engine oil MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 5 of 1146

,

b

00-I

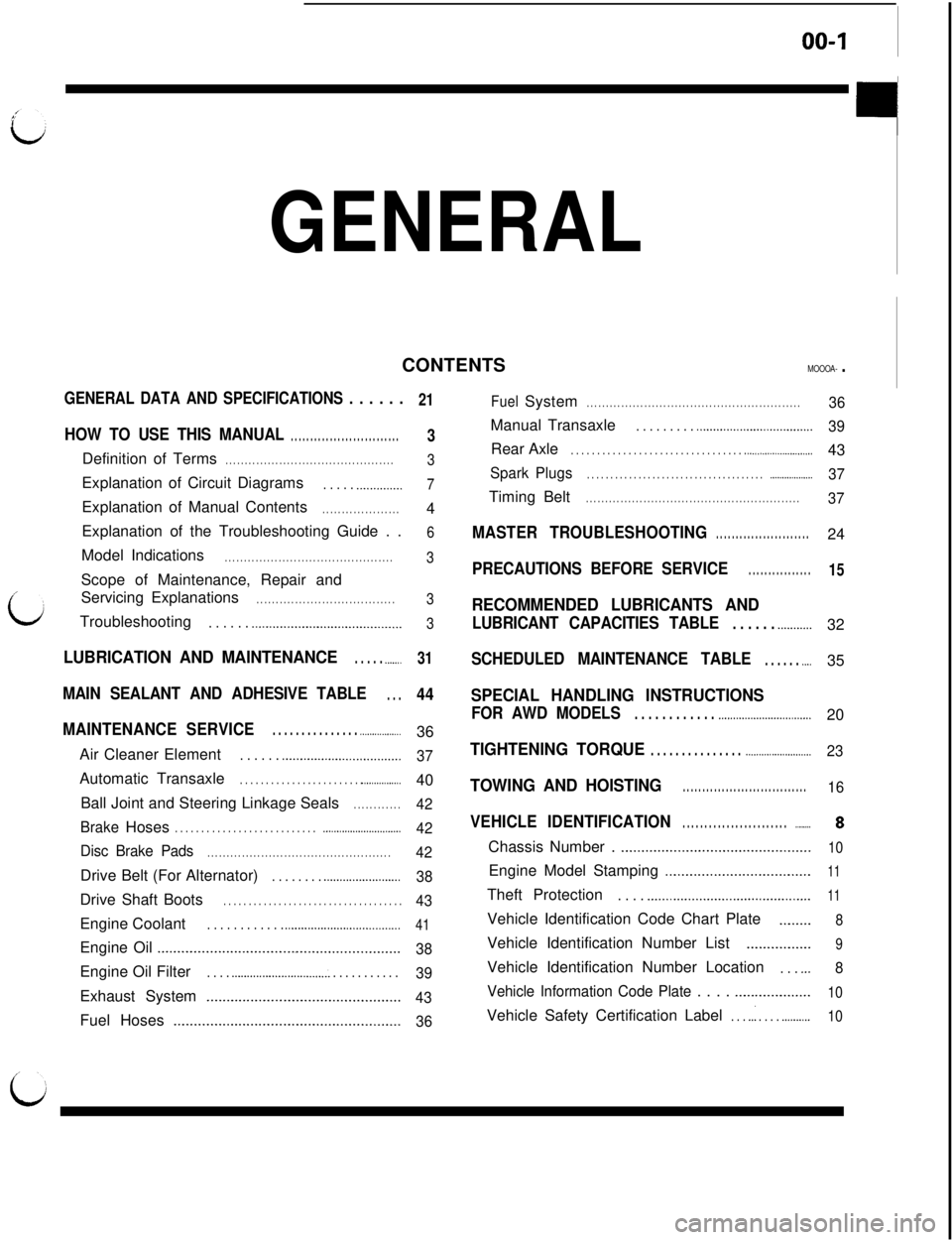

GENERALCONTENTS

MOOOA- .

GENERAL DATA AND SPECIFICATIONS . . . . . .21

HOW TO USE THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . .3Definition of Terms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Explanation of Circuit Diagrams

. . . . . .._...........7Explanation of Manual Contents

. . . . . . . . . . . . . . . . . . . .4

Explanation of the Troubleshooting Guide . .

6ModelIndications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Scope of Maintenance, Repair and

ServicingExplanations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Troubleshooting

. . . . . . .._.......................................3

LUBRICATION AND MAINTENANCE. . . . . .._....31SCHEDULED MAINTENANCE TABLE. . . . . . .._.

MAIN SEALANT AND ADHESIVE TABLE. . .44

MAINTENANCE SERVICE

. . . . . . . . . . . . . . . .._......_.....__Air Cleaner Element

. . . . . . .._......._......_................Automatic Transaxle

. . . . . . . . . . . . . . . . . . . . . . . . .._......._.....Ball Joint and Steering Linkage Seals

. . . . . . . . . . . .

BrakeHoses. . . . . . . . . . . . . . . . . . . . . . . . . . . .._......._.._...._......._..

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Drive Belt (For Alternator)

. . . . . . . . .._.........._..........Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engine Coolant

. . . . . . . . . . . . ..__.._.............................Engine Oil

.._....__._.................................................Engine Oil Filter

. . . . .._._.......__.................. . . . . . . . . . . .Exhaust System

_....._......._.....__._............,...........Fuel Hoses

..__......__............................................36

3740

42

42

42

38

43

41

38

39

43

36

FuelSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Manual Transaxle

. . . . . . . . . .._........................_.......Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._..._.._..____.._.......

SparkPlugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...............TimingBelt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MASTER TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . .

PRECAUTIONS BEFORE SERVICE. . . . . . . . . . . . . . . .

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE. . . . . . .._........

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS. . . . . . . . . . . . .._...._........................

TIGHTENING TORQUE. . . . . . . . . . . . . . . ..__.....................

TOWING AND HOISTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . .._.....Chassis Number .

.._............................................Engine Model Stamping

.._..........................._...._Theft Protection

. . . . .._.........................................Vehicle Identification Code Chart Plate

.._.....Vehicle Identification Number List

.._._....._..._.Vehicle Identification Number Location

. . . .._

Vehicle Information Code Plate . . . . .._._......_.......Vehicle Safety Certification Label

. . . ..I . . . . .._..._...

36

3943

37

3724

1532

35

20

23

16

8

10

11

11

8

9

8

10

10

Page 8 of 1146

GENERAL - How to Use This Manual

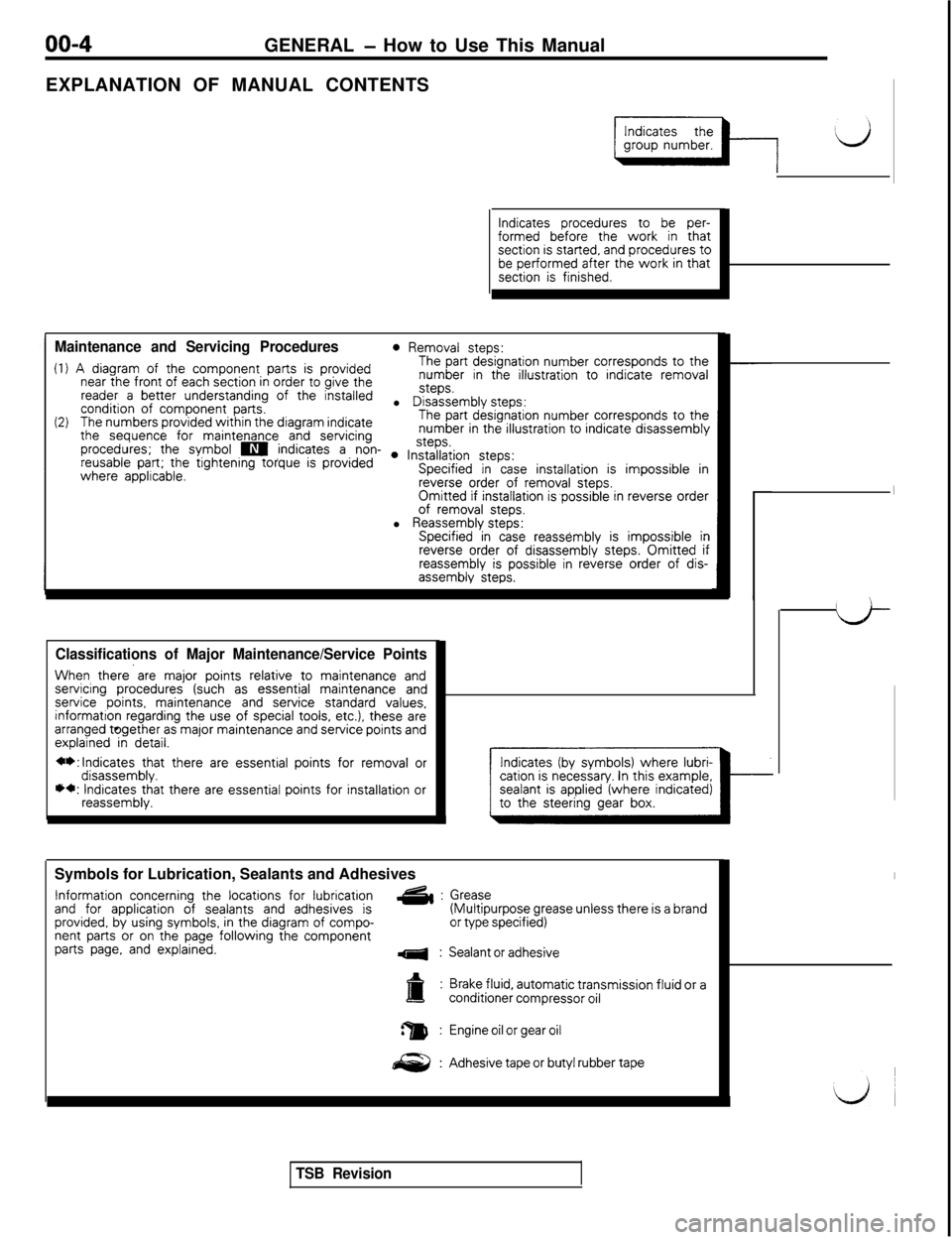

EXPLANATION OF MANUAL CONTENTS

Indicates procedures to be per-formed before the work in thatsection is started, and procedures tobe performed after the work in thatsection is finished.

Maintenance and Servicing Procedures0 Removal steps:

(1) A diagram of the component parts is providedThe part designation number corresponds to the

near the front of each section in order to give thenumber in the illustration to indicate removal

reader a better understanding of the installedsteps.

condition of component parts.l Disassembly steps:

(2)The numbers provided within the diagram indicateThe part designation number corresponds to the

the sequence for maintenance and servicingnumber in the illustration to indicate disassembly

procedures; the symbol m indicates a non- . ln~~~~iion steps:reusable part; the tightening torque is providedwhere applicable.Specified in case installation is impossible inreverse order of removal steps.Omitted if installation is,possible in reverse orderof removal steps.l Reassembly steps:Specified in case reassembly is impossible inreverse order of disassembly steps. Omitted ifreassembly is possible in reverse order of dis-assembly steps.

Classifications of Major Maintenance/Service Points

When there’are major points relative to maintenance andservicing procedures (such as essential maintenance andservice points, maintenance and service standard values,informatton regarding the use of special toois, etc.), these arearranged together as major maintenance and service points andexplained in detail.

**:lndicates that there are essential points for removal ordisassembly.*+: Indicates that there are essential points for installation orreassembly.Symbols for Lubrication, Sealants and Adhesives

Information concerning the locations for lubricationand for application of sealants and adhesives isG&:

provided, by using symbols, in the diagram of compo-nent parts or on the page following the componentparts page, and explained.4:

Indicates (by symbols) where lubri-cation is necessary. In this example,

Grease(Multipurpose grease unless there is a brandor type specified)

Sealant or adhesive

Brake fluid, automatic transmission fluid or aconditioner compressor oil

Engine oil or gear oil

Adhesive tape or butyl rubber tape

TSB Revision

Page 30 of 1146

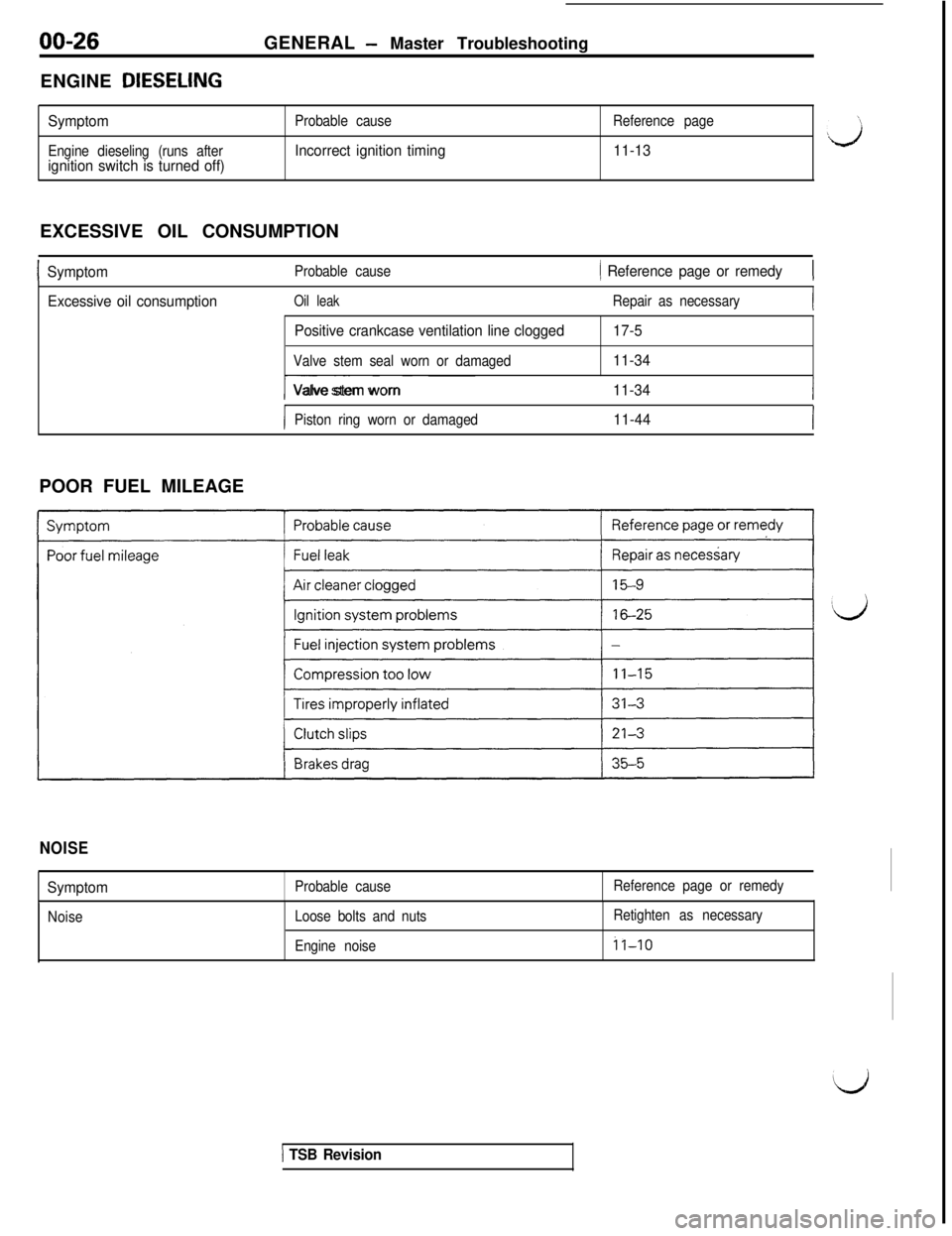

00-26GENERAL - Master Troubleshooting

ENGINE DIESELING

Symptom

Engine dieseling (runs afterignition switch is turned off)

Probable cause

Incorrect ignition timing

Reference page

11-13EXCESSIVE OIL CONSUMPTION

ISymptomProbable cause( Reference page or remedy(

Excessive oil consumptionOil leakRepair as necessary

Positive crankcase ventilation line clogged

Valve stem seal worn or damaged

17-5

11-34

I----Valve stem worn11-34I

IPiston ring worn or damaged11-44IPOOR FUEL MILEAGE

NOISE

SymptomProbable causeReference page or remedy

NoiseLoose bolts and nutsRetighten as necessary

Engine noise

il-10

) TSB Revision

Page 35 of 1146

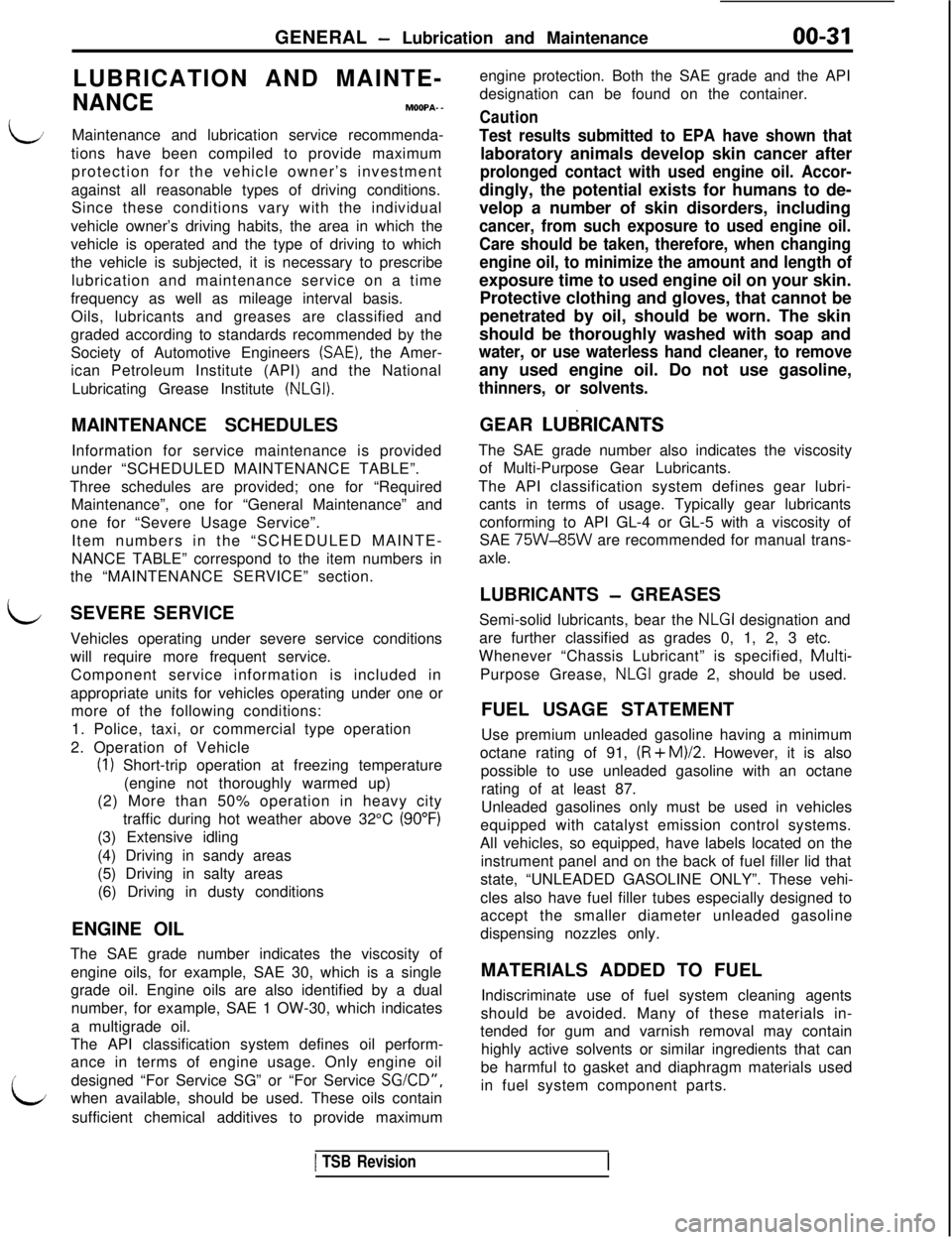

GENERAL - Lubrication and Maintenance00-31LUBRICATION AND MAINTE-

NANCEMOOPA- -

iiMaintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the

Society of Automotive Engineers

(SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

LSEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one or

more of the following conditions:

1. Police, taxi, or commercial type operation

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above 32°C

(90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE 1 OW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

idesigned “For Service SG” or “For Service

SGXD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximumengine protection. Both the SAE grade and the API

designation can be found on the container.

Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-dingly, the potential exists for humans to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be taken, therefore, when changing

engine oil, to minimize the amount and length ofexposure time to used engine oil on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.GEAR

LUEiRlCANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classification system defines gear lubri-

cants in terms of usage. Typically gear lubricants

conforming to API GL-4 or GL-5 with a viscosity of

SAE

75W-85W are recommended for manual trans-

axle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the

NLGI designation and

are further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified,

Multi-Purpose Grease,

NLGI grade 2, should be used.

FUEL USAGE STATEMENT

Use premium unleaded gasoline having a minimum

octane rating of 91,

(R + M)/2. However, it is also

possible to use unleaded gasoline with an octane

rating of at least 87.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed to

accept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED TO FUEL

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials used

in fuel system component parts.

1 TSB Revision

Page 36 of 1146

00-32 GENERAL - Recommended Lubricants and Lubricant Capacities Table

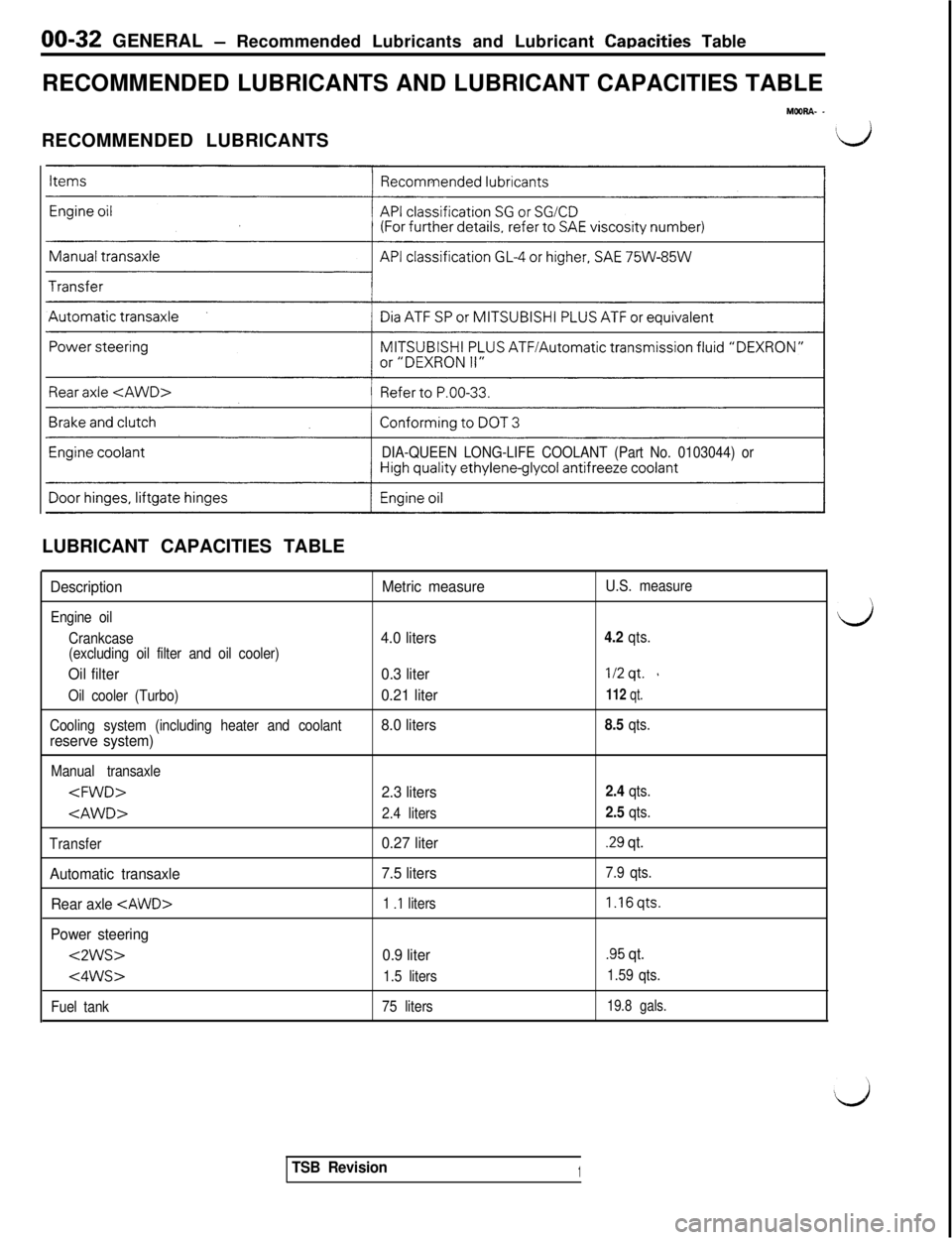

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

MOORA- -RECOMMENDED LUBRICANTS

\L/

DIA-QUEEN LONG-LIFE COOLANT (Part No. 0103044) orLUBRICANT CAPACITIES TABLE

Description

Engine oil

Crankcase

(excluding oil filter and oil cooler)

Oil filter

Oil cooler (Turbo)

Cooling system (including heater and coolant

reserve system)

Manual transaxle

Transfer

Automatic transaxle

Rear axle

Power steering

<2ws>

<4ws>

Fuel tank

Metric measureU.S. measure

4.0 liters4.2 qts.

0.3 liter1/2qt. s

0.21 liter112 qt.

8.0 liters8.5 qts.

2.3 liters2.4 qts.

2.4 liters

2.5 qts.

0.27 liter.29 qt.

7.5 liters

7.9 qts.

1

.I liters1.16qts.

0.9 liter

.95 qt.

1.5 liters1.59 qts.

75 liters

19.8 gals.

TSB Revision1

d

Page 37 of 1146

GENERAL - Recommended Lubricants and Lubricant Capacities Table 00-334027

8016

60

1050032

-1014

-155

-20-4-23-10

-29-20104

6SAE 5W-20 Not recommended for sustainedhigh speed vehicle operation.

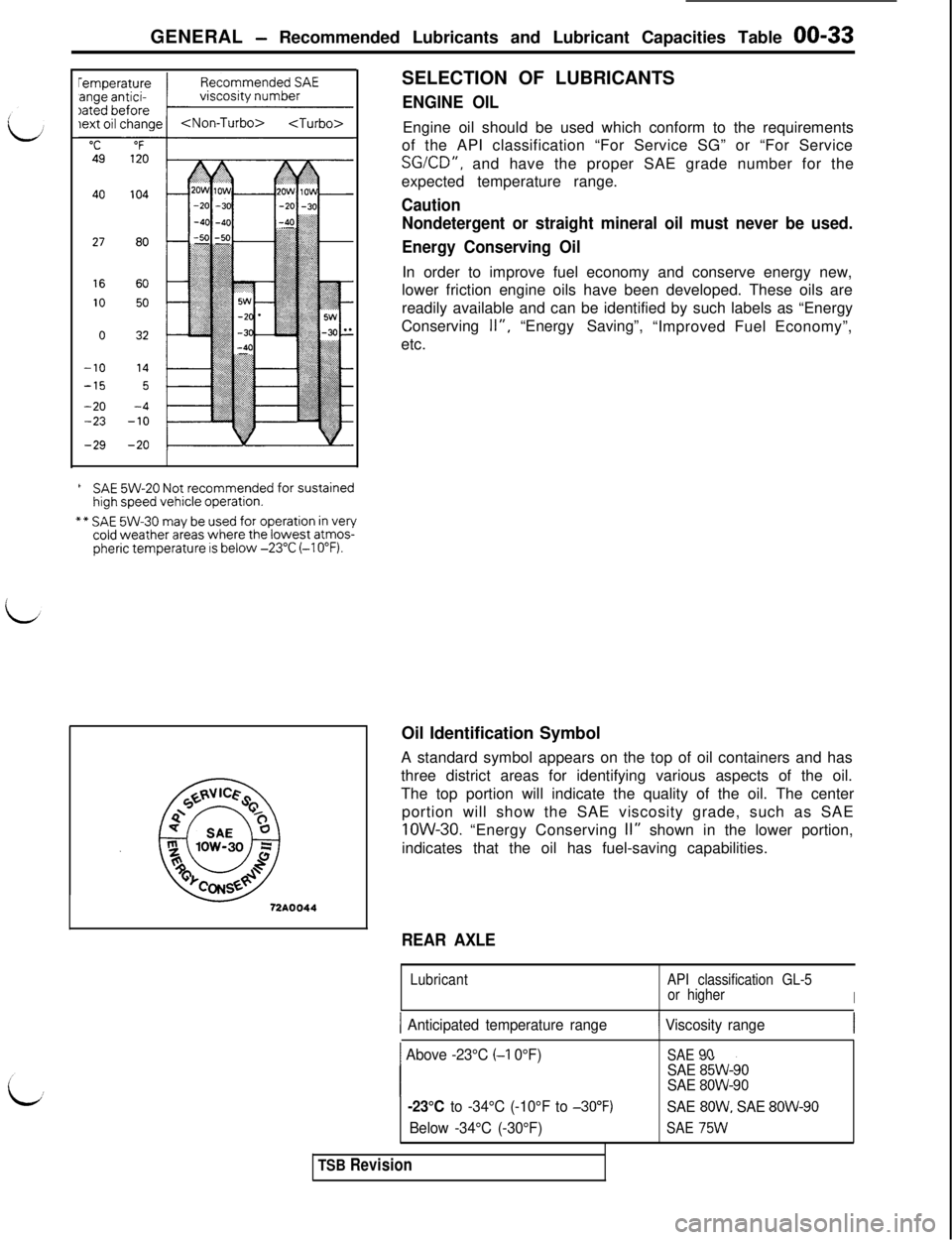

** SAE 5W-30 may be used for operation in verycold weather areas where the lowest atmos-pheric temperature is below -23°C (-10°F).SELECTION OF LUBRICANTS

ENGINE OILEngine oil should be used which conform to the requirements

of the API classification “For Service SG” or “For Service

SGKD”, and have the proper SAE grade number for the

expected temperature range.

Caution

Nondetergent or straight mineral oil must never be used.

Energy Conserving OilIn order to improve fuel economy and conserve energy new,

lower friction engine oils have been developed. These oils are

readily available and can be identified by such labels as “Energy

Conserving

II”,“Energy Saving”,

“Improved Fuel Economy”,

etc.

Oil Identification Symbol

A standard symbol appears on the top of oil containers and has

three district areas for identifying various aspects of the oil.

The top portion will indicate the quality of the oil. The center

portion will show the SAE viscosity grade, such as SAEIOW-30. “Energy Conserving

II” shown in the lower portion,

indicates that the oil has fuel-saving capabilities.

72AOO.34

REAR AXLE

LubricantAPI classification GL-5

or higher

I

1 Anticipated temperature range

1 Above -23°C k-1 0°F)

1 Viscosity range

-23°C to -34°C (-10°F to -30°F)

Below -34°C (-30°F)

SAE 90SAE 85W-90SAE 8OW-90

SAE 80W. SAE 8OW-90

SAE 75W

TSB Revision

Page 40 of 1146

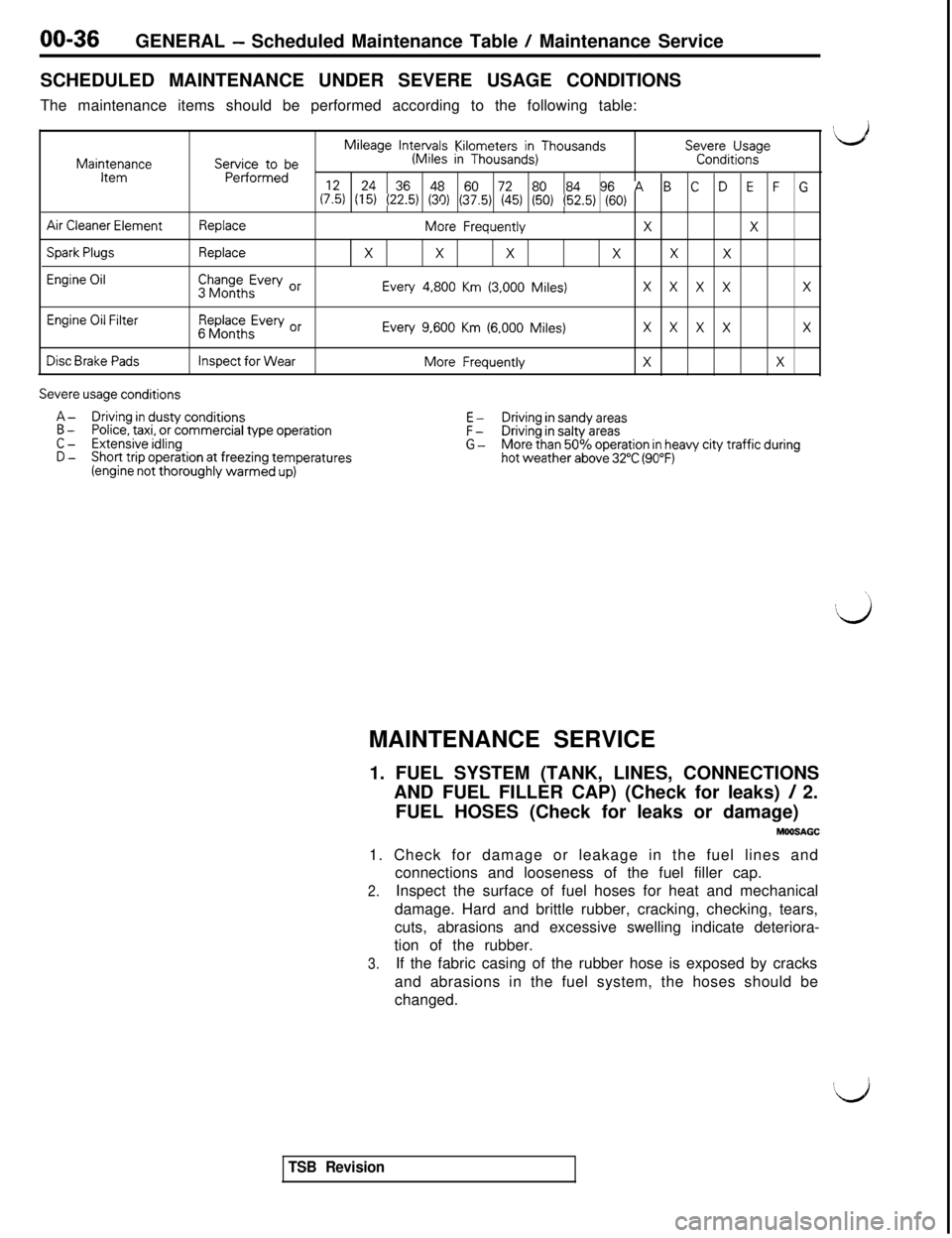

00-36GENERAL - Scheduled Maintenance Table / Maintenance Service

SCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

Mileage Intervals Kilometers in ThousandsSevere Usage

MaintenanceService to be(Miles in Thousands)Conditions

itemPerformed

(6 (15) (22.5) (30) (37.5) (45) (50) (52.5) (60)24 36 48 60 72 80 84 96 A B C D E F G

Air Cleaner ElementReplaceMore FrequentlyXX

Spark PlugsReplaceXXXXXX

Engine OilChange Every Or3 MonthsEvery 4,800 Km (3,000 Miles)x x x xX

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 Km (6.000 Miles)x x x xX

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditions

A-Driving in dusty conditionsE -B -Police, taxi, or commercial type operationF -Driving in sandy areas

C -Extensive idlingG -Driving in salty areas

D -Short trip operation at freezing temperaturesMore than 50% operation in heavy city traffic during

(engine not thoroughly warmed up)hot weather above 32°C (90°F)MAINTENANCE SERVICE

1. FUEL SYSTEM (TANK, LINES, CONNECTIONS

AND FUEL FILLER CAP) (Check for leaks)

/ 2.

FUEL HOSES (Check for leaks or damage)MWShGC

1. Check for damage or leakage in the fuel lines and

connections and looseness of the fuel filler cap.

2.Inspect the surface of fuel hoses for heat and mechanical

damage. Hard and brittle rubber, cracking, checking, tears,

cuts, abrasions and excessive swelling indicate deteriora-

tion of the rubber.

3.If the fabric casing of the rubber hose is exposed by cracks

and abrasions in the fuel system, the hoses should be

changed.

TSB Revision

Page 42 of 1146

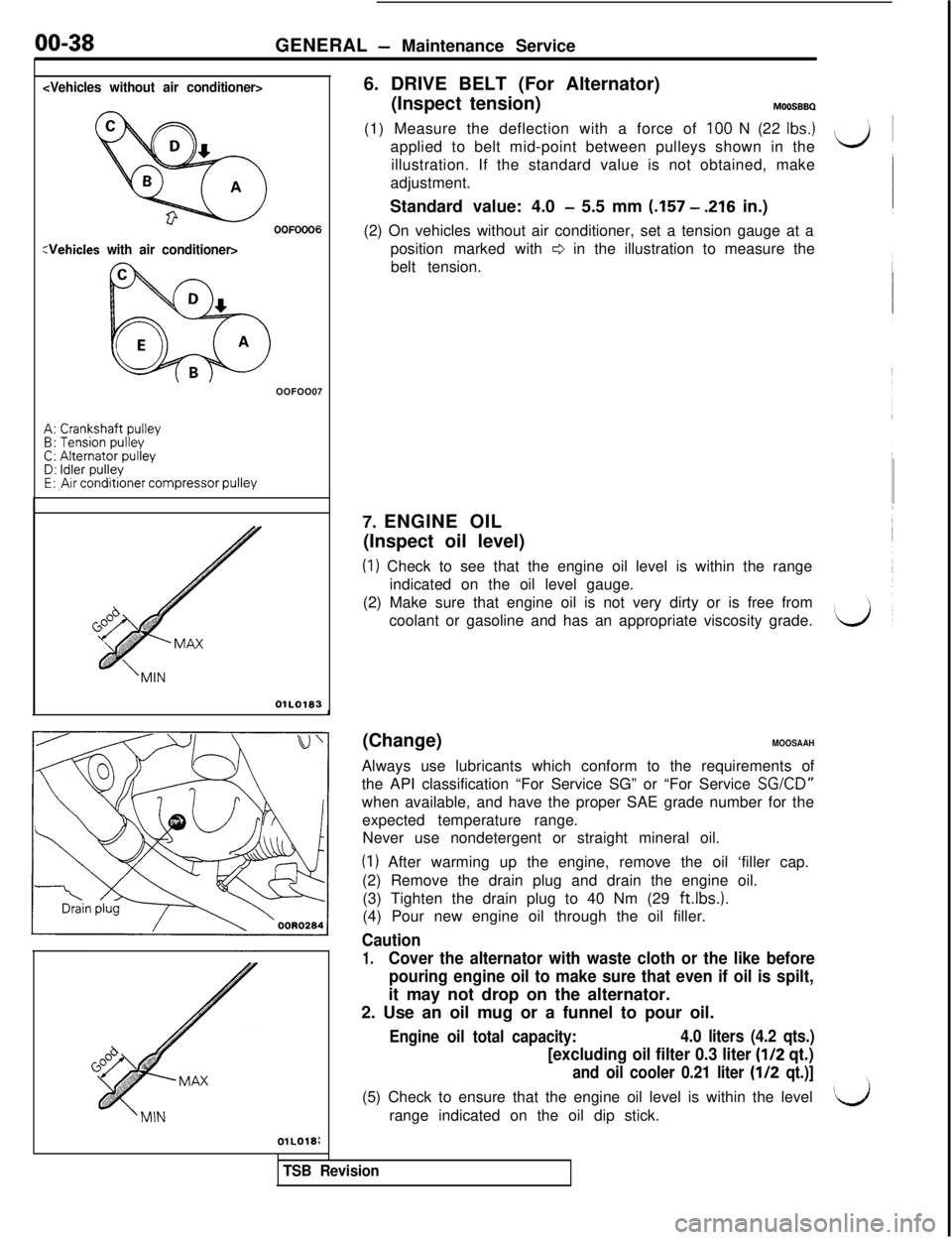

00-38GENERAL - Maintenance Service

00F0006

:Vehicles with air conditioner>OOFOO07

A: Crankshaft pulleyB: Tension pulleyC: Alternator pulleyD: Idler pulleyE: ,Air conditioner compressor pulley

OlLO183

OlLO18:(Inspect tension)

MOOS88(1(1) Measure the deflection with a force of

100 N (22 Ibs.)applied to belt mid-point between pulleys shown in the

illustration. If the standard value is not obtained, make

adjustment.

Standard value: 4.0

- 5.5 mm (.157 - 216 in.)

(2) On vehicles without air conditioner, set a tension gauge at a

position marked with

r3 in the illustration to measure the

belt tension.

7. ENGINE OIL

(Inspect oil level)

(I) Check to see that the engine oil level is within the range

indicated on the oil level gauge.

(2) Make sure that engine oil is not very dirty or is free from

coolant or gasoline and has an appropriate viscosity grade.J

(Change)

MOOSAAHAlways use lubricants which conform to the requirements of

the API classification “For Service SG” or “For Service

SGKD”when available, and have the proper SAE grade number for the

expected temperature range.

Never use nondetergent or straight mineral oil.

(1) After warming up the engine, remove the oil ‘filler cap.

(2) Remove the drain plug and drain the engine oil.

(3) Tighten the drain plug to 40 Nm (29 ft.lbs.).

(4) Pour new engine oil through the oil filler.

Caution

1.Cover the alternator with waste cloth or the like before

pouring engine oil to make sure that even if oil is spilt,it may not drop on the alternator.

2. Use an oil mug or a funnel to pour oil.

Engine oil total capacity:4.0 liters (4.2 qts.)

[excluding oil filter 0.3 liter (l/2 qt.)

and oil cooler 0.21 liter (l/2 qt.)](5) Check to ensure that the engine oil level is within the level

range indicated on the oil dip stick.

TSB Revision

Page 43 of 1146

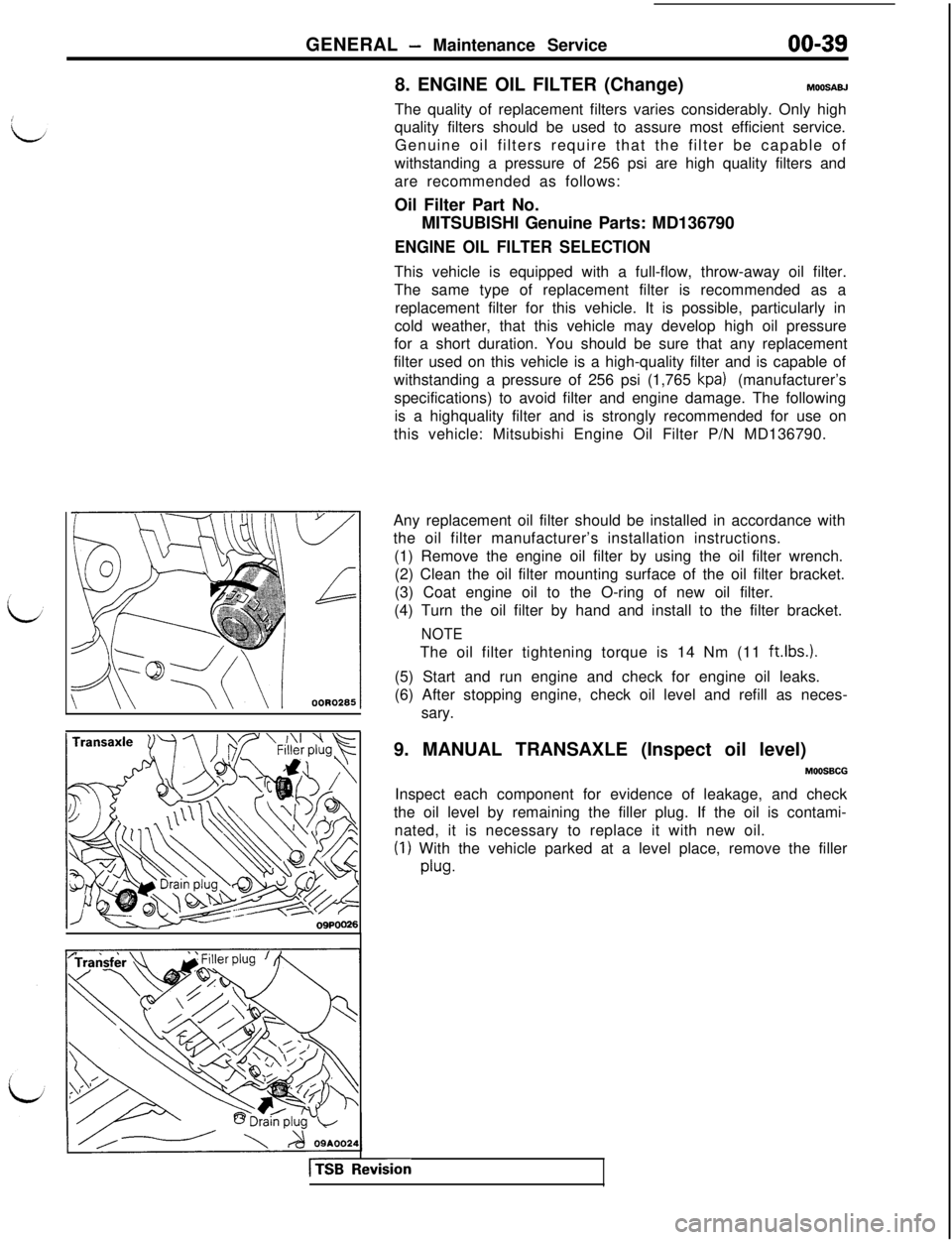

GENERAL - Maintenance Service00-39ogPOO268. ENGINE OIL FILTER (Change)

MOOEAEJThe quality of replacement filters varies considerably. Only high

quality filters should be used to assure most efficient service.

Genuine oil filters require that the filter be capable of

withstanding a pressure of 256 psi are high quality filters and

are recommended as follows:

Oil Filter Part No.

MITSUBISHI Genuine Parts: MD136790

ENGINE OIL FILTER SELECTIONThis vehicle is equipped with a full-flow, throw-away oil filter.

The same type of replacement filter is recommended as a

replacement filter for this vehicle. It is possible, particularly in

cold weather, that this vehicle may develop high oil pressure

for a short duration. You should be sure that any replacement

filter used on this vehicle is a high-quality filter and is capable of

withstanding a pressure of 256 psi (1,765

kpa) (manufacturer’s

specifications) to avoid filter and engine damage. The following

is a highquality filter and is strongly recommended for use on

this vehicle: Mitsubishi Engine Oil Filter P/N MD136790.

Any replacement oil filter should be installed in accordance with

the oil filter manufacturer’s installation instructions.

(1) Remove the engine oil filter by using the oil filter wrench.

(2) Clean the oil filter mounting surface of the oil filter bracket.

(3) Coat engine oil to the O-ring of new oil filter.

(4) Turn the oil filter by hand and install to the filter bracket.

NOTEThe oil filter tightening torque is 14 Nm (11

ft.lbs.1.(5) Start and run engine and check for engine oil leaks.

(6) After stopping engine, check oil level and refill as neces-

sary.

9. MANUAL TRANSAXLE (Inspect oil level)

MOOSBCGInspect each component for evidence of leakage, and check

the oil level by remaining the filler plug. If the oil is contami-

nated, it is necessary to replace it with new oil.

(1) With the vehicle parked at a level place, remove the filler

plug.

-Revision

Page 45 of 1146

GENERAL - Maintenance Service00-41

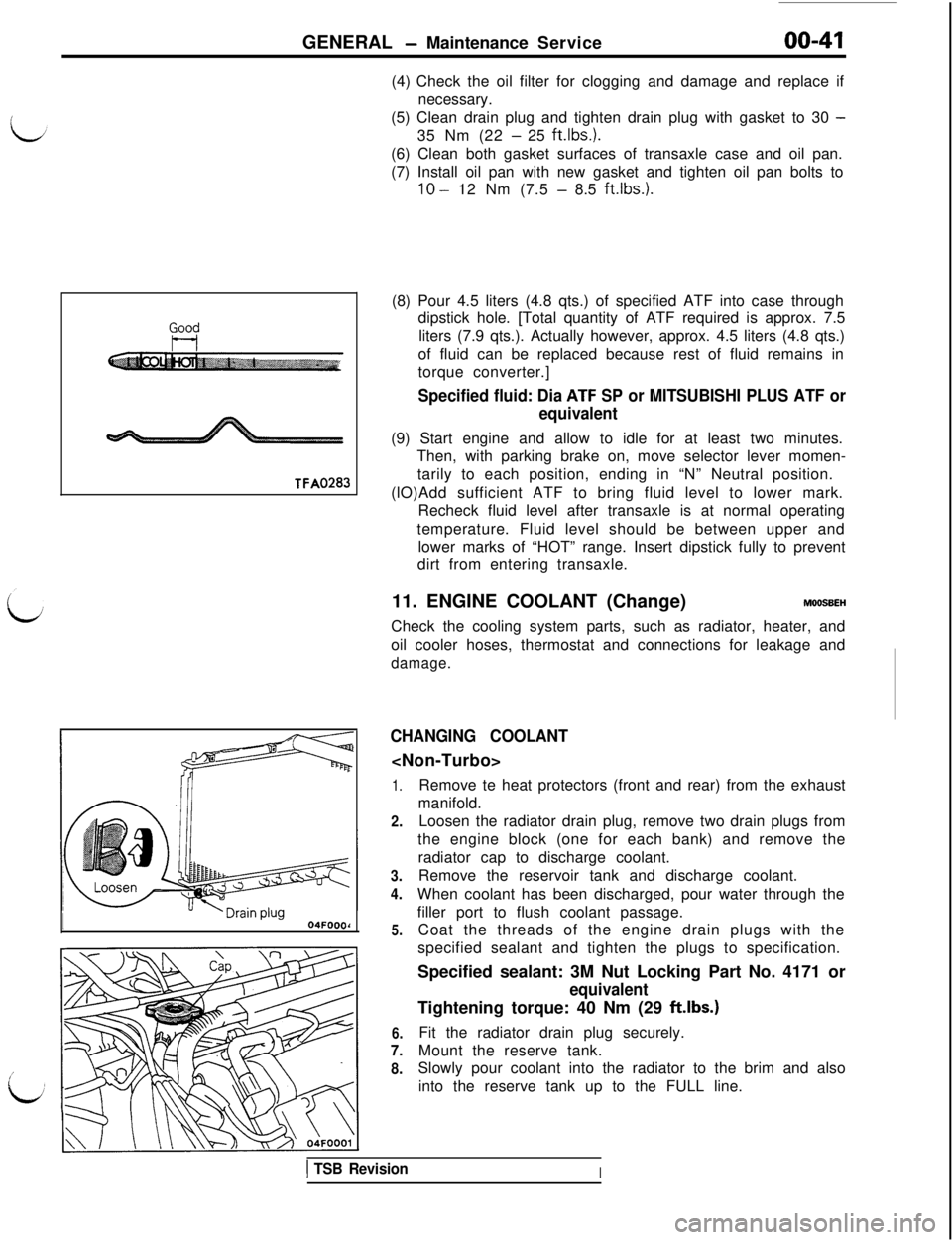

Good

t-lVA0283

I04FOOOd(4) Check the oil filter for clogging and damage and replace if

necessary.

(5) Clean drain plug and tighten drain plug with gasket to 30

-35 Nm (22

- 25 ft.lbs.).

(6) Clean both gasket surfaces of transaxle case and oil pan.

(7) Install oil pan with new gasket and tighten oil pan bolts to

10 - 12 Nm (7.5 - 8.5 ft.lbs.).

(8) Pour 4.5 liters (4.8 qts.) of specified ATF into case through

dipstick hole. [Total quantity of ATF required is approx. 7.5

liters (7.9 qts.). Actually however, approx. 4.5 liters (4.8 qts.)

of fluid can be replaced because rest of fluid remains in

torque converter.]

Specified fluid: Dia ATF SP or MITSUBISHI PLUS ATF or

equivalent(9) Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever momen-

tarily to each position, ending in “N” Neutral position.

(lO)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature. Fluid level should be between upper and

lower marks of “HOT” range. Insert dipstick fully to prevent

dirt from entering transaxle.

11. ENGINE COOLANT (Change)

MOOSBEHCheck the cooling system parts, such as radiator, heater, and

oil cooler hoses, thermostat and connections for leakage and

damage.

CHANGING COOLANT

1.

2.

3.

4.

5.

6.

7.

8.Remove te heat protectors (front and rear) from the exhaust

manifold.

Loosen the radiator drain plug, remove two drain plugs from

the engine block (one for each bank) and remove the

radiator cap to discharge coolant.

Remove the reservoir tank and discharge coolant.

When coolant has been discharged, pour water through the

filler port to flush coolant passage.

Coat the threads of the engine drain plugs with the

specified sealant and tighten the plugs to specification.

Specified sealant: 3M Nut Locking Part No. 4171 or

equivalentTightening torque: 40 Nm (29

ftlbs.)Fit the radiator drain plug securely.

Mount the reserve tank.

Slowly pour coolant into the radiator to the brim and also

into the reserve tank up to the FULL line.

1 TSB RevisionI