MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1161 of 1500

Page 1162 of 1500

CLUTCH CONTROL

CLUTCH21A-7

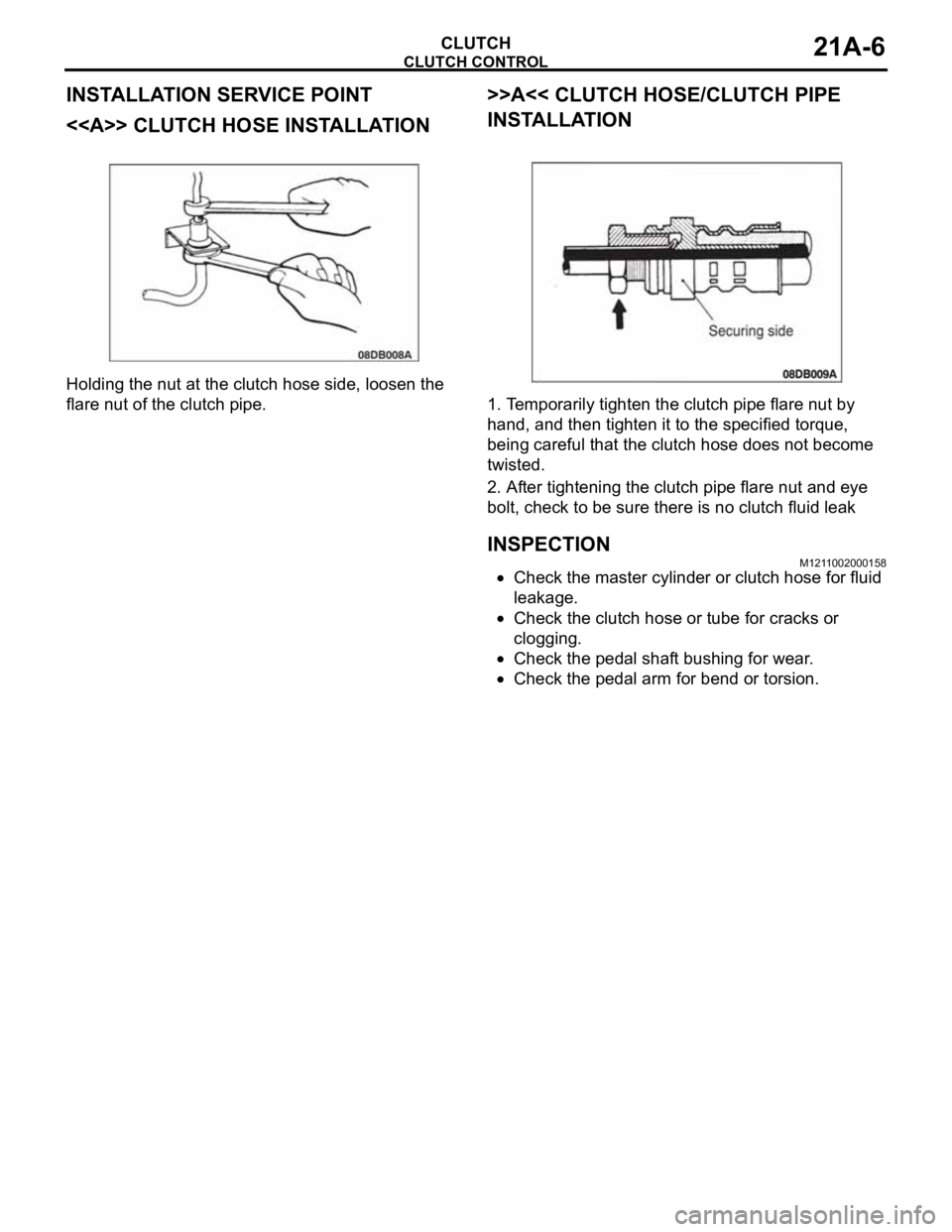

DISASSEMBLY AND REASSEMBLY

M1211002100230

CLUTCH MASTER CYLINDER

Do not disassemble the piston assembly.

Disassembly steps

1. Piston stopper ring

2. Piston assembly

>>A<<3. Pushrod assembly

4. Boot5. Spring pin

6. Nipple

7. Seal

8. Master cylinder bodyDisassembly steps (Continued)

Page 1163 of 1500

CLUTCH CONTROL

CLUTCH21A-8

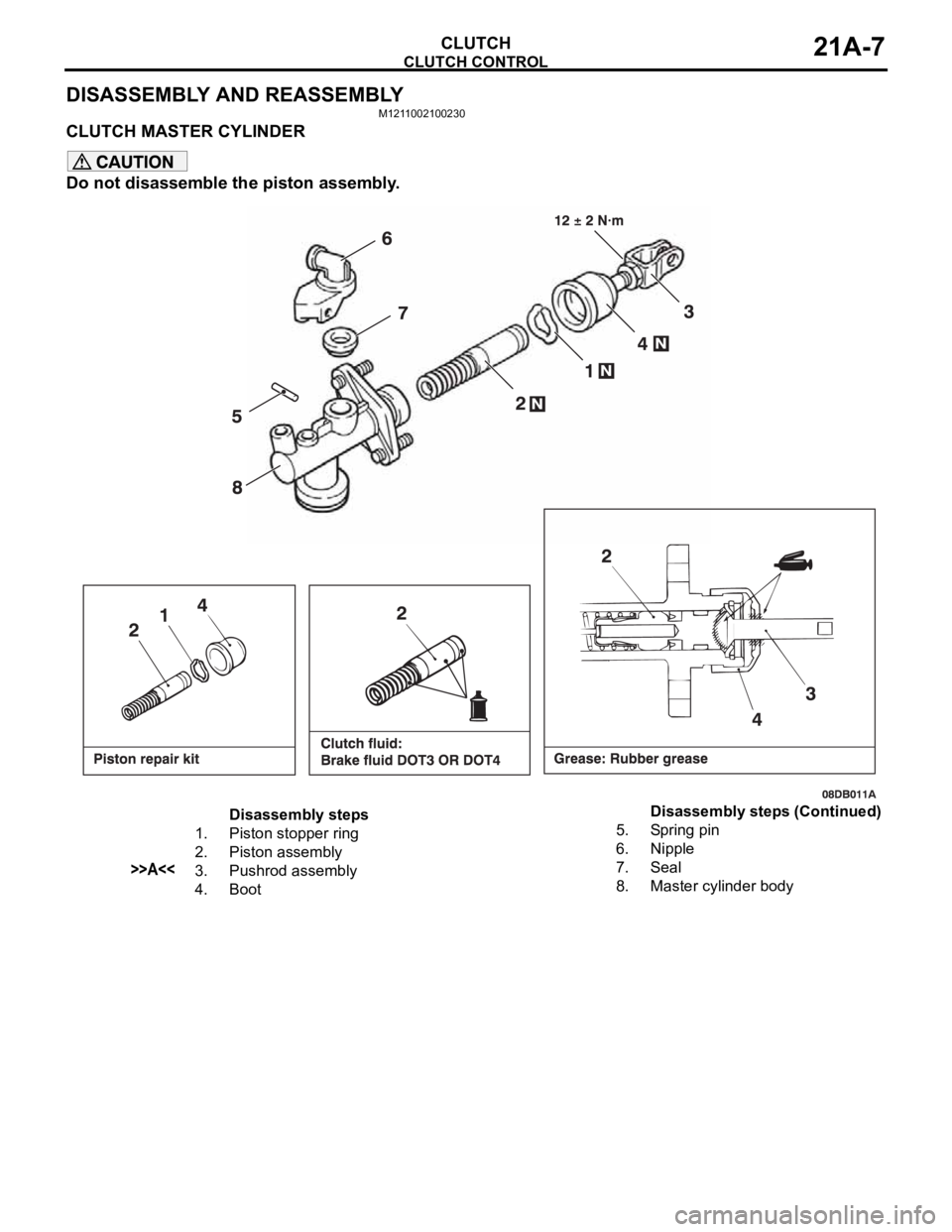

REASSEMBLY SERVICE POINT

>>A<< PUSHROD ASSEMBLY

INSTALLATIONSet the length of the pushrod assembly to the

dimension shown to make the adjustment of the

clutch pedal easier.

INSPECTIONM1211002200152

Check inside the cylinder body for rust and scars.

Check the piston for rust and scars.

Check the pipe connection for clogging.

Page 1164 of 1500

35-1

GROUP 35

SERVICE BRAKES

CONTENTS

BASIC BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35A

ANTI-LOCK BRAKING SYSTEM (ABS). . . . . . . . . . . . . . . . . . .35B

Page 1165 of 1500

NOTES

Page 1166 of 1500

35A-1

GROUP 35A

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .35A-2

BASIC BRAKE SYSTEM DIAGNOSIS35A-3

INTRODUCTION TO BASIC BRAKE

SYSTEM DIAGNOSIS . . . . . . . . . . . . . . . . 35A-3

BASIC BRAKE SYSTEM DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . . . 35A-3

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 35A-3

SYMPTOM PROCEDURES . . . . . . . . . . . . 35A-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .35A-12

ON-VEHICLE SERVICE . . . . . . . . . . .35A-13

BRAKE PEDAL CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 35A-13

BRAKE BOOSTER OPERATING TEST . . . 35A-14

CHECK VALVE OPERATION CHECK . . . . 35A-15

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 35A-16

BRAKE FLUID LEVEL SENSOR CHECK. . 35A-17

DISC BRAKE PAD CHECK AND

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 35A-17

DISC BRAKE ROTOR CHECK . . . . . . . . . . 35A-19

MASTER CYLINDER FUNCTION CHECK . 35A-23

BRAKE PEDAL. . . . . . . . . . . . . . . . . .35A-24

REMOVAL AND INSTALLATION . . . . . . . . 35A-24

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-25

MASTER CYLINDER ASSEMBLY

AND BRAKE BOOSTER . . . . . . . . . .35A-26

REMOVAL AND INSTALLATION . . . . . . . . 35A-26

MASTER CYLINDER . . . . . . . . . . . . . . . . . 35A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-29

DISC BRAKE ASSEMBLY . . . . . . . . .35A-30

REMOVAL AND INSTALLATION . . . . . . . . 35A-30

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-32

DISASSEMBLY AND ASSEMBLY

DISASSEMBLY AND ASSEMBLY

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 35A-38

SPECIFICATIONS . . . . . . . . . . . . . . .35A-40

FASTENER TIGHTENING

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 35A-40

GENERAL SPECIFICATIONS . . . . . . . . . . 35A-40

SERVICE SPECIFICATIONS . . . . . . . . . . . 35A-41

LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . 35A-41

Page 1167 of 1500

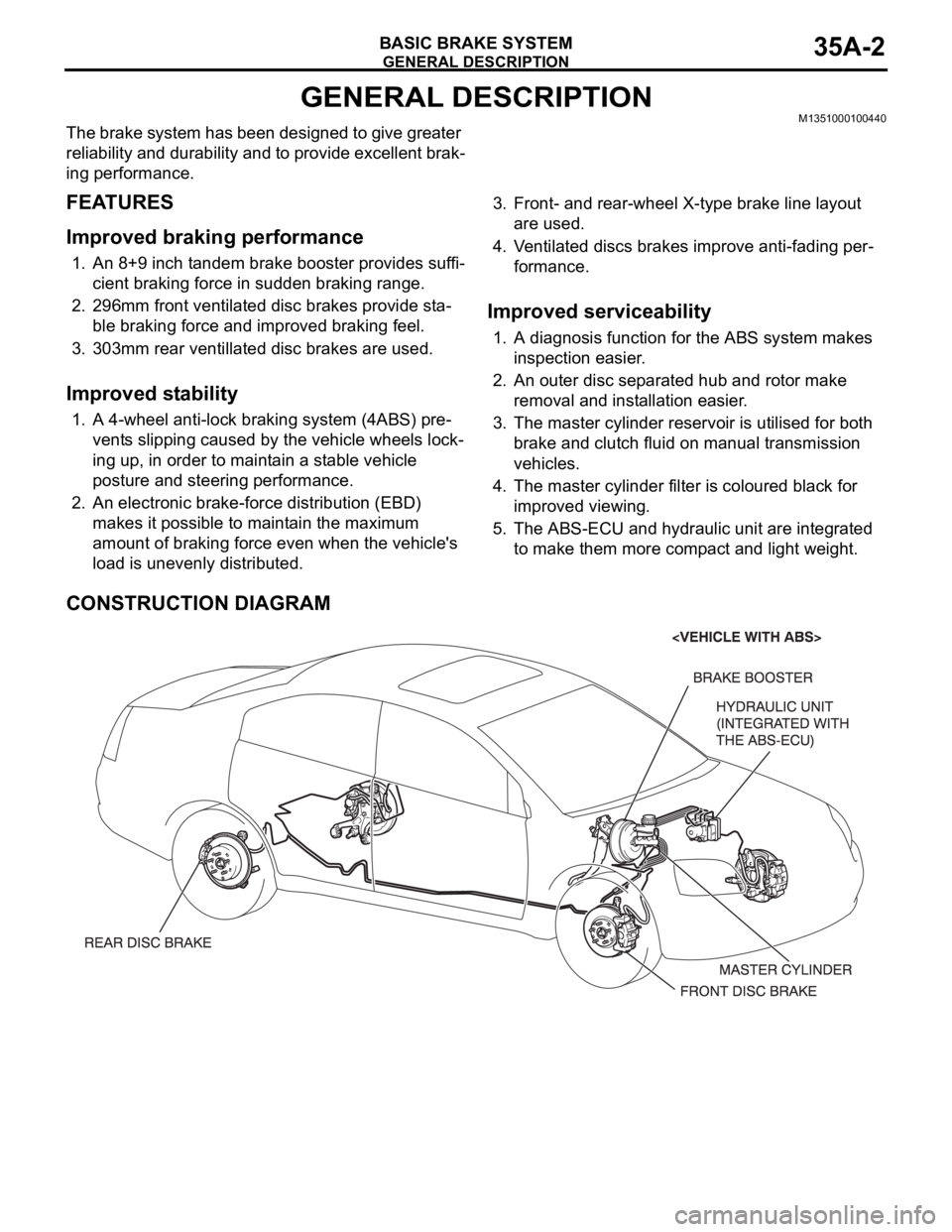

GENERAL DESCRIPTION

BASIC BRAKE SYSTEM35A-2

GENERAL DESCRIPTIONM1351000100440

The brake system has been designed to give greater

reliability and durability and to provide excellent brak-

ing performance.

FEATURES

.

Improved braking performance

1. An 8+9 inch tandem brake booster provides suffi-

cient braking force in sudden braking range.

2. 296mm front ventilated disc brakes provide sta-

ble braking force and improved braking feel.

3. 303mm rear ventillated disc brakes are used.

.

Improved stability

1. A 4-wheel anti-lock braking system (4ABS) pre-

vents slipping caused by the vehicle wheels lock-

ing up, in order to maintain a stable vehicle

posture and steering performance.

2. An electronic brake-force distribution (EBD)

makes it possible to maintain the maximum

amount of braking force even when the vehicle's

load is unevenly distributed. 3. Front- and rear-wheel X-type brake line layout

are used.

4. Ventilated discs brakes improve anti-fading per-

formance.

.

Improved serviceability

1. A diagnosis function for the ABS system makes

inspection easier.

2. An outer disc separated hub and rotor make

removal and installation easier.

3. The master cylinder reservoir is utilised for both

brake and clutch fluid on manual transmission

vehicles.

4. The master cylinder filter is coloured black for

improved viewing.

5. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

CONSTRUCTION DIAGRAM

Page 1168 of 1500

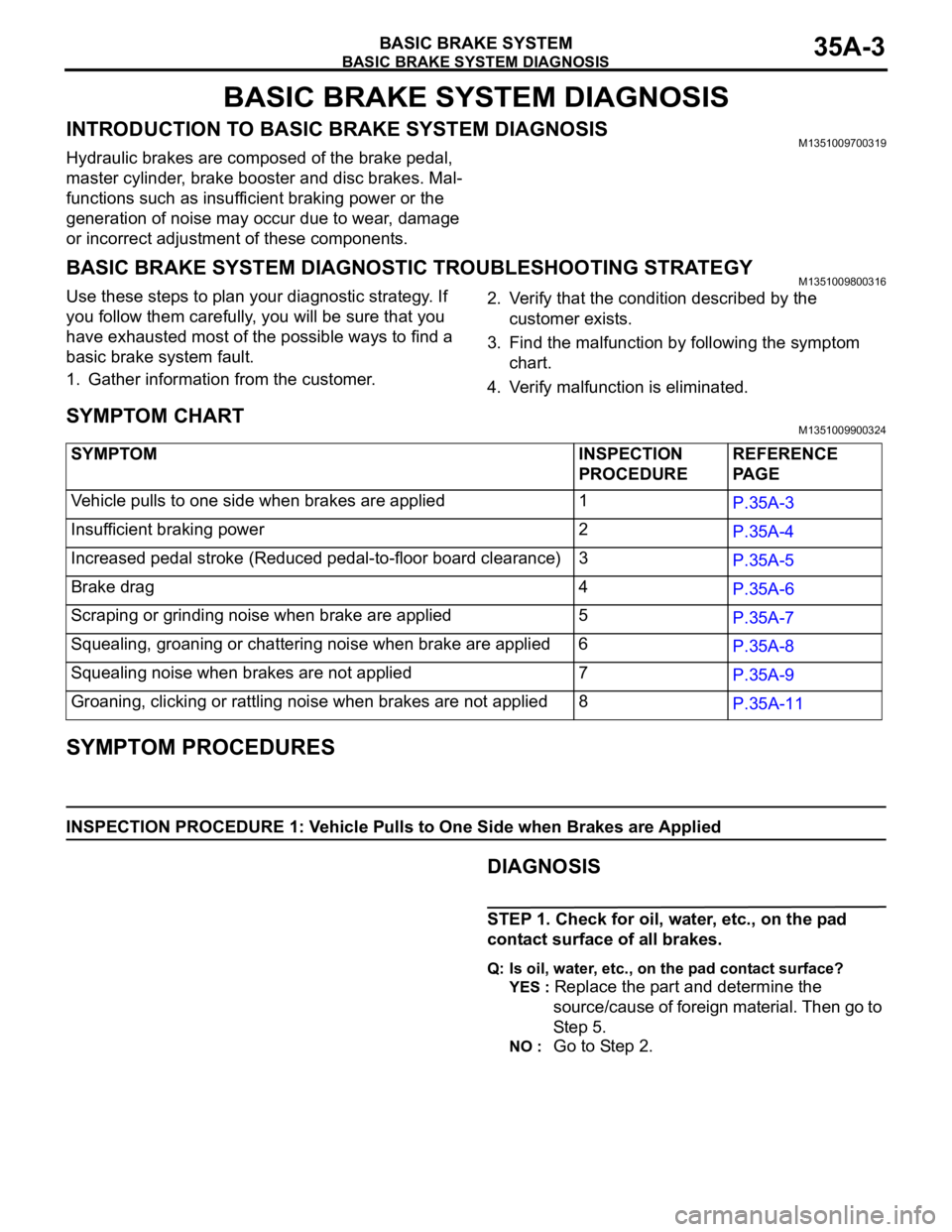

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-3

BASIC BRAKE SYSTEM DIAGNOSIS

INTRODUCTION TO BASIC BRAKE SYSTEM DIAGNOSISM1351009700319

Hydraulic brakes are composed of the brake pedal,

master cylinder, brake booster and disc brakes. Mal-

functions such as insufficient braking power or the

generation of noise may occur due to wear, damage

or incorrect adjustment of these components.

BASIC BRAKE SYSTEM DIAGNOSTIC TROUBLESHOOTING STRATEGYM1351009800316

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

basic brake system fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the symptom

chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1351009900324

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Vehicle Pulls to One Side when Brakes are Applied

.DIAGNOSIS

STEP 1. Check for oil, water, etc., on the pad

contact surface of all brakes.

Q: Is oil, water, etc., on the pad contact surface?

YES :

Replace the part and determine the

source/cause of foreign material. Then go to

St e p 5.

NO : Go to Step 2. SYMPTOM INSPECTION

PROCEDUREREFERENCE

PA G E

Vehicle pulls to one side when brakes are applied 1

P.35A-3

Insufficient braking power 2

P.35A-4

Increased pedal stroke (Reduced pedal-to-floor board clearance)3

P.35A-5

Brake drag 4

P.35A-6

Scraping or grinding noise when brake are applied 5

P.35A-7

Squealing, groaning or chattering noise when brake are applied 6

P.35A-8

Squealing noise when brakes are not applied 7

P.35A-9

Groaning, clicking or rattling noise when brakes are not applied8

P.35A-11

Page 1169 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-4

STEP 2. Check disc brake pistons for smooth

operation.

(1) With engine not running, depress the brake pedal

rapidly several times to deplete booster vacuum

reserves.

(2) Test each disc brake assembly one at a time.

a. Remove the lower caliper bolt, then remove

caliper from mount.

b. Have an assistant slowly depress the brake

pedal. Confirm piston(s) extend slowly and

smoothly with no jumpiness. Repeat for each

disc brake assembly.

Q: Do (does) the piston(s) move correctly?

YES :

Go to Step 3.

NO : Disassemble and inspect the brake

assembly (Front: refer to P.35A-33, Rear:

refer to P.35A-36). Then go to Step 5.

STEP 3. Check brake disc(s) for runout.

Refer to P.35A-19.

Q: Is runout outside of specifications?

YES :

Repair or replace the brake disc(s) as

necessary. Then go to Step 5.

NO : Go to Step 4.

STEP 4. Check brake discs for correct thickness.

Refer to P.35A-19.

Q: Is the thickness outside of specifications?

YES :

Repair or replace the brake disc(s) as

necessary. Then go to Step 5.

NO : Perform the brake line bleeding. Then go to

St e p 5.

STEP 5. Retest the system.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO : Start over at Step 1. If a new symptom

appears, refer to the appropriate symptom

chart.

INSPECTION PROCEDURE 2: Insufficient Braking Power

.

DIAGNOSIS

STEP 1. Check that the specified brake fluid is

used, its level is correct, and no contamination is

found.

Q: Is there a fault?

YES :

Refill or replace with the specified brake

fluid DOT 3 or DOT 4. Bleed the brakes if

necessary (Refer to P.35A-16). Then go to

Step 7.

NO : Go to Step 2.

STEP 2. Check for spongy (not firm) brakes.

(1) With engine not running, depress the brake pedal

rapidly several times to deplete the booster

vacuum reserve.

(2) With the brake pedal fully released, depress the

brake pedal slowly until it stops.

(3) With a measuring device (ruler, etc.) next to the

brake pedal, depress the pedal firmly and

measure the distance the pedal traveled.

Q: Is the distance greater than 20 mm (0.8 inch)?

YES :

Bleed the brakes to remove air in the fluid

(Refer to P.35A-16). Then go to Step 7.

NO : Go to Step 3.

STEP 3. Check the brake booster function.

Refer to P.35A-14.

Q: Is there a fault?

YES :

Replace the brake booster. Then go to Step

7.

NO : Go to Step 4.

Page 1170 of 1500

BASIC BRAKE SYSTEM DIAGNOSIS

BASIC BRAKE SYSTEM35A-5

STEP 4. Check for pinched or restricted brake

tube or hose.

Q: Is there a pinched or restricted brake tube or hose?

YES :

Replace that complete section of brake tube

or brake hose. Then go to Step 7.

NO : Go to Step 5.

STEP 5. Check for oil, water, etc., on the pad

contact surfaces of all brakes.

Q: Is oil, water, etc., on the pad contact surface?

YES :

Replace the part and determine the

source/cause of foreign material. Recheck

symptom. Then go to Step 7.

NO : The procedure is complete. If condition

persists for vehicles without ABS, go to Step

6.

STEP 7. Recheck symptom.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO : Start over at step 1. If a new symptom

surfaces, refer to the appropriate symptom

chart.

INSPECTION PROCEDURE 3: Increased Pedal Stroke (Reduced Pedal-to-Floor Board Clearance)

.

DIAGNOSIS

STEP 1. Check for spongy (not firm) brakes.

(1) With engine not running, depress the brake pedal

rapidly several times to deplete booster vacuum

reserve.

(2) With the brake pedal fully released, depress the

brake pedal slowly until it stops.

(3) With a measuring device (ruler, etc.) next to the

brake pedal, depress the pedal firmly and

measure the distance the pedal traveled.

Q: Is the distance greater than 20 mm (0.8 inch)?

YES :

Bleed the brakes to remove air in the fluid

(Refer to P.35A-16). Then go to Step 7.

NO : Go to Step 2.

STEP 2. Check the pad for wear.

Refer to P.35A-17.

Q: Is the pad thickness outside of specifications?

YES :

Replace the part. Then go to Step 7.

NO : Go to Step 3.

STEP 3. Check the vacuum hose and check valve

for damage.

Refer to P.35A-15.

Q: Is there a damage?

YES :

Replace the part. Then go to Step 7.

NO : Go to Step 4.

STEP 4. Check the master cylinder function.

Refer to P.35A-23.

Q: Is there a fault?

YES :

Repair it. Then go to Step 7.

NO : Go to Step 5.

STEP 5. Check for brake fluid leaks.

Q: Is there a leak?

YES :

Check the connection for looseness,

corrosion, etc. Clean and repair as

necessary. If leaking in any tube or hose

section, replace the complete tube or hose.

Then go to Step 7 .

NO : Go to Step 6.

STEP 6. Check for excessive clearance between

the push rod and primary piston.

Refer to P.35A-26.

Q: Is the clearance outside of specifications?

YES :

Adjust the clearance. Then go to Step 7.

NO : Go to Step 7.

STEP 7. Recheck symptom.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO : Start over at step 1. If a new symptom

surfaces, refer to the symptom chart.