Tensioner MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 57 of 1146

ENGINE - Specifications

/

L

L/

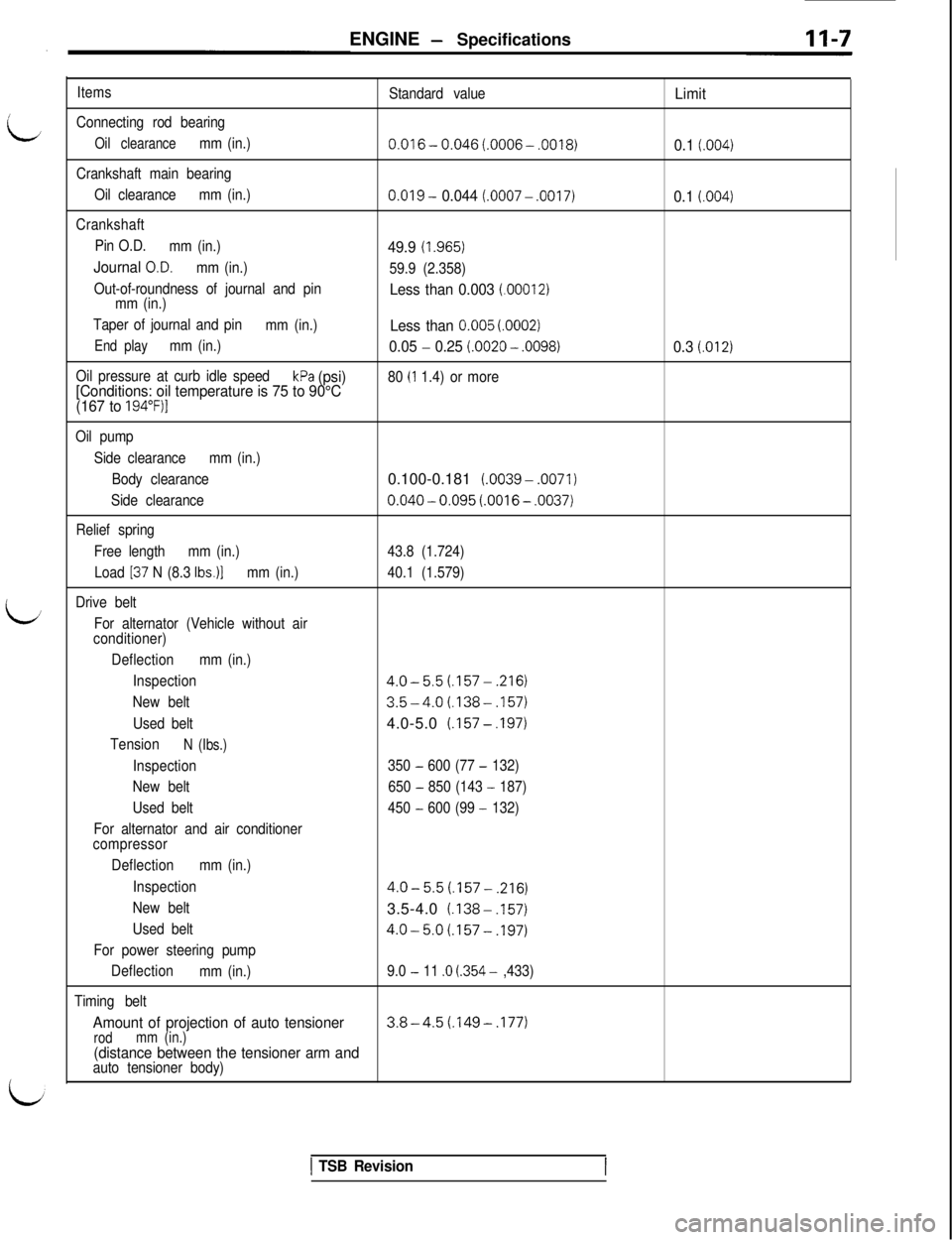

Items

Connecting rod bearing

Oil clearancemm (in.)

Crankshaft main bearing

Oil clearancemm (in.)

Crankshaft

Pin O.D.

mm (in.)

Journal O.D.mm (in.)

Out-of-roundness of journal and pin

mm (in.)

Taper of journal and pin

mm (in.)

End playmm (in.)

Oil pressure at curb idle speed

kPa (psi)

[Conditions: oil temperature is 75 to 90°C

(167 to

194”F)l

Standard value

0.016- 0.046 (.0006- .0018)

0.019 - 0.044 (.0007 - .0017)

49.9 (I ,965)

59.9 (2.358)

Less than 0.003 (.00012)

Less than 0.005 (0002)

0.05 - 0.25 (0020 - .0098)

80 (I 1.4) or more

Limit

0.1

(.004)

0.1 (.004)

0.3 (.012)

Oil pump

Side clearancemm (in.)

Body clearance0.100-0.181 (.0039-.0071)

Side clearance0.040 - 0.095 (.0016 - .0037)

Relief spring

Free lengthmm (in.)43.8 (1.724)

Load

137 N (8.3 Ibs.)]mm (in.)40.1 (1.579)

Drive belt

For alternator (Vehicle without air

conditioner)

Deflectionmm (in.)

Inspection

4.0-5.5(.157-,216)

New belt3.5-4.0(.138-,157)

Used belt4.0-5.0 (.157- ,197)

TensionN (Ibs.)

Inspection350 - 600 (77 - 132)

New belt650

- 850 (143 - 187)

Used belt450

- 600 (99 - 132)

For alternator and air conditioner

compressor

Deflectionmm (in.)

Inspection

4.0-5.5(.157-,216)

New belt3.5-4.0 (1388.157)

Used belt4.0-5.0(.157-,197)

For power steering pump

Deflection

mm (in.)9.0

- 11 .o (354 - ,433)

Timing belt

Amount of projection of auto tensioner3.8-4.5(.149-,177)rodmm (in.)(distance between the tensioner arm andauto tensioner body)

1 TSB Revision

Page 59 of 1146

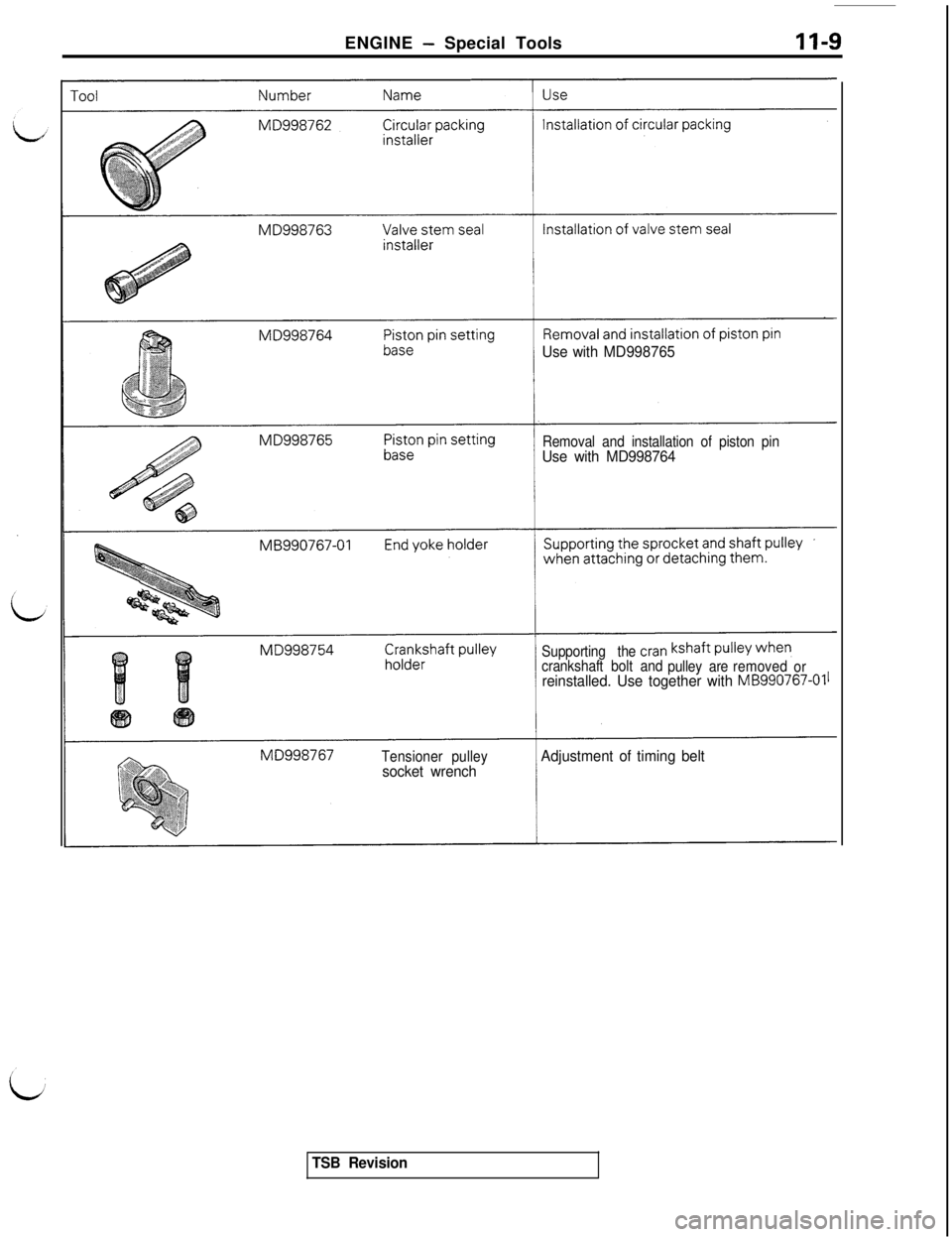

ENGINE - Special ToolsII-9

Use withMD998765

Removal and installation of piston pinUse with MD998764

Supporting thecrancrankshaft bolt and

pulley areremoved

orreinstalled. Use together with MB990767-01

Tensioner pulley

socket wrenchAdjustment of timing belt

TSB Revision

Page 76 of 1146

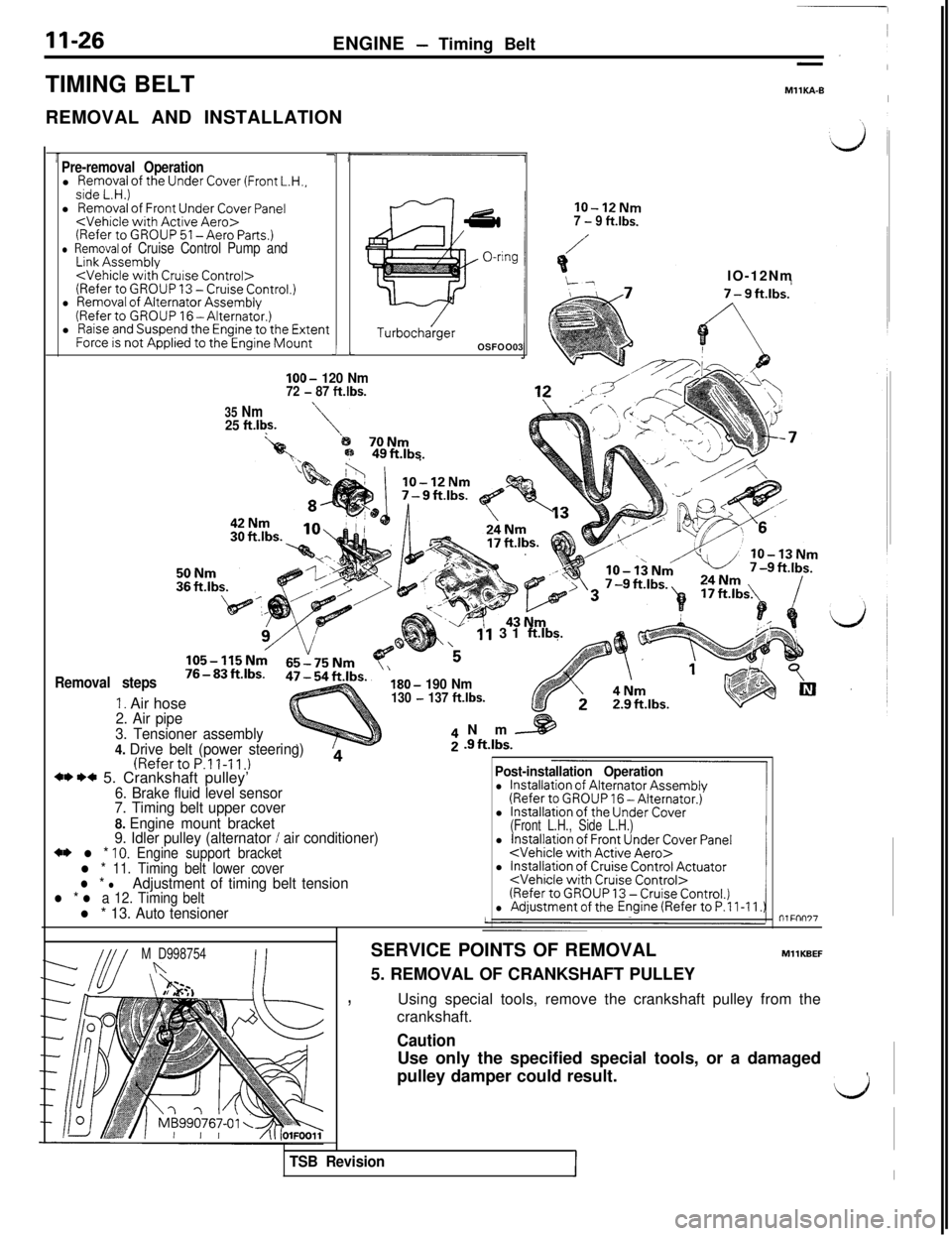

11-26ENGINE - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

MllKA-BI

Pre-removal Operationl Removal of the Under Cover (Front L.H.,side L.H.)l Removal of Front Under Cover Panel

l Raise and Suspend the Engine to the ExtentForce is not Applied to the Engine Mounti LIOO-

120 Nm72 - 87 ft.lbs.

35 Nm25 ft.l$.

TurbochargerOSFOO03

lo-12Nm7 - 9 ft.lbs.

Removal steps

1. Air hose

11 31 ftlbs.

‘5IO-12Nm

B;p 49ftJbs.

\

180- 190 Nm130 - 137 ft.lbs.

2. Air pipe

3. Tensioner assembly

4. Drive belt (power steering)

(RefertoP.ll-11.)4** I)* 5. Crankshaft pulley’6. Brake fluid level sensor

7. Timing belt upper cover

8. Engine mount bracket

9. Idler pulley (alternator

/ air conditioner)+* l * 10. Engine support bracketl * 11. Timing belt lower coverl * lAdjustment of timing belt tensionl * l a 12. Timing beltl * 13. Auto tensionerNm

[email protected].

Post-installation Operation

l Installation of Alternator Assembly(Refer to GROUP 16 -Alternator.)

l Installation of the Under Cover(Front L.H., Side L.H.)l Installation of Front Under Cover Panel

l Installation of Cruise Control Actuator

M D998754nSERVICE POINTS OF REMOVAL

5. REMOVAL OF CRANKSHAFT PULLEYMllKBEF

,Using special tools, remove the crankshaft pulley from the

crankshaft.

TSB RevisionII

CautionUse only the specified special tools, or a damaged

pulley damper could result.

,

LJ

Page 77 of 1146

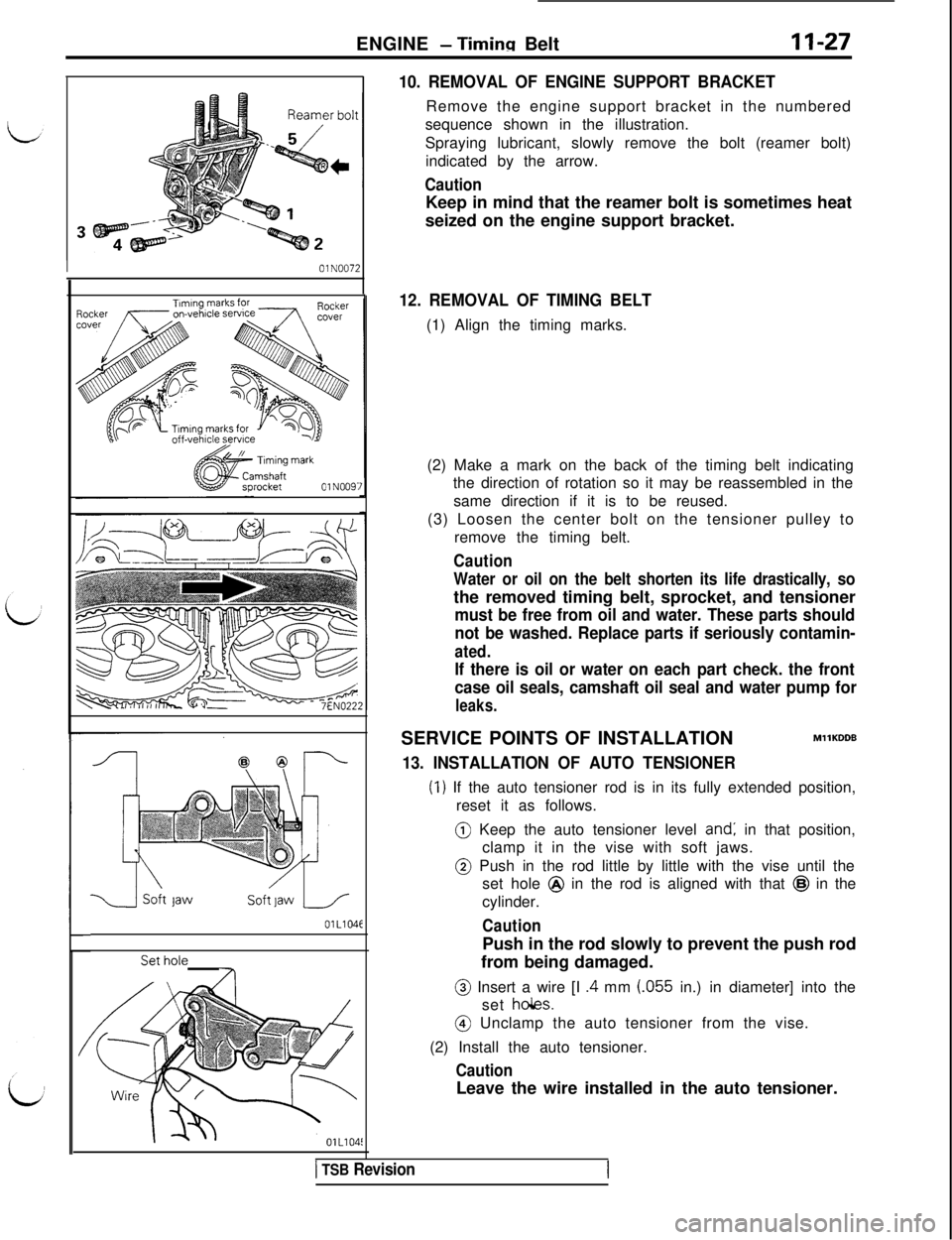

ENGINE - Timinn Belt11-27

r bol

I01 NO07

10. REMOVAL OF ENGINE SUPPORT BRACKETRemove the engine support bracket in the numbered

sequence shown in the illustration.

Spraying lubricant, slowly remove the bolt (reamer bolt)

indicated by the arrow.

CautionKeep in mind that the reamer bolt is sometimes heat

seized on the engine support bracket.

Timing mark

mshaftrocket01 N009:

d Soft jawSoft jaw

OlL104E

Set hole

n

12. REMOVAL OF TIMING BELT(1) Align the timing marks.

(2) Make a mark on the back of the timing belt indicating

the direction of rotation so it may be reassembled in the

same direction if it is to be reused.

(3) Loosen the center bolt on the tensioner pulley to

remove the timing belt.

Caution

Water or oil on the belt shorten its life drastically, sothe removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contamin-

ated.

If there is oil or water on each part check. the front

case oil seals, camshaft oil seal and water pump for

leaks.SERVICE POINTS OF INSTALLATION

MllKDDB

13. INSTALLATION OF AUTO TENSIONER

(‘I) If the auto tensioner rod is in its fully extended position,

reset it as follows.@ Keep the auto tensioner level

and: in that position,

clamp it in the vise with soft jaws.@ Push in the rod little by little with the vise until the

set hole @ in the rod is aligned with that @ in the

cylinder.

CautionPush in the rod slowly to prevent the push rod

from being damaged.@ Insert a wire [I

.4 mm (.055 in.) in diameter] into the

set

ho&.@ Unclamp the auto tensioner from the vise.

(2) Install the auto tensioner.

CautionLeave the wire installed in the auto tensioner.

1 TSB Revision

Page 79 of 1146

ENGINE - Timing Belt11-29

OlN004t

& Pin hole

nilnq

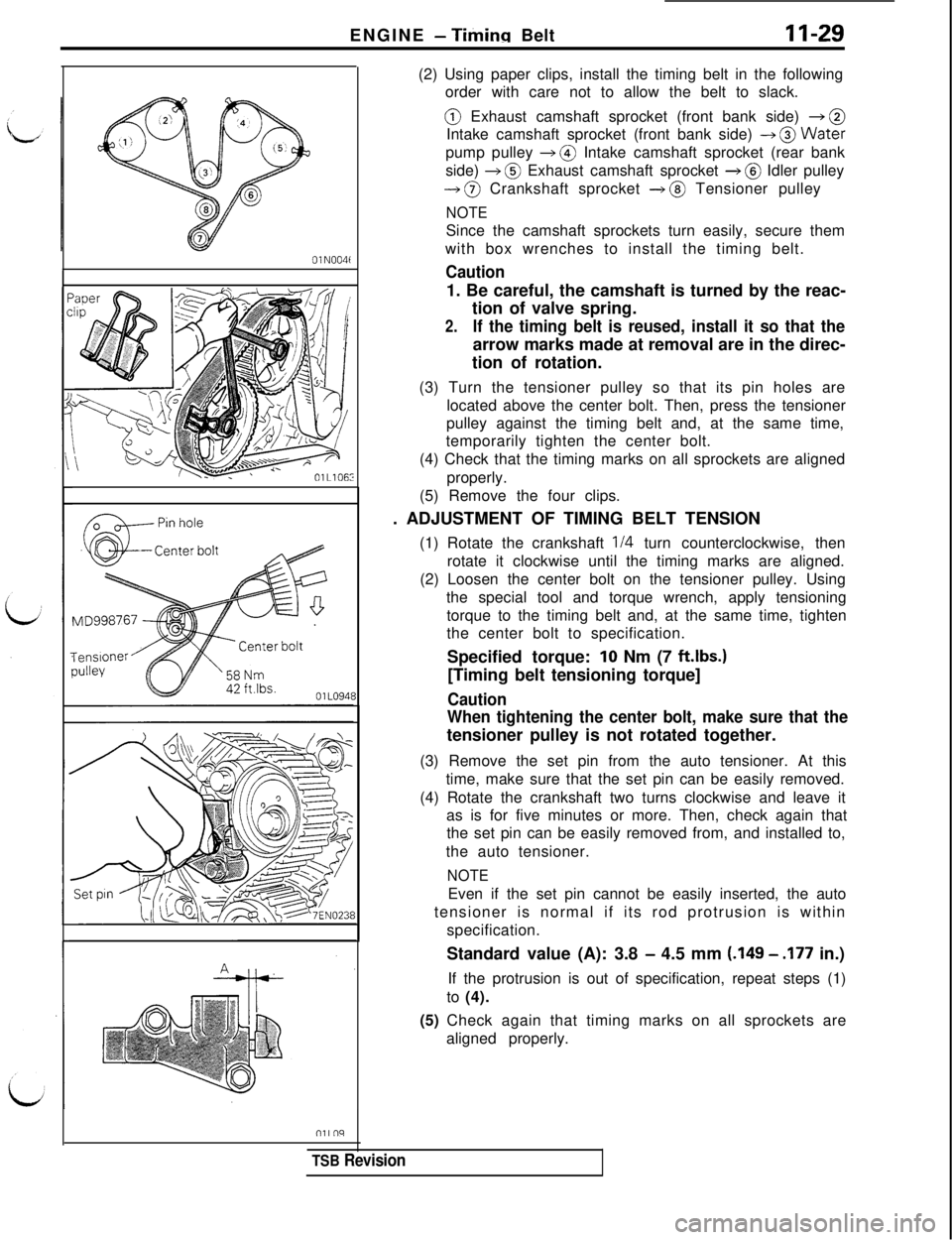

8(2) Using paper clips, install the timing belt in the following

order with care not to allow the belt to slack.@ Exhaust camshaft sprocket (front bank side)

+ @

Intake camshaft sprocket (front bank side)

-+ @Waterpump pulley

+ @ Intake camshaft sprocket (rear bank

side)

+ @ Exhaust camshaft sprocket + @ Idler pulley

-+ @ Crankshaft sprocket + @ Tensioner pulley

NOTESince the camshaft sprockets turn easily, secure them

with box wrenches to install the timing belt.

Caution1. Be careful, the camshaft is turned by the reac-

tion of valve spring.

2.If the timing belt is reused, install it so that thearrow marks made at removal are in the direc-

tion of rotation.

(3) Turn the tensioner pulley so that its pin holes are

located above the center bolt. Then, press the tensioner

pulley against the timing belt and, at the same time,

temporarily tighten the center bolt.

(4) Check that the timing marks on all sprockets are aligned

properly.

(5) Remove the four clips.

. ADJUSTMENT OF TIMING BELT TENSION

(1) Rotate the crankshaft

114 turn counterclockwise, then

rotate it clockwise until the timing marks are aligned.

(2) Loosen the center bolt on the tensioner pulley. Using

the special tool and torque wrench, apply tensioning

torque to the timing belt and, at the same time, tighten

the center bolt to specification.

Specified torque:

10 Nm (7 ftlbs.)

[Timing belt tensioning torque]

Caution

When tightening the center bolt, make sure that thetensioner pulley is not rotated together.

(3) Remove the set pin from the auto tensioner. At this

time, make sure that the set pin can be easily removed.

(4) Rotate the crankshaft two turns clockwise and leave it

as is for five minutes or more. Then, check again that

the set pin can be easily removed from, and installed to,

the auto tensioner.

NOTEEven if the set pin cannot be easily inserted, the auto

tensioner is normal if its rod protrusion is within

specification.

Standard value (A): 3.8

- 4.5 mm (.I49 - .I77 in.)

If the protrusion is out of specification, repeat steps (1)

to (4).

(5) Check again that timing marks on all sprockets are

aligned properly.

TSB Revision

Page 856 of 1146

37A-28

STEERING - Power Steering Oil Pump

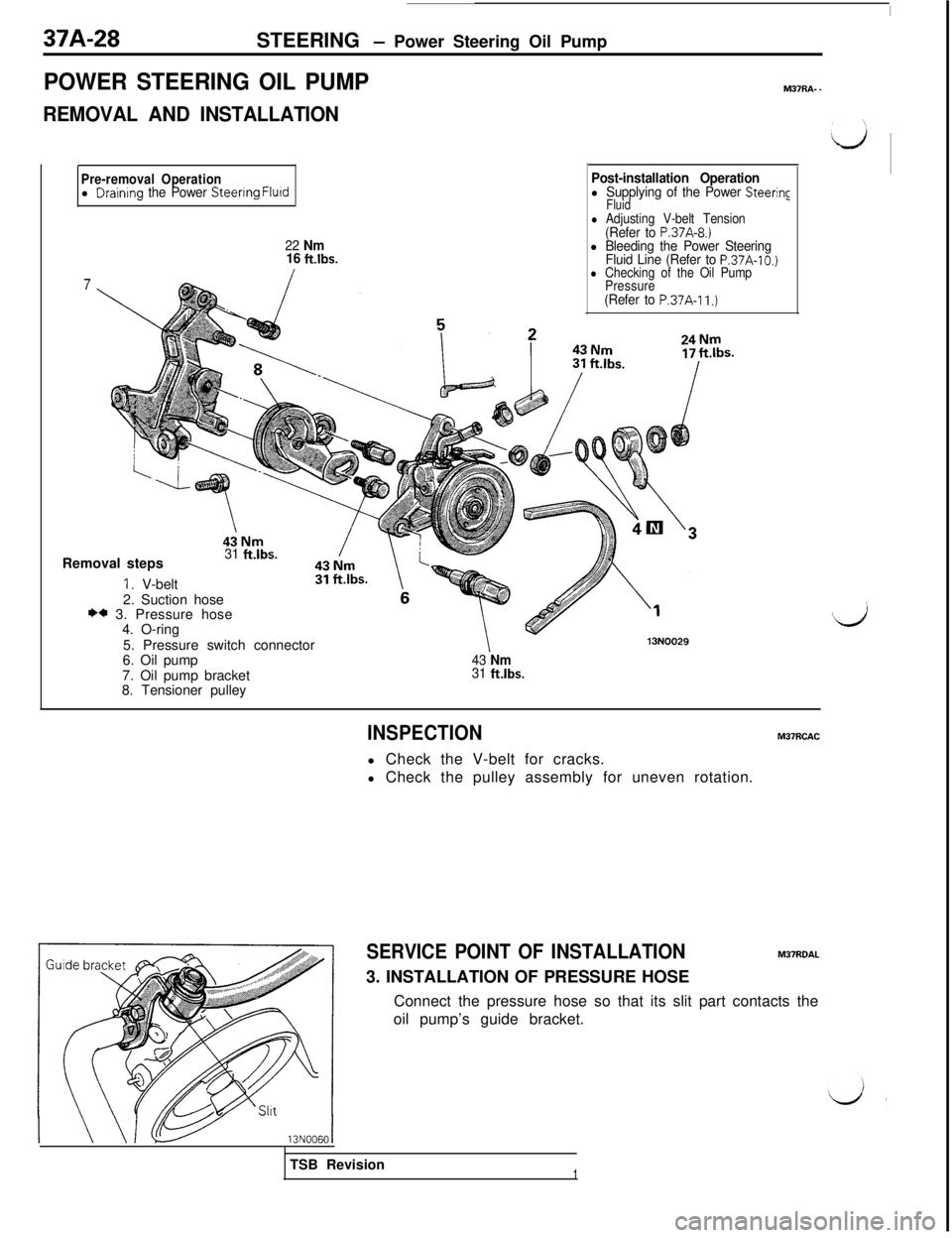

POWER STEERING OIL PUMP

REMOVAL AND INSTALLATION

I

M37RA-.

Pre-removal Operationl Draintng the Power Steenng Flurd

22 Nm

16 ft.lbs.

7

Post-installation Operationl Supplying of the Power Steering

Fluid

l Adjusting V-belt Tension(Refer to P.37A-8.)l Bleeding the Power Steering

Fluid Line (Refer to P.37A-10.)l Checking of the Oil Pump

Pressure

(Refer to P.37A-11.)Removal steps

31 ft.lbs.

1. V-belt

2. Suction hose

** 3. Pressure hose

4. O-ring

5. Pressure switch connector

6. Oil pump

7. Oil pump bracket

8. Tensioner pulley

43 Nm31 fklbs.

13N0029

Ij

INSPECTIONM37RCACl Check the V-belt for cracks.

l Check the pulley assembly for uneven rotation.

SERVICE POINT OF INSTALLATIONM37ROAL3. INSTALLATION OF PRESSURE HOSE

Connect the pressure hose so that its slit part contacts the

oil pump’s guide bracket.

TSB Revision

1