MITSUBISHI 380 2005 Workshop Manual

380 2005

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57086/w960_57086-0.png

MITSUBISHI 380 2005 Workshop Manual

Trending: Dash, windshield wipers, headlamp, wheel bolts, Alarm, fuel tank capacity, oil reset

Page 1191 of 1500

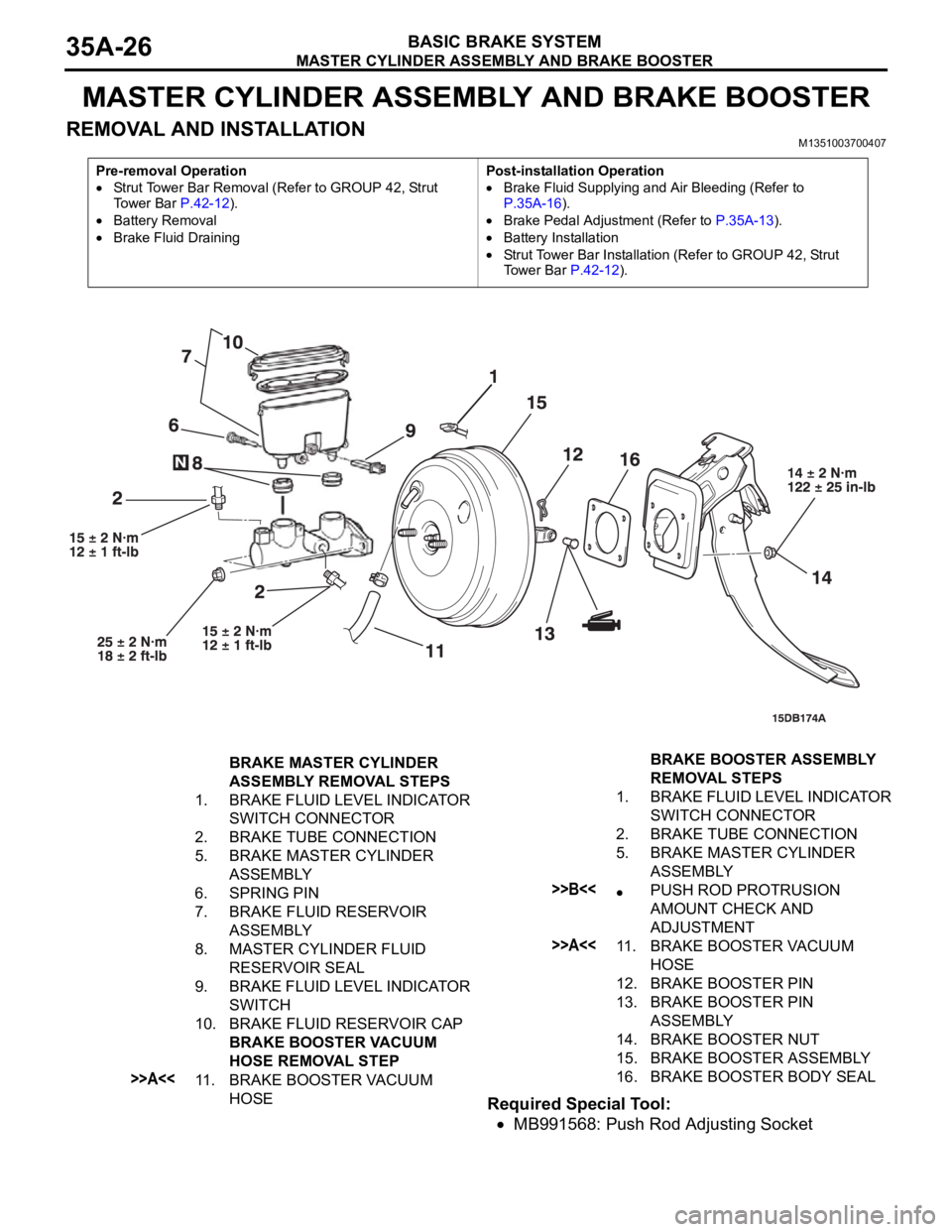

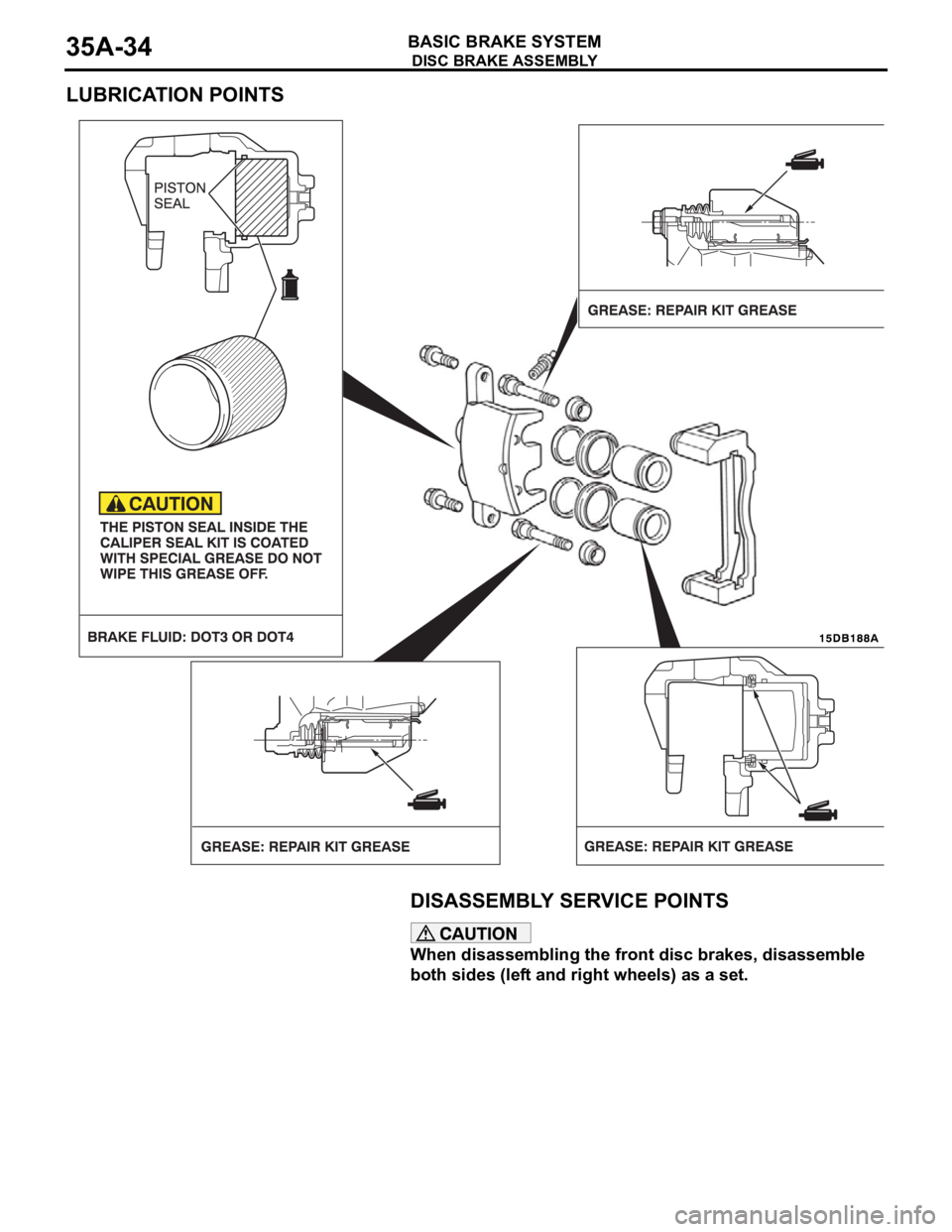

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM35A-26

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

REMOVAL AND INSTALLATIONM1351003700407

Required Special Tool:

MB991568: Push Rod Adjusting Socket

Pre-removal Operation

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Battery Removal

Brake Fluid DrainingPost-installation Operation

Brake Fluid Supplying and Air Bleeding (Refer to

P.35A-16).

Brake Pedal Adjustment (Refer to P.35A-13).

Battery Installation

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

BRAKE MASTER CYLINDER

ASSEMBLY REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

6. SPRING PIN

7. BRAKE FLUID RESERVOIR

ASSEMBLY

8. MASTER CYLINDER FLUID

RESERVOIR SEAL

9. BRAKE FLUID LEVEL INDICATOR

SWITCH

10. BRAKE FLUID RESERVOIR CAP

BRAKE BOOSTER VACUUM

HOSE REMOVAL STEP

>>A<<11. BRAKE BOOSTER VACUUM

HOSE BRAKE BOOSTER ASSEMBLY

REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

>>B<

AMOUNT CHECK AND

ADJUSTMENT

>>A<<11. BRAKE BOOSTER VACUUM

HOSE

12. BRAKE BOOSTER PIN

13. BRAKE BOOSTER PIN

ASSEMBLY

14. BRAKE BOOSTER NUT

15. BRAKE BOOSTER ASSEMBLY

16. BRAKE BOOSTER BODY SEAL

Page 1192 of 1500

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM35A-27

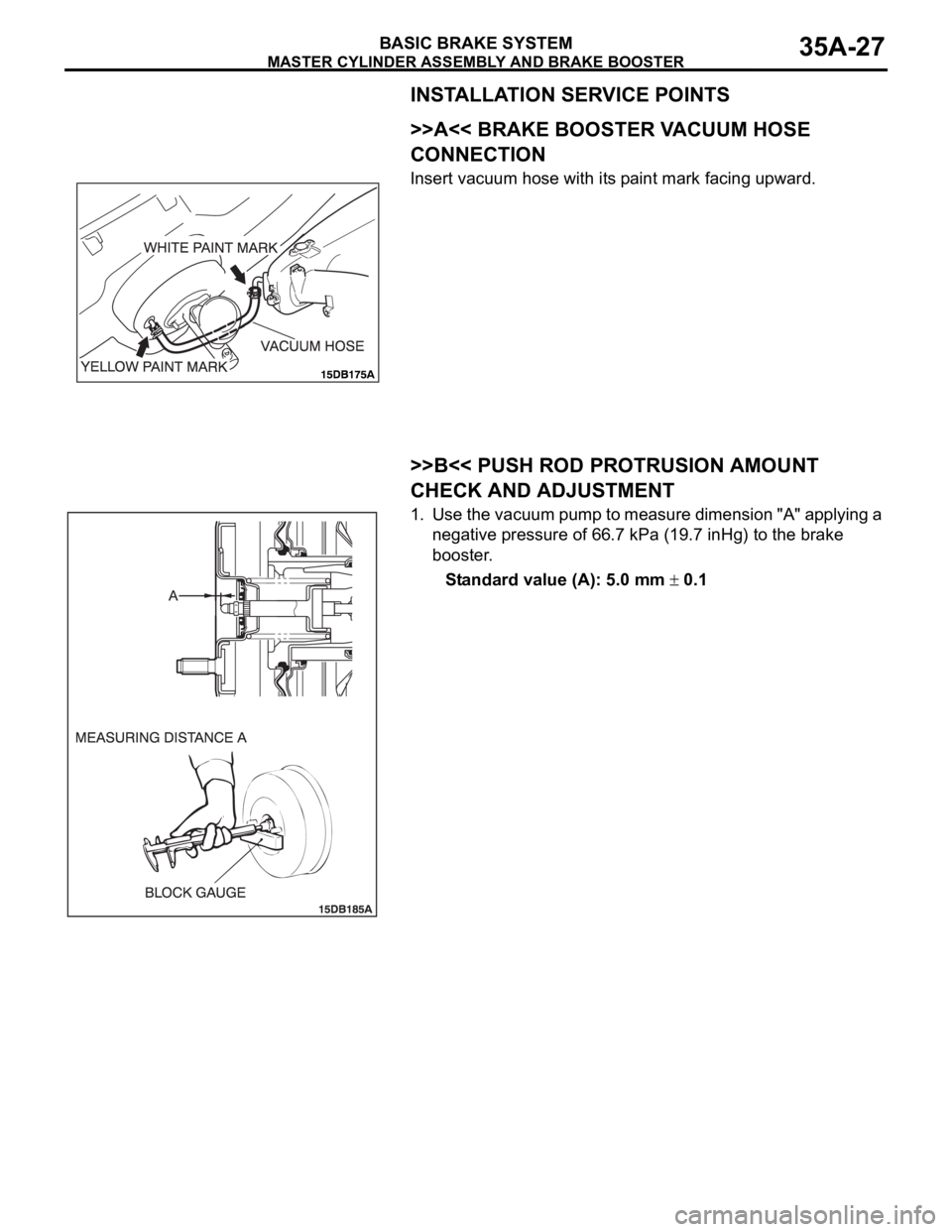

INSTALLATION SERVICE POINTS

.

>>A<< BRAKE BOOSTER VACUUM HOSE

CONNECTION

Insert vacuum hose with its paint mark facing upward.

.

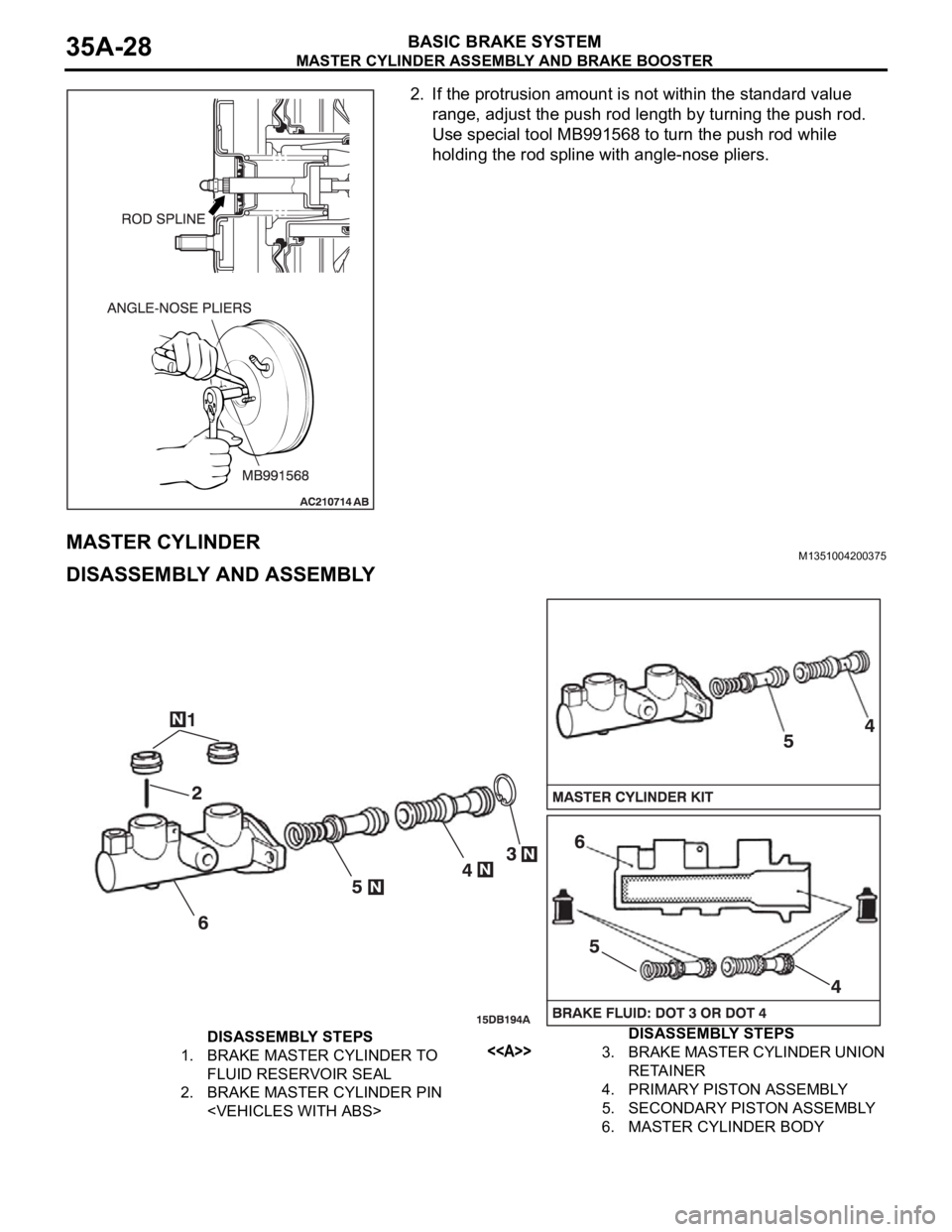

>>B<< PUSH ROD PROTRUSION AMOUNT

CHECK AND ADJUSTMENT

1. Use the vacuum pump to measure dimension "A" applying a

negative pressure of 66.7 kPa (19.7 inHg) to the brake

booster.

Standard value (A): 5.0 mm

0.1

Page 1193 of 1500

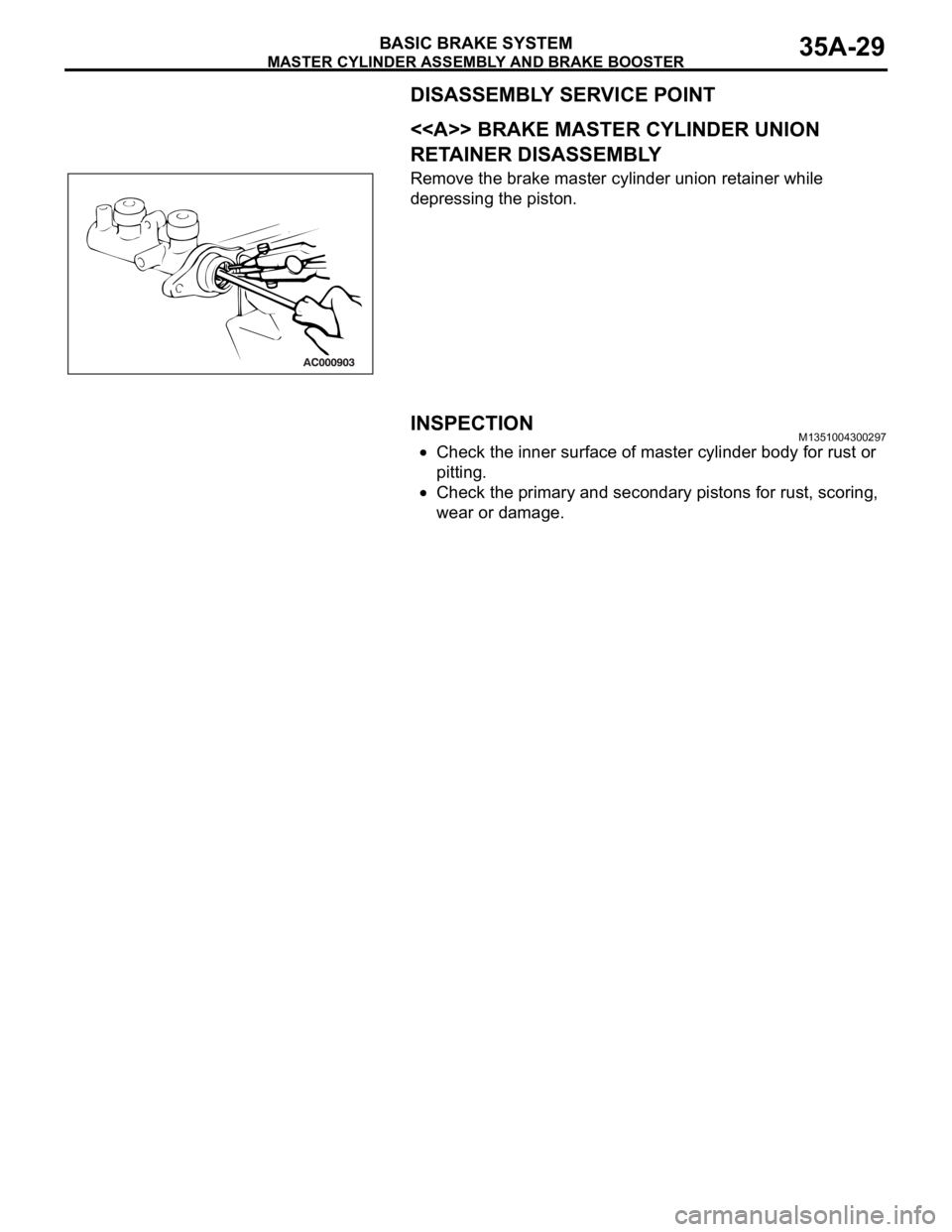

Page 1194 of 1500

Page 1195 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-30

DISC BRAKE ASSEMBLY

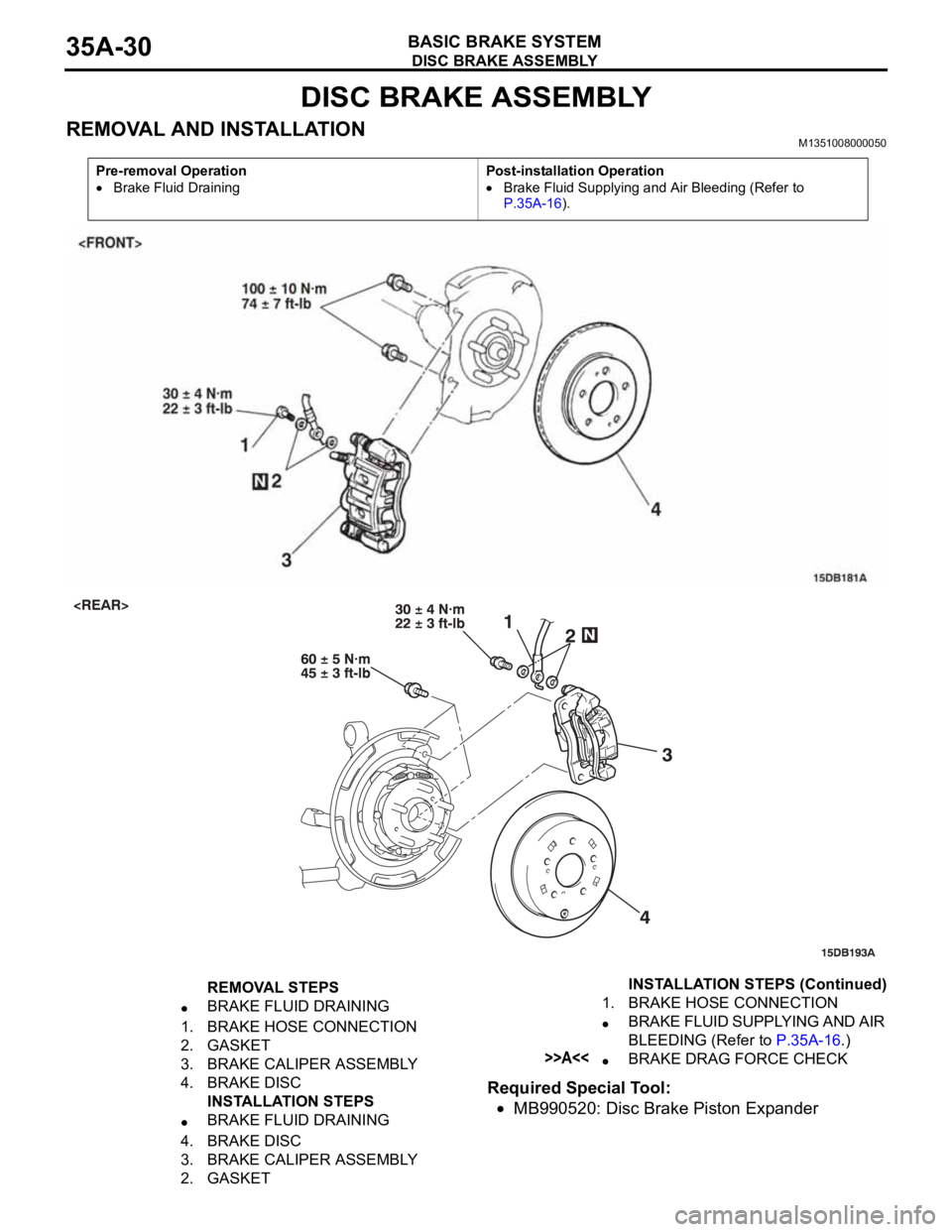

REMOVAL AND INSTALLATIONM1351008000050

Required Special Tool:

MB990520: Disc Brake Piston Expander

Pre-removal Operation

Brake Fluid DrainingPost-installation OperationBrake Fluid Supplying and Air Bleeding (Refer to

P.35A-16).

REMOVAL STEPS

BRAKE FLUID DRAINING

1. BRAKE HOSE CONNECTION

2. GASKET

3. BRAKE CALIPER ASSEMBLY

4. BRAKE DISC

INSTALLATION STEPS

BRAKE FLUID DRAINING

4. BRAKE DISC

3. BRAKE CALIPER ASSEMBLY

2. GASKET1. BRAKE HOSE CONNECTION

BRAKE FLUID SUPPLYING AND AIR

BLEEDING (Refer to P.35A-16.)

>>A<

Page 1196 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-31

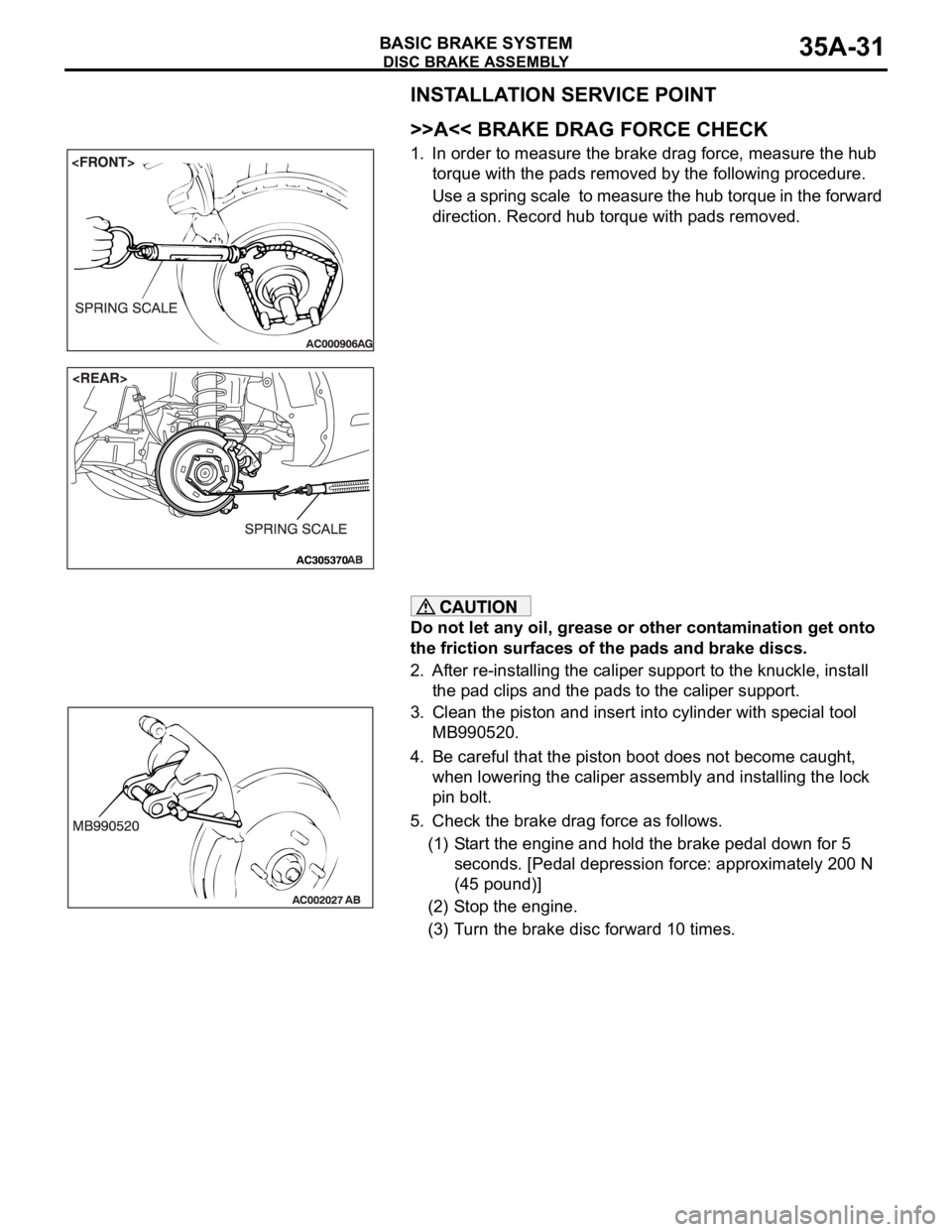

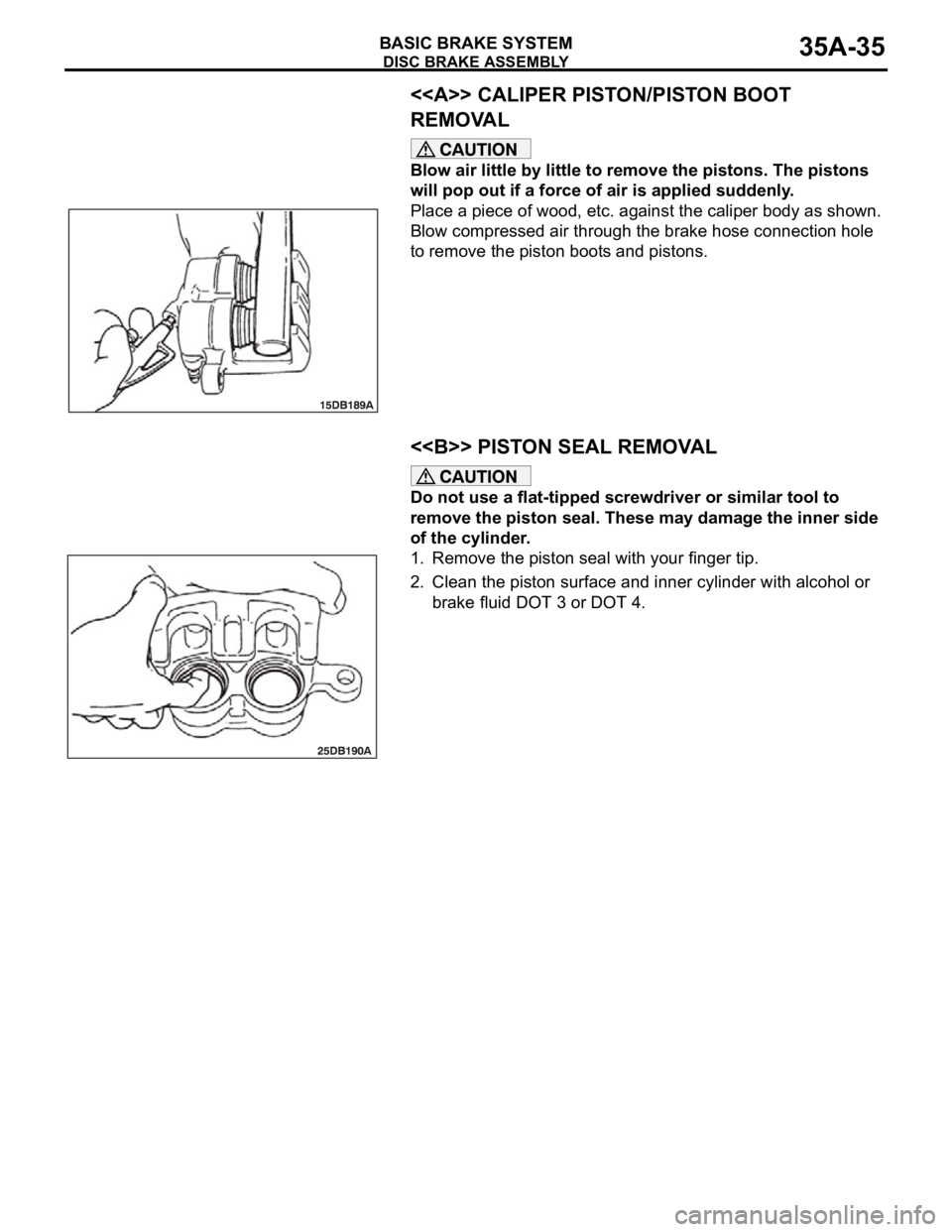

INSTALLATION SERVICE POINT

.

>>A<< BRAKE DRAG FORCE CHECK

1. In order to measure the brake drag force, measure the hub

torque with the pads removed by the following procedure.

Use a spring scale to measure the hub torque in the forward

direction. Record hub torque with pads removed.

Do not let any oil, grease or other contamination get onto

the friction surfaces of the pads and brake discs.

2. After re-installing the caliper support to the knuckle, install

the pad clips and the pads to the caliper support.

3. Clean the piston and insert into cylinder with special tool

MB990520.

4. Be careful that the piston boot does not become caught,

when lowering the caliper assembly and installing the lock

pin bolt.

5. Check the brake drag force as follows.

(1) Start the engine and hold the brake pedal down for 5

seconds. [Pedal depression force: approximately 200 N

(45 pound)]

(2) Stop the engine.

(3) Turn the brake disc forward 10 times.

Page 1197 of 1500

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-32

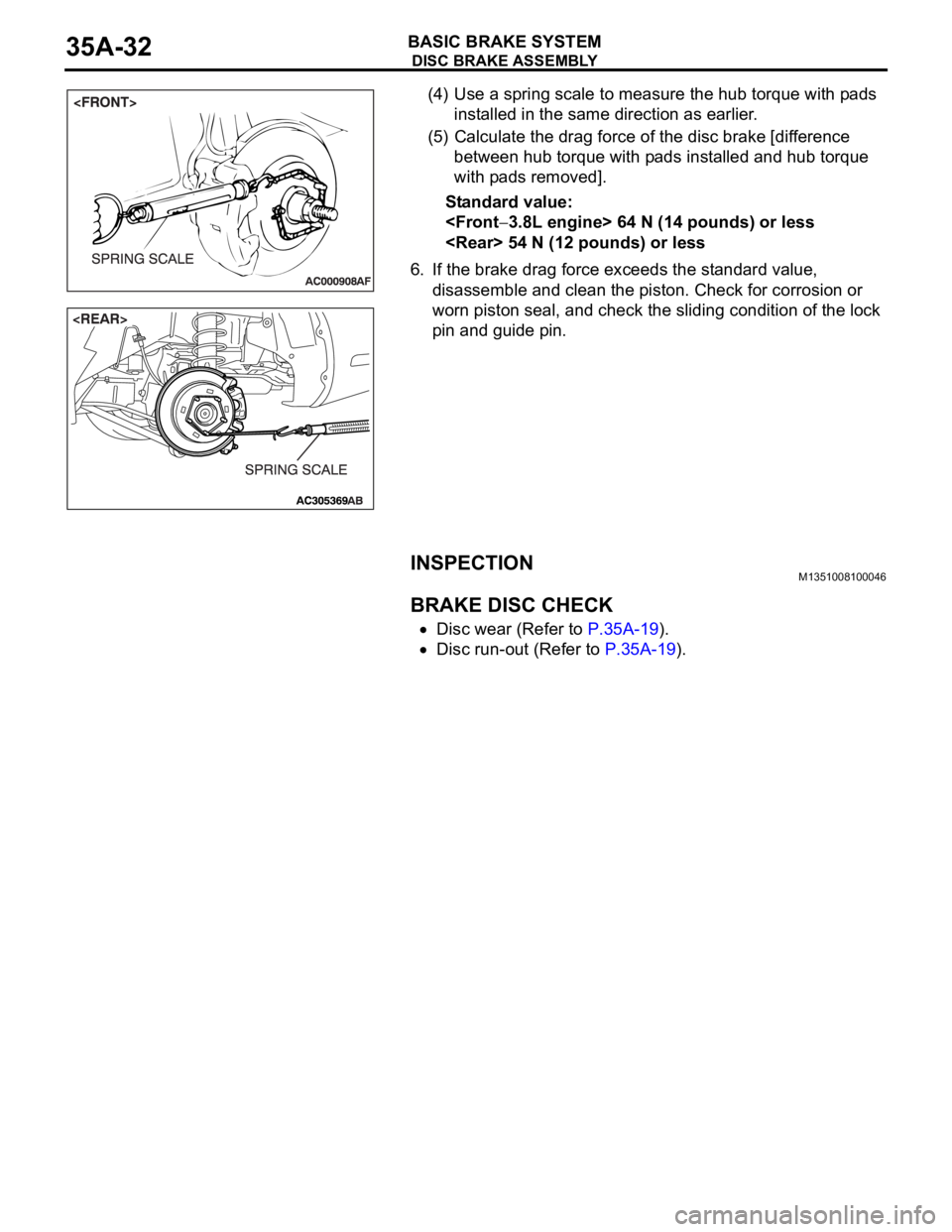

(4) Use a spring scale to measure the hub torque with pads

installed in the same direction as earlier.

(5) Calculate the drag force of the disc brake [difference

between hub torque with pads installed and hub torque

with pads removed].

Standard value:

3.8L engine> 64 N (14 pounds) or less

54 N (12 pounds) or less

6. If the brake drag force exceeds the standard value,

disassemble and clean the piston. Check for corrosion or

worn piston seal, and check the sliding condition of the lock

pin and guide pin.

INSPECTIONM1351008100046.

BRAKE DISC CHECK

Disc wear (Refer to P.35A-19).

Disc run-out (Refer to P.35A-19).

Page 1198 of 1500

Page 1199 of 1500

DISC BRAKE ASSEMBLY

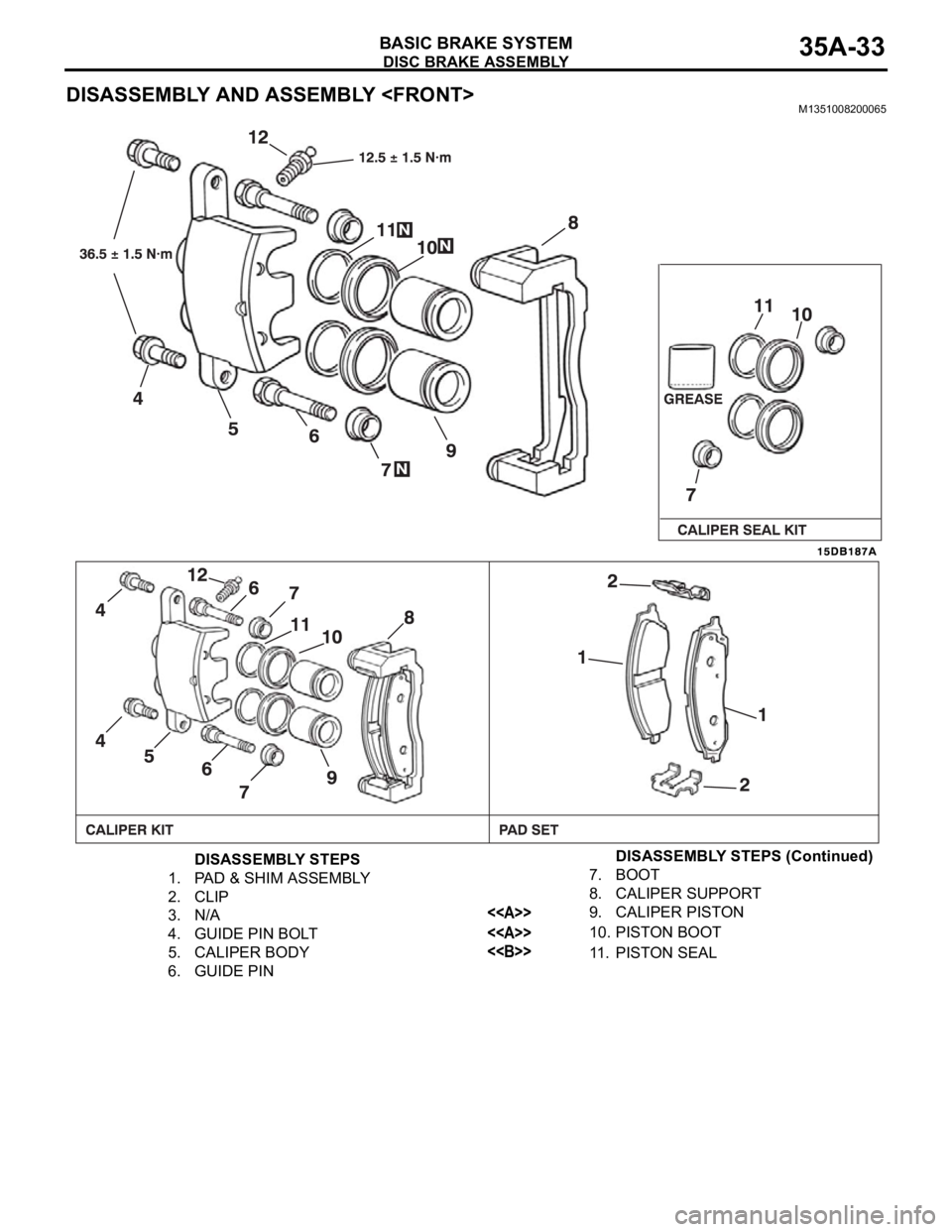

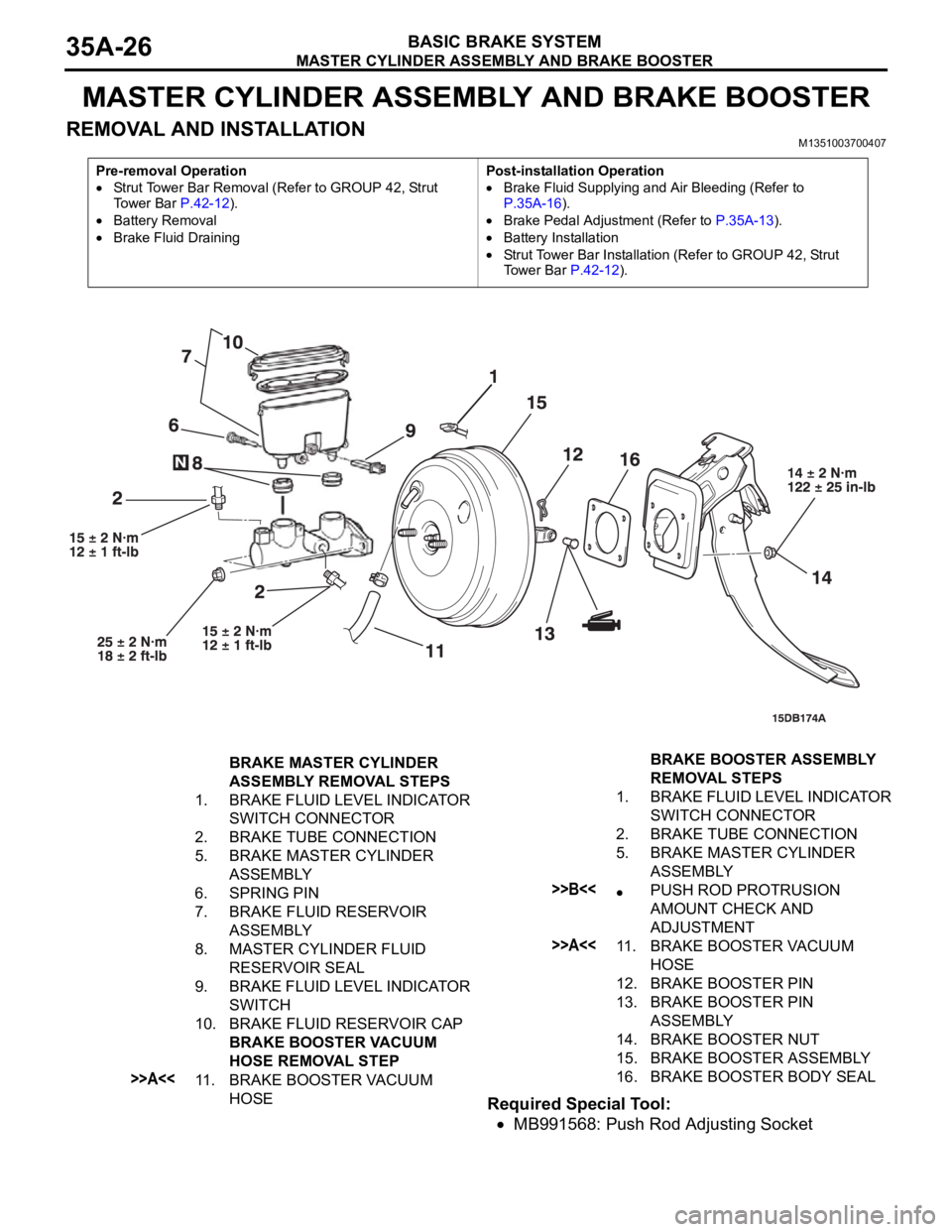

BASIC BRAKE SYSTEM35A-34

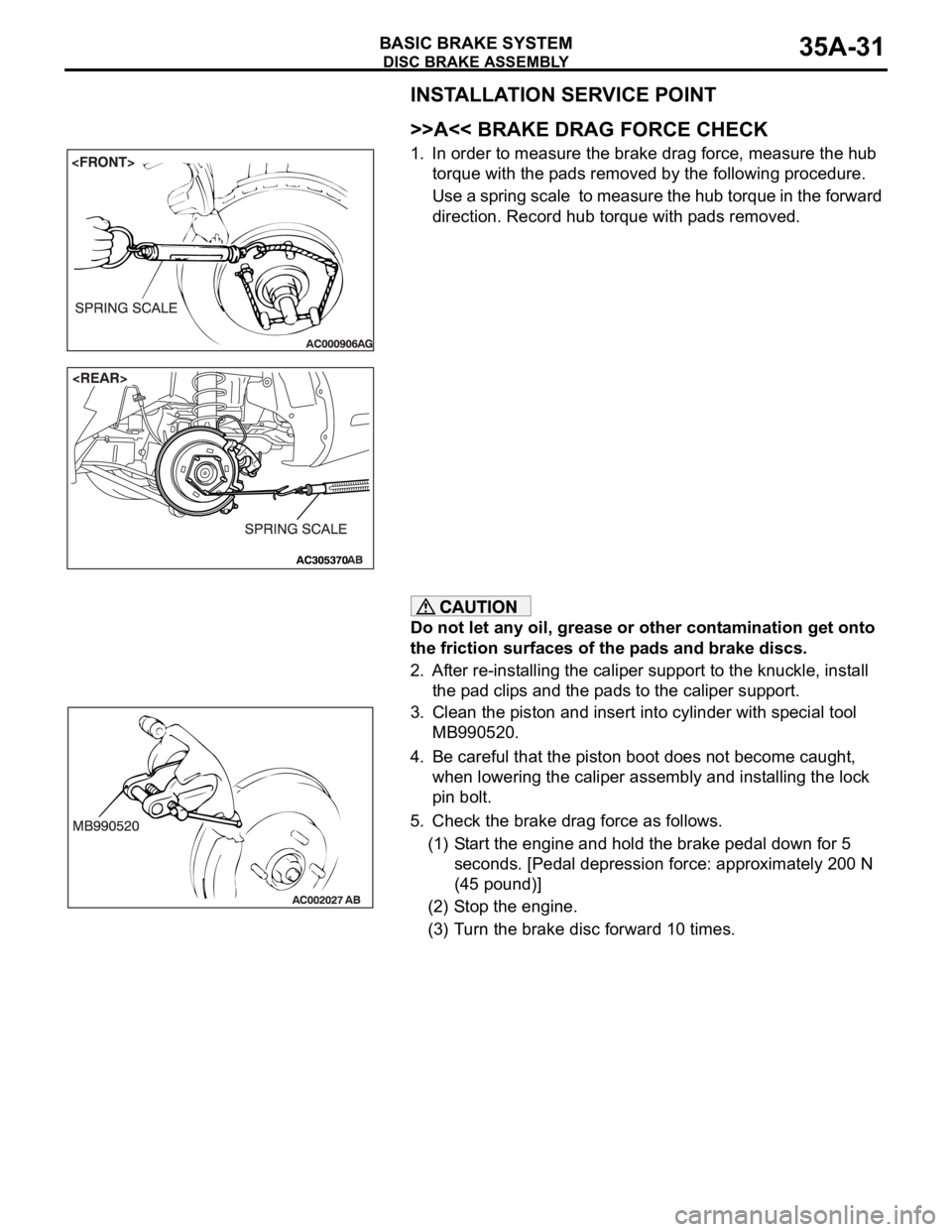

LUBRICATION POINTS

DISASSEMBLY SERVICE POINTS

When disassembling the front disc brakes, disassemble

both sides (left and right wheels) as a set.

.

Page 1200 of 1500

Trending: transmission fluid, run flat, brake rotor, jack points, change wheel, open hood, trunk