light MITSUBISHI 3000GT 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 510 of 1146

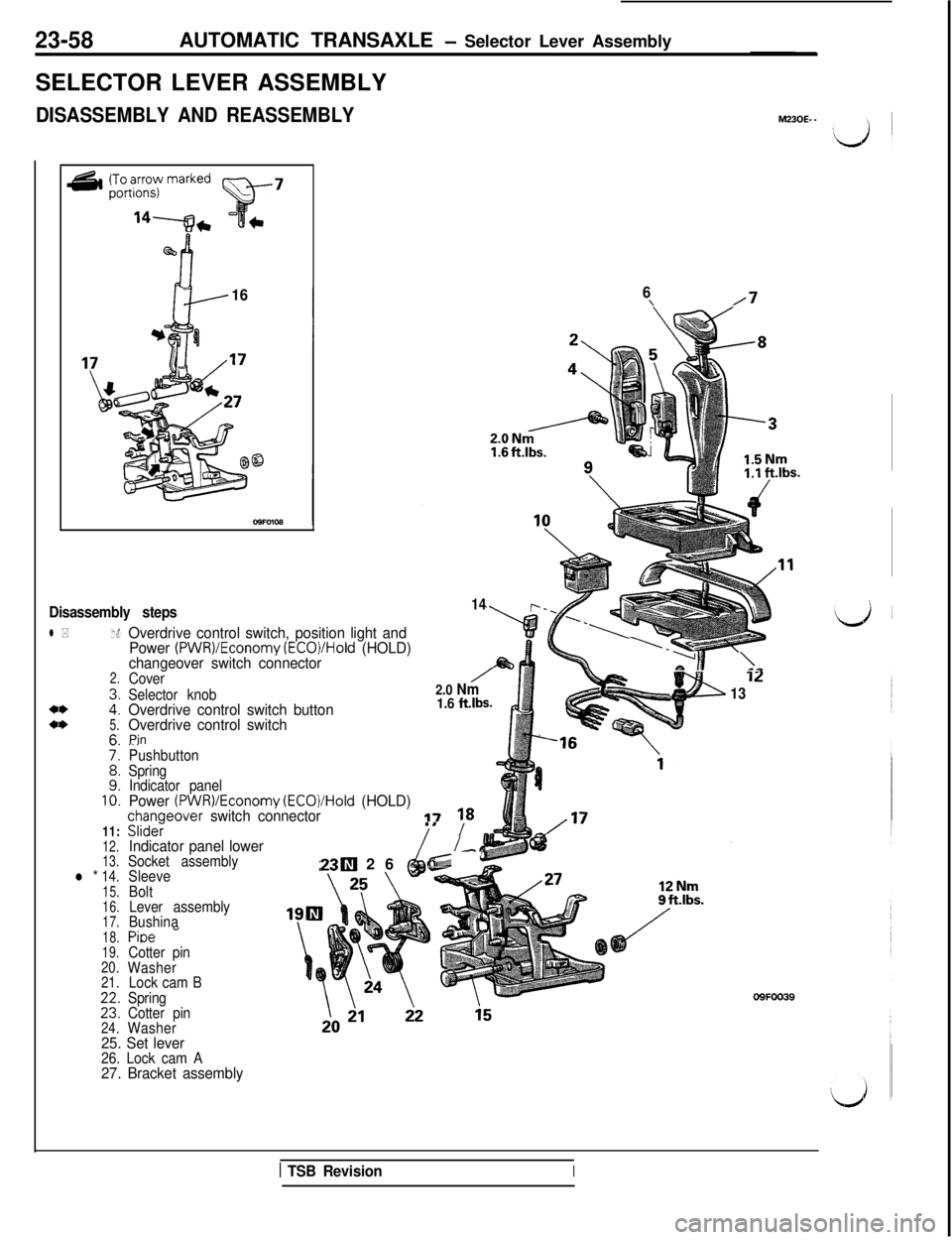

23-58AUTOMATIC TRANSAXLE - Selector Lever Assembly

SELECTOR LEVER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

@b

h-

16

Disassembly steps

l *1.

2.

**i:a*5.

76:

::10.11:

12.

13.

l * 14.15.

16.

17.

18.

19.

20.

21.

224.

6\/7

14

Overdrive control switch, position light and

Power (PWRVEconomy (ECO)/Hold (HOLD)\.GLg

changeover switch connectorCover/>I \-

Selector knob2.0 Nm

Overdrive control switch button1.6 ftlbs.

13

Overdrive control switchPin..,Pushbutton

Spring

Indicator panel

Power (PWRVEconomy (ECOVHold (HOLD)chanaeover switch connector17 18SliderIndicator panel lowerSocket assembly

Sleeve

Bolt

Lever assembly

BushinaI

23W 26fi& -’

Pioe ”Cotter pin

Washer

Lock cam B

Spring

Cotter pin

Washer

25. Set lever26. Lock cam A27. Bracket assembly09FOO39

1 TSB RevisionI

Page 516 of 1146

23-64

AUTOMATIC, TRANSAXLE - Transaxle Assembly

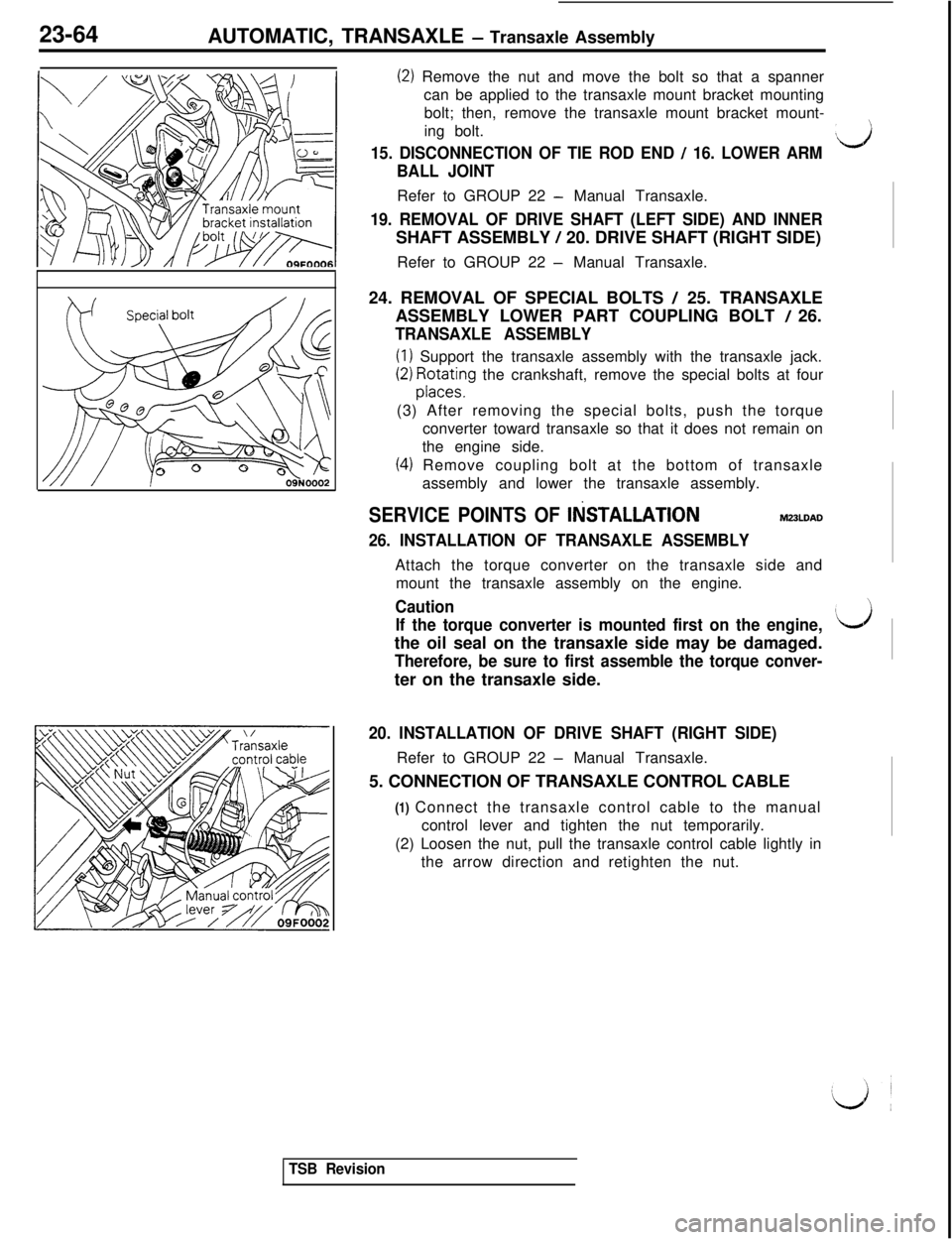

(2) Remove the nut and move the bolt so that a spanner

can be applied to the transaxle mount bracket mounting

bolt; then, remove the transaxle mount bracket mount-

ing bolt.

15. DISCONNECTION OF TIE ROD END / 16. LOWER ARM$3

BALL JOINTRefer to GROUP 22

- Manual Transaxle.

19. REMOVAL OF DRIVE SHAFT (LEFT SIDE) AND INNERSHAFT ASSEMBLY

/ 20. DRIVE SHAFT (RIGHT SIDE)

Refer to GROUP 22

- Manual Transaxle.

24. REMOVAL OF SPECIAL BOLTS

/ 25. TRANSAXLE

ASSEMBLY LOWER PART COUPLING BOLT

/ 26.

TRANSAXLE ASSEMBLY

(1) Support the transaxle assembly with the transaxle jack.

(2) ;;F;ng the crankshaft, remove the special bolts at four

(3) After removing the special bolts, push the torque

converter toward transaxle so that it does not remain on

the engine side.

(4) Remove coupling bolt at the bottom of transaxle

assembly and lower the transaxle assembly.

SERVICE POINTS OF IliSTALLATlONM23LDAD

26. INSTALLATION OF TRANSAXLE ASSEMBLYAttach the torque converter on the transaxle side and

mount the transaxle assembly on the engine.

Caution

If the torque converter is mounted first on the engine,

Idthe oil seal on the transaxle side may be damaged.

Therefore, be sure to first assemble the torque conver-ter on the transaxle side.

20. INSTALLATION OF DRIVE SHAFT (RIGHT SIDE)Refer to GROUP 22

- Manual Transaxle.

5. CONNECTION OF TRANSAXLE CONTROL CABLE

(1) Connect the transaxle control cable to the manual

control lever and tighten the nut temporarily.

(2) Loosen the nut, pull the transaxle control cable lightly in

the arrow direction and retighten the nut.

TSB Revision

Page 588 of 1146

26-12FRONT AXLE - Drive Shaft

-01

M 8990635-0112R0258

llA0286i

llN0027

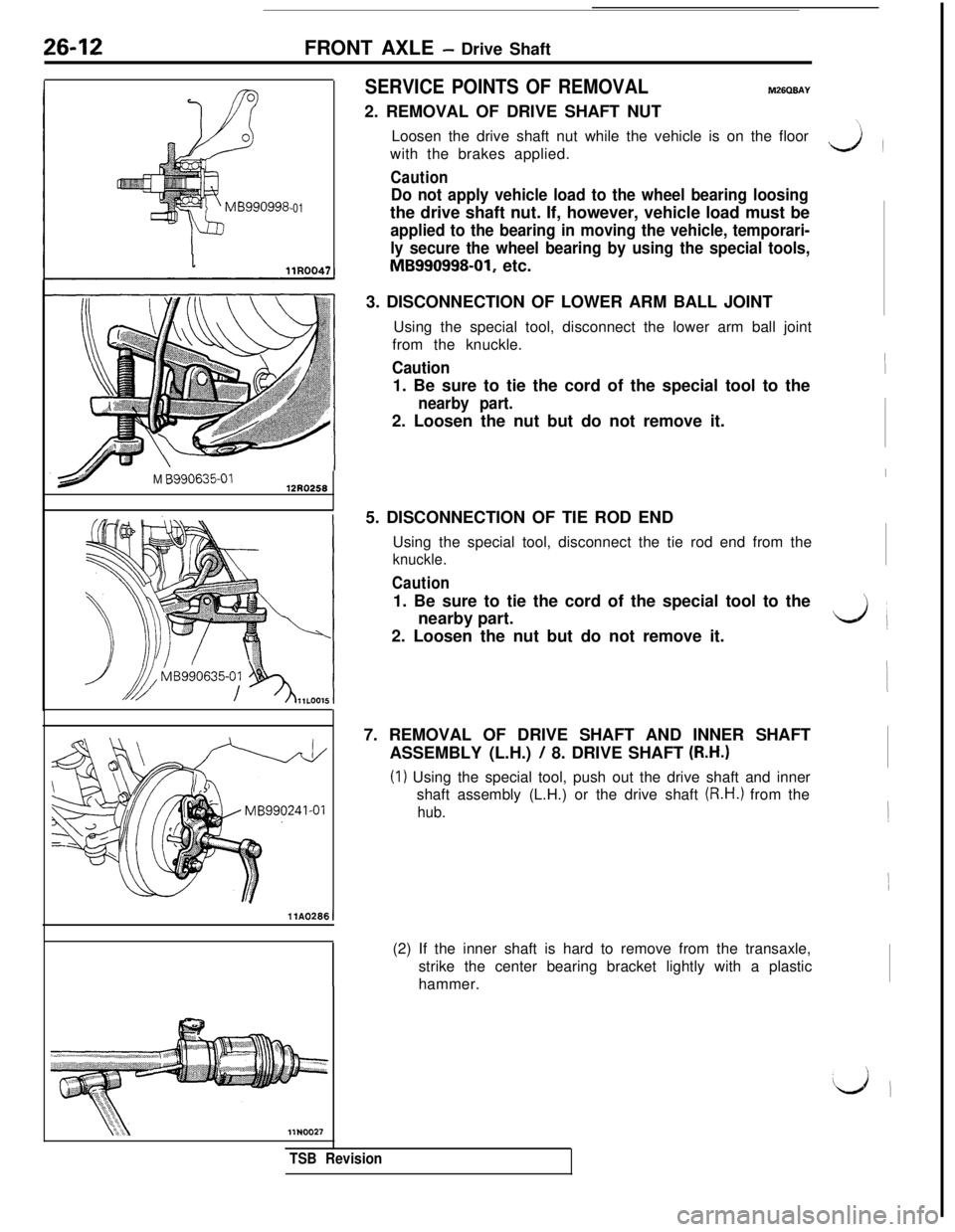

SERVICE POINTS OF REMOVALM26QBAY2. REMOVAL OF DRIVE SHAFT NUT

Loosen the drive shaft nut while the vehicle is on the floor

with the brakes applied.

Caution

Do not apply vehicle load to the wheel bearing loosingthe drive shaft nut. If, however, vehicle load must be

applied to the bearing in moving the vehicle, temporari-

ly secure the wheel bearing by using the special tools,

MB990998-01, etc.

3. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.2. Loosen the nut but do not remove it.

5. DISCONNECTION OF TIE ROD END

Using the special tool, disconnect the tie rod end from the

knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

7. REMOVAL OF DRIVE SHAFT AND INNER SHAFT

ASSEMBLY (L.H.)

/ 8. DRIVE SHAFT (R.H.)

(I) Using the special tool, push out the drive shaft and inner

shaft assembly (L.H.) or the drive shaft

(R.H.) from the

hub.(2) If the inner shaft is hard to remove from the transaxle,

strike the center bearing bracket lightly with a plastic

hammer.

‘\

L+i

TSB Revision

Page 613 of 1146

REAR AXLE

I-

Axle housing

MB990938-01

3fe

tiB990931-01

llA0039

MB990641

llN0015

r

- llAQ034llN000711 A0033

llN0008

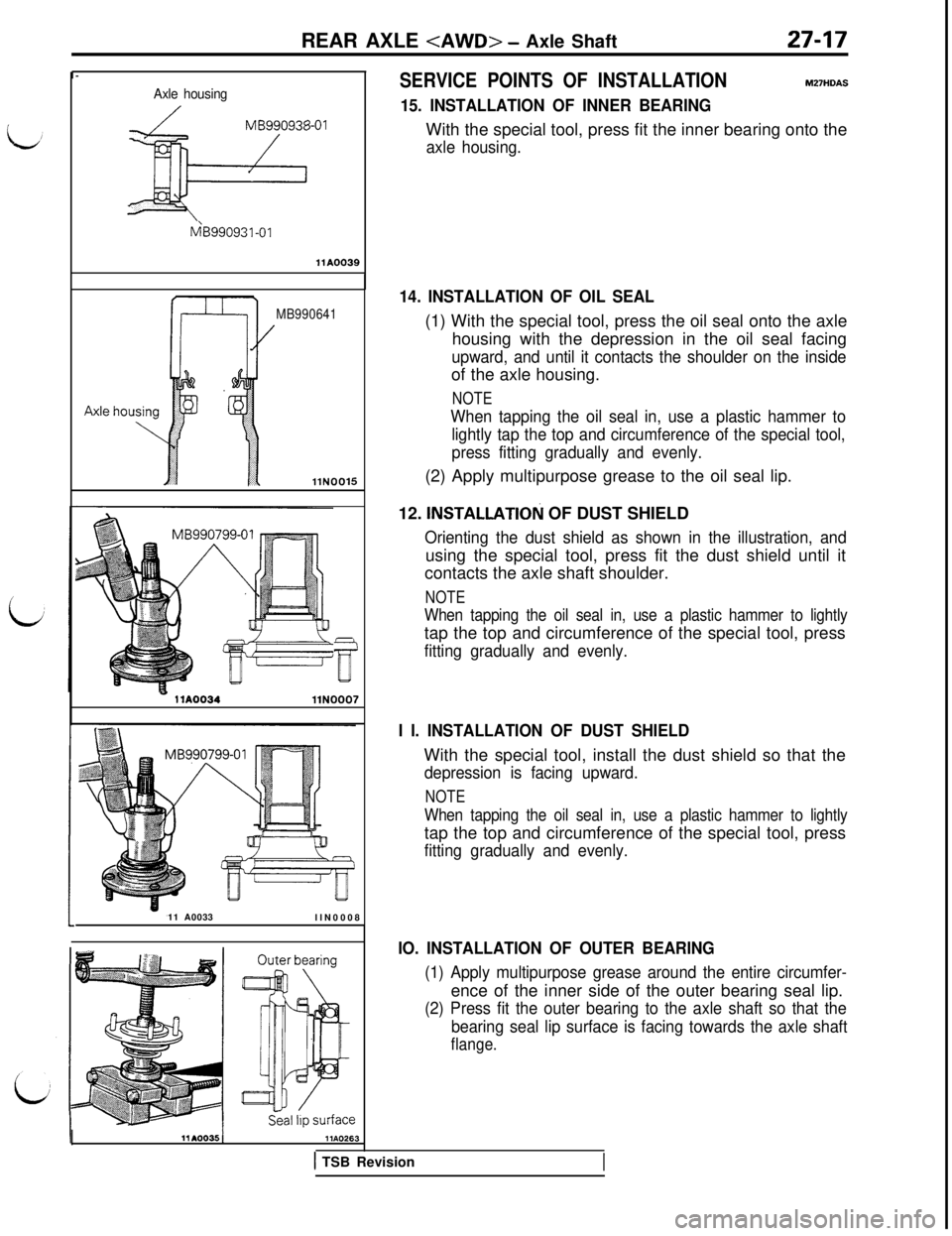

SERVICE POINTS OF INSTALLATIONM27HOAS

15. INSTALLATION OF INNER BEARINGWith the special tool, press fit the inner bearing onto the

axle housing.

14. INSTALLATION OF OIL SEAL(1) With the special tool, press the oil seal onto the axle

housing with the depression in the oil seal facing

upward, and until it contacts the shoulder on the insideof the axle housing.

NOTE

When tapping the oil seal in, use a plastic hammer to

lightly tap the top and circumference of the special tool,

press fitting gradually and evenly.(2) Apply multipurpose grease to the oil seal lip.

12.

INSTALLATlOkl OF DUST SHIELD

Orienting the dust shield as shown in the illustration, andusing the special tool, press fit the dust shield until it

contacts the axle shaft shoulder.

NOTE

When tapping the oil seal in, use a plastic hammer to lightlytap the top and circumference of the special tool, press

fitting gradually and evenly.

I I. INSTALLATION OF DUST SHIELDWith the special tool, install the dust shield so that the

depression is facing upward.

NOTE

When tapping the oil seal in, use a plastic hammer to lightlytap the top and circumference of the special tool, press

fitting gradually and evenly.

IO. INSTALLATION OF OUTER BEARING

(1) Apply multipurpose grease around the entire circumfer-ence of the inner side of the outer bearing seal lip.

(2) Press fit the outer bearing to the axle shaft so that the

bearing seal lip surface is facing towards the axle shaft

flange.

1 TSB Revision

Page 643 of 1146

32-1

POWER PLANTMOUNT

CONTENTSMZAA- _

ENGINE MOUNTING........................................

3SPECIFICATIONS................................................2

ENGINE ROLL STOPPER

5Service Specifications....................................2....................................

TRANSAXLE MOUNTING................................4RIGHT MEMBER, LEFT MEMBER AND

CROSSMEMBER”................................................6TROUBLESHOOTING........................................2

SPECIAL TOOLSAbnormal Noise....................................................

2

Excessive Engine Wobble or Vibration

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 647 of 1146

POWER PLANT MOUNT - Engine Roll Stopper

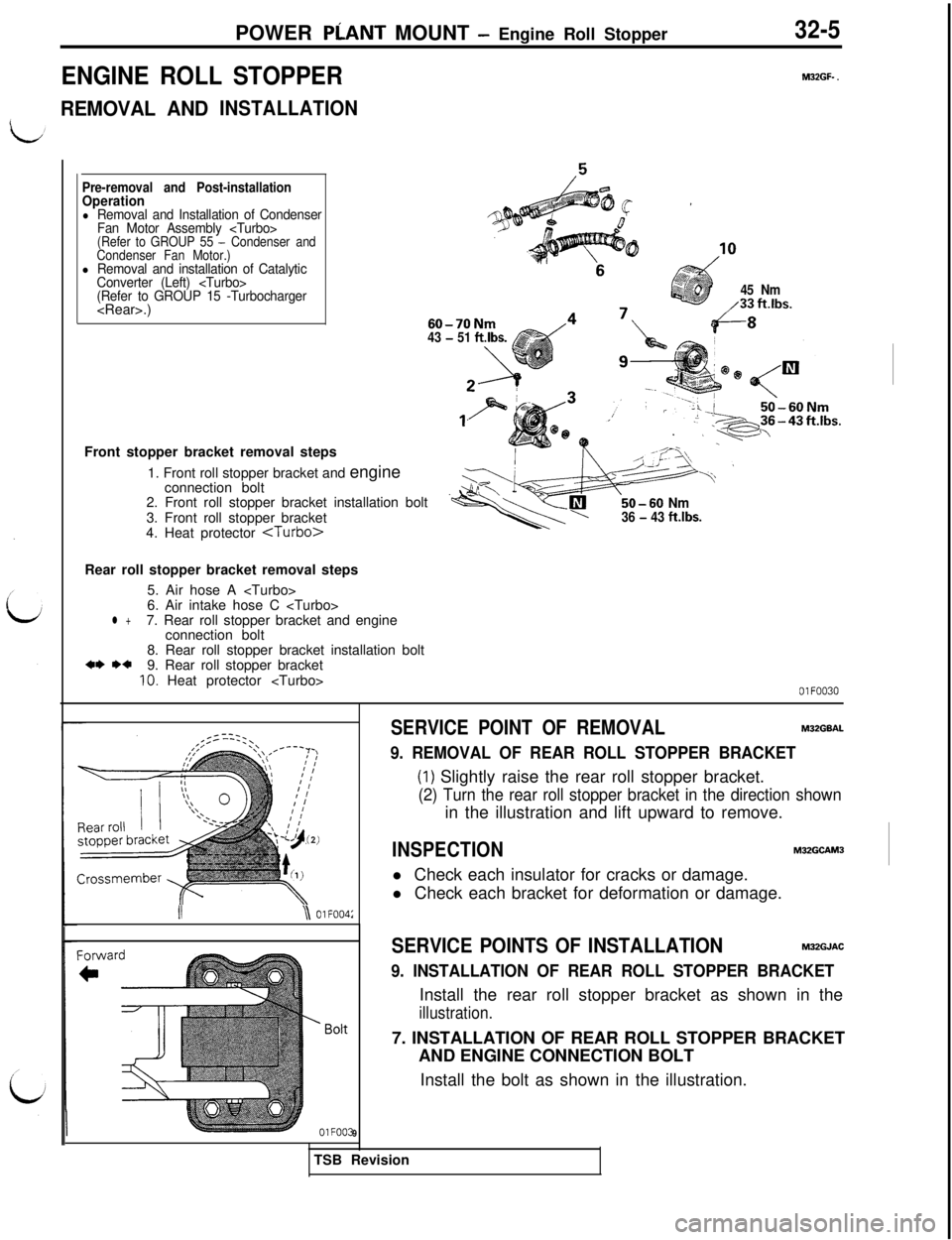

ENGINE ROLL STOPPER

REMOVAL ANDINSTALLATION

32-5

MJZGF- .

Pre-removal and Post-installationOperationl Removal and Installation of Condenser

Fan Motor Assembly

(Refer to GROUP 55 - Condenser and

Condenser Fan Motor.)

l Removal and installation of Catalytic

Converter (Left)

(Refer to GROUP 15 -Turbocharger

45 Nm/33 ft.lbs.

43

- 51 ftlbs.Front stopper bracket removal steps

1. Front roll stopper bracket and engine

connection bolt

2. Front roll stopper bracket installation bolt

3. Front roll stopper bracket

4. Heat protector

50-60 Nm36 - 43 ft.lbs.Rear roll stopper bracket removal steps

5. Air hose A

6. Air intake hose C

l +7. Rear roll stopper bracket and engine

connection bolt

8. Rear roll stopper bracket installation bolt

+* *+9. Rear roll stopper bracketIO. Heat protector

II\ OlFOO4:

SERVICE POINT OF REMOVALM32GEAL

9. REMOVAL OF REAR ROLL STOPPER BRACKET

(1) Slightly raise the rear roll stopper bracket.

(2) Turn the rear roll stopper bracket in the direction shownin the illustration and lift upward to remove.

INSPECTIONM32GCAM3l Check each insulator for cracks or damage.

l Check each bracket for deformation or damage.

9TSB Revision

SERVICE POINTS OF INSTALLATIONM32GJAC

9. INSTALLATION OF REAR ROLL STOPPER BRACKETInstall the rear roll stopper bracket as shown in the

illustration.7. INSTALLATION OF REAR ROLL STOPPER BRACKET

AND ENGINE CONNECTION BOLT

Install the bolt as shown in the illustration.

Page 663 of 1146

33B-1

ELECTRONIC

CONTROL

SUSPENSION

CONTENTSM33AA-B

CIRCUIT DIAGRAM

22SPECIAL TOOLS........................................................................3

................................................................

DAMPING FORCE CHANGEOVERSPECIFICATIONS....................................................................2

ACTUATOR................................................................................20General Specifications.......................................................2

ECS CONTROL UNIT................................................................21Service Specifications.......................................................3

ECS INDICATOR LIGHT............................................................20STEERING ANGULAR VELOCITYa .

ECS SWITCH............................................................................

19

G SENSOR................................................................................

19

POSITION DETECTION SWITCH............................................20

SERVICE ADJUSTMENT PROCEDURES

............................

12

On-Vehicle Inspection........................................................12

SENSOR*....................................................................................-IY

STOP LIGHT SWITCH............................................................20

THROTTLE POSITION SENSOR

............................................20

TROUBLESHOOTING............................................................4

VEHICLE SPEED SENSOR....................................................

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(I)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, aiir bagmodule, clock spring, interconnecting wiring.Other SRS-related components (that may have 1:o be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

Ei2B -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 666 of 1146

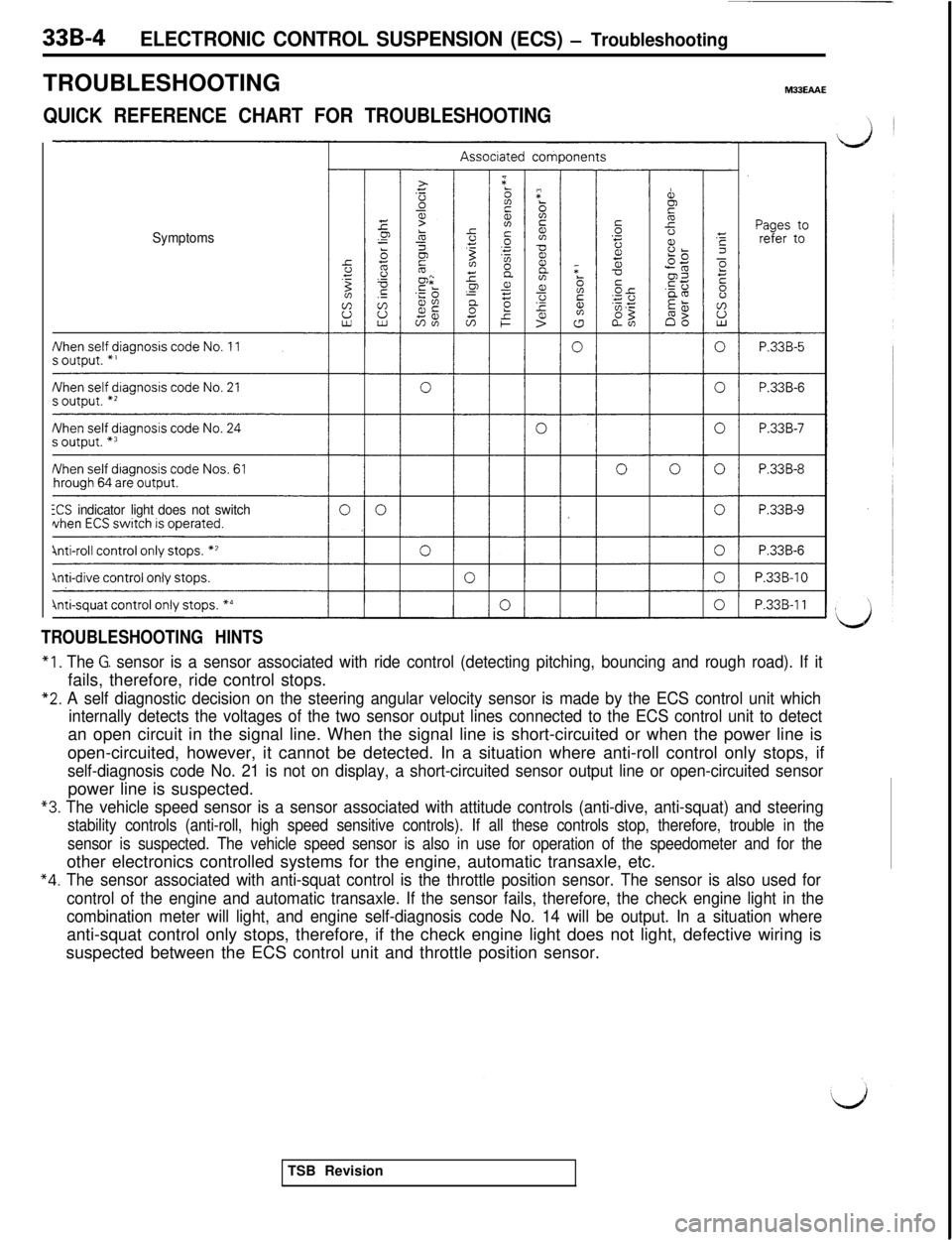

33B-4ELECTRONIC CONTROL SUSPENSION (ECS) - TroubleshootingTROUBLESHOOTING

M33EAAE

QUICK REFERENCE CHART FOR TROUBLESHOOTING

SymptomsXS

indicator lightdoes not switch

TROUBLESHOOTING HINTS

“1. The G. sensor is a sensor associated with ride control (detecting pitching, bouncing and rough road). If itfails, therefore, ride control stops.

“2. A self diagnostic decision on the steering angular velocity sensor is made by the ECS control unit which

internally detects the voltages of the two sensor output lines connected to the ECS control unit to detectan open circuit in the signal line. When the signal line is short-circuited or when the power line is

open-circuited, however, it cannot be detected. In a situation where anti-roll control only stops, if

self-diagnosis code No. 21 is not on display, a short-circuited sensor output line or open-circuited sensorpower line is suspected.

“3. The vehicle speed sensor is a sensor associated with attitude controls (anti-dive, anti-squat) and steering

stability controls (anti-roll, high speed sensitive controls). If all these controls stop, therefore, trouble in the

sensor is suspected. The vehicle speed sensor is also in use for operation of the speedometer and for theother electronics controlled systems for the engine, automatic transaxle, etc.

“4. The sensor associated with anti-squat control is the throttle position sensor. The sensor is also used for

control of the engine and automatic transaxle. If the sensor fails, therefore, the check engine light in the

combination meter will light, and engine self-diagnosis code No. 14 will be output. In a situation whereanti-squat control only stops, therefore, if the check engine light does not light, defective wiring is

suspected between the ECS control unit and throttle position sensor.

TSB Revision

Page 671 of 1146

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting:33B-9

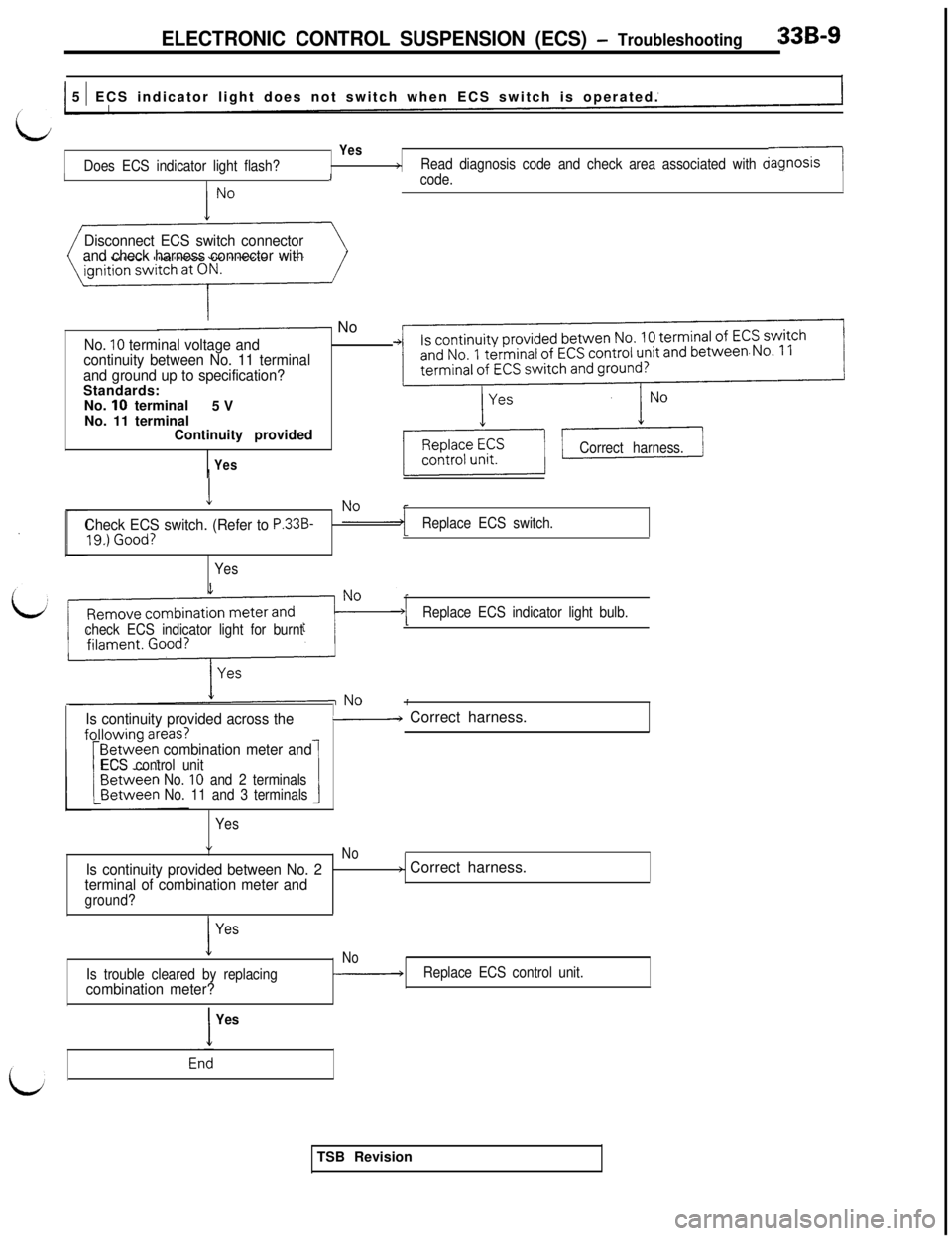

1 5 1 ECS indicator light does not switch when ECS switch is operated.

Yes

Does ECS indicator light flash?+Read diagnosis code and check area associated with dralgnosrs.---IIIcode.

Disconnect ECS switch connector

and check harness connector with

- No

No. 10 terminal voltage and

continuity between No. 11 terminal

and ground up to specification?Standards:

No.

10 terminal

5 V

No. 11 terminal

Continuity provided

YesCorrect harness.

Check ECS switch. (Refer to P.33B-

YesReplace ECS switch.

check ECS indicator light for burntReplace ECS indicator light bulb.

Is continuity provided across the- Correct harness.

combination meter andECS control unit

No. 10 and 2 terminals

No. 11 and 3 terminals

Yes

”No

Is continuity provided between No. 2> Correct harness.

terminal of combination meter andground?

I

Yes

No

Is trouble cleared by replacingcombination meter?

-Replace ECS control unit.

IYesTSB Revision

Page 672 of 1146

33B-10 ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting

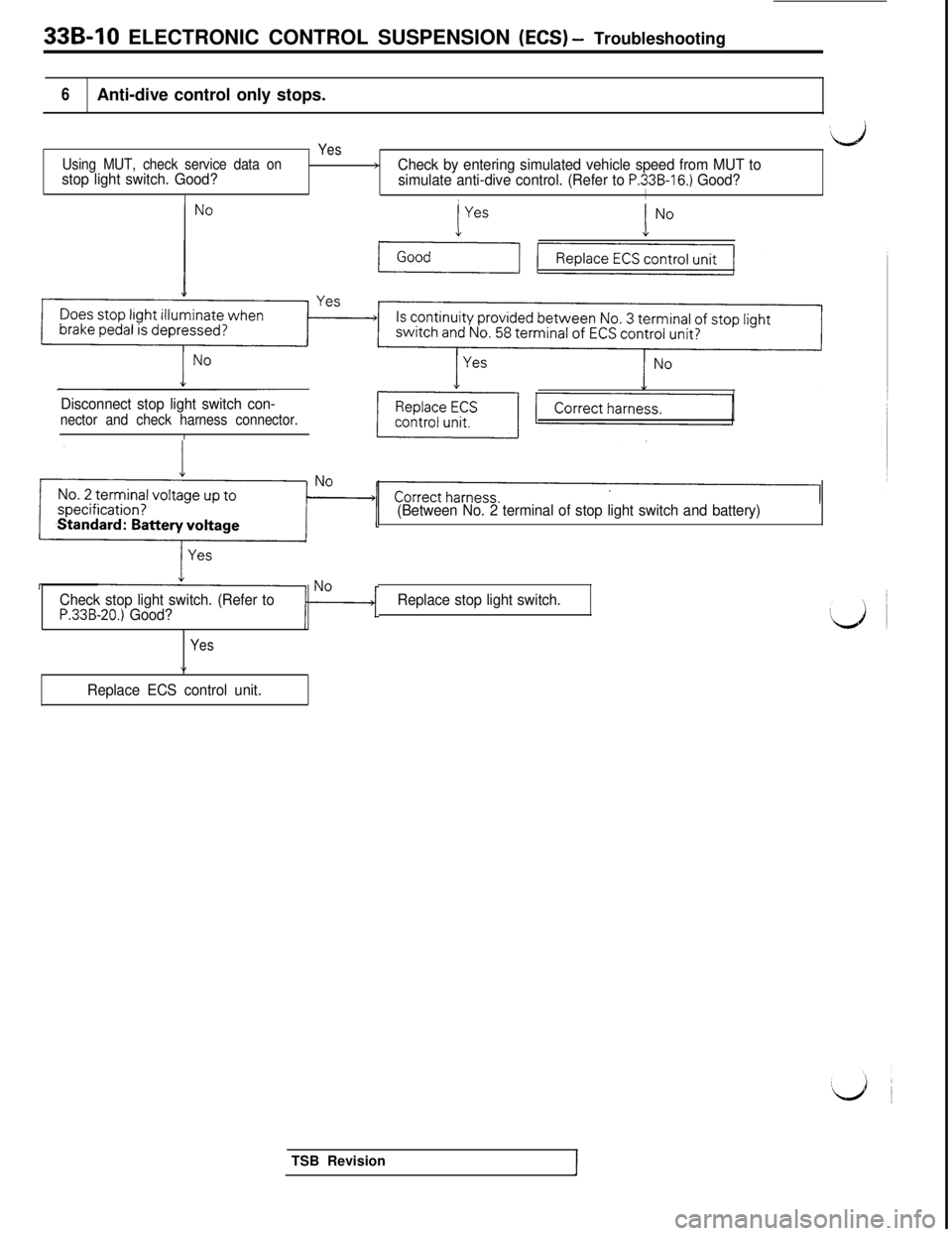

6Anti-dive control only stops.

Yes

Using MUT, check service data on

stop light switch. Good?>Check by entering simulated vehicle speed from MUT to

simulate anti-dive control. (Refer to P.33B-16.) Good?

,I

ch

Disconnect stop light switch con-

nector and check harness connector.f

(Between No. 2 terminal of stop light switch and battery)

Check stop light switch. (Refer to

P.33B-20.) Good?

Yes

”

Replace ECS control unit.Replace stop light switch.TSB Revision