Ignition MITSUBISHI 3000GT 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1994, Model line: 3000GT, Model: MITSUBISHI 3000GT 1994 2.GPages: 738, PDF Size: 35.06 MB

Page 484 of 738

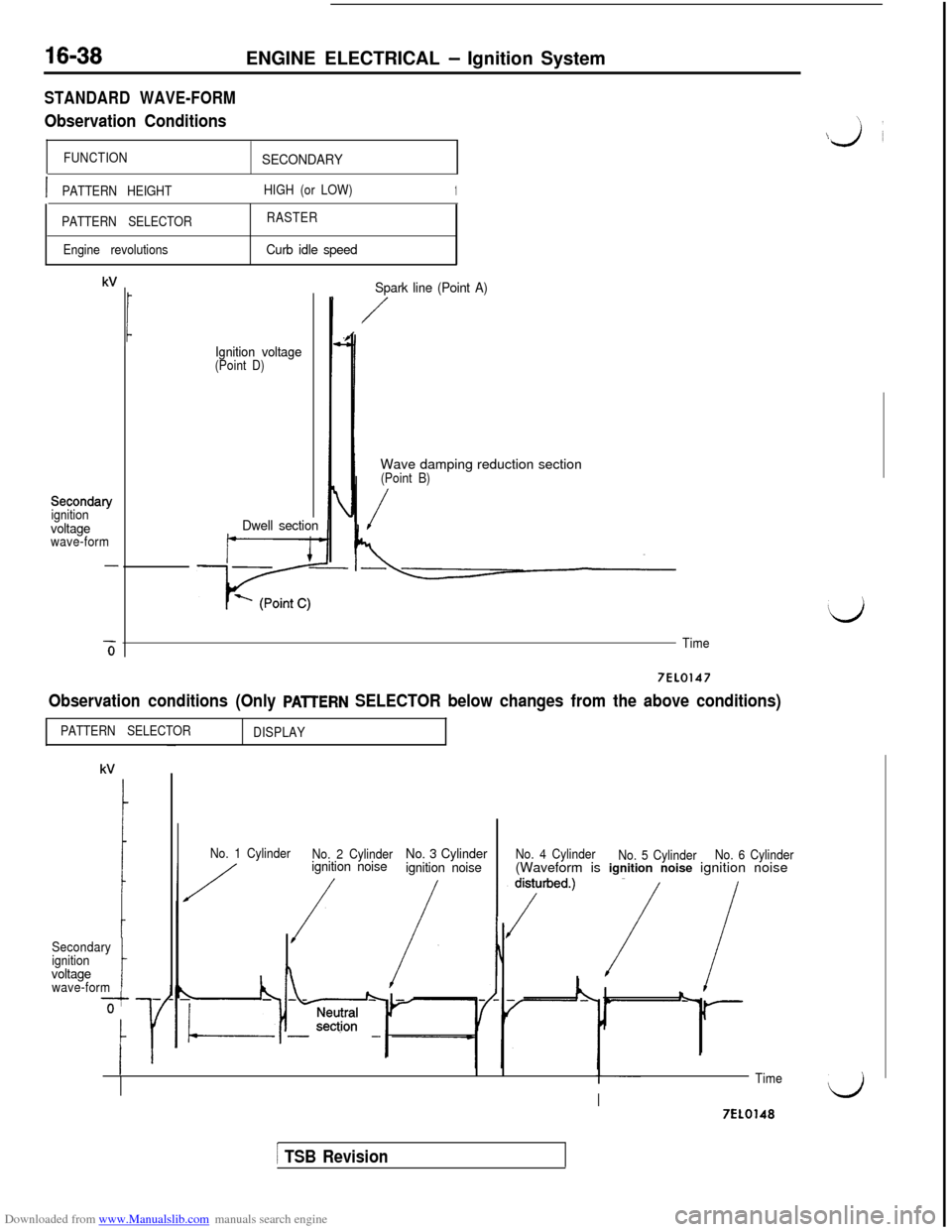

Downloaded from www.Manualslib.com manuals search engine 16-38ENGINE ELECTRICAL - Ignition System

STANDARD WAVE-FORM

Observation Conditions

FUNCTIONSECONDARY

\

\j’i

IPATTERN HEIGHTHIGH (or LOW)1

PATTERN SELECTORRASTER

Engine revolutions

Curb idle speed

kV

Secondary

ignition

voltagewave-form

-6

Ignition voltage(Point D)

Dwell sectionSpark line (Point A)

/Wave damping reduction section

(Point B)

/

Time

7EL0147

Observation conditions (Only PAlTERN SELECTOR below changes from the above conditions)

PATTERN SELECTOR

DISPLAY

Secondary

ignition

voltagewave-formt

No. 1 Cylinder

No. 2 Cylinderignition noiseNo. 3 Cylinder

ignition noiseNo. 4 Cylinder

No. 5 CylinderNo. 6 Cylinder(Waveform is ignition noise ignition noise

TimeI)I7EL0148

1 TSB Revision

Page 485 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-39

Wave-form Observation PointsPoint A: The height, length and

slope~of the spark line (refer to abnormal wave-form examples 1, 2, 3

and 4) show the following ‘trends.’\

Spark linePlug gapCondition of Compression Concentration

electrode

forceIgnition timing Sparkof air mixture

plug cable

LengthLongSmallNormal.

LowRichAdvancedLeak

ShortLarge

Large wear

HighLeanRetardedHigh

resistance

Height

HighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormal

Low

Rich _AdvancedLeak

SlopeLargePlug is fouled

-

Point B: Number of vibrations in reduction vibration section (Refer to abnormal wave-form example 5)

Point C: Number of vibrations at beginning of dwell section (Refer to abnormal wave-form example 5)

Point D: Ignition voltage height (distribution per each cylinder) shows the following trends.

Ignition

voltagePlug gapCondition of CompressionConcentration

electrodeIgnition timing Spark

forceof air mixtureplugcable

HighLarge

Large wearHighLean

RetardedHigh

resistance

LowSmallNormal

LowRich

AdvancedLeak

TSB Revision

Page 486 of 738

Downloaded from www.Manualslib.com manuals search engine 16-40ENGINE ELECTRICAL - Ignition System

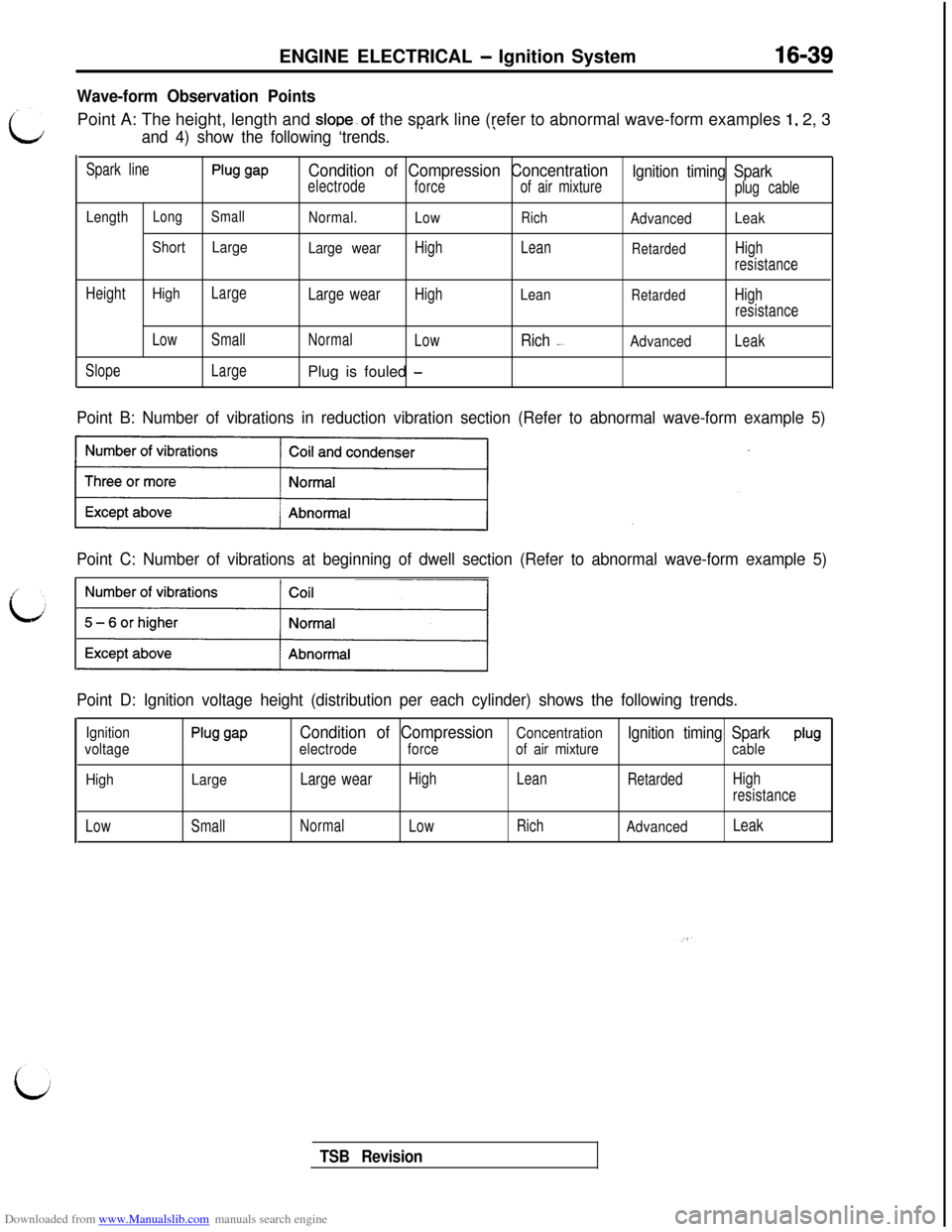

EXAMPLES OF ABNORMAL WAVE-FORMS

off.

and abnormal wave-form exam-

(Causinga dual ignition)

TSB Revision

Page 487 of 738

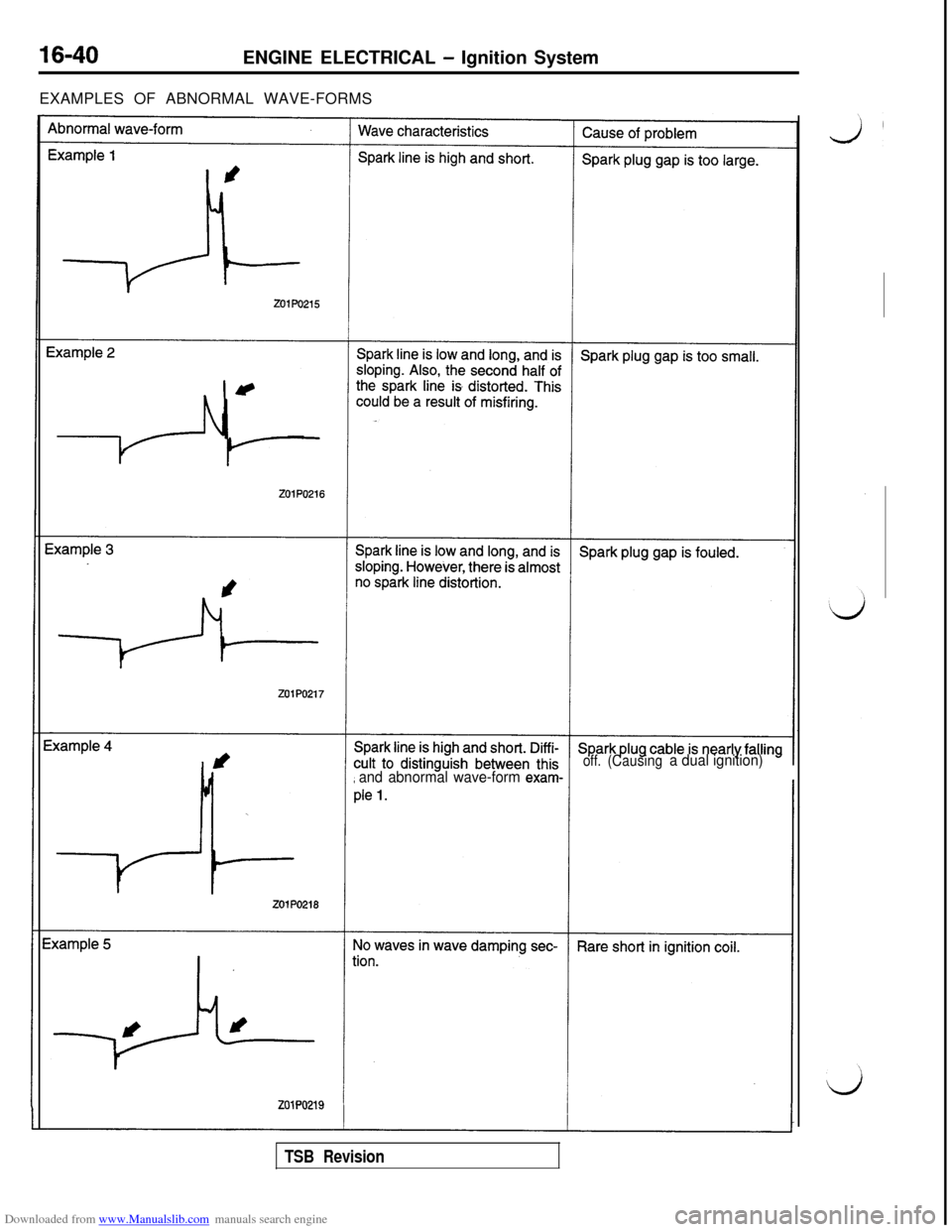

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - lanition Svstem16-41

/

L

i

Analyzer

GroundL

01L1008

STANDARD WAVE-FORM

Observation ConditionsIGNITION PRIMARY VOLTAGE WAVE-FORM

CHECK

MEASUREMENT METHOD

(1)Remove the ignition coil connector and connect the special

tool (harness connector: MD998464) in between.

(2) When observing the No. 1 - No. 4 cylinder group, connectthe primary pickup of the analyzer probe to the ignition

coil side connector terminal No. 2 (black clip on the special

tool).

For the No. 2 - No. 5 cylinder group, connect to terminal

No. 1 (red clip), and for the No. 3

- No. 6 cylinder group,connect to terminal No. 4 (white clip).

(3) Ground the primary pickup ground terminal.

(4) Clamp the spark plug cable with the trigger pickup.

NOTE(1) Clamp the spark plug cable of cylinder No. 1, No.

2 or No. 3 which belongs to the same group of the

cylinder to which the primary pickup is connected.

(2) The wave-form of any cylinder in the same group

is displayed on the left side of the screen.

FUNCTION

PRIMARY

PATTERN HEIGHTHIGH (or LOW)

PAVERN SELECTOR

Engine revolutionsRASTER

Curb idle speed

(V)

100

Primary Primary*ignition ignition

voltage voltage

wave-form

owave-formkr

0

Zener

voltage

(Point C)

Dwell

section

b

Spark line (Point A)

/b-4

Wave damping reduction section (Point B)

/

Time

7EL0149

/ TSB Revision

Page 488 of 738

Downloaded from www.Manualslib.com manuals search engine 16-42ENGINE ELECTRICAL - Ignition System

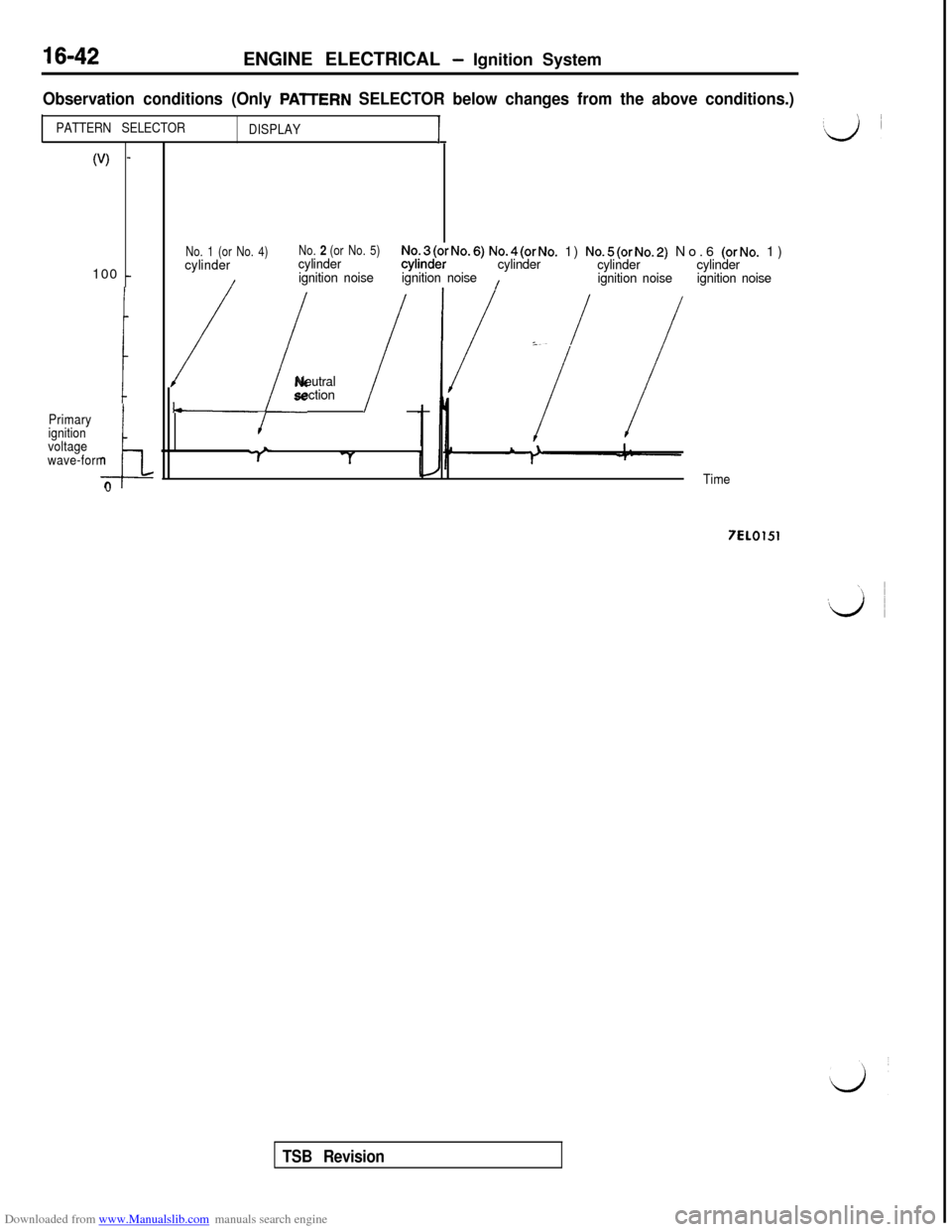

Observation conditions (Only PAlTERN SELECTOR below changes from the above conditions.)

PATTERN SELECTOR

DISPLAY1

(V) -100

-

Primary

ignition

voltage

i

wave-form

0No. 1 (or No. 4)

cylinderNo. 2 (or No. 5)cylinderNq.3(orNo.6) No.4(orNo. 1) No.5(orNo.2) No.6 (orNo. 1)

ignition noisecylinder

ignition noisecylinder

cylinder

ignition noisecylinder

/

I

/ignition noise

:./ /Neutral

section

/

Time

7EL0151

TSB Revision

Page 489 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-43

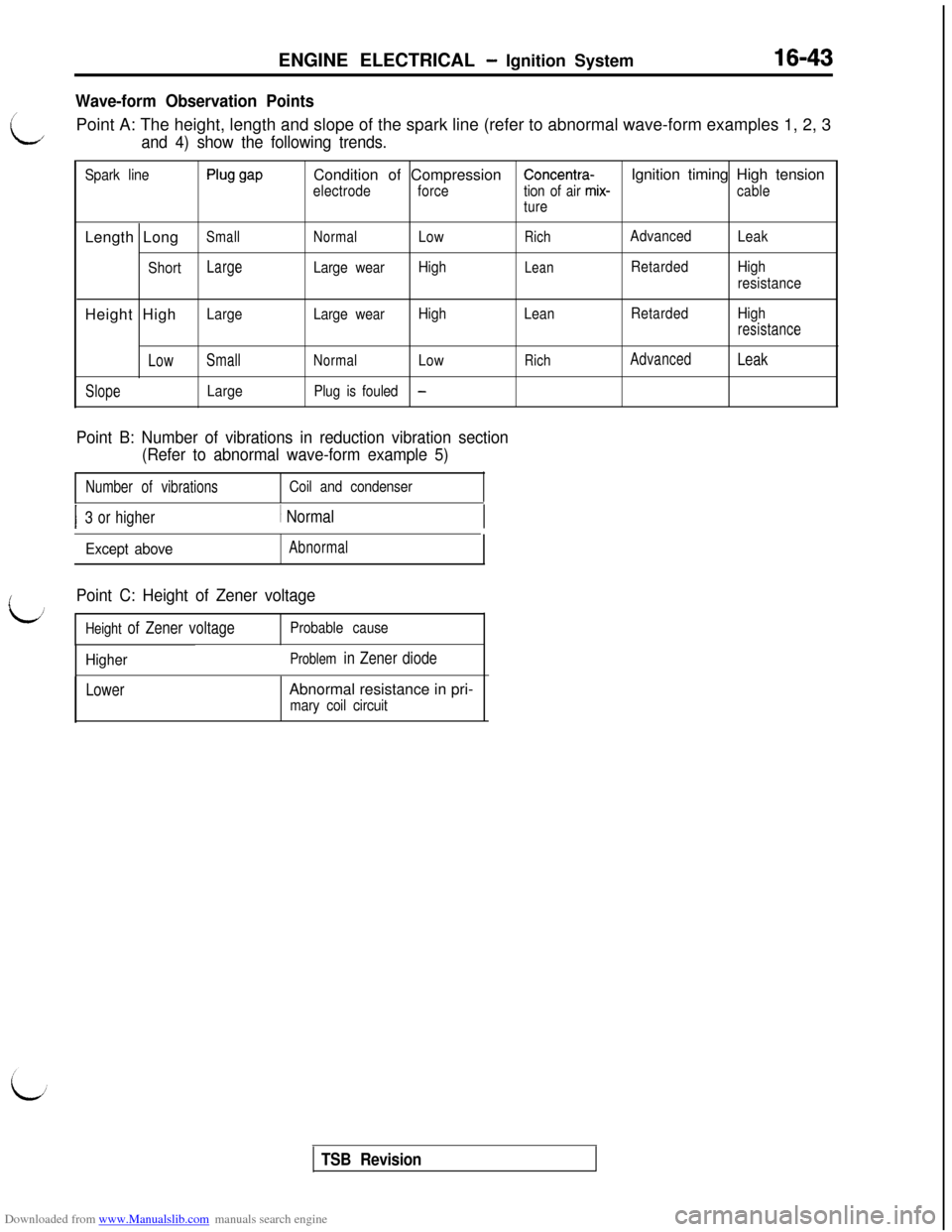

Wave-form Observation Points/

LPoint A: The height, length and slope of the spark line (refer to abnormal wave-form examples 1, 2, 3and 4) show the following trends.

Spark linePlug gapCondition of CompressionConcentra-Ignition timing High tension

electrodeforcetion of air mix-cable

tureLength Long

SmallNormalLowRichAdvanced

Leak

Short

LargeLarge wearHighLeanRetardedHigh

resistanceHeight High

LargeLarge wearHighLeanRetardedHigh

resistance

LowSmall

NormalLowRichAdvancedLeak

SlopeLargePlug is fouled-

Point B: Number of vibrations in reduction vibration section

(Refer to abnormal wave-form example 5)

Number of vibrationsCoil and condenser

I3 or higher/ Normal

Except aboveAbnormal

Point C: Height of Zener voltage

Height of Zener voltageProbable cause

HigherProblem in Zener diode

LowerAbnormal resistance in pri-

mary coil circuit

TSB Revision

Page 490 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System

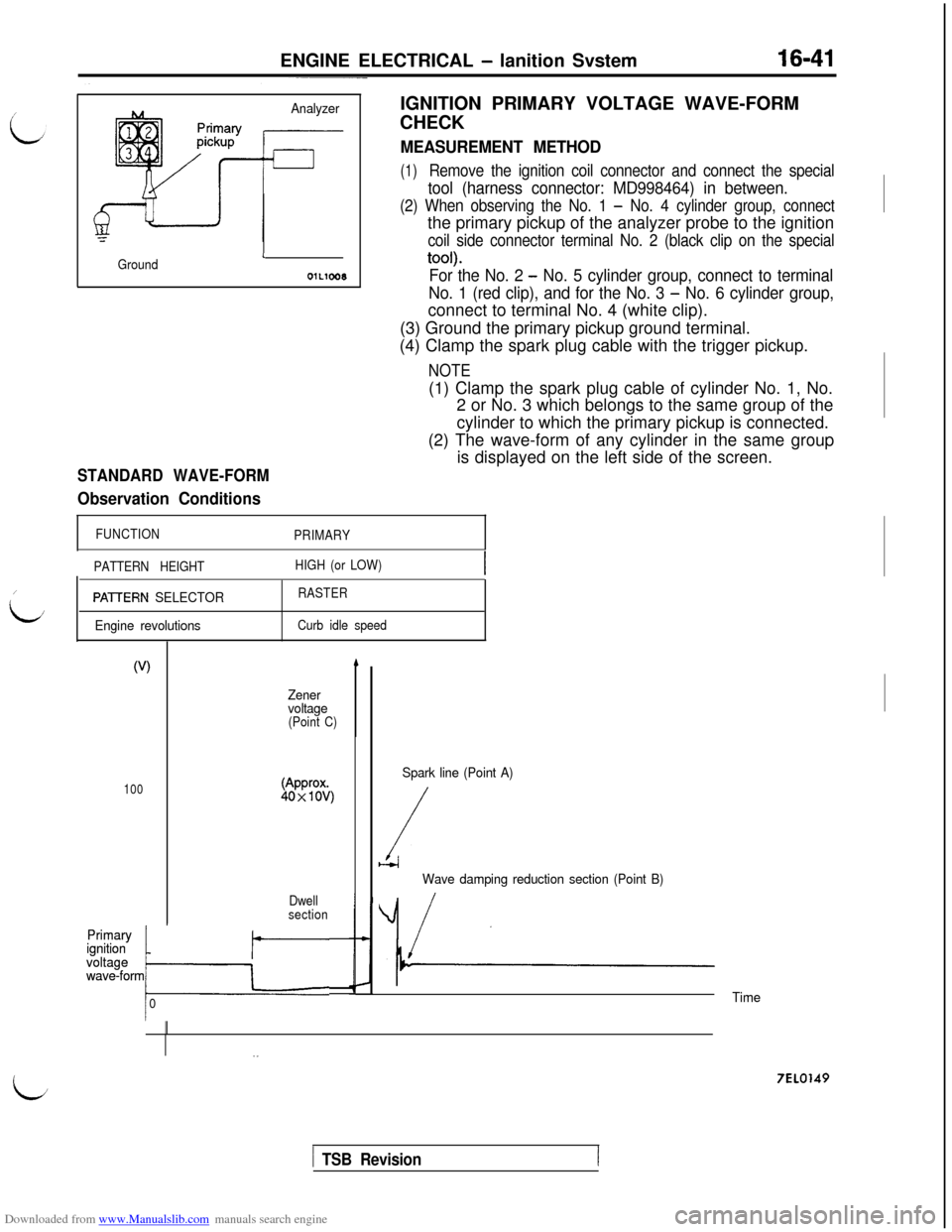

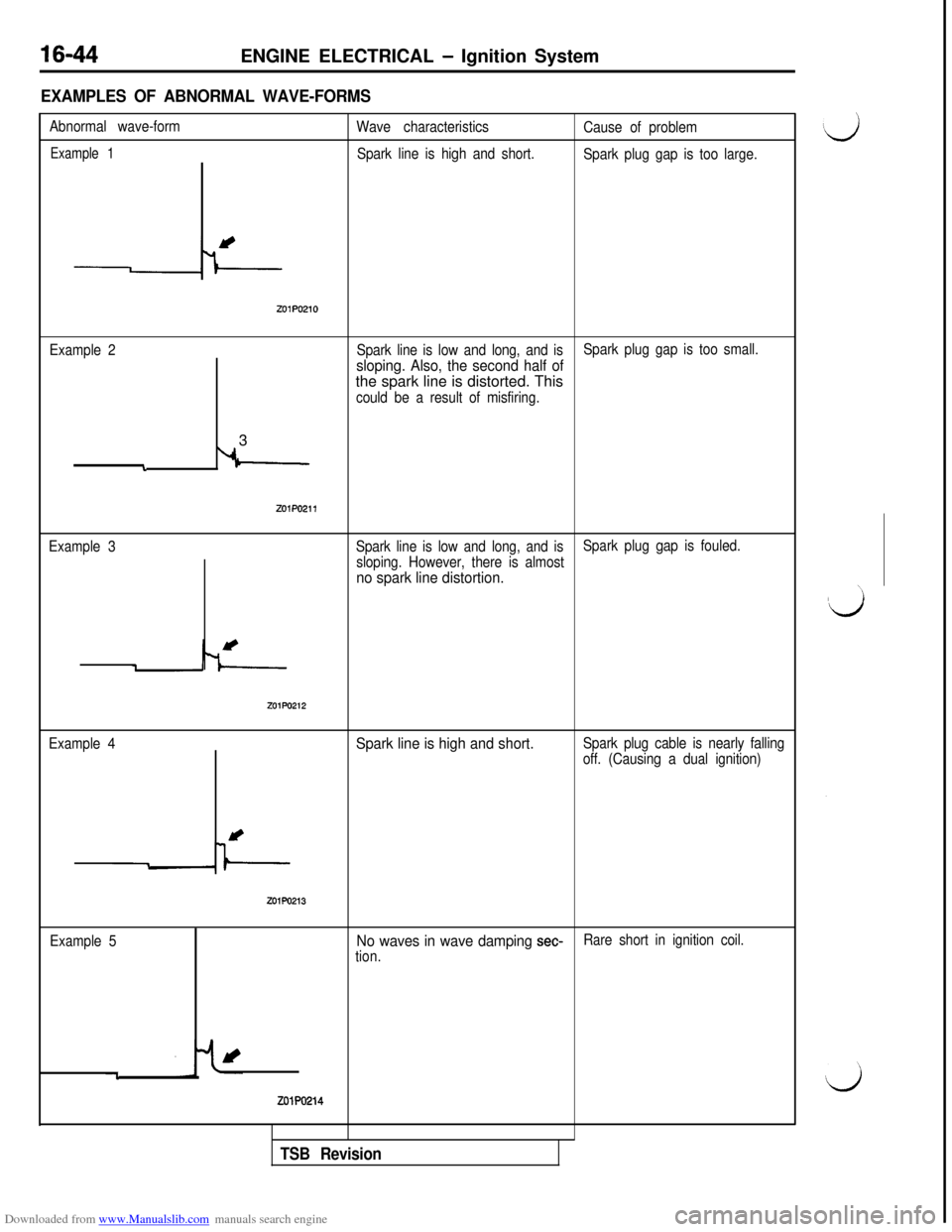

EXAMPLES OF ABNORMAL WAVE-FORMS

Abnormal wave-form

Wave characteristics

Cause of problem

Example 1Spark line is high and short.

Spark plug gap is too large.

z01P0210

Example 2Spark line is low and long, and is

sloping. Also, the second half of

Spark plug gap is too small.the spark line is distorted. This

could be a result of misfiring.3

i

Example 3

zo1Po211

Spark line is low and long, and is

sloping. However, there is almostSpark plug gap is fouled.

no spark line distortion.

ZOlPO212

Example 4Spark line is high and short.Spark plug cable is nearly falling

off. (Causing a dual ignition)

ZOlPO213

Example 5No waves in wave damping set-tion.Rare short in ignition coil.

-l

zolPo214

TSB Revision

Page 491 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-45 l

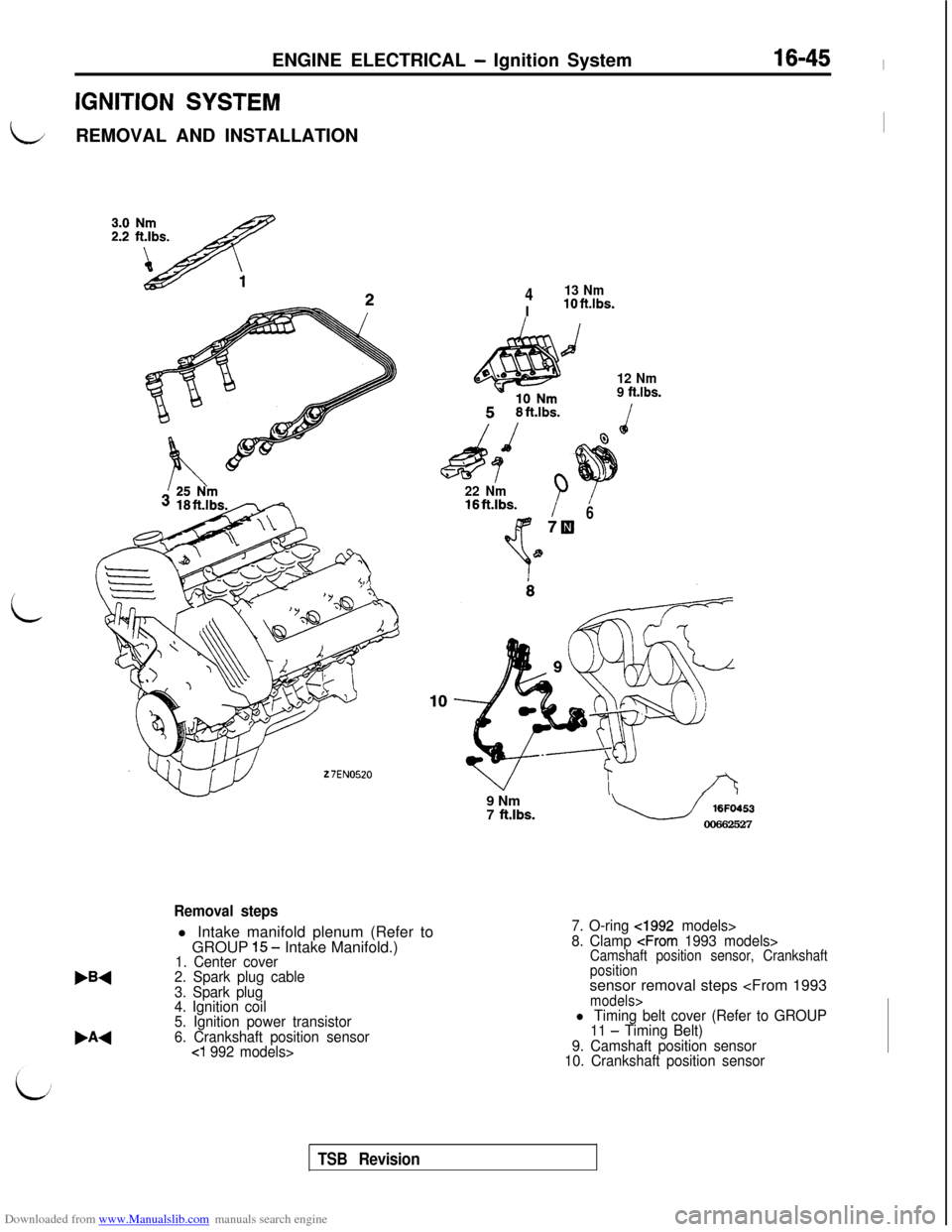

IGNITION SYSTEM

LREMOVAL AND INSTALLATIONI

i

27EN0520

413 NmIlOft.lbs.

d

12 Nm

9 ft.lbs.

22 Nm16ftAbs.B678

W1

,A4

Removal stepsl Intake manifold plenum (Refer to

GROUP

1.5 - Intake Manifold.)1. Center cover

2. Spark plug cable

3. Spark plug

4. Ignition coil

5. Ignition power transistor

6. Crankshaft position sensor

cl 992 models>9 Nm

7

ft.lbs.u 16FO453

00662527

7. O-ring cl992 models>

8. Clamp

positionsensor removal steps

11 - Timing Belt)

9. Camshaft position sensor

10. Crankshaft position sensor

TSB Revision

Page 492 of 738

Downloaded from www.Manualslib.com manuals search engine 16-46ENGINE ELECTRICAL - Ignition Svstem

27ELOO95JINSTALLATION SERVICE POINTS.A+CRANKSHAFT

POSITION SENSOR INSTALLATION

(1) Turn the crankshaft so that the No. 1 cylinder is at

compression top dead center.

Caution

Be careful not to turn it to the No.

4 cylinder com-

pression top dead center by mistake.

(2) Install, lining up the matchmarks on the crankshaft

position sensor housing and the coupling.

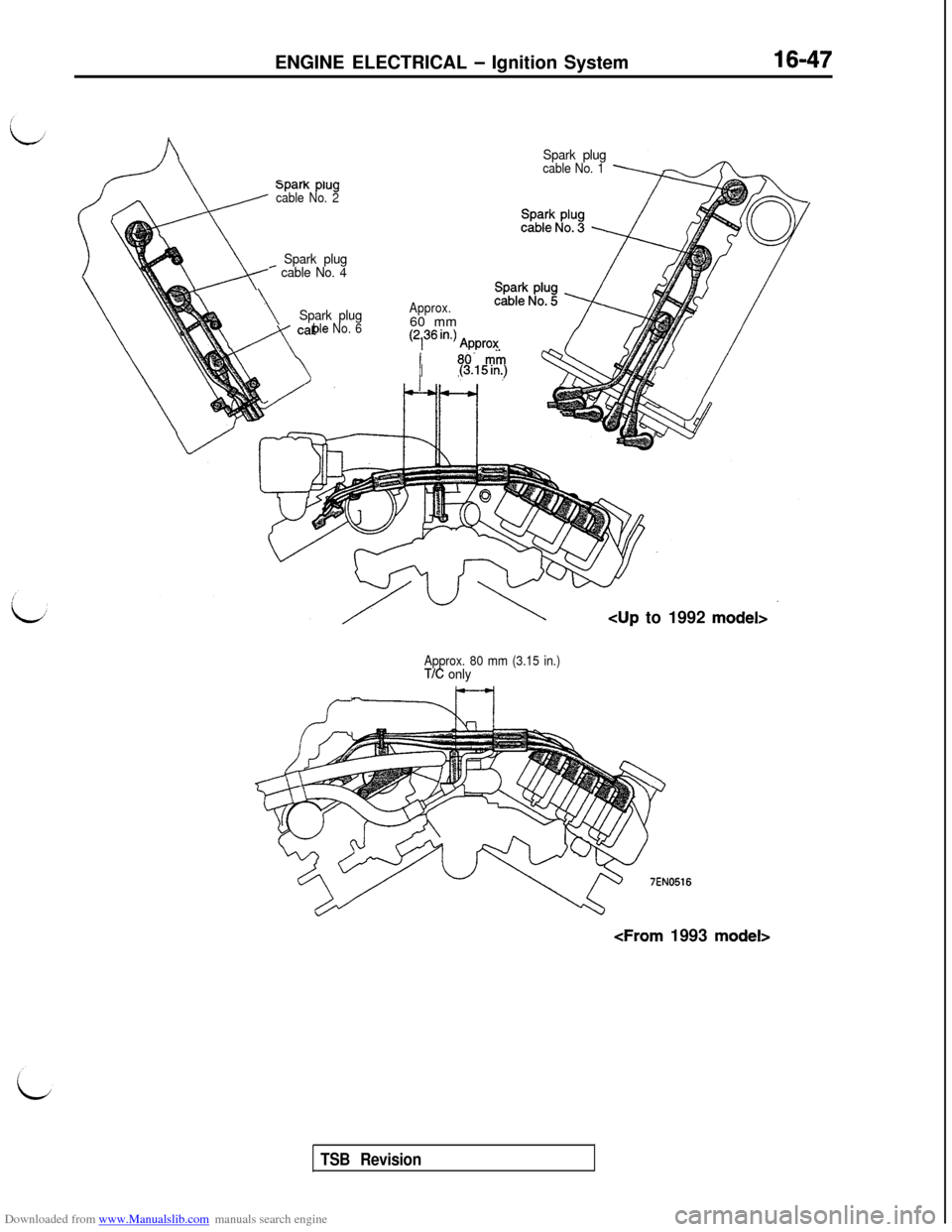

,B+SPARK PLUG CABLE INSTALLATION

Improper arrangement of spark plug cables will induce

voltage between the cables, causing miss firing and devel-

oping a surge at acceleration in high-speed operation.

Therefore, be careful to arrange the spark plug cables

properly by the following procedure.

1.install the spark plug cable clamps as shown in the

illustration.

2.The numerals on the support and clamp indicate the

spark plug cable No.

3.Pay attention to the following items when the spark

plug cables are installed.

(1)Install the cables securely to avoid possible contact

with metal parts.(2) Install the cables neatly, ensuring they are not

too tight, loose, twisted or kinked.

/ TSB Revision

Page 493 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Ignition System16-47

Spark plugcable No. 1

Spark plugr cable No. 4

\Spark plug‘de No. 6

sparK piug

cable No. 2

Approx.60 mm

(2,36in.) Approx

I(3.15in.)cup to 1992

model>

Approx. 80 mm (3.15 in.)TIC only

TSB Revision