Battery MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 481 of 1500

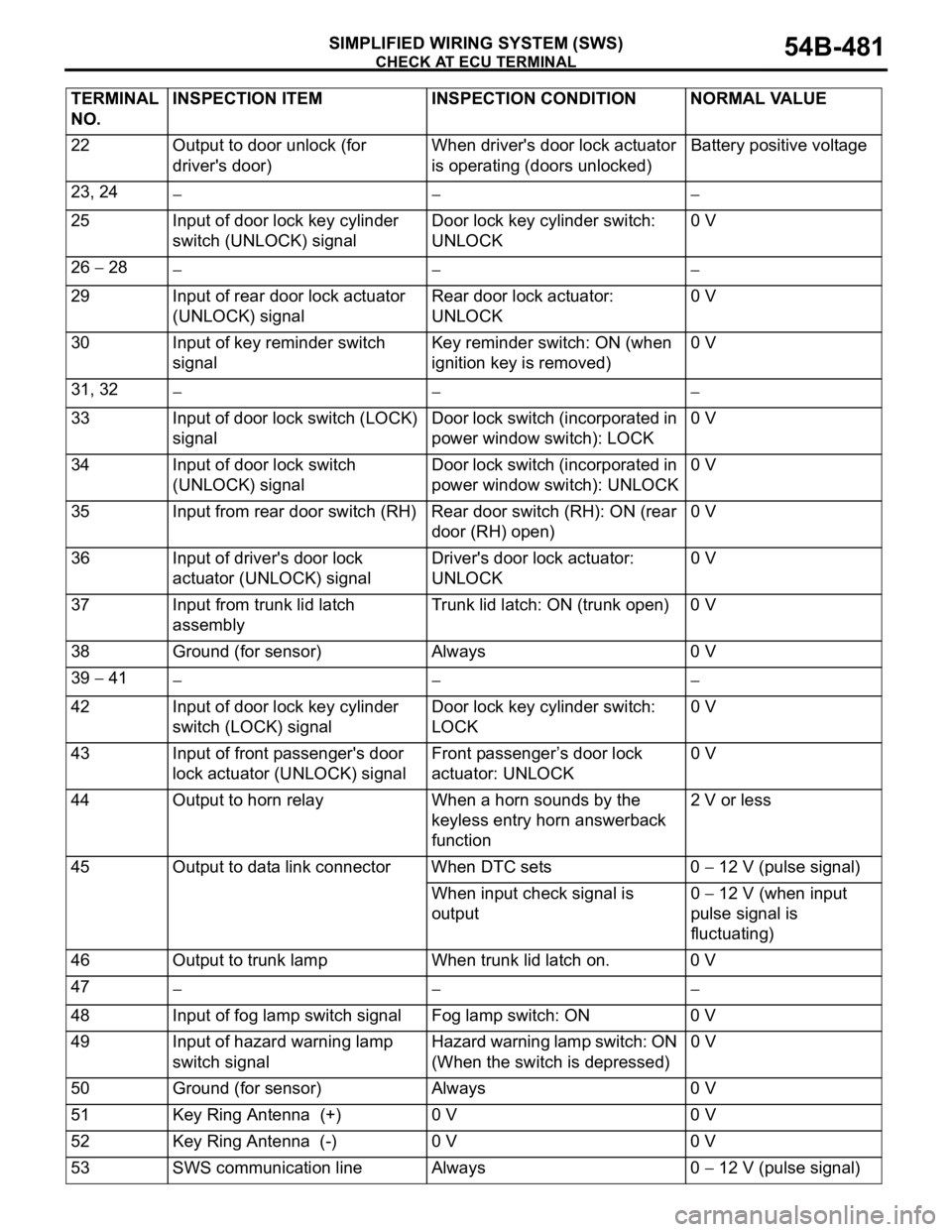

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-481

22 Output to door unlock (for

driver's door)When driver's door lock actuator

is operating (doors unlocked)Battery positive voltage

23, 24

25 Input of door lock key cylinder

switch (UNLOCK) signalDoor lock key cylinder switch:

UNLOCK0 V

26

28

29 Input of rear door lock actuator

(UNLOCK) signalRear door lock actuator:

UNLOCK0 V

30 Input of key reminder switch

signalKey reminder switch: ON (when

ignition key is removed)0 V

31, 32

33 Input of door lock switch (LOCK)

signalDoor lock switch (incorporated in

power window switch): LOCK0 V

34 Input of door lock switch

(UNLOCK) signalDoor lock switch (incorporated in

power window switch): UNLOCK0 V

35 Input from rear door switch (RH) Rear door switch (RH): ON (rear

door (RH) open)0 V

36 Input of driver's door lock

actuator (UNLOCK) signalDriver's door lock actuator:

UNLOCK0 V

37 Input from trunk lid latch

assemblyTrunk lid latch: ON (trunk open) 0 V

38 Ground (for sensor) Always 0 V

39

41

42 Input of door lock key cylinder

switch (LOCK) signalDoor lock key cylinder switch:

LOCK0 V

43 Input of front passenger's door

lock actuator (UNLOCK) signalFront passenger’s door lock

actuator: UNLOCK0 V

44 Output to horn relay When a horn sounds by the

keyless entry horn answerback

function2 V or less

45 Output to data link connector When DTC sets 0

12 V (pulse signal)

When input check signal is

output0

12 V (when input

pulse signal is

fluctuating)

46 Output to trunk lamp When trunk lid latch on. 0 V

47

48 Input of fog lamp switch signal Fog lamp switch: ON 0 V

49 Input of hazard warning lamp

switch signalHazard warning lamp switch: ON

(When the switch is depressed)0 V

50 Ground (for sensor) Always 0 V

51 Key Ring Antenna (+) 0 V 0 V

52 Key Ring Antenna (-) 0 V 0 V

53 SWS communication line Always 0

12 V (pulse signal) TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

Page 483 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-483

COLUMN SWITCH

TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

1 Battery power supply Always Battery positive voltage

2 Input of data request signal Always 0

12 V (pulse signal)

3 SWS communication line Always 0

12 V (pulse signal)

4Ground Always 0 V

5

6 Output of signal from variable

intermittent wiper control switch:

"FAST" to "SLOW"Igniting switch: "ACC,"

Variable intermittent wiper

control switch: "FAST" to

"SLOW"0 2.5 V

7

8 Output of backup signal from

windshield wiper switchWindshield low-speed wiper

switch or windshield high-speed

wiper switch: ON0 V

9 Power supply to ignition switch

(IG1)Ignition switch: "ON" Battery positive voltage

10 Output of backup signal from

headlamp switchIgnition switch: "ON,"

Headlamp switch: ON0 V

Page 484 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-484

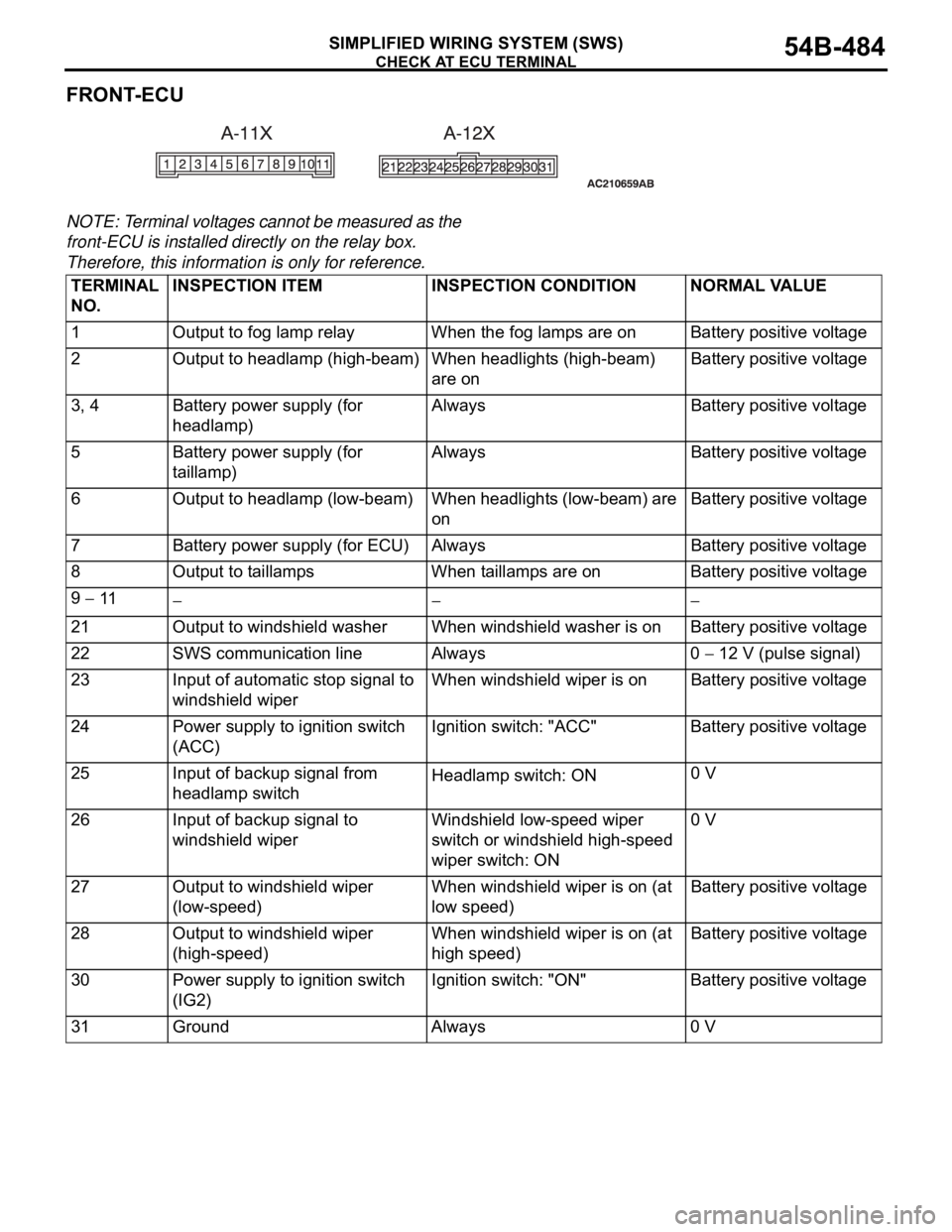

FRONT-ECU

NOTE: Terminal voltages cannot be measured as the

front-ECU is installed directly on the relay box.

Therefore, this information is only for reference.

TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

1 Output to fog lamp relay When the fog lamps are on Battery positive voltage

2 Output to headlamp (high-beam) When headlights (high-beam)

are onBattery positive voltage

3, 4 Battery power supply (for

headlamp)Always Battery positive voltage

5 Battery power supply (for

taillamp)Always Battery positive voltage

6 Output to headlamp (low-beam) When headlights (low-beam) are

onBattery positive voltage

7 Battery power supply (for ECU) Always Battery positive voltage

8 Output to taillamps When taillamps are on Battery positive voltage

9

11

21 Output to windshield washer When windshield washer is on Battery positive voltage

22 SWS communication line Always 0

12 V (pulse signal)

23 Input of automatic stop signal to

windshield wiperWhen windshield wiper is on Battery positive voltage

24 Power supply to ignition switch

(ACC)Ignition switch: "ACC" Battery positive voltage

25 Input of backup signal from

headlamp switchHeadlamp switch: ON0 V

26 Input of backup signal to

windshield wiperWindshield low-speed wiper

switch or windshield high-speed

wiper switch: ON0 V

27 Output to windshield wiper

(low-speed)When windshield wiper is on (at

low speed)Battery positive voltage

28 Output to windshield wiper

(high-speed)When windshield wiper is on (at

high speed)Battery positive voltage

30 Power supply to ignition switch

(IG2)Ignition switch: "ON" Battery positive voltage

31 Ground Always 0 V

Page 485 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-485

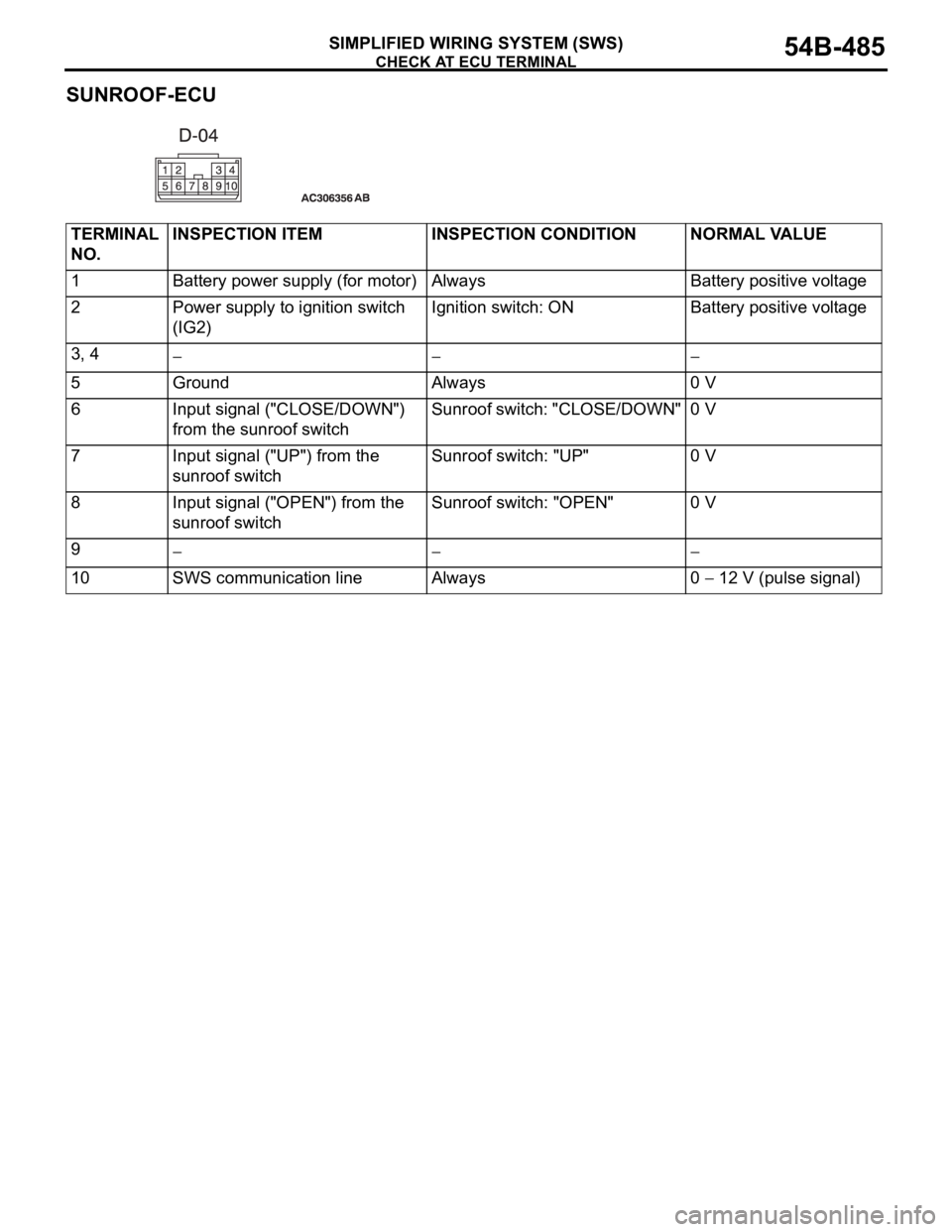

SUNROOF-ECU

TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

1 Battery power supply (for motor) Always Battery positive voltage

2 Power supply to ignition switch

(IG2)Ignition switch: ON Battery positive voltage

3, 4

5Ground Always 0 V

6 Input signal ("CLOSE/DOWN")

from the sunroof switch Sunroof switch: "CLOSE/DOWN" 0 V

7 Input signal ("UP") from the

sunroof switch Sunroof switch: "UP" 0 V

8 Input signal ("OPEN") from the

sunroof switch Sunroof switch: "OPEN" 0 V

9

10 SWS communication line Always 0 12 V (pulse signal)

Page 512 of 1500

FRONT SEAT ASSEMBLY

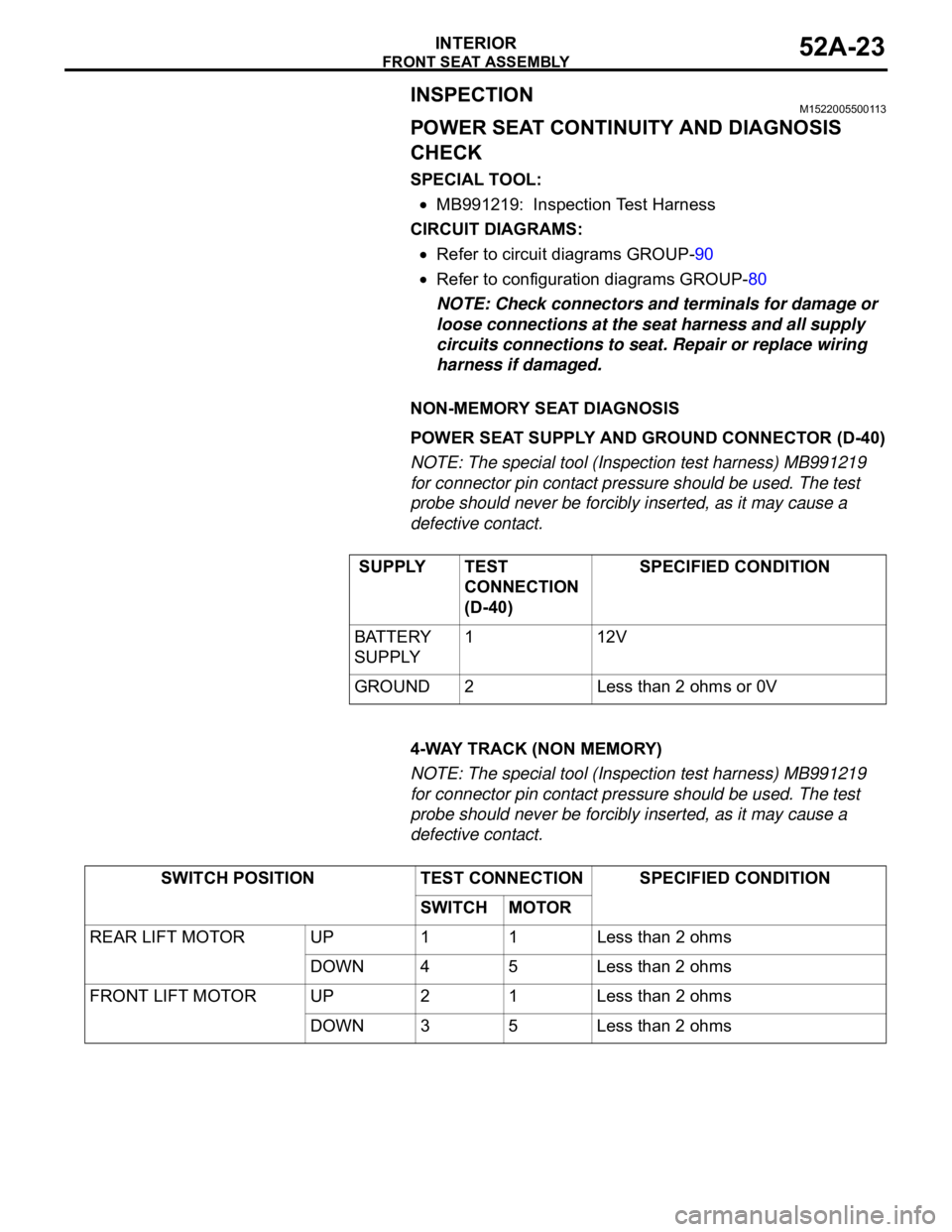

INTERIOR52A-23

INSPECTIONM1522005500113

POWER SEAT CONTINUITY AND DIAGNOSIS

CHECK

SPECIAL TOOL:

MB991219: Inspection Test Harness

CIRCUIT DIAGRAMS:

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

NOTE: Check connectors and terminals for damage or

loose connections at the seat harness and all supply

circuits connections to seat. Repair or replace wiring

harness if damaged.

NON-MEMORY SEAT DIAGNOSIS

POWER SEAT SUPPLY AND GROUND CONNECTOR (D-40)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

4-WAY TRACK (NON MEMORY)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact. SUPPLY TEST

CONNECTION

(D-40) SPECIFIED CONDITION

BATTERY

SUPPLY112V

GROUND 2 Less than 2 ohms or 0V

SWITCH POSITION TEST CONNECTION SPECIFIED CONDITION

SWITCH MOTOR

REAR LIFT MOTOR UP 1 1 Less than 2 ohms

DOWN 4 5 Less than 2 ohms

FRONT LIFT MOTOR UP 2 1 Less than 2 ohms

DOWN 3 5 Less than 2 ohms

Page 514 of 1500

FRONT SEAT ASSEMBLY

INTERIOR52A-25

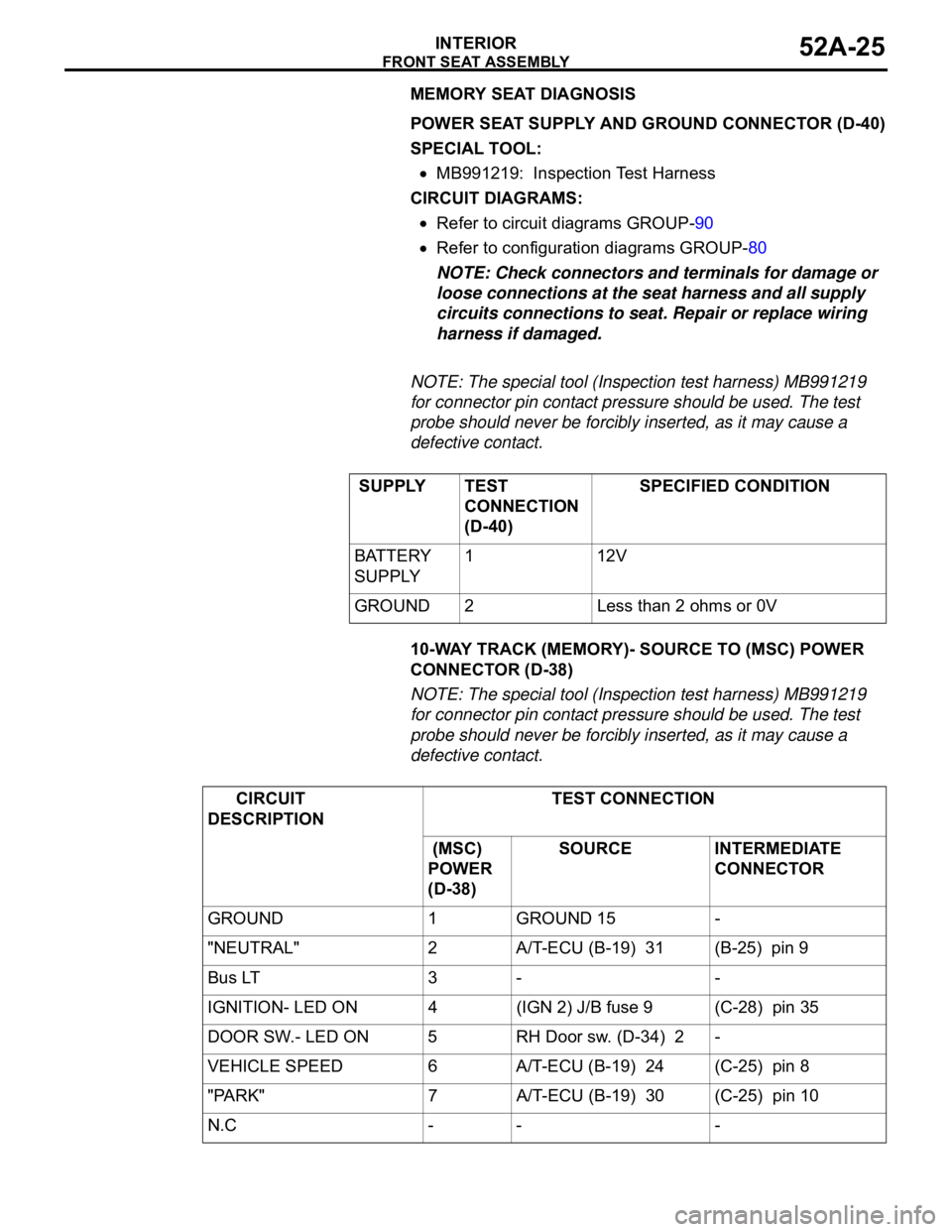

MEMORY SEAT DIAGNOSIS

POWER SEAT SUPPLY AND GROUND CONNECTOR (D-40)

SPECIAL TOOL:

MB991219: Inspection Test Harness

CIRCUIT DIAGRAMS:

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

NOTE: Check connectors and terminals for damage or

loose connections at the seat harness and all supply

circuits connections to seat. Repair or replace wiring

harness if damaged.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

10-WAY TRACK (MEMORY)- SOURCE TO (MSC) POWER

CONNECTOR (D-38)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact. SUPPLY TEST

CONNECTION

(D-40) SPECIFIED CONDITION

BATTERY

SUPPLY112V

GROUND 2 Less than 2 ohms or 0V

CIRCUIT

DESCRIPTION TEST CONNECTION

(MSC)

POWER

(D-38) SOURCE INTERMEDIATE

CONNECTOR

GROUND 1 GROUND 15 -

"NEUTRAL" 2 A/T-ECU (B-19) 31 (B-25) pin 9

Bus LT 3 - -

IGNITION- LED ON 4 (IGN 2) J/B fuse 9 (C-28) pin 35

DOOR SW.- LED ON 5 RH Door sw. (D-34) 2 -

VEHICLE SPEED 6 A/T-ECU (B-19) 24 (C-25) pin 8

"PARK" 7 A/T-ECU (B-19) 30 (C-25) pin 10

N.C - - -

Page 547 of 1500

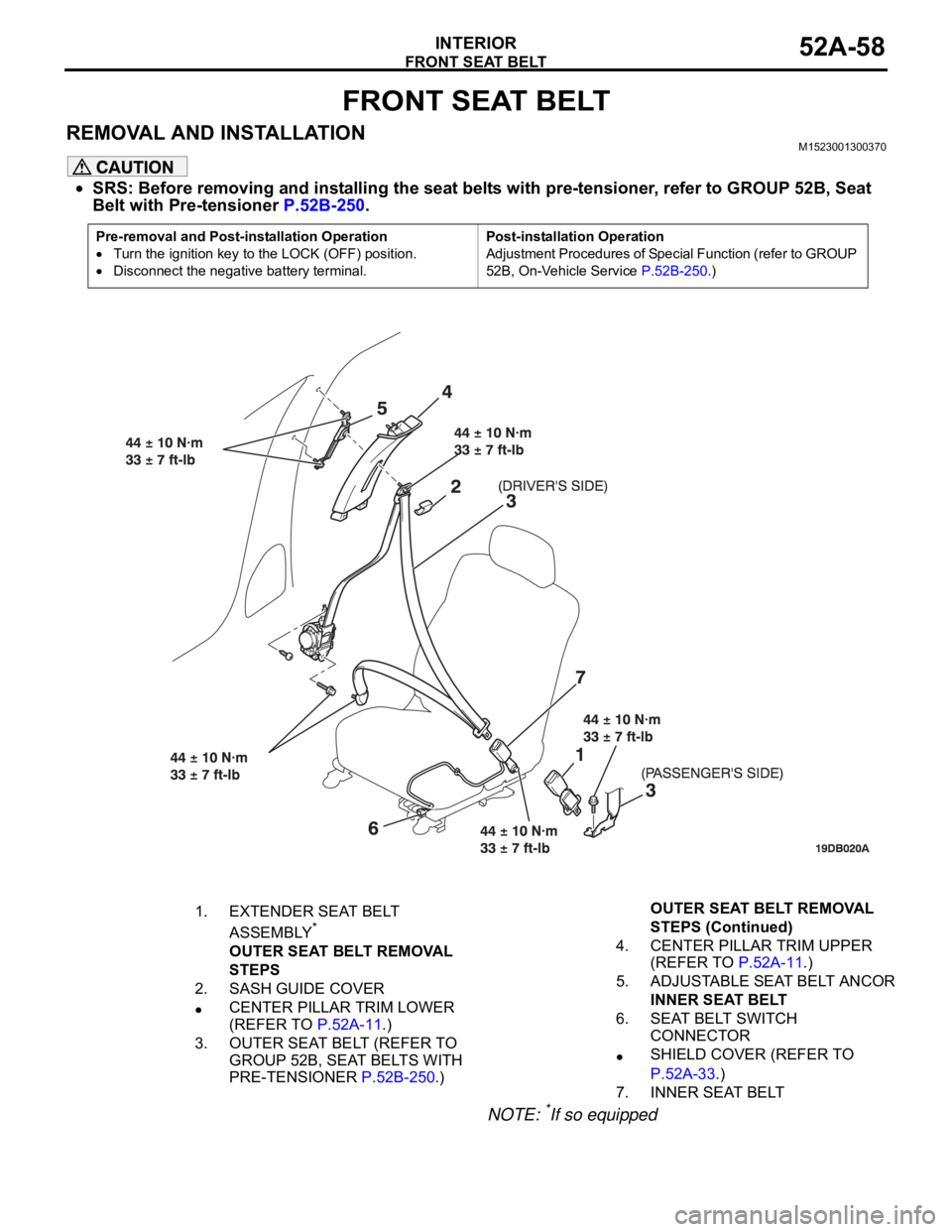

FRONT SEAT BELT

INTERIOR52A-58

FRONT SEAT BELT

REMOVAL AND INSTALLATIONM1523001300370

SRS: Before removing and installing the seat belts with pre-tensioner, refer to GROUP 52B, Seat

Belt with Pre-tensioner P.52B-250.

NOTE:

*If so equipped

Pre-removal and Post-installation Operation

Turn the ignition key to the LOCK (OFF) position.

Disconnect the negative battery terminal.Post-installation Operation

Adjustment Procedures of Special Function (refer to GROUP

52B, On-Vehicle Service P.52B-250.)

1. EXTENDER SEAT BELT

ASSEMBLY*

OUTER SEAT BELT REMOVAL

STEPS

2. SASH GUIDE COVER

CENTER PILLAR TRIM LOWER

(REFER TO P.52A-11.)

3. OUTER SEAT BELT (REFER TO

GROUP 52B, SEAT BELTS WITH

PRE-TENSIONER P.52B-250.)4. CENTER PILLAR TRIM UPPER

(REFER TO P.52A-11.)

5. ADJUSTABLE SEAT BELT ANCOR

INNER SEAT BELT

6. SEAT BELT SWITCH

CONNECTOR

SHIELD COVER (REFER TO

P.52A-33.)

7. INNER SEAT BELTOUTER SEAT BELT REMOVAL

STEPS (Continued)

Page 589 of 1500

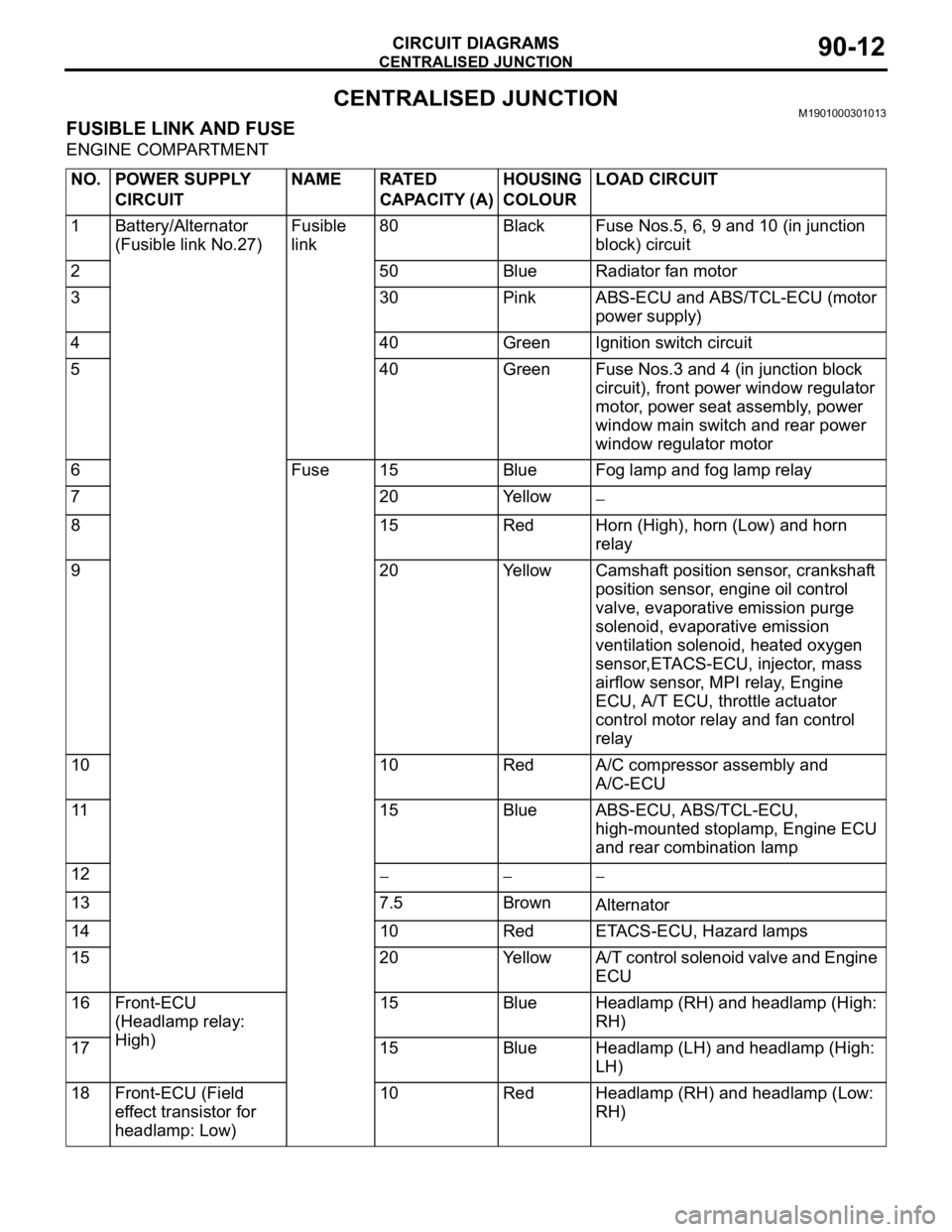

CENTRALISED JUNCTION

CIRCUIT DIAGRAMS90-12

CENTRALISED JUNCTIONM1901000301013

FUSIBLE LINK AND FUSE

ENGINE COMPARTMENT

NO. POWER SUPPLY

CIRCUITNAME RATED

CAPACITY (A)HOUSING

COLOURLOAD CIRCUIT

1 Battery/Alternator

(Fusible link No.27)Fusible

link80 Black Fuse Nos.5, 6, 9 and 10 (in junction

block) circuit

2 50 Blue Radiator fan motor

3 30 Pink ABS-ECU and ABS/TCL-ECU (motor

power supply)

4 40 Green Ignition switch circuit

5 40 Green Fuse Nos.3 and 4 (in junction block

circuit), front power window regulator

motor, power seat assembly, power

window main switch and rear power

window regulator motor

6 Fuse 15 Blue Fog lamp and fog lamp relay

720Yellow

8 15 Red Horn (High), horn (Low) and horn

relay

9 20 Yellow Camshaft position sensor, crankshaft

position sensor, engine oil control

valve, evaporative emission purge

solenoid, evaporative emission

ventilation solenoid, heated oxygen

sensor,ETACS-ECU, injector, mass

airflow sensor, MPI relay, Engine

ECU, A/T ECU, throttle actuator

control motor relay and fan control

relay

10 10 Red A/C compressor assembly and

A/C-ECU

11 15 Blue ABS-ECU, ABS/TCL-ECU,

high-mounted stoplamp, Engine ECU

and rear combination lamp

12

13 7.5 Brown

Alternator

14 10 Red ETACS-ECU, Hazard lamps

15 20 Yellow A/T control solenoid valve and Engine

ECU

16 Front-ECU

(Headlamp relay:

High)15 Blue Headlamp (RH) and headlamp (High:

RH)

17 15 Blue Headlamp (LH) and headlamp (High:

LH)

18 Front-ECU (Field

effect transistor for

headlamp: Low)10 Red Headlamp (RH) and headlamp (Low:

RH)

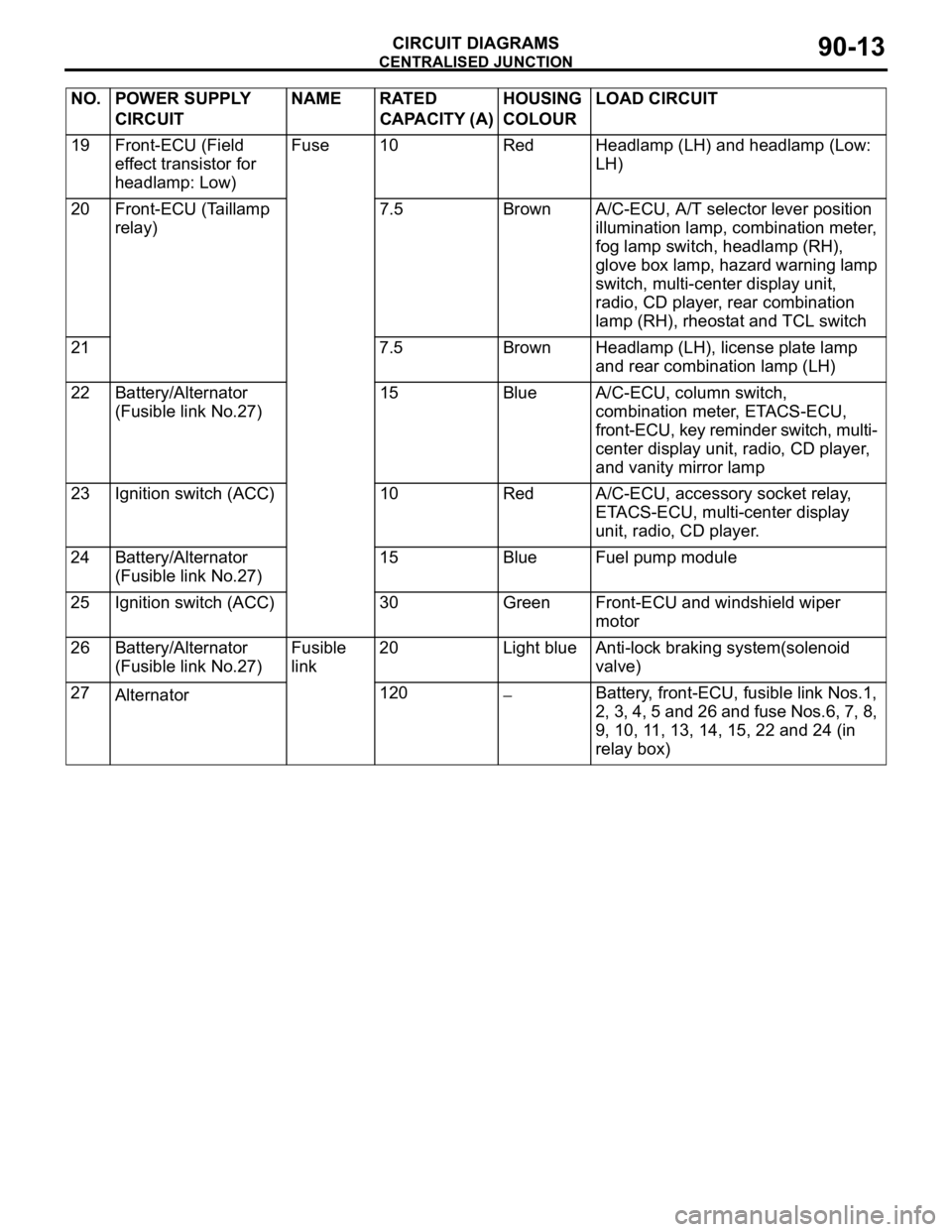

Page 590 of 1500

CENTRALISED JUNCTION

CIRCUIT DIAGRAMS90-13

19 Front-ECU (Field

effect transistor for

headlamp: Low)Fuse 10 Red Headlamp (LH) and headlamp (Low:

LH)

20 Front-ECU (Taillamp

relay)7.5 Brown A/C-ECU, A/T selector lever position

illumination lamp, combination meter,

fog lamp switch, headlamp (RH),

glove box lamp, hazard warning lamp

switch, multi-center display unit,

radio, CD player, rear combination

lamp (RH), rheostat and TCL switch

21 7.5 Brown Headlamp (LH), license plate lamp

and rear combination lamp (LH)

22 Battery/Alternator

(Fusible link No.27)15 Blue A/C-ECU, column switch,

combination meter, ETACS-ECU,

front-ECU, key reminder switch, multi-

center display unit, radio, CD player,

and vanity mirror lamp

23 Ignition switch (ACC) 10 Red A/C-ECU, accessory socket relay,

ETACS-ECU, multi-center display

unit, radio, CD player.

24 Battery/Alternator

(Fusible link No.27)15 Blue Fuel pump module

25 Ignition switch (ACC) 30 Green Front-ECU and windshield wiper

motor

26 Battery/Alternator

(Fusible link No.27)Fusible

link20 Light blue Anti-lock braking system(solenoid

valve)

27

Alternator120

Battery, front-ECU, fusible link Nos.1,

2, 3, 4, 5 and 26 and fuse Nos.6, 7, 8,

9, 10, 11, 13, 14, 15, 22 and 24 (in

relay box) NO. POWER SUPPLY

CIRCUITNAME RATED

CAPACITY (A)HOUSING

COLOURLOAD CIRCUIT

Page 707 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-6

HOW TO READ AND ERASE DIAGNOSTIC

TROUBLE CODES

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

NOTE: If the battery voltage is low, diagnostic trouble codes will

not be output. Check the battery if diagnostic tool does not dis-

play.

1. Connect the diagnostic tool to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System Select."

5. Choose "AUTO A/C" from the "BODY" tab.

6. Select "MITSUBISHI."

7. Select "Diagnostic Trouble Code."

8. If a DTC is set, it is shown.

9. Choose "Erase DTC" to erase the DTC.

HOW TO READ DATA LIST

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)