MITSUBISHI 380 2005 Workshop Manual

380 2005

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57086/w960_57086-0.png

MITSUBISHI 380 2005 Workshop Manual

Trending: jump start, navigation, oil temperature, engine, recommended oil, battery location, auto transmission

Page 1451 of 1500

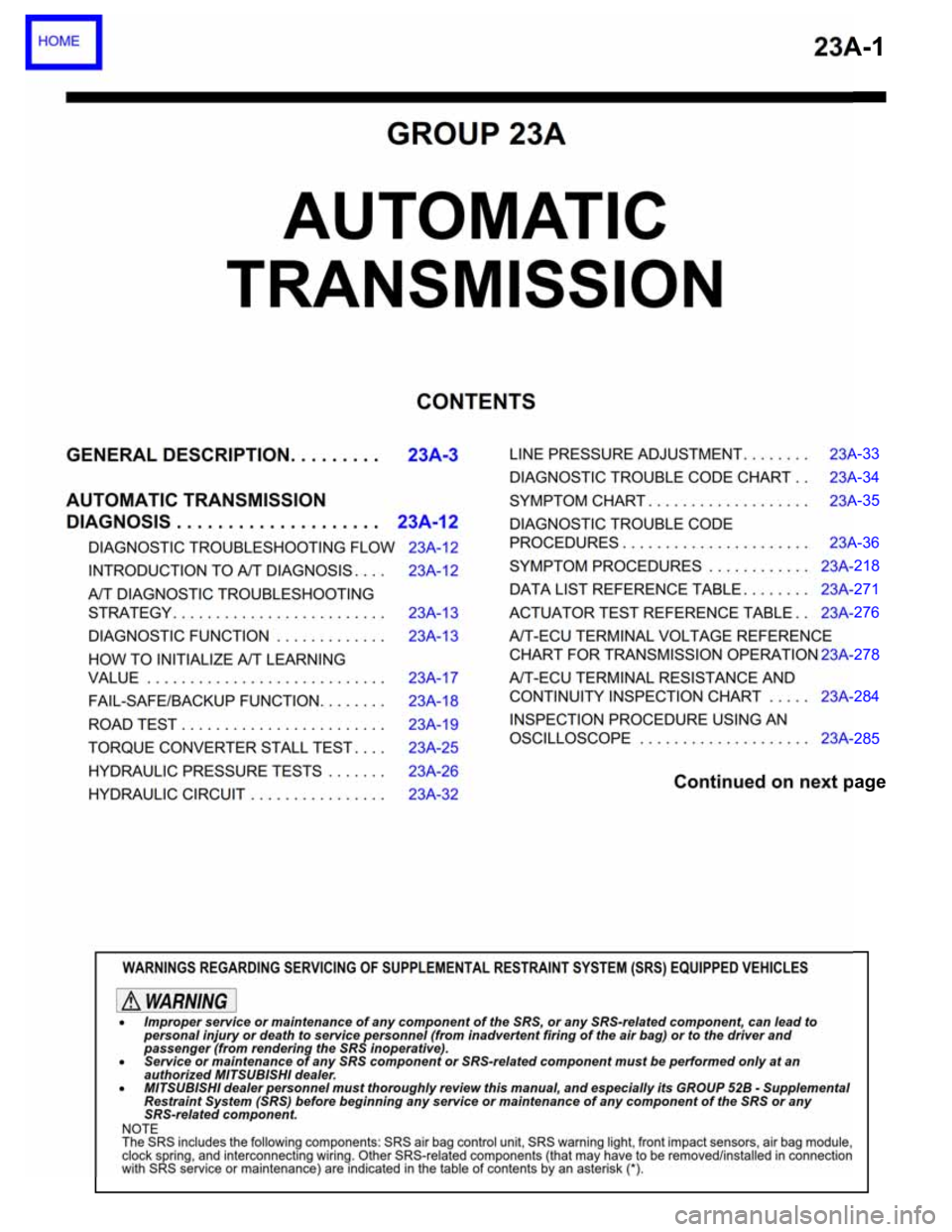

SPECIAL TOOLS

REAR AXLE27-4

SPECIAL TOOLSM1271000600525

ON-VEHICLE SERVICE

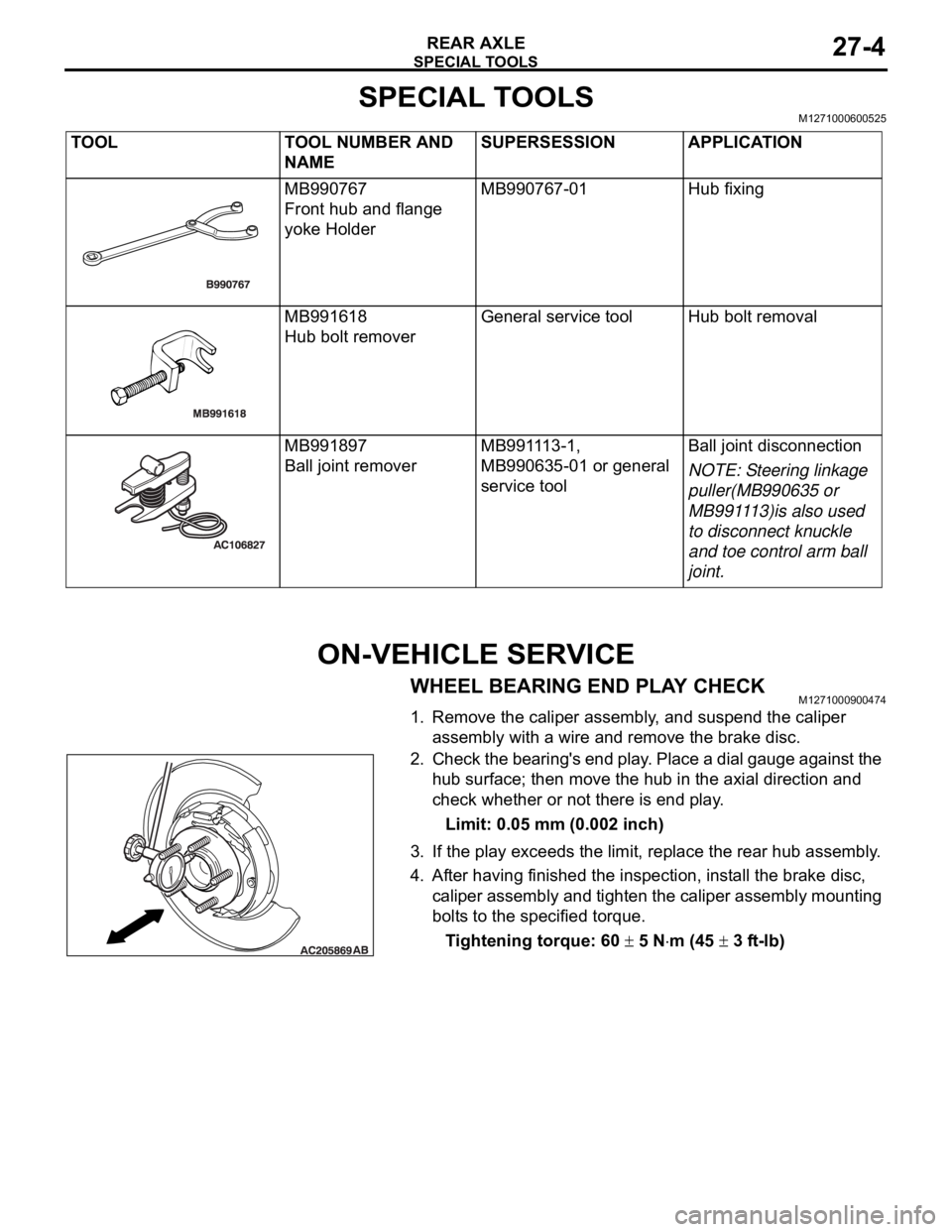

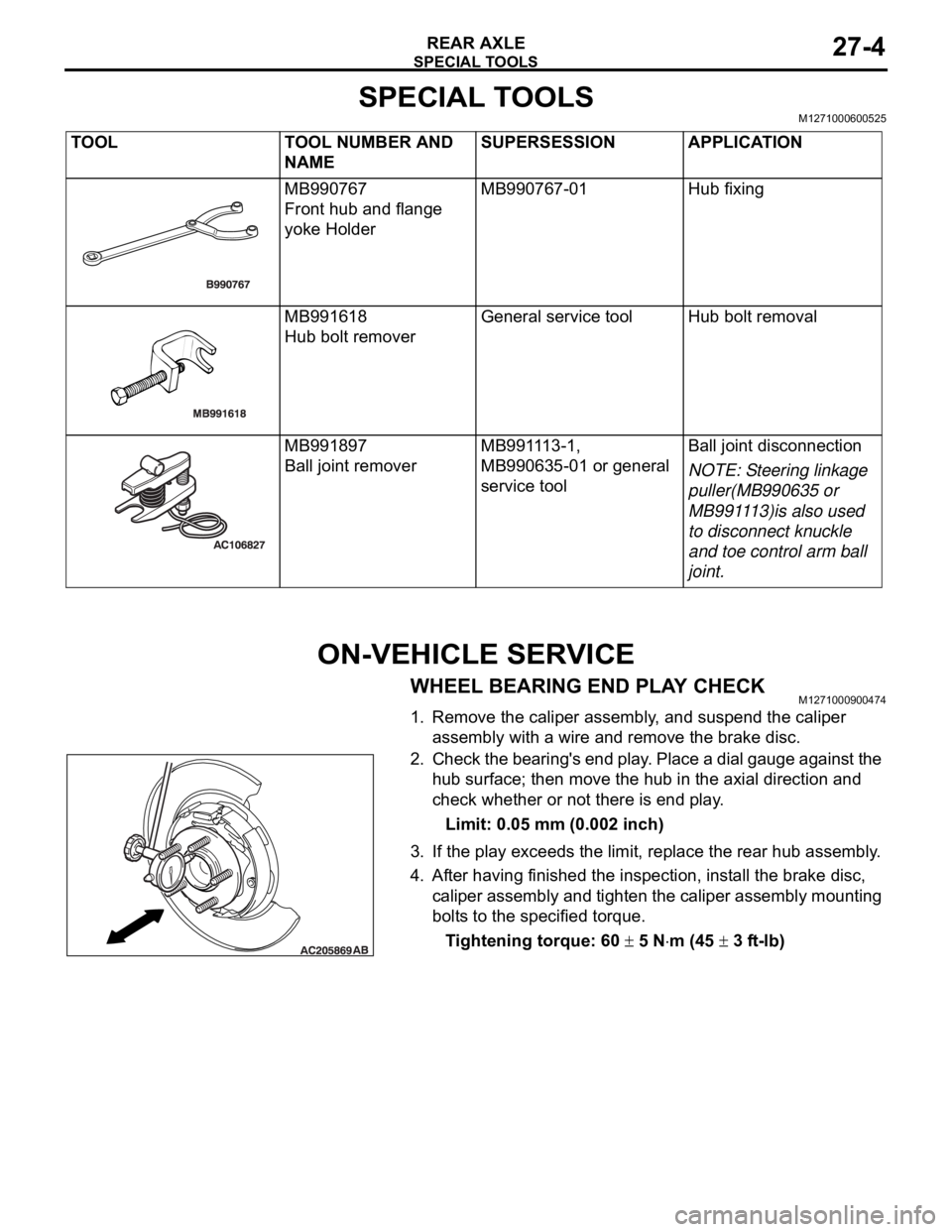

WHEEL BEARING END PLAY CHECKM1271000900474

1. Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

2. Check the bearing's end play. Place a dial gauge against the

hub surface; then move the hub in the axial direction and

check whether or not there is end play.

Limit: 0.05 mm (0.002 inch)

3. If the play exceeds the limit, replace the rear hub assembly.

4. After having finished the inspection, install the brake disc,

caliper assembly and tighten the caliper assembly mounting

bolts to the specified torque.

Tightening torque: 60

5 Nm (45 3 ft-lb) TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB990767

Front hub and flange

yoke HolderMB990767-01 Hub fixing

MB991618

Hub bolt removerGeneral service tool Hub bolt removal

MB991897

Ball joint removerMB991113-1,

MB990635-01 or general

service toolBall joint disconnection

NOTE: Steering linkage

puller(MB990635 or

MB991113)is also used

to disconnect knuckle

and toe control arm ball

joint.

Page 1452 of 1500

ON-VEHICLE SERVICE

REAR AXLE27-5

REAR HUB ROTARY-SLIDING RESISTANCE

CHECK

M1271001100266

1. Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

2. Turn the hub a few times to seat the bearing.

3. Wind a rope around the hub bolt and turn the hub by pulling

at a 90 degree angle with a spring balance. Measure to

determine whether or not the rotary-sliding resistance of the

rear hub is within the limit value.

Limit: 24 N (5.4 pounds)

4. If the rotary

sliding resistance exceeds the limit value,

replace the rear hub assembly.

5. After having finished the inspection, install the brake disc,

caliper assembly and tighten the caliper assembly mounting

bolts to the specified torque.

Tightening torque: 60

5 Nm (45 3 ft-lb)

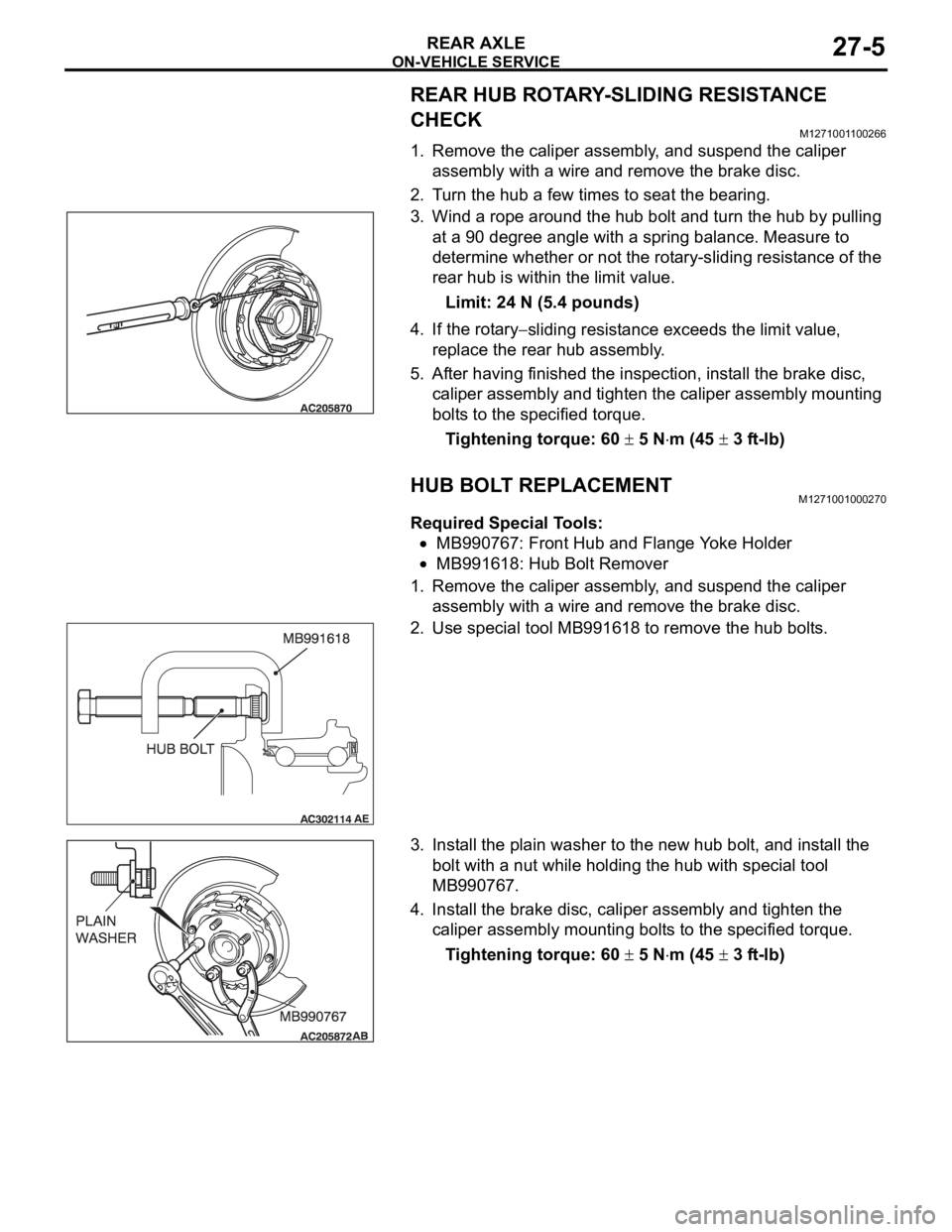

HUB BOLT REPLACEMENTM1271001000270

Required Special Tools:

MB990767: Front Hub and Flange Yoke Holder

MB991618: Hub Bolt Remover

1. Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

2. Use special tool MB991618 to remove the hub bolts.

3. Install the plain washer to the new hub bolt, and install the

bolt with a nut while holding the hub with special tool

MB990767.

4. Install the brake disc, caliper assembly and tighten the

caliper assembly mounting bolts to the specified torque.

Tightening torque: 60

5 Nm (45 3 ft-lb)

Page 1453 of 1500

Page 1454 of 1500

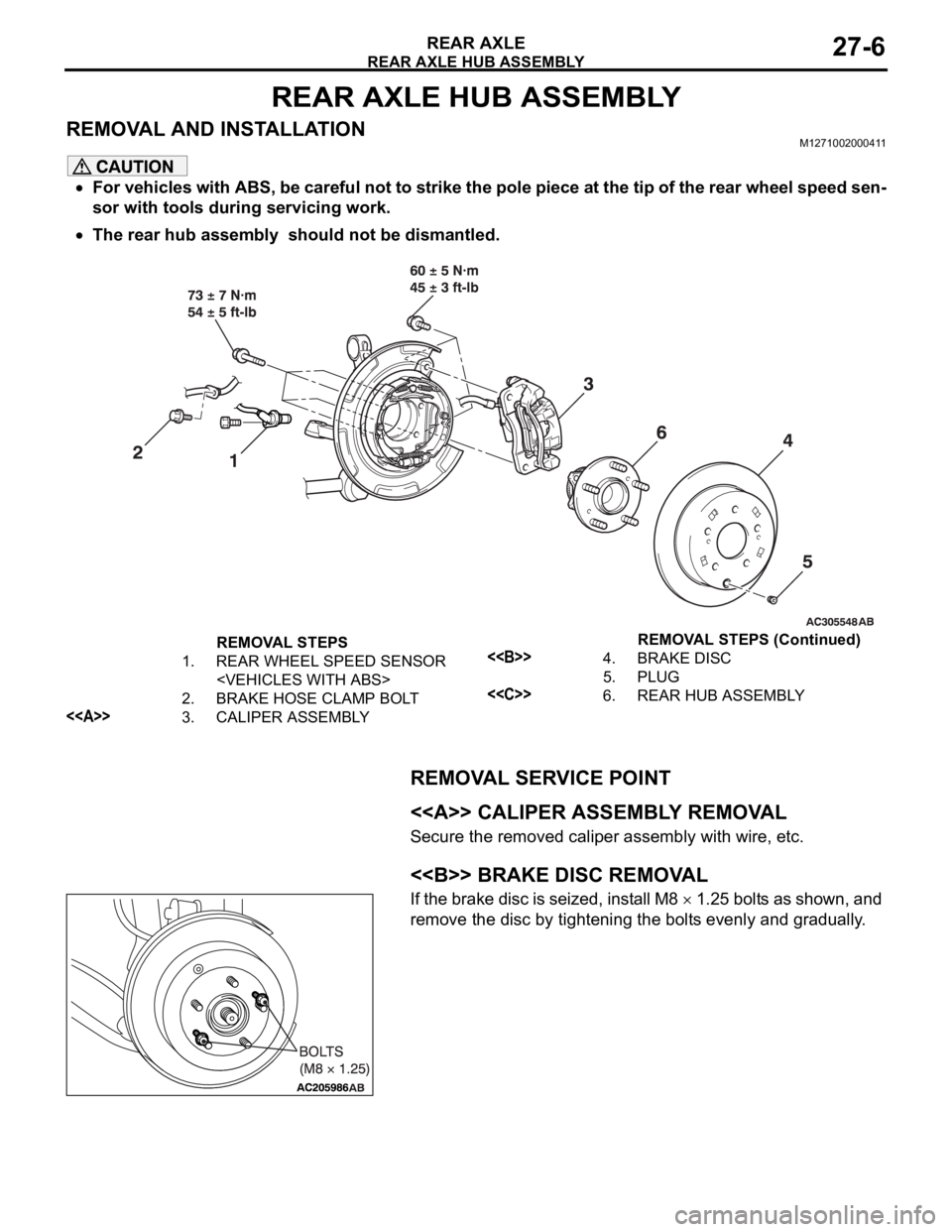

REAR AXLE HUB ASSEMBLY

REAR AXLE27-7

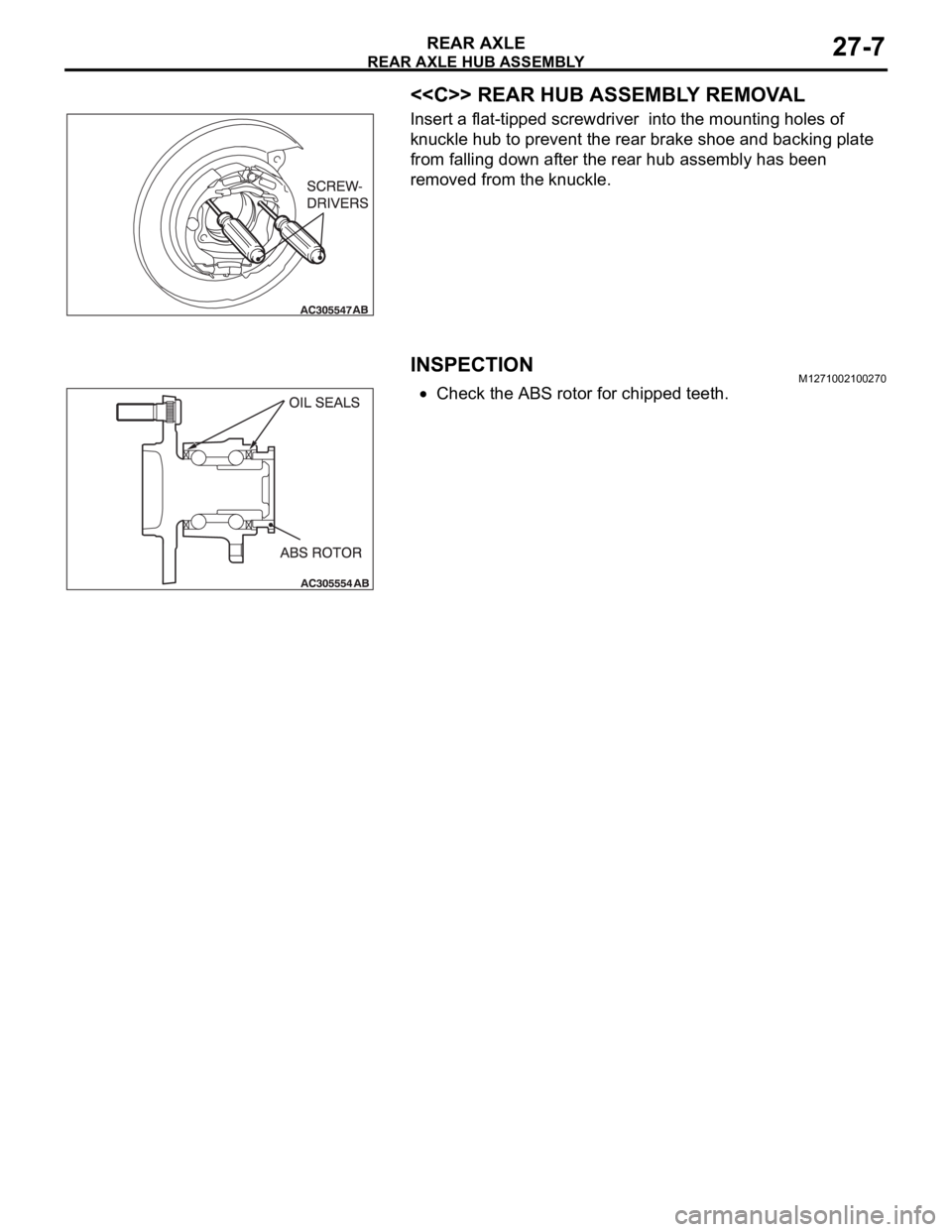

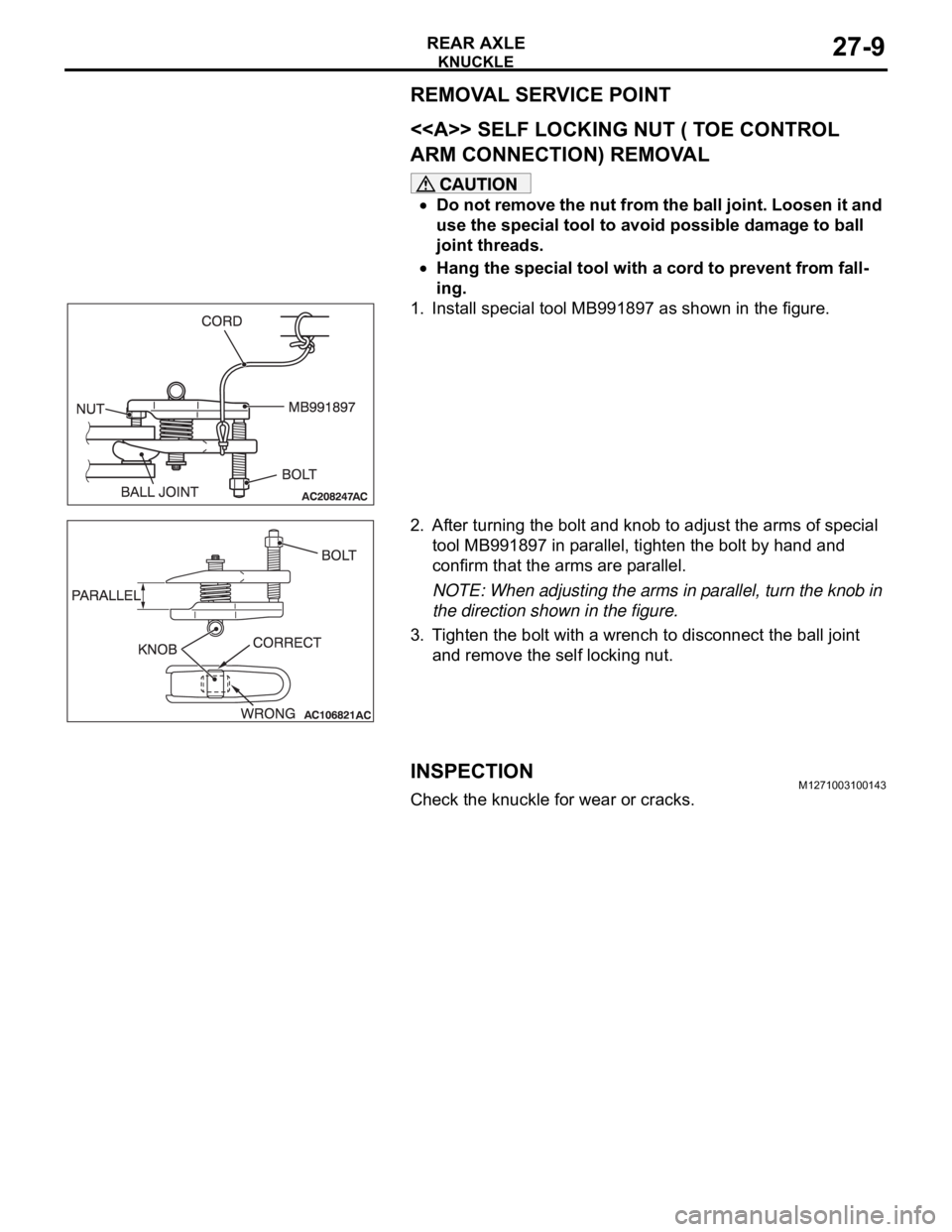

<> REAR HUB ASSEMBLY REMOVAL

Insert a flat-tipped screwdriver into the mounting holes of

knuckle hub to prevent the rear brake shoe and backing plate

from falling down after the rear hub assembly has been

removed from the knuckle.

INSPECTIONM1271002100270

Check the ABS rotor for chipped teeth.

Page 1455 of 1500

Page 1456 of 1500

Page 1457 of 1500

SPECIFICATIONS

REAR AXLE27-10

SPECIFICATIONS

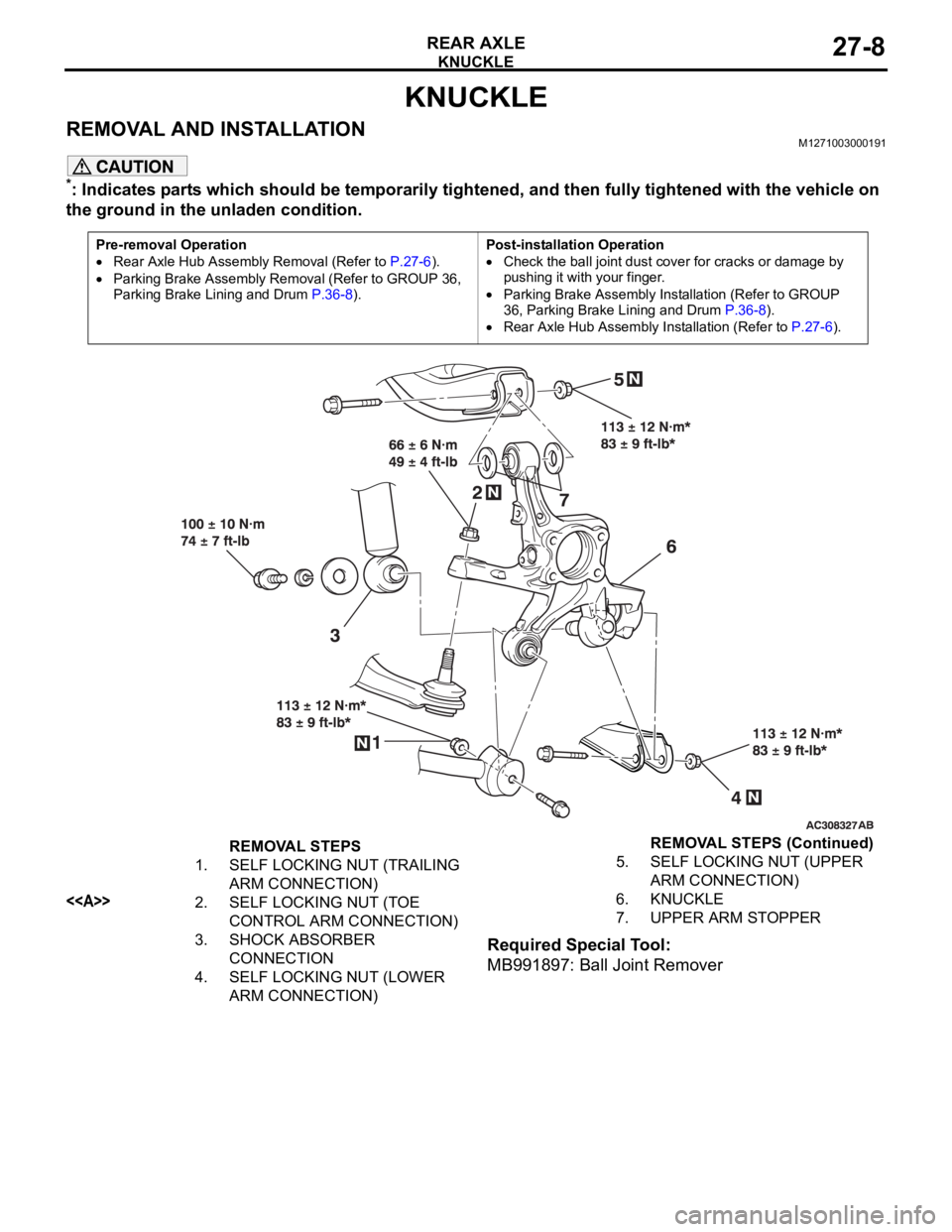

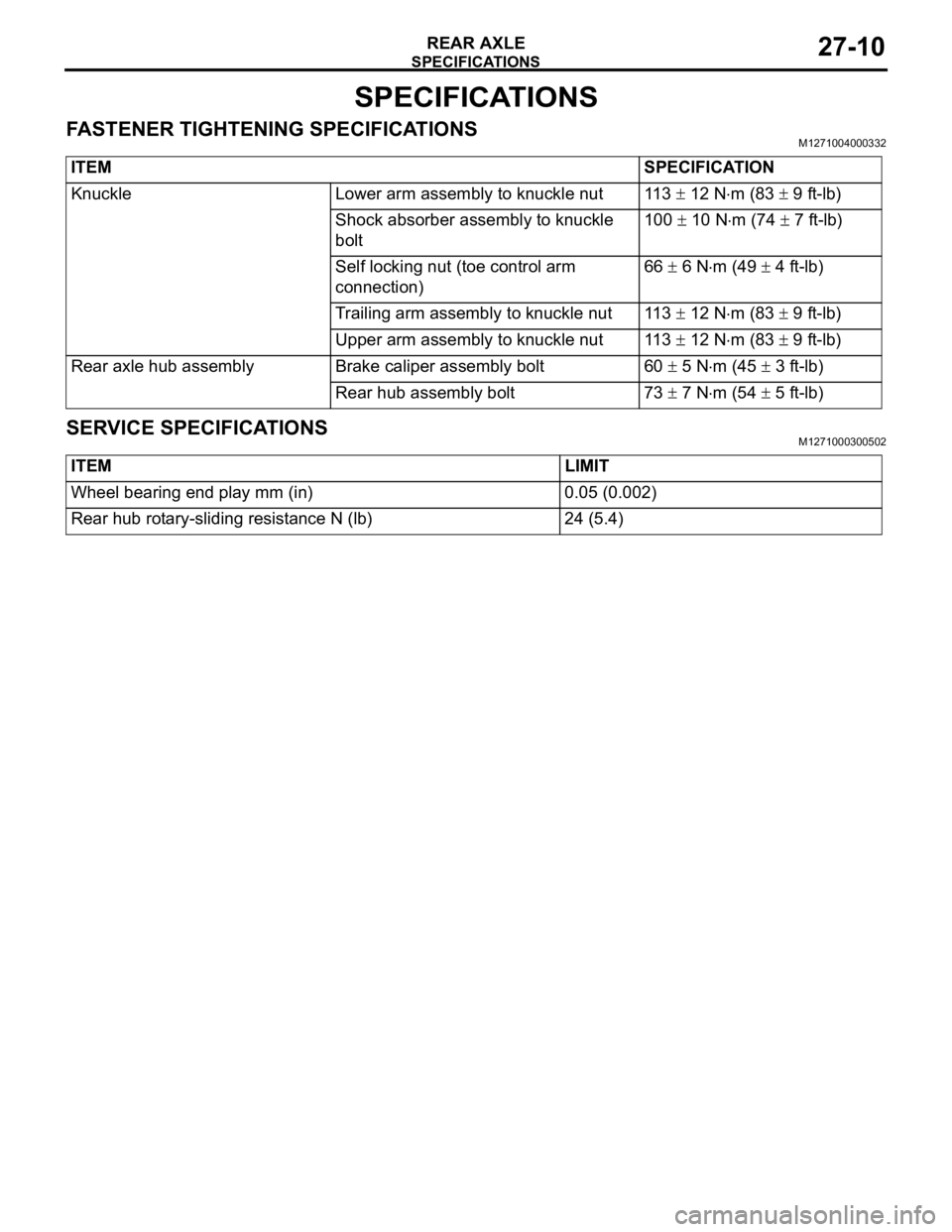

FASTENER TIGHTENING SPECIFICATIONSM1271004000332

SERVICE SPECIFICATIONSM1271000300502

ITEM SPECIFICATION

Knuckle Lower arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Shock absorber assembly to knuckle

bolt100

10 Nm (74 7 ft-lb)

Self locking nut (toe control arm

connection)66

6 Nm (49 4 ft-lb)

Trailing arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Upper arm assembly to knuckle nut 113

12 Nm (83 9 ft-lb)

Rear axle hub assembly Brake caliper assembly bolt 60

5 Nm (45 3 ft-lb)

Rear hub assembly bolt 73

7 Nm (54 5 ft-lb)

ITEM LIMIT

Wheel bearing end play mm (in) 0.05 (0.002)

Rear hub rotary-sliding resistance N (lb) 24 (5.4)

Page 1458 of 1500

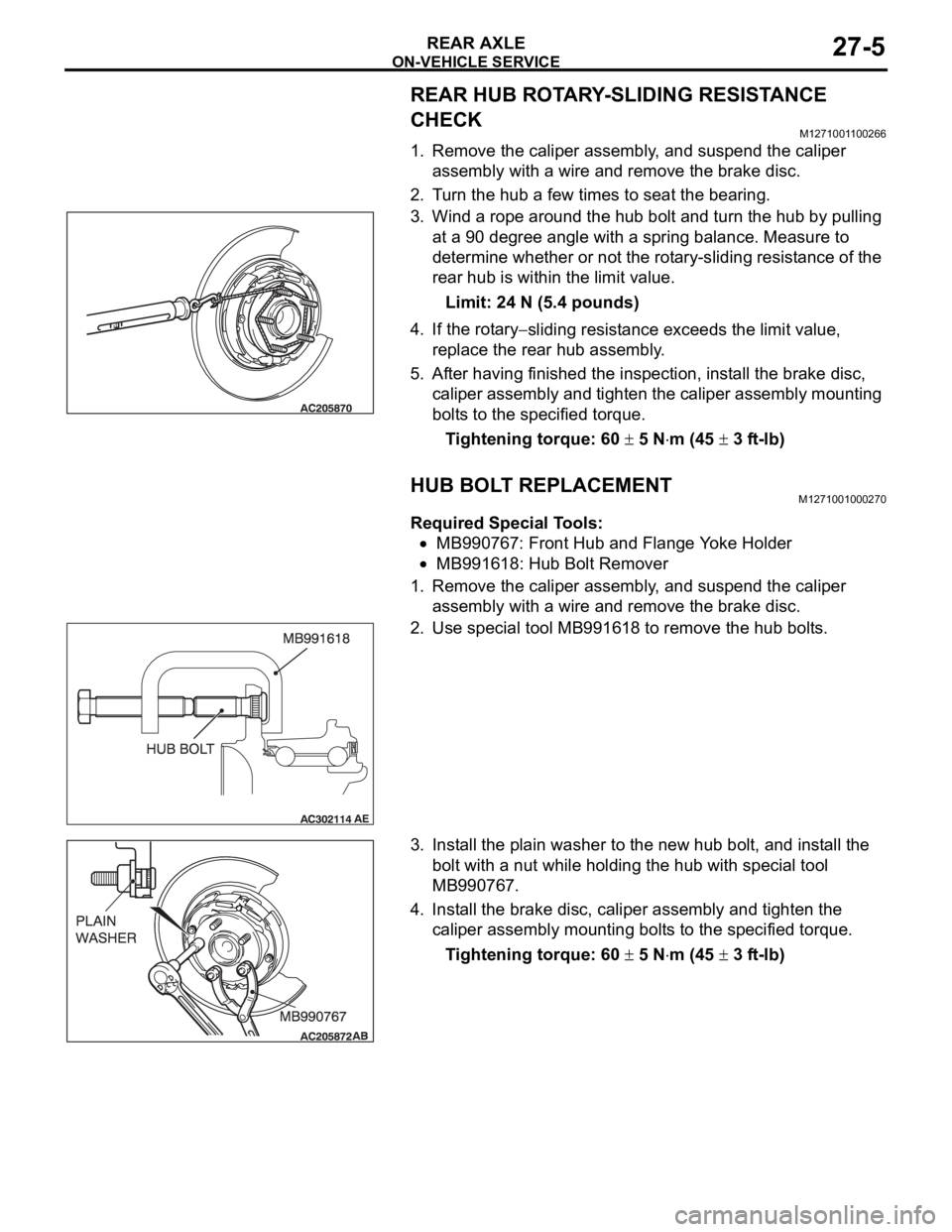

23-1

GROUP 23

AUTOMATIC

TRANSAXLE

CONTENTS

AUTOMATIC TRANSAXLE . . . . . . . . . . . . . . . . . . . . . . . . . . . .23A

AUTOMATIC TRANSAXLE OVERHAUL. . . . . . . . . . . . . . . . . .23B

Page 1459 of 1500

Page 1460 of 1500

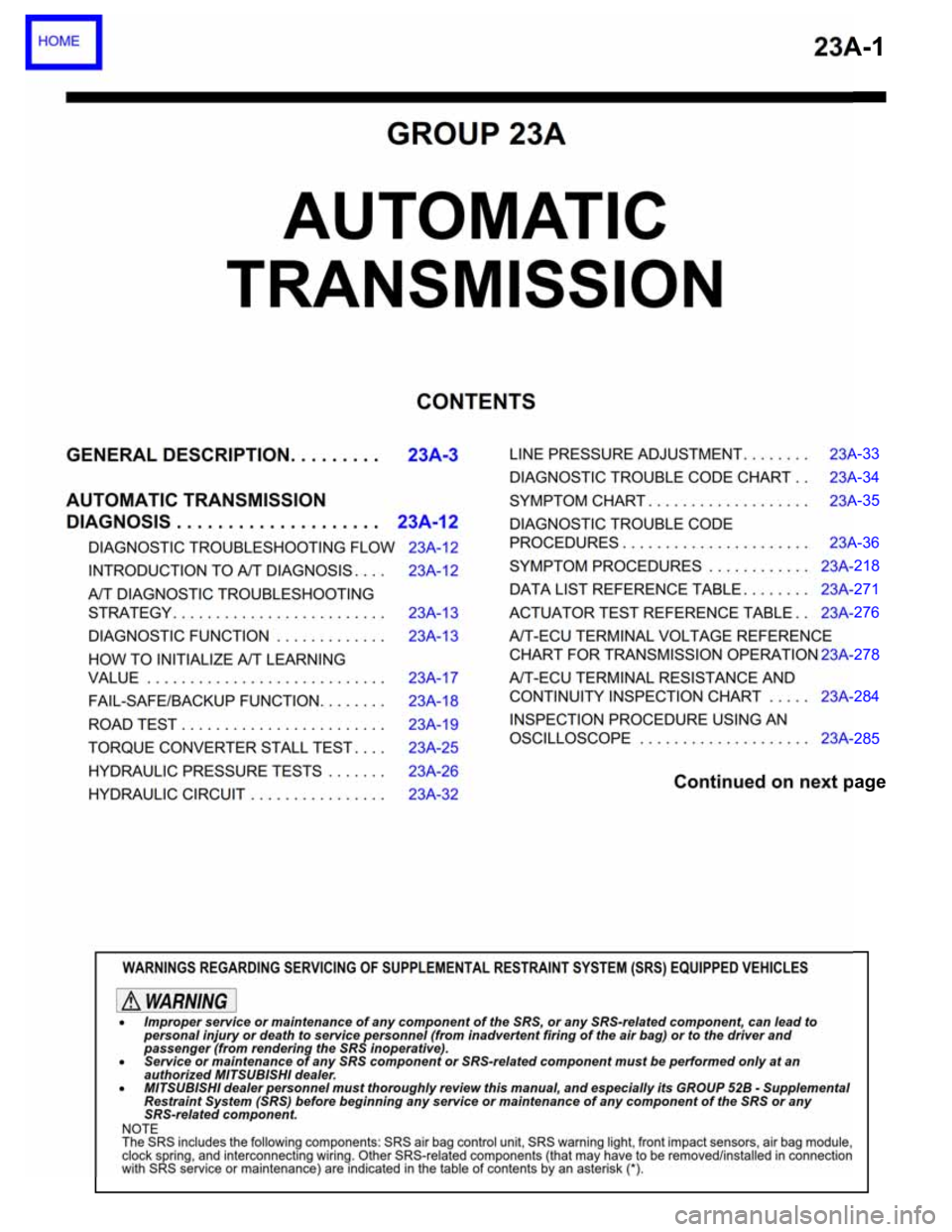

23A-1

GROUP 23A

AUTOMATIC

TRANSMISSION

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .23A-3

AUTOMATIC TRANSMISSION

DIAGNOSIS . . . . . . . . . . . . . . . . . . . .23A-12

DIAGNOSTIC TROUBLESHOOTING FLOW23A-12

INTRODUCTION TO A/T DIAGNOSIS . . . . 23A-12

A/T DIAGNOSTIC TROUBLESHOOTING

STRATEGY . . . . . . . . . . . . . . . . . . . . . . . . . 23A-13

DIAGNOSTIC FUNCTION . . . . . . . . . . . . . 23A-13

HOW TO INITIALIZE A/T LEARNING

VALUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-17

FAIL-SAFE/BACKUP FUNCTION. . . . . . . . 23A-18

ROAD TEST . . . . . . . . . . . . . . . . . . . . . . . . 23A-19

TORQUE CONVERTER STALL TEST . . . . 23A-25

HYDRAULIC PRESSURE TESTS . . . . . . . 23A-26

HYDRAULIC CIRCUIT . . . . . . . . . . . . . . . . 23A-32LINE PRESSURE ADJUSTMENT . . . . . . . . 23A-33

DIAGNOSTIC TROUBLE CODE CHART . . 23A-34

SYMPTOM CHART . . . . . . . . . . . . . . . . . . . 23A-35

DIAGNOSTIC TROUBLE CODE

PROCEDURES . . . . . . . . . . . . . . . . . . . . . . 23A-36

SYMPTOM PROCEDURES . . . . . . . . . . . . 23A-218

DATA LIST REFERENCE TABLE . . . . . . . . 23A-271

ACTUATOR TEST REFERENCE TABLE . . 23A-276

A/T-ECU TERMINAL VOLTAGE REFERENCE

CHART FOR TRANSMISSION OPERATION23A-278

A/T-ECU TERMINAL RESISTANCE AND

CONTINUITY INSPECTION CHART . . . . . 23A-284

INSPECTION PROCEDURE USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . . . 23A-285

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

Trending: door lock, Transmitter, wheel alignment, Interior light, Fuel pump wiring, Relay box, lock