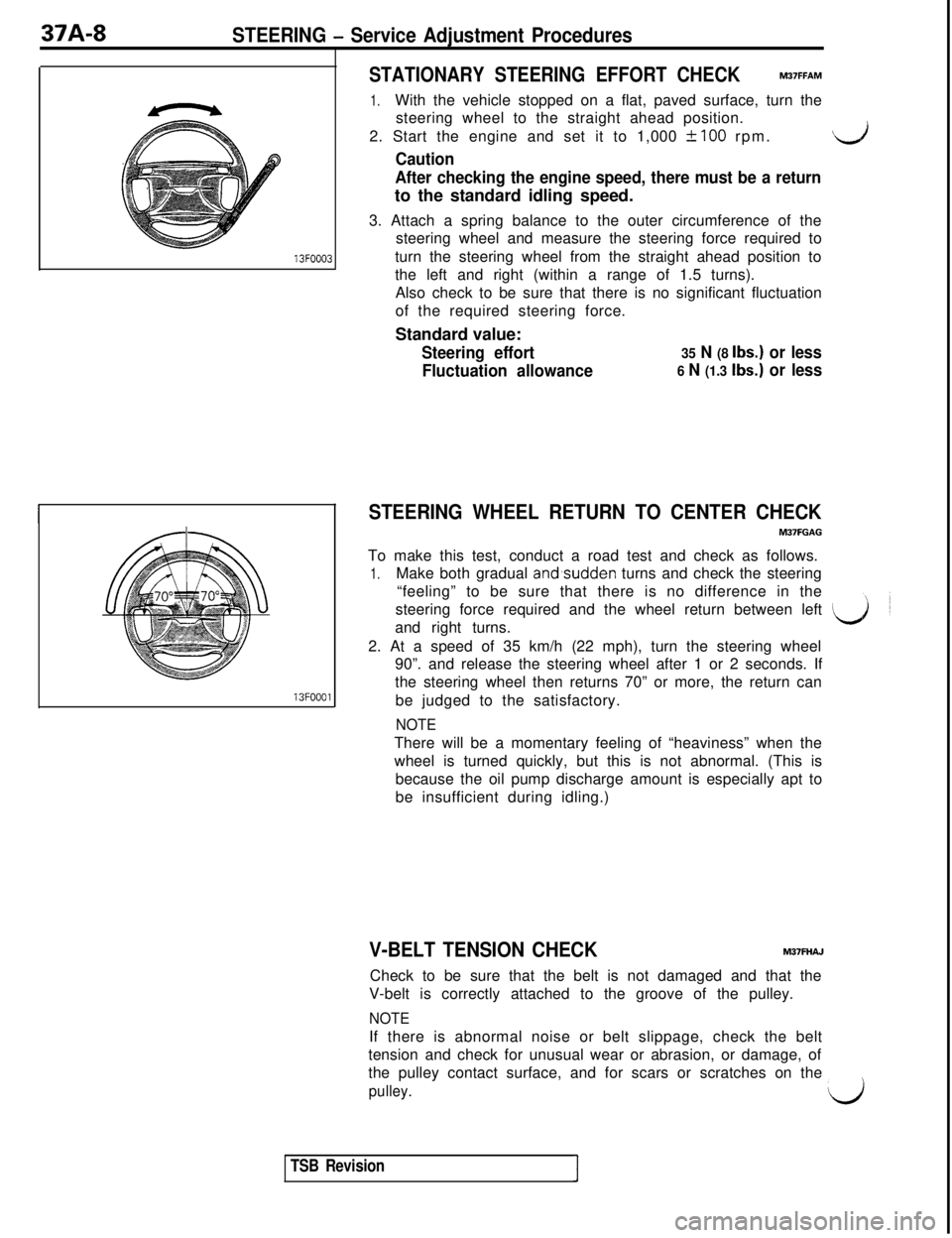

STATIONARY STEERING EFFORT CHECKM37FFAM

1.With the vehicle stopped on a flat, paved surface, turn the

steering wheel to the straight ahead position.

2. Start the engine and set it to 1,000

+ 100 rpm.d

Caution

After checking the engine speed, there must be a returnto the standard idling speed.

3. Attach a spring balance to the outer circumference of the

steering wheel and measure the steering force required to

turn the steering wheel from the straight ahead position to

the left and right (within a range of 1.5 turns).

Also check to be sure that there is no significant fluctuation

of the required steering force.

Standard value:

Steering effort35 N (8 Ibs.) or less

Fluctuation allowance

6 N (1.3 Ibs.) or less

STEERING WHEEL RETURN TO CENTER CHECK

M37FGACiTo make this test, conduct a road test and check as follows.

1.Make both gradual and,sudden turns and check the steering

“feeling” to be sure that there is no difference in the

steering force required and the wheel return between left

and right turns.

2. At a speed of 35 km/h (22 mph), turn the steering wheel

90”. and release the steering wheel after 1 or 2 seconds. If

the steering wheel then returns 70” or more, the return can

be judged to the satisfactory.

NOTEThere will be a momentary feeling of “heaviness” when the

wheel is turned quickly, but this is not abnormal. (This is

because the oil pump discharge amount is especially apt to

be insufficient during idling.)

V-BELT TENSION CHECKM37FHAJCheck to be sure that the belt is not damaged and that the

V-belt is correctly attached to the groove of the pulley.

NOTEIf there is abnormal noise or belt slippage, check the belt

tension and check for unusual wear or abrasion, or damage, of

the pulley contact surface, and for scars or scratches on the

pulley.d

TSB RevisionI

Page 863 of 1146

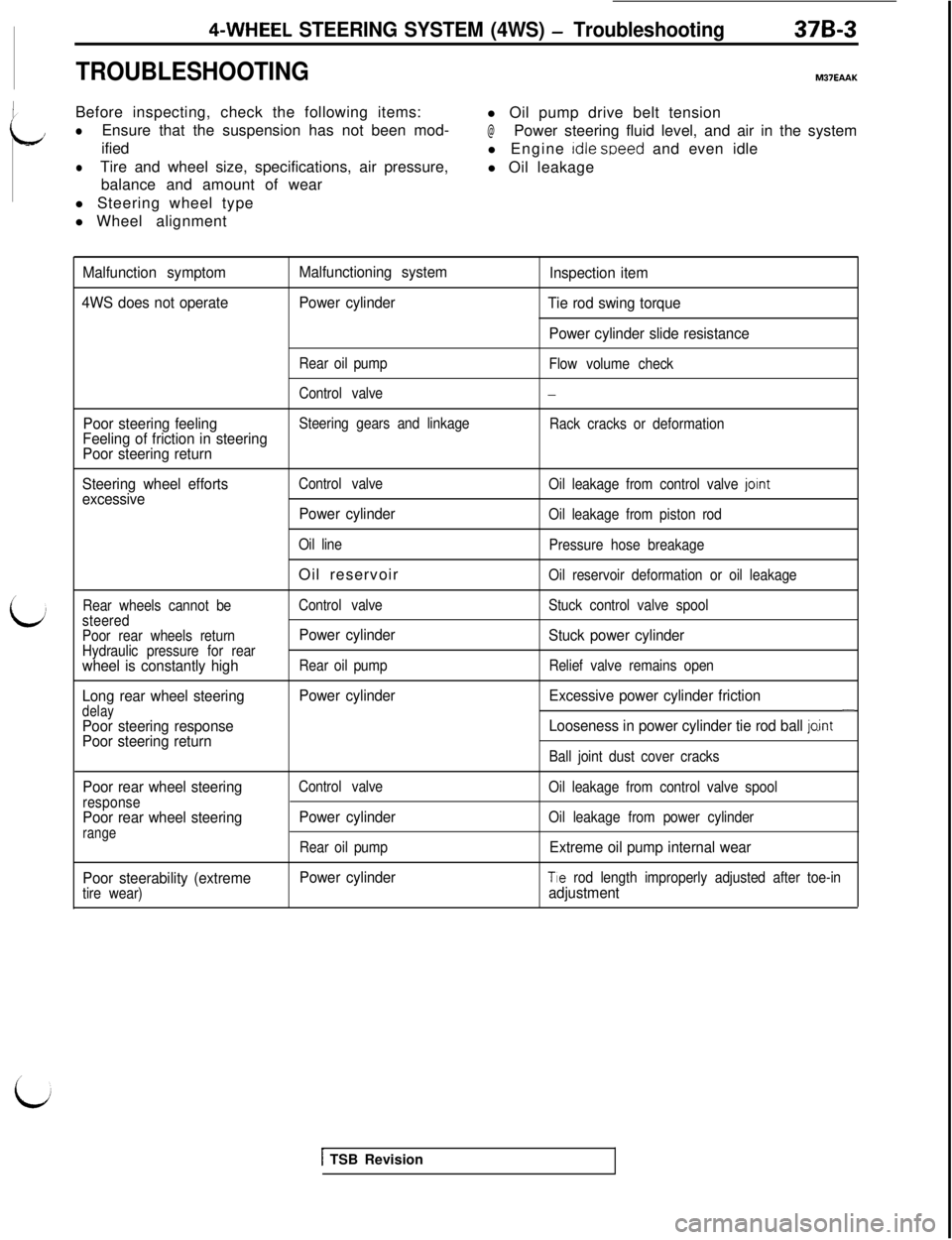

4-WHEEL STEERING SYSTEM (4WS) - Troubleshooting

TROUBLESHOOTING

37B-3

M37EMKBefore inspecting, check the following items:

l Oil pump drive belt tension

lEnsure that the suspension has not been mod-@Power steering fluid level, and air in the system

ified

l Engine

Idle soeed and even idle

lTire and wheel size, specifications, air pressure,

l Oil leakage

balance and amount of wear

l Steering wheel type

l Wheel alignment

Malfunction symptom

4WS does not operateMalfunctioning system

Power cylinderInspection item

Tie rod swing torque

Power cylinder slide resistance

Rear oil pump

Flow volume check

Control valve

-

Poor steering feelingSteering gears and linkage

Rack cracks or deformationFeeling of friction in steering

Poor steering return

Steering wheel efforts

excessive

Control valve

Oil leakage from control valve jornt

Rear wheels cannot be

steered

Poor rear wheels return

Hydraulic pressure for rear

wheel is constantly high

Long rear wheel steering

delayPoor steering response

Poor steering returnPower cylinder

Oil lineOil reservoir

Control valve

Power cylinder

Rear oil pump

Power cylinder

Oil leakage from piston rod

Pressure hose breakage

Oil reservoir deformation or oil leakage

Stuck control valve spool

Stuck power cylinder

Relief valve remains open

Excessive power cylinder friction-

Looseness in power cylinder tie rod ball jo.int

Ball joint dust cover cracks

Poor rear wheel steeringresponsePoor rear wheel steeringrange

Poor steerability (extremetire wear)Control valve

Power cylinder

Rear oil pump

Power cylinder

Oil leakage from control valve spool

Oil leakage from power cylinder

Extreme oil pump internal wear

Tie rod length improperly adjusted after toe-inadjustment

[ TSB Revision

Page 873 of 1146

42-1

BODY

CONTENTSM42AA- -

CENTER PILLAR GLASS........................................................32

CENTRAL DOOR LOCKING SYSTEM

................................55

DOOR ASSEMBLY....................................................................40

DOOR GLASS AND REGULATOR

........................................42

DOOR HANDLE AND LATCH

................................................54

DOOR TRIM AND WATERPROOF FILM

............................41

DRIP LINE WEATHERSTRIP....................................................65

ENGINE HOOD........................................................................18

FENDER*....................................................................................23

FUEL TANK FILLER DOOR

....................................................22

LIFTGATE....................................................................................20

LIFTGATE GLASS....................................................................37

LOOSE PANEL

........................................................................24

POWER WINDOW

....................................................................43

QUARTER WINDOW GLASS

................................................33SERVICE ADJUSTMENT PROCEDURES

............................

Door Adjustment................................................................Door inside Handle Play Check............................................Door Window Glass Adjustment........................................Floor Pan inspection............................................................Fuel Filler Door Adjustment................................................Hood Adjustment................................................................Liftgate Adjustment............................................................

SPECIAL TOOLS........................................................................

SPECIFICATIONS....................................................................

General Specifications........................................................Sealants and Adhesives........................................................

ServiceSpecifications........................................................

TROUBLESHOOTING............................................................

WINDOW GLASS....................................................................

WINDSHIELD............................................................................

13

14

16

14

17

14

13

13

4

2

2

3

3

5

25

28

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of the

SRS or any SRS-related component.

Page 887 of 1146

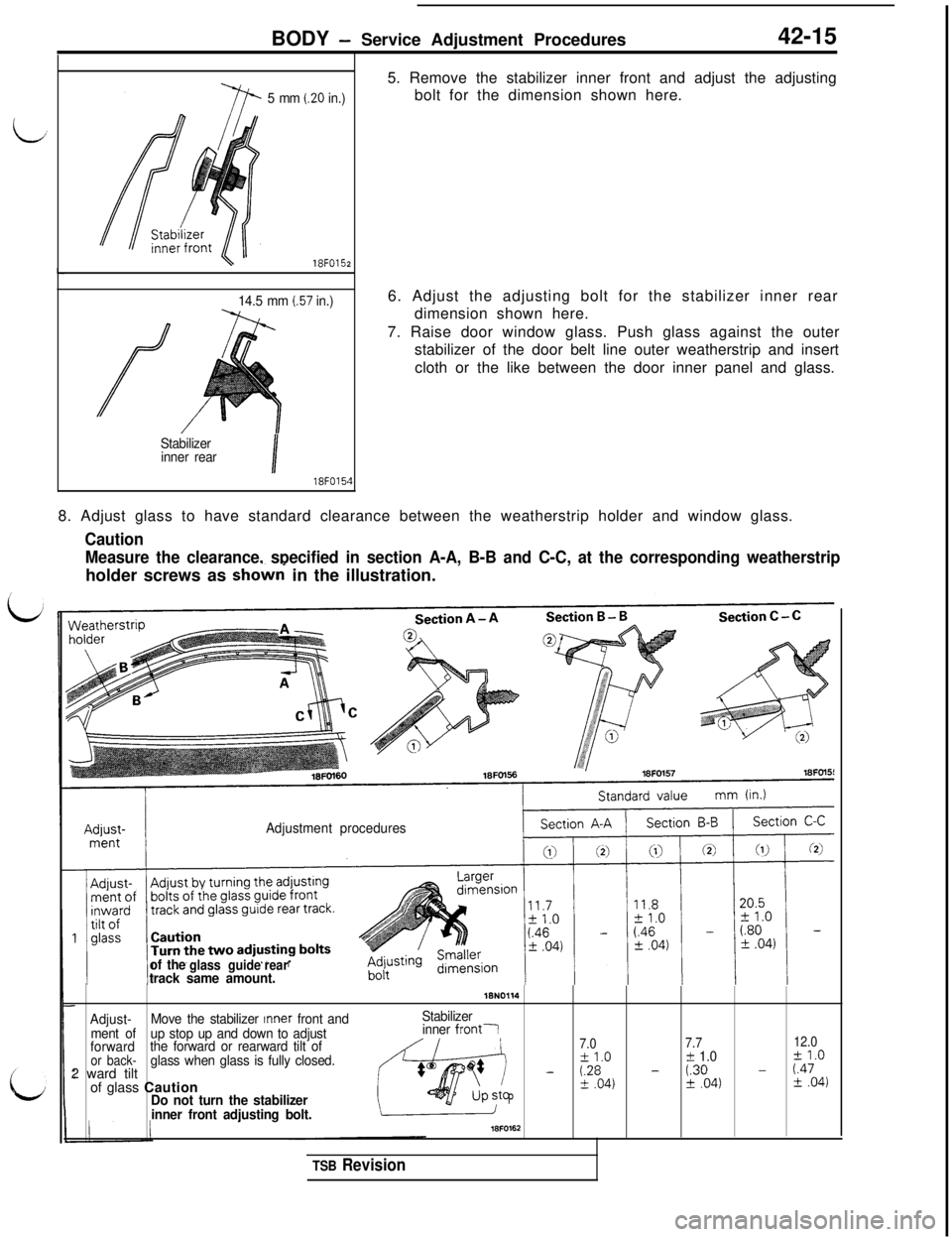

BODY - Service Adjustment Procedures42-15lSFO15

2

5 mm (20 in.)

14.5 mm

(.57 in.)

Stabilizer

inner rear

I18FO15‘5. Remove the stabilizer inner front and adjust the adjusting

bolt for the dimension shown here.

6. Adjust the adjusting bolt for the stabilizer inner rear

dimension shown here.

7. Raise door window glass. Push glass against the outer

stabilizer of the door belt line outer weatherstrip and insert

cloth or the like between the door inner panel and glass.

8. Adjust glass to have standard clearance between the weatherstrip holder and window glass.

Caution

Measure the clearance, specified in section A-A, B-B and C-C, at the corresponding weatherstripholder screws as

shown in the illustration.

Adjustment procedures

of theglass guidereartrack same amount.

18N0114

Adjust-Move the stabilizer Inner front and

ment ofup stop up and down to adjust

forwardthe forward or rearward tilt of

or back-glass when glass is fully closed.2 ward tilt

of glass Caution

Do not turn the stabilizer

inner front adjusting bolt.

Stabilizer

inner front17.07.712.0iI 1.0+ 1.0iz 1.0-(.28 -i.30-t.47t ,041z!z .04)IL .04)

P

18FOl62

TSB Revision

Page 957 of 1146

EXTERIOR - Garnishes and Mouldings51-19

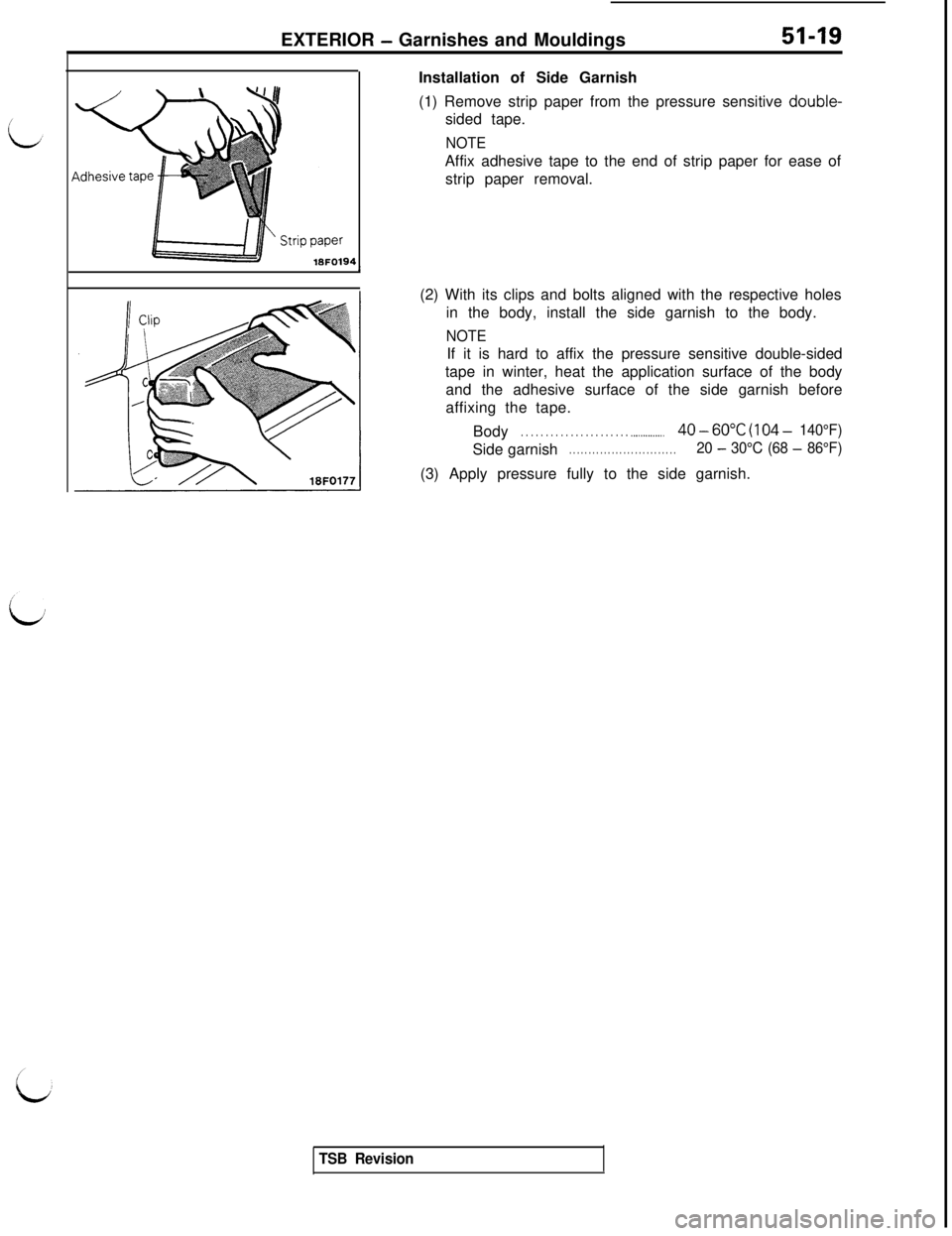

18FO194Installation of Side Garnish

(1) Remove strip paper from the pressure sensitive double-

sided tape.

NOTEAffix adhesive tape to the end of strip paper for ease of

strip paper removal.

(2) With its clips and bolts aligned with the respective holes

in the body, install the side garnish to the body.

NOTEIf it is hard to affix the pressure sensitive double-sided

tape in winter, heat the application surface of the body

and the adhesive surface of the side garnish before

affixing the tape.

Body

. . . . . . . . . . . . . . . . . . . . . . .._...........40-60°C (104- 140°F)Side garnish

. . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 30°C (68 - 86°F)(3) Apply pressure fully to the side garnish.

TSB Revision