engine MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 990 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

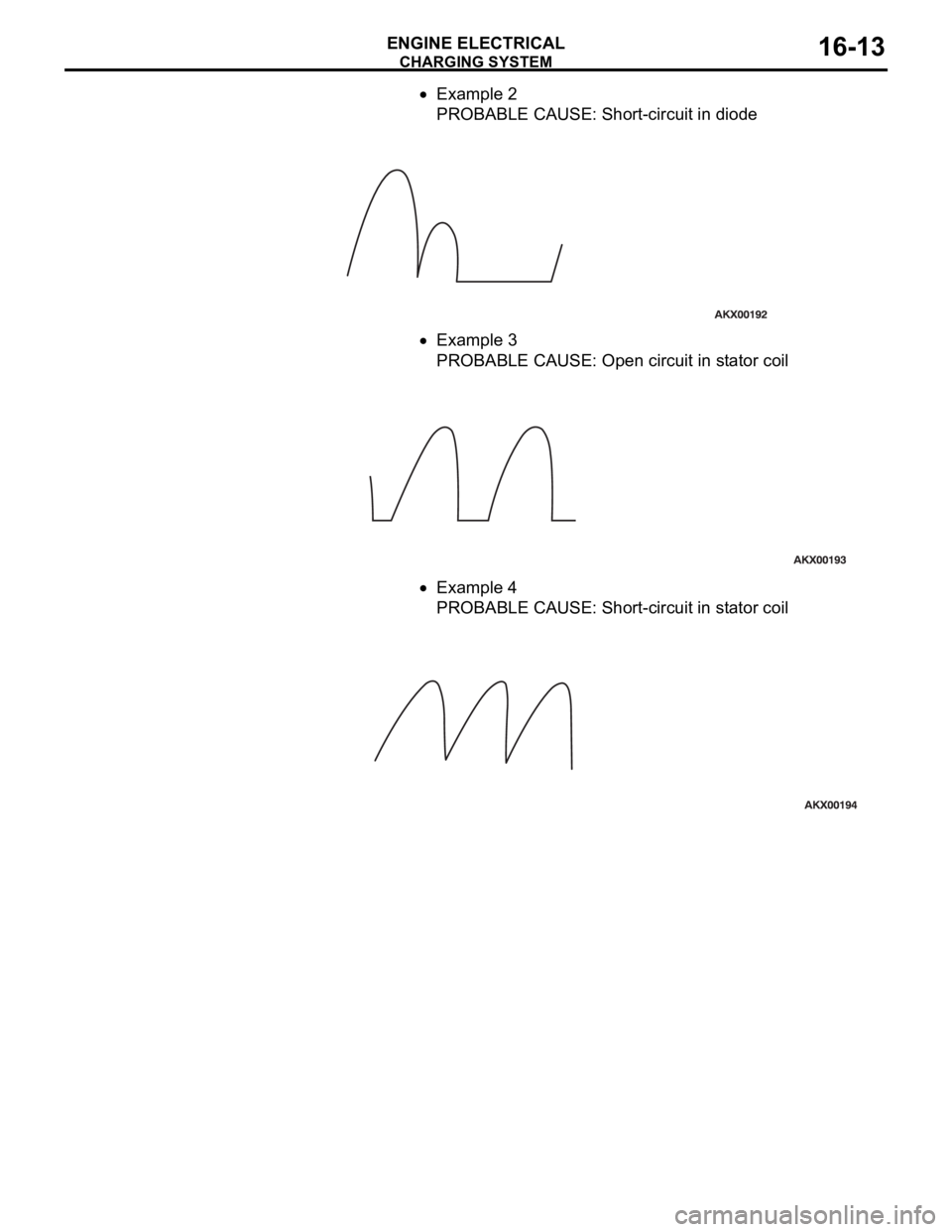

Example 2

PROBABLE CAUSE: Short-circuit in diode

Example 3

PROBABLE CAUSE: Open circuit in stator coil

Example 4

PROBABLE CAUSE: Short-circuit in stator coil

Page 991 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-14

ALTERNATOR ASSEMBLY

REMOVAL AND INSTALLATION M1161001400601

REMOVAL SERVICE POINT

.

<> A/C COMPRESSOR ASSEMBLY REMOVAL

Remove the compressor from the compressor bracket with the

hose still attached.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Side Under Cover Removal and Installation (Refer to

GROUP 51, Under Cover P.51-13).

REMOVAL STEPS

1.

ALTERNATOR DRIVE BELT

2.

ALTERNATOR CONNECTOR3. A/C COMPRESSOR ASSEMBLY

CONNECTOR

<>4. A/C COMPRESSOR ASSEMBLY

<>5.

ALTERNATOR ASSEMBLY REMOVAL STEPS (Continued)

Page 992 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-15

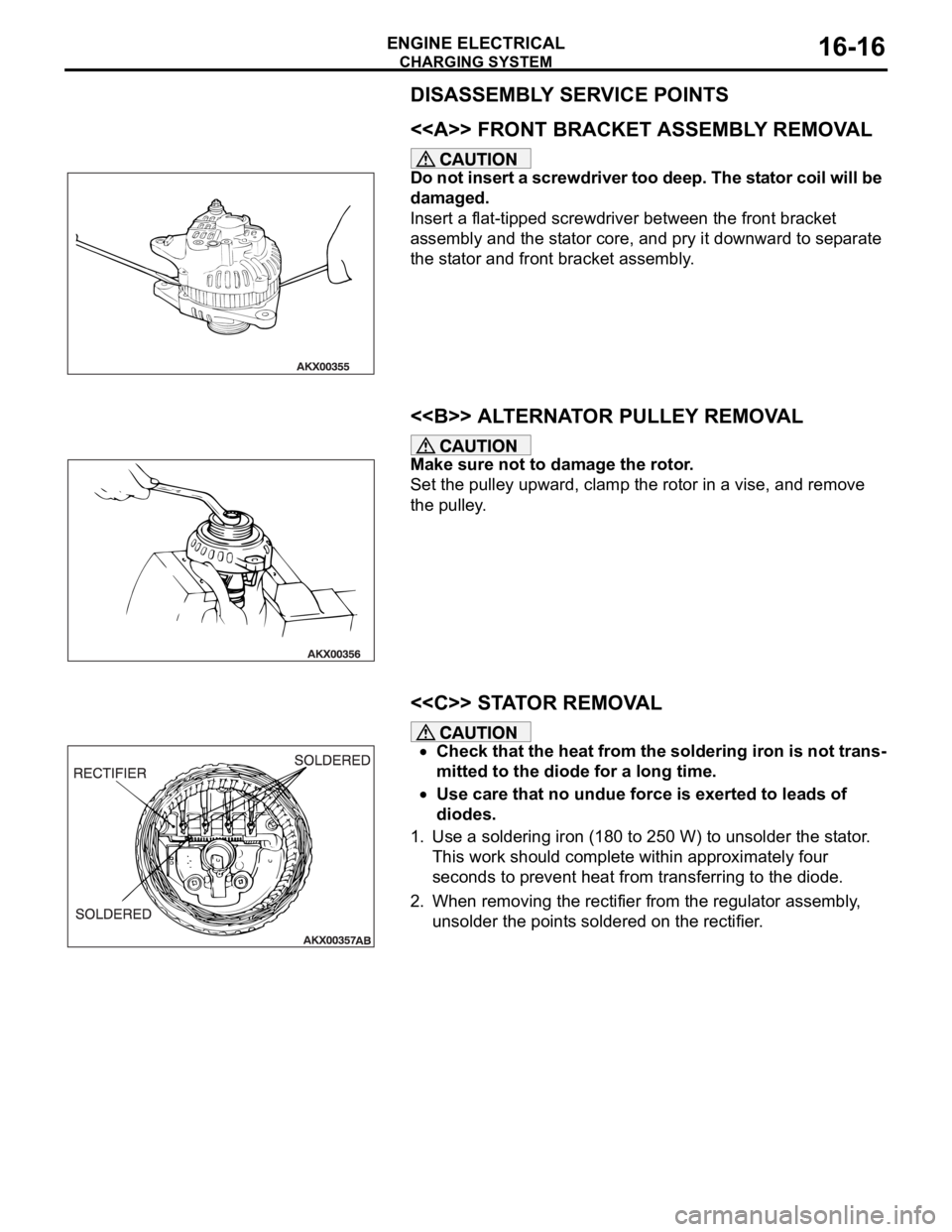

NOTE: Place the removed A/C compressor where it will not be

a hindrance when removing and installing the alternator, and

secure it with a cord or wire.

.

<> ALTERNATOR ASSEMBLY REMOVAL

Move the A/C compressor assembly to one side, and then

remove the alternator assembly from under the vehicle.

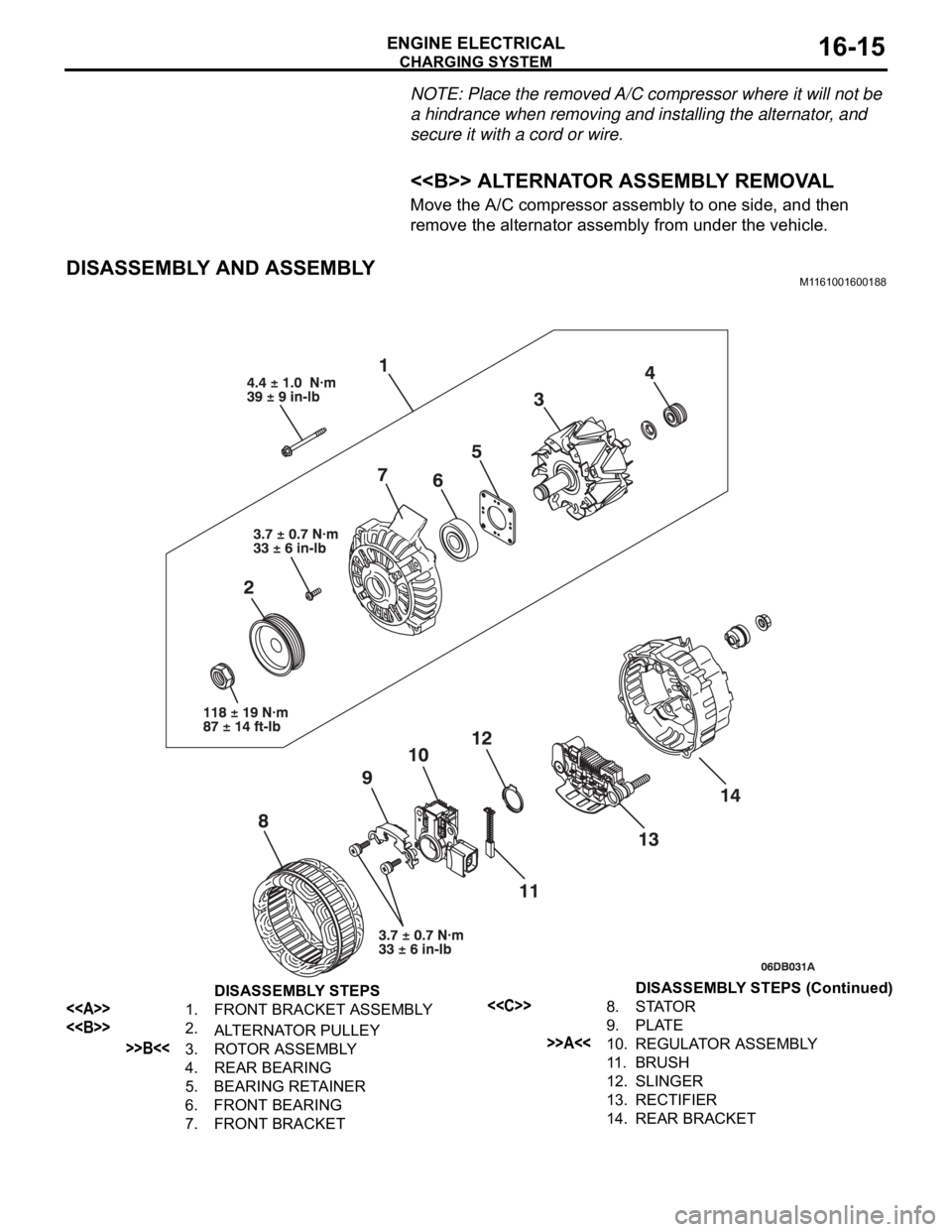

DISASSEMBLY AND ASSEMBLYM1161001600188

DISASSEMBLY STEPS

<>1. FRONT BRACKET ASSEMBLY

<>2.

ALTERNATOR PULLEY

>>B<<3. ROTOR ASSEMBLY

4. REAR BEARING

5. BEARING RETAINER

6. FRONT BEARING

7. FRONT BRACKET

<

9. PLATE

>>A<<10. REGULATOR ASSEMBLY

11. BRUSH

12. SLINGER

13. RECTIFIER

14. REAR BRACKETDISASSEMBLY STEPS (Continued)

Page 993 of 1500

Page 994 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-17

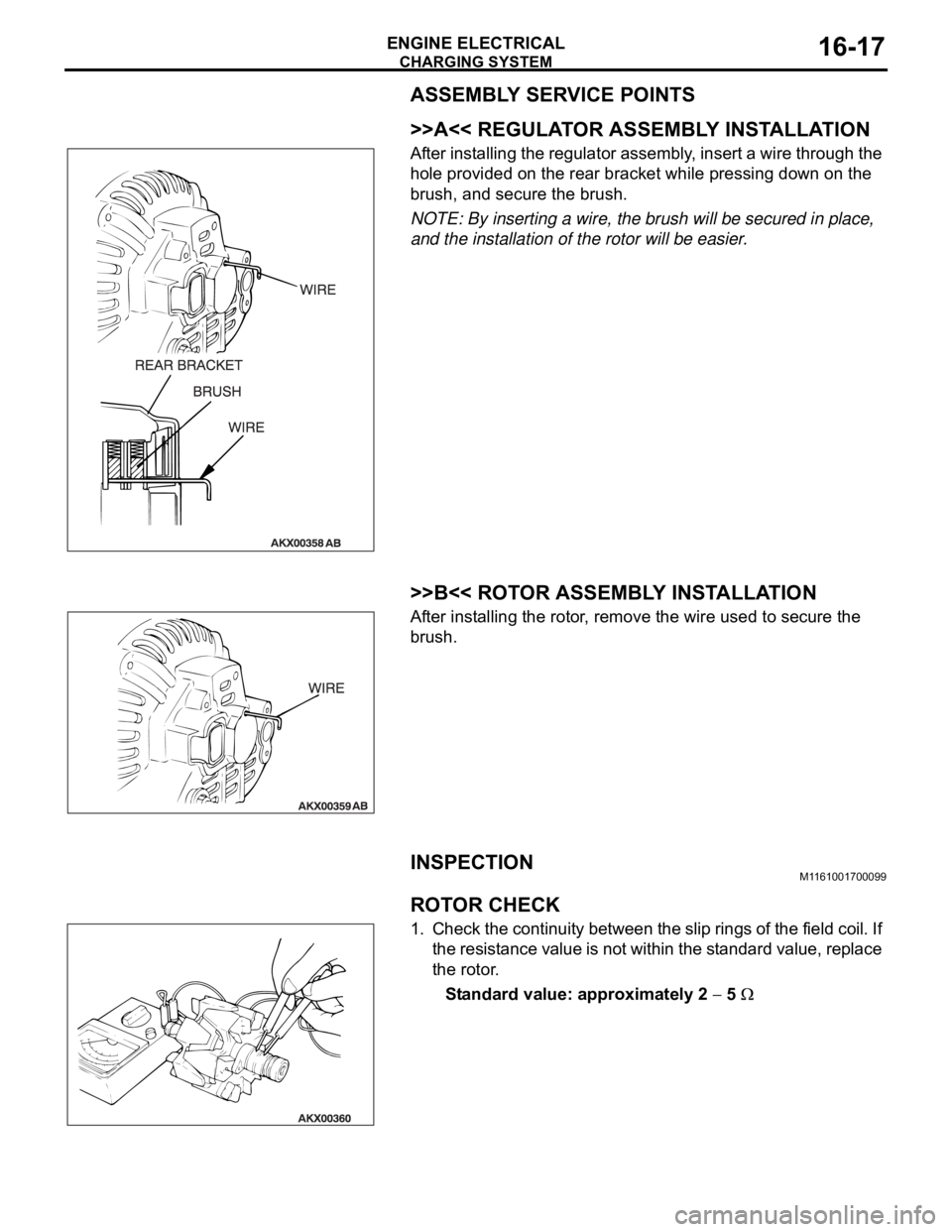

ASSEMBLY SERVICE POINTS

.

>>A<< REGULATOR ASSEMBLY INSTALLATION

After installing the regulator assembly, insert a wire through the

hole provided on the rear bracket while pressing down on the

brush, and secure the brush.

NOTE: By inserting a wire, the brush will be secured in place,

and the installation of the rotor will be easier.

.

>>B<< ROTOR ASSEMBLY INSTALLATION

After installing the rotor, remove the wire used to secure the

brush.

INSPECTIONM1161001700099.

ROTOR CHECK

1. Check the continuity between the slip rings of the field coil. If

the resistance value is not within the standard value, replace

the rotor.

Standard value: approximately 2

5

Page 995 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

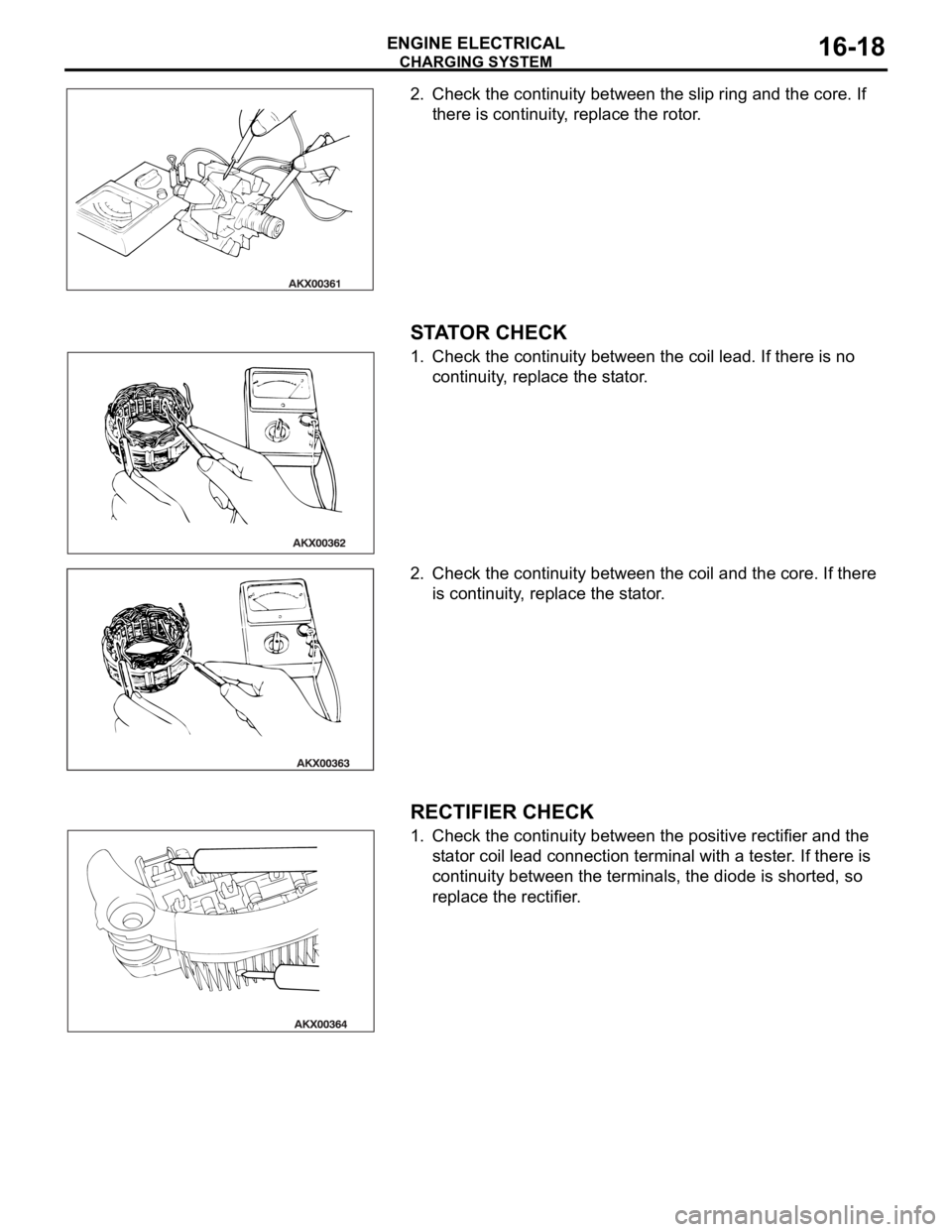

2. Check the continuity between the slip ring and the core. If

there is continuity, replace the rotor.

.

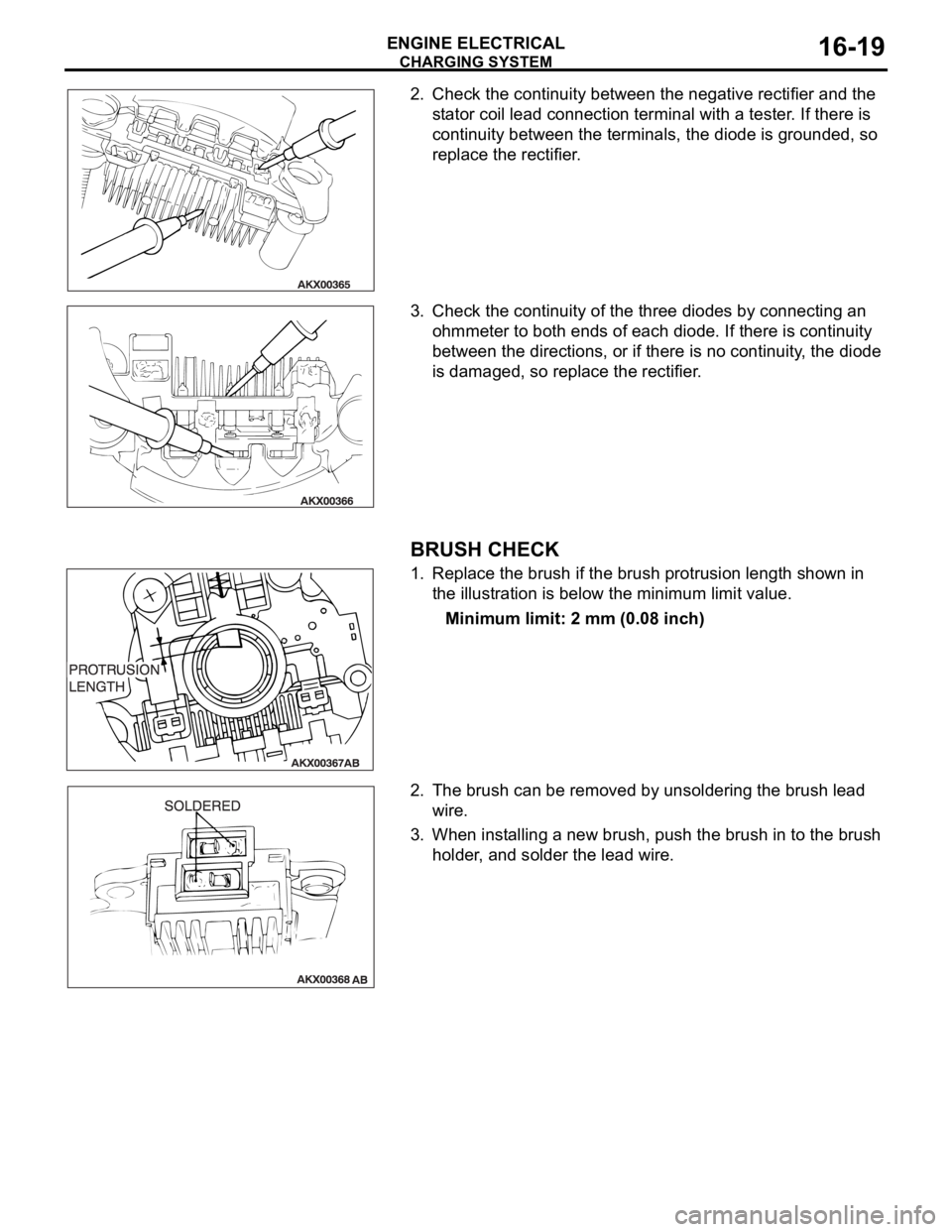

STATOR CHECK

1. Check the continuity between the coil lead. If there is no

continuity, replace the stator.

2. Check the continuity between the coil and the core. If there

is continuity, replace the stator.

.

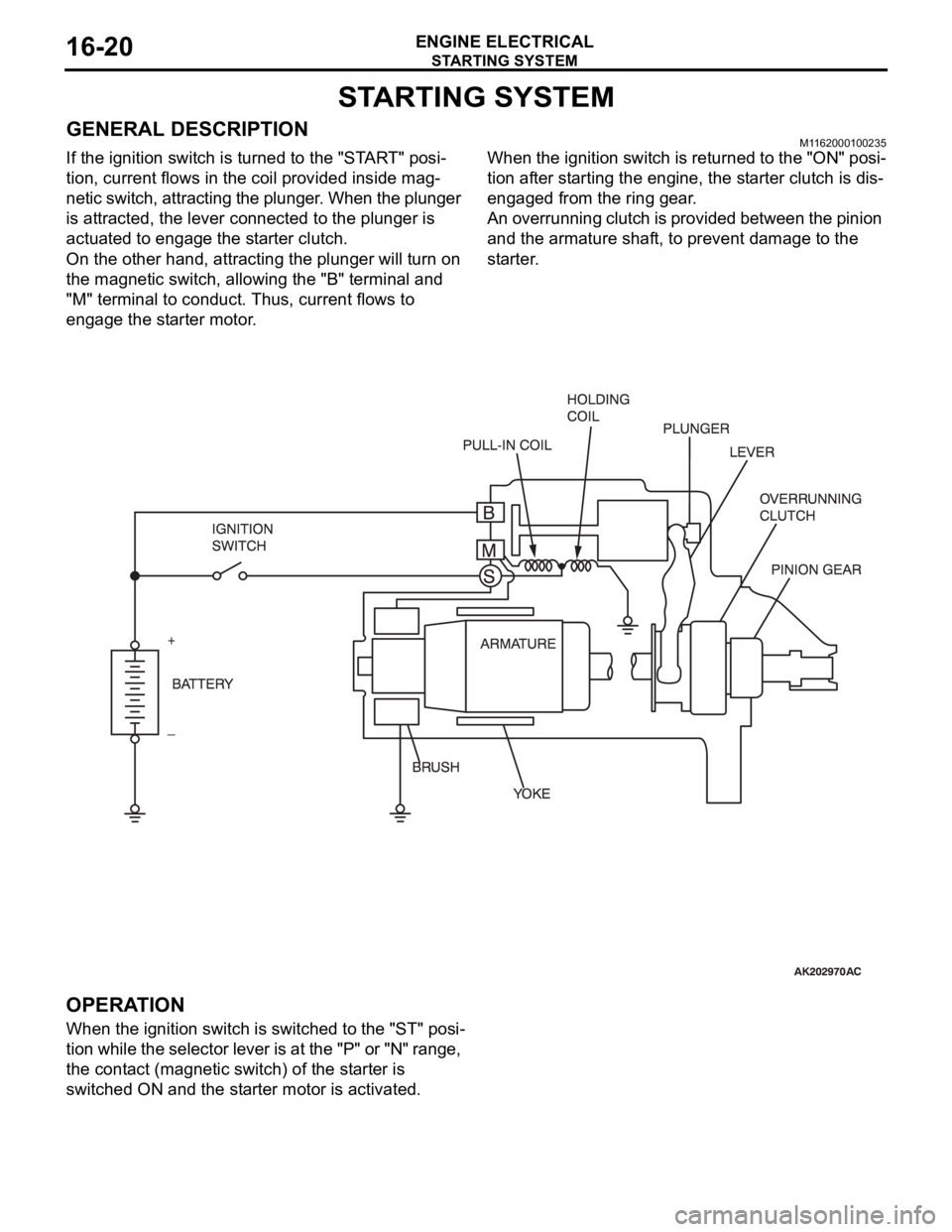

RECTIFIER CHECK

1. Check the continuity between the positive rectifier and the

stator coil lead connection terminal with a tester. If there is

continuity between the terminals, the diode is shorted, so

replace the rectifier.

Page 996 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-19

2. Check the continuity between the negative rectifier and the

stator coil lead connection terminal with a tester. If there is

continuity between the terminals, the diode is grounded, so

replace the rectifier.

3. Check the continuity of the three diodes by connecting an

ohmmeter to both ends of each diode. If there is continuity

between the directions, or if there is no continuity, the diode

is damaged, so replace the rectifier.

.

BRUSH CHECK

1. Replace the brush if the brush protrusion length shown in

the illustration is below the minimum limit value.

Minimum limit: 2 mm (0.08 inch)

2. The brush can be removed by unsoldering the brush lead

wire.

3. When installing a new brush, push the brush in to the brush

holder, and solder the lead wire.

Page 997 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-20

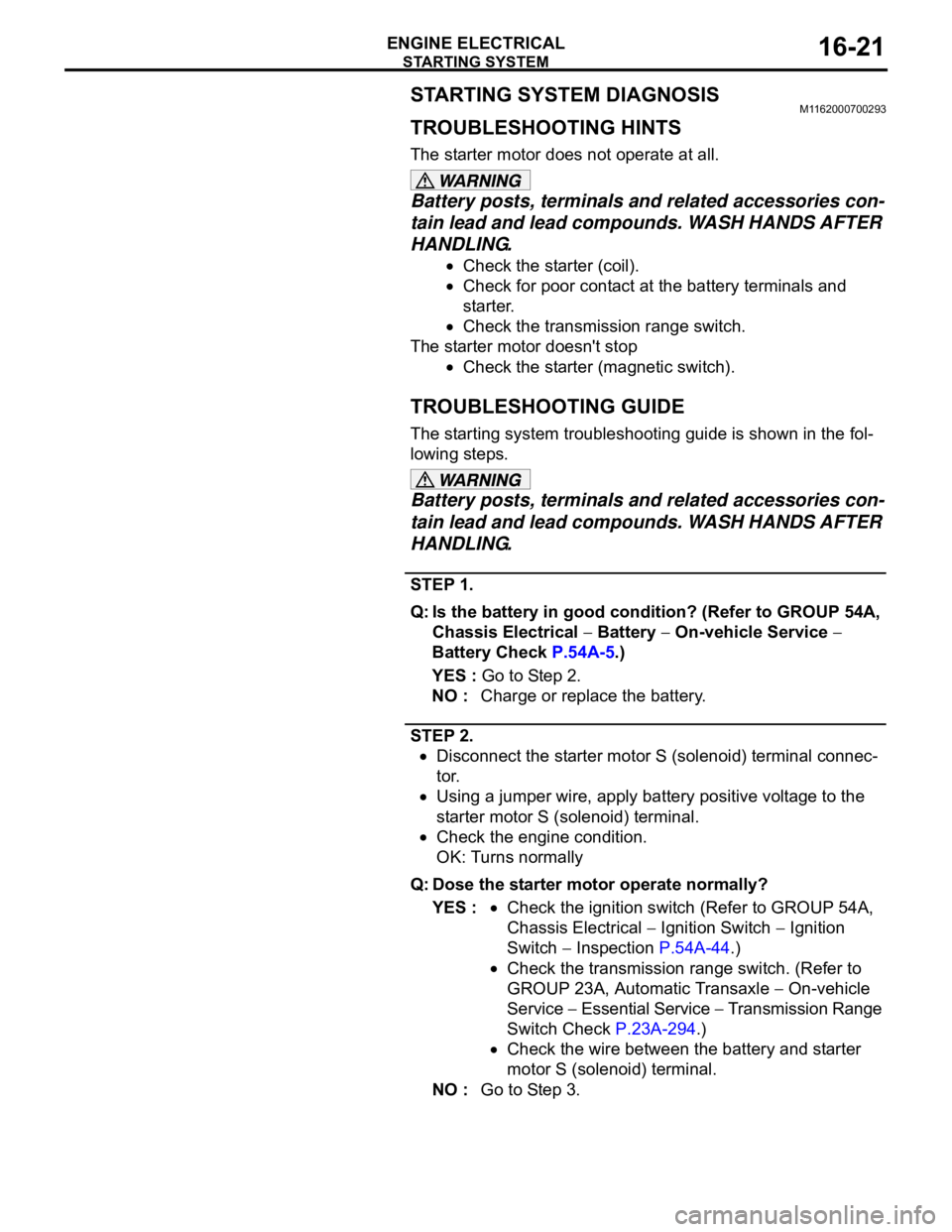

STARTING SYSTEM

GENERAL DESCRIPTIONM1162000100235

If the ignition switch is turned to the "START" posi-

tion, current flows in the coil provided inside mag-

netic switch, attracting the plunger. When the plunger

is attracted, the lever connected to the plunger is

actuated to engage the starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.When the ignition switch is returned to the "ON" posi-

tion after starting the engine, the starter clutch is dis-

engaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

OPERATION

When the ignition switch is switched to the "ST" posi-

tion while the selector lever is at the "P" or "N" range,

the contact (magnetic switch) of the starter is

switched ON and the starter motor is activated.

Page 998 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-21

STARTING SYSTEM DIAGNOSISM1162000700293

TROUBLESHOOTING HINTS

The starter motor does not operate at all.

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

Check the starter (coil).

Check for poor contact at the battery terminals and

starter.

Check the transmission range switch.

The starter motor doesn't stop

Check the starter (magnetic switch).

TROUBLESHOOTING GUIDE

The starting system troubleshooting guide is shown in the fol-

lowing steps.

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

STEP 1.

Q: Is the battery in good condition? (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

YES : Go to Step 2.

NO : Charge or replace the battery.

STEP 2.

Disconnect the starter motor S (solenoid) terminal connec-

tor.

Using a jumper wire, apply battery positive voltage to the

starter motor S (solenoid) terminal.

Check the engine condition.

OK: Turns normally

Q: Dose the starter motor operate normally?

YES :

Check the ignition switch (Refer to GROUP 54A,

Chassis Electrical

Ignition Switch Ignition

Switch

Inspection P.54A-44.)

Check the transmission range switch. (Refer to

GROUP 23A, Automatic Transaxle

On-vehicle

Service

Essential Service Transmission Range

Switch Check P.23A-294.)

Check the wire between the battery and starter

motor S (solenoid) terminal.

NO : Go to Step 3.

Page 999 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-22

STEP 3.

Check the cable between starter B (battery) terminal and

battery positive terminal for connection and continuity.

Q: Is the starter cable in good condition?

YES : Go to Step 4.

NO : Repair or replace the cable.

STEP 4.

Check the connection and the continuity of the cable

between the starter motor body and the negative battery

terminal.

Q: Is the ground wire in good condition?

YES : Go to Step 5.

NO : Repair or replace the cable.

STEP 5.

Q: Is the starter motor in good condition? (Refer to Starting

System

Starter Motor Assembly Inspection P.16-17.)

YES : Excessive rotational resistance of the engine.

NO : Replace the starter motor.