Battery MITSUBISHI 380 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 822 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-121

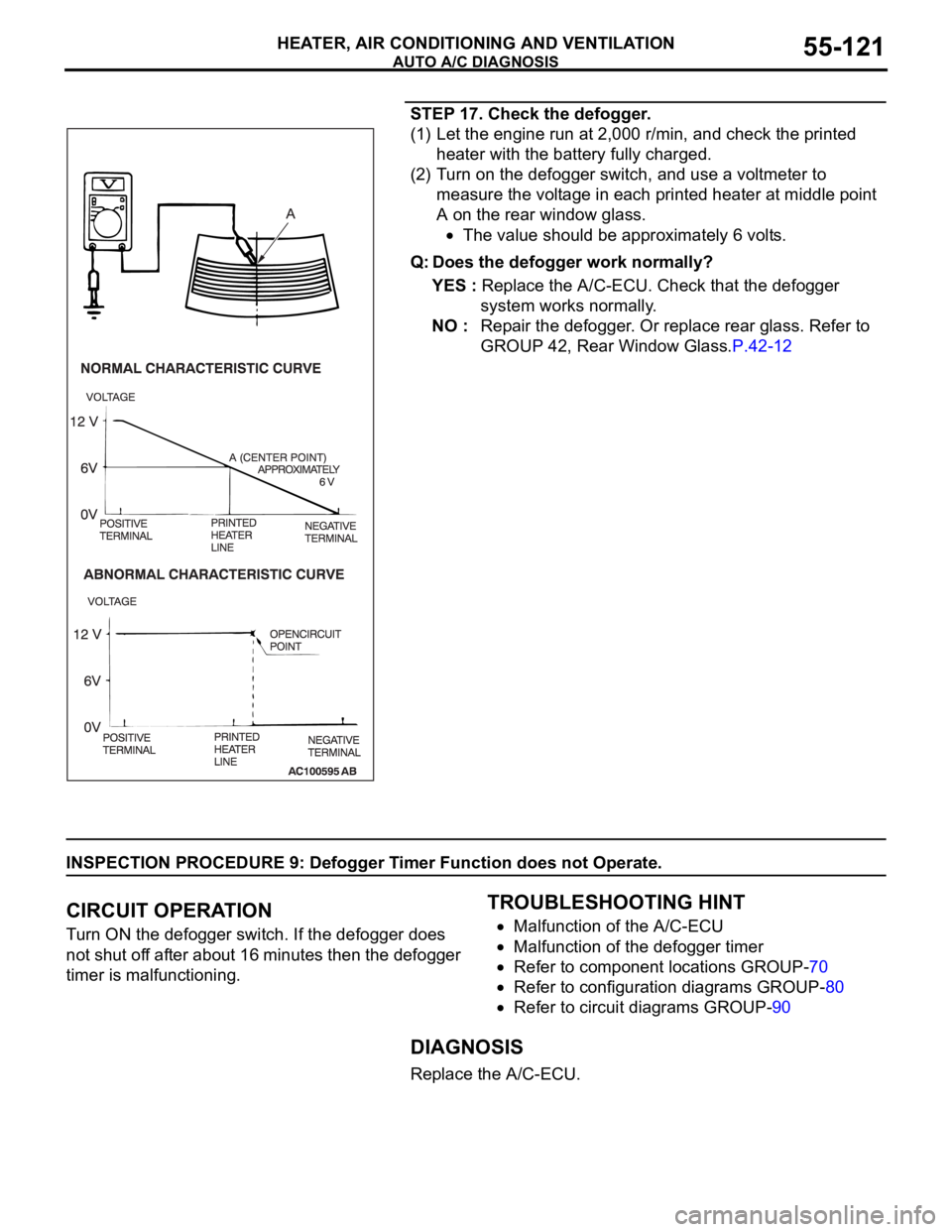

STEP 17. Check the defogger.

(1) Let the engine run at 2,000 r/min, and check the printed

heater with the battery fully charged.

(2) Turn on the defogger switch, and use a voltmeter to

measure the voltage in each printed heater at middle point

A on the rear window glass.

The value should be approximately 6 volts.

Q: Does the defogger work normally?

YES : Replace the A/C-ECU. Check that the defogger

system works normally.

NO : Repair the defogger. Or replace rear glass. Refer to

GROUP 42, Rear Window Glass.P.42-12

INSPECTION PROCEDURE 9: Defogger Timer Function does not Operate.

.

CIRCUIT OPERATION

Turn ON the defogger switch. If the defogger does

not shut off after about 16 minutes then the defogger

timer is malfunctioning.

.

TROUBLESHOOTING HINT

Malfunction of the A/C-ECU

Malfunction of the defogger timer

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Replace the A/C-ECU.

Page 824 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-123

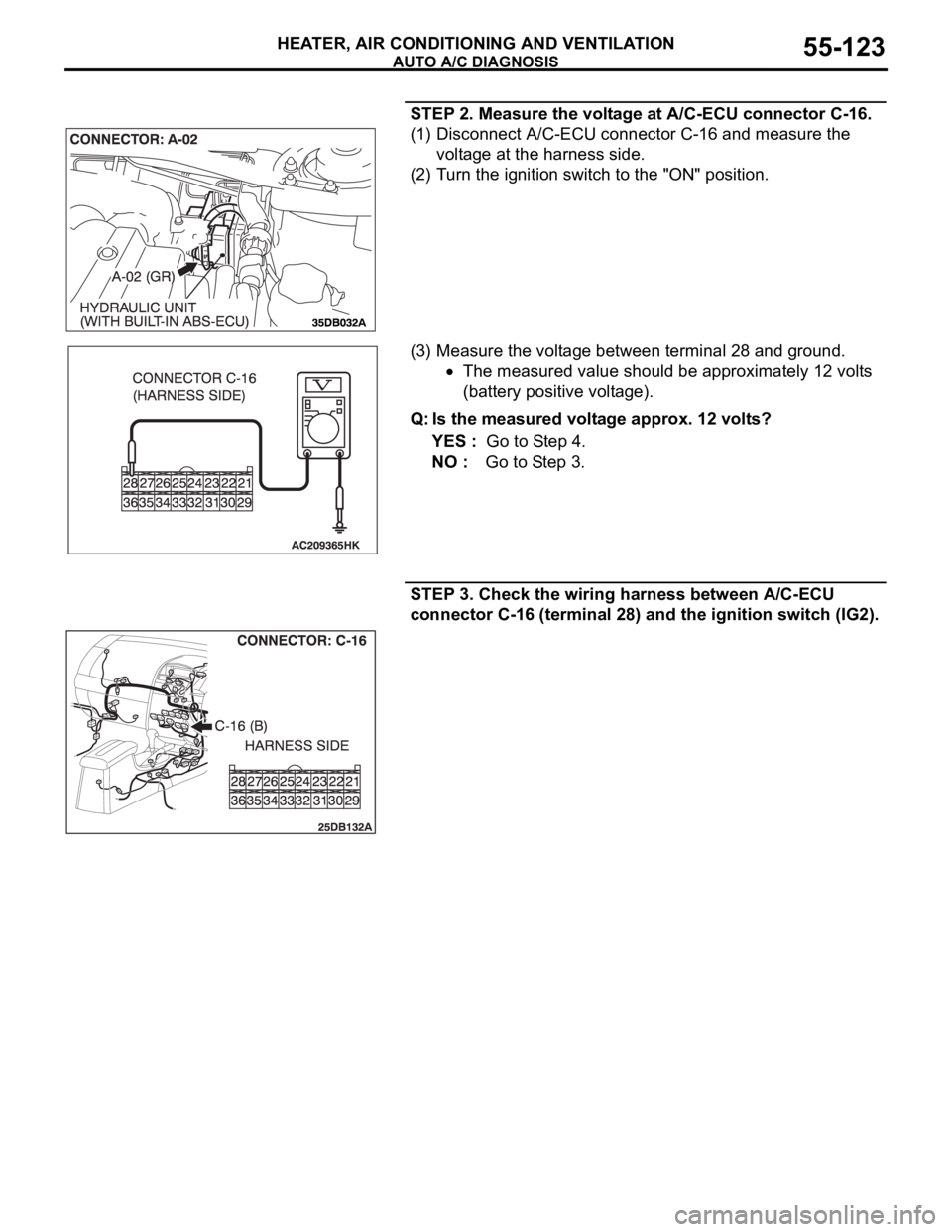

STEP 2. Measure the voltage at A/C-ECU connector C-16.

(1) Disconnect A/C-ECU connector C-16 and measure the

voltage at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 28 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 4.

NO : Go to Step 3.

STEP 3. Check the wiring harness between A/C-ECU

connector C-16 (terminal 28) and the ignition switch (IG2).

Page 825 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-124

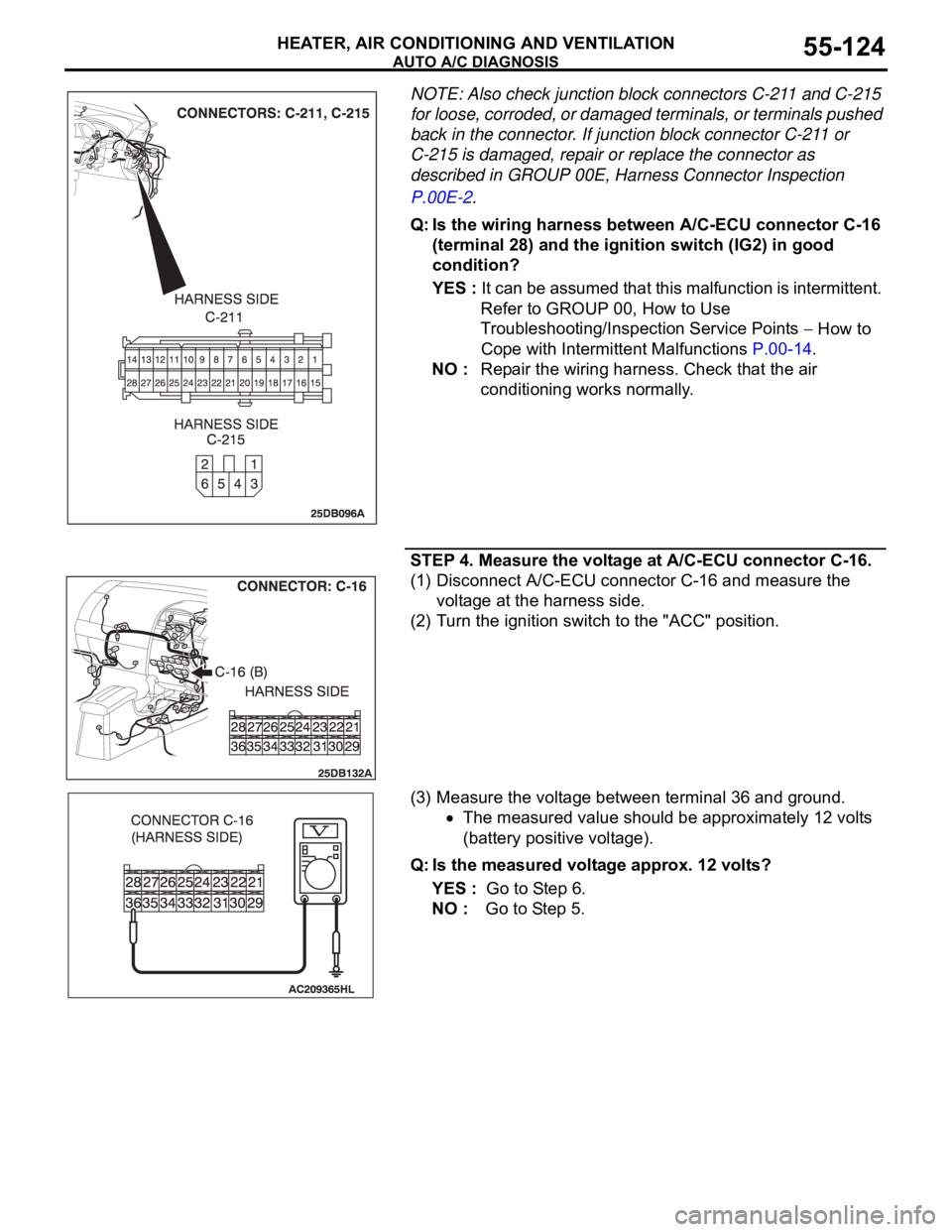

NOTE: Also check junction block connectors C-211 and C-215

for loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If junction block connector C-211 or

C-215 is damaged, repair or replace the connector as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between A/C-ECU connector C-16

(terminal 28) and the ignition switch (IG2) in good

condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 4. Measure the voltage at A/C-ECU connector C-16.

(1) Disconnect A/C-ECU connector C-16 and measure the

voltage at the harness side.

(2) Turn the ignition switch to the "ACC" position.

(3) Measure the voltage between terminal 36 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 6.

NO : Go to Step 5.

Page 827 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-126

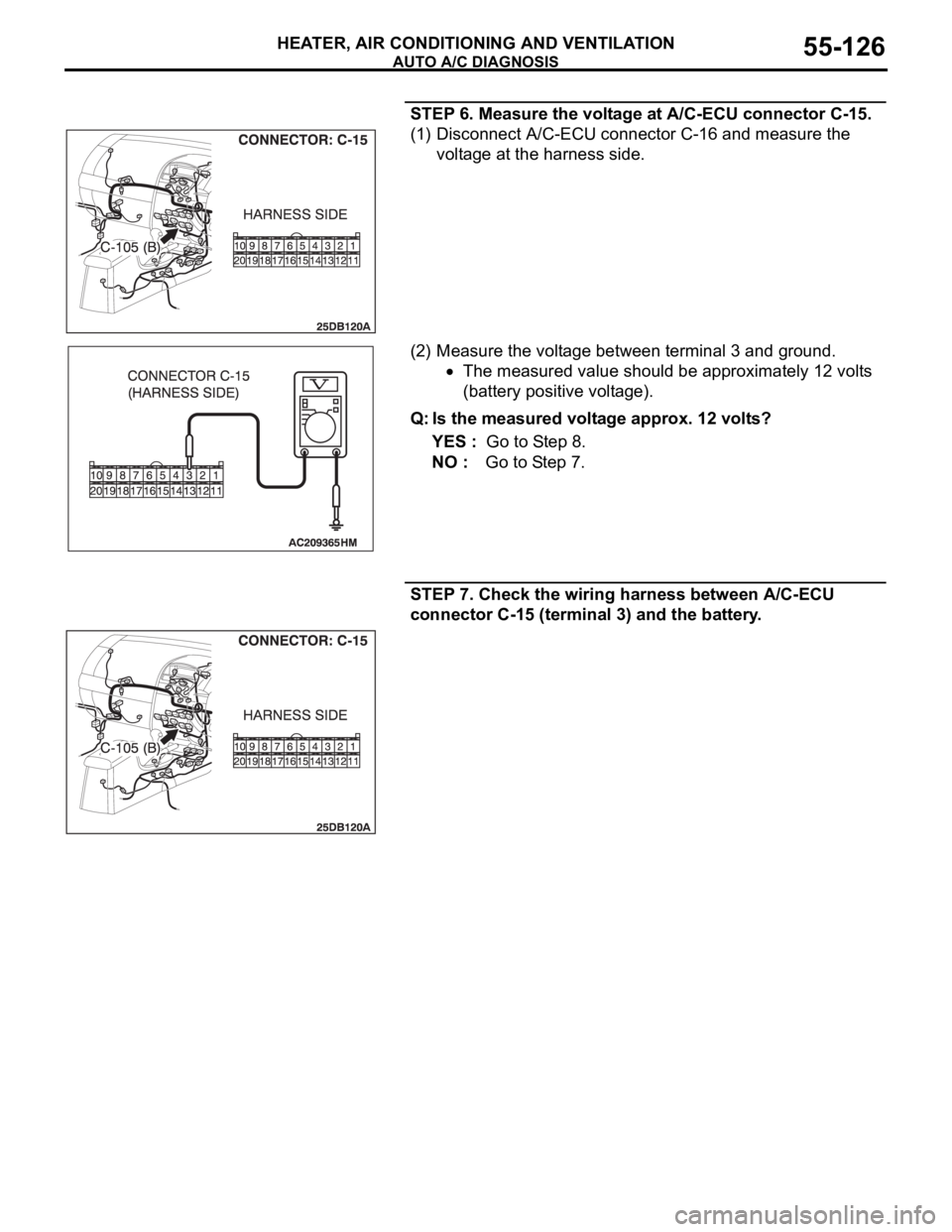

STEP 6. Measure the voltage at A/C-ECU connector C-15.

(1) Disconnect A/C-ECU connector C-16 and measure the

voltage at the harness side.

(2) Measure the voltage between terminal 3 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 8.

NO : Go to Step 7.

STEP 7. Check the wiring harness between A/C-ECU

connector C-15 (terminal 3) and the battery.

Page 828 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-127

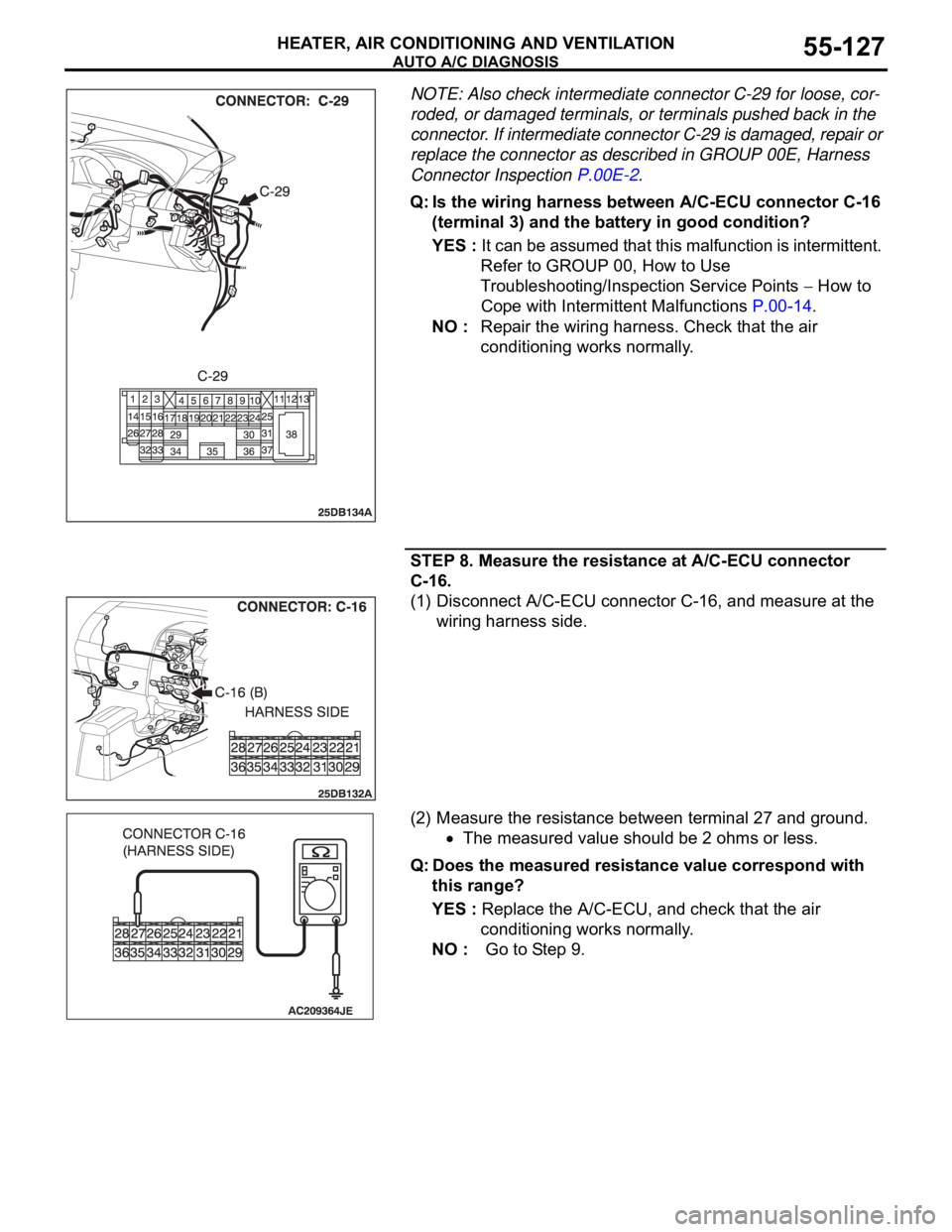

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C-ECU connector C-16

(terminal 3) and the battery in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 8. Measure the resistance at A/C-ECU connector

C-16.

(1) Disconnect A/C-ECU connector C-16, and measure at the

wiring harness side.

(2) Measure the resistance between terminal 27 and ground.

The measured value should be 2 ohms or less.

Q: Does the measured resistance value correspond with

this range?

YES : Replace the A/C-ECU, and check that the air

conditioning works normally.

NO : Go to Step 9.

Page 838 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-137

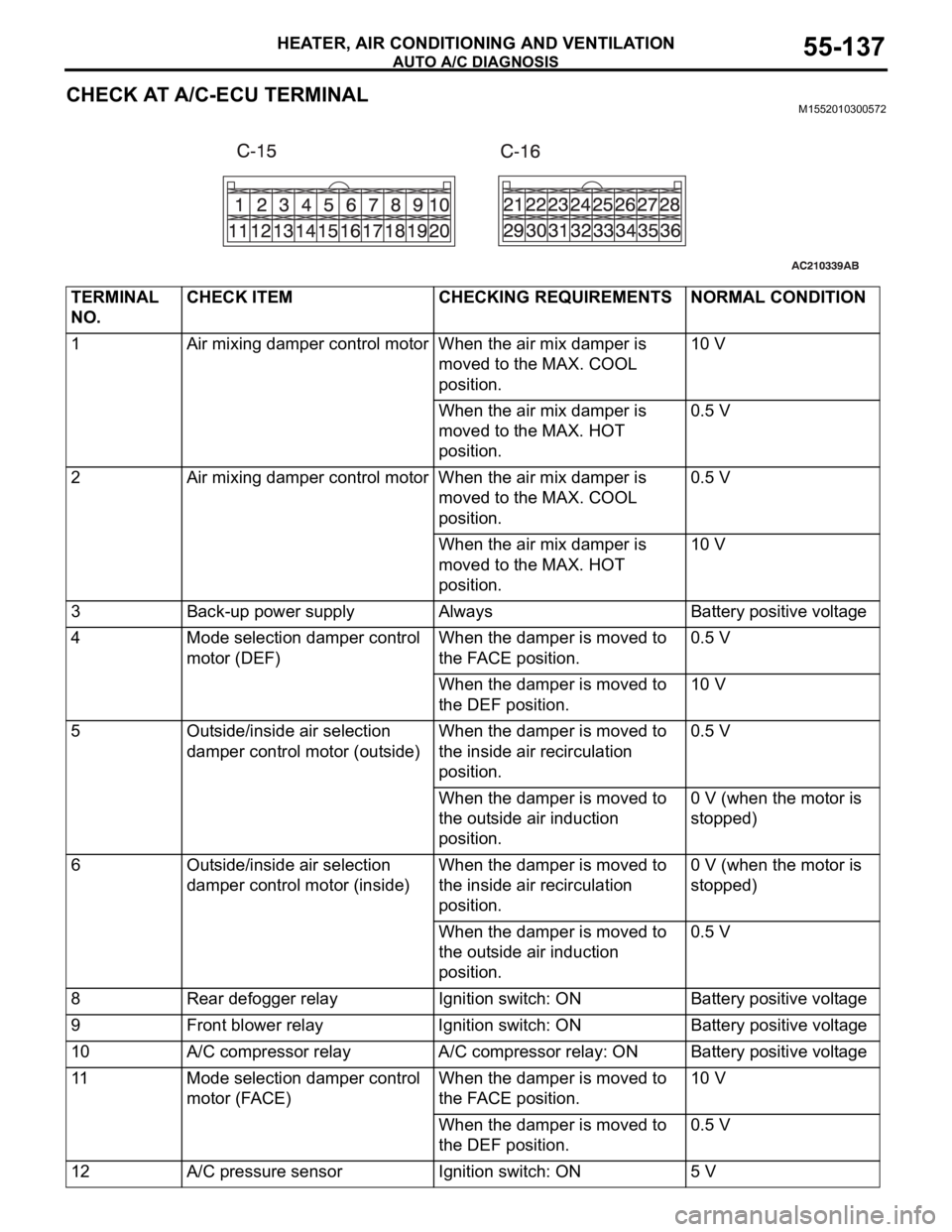

CHECK AT A/C-ECU TERMINALM1552010300572

TERMINAL

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL CONDITION

1 Air mixing damper control motor When the air mix damper is

moved to the MAX. COOL

position. 10 V

When the air mix damper is

moved to the MAX. HOT

position. 0.5 V

2 Air mixing damper control motor When the air mix damper is

moved to the MAX. COOL

position. 0.5 V

When the air mix damper is

moved to the MAX. HOT

position. 10 V

3 Back-up power supply Always Battery positive voltage

4 Mode selection damper control

motor (DEF)When the damper is moved to

the FACE position. 0.5 V

When the damper is moved to

the DEF position. 10 V

5 Outside/inside air selection

damper control motor (outside)When the damper is moved to

the inside air recirculation

position.0.5 V

When the damper is moved to

the outside air induction

position.0 V (when the motor is

stopped)

6 Outside/inside air selection

damper control motor (inside)When the damper is moved to

the inside air recirculation

position.0 V (when the motor is

stopped)

When the damper is moved to

the outside air induction

position.0.5 V

8 Rear defogger relay Ignition switch: ON Battery positive voltage

9 Front blower relay Ignition switch: ON Battery positive voltage

10 A/C compressor relay A/C compressor relay: ON Battery positive voltage

11 Mode selection damper control

motor (FACE)When the damper is moved to

the FACE position. 10 V

When the damper is moved to

the DEF position. 0.5 V

12 A/C pressure sensor Ignition switch: ON 5 V

Page 839 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-138

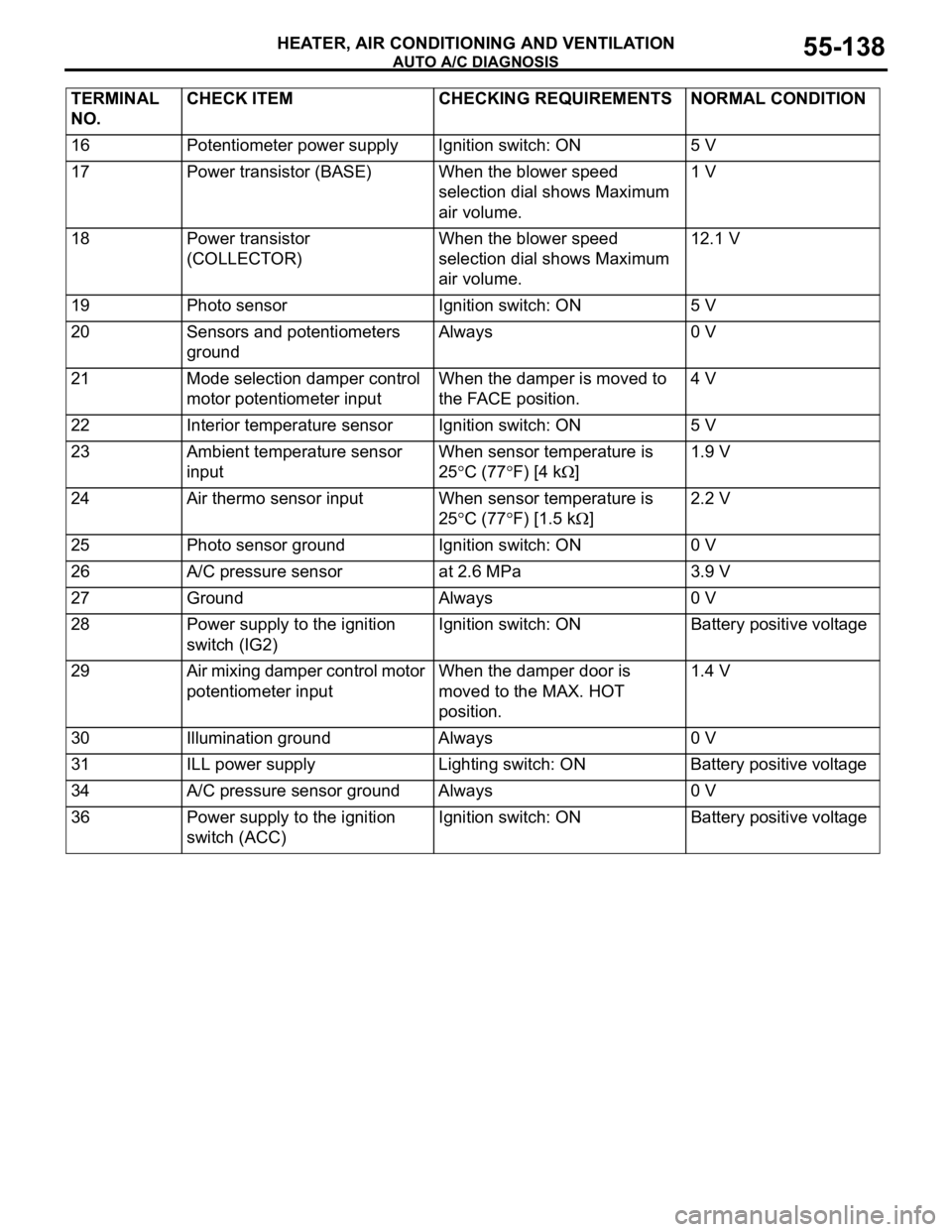

16 Potentiometer power supply Ignition switch: ON 5 V

17 Power transistor (BASE) When the blower speed

selection dial shows Maximum

air volume.1 V

18 Power transistor

(COLLECTOR)When the blower speed

selection dial shows Maximum

air volume.12.1 V

19 Photo sensor Ignition switch: ON 5 V

20 Sensors and potentiometers

groundAlways 0 V

21 Mode selection damper control

motor potentiometer inputWhen the damper is moved to

the FACE position. 4 V

22 Interior temperature sensor Ignition switch: ON 5 V

23 Ambient temperature sensor

inputWhen sensor temperature is

25

C (77F) [4 k]1.9 V

24 Air thermo sensor input When sensor temperature is

25

C (77F) [1.5 k]2.2 V

25 Photo sensor ground Ignition switch: ON 0 V

26 A/C pressure sensor at 2.6 MPa 3.9 V

27 Ground Always 0 V

28 Power supply to the ignition

switch (IG2)Ignition switch: ON Battery positive voltage

29 Air mixing damper control motor

potentiometer inputWhen the damper door is

moved to the MAX. HOT

position.1.4 V

30 Illumination ground Always 0 V

31 ILL power supply Lighting switch: ON Battery positive voltage

34 A/C pressure sensor ground Always 0 V

36 Power supply to the ignition

switch (ACC)Ignition switch: ON Battery positive voltage TERMINAL

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL CONDITION

Page 842 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-141

ON-VEHICLE SERVICE

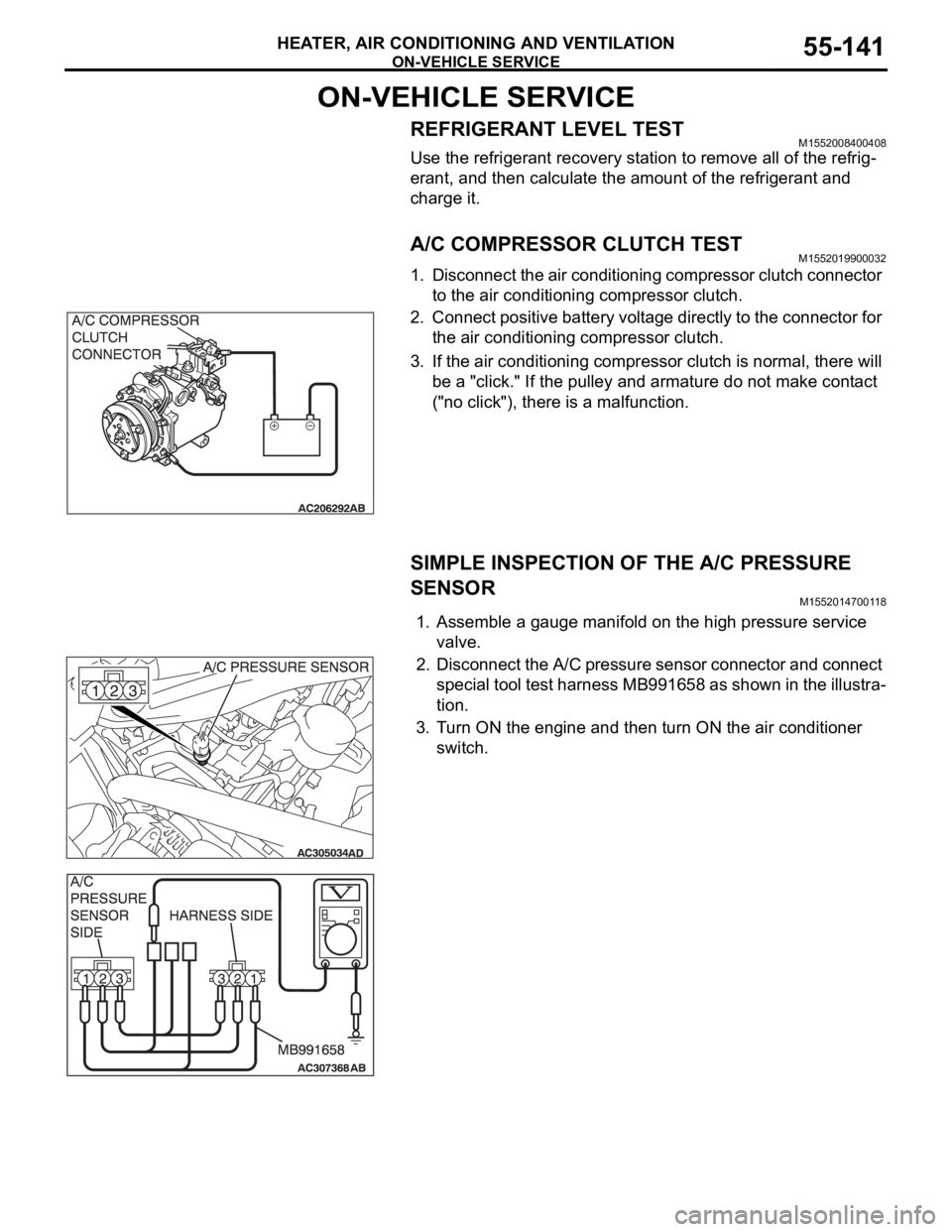

REFRIGERANT LEVEL TESTM1552008400408

Use the refrigerant recovery station to remove all of the refrig-

erant, and then calculate the amount of the refrigerant and

charge it.

A/C COMPRESSOR CLUTCH TESTM1552019900032

1. Disconnect the air conditioning compressor clutch connector

to the air conditioning compressor clutch.

2. Connect positive battery voltage directly to the connector for

the air conditioning compressor clutch.

3. If the air conditioning compressor clutch is normal, there will

be a "click." If the pulley and armature do not make contact

("no click"), there is a malfunction.

SIMPLE INSPECTION OF THE A/C PRESSURE

SENSOR

M1552014700118

1. Assemble a gauge manifold on the high pressure service

valve.

2. Disconnect the A/C pressure sensor connector and connect

special tool test harness MB991658 as shown in the illustra-

tion.

3. Turn ON the engine and then turn ON the air conditioner

switch.

Page 849 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-148

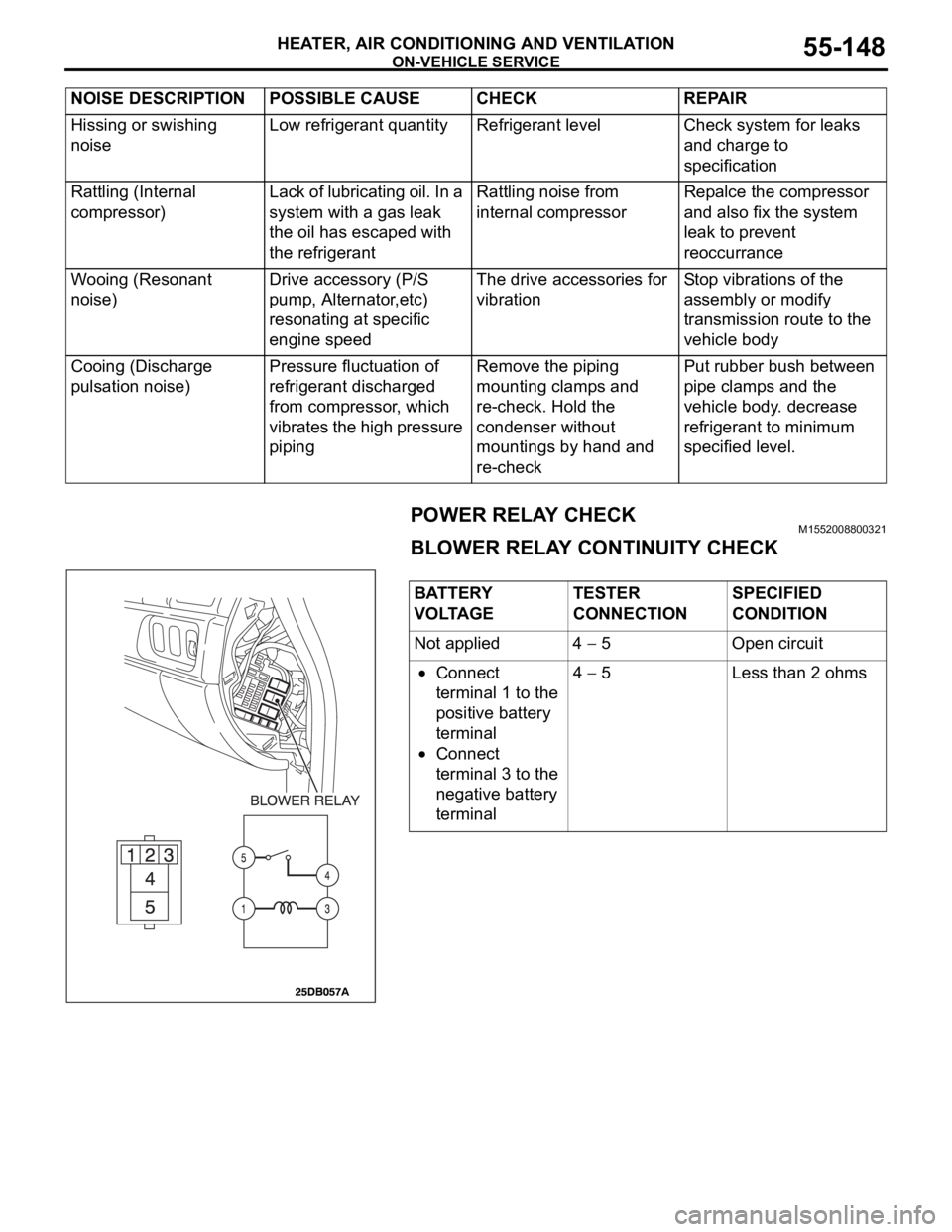

POWER RELAY CHECKM1552008800321

BLOWER RELAY CONTINUITY CHECK

Hissing or swishing

noiseLow refrigerant quantity Refrigerant level Check system for leaks

and charge to

specification

Rattling (Internal

compressor)Lack of lubricating oil. In a

system with a gas leak

the oil has escaped with

the refrigerantRattling noise from

internal compressorRepalce the compressor

and also fix the system

leak to prevent

reoccurrance

Wooing (Resonant

noise)Drive accessory (P/S

pump, Alternator,etc)

resonating at specific

engine speedThe drive accessories for

vibrationStop vibrations of the

assembly or modify

transmission route to the

vehicle body

Cooing (Discharge

pulsation noise)Pressure fluctuation of

refrigerant discharged

from compressor, which

vibrates the high pressure

pipingRemove the piping

mounting clamps and

re-check. Hold the

condenser without

mountings by hand and

re-checkPut rubber bush between

pipe clamps and the

vehicle body. decrease

refrigerant to minimum

specified level. NOISE DESCRIPTION POSSIBLE CAUSE CHECK REPAIR

BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect

terminal 1 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal4

5 Less than 2 ohms

Page 850 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-149

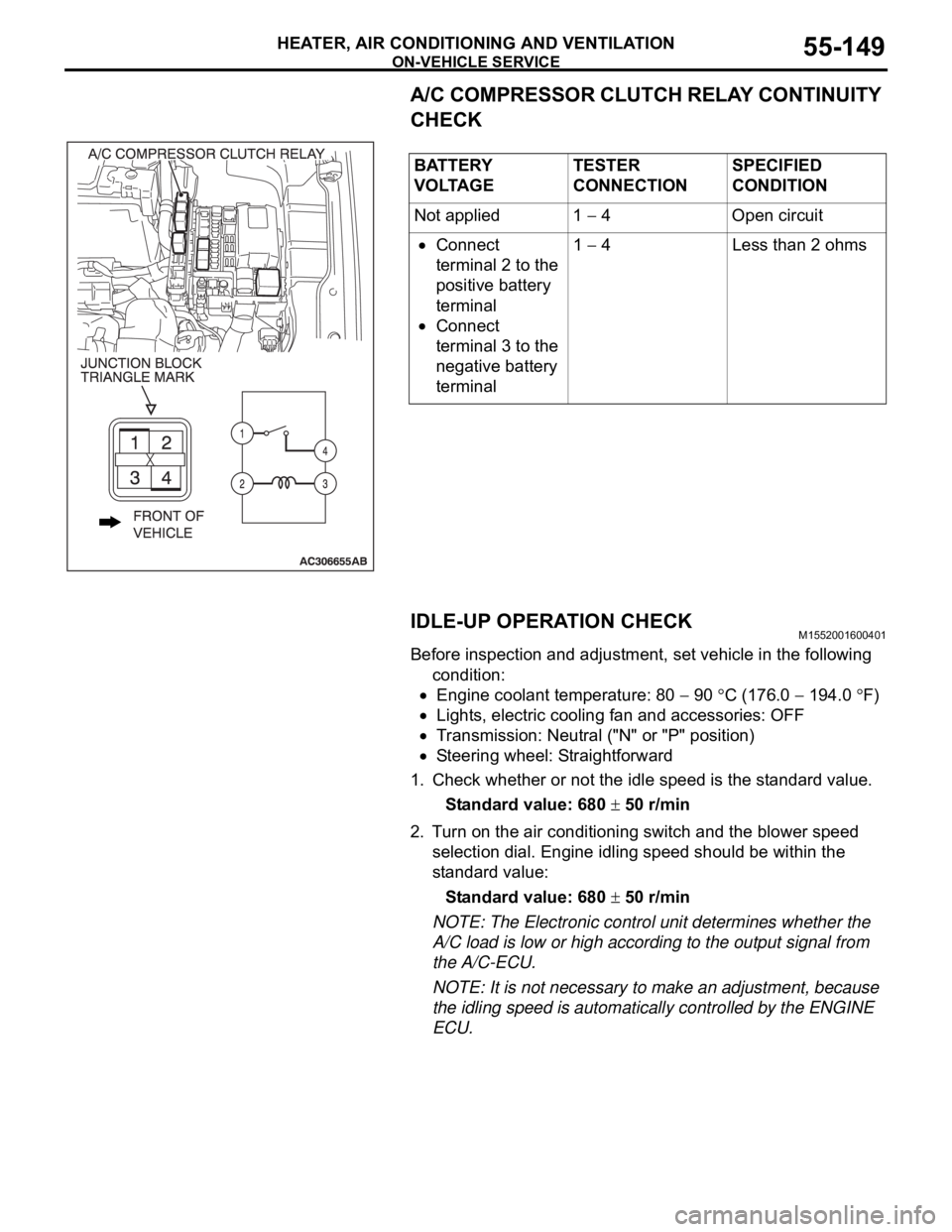

A/C COMPRESSOR CLUTCH RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600401

Before inspection and adjustment, set vehicle in the following

condition:

Engine coolant temperature: 80 90 C (176.0 194.0 F)

Lights, electric cooling fan and accessories: OFF

Transmission: Neutral ("N" or "P" position)

Steering wheel: Straightforward

1. Check whether or not the idle speed is the standard value.

Standard value: 680

50 r/min

2. Turn on the air conditioning switch and the blower speed

selection dial. Engine idling speed should be within the

standard value:

Standard value: 680

50 r/min

NOTE: The Electronic control unit determines whether the

A/C load is low or high according to the output signal from

the A/C-ECU.

NOTE: It is not necessary to make an adjustment, because

the idling speed is automatically controlled by the ENGINE

ECU. BATTERY

V O LTA G ETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms