differential MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 614 of 1146

27-18REAR AXLE

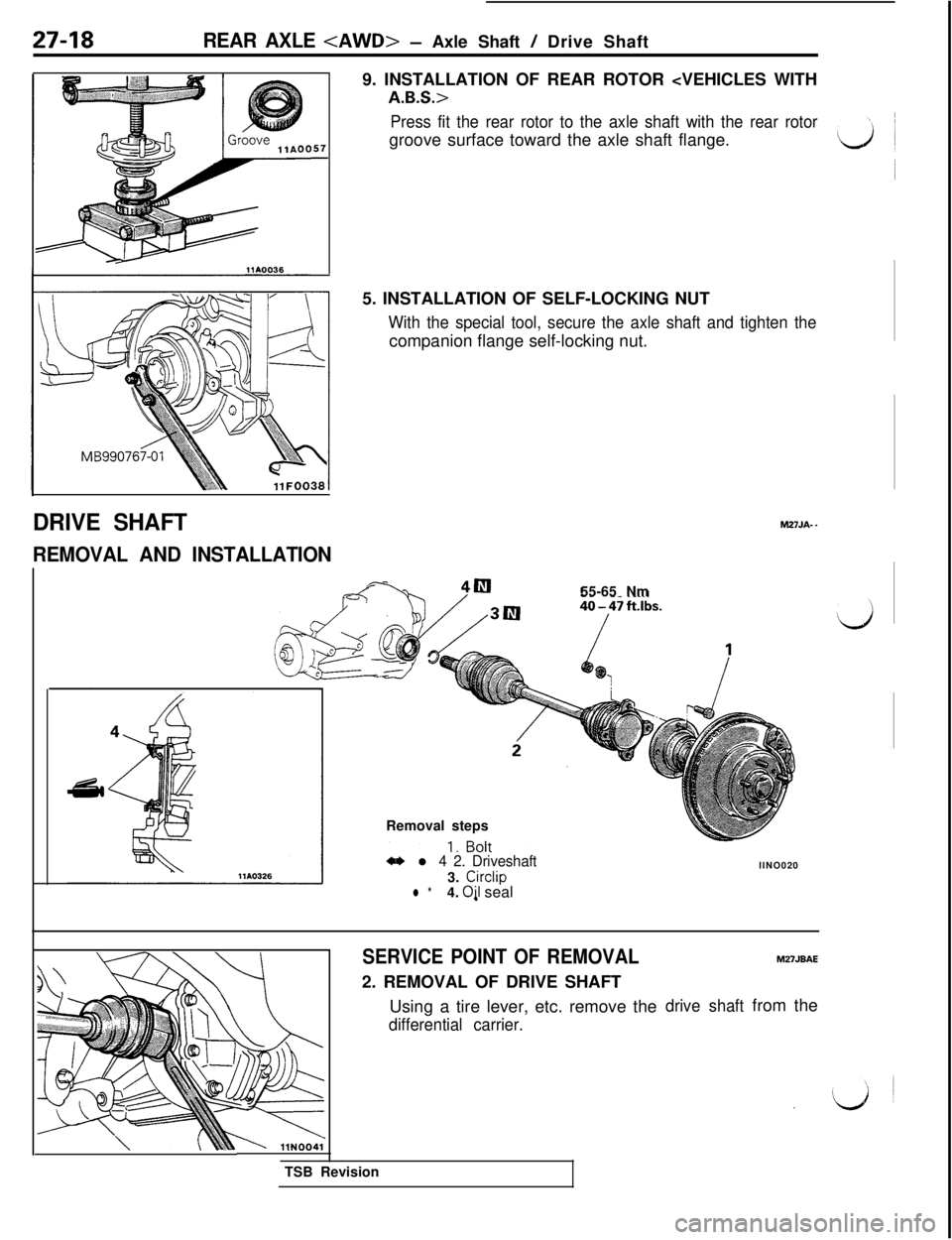

57-9. INSTALLATION OF REAR ROTOR

Press fit the rear rotor to the axle shaft with the rear rotorgroove surface toward the axle shaft flange.

5. INSTALLATION OF SELF-LOCKING NUT

With the special tool, secure the axle shaft and tighten thecompanion flange self-locking nut.

DRIVE SHAFT

REMOVAL AND INSTALLATIONM27JA-

-55-65 Nm

Removal steps4I)

l 4 2. Driveshaft3.

Circlipl *4. Oil sealllNO020

SERVICE POINT OF REMOVAL2. REMOVAL OF DRIVE SHAFT

Using a tire lever, etc. remove the

differential carrier.TSB Revision

drive shaftfrom the

M27JBAE

Page 615 of 1146

REAR AXLE

i

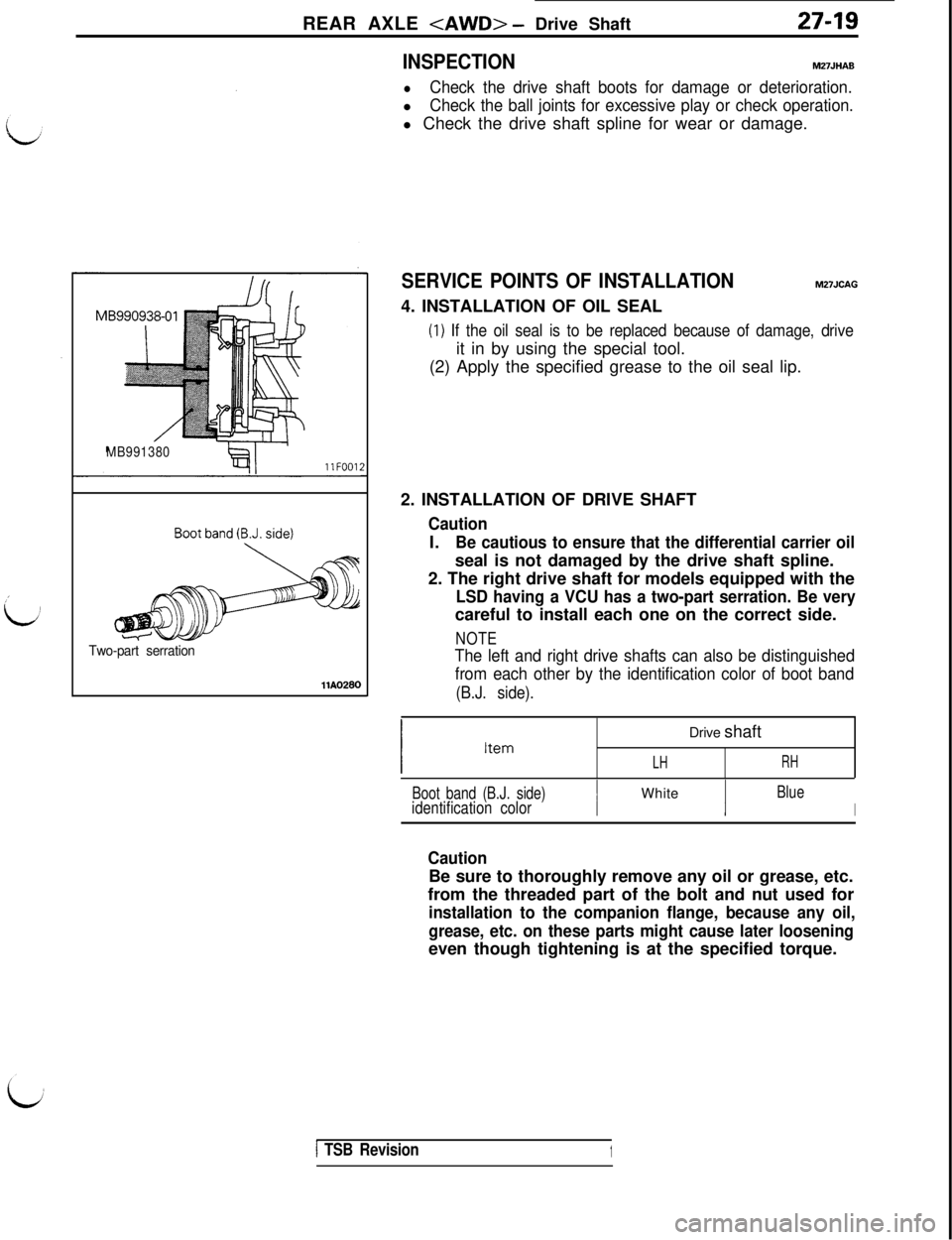

INSPECTIONM27JHAB

lCheck the drive shaft boots for damage or deterioration.l

Check the ball joints for excessive play or check operation.l Check the drive shaft spline for wear or damage.

MB991380llFOO1;

Two-part serration

llAO280

SERVICE POINTS OF INSTALLATIONM27JCAG4. INSTALLATION OF OIL SEAL

(1) If the oil seal is to be replaced because of damage, driveit in by using the special tool.

(2) Apply the specified grease to the oil seal lip.

2. INSTALLATION OF DRIVE SHAFT

CautionI.

Be cautious to ensure that the differential carrier oilseal is not damaged by the drive shaft spline.

2. The right drive shaft for models equipped with the

LSD having a VCU has a two-part serration. Be verycareful to install each one on the correct side.

NOTE

The left and right drive shafts can also be distinguished

from each other by the identification color of boot band

(B.J. side).Drive shaft

LHRH

Boot band (B.J. side)identification colorIWhite

Blue

I

CautionBe sure to thoroughly remove any oil or grease, etc.

from the threaded part of the bolt and nut used for

installation to the companion flange, because any oil,

grease, etc. on these parts might cause later looseningeven though tightening is at the specified torque.

1 TSB Revision1

Page 620 of 1146

27-24REAR AXLE

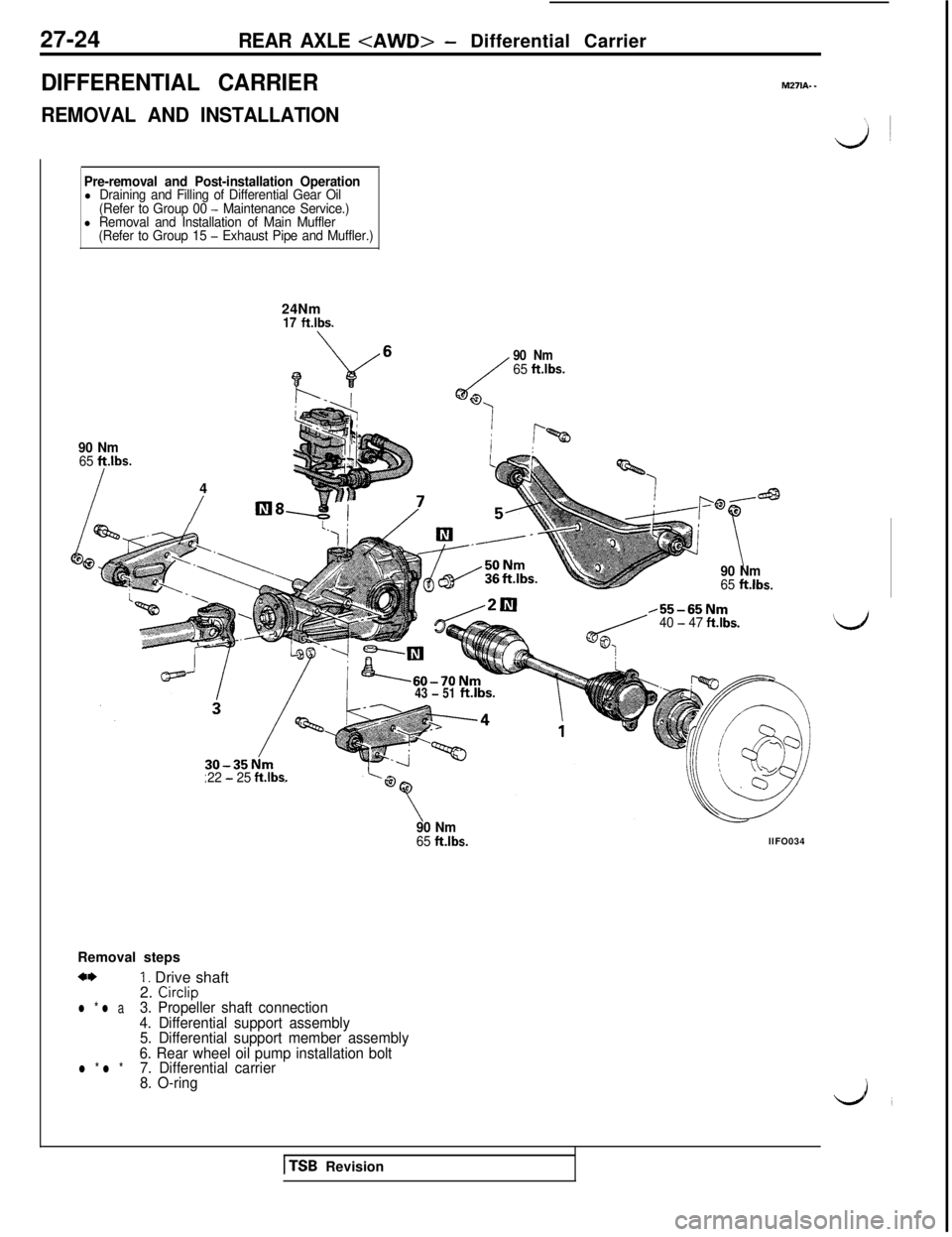

DIFFERENTIAL CARRIER

REMOVAL AND INSTALLATION

M271A. -

Pre-removal and Post-installation Operationl Draining and Filling of Differential Gear Oil

(Refer to Group 00 - Maintenance Service.)l Removal and Installation of Main Muffler

(Refer to Group 15 - Exhaust Pipe and Muffler.)24Nm

17 ft.lbs.

90 Nm65 ft.lbs.4

/lIl8

c/

90 Nm65 ft.lbs.

63

i

i !f%

43 - 51ft.lbs.

90 Nm65 ftlbs.

,55-65Nm40 - 47 fklbs.

22 - 25 ft.lbs.

90 Nm65 ft.lbs.llFO034

Removal steps

a*1. Drive shaft

2. Circlipl * l a3. Propeller shaft connection

4. Differential support assembly

5. Differential support member assembly

6. Rear wheel oil pump installation bolt

l * l *7. Differential carrier

8. O-ring

1 TSB Revision

Page 621 of 1146

REAR AXLE

27-25

Mating marks

//

MB991 153

MBggo8477J=f 4

Differential support member

llNOOl1

DifferentialllN0053

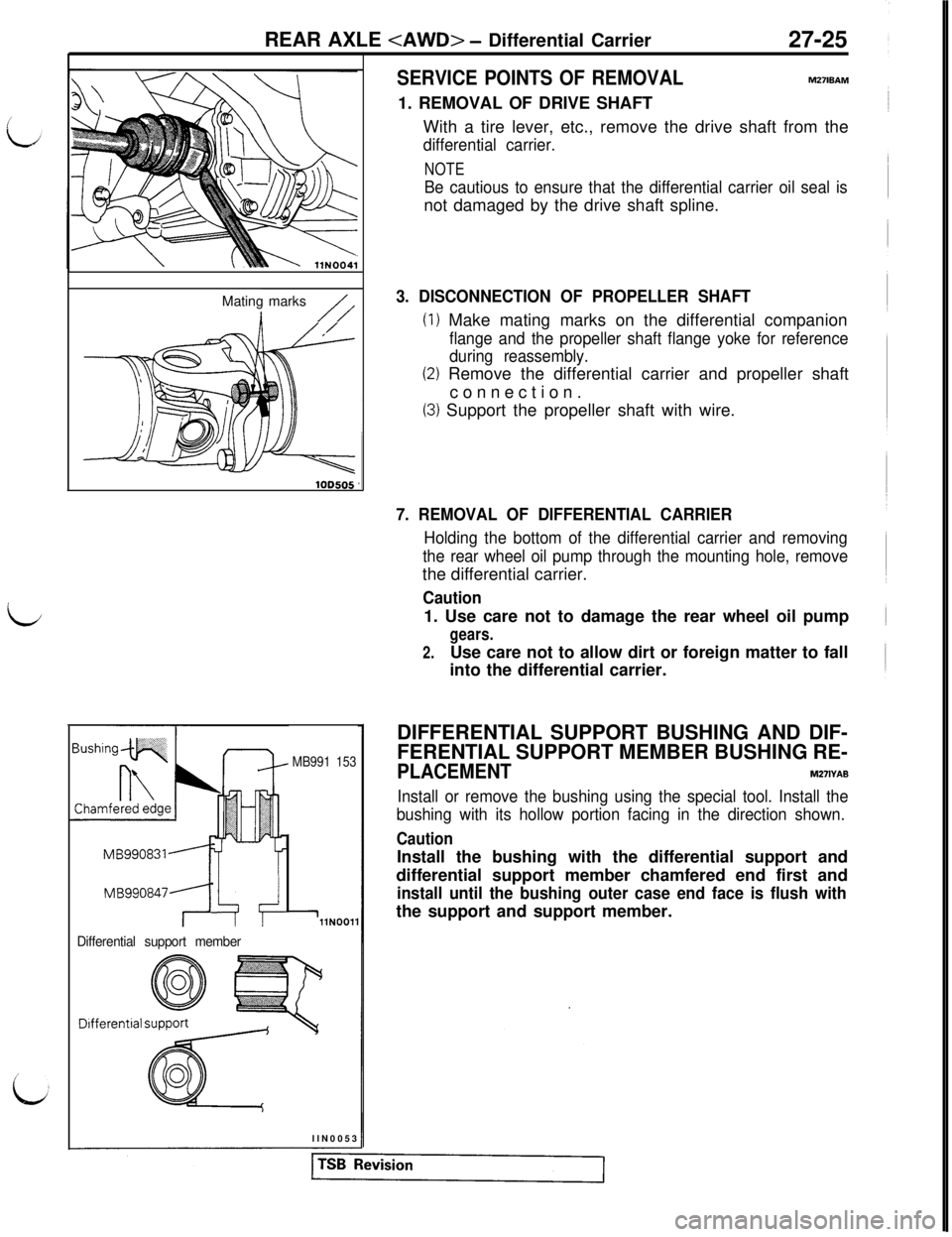

SERVICE POINTS OF REMOVALm27wAm

1. REMOVAL OF DRIVE SHAFT

With a tire lever, etc., remove the drive shaft from the

differential carrier.

NOTE

Be cautious to ensure that the differential carrier oil seal isnot damaged by the drive shaft spline.

3. DISCONNECTION OF PROPELLER SHAFT

(1) Make mating marks on the differential companion

flange and the propeller shaft flange yoke for reference

during reassembly.

(2) Remove the differential carrier and propeller shaft

connection.

(3) Support the propeller shaft with wire.

7. REMOVAL OF DIFFERENTIAL CARRIER

Holding the bottom of the differential carrier and removing

the rear wheel oil pump through the mounting hole, removethe differential carrier.

Caution1. Use care not to damage the rear wheel oil pump

gears.

2.Use care not to allow dirt or foreign matter to fall

into the differential carrier.

DIFFERENTIAL SUPPORT BUSHING AND DIF-

FERENTIAL SUPPORT MEMBER BUSHING RE-

PLACEMENTM271YAB

Install or remove the bushing using the special tool. Install the

bushing with its hollow portion facing in the direction shown.

CautionInstall the bushing with the differential support and

differential support member chamfered end first and

install until the bushing outer case end face is flush withthe support and support member.

Page 622 of 1146

27-26

REAR AXLE

SERVICE POINTS OF INSTALLATION

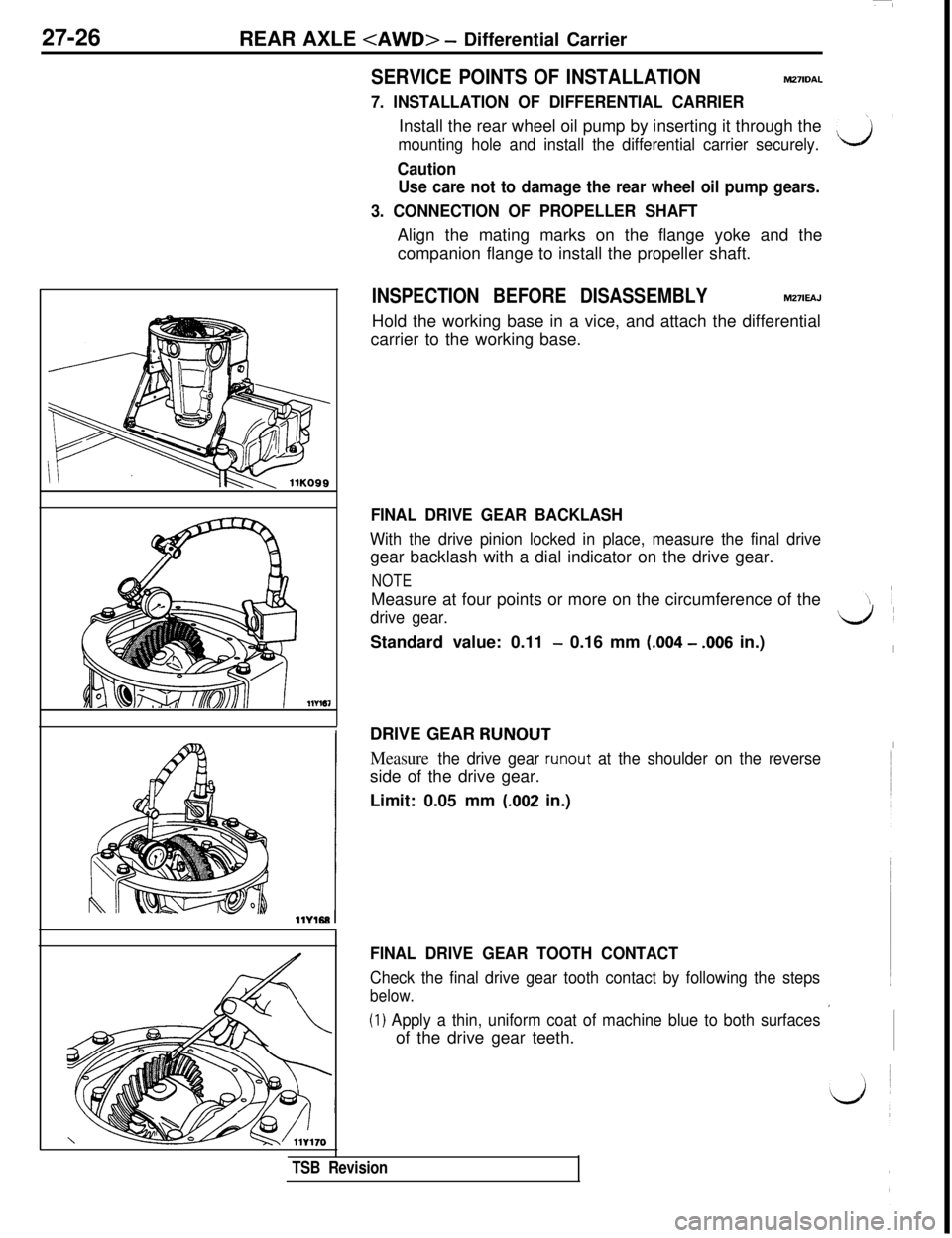

7. INSTALLATION OF DIFFERENTIAL CARRIERm27lDAL

Install the rear wheel oil pump by inserting it through the

mounting hole and install the differential carrier securely.\yiIlYl61

Caution

Use care not to damage the rear wheel oil pump gears.

3. CONNECTION OF PROPELLER SHAFTAlign the mating marks on the flange yoke and the

companion flange to install the propeller shaft.

INSPECTION BEFORE DISASSEMBLYM27lEAJHold the working base in a vice, and attach the differential

carrier to the working base.

FINAL DRIVE GEAR BACKLASH

With the drive pinion locked in place, measure the final drivegear backlash with a dial indicator on the drive gear.

NOTEMeasure at four points or more on the circumference of the

drive gear.d’Standard value: 0.11

- 0.16 mm (.004 - .006 in.)IDRIVE GEAR

RUNOUTI

Measure the drive gear runout at the shoulder on the reverseside of the drive gear.

Limit: 0.05 mm

(.002 in.)

FINAL DRIVE GEAR TOOTH CONTACT

Check the final drive gear tooth contact by following the steps

below.

(1) Apply a thin, uniform coat of machine blue to both surfaces ’of the drive gear teeth.

TSB Revision

Page 623 of 1146

/

i.J

I

i

REAR AXLE

CT2flG0076

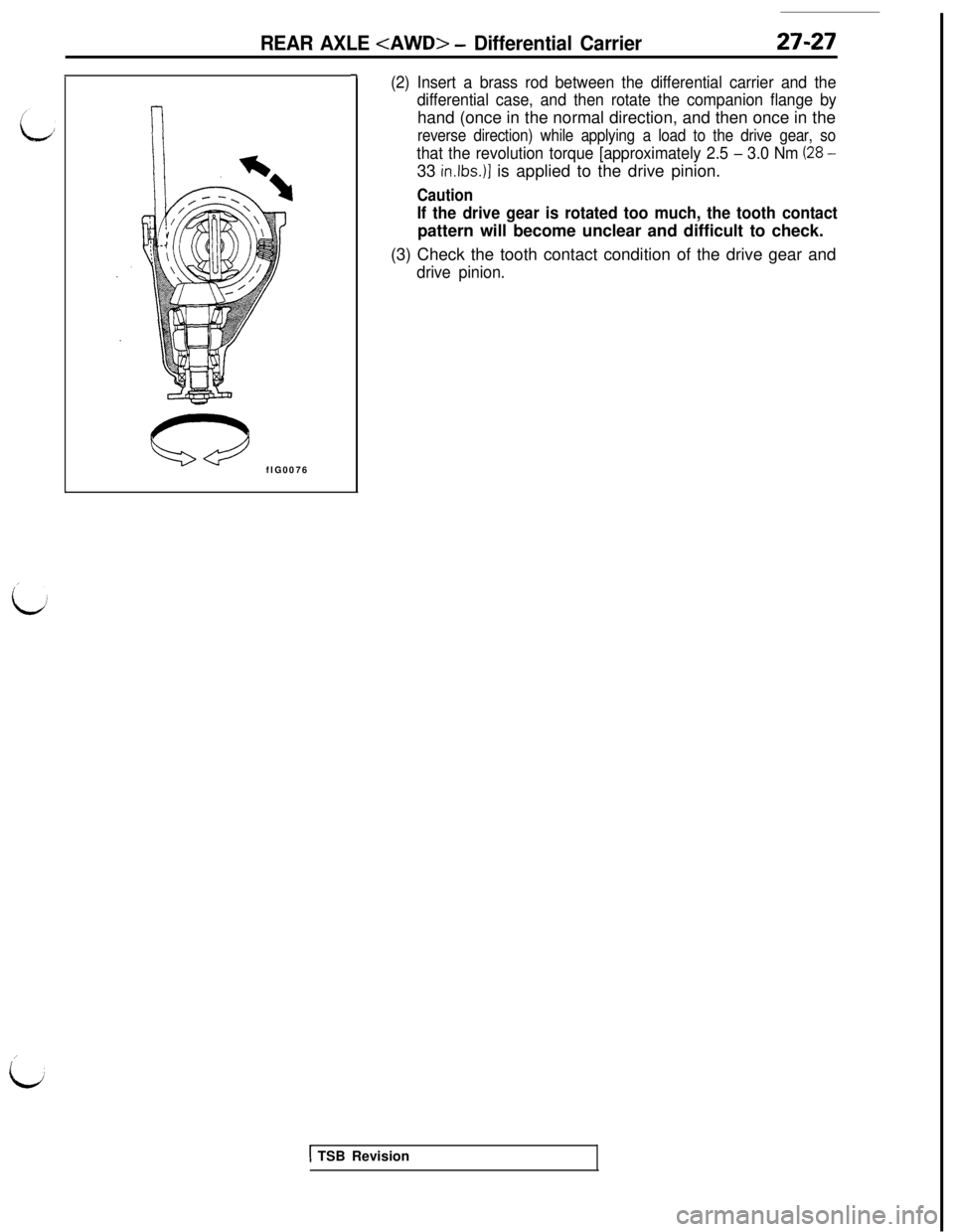

-7(2) Insert a brass rod between the differential carrier and the

differential case, and then rotate the companion flange byhand (once in the normal direction, and then once in the

reverse direction) while applying a load to the drive gear, so

that the revolution torque [approximately 2.5 - 3.0 Nm (28 -33

in.lbs.)] is applied to the drive pinion.

Caution

If the drive gear is rotated too much, the tooth contactpattern will become unclear and difficult to check.

(3) Check the tooth contact condition of the drive gear and

drive pinion.

1 TSB Revision

Page 624 of 1146

27-28

REAR AXLE

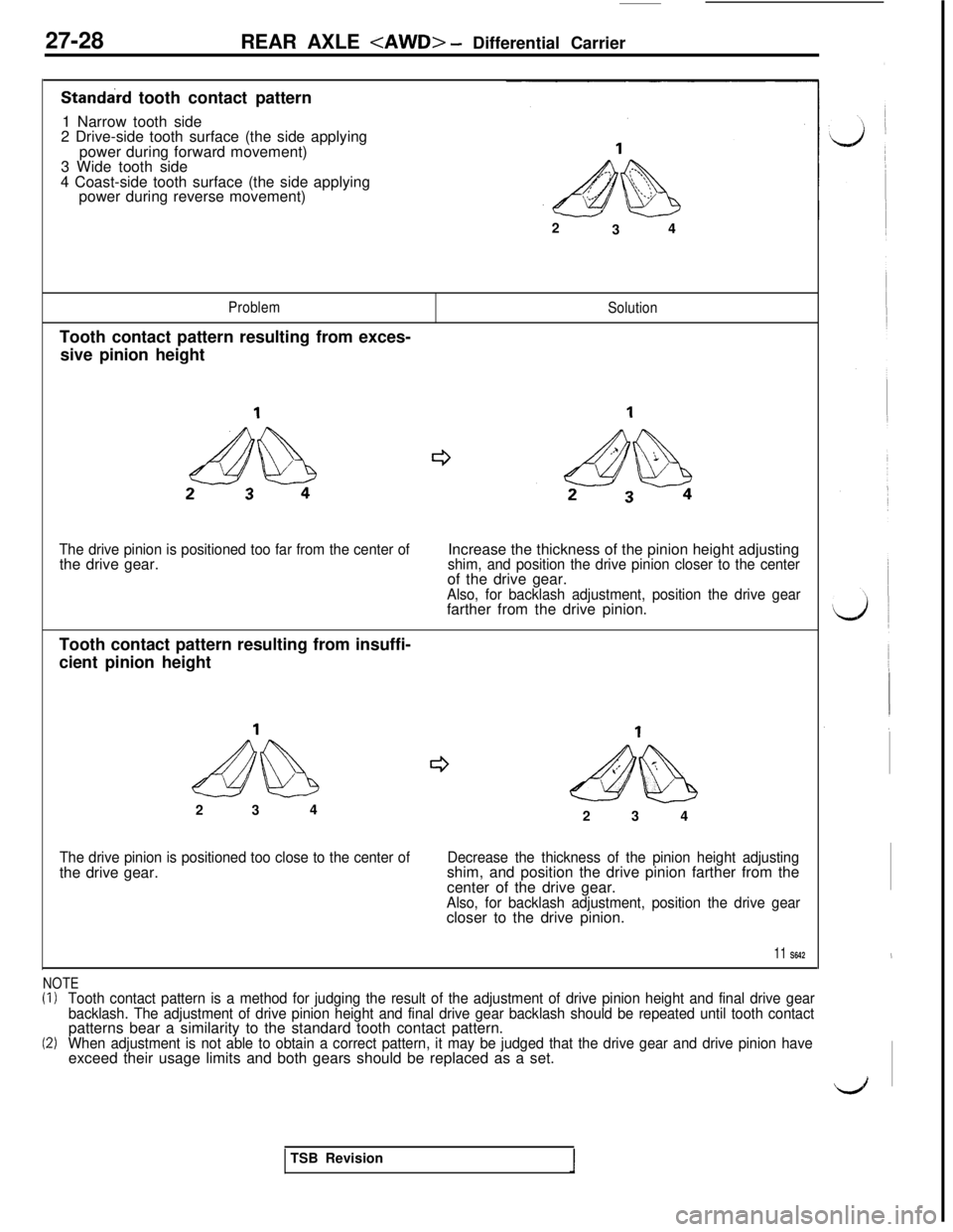

Standard tooth contact pattern

1 Narrow tooth side

2 Drive-side tooth surface (the side applying

power during forward movement)

3 Wide tooth side

4 Coast-side tooth surface (the side applying

power during reverse movement)

2

34

ProblemTooth contact pattern resulting from exces-

sive pinion heightSolution

The drive pinion is positioned too far from the center ofthe drive gear.Increase the thickness of the pinion height adjustingshim, and position the drive pinion closer to the centerof the drive gear.

Also, for backlash adjustment, position the drive gearfarther from the drive pinion.

Tooth contact pattern resulting from insuffi-

cient pinion height

ectdb

e52 34&$%$I$&2 3 4

The drive pinion is positioned too close to the center ofthe drive gear.Decrease the thickness of the pinion height adjustingshim, and position the drive pinion farther from the

center of the drive gear.

Also, for backlash adjustment, position the drive gearcloser to the drive pinion.

11 S642

NOTE(I)Tooth contact pattern is a method for judging the result of the adjustment of drive pinion height and final drive gear

backlash. The adjustment of drive pinion height and final drive gear backlash should be repeated until tooth contactpatterns bear a similarity to the standard tooth contact pattern.

(2)When adjustment is not able to obtain a correct pattern, it may be judged that the drive gear and drive pinion haveexceed their usage limits and both gears should be replaced as a set.

,

dTSB Revision

Page 625 of 1146

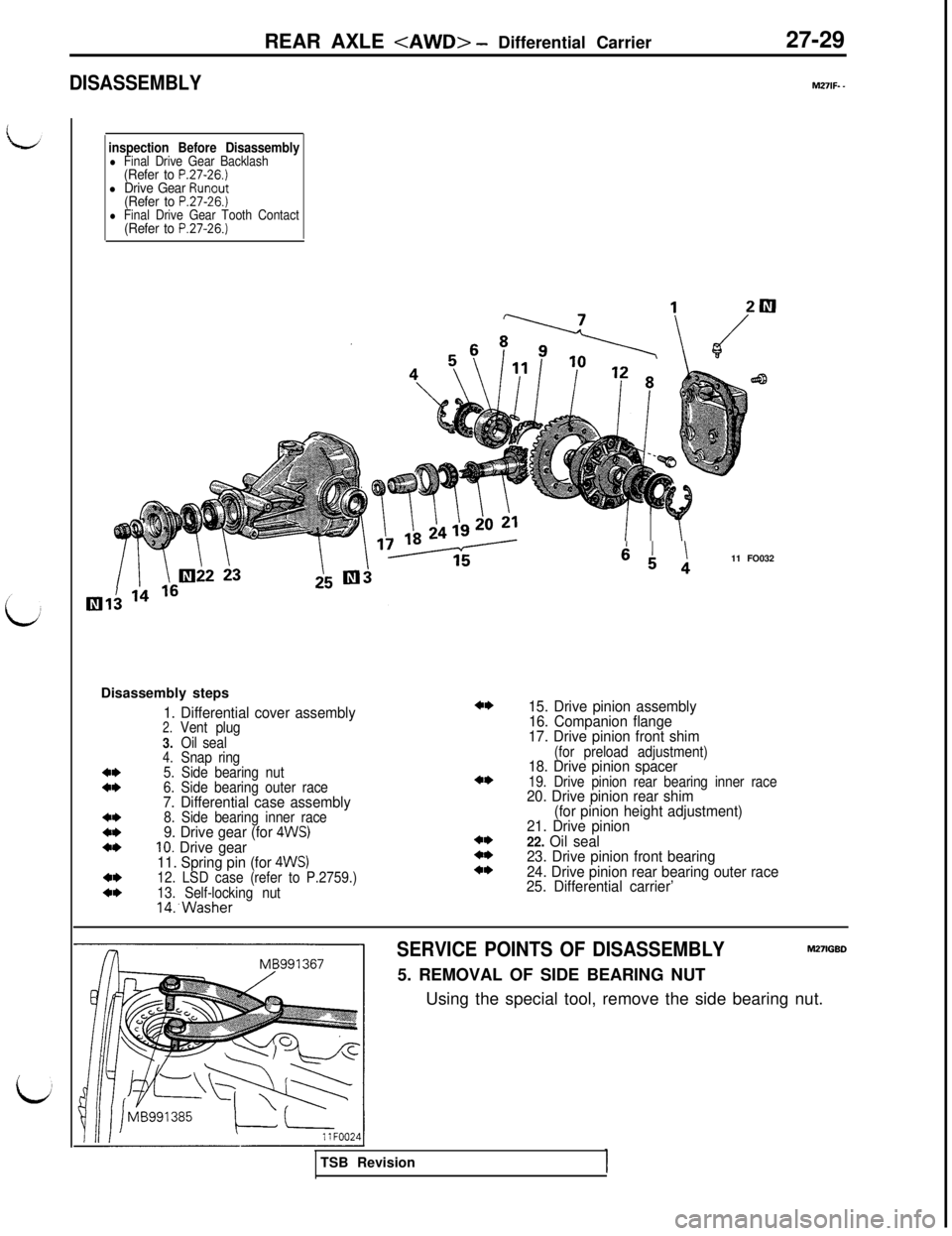

DISASSEMBLYREAR AXLE

M27lF- -

inspection Before Disassemblyl Final Drive Gear Backlash(Refer to P.27-26.)l Drive Gear Runout(Refer to P.27-26.)l Final Drive Gear Tooth Contact(Refer to P.27-26.)Disassembly steps

1. Differential cover assembly2.Vent plug

3.Oil seal

4.Snap ring4*5. Side bearing nut4*6. Side bearing outer race7. Differential case assembly4*8. Side bearing inner race4*9. Drive gear (for 4WS)4*10. Drive gear

11. Spring pin (for 4WS)4*12. LSD case (refer to P.2759.)4*13. Self-locking nut14:Washer

4*

4*

4*4*4*

64 111 FO032

15. Drive pinion assembly

16. Companion flange

17. Drive pinion front shim

(for preload adjustment)18. Drive pinion spacer19. Drive pinion rear bearing inner race20. Drive pinion rear shim

(for pinion height adjustment)

21. Drive pinion

22. Oil seal

23. Drive pinion front bearing

24. Drive pinion rear bearing outer race

25. Differential carrier’

SERVICE POINTS OF DISASSEMBLYM27lGBD5. REMOVAL OF SIDE BEARING NUT

Using the special tool, remove the side bearing nut.

TSB Revision

Page 626 of 1146

27-30REAR AXLE

VlB990811-01

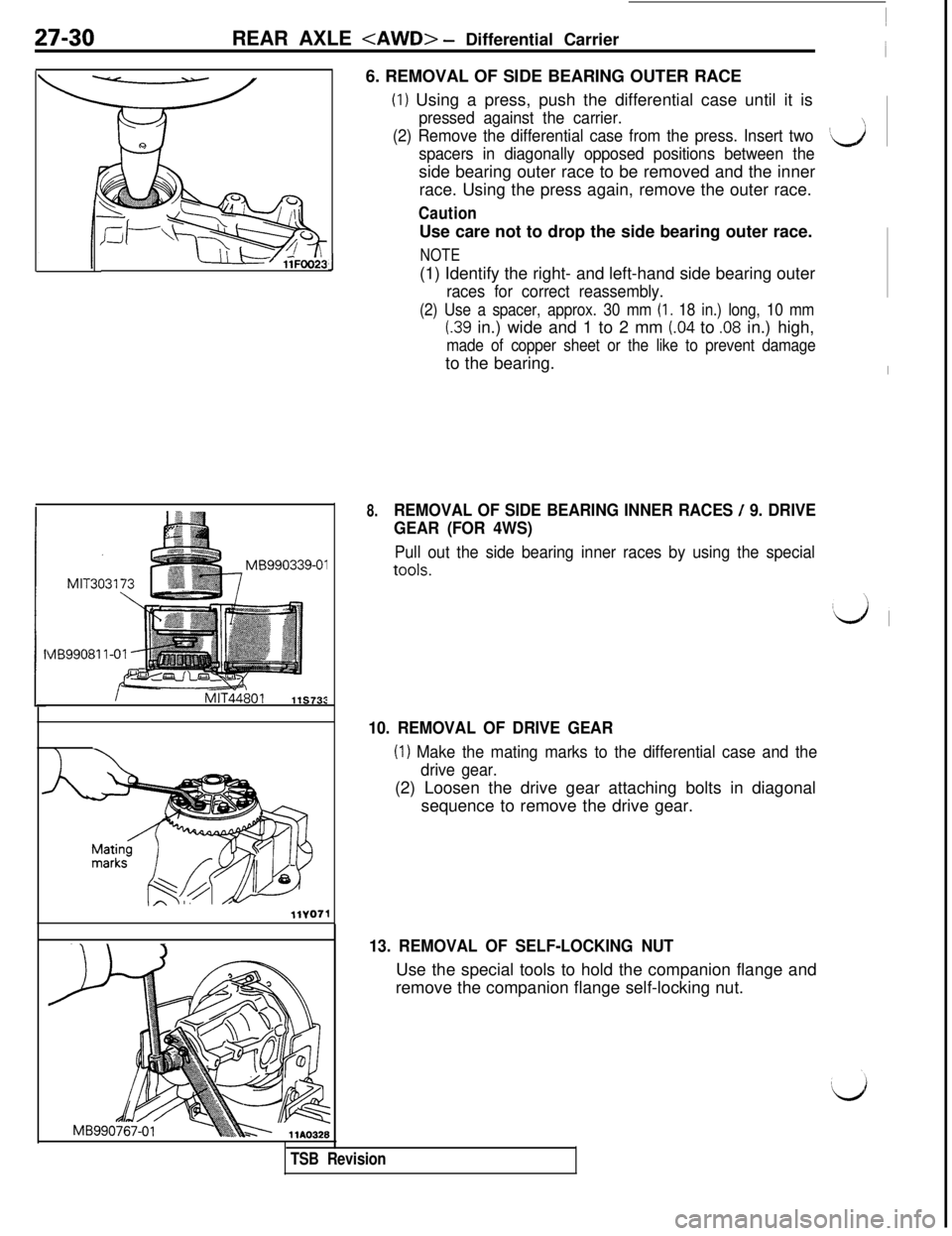

J6. REMOVAL OF SIDE BEARING OUTER RACE

(I) Using a press, push the differential case until it is

pressed against the carrier.

(2) Remove the differential case from the press. Insert two

spacers in diagonally opposed positions between the‘dside bearing outer race to be removed and the inner

race. Using the press again, remove the outer race.

CautionUse care not to drop the side bearing outer race.

NOTE(1) Identify the right- and left-hand side bearing outer

races for correct reassembly.

(2) Use a spacer, approx. 30 mm (I. 18 in.) long, 10 mm

I.39 in.) wide and 1 to 2 mm (.04 to .08 in.) high,

made of copper sheet or the like to prevent damageto the bearing.

8.REMOVAL OF SIDE BEARING INNER RACES / 9. DRIVE

GEAR (FOR 4WS)

Pull out the side bearing inner races by using the special

tools.

10. REMOVAL OF DRIVE GEAR

(I) Make the mating marks to the differential case and the

drive gear.(2) Loosen the drive gear attaching bolts in diagonal

sequence to remove the drive gear.

13. REMOVAL OF SELF-LOCKING NUTUse the special tools to hold the companion flange and

remove the companion flange self-locking nut.

TSB Revision

Page 627 of 1146

REAR AXLE

Mating marks

MB990339-01

llY175J

1

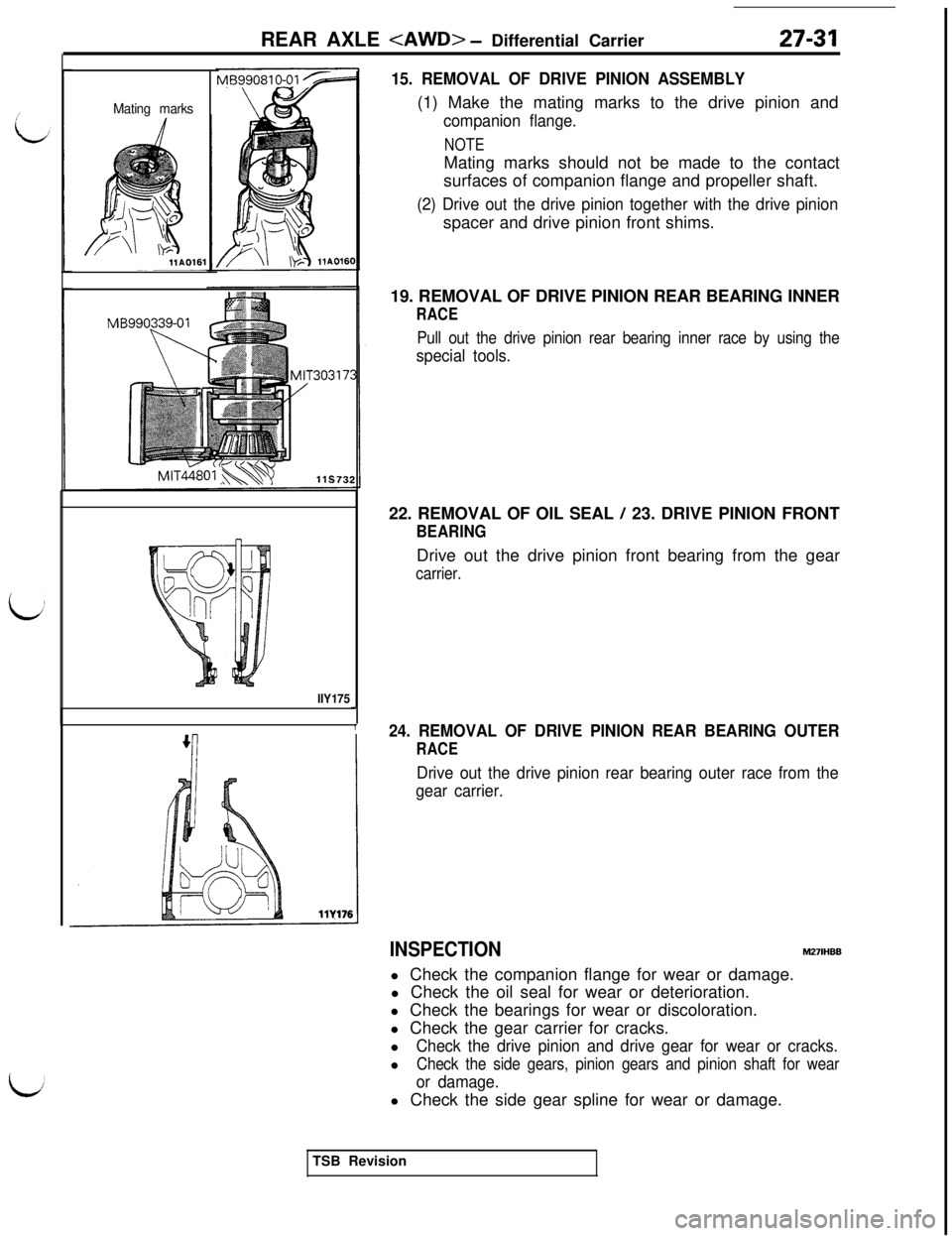

15. REMOVAL OF DRIVE PINION ASSEMBLY(1) Make the mating marks to the drive pinion and

companion flange.

NOTEMating marks should not be made to the contact

surfaces of companion flange and propeller shaft.

(2) Drive out the drive pinion together with the drive pinionspacer and drive pinion front shims.

19. REMOVAL OF DRIVE PINION REAR BEARING INNER

RACE

Pull out the drive pinion rear bearing inner race by using the

special tools.22. REMOVAL OF OIL SEAL

/ 23. DRIVE PINION FRONT

BEARINGDrive out the drive pinion front bearing from the gear

carrier.

24. REMOVAL OF DRIVE PINION REAR BEARING OUTER

RACE

Drive out the drive pinion rear bearing outer race from the

gear carrier.

INSPECTIONM27lHBBl Check the companion flange for wear or damage.

l Check the oil seal for wear or deterioration.

l Check the bearings for wear or discoloration.

l Check the gear carrier for cracks.

l

Check the drive pinion and drive gear for wear or cracks.l

Check the side gears, pinion gears and pinion shaft for wear

or damage.l Check the side gear spline for wear or damage.

TSB Revision