engine MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1239 of 1500

VEHICLE IDENTIFICATION

GENERAL00-18

VEHICLE IDENTIFICATION

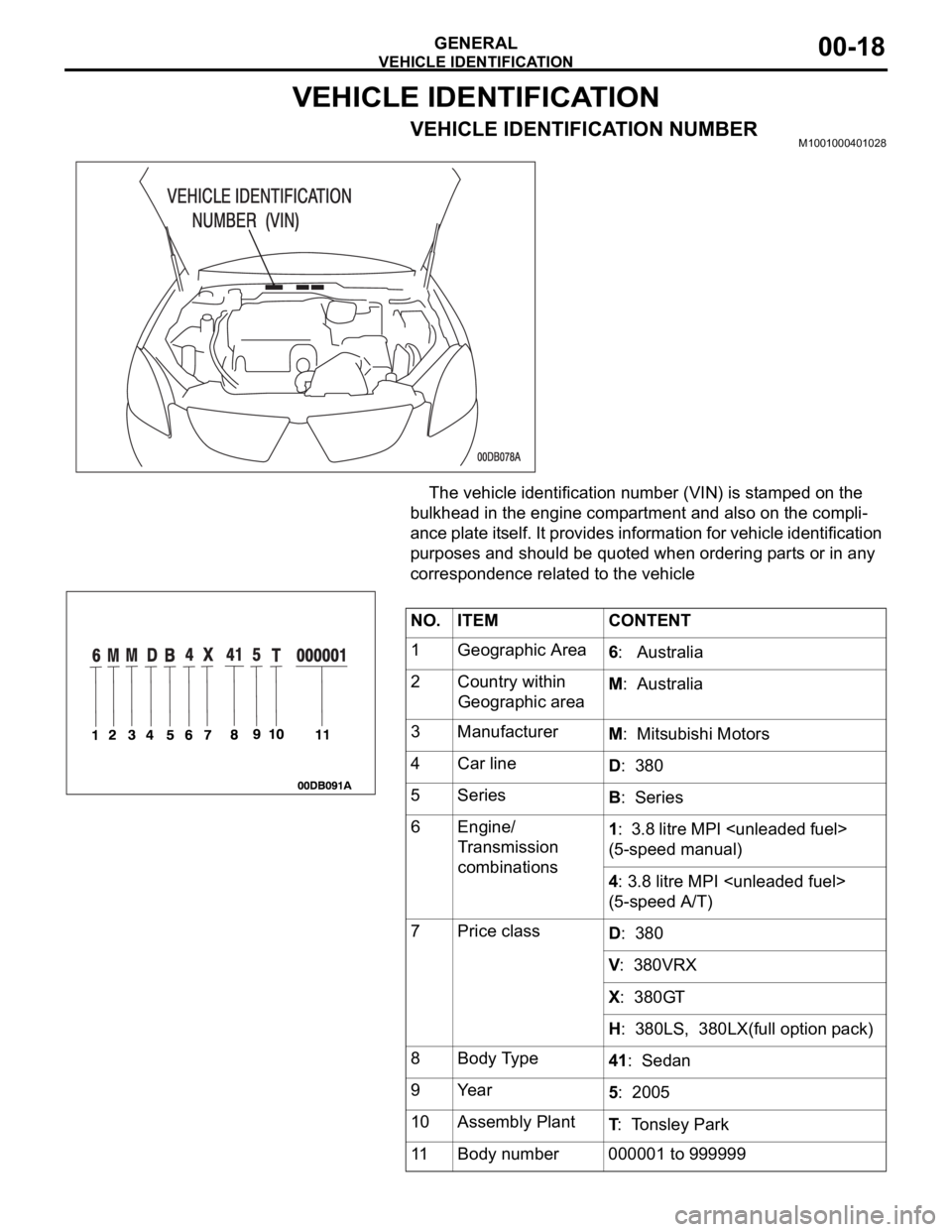

VEHICLE IDENTIFICATION NUMBERM1001000401028

The vehicle identification number (VIN) is stamped on the

bulkhead in the engine compartment and also on the compli-

ance plate itself. It provides information for vehicle identification

purposes and should be quoted when ordering parts or in any

correspondence related to the vehicle

NO. ITEM CONTENT

1 Geographic Area

6: Australia

2 Country within

Geographic areaM: Australia

3 Manufacturer

M: Mitsubishi Motors

4 Car line

D: 380

5Series

B: Series

6 Engine/

Transmission

combinations1: 3.8 litre MPI

(5-speed manual)

4: 3.8 litre MPI

(5-speed A/T)

7Price class

D: 380

V: 380VRX

X: 380GT

H: 380LS, 380LX(full option pack)

8 Body Type

41: Sedan

9Year

5: 2005

10 Assembly Plant

T: Tonsley Park

11 Body number 000001 to 999999

Page 1240 of 1500

VEHICLE IDENTIFICATION

GENERAL00-19

VEHICLE INFORMATION NUMBER LIST

NOTE: ** = Becomes 380LX as a full option pack.

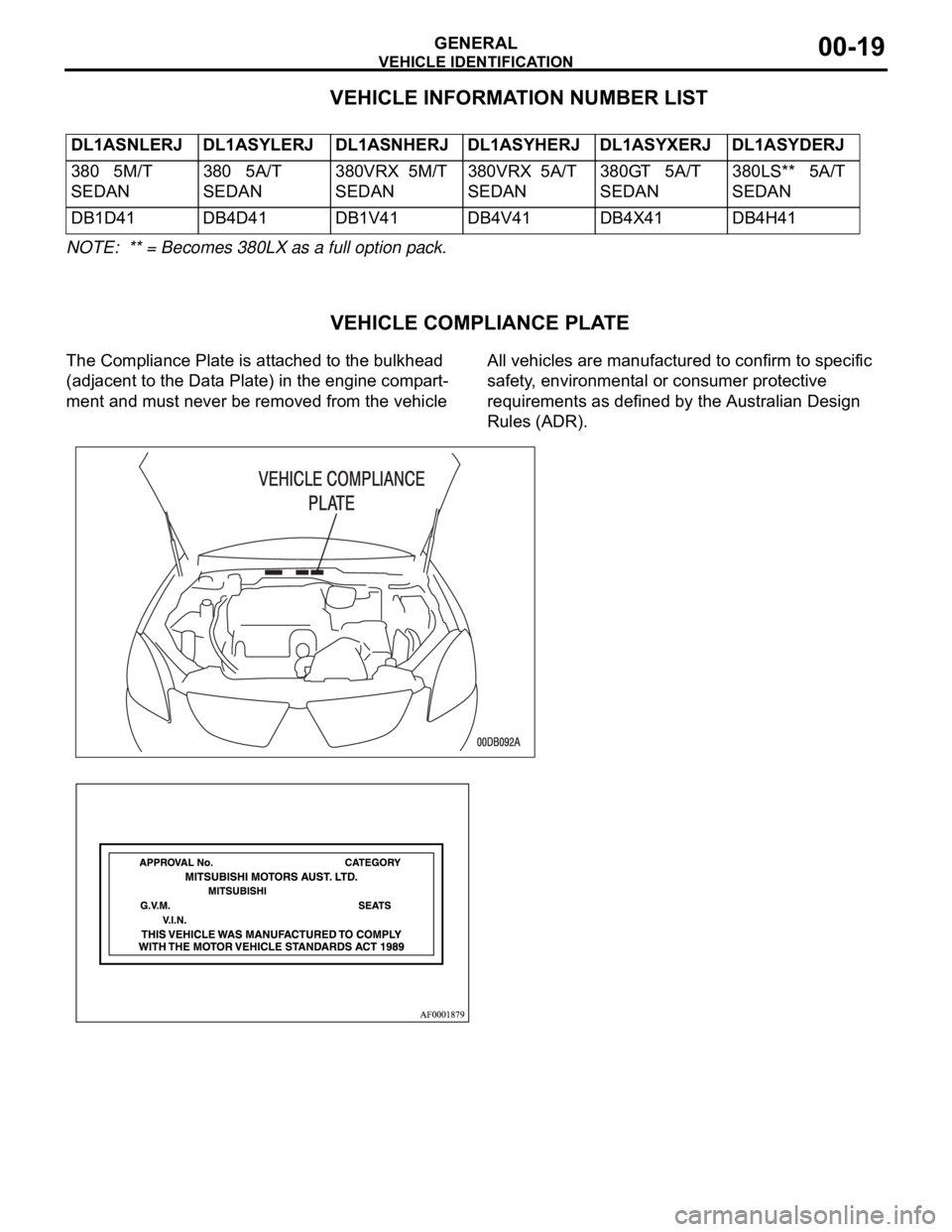

VEHICLE COMPLIANCE PLATE

The Compliance Plate is attached to the bulkhead

(adjacent to the Data Plate) in the engine compart-

ment and must never be removed from the vehicle All vehicles are manufactured to confirm to specific

safety, environmental or consumer protective

requirements as defined by the Australian Design

Rules (ADR). DL1ASNLERJ DL1ASYLERJ DL1ASNHERJ DL1ASYHERJ DL1ASYXERJ DL1ASYDERJ

380 5M/T

SEDAN380 5A/T

SEDAN380VRX 5M/T

SEDAN380VRX 5A/T

SEDAN380GT 5A/T

SEDAN380LS** 5A/T

SEDAN

DB1D41 DB4D41 DB1V41 DB4V41 DB4X41 DB4H41

Page 1241 of 1500

VEHICLE IDENTIFICATION

GENERAL00-20

VEHICLE DATA PLATEM1001005400707

The vehicle data plate is attached on the bulk-

head, between the vehicle identification number (VIN) and the

compliance plate at the top outer panel in the engine compart-

ment.

The plate shows vehicle option codes, trim codes and a daily

body sequential build number.

AUSTRALIAN DESIGN RULES

Australian Design Rules require the manufacturer of components and/ or a complete vehicle to conform to

specific safety, environmental or consumer protective requirements as defined by that particular rule. There is

legislation that requires, amongst other things that no modifications be made to a vehicle that would cause

that vehicle not to comply with the Design Rules of that vehicle (parts replacement using approved Mitsubishi

Motors Australia Limited components is permissible). Before interchanging or adding optional equipment or

using non-Genuine Parts, it is recommended that advice be sought from an Authorised Mitsubishi Motors

Australia Limited Dealer or from a Mitsubishi Motors Australia Limited Regional Office, because it is possible

to inadvertently cause a vehicle not to comply with a Design Rule.

Page 1243 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-22

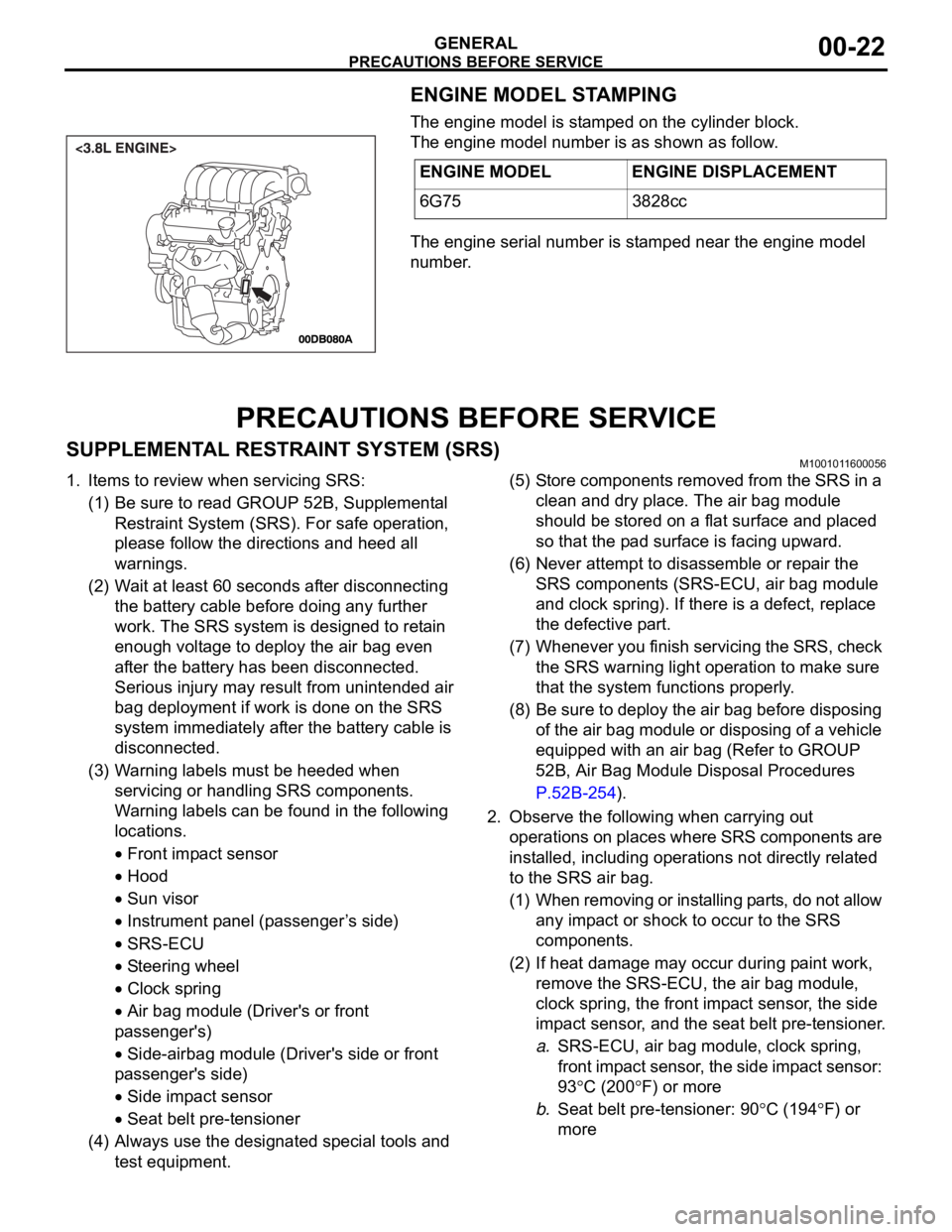

ENGINE MODEL STAMPING

The engine model is stamped on the cylinder block.

The engine model number is as shown as follow.

The engine serial number is stamped near the engine model

number.

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)M1001011600056

1. Items to review when servicing SRS:

(1) Be sure to read GROUP 52B, Supplemental

Restraint System (SRS). For safe operation,

please follow the directions and heed all

warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

Warning labels can be found in the following

locations.

Front impact sensor

Hood

Sun visor

Instrument panel (passenger ’s side)

SRS-ECU

Steering wheel

Clock spring

Air bag module (Driver's or front

passenger's)

Side-airbag module (Driver's side or front

passenger's side)

Side impact sensor

Seat belt pre-tensioner

(4) Always use the designated special tools and

test equipment.(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag (Refer to GROUP

52B, Air Bag Module Disposal Procedures

P.52B-254).

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

a.SRS-ECU, air bag module, clock spring,

front impact sensor, the side impact sensor:

93

C (200F) or more

b.Seat belt pre-tensioner: 90

C (194F) or

more ENGINE MODEL ENGINE DISPLACEMENT

6G75 3828cc

Page 1244 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-23

HOW TO PERFORM VEHICLE IDENTIFICATION

NUMBER (VIN) WRITING

M1001011400063

The Vehicle Identification Number (VIN) is stored in the ECU by

the vehicle manufacture. If the VIN to be stored in the ECU is

eliminated fraudulently, the Malfunction Indicator Lamp (Check

Engine Lamp) illuminates and Diagnostic Trouble Code (DTC)

No.P0630 (VIN malfunction) is shown. When the ECU is

replaced, and entry of the VIN necessary due to DTC No.

P0630 (VIN malfunction). Enter the VIN in accordance with the

procedure as follows:

.

WRITING PROCEDURE

Required Special Tools:

Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (BLUE)

To prevent damage to DIAGNOSTIC TOOL (MUT-III), always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting.

1. Connect Diagnostic Tool to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Confirm DTC No.P0630 (EEPROM malfunction) is not

shown.

NOTE: When DTC No. P0630 (EEPROM malfunction) is

shown, the VIN cannot be stored even if entered. Therefore,

the troubleshooting is performed when this DTC is shown.

4. Select "Coding" form the menu screen.

5. Select "VIN writing" form the menu screen.

6. Enter the VIN.

7. After entry of the VIN, turn the ignition switch to the "LOCK"

(OFF) position. After ten seconds or more passed, turn to

the "ON" position again.

8. Confirm DTC No.P0630 (VIN malfunction) is not shown.

NOTE: When DTC No.P0630 (VIN malfunction) is shown,

enter the VIN again because that would be not appropriate.

Page 1245 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-24

SERVICING ELECTRICAL SYSTEMM1001011900057

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Note the following before proceeding with working on the

electrical system.

Never perform unauthorized modifications to any electrical

device or wiring. Such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result in

a fire in the vehicle.

Before connecting or disconnecting the negative bat-

tery cable, be sure to turn the ignition switch to the

"LOCK" (OFF) position and turn off the lights (If this is

not done, there is the possibility of semiconductor

parts being damaged).

After completion of the work (and the negative battery

terminals is connected), warm up the engine and allow

it to idle for approximately 10 minutes under the condi-

tions described below in order to stabilize engine con-

trol conditions, and then check to be sure that the idle

is satisfactory.

Engine coolant temperature: 85 to 95C (185 to

203

F)

Lights and all accessories: OFF

Transaxle: "N" or "P" position

Steering wheel: straight-forward position

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

VEHICLE WASHINGM1001012000057

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least approximately 50 cm (20

inches) from any plastic parts and all opening parts (doors, lug-

gage compartment, etc.).

Page 1252 of 1500

GENERAL DATA AND SPECIFICATIONS

GENERAL00-31

GENERAL DATA AND SPECIFICATIONSM1001000900473.

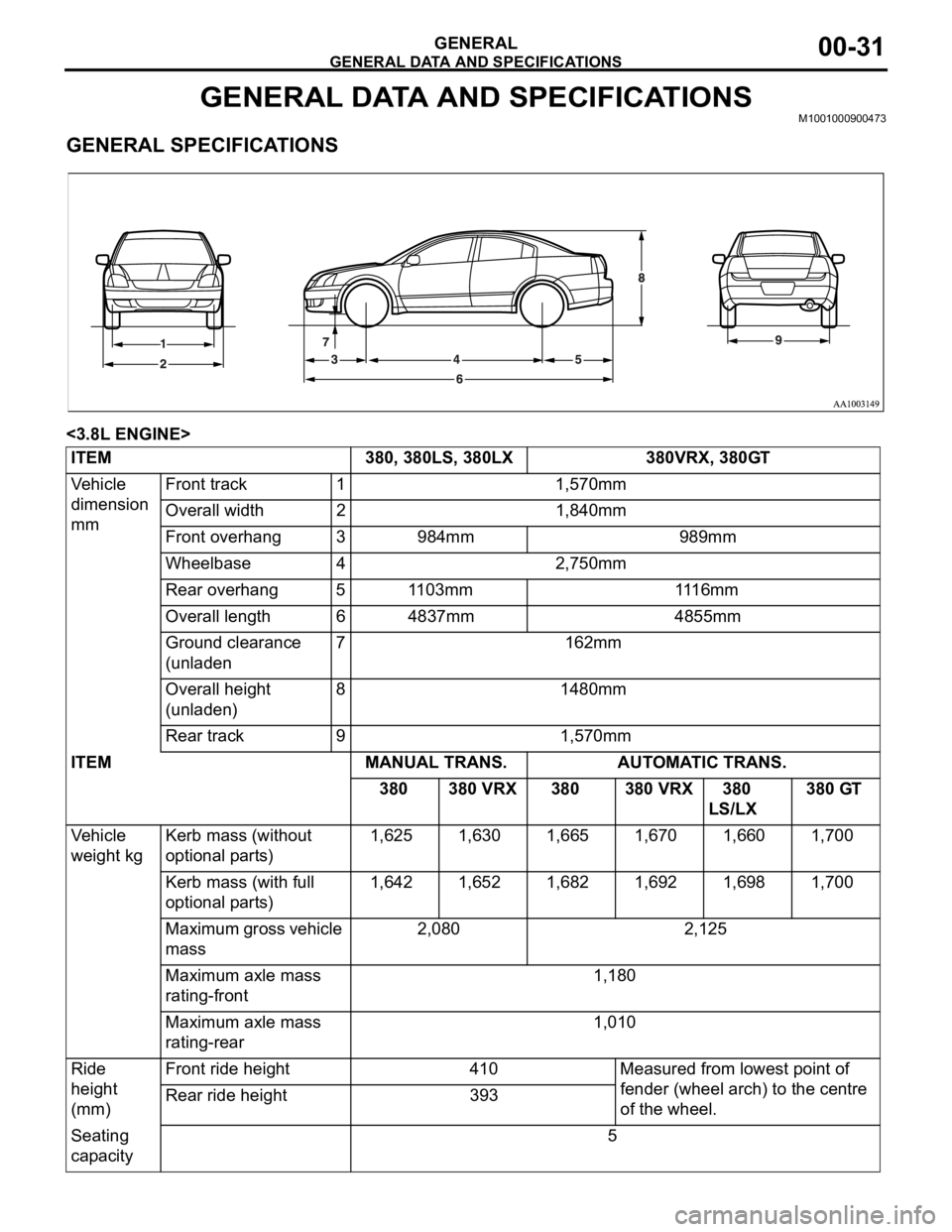

GENERAL SPECIFICATIONS

<3.8L ENGINE>

ITEM 380, 380LS, 380LX 380VRX, 380GT

Vehicle

dimension

mmFront track 1 1,570mm

Overall width 2 1,840mm

Front overhang 3 984mm 989mm

Wheelbase 4 2,750mm

Rear overhang 5 1103mm 1116mm

Overall length 6 4837mm 4855mm

Ground clearance

(unladen7 162mm

Overall height

(unladen)8 1480mm

Rear track 9 1,570mm

ITEM MANUAL TRANS. AUTOMATIC TRANS.

380 380 VRX 380 380 VRX 380

LS/LX 380 GT

Vehicle

weight kgKerb mass (without

optional parts) 1,625 1,630 1,665 1,670 1,660 1,700

Kerb mass (with full

optional parts) 1,642 1,652 1,682 1,692 1,698 1,700

Maximum gross vehicle

mass 2,080 2,125

Maximum axle mass

rating-front 1,180

Maximum axle mass

rating-rear 1,010

Ride

height

(mm)Front ride height 410 Measured from lowest point of

fender (wheel arch) to the centre

of the wheel. Rear ride height 393

Seating

capacity 5

Page 1253 of 1500

TIGHTENING TORQUE

GENERAL00-32

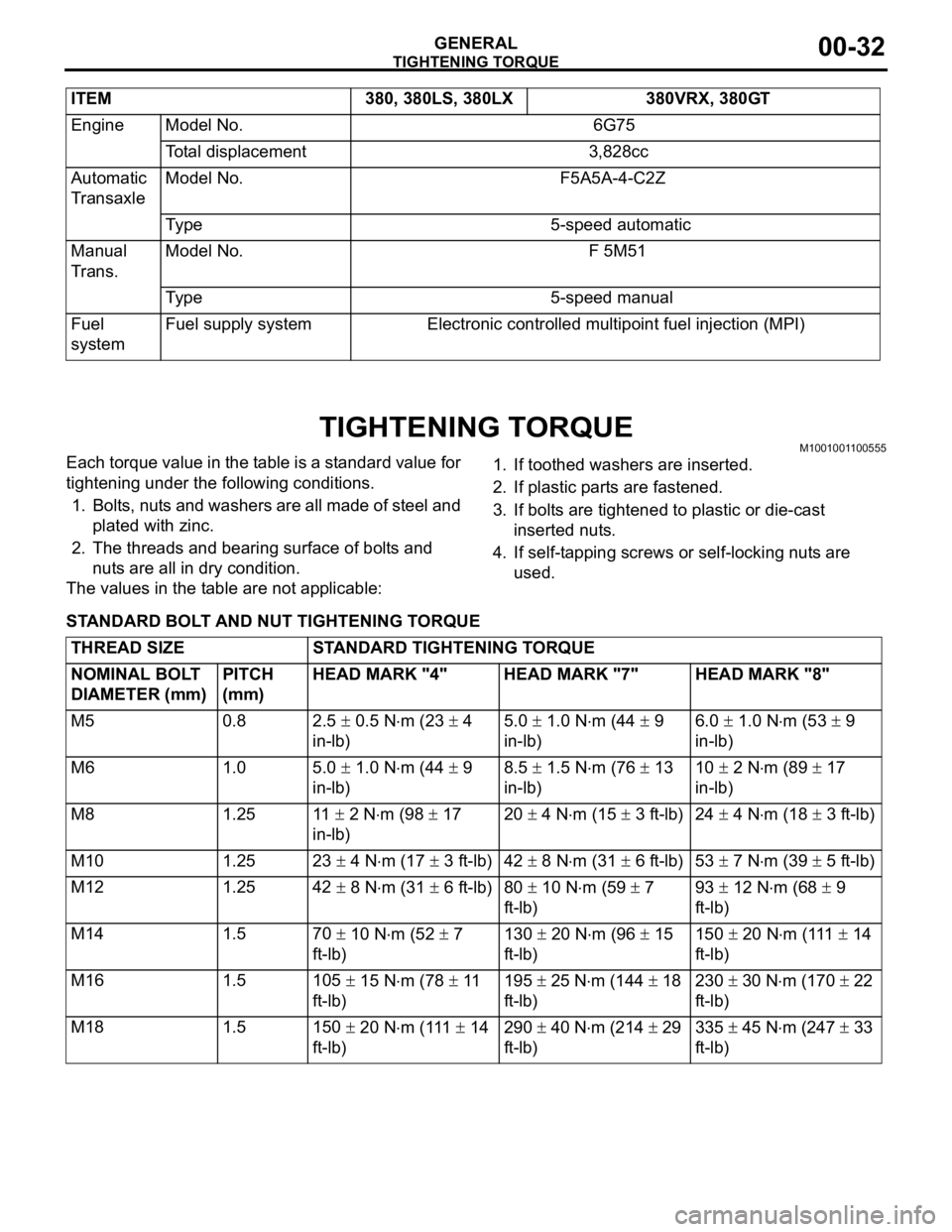

TIGHTENING TORQUEM1001001100555

Each torque value in the table is a standard value for

tightening under the following conditions.

1. Bolts, nuts and washers are all made of steel and

plated with zinc.

2. The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:1. If toothed washers are inserted.

2. If plastic parts are fastened.

3. If bolts are tightened to plastic or die-cast

inserted nuts.

4. If self-tapping screws or self-locking nuts are

used.

STANDARD BOLT AND NUT TIGHTENING TORQUE Engine Model No. 6G75

Total displacement 3,828cc

Automatic

TransaxleModel No. F5A5A-4-C2Z

Type 5-speed automatic

Manual

Trans.Model No. F 5M51

Type 5-speed manual

Fuel

systemFuel supply system Electronic controlled multipoint fuel injection (MPI) ITEM 380, 380LS, 380LX 380VRX, 380GT

THREAD SIZE STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER (mm)PITCH

(mm)HEAD MARK "4" HEAD MARK "7" HEAD MARK "8"

M5 0.8 2.5

0.5 Nm (23 4

in-lb)5.0 1.0 Nm (44 9

in-lb)6.0 1.0 Nm (53 9

in-lb)

M6 1.0 5.0

1.0 Nm (44 9

in-lb)8.5 1.5 Nm (76 13

in-lb)10 2 Nm (89 17

in-lb)

M8 1.25 11

2 Nm (98 17

in-lb)20 4 Nm (15 3 ft-lb) 24 4 Nm (18 3 ft-lb)

M10 1.25 23

4 Nm (17 3 ft-lb) 42 8 Nm (31 6 ft-lb) 53 7 Nm (39 5 ft-lb)

M12 1.25 42

8 Nm (31 6 ft-lb) 80 10 Nm (59 7

ft-lb)93 12 Nm (68 9

ft-lb)

M14 1.5 70

10 Nm (52 7

ft-lb)130 20 Nm (96 15

ft-lb)150 20 Nm ( 111 14

ft-lb)

M16 1.5 105

15 Nm (78 11

ft-lb)195 25 Nm (144 18

ft-lb)230 30 Nm (170 22

ft-lb)

M18 1.5 150

20 Nm ( 111 14

ft-lb)290 40 Nm (214 29

ft-lb)335 45 Nm (247 33

ft-lb)

Page 1255 of 1500

LUBRICATION AND MAINTENANCE

GENERAL00-34

LUBRICATION AND MAINTENANCEM1001001200336

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum pro-

tection for the vehicle owner's investment against all

reasonable types of driving conditions. Since these

conditions vary with the individual vehicle owner's

driving habits, the area in which the vehicle is oper-

ated and the type of driving to which the vehicle is

subjected, it is necessary to prescribe lubrication and

maintenance service on a time frequency as well as

mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the

Society of Automotive Engineers (SAE) and the Aus-

tralian Petroleum Institute (API).

MAINTENANCE SCHEDULES

For Information on service maintenance refer to the

"Service handbook".

ENGINE OIL

Tests have shown that laboratory animals

develop skin cancer after prolonged contact with

used engine oil. Accordingly, the potential exists

for humans to develop a number of skin disor-

ders, including cancer, from such exposure to

used engine oil. Therefore, when changing

engine oil, be careful not to touch it as much as

possible. Protective clothing and gloves, that

cannot be penetrated by oil, should be worn. The

skin should be thoroughly washed with soap and

water, or use waterless hand cleaner, to remove

any used engine oil. Do not use petrol, thinners,

or solvents.Either of the following engine oils should be used:

1. Engine oil conforming to the ACEA classification:

"For service A1, A2 or A3.

2. Engine oil conforming to the API classification:

"For service SG" or higher.

FUEL USAGE STATEMENT

Using leaded petrol in this car will damage the

catalytic converters and heated oxygen sensors,

and affect the warranty coverage validity.

This vehicle must use unleaded petrol only.

This vehicle has a fuel filler tube which is especially

designed to accept only the smaller-diameter

unleaded petrol dispensing nozzle.

The 3.8L model is designed to operate on unleaded

petrol having an octane rating (DIN 51607) of 90

RON or higher.

.

PETROL CONTAINING ALCOHOL

Some petrol sold at service stations contain alcohol

although they may not be so identified.

Using fuels containing alcohol is not recommended

unless the nature of the blend can be determined as

being satisfactory, as follows.

Gasohol: A mixture of 10% ethanol and 90%

unleaded gasoline may be used in your vehicle. If

driveability problems are experienced as a result of

using gasohol, it is recommended that the vehicle be

operated on petrol.

Methanol: Do not use petrol containing methanol

(wood alcohol). Using this type of alcohol can result

in vehicle performance deterioration and damage

critical parts in the fuel system components. Fuel

system damage and performance problems resulting

from the use of petrol containing methanol may not

be covered by the new vehicle warranty.

MATERIALS ADDED TO FUEL

Indiscriminate use of fuel system cleaning agents

should be avoided. Many materials intended for gum

and varnish removal may contain highly active sol-

vents or similar ingredients that can be harmful to

gasket and diaphragm materials used in fuel system

component parts.

Page 1256 of 1500

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

GENERAL00-35

RECOMMENDED LUBRICANTS AND LUBRICANT

CAPACITIES TABLE

M1001001300504

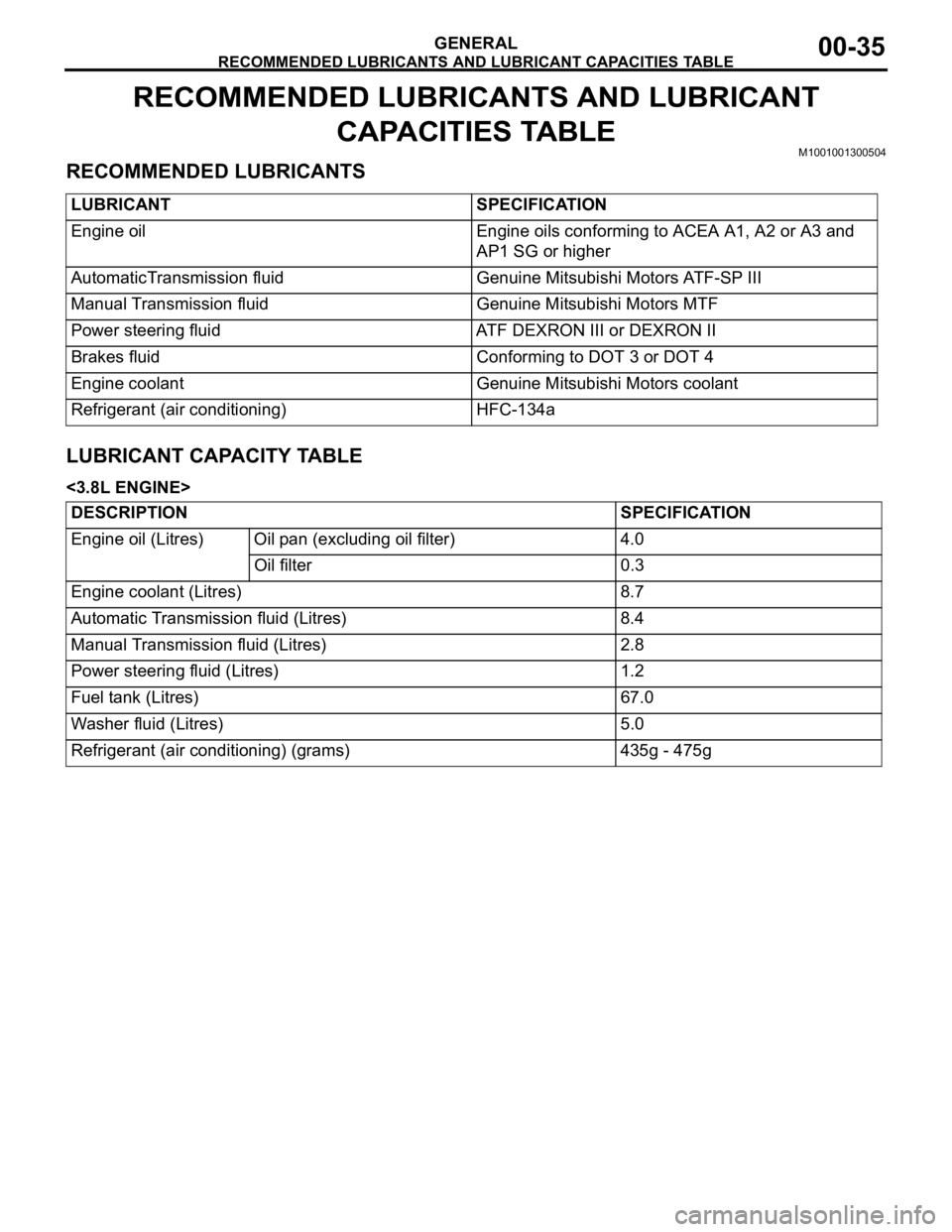

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITY TABLE

<3.8L ENGINE>LUBRICANT SPECIFICATION

Engine oil Engine oils conforming to ACEA A1, A2 or A3 and

AP1 SG or higher

AutomaticTransmission fluid Genuine Mitsubishi Motors ATF-SP III

Manual Transmission fluid Genuine Mitsubishi Motors MTF

Power steering fluid ATF DEXRON III or DEXRON II

Brakes fluid Conforming to DOT 3 or DOT 4

Engine coolant Genuine Mitsubishi Motors coolant

Refrigerant (air conditioning) HFC-134a

DESCRIPTION SPECIFICATION

Engine oil (Litres) Oil pan (excluding oil filter) 4.0

Oil filter 0.3

Engine coolant (Litres) 8.7

Automatic Transmission fluid (Litres) 8.4

Manual Transmission fluid (Litres) 2.8

Power steering fluid (Litres) 1.2

Fuel tank (Litres) 67.0

Washer fluid (Litres) 5.0

Refrigerant (air conditioning) (grams) 435g - 475g