light MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 192 of 1146

13-86FUEL SYSTEM - On-vehicle Inspection of MPI Components

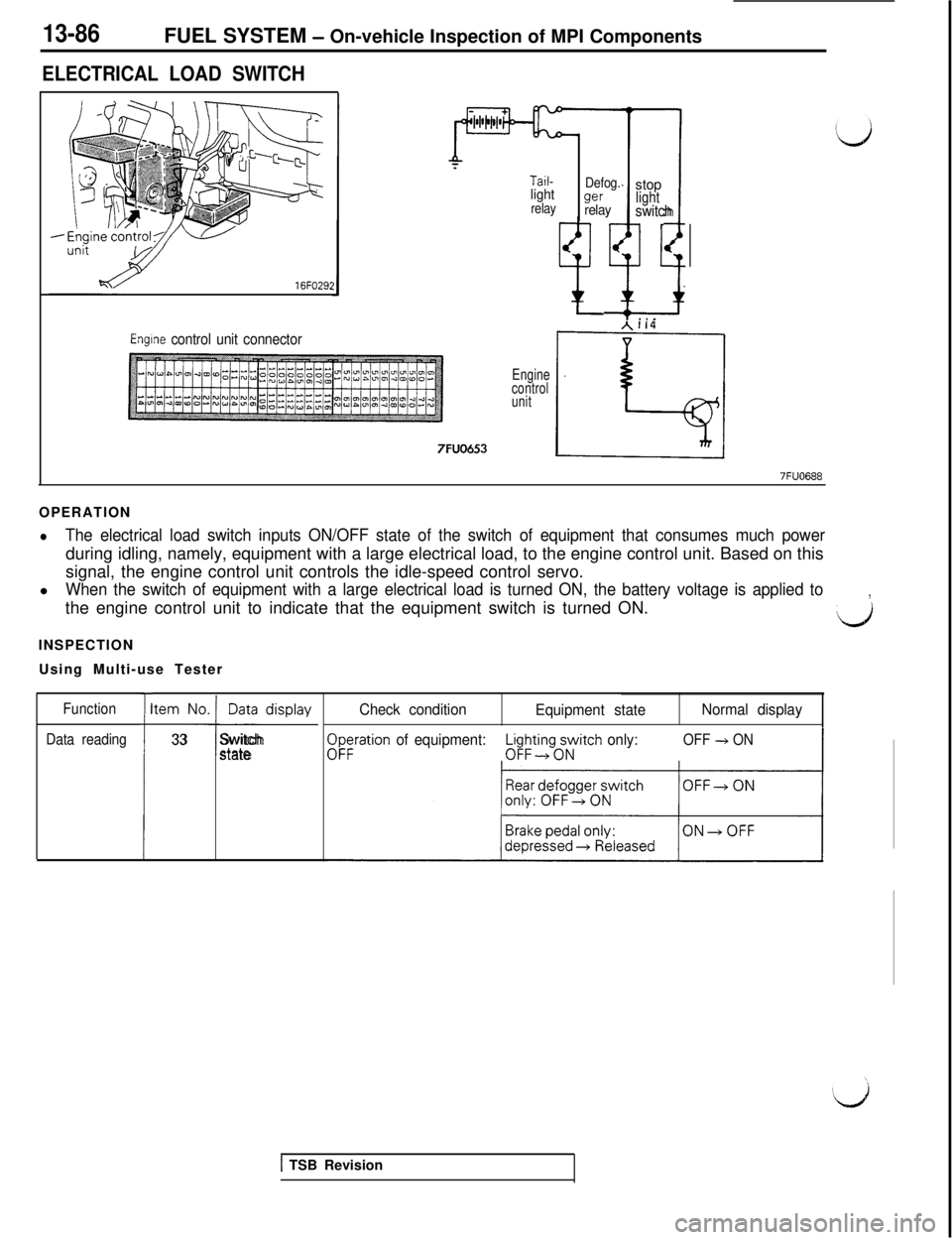

ELECTRICAL LOAD SWITCH16FO29;

Tail-lightrelayDefog.wrelaystoplight

t;1

switch

ti* . .

Engine control unit connector

Engine

control

unit7FUO653

7FUO688OPERATION

lThe electrical load switch inputs ON/OFF state of the switch of equipment that consumes much powerduring idling, namely, equipment with a large electrical load, to the engine control unit. Based on this

signal, the engine control unit controls the idle-speed control servo.

l

When the switch of equipment with a large electrical load is turned ON, the battery voltage is applied tothe engine control unit to indicate that the equipment switch is turned ON.,

LJINSPECTION

Using Multi-use Tester

Function

Data reading

I

tem No. Data display

-I-

33Switchstate

Check condition

Equipment stateNormal display

$;ration of equipment:L$ing;Atch only:OFF + ON-3

1 TSB Revision

Page 193 of 1146

FUEL SYSTEM - On-vehicle InsDection of MPI ComDonents

/

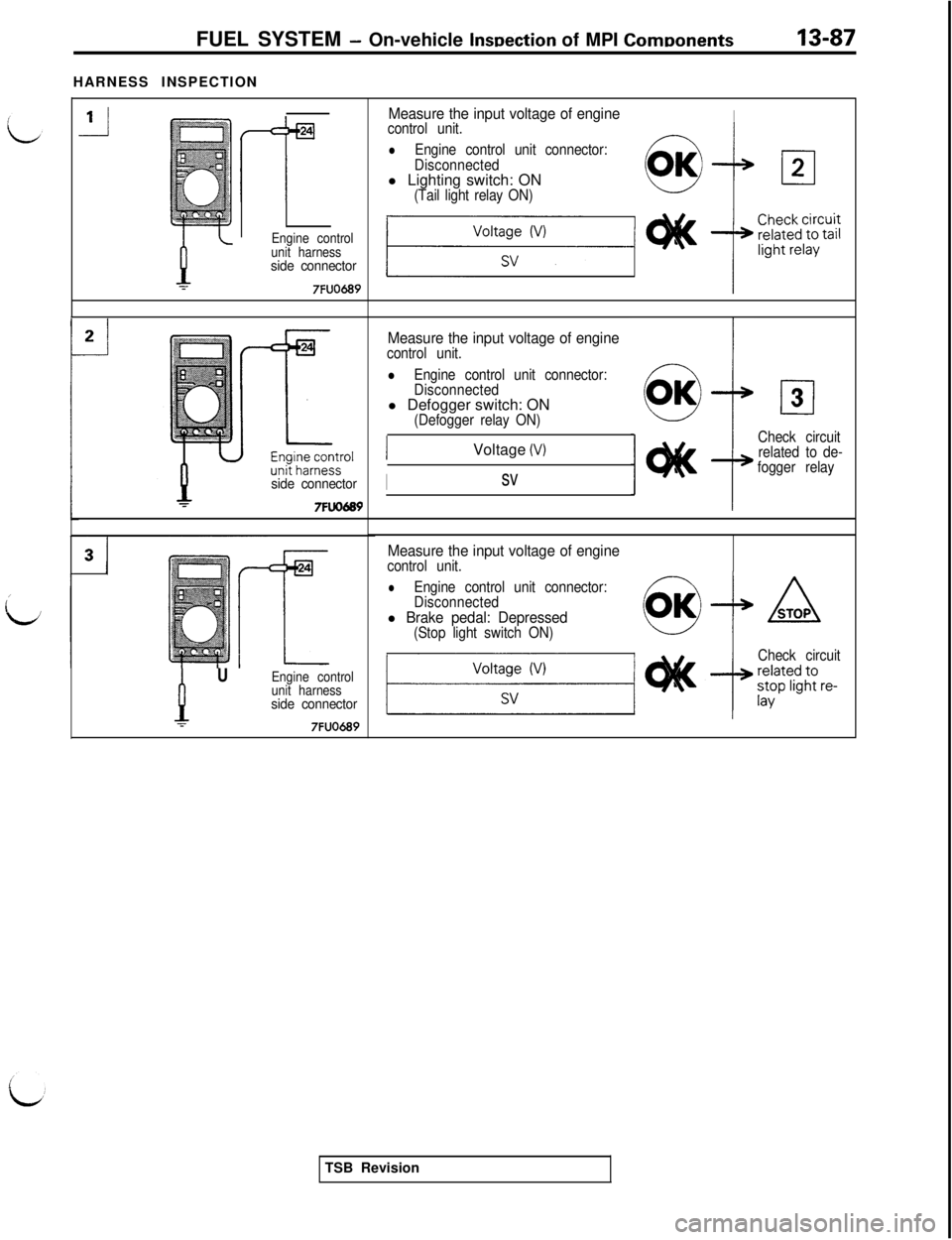

idHARNESS INSPECTION

Engine control

unit harness

side connector7FUO689

side connector7FuO689

PU

Engine control

unit harness

side connectorT7FUO689

Measure the input voltage of engineIcontrol unit.

lEngine control unit connector:

Disconnectedl Lighting switch: ON

(Tail light relay ON)

Measure the input voltage of enginecontrol unit.

lEngine control unit connector:

Disconnectedl Defogger switch: ON

(Defogger relay ON)Voltage

(V)

Isv

cl3

Check circuit

related to de-

fogger relay

Measure the input voltage of enginecontrol unit.

lEngine control unit connector:

Disconnected

l Brake pedal: Depressed(Stop light switch ON)

Check circuitTSB Revision

Page 198 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

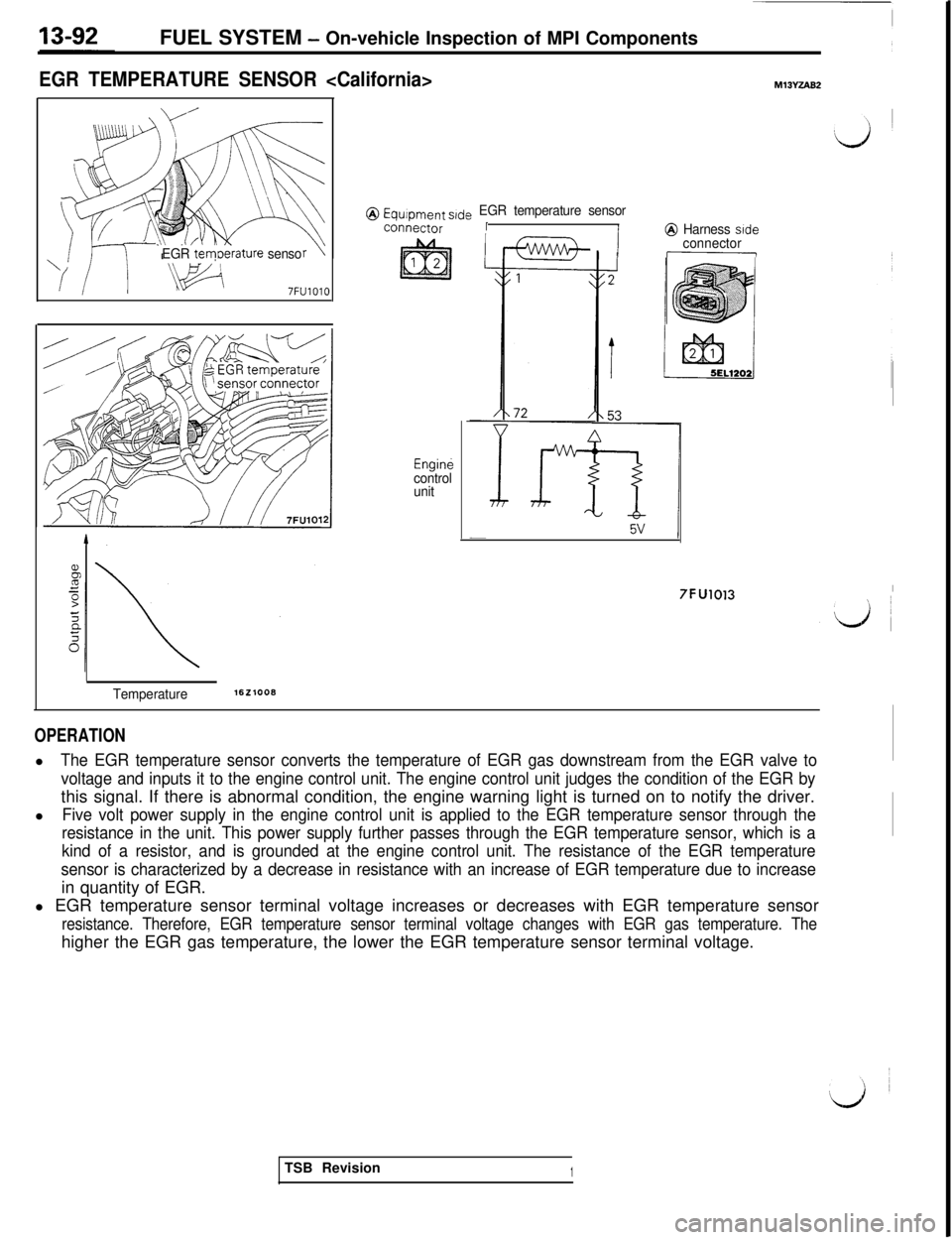

EGR TEMPERATURE SENSOR

EGR tem0erature senso

7FUlOlO

@ Equipment s,de EGR temperature sensor

connectorII@ Harness side

Enginecontrol

unit

I Iconnector

7FU1013I

Temperature1621008

OPERATIONl

The EGR temperature sensor converts the temperature of EGR gas downstream from the EGR valve to

voltage and inputs it to the engine control unit. The engine control unit judges the condition of the EGR bythis signal. If there is abnormal condition, the engine warning light is turned on to notify the driver.

l

Five volt power supply in the engine control unit is applied to the EGR temperature sensor through the

resistance in the unit. This power supply further passes through the EGR temperature sensor, which is a

kind of a resistor, and is grounded at the engine control unit. The resistance of the EGR temperature

sensor is characterized by a decrease in resistance with an increase of EGR temperature due to increasein quantity of EGR.

l EGR temperature sensor terminal voltage increases or decreases with EGR temperature sensor

resistance. Therefore, EGR temperature sensor terminal voltage changes with EGR gas temperature. Thehigher the EGR gas temperature, the lower the EGR temperature sensor terminal voltage.

TSB Revision

1

Page 220 of 1146

13-114FUEL SYSTEM - On-vehicle Inspection of MPI Components

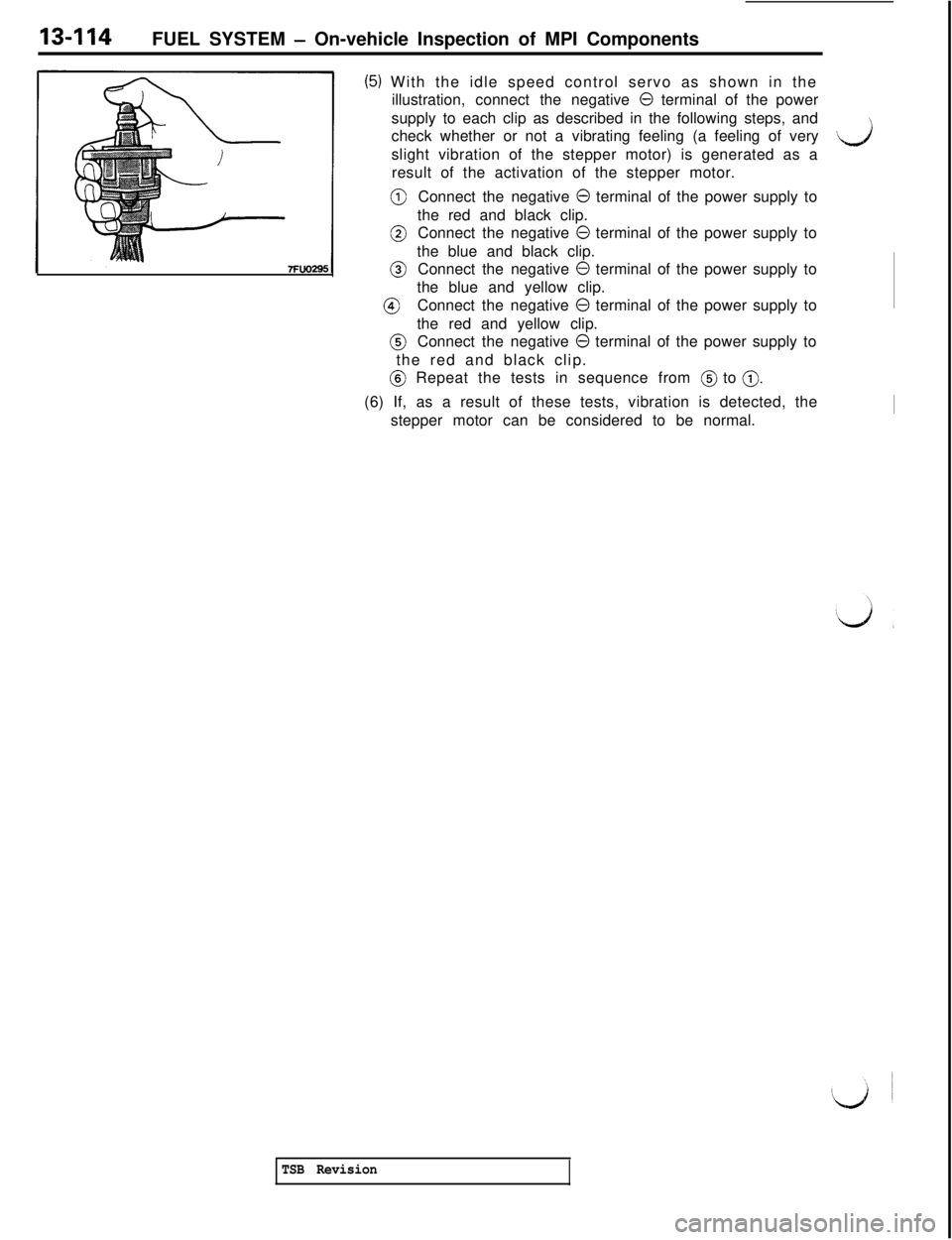

(5) With the idle speed control servo as shown in the

illustration, connect the negative

0 terminal of the power

supply to each clip as described in the following steps, and

check whether or not a vibrating feeling (a feeling of very

(slight vibration of the stepper motor) is generated as aJresult of the activation of the stepper motor.@Connect the negative

0 terminal of the power supply to

the red and black clip.@Connect the negative

0 terminal of the power supply to

the blue and black clip.@Connect the negative

0 terminal of the power supply to@the blue and yellow clip.

Connect the negative

0 terminal of the power supply to

the red and yellow clip.@Connect the negative

0 terminal of the power supply to

the red and black clip.@ Repeat the tests in sequence from @ to

0.(6) If, as a result of these tests, vibration is detected, the

stepper motor can be considered to be normal.

TSB Revision

Page 222 of 1146

13-116FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

(d

FunctionItem No. Data displayCheck condition

Engine state

Standard valueData reading 44

Ignitionadvancel Engine: Warming up

750 rpm (Idle)7 - 23”BTDCl Timing light: Set (settiming light to check2,000 rpm30 - 40”BTDC

‘

Function

Data listItem No.Data displayCheckTerminalStandard value

condition

condition

36Continuity present or

not present betweenl Engine:

IdlingIgnition timing ad-ON

ignition timing adjustmentjustment terminal isterminal and groundgrounded

Ignition timing ad-OFFjustment terminal is

disconnected from

ground

Function

Actuator testItem No.

DriveCheck conditionNormal condition

17Set to ignition timingl Engine: idling5”BTDCadjustment model Timing light: set\

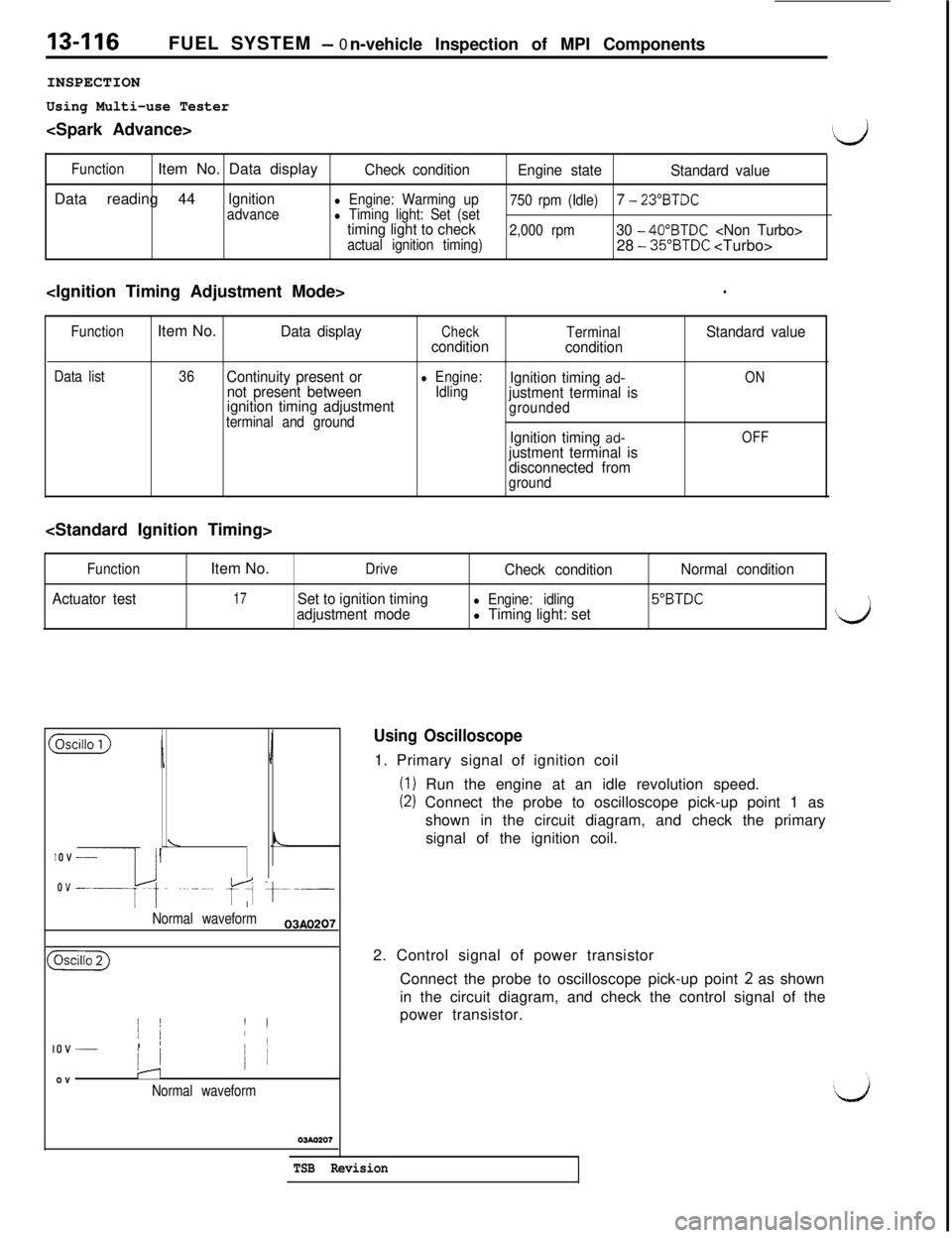

($Gizi)

IJ

\LIOV _

ovep~,. ..~_~.~ fA t---.-

I

Normal waveform03AO207

(

j /’ II

IOV _I ’/

/ 1ovIJ

Normal waveform

Using Oscilloscope1. Primary signal of ignition coil

(I) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point 1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2. Control signal of power transistor

Connect the probe to oscilloscope pick-up point

2 as shown

in the circuit diagram, and check the control signal of the

power transistor.

TSB Revision

Page 246 of 1146

13-140FUEL SYSTEM - On-vehicle Inspection of MPI Components

(14)Stop the engine and check for a change of the value

indicated by the fuel pressure gauge. The condition is

normal if there is no decrease of the indicated value within~

two minutes.

,If there is a decrease of the indicated value, monitor the

:d ’speed of the decrease, and, referring to the table below,

determine the cause of the problem and make the

appropriate repair.

Condition

After the engine is stopped, thefuel pressure drops gradually.Probable cause

Injector leakage.

Leakage at the fuel pressure

regulator valve seat.Remedy

Replace the injector.

Replace the fuel pressure regulator.

There is a sudden sharp drop of

the fuel pressure immediately

after the engine is stopped.The check valve (within the fuelpump) is not closed.Replace the fuel pump.

(15)Remove all remaining pressure from inside the fuel pipe.(16)Disconnect the fuel pressure gauge and the special tool

from the delivery pipe.

CautionBecause there will be.a slight amount of remaining

pressure in the fuel pipe line, use rags to cover so thatfuel doesn’t splatter.

(17)Replace the O-ring at the end of the fuel high-pressure hose

with a new one.(I 8)After connecting the fuel high-pressure hose to the delivery

pipe, tighten the installation bolt at the specified torque.

dTightening torque: 5.0 Nm (3.6 ftlbs.)

(19)Check to be sure that there is no fuel leakage.@ Apply battery voltage to the terminal for activation of

the fuel pump so as to activate the fuel pump.@ With fuel pressure applied, check for leakage of the fuel

line.

TSB Revision

Page 248 of 1146

13-142FUEL SYSTEM - Injector

SERVICE POINT OF REMOVAL

MlBSSAI1. DISCONNECTION OF HIGH PRESSURE FUEL HOSE

Bleed the residual pressure within the fuel pipe line so as to

LA;prevent the flow of fuel.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

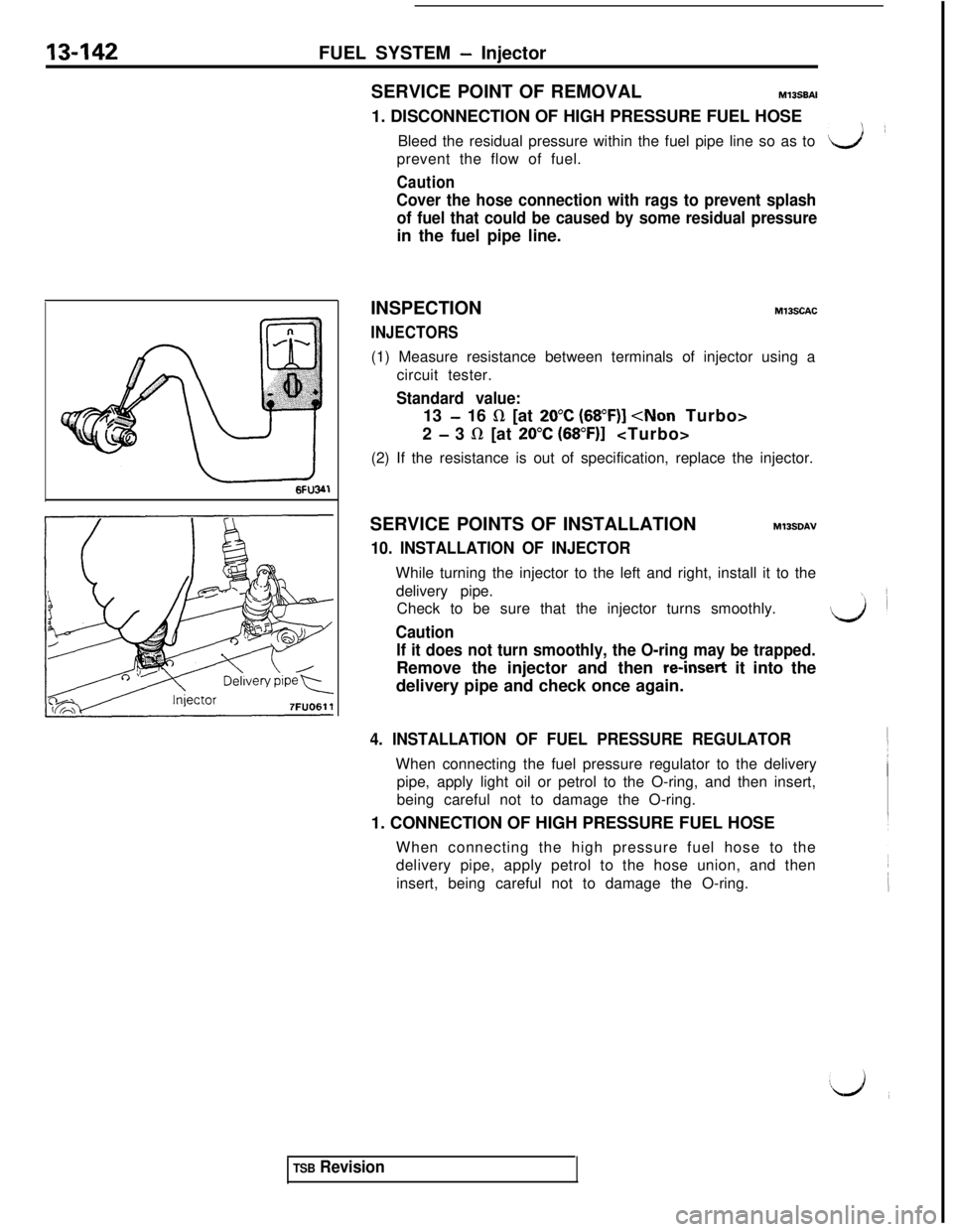

INSPECTION

INJECTORS

M13SCAC(1) Measure resistance between terminals of injector using a

circuit tester.

Standard value:13

- 16 R [at 20°C (68”F)]

2

- 3 LR [at 20°C (68”F)l

(2) If the resistance is out of specification, replace the injector.

SERVICE POINTS OF INSTALLATION

MlBSDAV

10. INSTALLATION OF INJECTORWhile turning the injector to the left and right, install it to the

delivery pipe.

Check to be sure that the injector turns smoothly.

LCaution

If it does not turn smoothly, the O-ring may be trapped.Remove the injector and then

m-insert it into the

delivery pipe and check once again.

4. INSTALLATION OF FUEL PRESSURE REGULATORWhen connecting the fuel pressure regulator to the delivery

pipe, apply light oil or petrol to the O-ring, and then insert,

being careful not to damage the O-ring.

1. CONNECTION OF HIGH PRESSURE FUEL HOSE

When connecting the high pressure fuel hose to the

delivery pipe, apply petrol to the hose union, and then

insert, being careful not to damage the O-ring.

TSB Revision

Page 253 of 1146

FUEL SYSTEM - Fuel Tank13-147

Rubber hose

ngn

03FOOl

9

OSFOOB

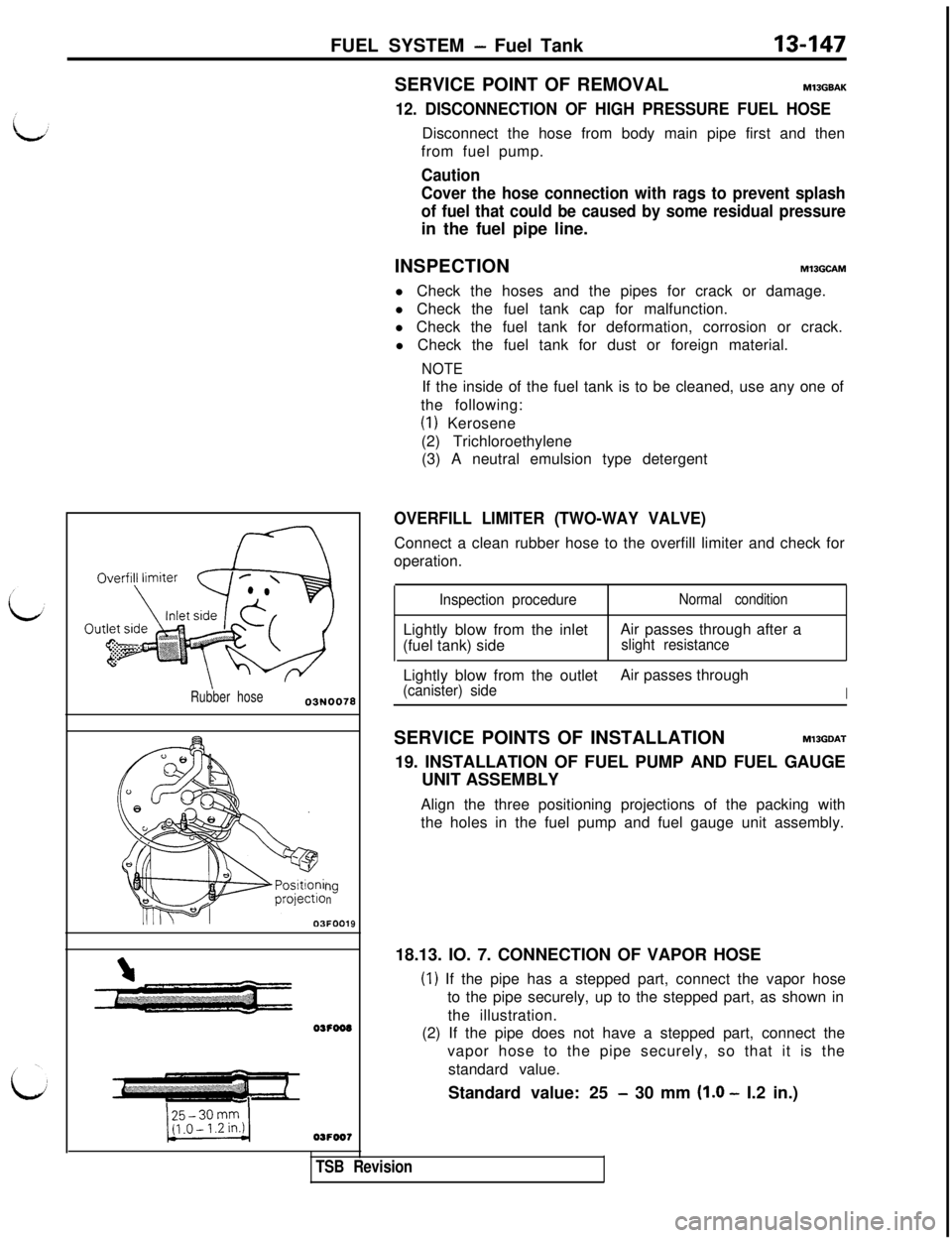

05FOO7SERVICE POINT OF REMOVAL

MlBGBAK

12. DISCONNECTION OF HIGH PRESSURE FUEL HOSEDisconnect the hose from body main pipe first and then

from fuel pump.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

INSPECTION

MlBGCAMl Check the hoses and the pipes for crack or damage.

l Check the fuel tank cap for malfunction.

l Check the fuel tank for deformation, corrosion or crack.

l Check the fuel tank for dust or foreign material.

NOTEIf the inside of the fuel tank is to be cleaned, use any one of

the following:

(1) Kerosene

(2) Trichloroethylene

(3) A neutral emulsion type detergent

OVERFILL LIMITER (TWO-WAY VALVE)Connect a clean rubber hose to the overfill limiter and check for

operation.

Inspection procedureLightly blow from the inlet

(fuel tank) sideNormal conditionAir passes through after a

slight resistanceLightly blow from the outletAir passes through

(canister) sideISERVICE POINTS OF INSTALLATION

MlSGDAT19. INSTALLATION OF FUEL PUMP AND FUEL GAUGE

UNIT ASSEMBLY

Align the three positioning projections of the packing with

the holes in the fuel pump and fuel gauge unit assembly.

TSB Revision18.13. IO. 7. CONNECTION OF VAPOR HOSE

(1) If the pipe has a stepped part, connect the vapor hose

to the pipe securely, up to the stepped part, as shown in

the illustration.

(2) If the pipe does not have a stepped part, connect the

vapor hose to the pipe securely, so that it is the

standard value.

Standard value: 25

- 30 mm (1.0 - I.2 in.)

Page 256 of 1146

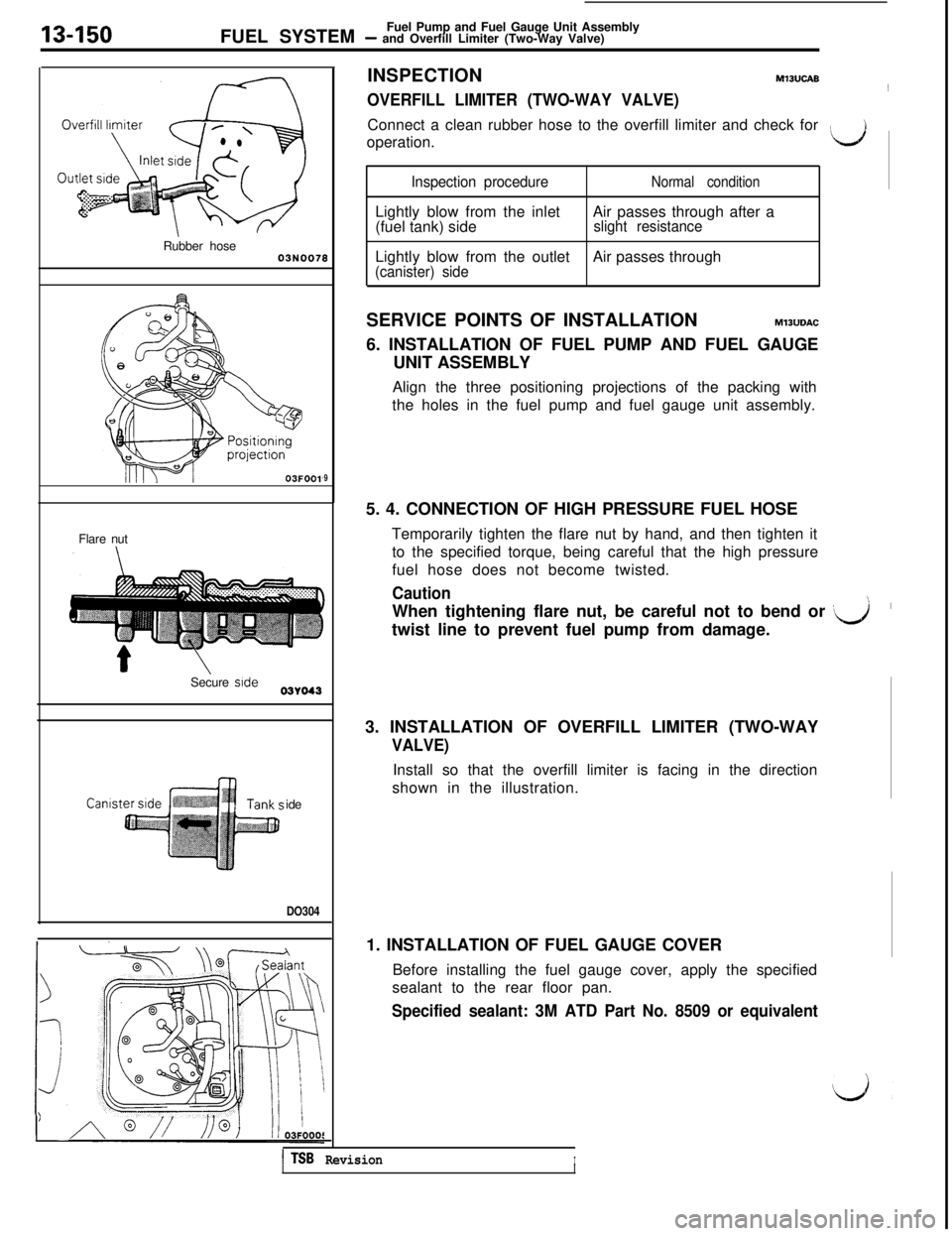

13-150FUEL SYSTEMFuel Pump and Fuel Gauge Unit Assembly- and Overfill Limiter (Two-Way Valve)

Rubber hose

9Flare nut

Secure side

03Yo43Camst

ide

DO304INSPECTION

MlBUCAB

OVERFILL LIMITER (TWO-WAY VALVE)~

Connect a clean rubber hose to the overfill limiter and check for

operation.

‘d

Inspection procedureNormal conditionLightly blow from the inlet

(fuel tank) sideAir passes through after a

slight resistanceLightly blow from the outlet

(canister) sideAir passes through

SERVICE POINTS OF INSTALLATION

M13UDAC6. INSTALLATION OF FUEL PUMP AND FUEL GAUGE

UNIT ASSEMBLY

Align the three positioning projections of the packing with

the holes in the fuel pump and fuel gauge unit assembly.

5. 4. CONNECTION OF HIGH PRESSURE FUEL HOSE

Temporarily tighten the flare nut by hand, and then tighten it

to the specified torque, being careful that the high pressure

fuel hose does not become twisted.

CautionWhen tightening flare nut, be careful not to bend or

[J’twist line to prevent fuel pump from damage.\3. INSTALLATION OF OVERFILL LIMITER (TWO-WAY

VALVE)Install so that the overfill limiter is facing in the direction

shown in the illustration.

1. INSTALLATION OF FUEL GAUGE COVER

Before installing the fuel gauge cover, apply the specified

sealant to the rear floor pan.

Specified sealant: 3M ATD Part No. 8509 or equivalent

1 TSB RevisionIII

Page 262 of 1146

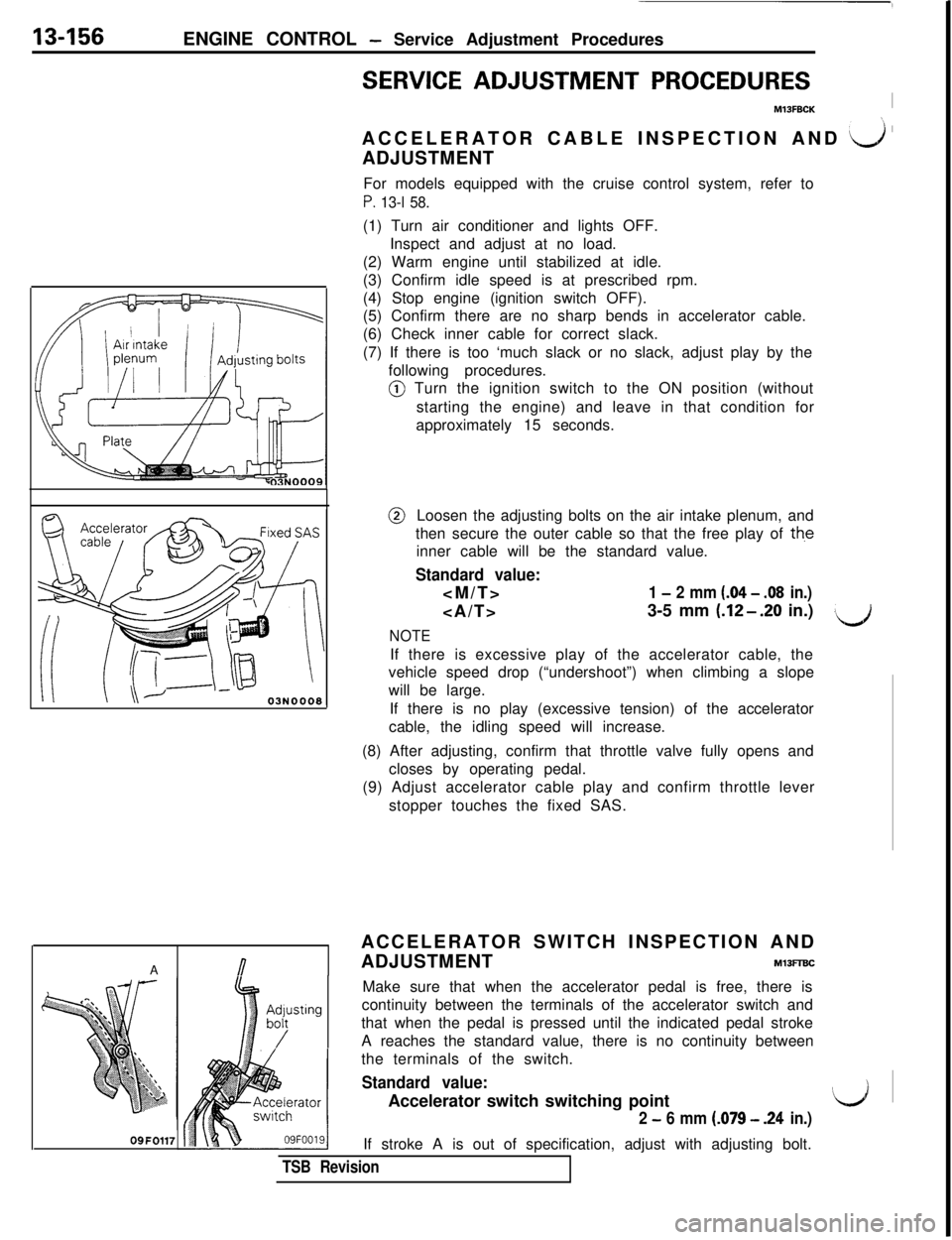

13-156ENGINE CONTROL - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

M13FBCKIACCELERATOR CABLE INSPECTION AND

a ’ADJUSTMENT

For models equipped with the cruise control system, refer to

P. 13-l 58.(1) Turn air conditioner and lights OFF.

Inspect and adjust at no load.

(2) Warm engine until stabilized at idle.

(3) Confirm idle speed is at prescribed rpm.

(4) Stop engine (ignition switch OFF).

(5) Confirm there are no sharp bends in accelerator cable.

(6) Check inner cable for correct slack.

(7) If there is too ‘much slack or no slack, adjust play by the

following procedures.@ Turn the ignition switch to the ON position (without

starting the engine) and leave in that condition for

approximately 15 seconds.@Loosen the adjusting bolts on the air intake plenum, and

then secure the outer cable so that the free play of

th,einner cable will be the standard value.

Standard value:

1 - 2 mm (.04 - .08 in.)3-5 mm

(.12-.20 in.)

NOTE

\JIf there is excessive play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a slope

will be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

(8) After adjusting, confirm that throttle valve fully opens and

closes by operating pedal.

(9) Adjust accelerator cable play and confirm throttle lever

stopper touches the fixed SAS.

ACCELERATOR SWITCH INSPECTION AND

A

nADJUSTMENTMlBFlBC

09FO117Make sure that when the accelerator pedal is free, there is

;$ustingcontinuity between the terminals of the accelerator switch and

/that when the pedal is pressed until the indicated pedal stroke

A reaches the standard value, there is no continuity between

the terminals of the switch.

Standard value:Accelerator switch switching point

2 - 6 mm (.079 - .24 in.)If stroke A is out of specification, adjust with adjusting bolt.

TSB Revision

\

‘LJ ~