MITSUBISHI 380 2005 Workshop Manual

380 2005

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57086/w960_57086-0.png

MITSUBISHI 380 2005 Workshop Manual

Trending: MPG, park lamp, service indicator, driver seat adjustment, set clock, warning light, Tail light

Page 1321 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-42

Connect oscilloscope to FL sensor signal terminal (16)

at ABS-ECU (A-02)

Connect oscilloscope to FR sensor signal terminal (9) at

ABS-ECU (A-02)

Connect oscilloscope to RL sensor signal terminal (6) at

ABS-ECU (A-02)

Connect oscilloscope to RR sensor signal terminal (8) at

ABS-ECU (A-02)

(6) Turn the ignition switch to the "ON" position.

Page 1322 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-43

(7) The recommended Supply Voltage at terminals 16, 9, 6,

and 8 are:

Set value: 10.0Volts - 14.5Volts

Q: Is the supply voltage within the set value?

YES : Check wheel speed sensor signal at ABS-ECU using

an oscillopscope

NO :

Refer to Power supply systemP.35B-63

Refer to Motor supply systemP.35B-48

Refer to Valve relay systemP.35B-56

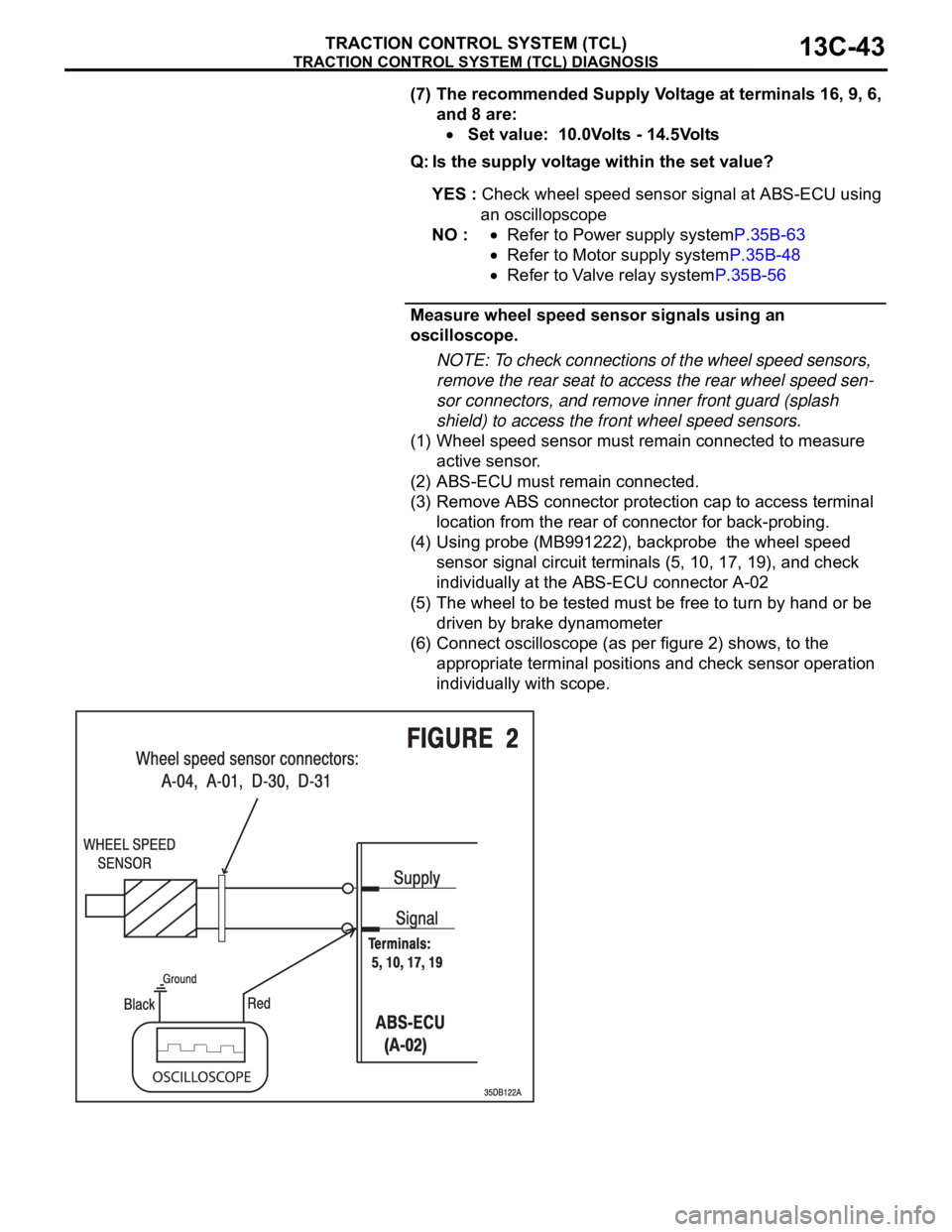

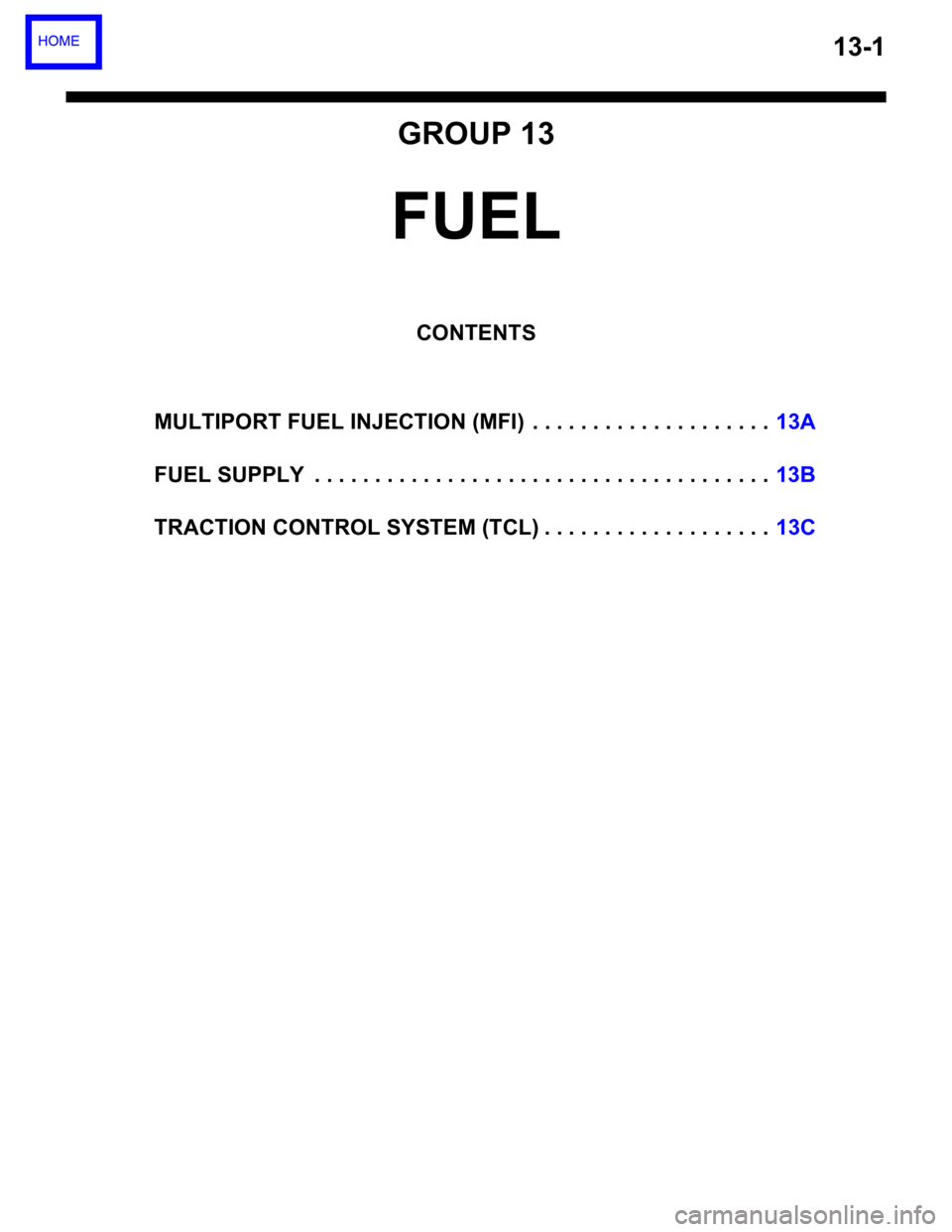

Measure wheel speed sensor signals using an

oscilloscope.

NOTE: To check connections of the wheel speed sensors,

remove the rear seat to access the rear wheel speed sen-

sor connectors, and remove inner front guard (splash

shield) to access the front wheel speed sensors.

(1) Wheel speed sensor must remain connected to measure

active sensor.

(2) ABS-ECU must remain connected.

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222), backprobe the wheel speed

sensor signal circuit terminals (5, 10, 17, 19), and check

individually at the ABS-ECU connector A-02

(5) The wheel to be tested must be free to turn by hand or be

driven by brake dynamometer

(6) Connect oscilloscope (as per figure 2) shows, to the

appropriate terminal positions and check sensor operation

individually with scope.

Page 1323 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-44

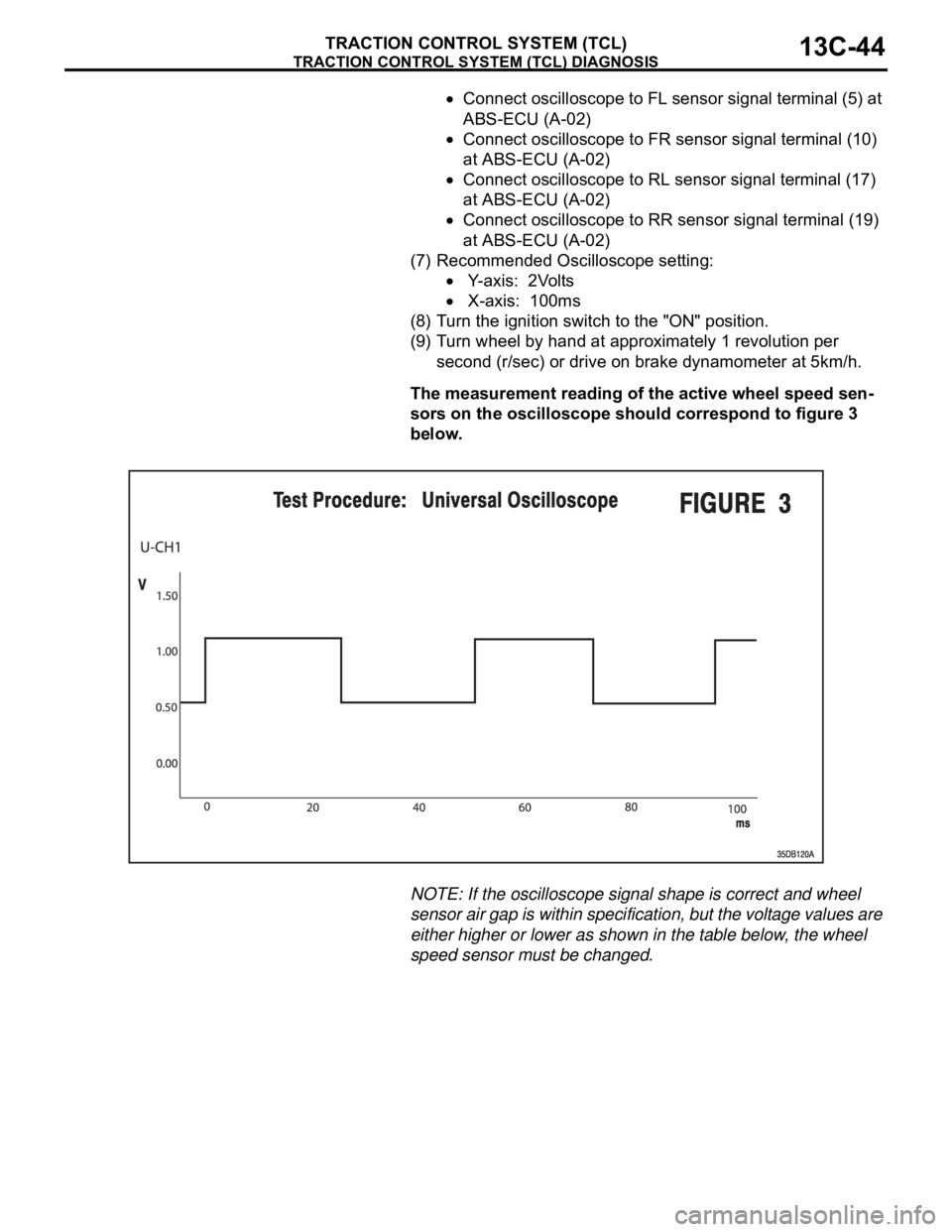

Connect oscilloscope to FL sensor signal terminal (5) at

ABS-ECU (A-02)

Connect oscilloscope to FR sensor signal terminal (10)

at ABS-ECU (A-02)

Connect oscilloscope to RL sensor signal terminal (17)

at ABS-ECU (A-02)

Connect oscilloscope to RR sensor signal terminal (19)

at ABS-ECU (A-02)

(7) Recommended Oscilloscope setting:

Y-axis: 2Volts

X-axis: 100ms

(8) Turn the ignition switch to the "ON" position.

(9) Turn wheel by hand at approximately 1 revolution per

second (r/sec) or drive on brake dynamometer at 5km/h.

The measurement reading of the active wheel speed sen-

sors on the oscilloscope should correspond to figure 3

below.

NOTE: If the oscilloscope signal shape is correct and wheel

sensor air gap is within specification, but the voltage values are

either higher or lower as shown in the table below, the wheel

speed sensor must be changed.

Page 1324 of 1500

SPECIAL TOOLS

TRACTION CONTROL SYSTEM (TCL)13C-45

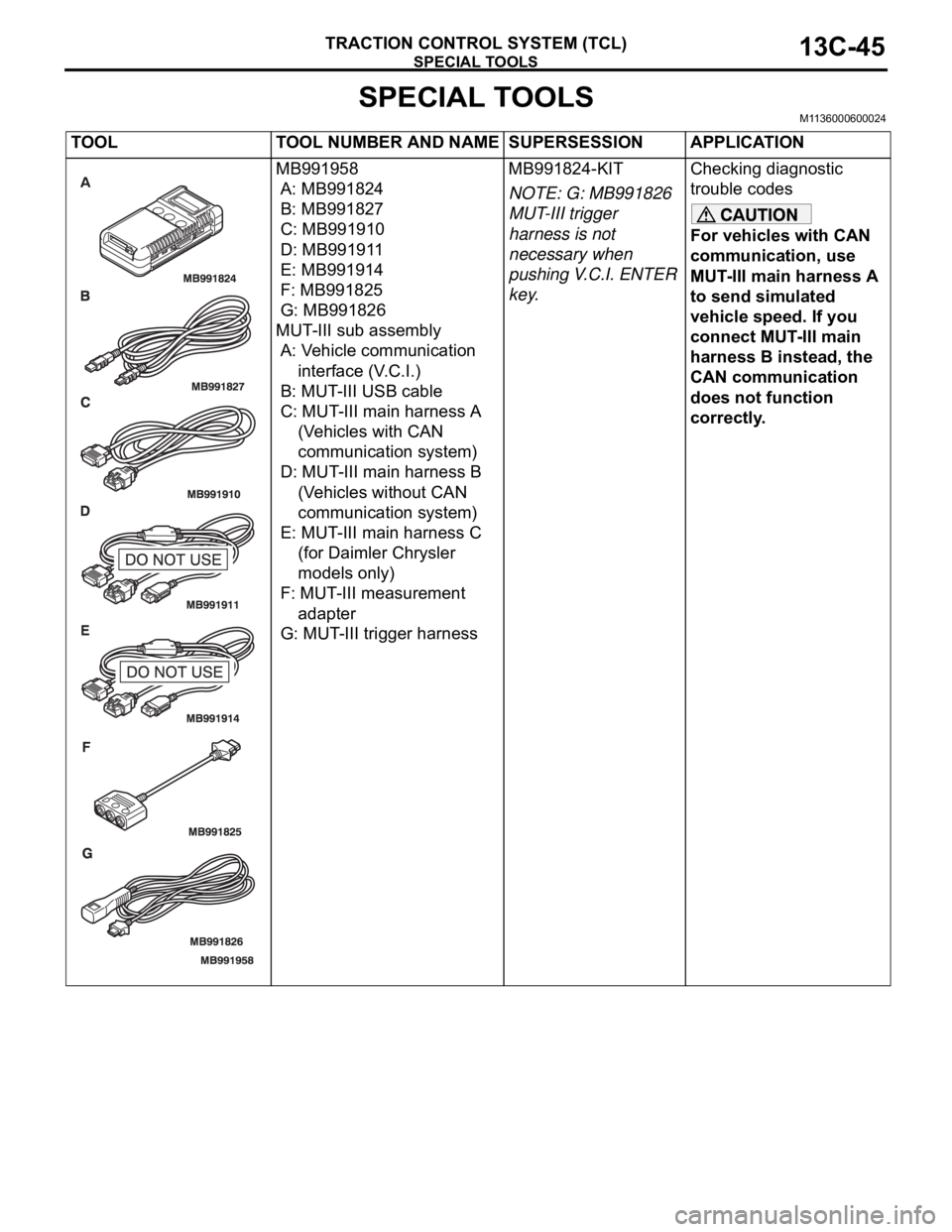

SPECIAL TOOLSM1136000600024

TOOL TOOL NUMBER AND NAME SUPERSESSION APPLICATION

MB991958

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III sub assembly

A: Vehicle communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness A

(Vehicles with CAN

communication system)

D: MUT-III main harness B

(Vehicles without CAN

communication system)

E: MUT-III main harness C

(for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger harnessMB991824-KIT

NOTE: G: MB991826

MUT-III trigger

harness is not

necessary when

pushing V.C.I. ENTER

key.Checking diagnostic

trouble codes

For vehicles with CAN

communication, use

MUT-III main harness A

to send simulated

vehicle speed. If you

connect MUT-III main

harness B instead, the

CAN communication

does not function

correctly.

Page 1325 of 1500

SPECIAL TOOLS

TRACTION CONTROL SYSTEM (TCL)13C-46

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222

Harness set

A: Inspection harness

B: LED harness

C: LED harness adapter

D: ProbeGeneral service tools Checking the continuity

and measuring the

voltage at the harness

connector TOOL TOOL NUMBER AND NAME SUPERSESSION APPLICATION

Page 1326 of 1500

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-47

ON-VEHICLE SERVICE

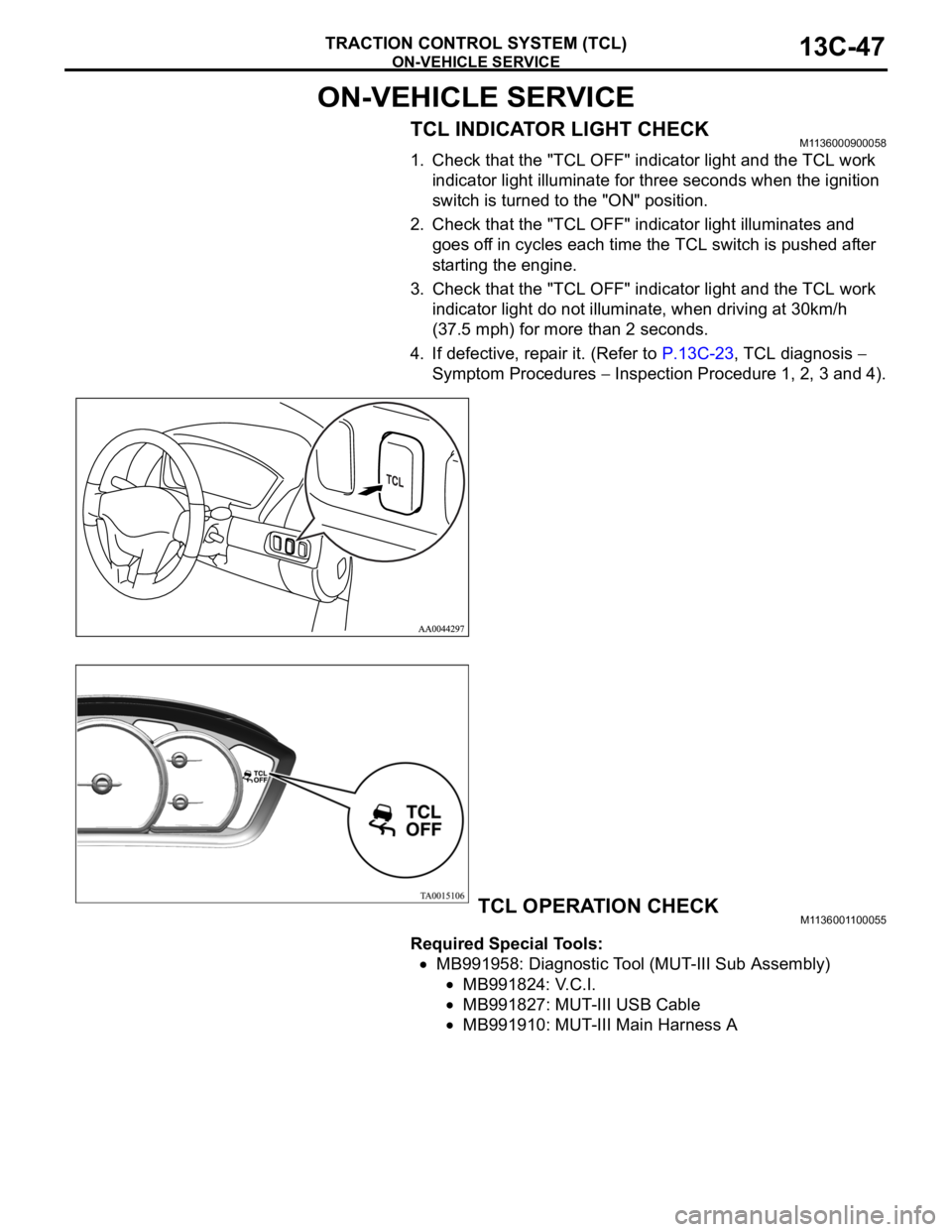

TCL INDICATOR LIGHT CHECKM1136000900058

1. Check that the "TCL OFF" indicator light and the TCL work

indicator light illuminate for three seconds when the ignition

switch is turned to the "ON" position.

2. Check that the "TCL OFF" indicator light illuminates and

goes off in cycles each time the TCL switch is pushed after

starting the engine.

3. Check that the "TCL OFF" indicator light and the TCL work

indicator light do not illuminate, when driving at 30km/h

(37.5 mph) for more than 2 seconds.

4. If defective, repair it. (Refer to P.13C-23, TCL diagnosis

Symptom Procedures

Inspection Procedure 1, 2, 3 and 4).

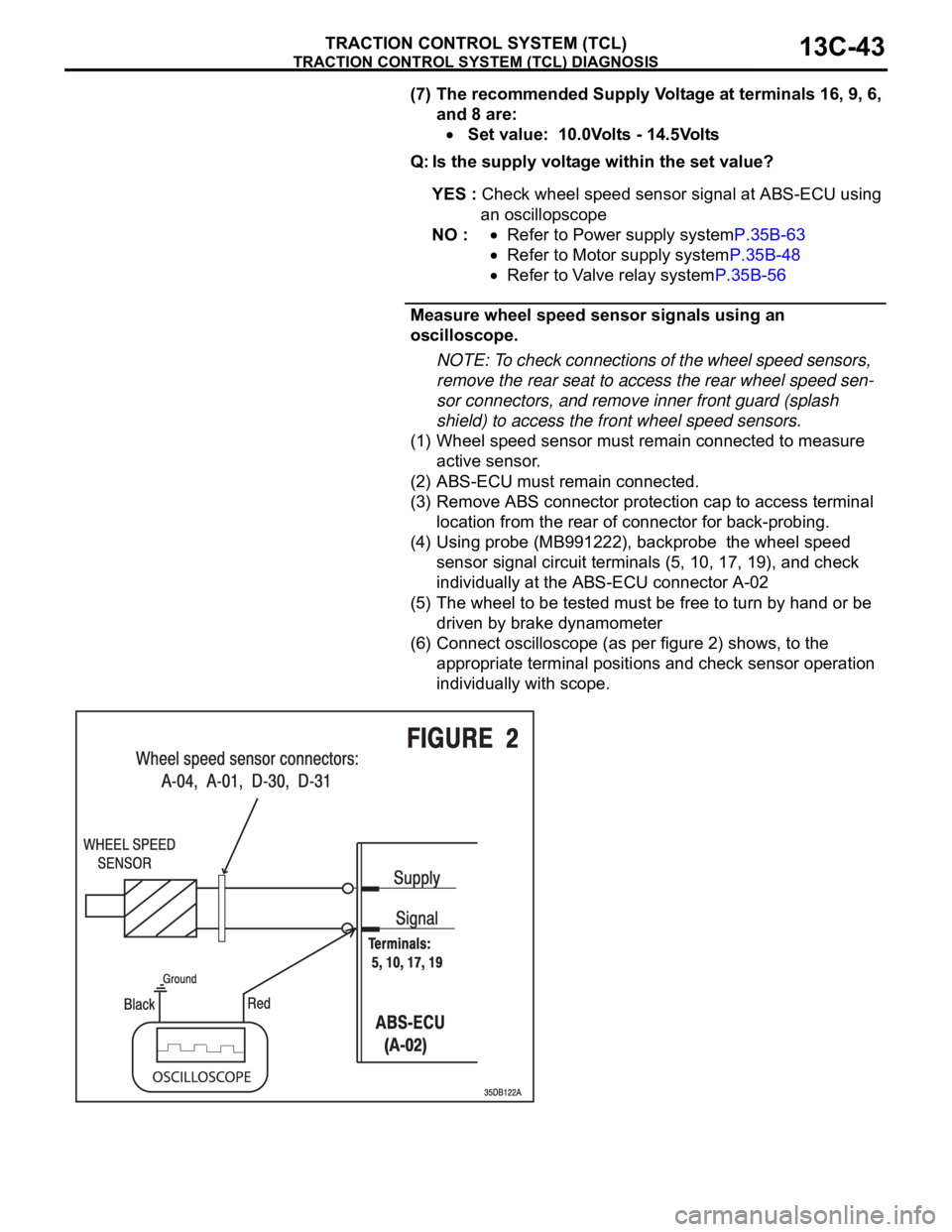

TCL OPERATION CHECKM1136001100055

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1327 of 1500

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-48

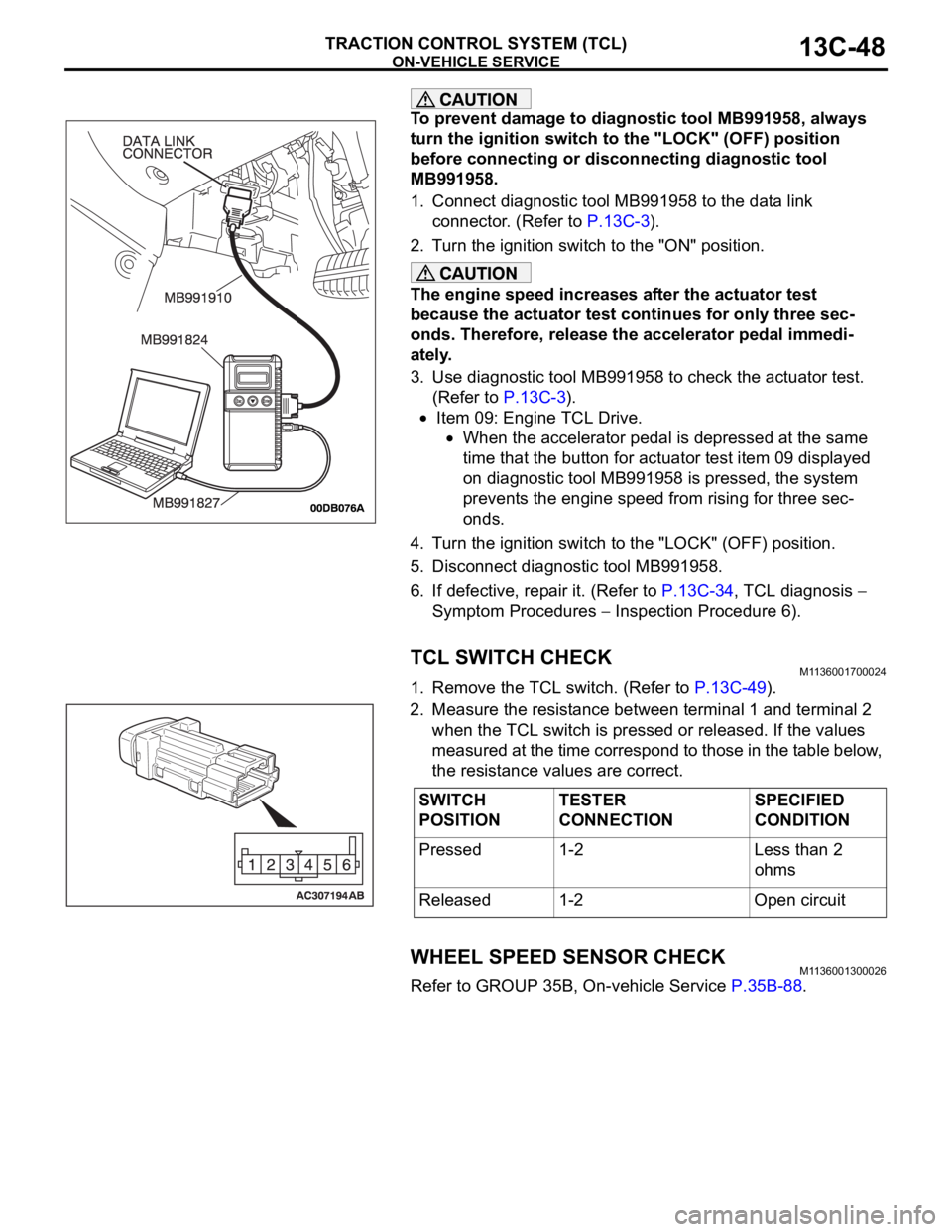

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

2. Turn the ignition switch to the "ON" position.

The engine speed increases after the actuator test

because the actuator test continues for only three sec-

onds. Therefore, release the accelerator pedal immedi-

ately.

3. Use diagnostic tool MB991958 to check the actuator test.

(Refer to P.13C-3).

Item 09: Engine TCL Drive.

When the accelerator pedal is depressed at the same

time that the button for actuator test item 09 displayed

on diagnostic tool MB991958 is pressed, the system

prevents the engine speed from rising for three sec-

onds.

4. Turn the ignition switch to the "LOCK" (OFF) position.

5. Disconnect diagnostic tool MB991958.

6. If defective, repair it. (Refer to P.13C-34, TCL diagnosis

Symptom Procedures

Inspection Procedure 6).

TCL SWITCH CHECKM1136001700024

1. Remove the TCL switch. (Refer to P.13C-49).

2. Measure the resistance between terminal 1 and terminal 2

when the TCL switch is pressed or released. If the values

measured at the time correspond to those in the table below,

the resistance values are correct.

WHEEL SPEED SENSOR CHECKM1136001300026

Refer to GROUP 35B, On-vehicle Service P.35B-88.

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

Pressed 1-2 Less than 2

ohms

Released 1-2 Open circuit

Page 1328 of 1500

TCL SWITCH

TRACTION CONTROL SYSTEM (TCL)13C-49

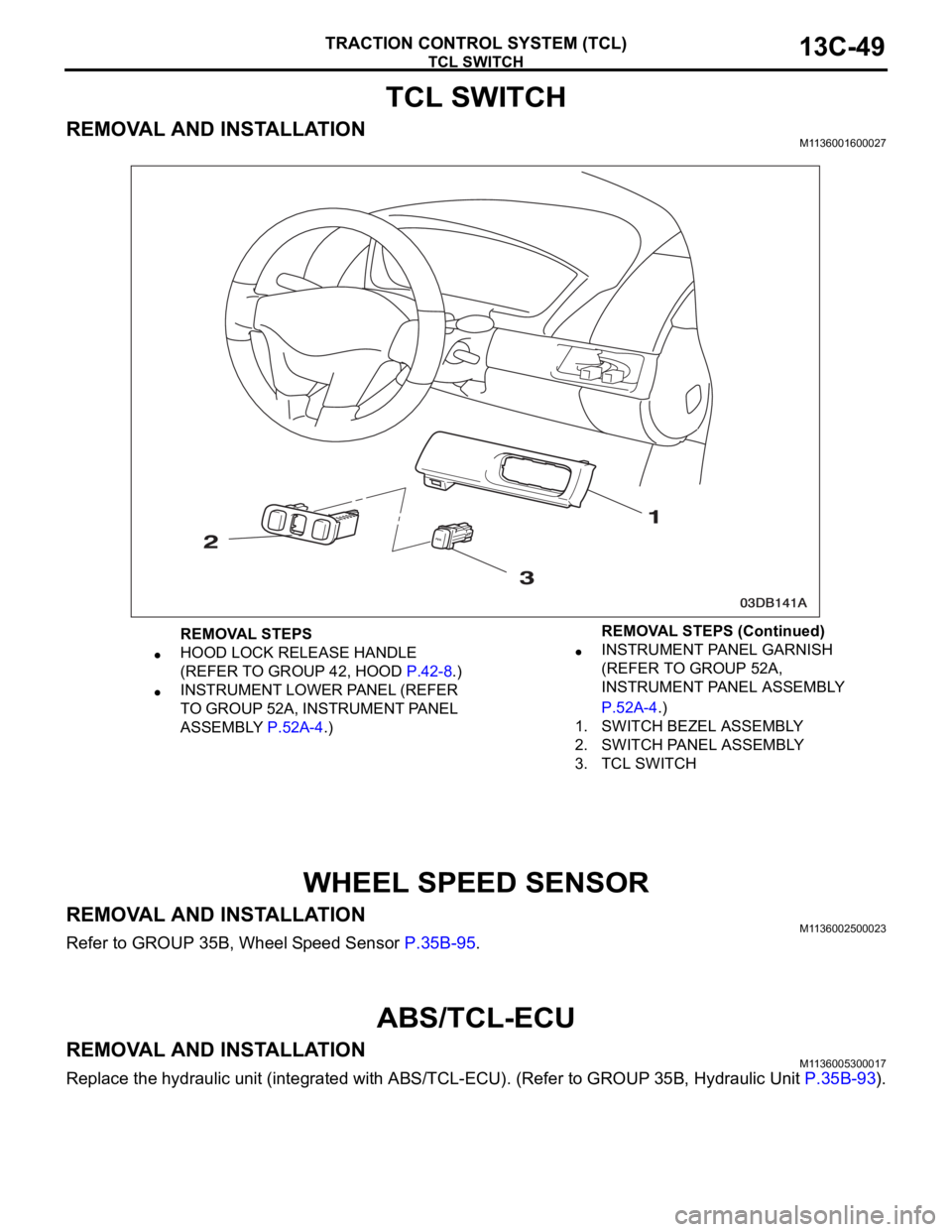

TCL SWITCH

REMOVAL AND INSTALLATIONM1136001600027

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATIONM1136002500023

Refer to GROUP 35B, Wheel Speed Sensor P.35B-95.

ABS/TCL-ECU

REMOVAL AND INSTALLATIONM1136005300017

Replace the hydraulic unit (integrated with ABS/TCL-ECU). (Refer to GROUP 35B, Hydraulic Unit P.35B-93).

REMOVAL STEPS

HOOD LOCK RELEASE HANDLE

(REFER TO GROUP 42, HOOD P.42-8.)

INSTRUMENT LOWER PANEL (REFER

TO GROUP 52A, INSTRUMENT PANEL

ASSEMBLY P.52A-4.)

INSTRUMENT PANEL GARNISH

(REFER TO GROUP 52A,

INSTRUMENT PANEL ASSEMBLY

P.52A-4.)

1. SWITCH BEZEL ASSEMBLY

2. SWITCH PANEL ASSEMBLY

3. TCL SWITCH REMOVAL STEPS (Continued)

Page 1329 of 1500

ABS/TCL-ECU

TRACTION CONTROL SYSTEM (TCL)13C-50

Page 1330 of 1500

13-1

GROUP 13

FUEL

CONTENTS

MULTIPORT FUEL INJECTION (MFI) . . . . . . . . . . . . . . . . . . . .13A

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13B

TRACTION CONTROL SYSTEM (TCL) . . . . . . . . . . . . . . . . . . .13C

Trending: fuel cap, seat memory, Wiring fuel pump, maintenance schedule, Shift, seats, Panic