light MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 366 of 1146

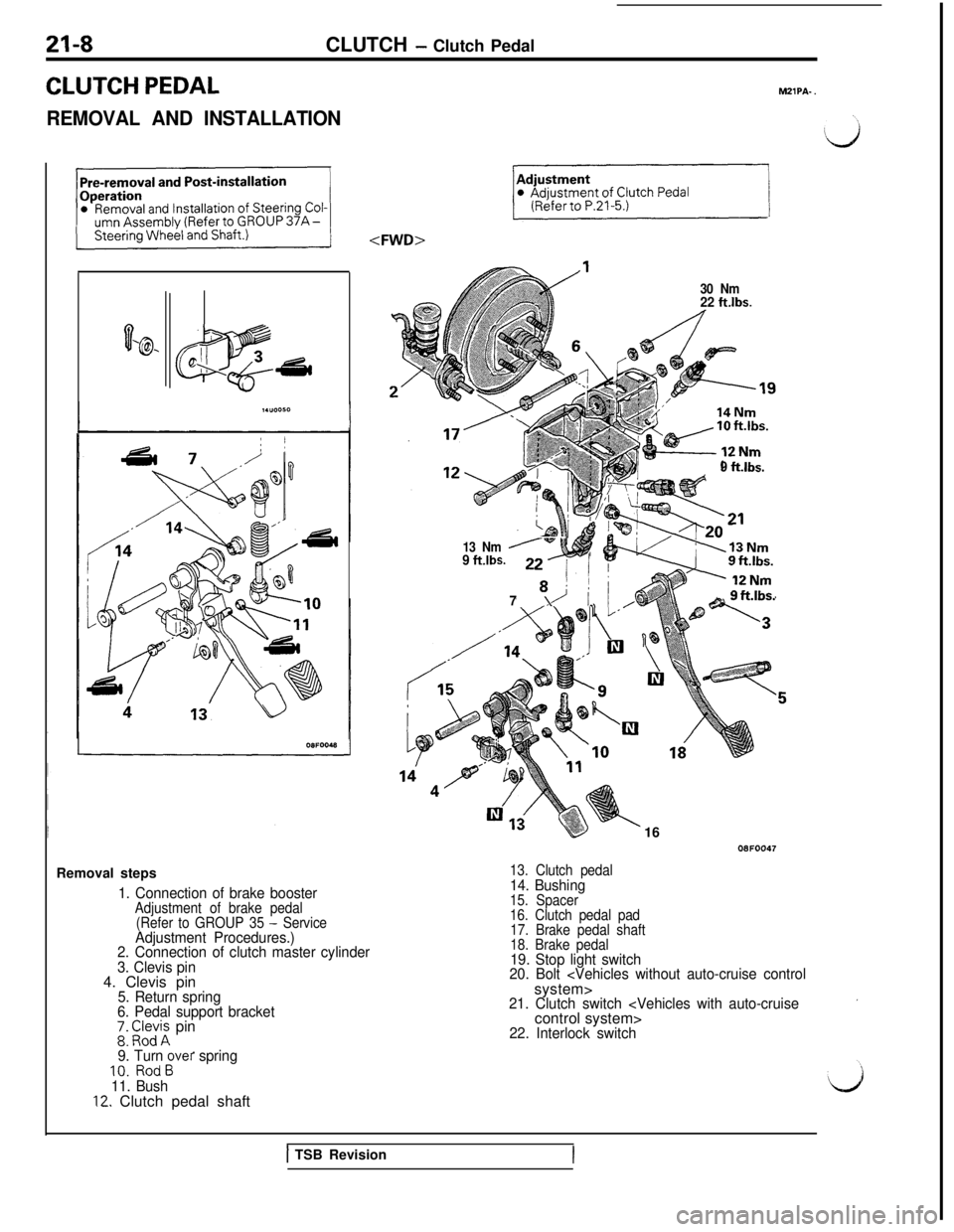

21-8CLUTCH - Clutch Pedal

CLUTCH PEDAL

REMOVAL AND INSTALLATIONMZlPA-

.

0‘@- D.,

a

;

IGsdRemoval steps

1. Connection of brake boosterAdjustment of brake pedal

(Refer to GROUP 35 - ServiceAdjustment Procedures.)

2. Connection of clutch master cylinder

3. Clevis pin4. Clevis pin

5. Return spring

6. Pedal support bracket

;: EIe;i; pin

9. Turn over spring10. RodB

11. Bush

12. Clutch pedal shaft

30 Nm22 ftlbs.

9 ft.lbs.

13 Nm

9 ft.lbs.Gw+,

8 !!

79 I_a 9ft.lbs.

k1608FOO47

13. Clutch pedal14. Bushing15. Spacer

16. Clutch pedal pad

17. Brake pedal shaft

18. Brake pedal

19. Stop light switch

20. Bolt

21. Clutch switch

22. Interlock switch

1 TSB Revision

Page 381 of 1146

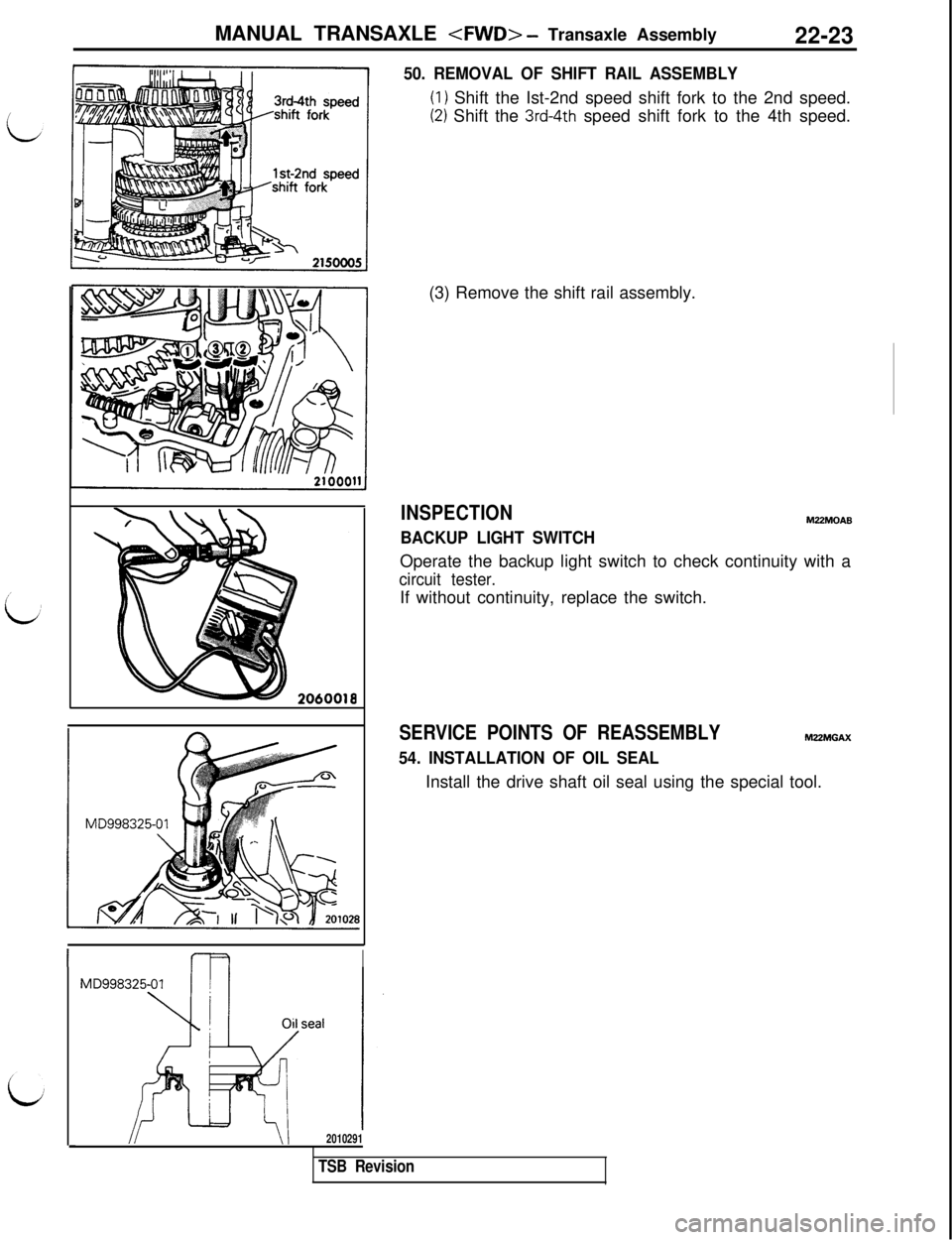

22-1

iv,MANUAL ~

TRANSAXLE

~

I

CONTENTSM22AA. -

MANUAL TRANSAXLE

GENERAL INFORMATION....................................................48

SERVICE ADJUSTMENT PROCEDURES

............................51

Drive Shaft OilSealsReplacement....................................

52Speedometer Cable Replacement....................................

53Transfer Oil Seal Replacement............................................53Transmission Oil Level Inspection....................................51Transmission Oil Replacement............................................51

SHIFT LEVER ASSEMBLY....................................................

53

SPECIAL TOOLS........................................................................50

SPECIFICATIONS

....................................................................49

General Specifications........................................................49Lubricants............................................................................49

TRANSAXLE ASSEMBLY....................................................56,60

TRANSAXLE CONTROL*........................................................54

TRANSFER ASSEMBLY

........................................................59

MANUAL TRANSAXLE

CLUTCH HOUSING ASSEMBLY............................................46

DIFFERENTIAL ASSEMBLY

....................................................43

5TH SPEED SYNCHRONIZER ASSEMBLY

........................28

GENERAL INFORMATION

....................................................2INTERMEDIATE GEAR ASSEMBLY

....................................

OUTPUT SHAFT ASSEMBLY................................................

SERVICE ADJUSTMENT PROCEDURES............................

Drive Shaft Oil Seals Replacement....................................Speedometer CableReplacement....................................Transmission Oil Level Inspection....................................Transmisston Oil Replacement............................................

SHIFT LEVER ASSEMBLY....................................................

SHIFT RAILS AND FORKS....................................................

SPECIAL TOOLS........................................................................

SPECIFICATIONS....................................................................

General Specifications........................................................

Lubricants............................................................................

Sealants and Adhesives........................................................Service Specifications........................................................

Snap Ring (for Adjustment) and Spacer............................

SPEEDOMETER DRIVEN GEAR ASSEMBLY....................

TRANSAXLE ASSEMBLY _____...._........__....................................

TRANSAXLE CONTROL*. . ..________.___.._ ..__._.__.__...............

36

41

9

10

9

9

9

13

42

6

3z

63

3

45

14

11TROUBLESHOOTING

___.._______._____.......,..................................8

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the

SRS inoperative).(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 398 of 1146

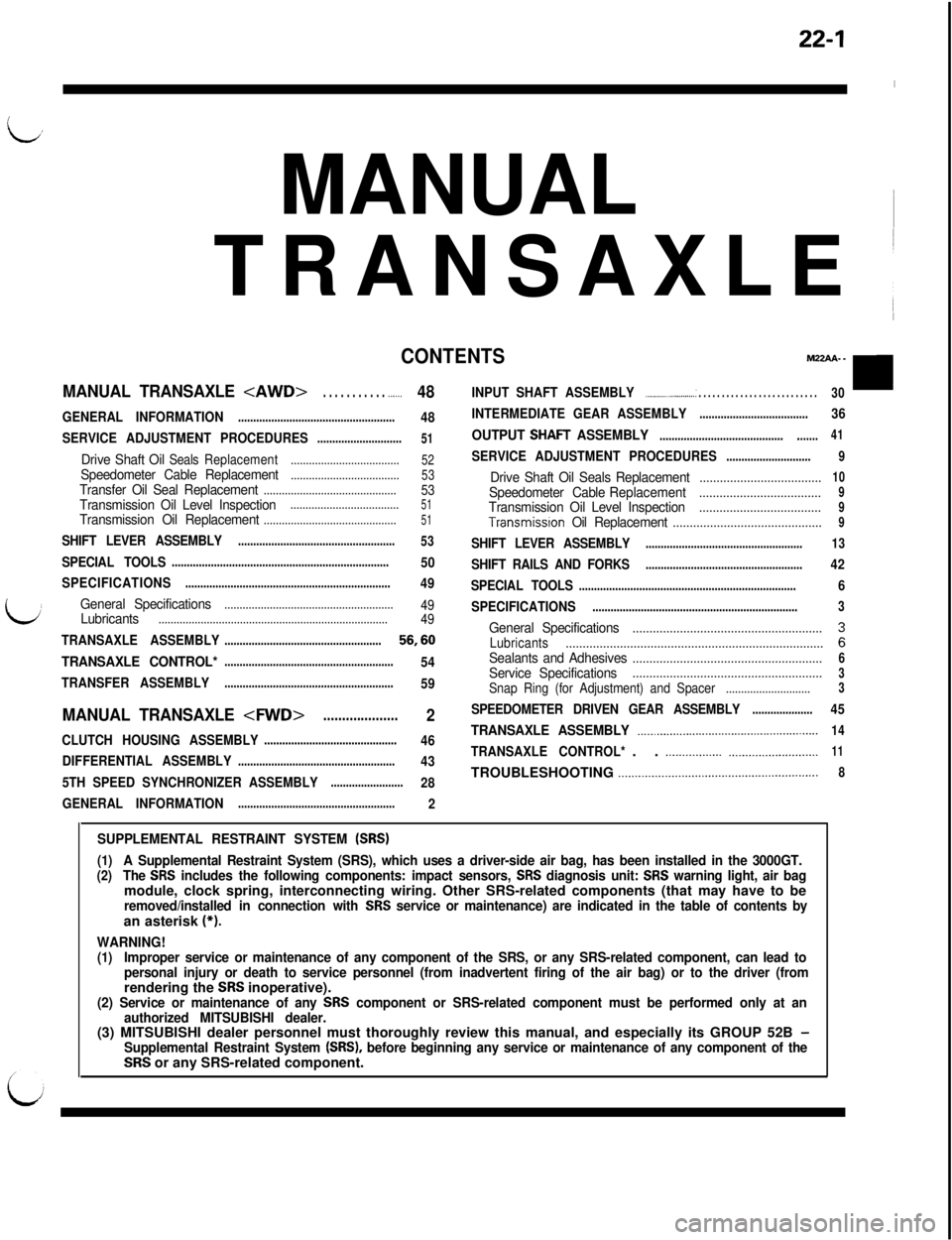

22-18MANUAL TRANSAXLE

TRANSAXLE ASSEMBLYIM22ME.A

I

DISASSEMBLY AND REASSEMBLY

l5-22Nmdl

11 - 15 ftlbs.

-42 Nm

- 30 ftlbs.30-35 Nm

4.0 -5.5Nm

22

- 25 ft.lbs.lIll42.9 -3.9ftlbs.

/I18

J6140-160Nm1102-115ftlbs.

3-5Nm2.5 - 3.5 ftlbs.

11Disassembly steps

1.Bolt2.Rear cover3.Wave spring4.Screw bolts5. Reverse brake cone

6. Backup light switch

7.Gasket8.Poppet plug9.Poppet springIO. Poppet ball11.Bolt12. Speedometer driven gear assembly13.Air breather+* +* 14. Spring pin

*+ l * 15. Lock nut*+ l + 16. Lock nut17. 5th speed synchronizer assembly

18. 5th speed shift fork

19.Synchronizer ring20. 5th speed gear21.Needle bearing22. 5th speed intermediate gearTSB Revision

Page 403 of 1146

MANUAL TRANSAXLE

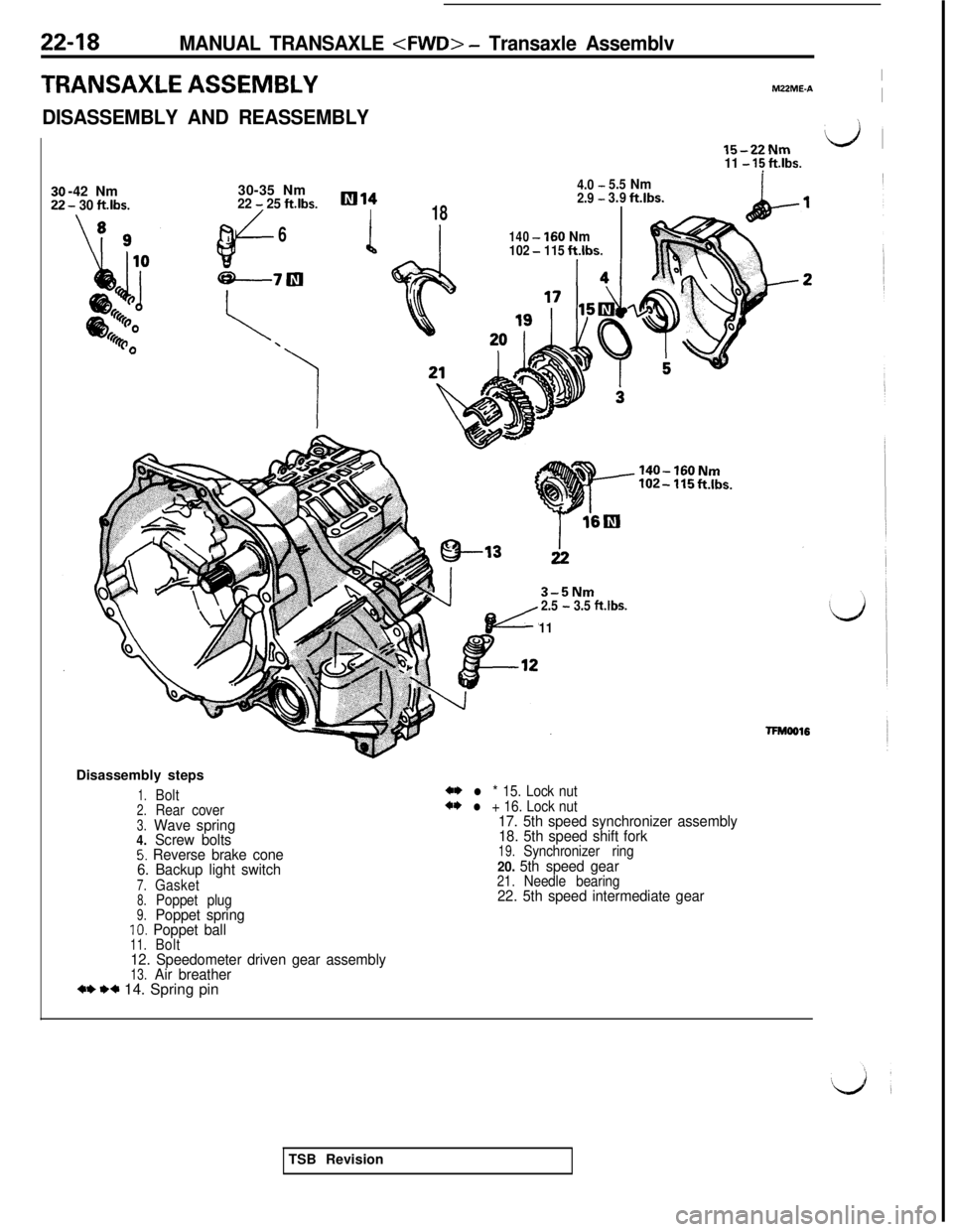

50. REMOVAL OF SHIFT RAIL ASSEMBLY

(I 1 Shift the Ist-2nd speed shift fork to the 2nd speed.

(2) Shift the 3rd-4th speed shift fork to the 4th speed.

MD998325-01

II

MD998325-01

/I\I2010291(3) Remove the shift rail assembly.

INSPECTIONM22MOAB

BACKUP LIGHT SWITCHOperate the backup light switch to check continuity with a

circuit tester.If without continuity, replace the switch.

SERVICE POINTS OF REASSEMBLYMZZMGAX

54. INSTALLATION OF OIL SEALInstall the drive shaft oil seal using the special tool.

TSB Revision

Page 443 of 1146

23-1

AUTOMATIC

TRANSAXLE

CONTENTSMZJAA- _

ANNULUS GEAR AND TRANSFER DRIVE GEARTransmission Fluid Level Inspection................................46SET................................................................................................

102Transmission Fluid Replacement........................................

46

DIFFERENTIAL........................................................................104SPECIAL TOOLS........................................................................

16

:......................................... 12IEND CLUTCH ASSEMBLY....................................................99SPECIFICATIONS..........................

FRONT CLUTCH ASSEMBLY................................................95

GENERAL INFORMATlON....................................................2

KICKDOWN SERVO................................................................

107

LOW-REVERSE BRAKE............................................................

107

OIL PUMP....................................................................................93

PLANETARY GEAR................................................................

100

REAR CLUTCH ASSEMBLY....................................................97

SELECTOR LEVER ASSEMBLY............................................58

SERVICE ADJUSTMENT PROCEDURES............................46

Accelerator Switch

Inspection and Adjustment................

50Drive Shaft Oil Seals Replacement....................................

52Inhibitor Switch and Control Cable Adjustment................

52Key Interlock Mechanism Check........................................50KickdownServo Adjustment................................................

47Line Pressure Adjustment....................................................

48Reducing Pressure Adjustment........................................

49Selector Lever Operation Check........................................

50Shift Lock Mechanism Check............................................51Speedometer Cable Replacement....................................53

General Specifications........................................................12Lubricants............................................................................15Service Specifications........................................................12Spacer and Snap Ring........................................................13Valve Body Spring Identification Chart............................13

SPEEDOMETER DRIVEN GEAR ASSEMBLY....................106

TRANSAXLE ASSEMBLY........................................................62

TRANSAXLE CONTROL*........................................................54

TRANSAXLE OIL COOLER, HOSES, TUBES

....................66

TRANSFER SHAFT....................................................................92

TROUBLESHOOTING............................................................

19

A/T Safety-lock System Troubleshooting........................44Converter Stall Test............................................................

43

Diagnosis and Test

................................................................

22

Element in Use at Each Position of Selector Lever........31Inspection

of ControlSystem............................................

28Inspection of Electronic Control System Components....32Oil Pressure Tests................................................................

39ShiftPatterns....................................................................

31,42Troubleshooting Guide........................................................

20

VALVE BODY. . . .._._.................................................................... 108

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3668GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to beremoved/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead topersonal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

(3) MlTSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of the

ISRS or any SRS-related component.

Page 475 of 1146

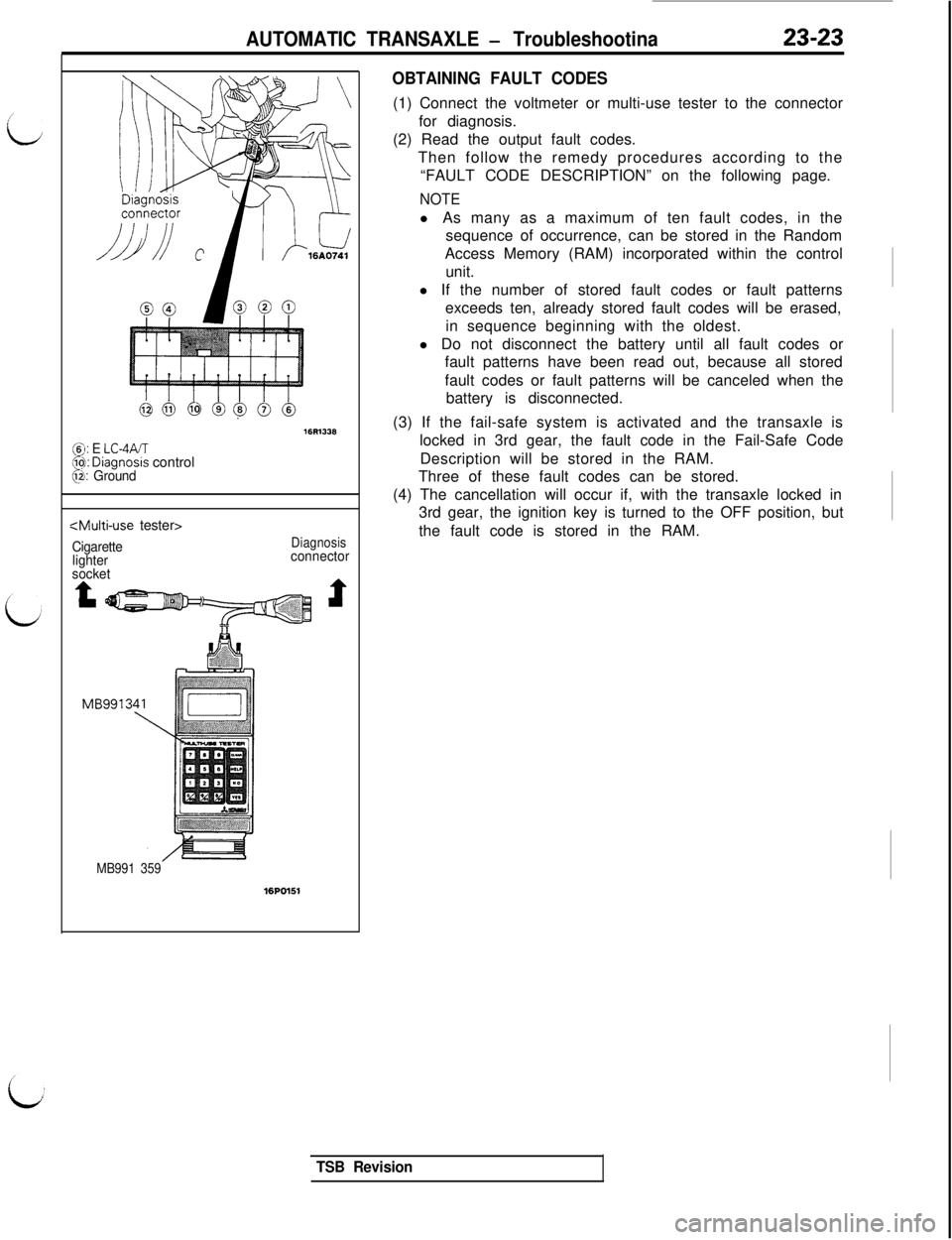

AUTOMATIC TRANSAXLE - Troubleshootina23-23

p: E LC-4A/T~9: Dlagnosls control@I: Ground

:Multi-use tester>

Cigarette

lighter

socketDiagnosisconnector

MB991 359

16POl51

OBTAINING FAULT CODES(1) Connect the voltmeter or multi-use tester to the connector

for diagnosis.

(2) Read the output fault codes.

Then follow the remedy procedures according to the

“FAULT CODE DESCRIPTION” on the following page.

NOTEl As many as a maximum of ten fault codes, in the

sequence of occurrence, can be stored in the Random

Access Memory (RAM) incorporated within the control

unit.

l If the number of stored fault codes or fault patterns

exceeds ten, already stored fault codes will be erased,

in sequence beginning with the oldest.

l Do not disconnect the battery until all fault codes or

fault patterns have been read out, because all stored

fault codes or fault patterns will be canceled when the

battery is disconnected.

(3) If the fail-safe system is activated and the transaxle is

locked in 3rd gear, the fault code in the Fail-Safe Code

Description will be stored in the RAM.

Three of these fault codes can be stored.

(4) The cancellation will occur if, with the transaxle locked in

3rd gear, the ignition key is turned to the OFF position, but

the fault code is stored in the RAM.

TSB Revision

Page 503 of 1146

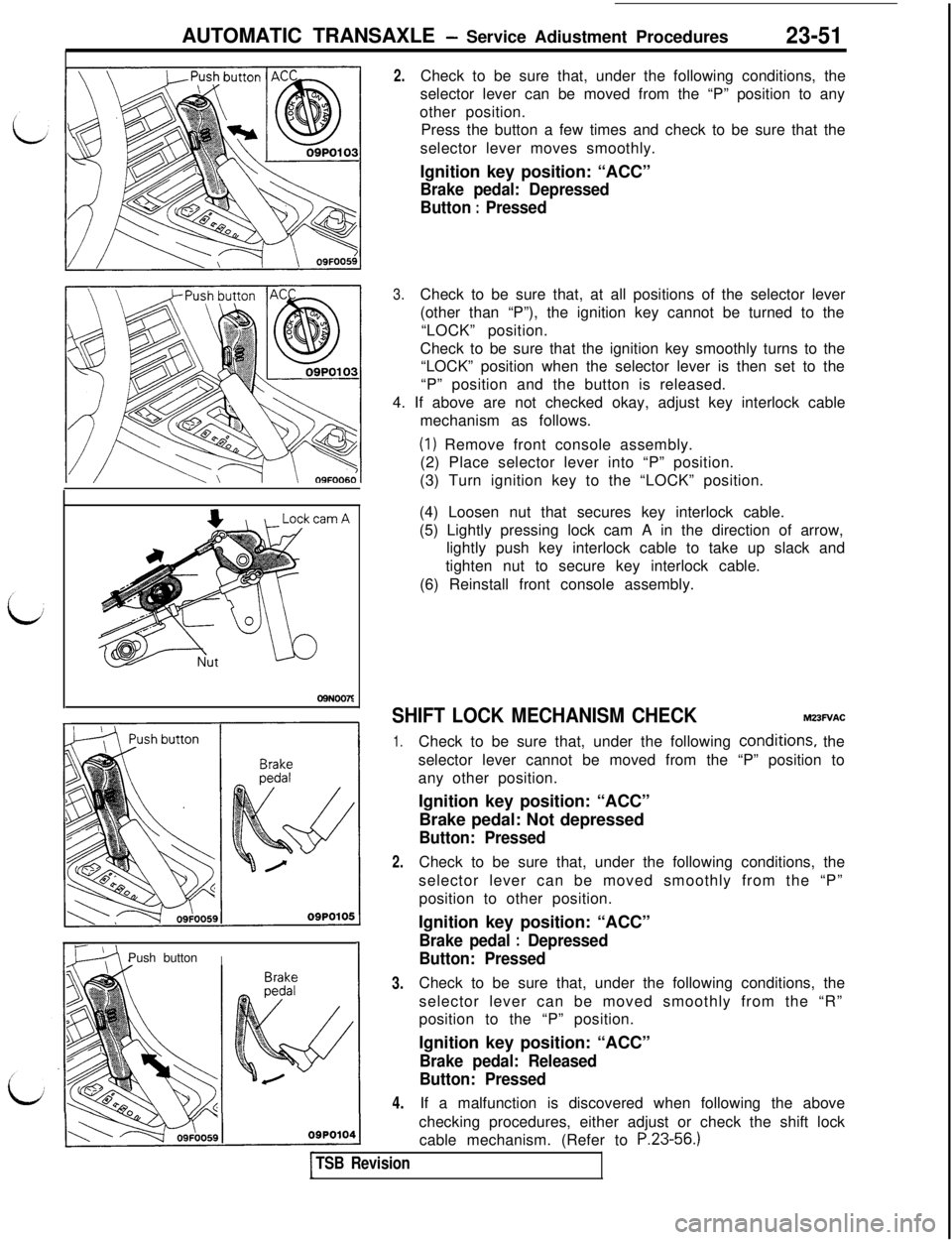

AUTOMATIC TRANSAXLE - Service Adiustment Procedures23-51

D9N007SPush button

II

2.Check to be sure that, under the following conditions, the

selector lever can be moved from the “P” position to any

other position.

Press the button a few times and check to be sure that the

selector lever moves smoothly.

Ignition key position: “ACC”

Brake pedal: Depressed

Button

: Pressed

3.Check to be sure that, at all positions of the selector lever

(other than “P”), the ignition key cannot be turned to the

“LOCK” position.

Check to be sure that the ignition key smoothly turns to the

“LOCK” position when the selector lever is then set to the

“P” position and the button is released.

4. If above are not checked okay, adjust key interlock cable

mechanism as follows.

(1) Remove front console assembly.

(2) Place selector lever into “P” position.

(3) Turn ignition key to the “LOCK” position.

(4) Loosen nut that secures key interlock cable.

(5) Lightly pressing lock cam A in the direction of arrow,

lightly push key interlock cable to take up slack and

tighten nut to secure key interlock cable.

(6) Reinstall front console assembly.

SHIFT LOCK MECHANISM CHECKMZ3FVAC

1.

2.

3.

4.Check to be sure that, under the following

condi,tions, the

selector lever cannot be moved from the “P” position to

any other position.

Ignition key position: “ACC”

Brake pedal: Not depressed

Button: PressedCheck to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “P”

position to other position.

Ignition key position: “ACC”

Brake pedal : Depressed

Button: PressedCheck to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “R”

position to the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button: PressedIf a malfunction is discovered when following the above

checking procedures, either adjust or check the shift lock

cable mechanism. (Refer to

P.23-56.)

TSB Revision

Page 504 of 1146

23-52

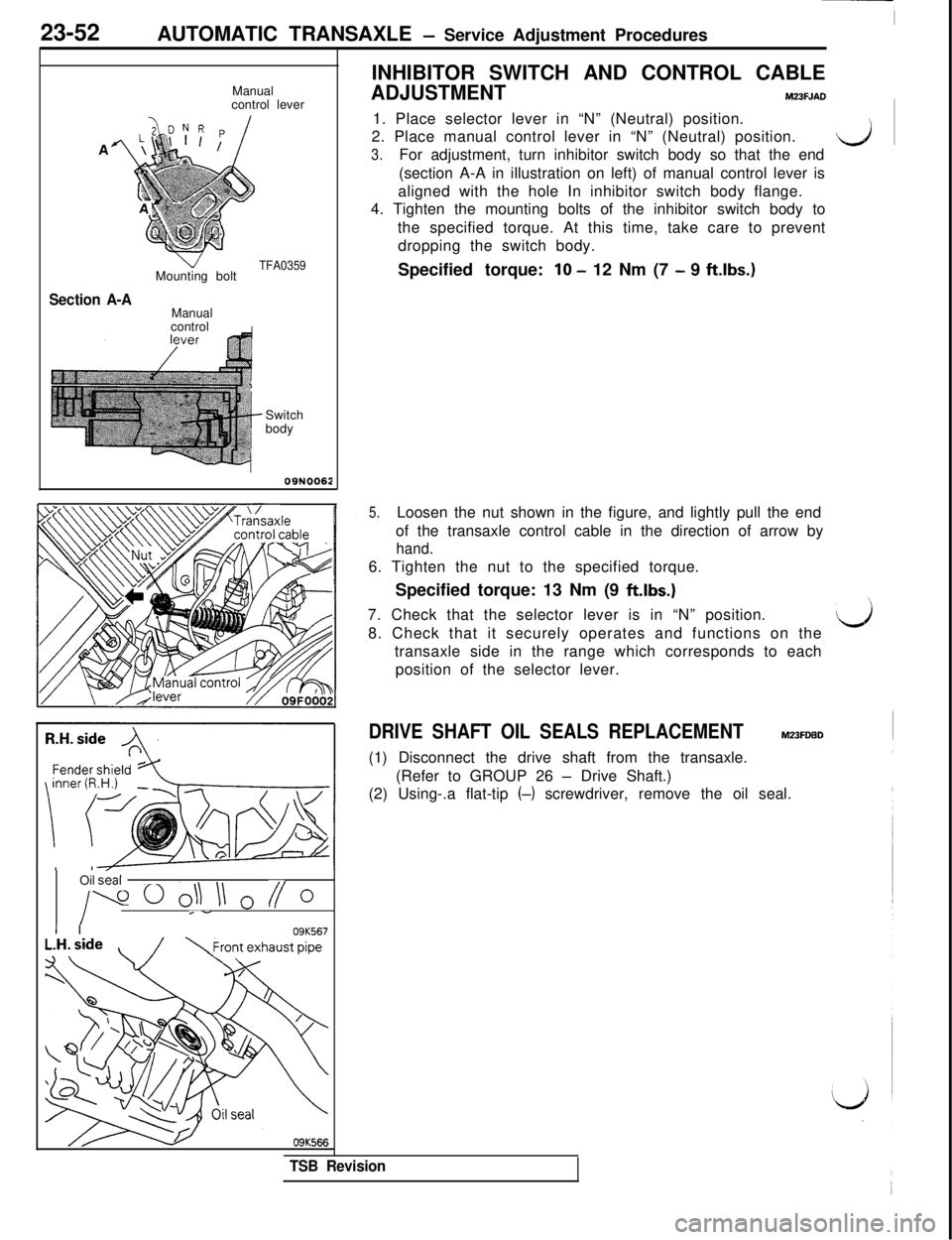

AUTOMATIC TRANSAXLE - Service Adjustment Procedures

Manual

control leverINHIBITOR SWITCH AND CONTROL CABLE

ADJUSTMENTM23FJADI1. Place selector lever in “N” (Neutral) position.

2. Place manual control lever in “N” (Neutral) position.

d3.For adjustment, turn inhibitor switch body so that the end

(section A-A in illustration on left) of manual control lever is

aligned with the hole In inhibitor switch body flange.

4. Tighten the mounting bolts of the inhibitor switch body to

the specified torque. At this time, take care to prevent

dropping the switch body.

TFA0359Mounting bolt

Section A-AManual

control

ISwitch

body

09N0062Oil

skal

1

v0 o\l II 0 // 0*-

I I09K567

09K566Specified torque:

10 - 12 Nm (7 - 9 ftlbs.)

5.Loosen the nut shown in the figure, and lightly pull the end

of the transaxle control cable in the direction of arrow by

hand.6. Tighten the nut to the specified torque.

Specified torque: 13 Nm (9

ftlbs.)7. Check that the selector lever is in “N” position.

8. Check that it securely operates and functions on the

transaxle side in the range which corresponds to each

position of the selector lever.

d

DRIVE SHAFT OIL SEALS REPLACEMENTM23FLN3D(1) Disconnect the drive shaft from the transaxle.

(Refer to GROUP 26

- Drive Shaft.)

(2) Using-.a flat-tip (-) screwdriver, remove the oil seal.

TSB Revision

Page 508 of 1146

23-56AUTOMATIC TRANSAXLE - Transaxle ControlOQPOOQQ

09FOO5

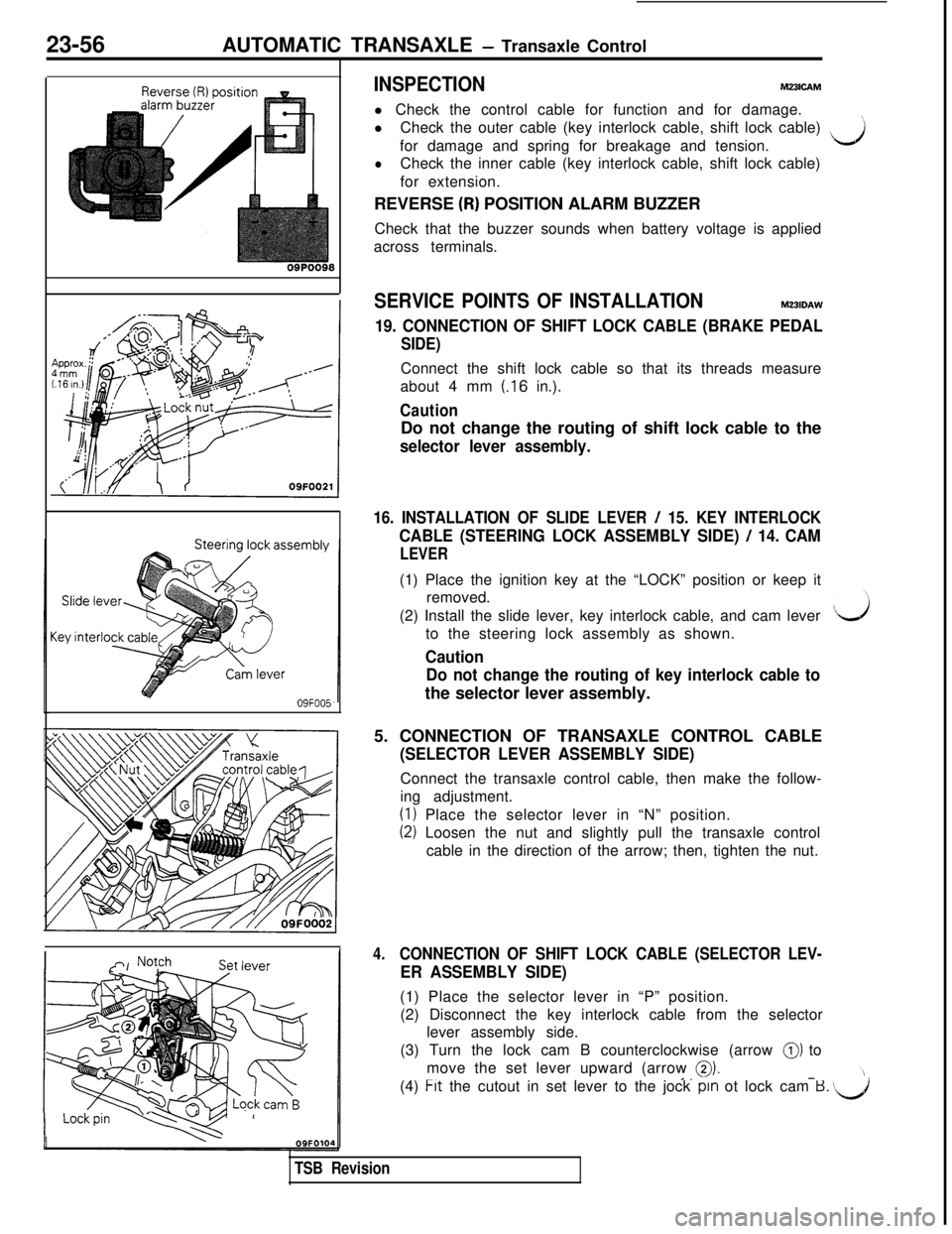

INSPECTIONM231CAMl Check the control cable for function and for damage.

lCheck the outer cable (key interlock cable, shift lock cable)

’for damage and spring for breakage and tension.~J

lCheck the inner cable (key interlock cable, shift lock cable)

for extension.

REVERSE

(R) POSITION ALARM BUZZER

Check that the buzzer sounds when battery voltage is applied

across terminals.

SERVICE POINTS OF INSTALLATIONM231DAW

19. CONNECTION OF SHIFT LOCK CABLE (BRAKE PEDAL

SIDE)Connect the shift lock cable so that its threads measure

about 4 mm

(.16 in.).

CautionDo not change the routing of shift lock cable to the

selector lever assembly.

16. INSTALLATION OF SLIDE LEVER / 15. KEY INTERLOCK

CABLE (STEERING LOCK ASSEMBLY SIDE) / 14. CAM

LEVER(1) Place the ignition key at the “LOCK” position or keep it

removed.

(2) Install the slide lever, key interlock cable, and cam lever

to the steering lock assembly as shown.

Caution

Do not change the routing of key interlock cable tothe selector lever assembly.

5. CONNECTION OF TRANSAXLE CONTROL CABLE

(SELECTOR LEVER ASSEMBLY SIDE)Connect the transaxle control cable, then make the follow-

ing adjustment.

(1) Place the selector lever in “N” position.

(2) Loosen the nut and slightly pull the transaxle control

cable in the direction of the arrow; then, tighten the nut.

4.CONNECTION OF SHIFT LOCK CABLE (SELECTOR LEV-

ER ASSEMBLY SIDE)(1) Place the selector lever in “P” position.

(2) Disconnect the key interlock cable from the selector

lever assembly side.

(3) Turn the lock cam B counterclockwise (arrow

0) to

move the set lever upward (arrow

0)._.-(4) Frt the cutout in set lever to the jock pm ot lock cam B. u

TSB Revision

Page 509 of 1146

AUTOMATIC TRANSAXLE - Transaxle Control23-57

09N0050Was

Nut

09N0049Was

Nut

0910046

I

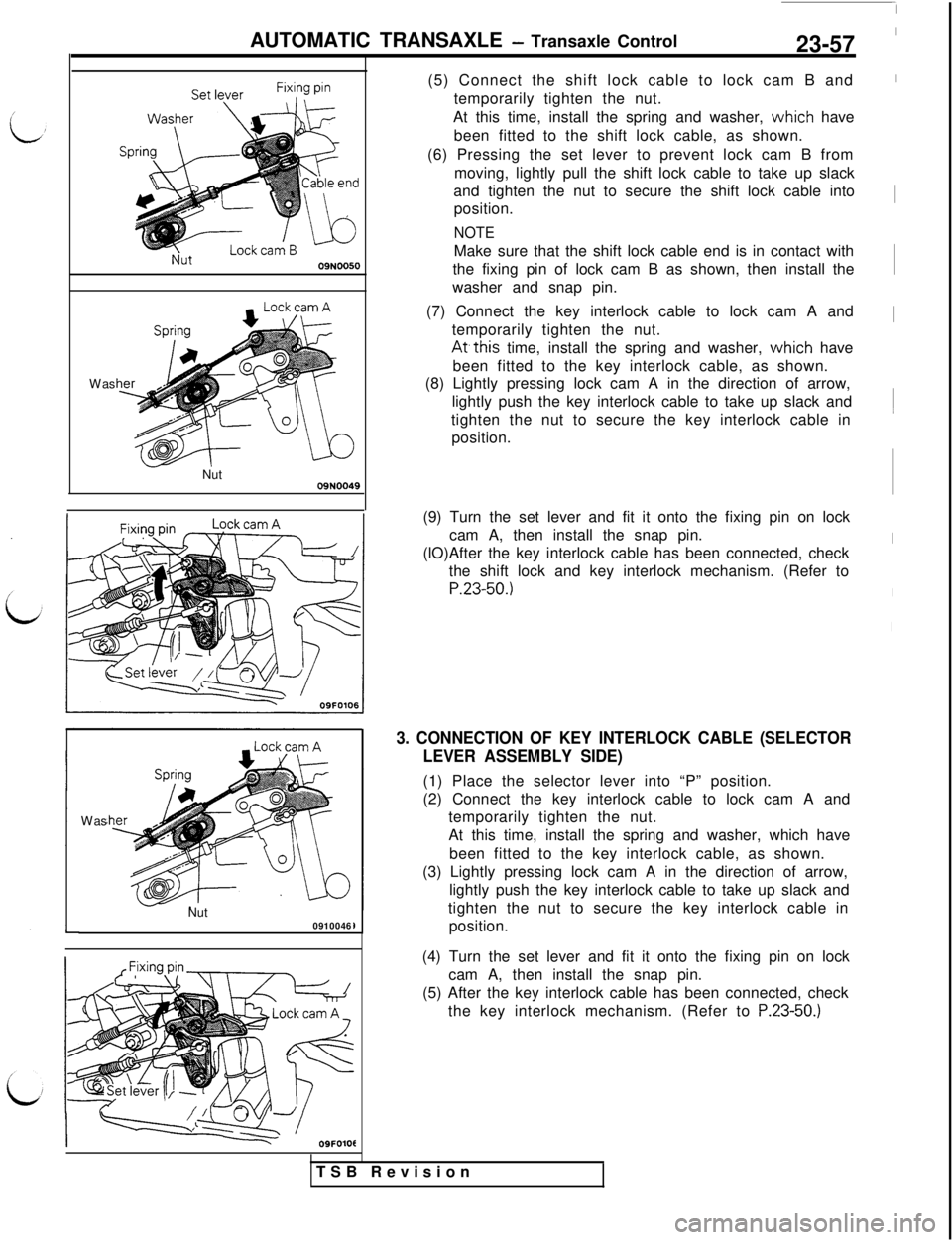

-09FOlOt(5) Connect the shift lock cable to lock cam B and

temporarily tighten the nut.

At this time, install the spring and washer,

vvhich have

been fitted to the shift lock cable, as shown.

(6) Pressing the set lever to prevent lock cam B from

moving, lightly pull the shift lock cable to take up slack

and tighten the nut to secure the shift lock cable into

position.

NOTEMake sure that the shift lock cable end is in contact with

the fixing pin of lock cam B as shown, then install the

washer and snap pin.

(7) Connect the key interlock cable to lock cam A and

temporarily tighten the nut.

At,this time, install the spring and washer, vvhich have

been fitted to the key interlock cable, as shown.

(8) Lightly pressing lock cam A in the direction of arrow,

lightly push the key interlock cable to take up slack and

tighten the nut to secure the key interlock cable in

position.

(9) Turn the set lever and fit it onto the fixing pin on lock

cam A, then install the snap pin.

(lO)After the key interlock cable has been connected, check

the shift lock and key interlock mechanism. (Refer to

P.23-50.)

3. CONNECTION OF KEY INTERLOCK CABLE (SELECTOR

LEVER ASSEMBLY SIDE)(1) Place the selector lever into “P” position.

(2) Connect the key interlock cable to lock cam A and

temporarily tighten the nut.

At this time, install the spring and washer, which have

been fitted to the key interlock cable, as shown.

(3) Lightly pressing lock cam A in the direction of arrow,

lightly push the key interlock cable to take up slack and

tighten the nut to secure the key interlock cable in

position.

(4) Turn the set lever and fit it onto the fixing pin on lock

cam A, then install the snap pin.

(5) After the key interlock cable has been connected, check

the key interlock mechanism. (Refer to

P.23-50.)TSB Revision

-1

I

I

I~

I~

I

I

I