engine MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1281 of 1500

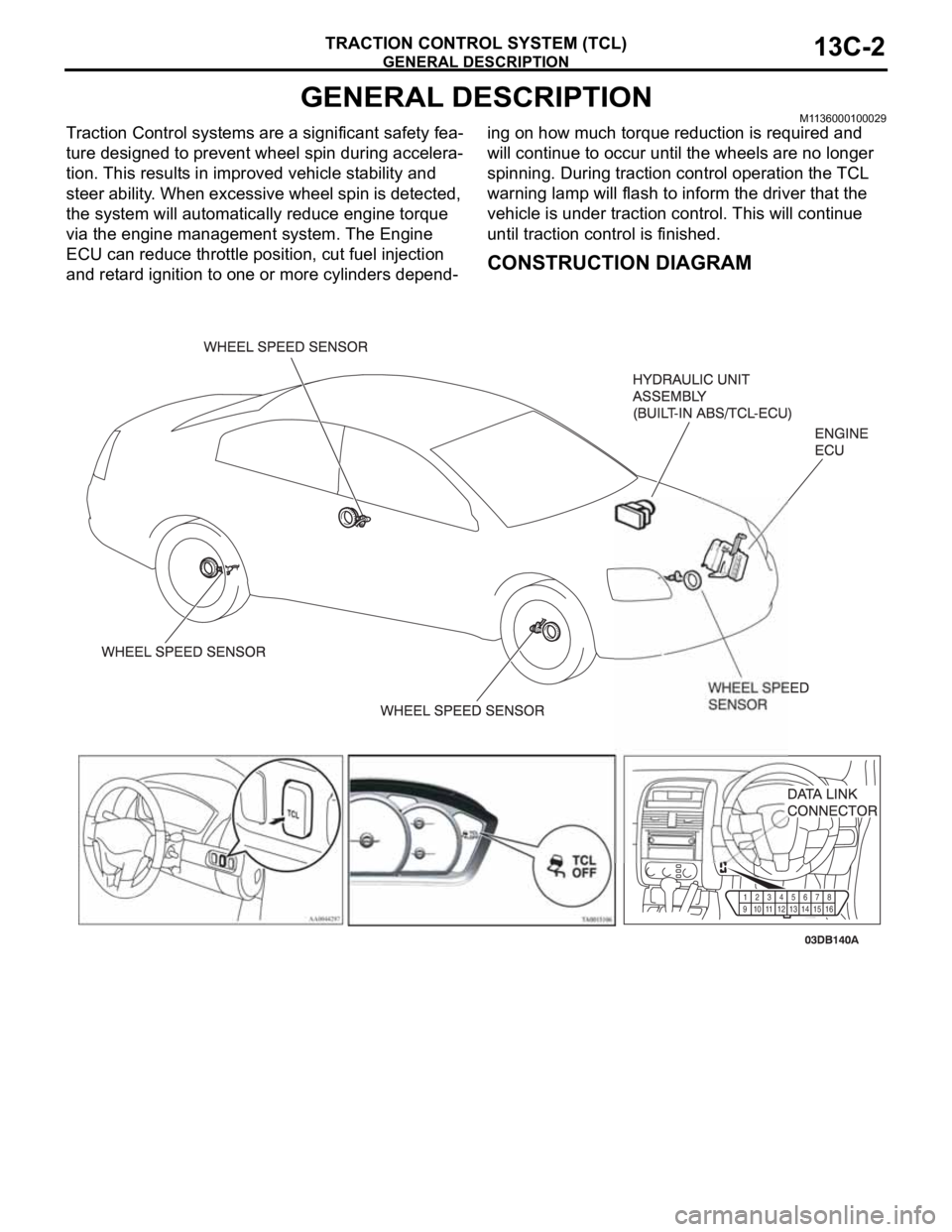

GENERAL DESCRIPTION

TRACTION CONTROL SYSTEM (TCL)13C-2

GENERAL DESCRIPTIONM1136000100029

Traction Control systems are a significant safety fea-

ture designed to prevent wheel spin during accelera-

tion. This results in improved vehicle stability and

steer ability. When excessive wheel spin is detected,

the system will automatically reduce engine torque

via the engine management system. The Engine

ECU can reduce throttle position, cut fuel injection

and retard ignition to one or more cylinders depend-ing on how much torque reduction is required and

will continue to occur until the wheels are no longer

spinning. During traction control operation the TCL

warning lamp will flash to inform the driver that the

vehicle is under traction control. This will continue

until traction control is finished.

CONSTRUCTION DIAGRAM

91011

1213141516 12345

678

Page 1282 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-3

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

INTRODUCTION TO TRACTION CONTROL SYSTEM (TCL) DIAGNOSISM1136004600026

TCL Diagnostic Trouble Code Detection

Conditions

TCL diagnostic trouble codes (TCL DTCs) are set

under different conditions, depending on the mal-

function detected. Most TCL DTCs will only be set

during vehicle operation. Some TCL DTCs will also

be set during the TCL self-check immediately after

the engine is started. When you check if an TCL DTC will be displayed again after the DTC has been

erased, you should recreate the TCL DTC set condi-

tions. Depending on the detection timing and set

conditions for the specific TCL DTC, you must either

drive the vehicle or turn the engine off and restart it.

To set the proper conditions for that DTC again, refer

to "TCL DTC SET CONDITIONS" for each TCL DTC

that you are trying to reset.

TROUBLESHOOTING STRATEGYM1136003100062

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will check most of the

possible causes of a TCL problem.

1. Gather information from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any TCL DTC. (Refer to

P.13C-3, Diagnosis Function

How to Read and

Erase Diagnostic Trouble Codes).

4. If you can verify the condition but no TCL DTCs

are set, and the malfunction may be intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunctions P.00-14).

5. If you can verify the condition but there is no TCL

DTCs, or the system cannot communicate with

diagnostic tool MB991958 (MUT-III sub

assembly), and find the fault. (Refer to P.13C-23,

Symptom Chart).6. If there is a TCL DTC, record the number of the

code, then erase the code from vehicle memory

using the diagnostic tool MB991958 (MUT-III sub

assembly). (Refer to P.13C-3, Diagnosis Function

How to Read and Erase Diagnostic Trouble

Codes).

7. Re-create the TCL DTC set conditions to see if

the same TCL DTC will set again. (Refer to

P.13C-3, Diagnosis Function

How to Read and

Erase Diagnostic Trouble Codes).

If the same TCL DTC sets again, perform the

diagnostic procedures for the set code. (Refer to

P.13C-8, Diagnostic Trouble Code Chart).

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wir-

ing is an open/ short circuit, the ABS 8 ECU

will shut off power supply to the respective

wheel speed sensor. All other wheel speed

sensors will operate normally. To restore the

power supply, the ignition switch must be

turned to the "OFF" position then to the "ON"

position again.

DIAGNOSIS FUNCTIONM1136003200025

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1289 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

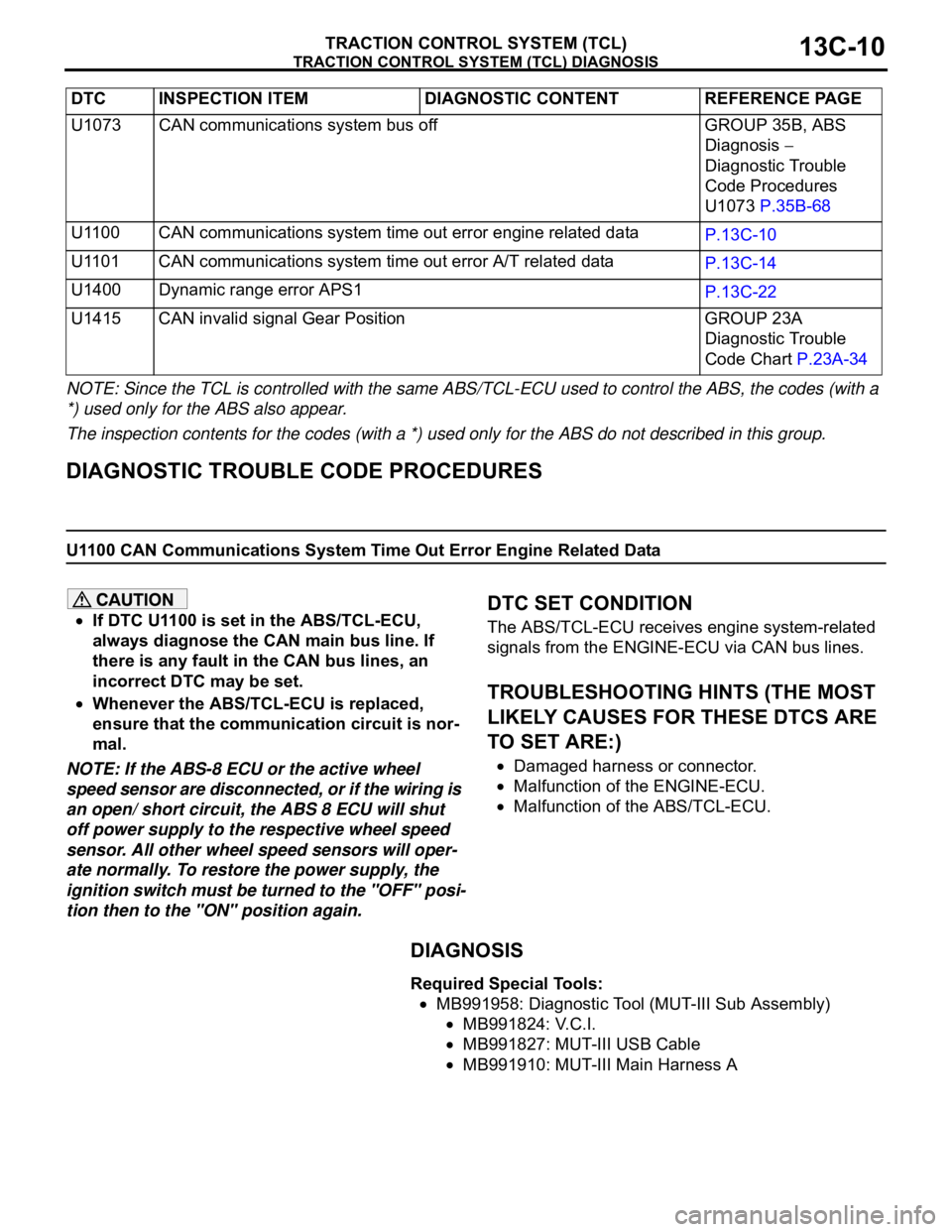

TRACTION CONTROL SYSTEM (TCL)13C-10

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the codes (with a

*) used only for the ABS also appear.

The inspection contents for the codes (with a *) used only for the ABS do not described in this group.

DIAGNOSTIC TROUBLE CODE PROCEDURES

U1100 CAN Communications System Time Out Error Engine Related Data

If DTC U1100 is set in the ABS/TCL-ECU,

always diagnose the CAN main bus line. If

there is any fault in the CAN bus lines, an

incorrect DTC may be set.

Whenever the ABS/TCL-ECU is replaced,

ensure that the communication circuit is nor-

mal.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

DTC SET CONDITION

The ABS/TCL-ECU receives engine system-related

signals from the ENGINE-ECU via CAN bus lines.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THESE DTCS ARE

TO SET ARE:)

Damaged harness or connector.

Malfunction of the ENGINE-ECU.

Malfunction of the ABS/TCL-ECU.

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A U1073 CAN communications system bus off GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

U1073 P.35B-68

U1100 CAN communications system time out error engine related data

P.13C-10

U1101 CAN communications system time out error A/T related data

P.13C-14

U1400 Dynamic range error APS1

P.13C-22

U1415 CAN invalid signal Gear Position GROUP 23A

Diagnostic Trouble

Code Chart P.23A-34 DTC INSPECTION ITEM DIAGNOSTIC CONTENT REFERENCE PAGE

Page 1291 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

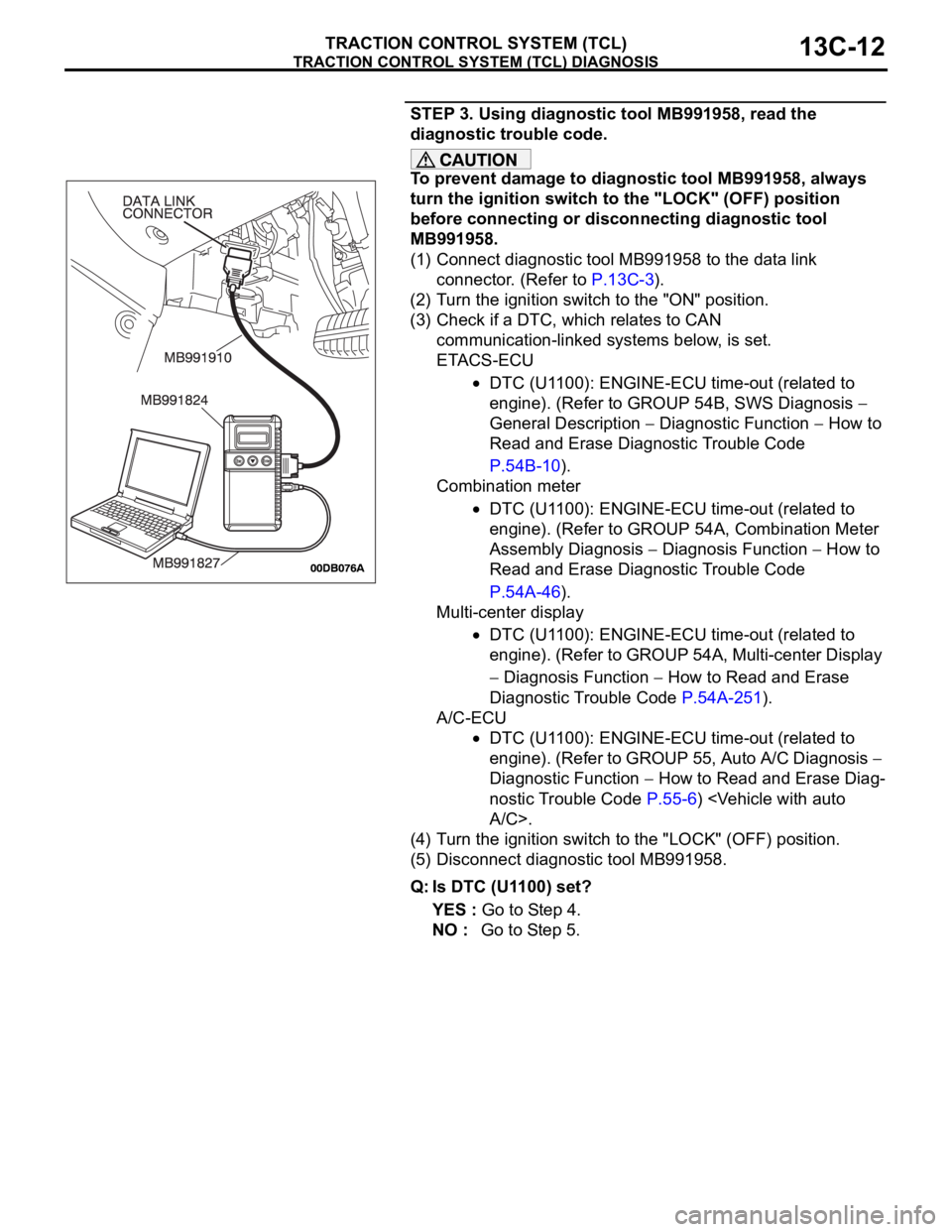

TRACTION CONTROL SYSTEM (TCL)13C-12

STEP 3. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Check if a DTC, which relates to CAN

communication-linked systems below, is set.

ETACS-ECU

DTC (U1100): ENGINE-ECU time-out (related to

engine). (Refer to GROUP 54B, SWS Diagnosis

General Description

Diagnostic Function How to

Read and Erase Diagnostic Trouble Code

P.54B-10).

Combination meter

DTC (U1100): ENGINE-ECU time-out (related to

engine). (Refer to GROUP 54A, Combination Meter

Assembly Diagnosis

Diagnosis Function How to

Read and Erase Diagnostic Trouble Code

P.54A-46).

Multi-center display

DTC (U1100): ENGINE-ECU time-out (related to

engine). (Refer to GROUP 54A, Multi-center Display

Diagnosis Function How to Read and Erase

Diagnostic Trouble Code P.54A-251).

A/C-ECU

DTC (U1100): ENGINE-ECU time-out (related to

engine). (Refer to GROUP 55, Auto A/C Diagnosis

Diagnostic Function

How to Read and Erase Diag-

nostic Trouble Code P.55-6)

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC (U1100) set?

YES : Go to Step 4.

NO : Go to Step 5.

Page 1292 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-13

STEP 4. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1100 set?

YES : Replace the Engine-ECU. [Refer to GROUP 13A,

Engine-ECU P.13A-675]. Then go to Step 6.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

STEP 5. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1100 set?

YES : Replace the hydraulic unit (integrated with

ABS/TCL-ECU). (Refer to GROUP 35B

Hydraulic

Unit P.35B-93). Then go to Step 6.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

Page 1296 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-17

STEP 4. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1101 set?

YES : Replace the Engine-ECU. [Refer to GROUP 13A,

Engine-ECU P.13A-675]. Then go to Step 6.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

STEP 5. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1101 set?

YES : Replace the hydraulic unit (integrated with

ABS/TCL-ECU). (Refer to GROUP 35B

Hydraulic

Unit P.35B-93). Then go to Step 6.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

Page 1297 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-18

STEP 6. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1101 set?

YES : Return to Step 1.

NO : The procedure is complete.

U1120 CAN Communications System TCL Uncontrollable by Engine Malfunction

If DTC U1120 is set in the ABS/TCL-ECU,

always diagnose the CAN main bus line. If

there is any fault in the CAN bus lines, an

incorrect DTC may be set.

Whenever the ABS/TCL-ECU is replaced,

ensure that the communication circuit is nor-

mal.

The engine control system-related DTC may

be set when DTC U1120 is set. (For details

refer to GROUP 00, Intersystem Affiliated DTC

Reference Table P.00-17). Diagnose the

engine control system first when the engine

control system-related DTC is set.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

DTC SET CONDITION

The ABS/TCL-ECU receives engine system-related

signals from the Engine-ECU via CAN bus lines. If a

fail-safe related data is contained in the signal from

the Engine-ECU, DTC U1120 will be stored.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THESE DTCS ARE

TO SET ARE:)

Damaged harness or connector.

Malfunction of the Engine-ECU.

Malfunction of the ABS/TCL-ECU.

Page 1299 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-20

STEP 2. Using diagnostic tool MB991958, diagnose the

CAN bus line.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 3.

NO : Repair the CAN bus lines. (Refer to GROUP 54C,

Diagnosis

Can Bus Diagnostic Chart P.54C-15).

Then go to Step 6.

STEP 3. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Check if a DTC, which relates to CAN

communication-linked systems below, is set.

A/C-ECU

DTC U1120: Failure Information on Engine-ECU

(related to engine). (Refer to GROUP 55, Auto A/C

Diagnosis

Diagnostic Function How to Read and

Erase Diagnostic Trouble Code P.55-6).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1120 set?

YES : Go to Step 4.

NO : Go to Step 5.

Page 1300 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-21

STEP 4. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1120 set?

YES : Replace the Engine-ECU. [Refer to GROUP 13A,

Engine-ECU P.13A-675]. Then go to Step 6.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

STEP 5. Using diagnostic tool MB991958, read the

diagnostic trouble code.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

(2) Turn the ignition switch to the "ON" position.

(3) Use diagnostic tool MB991958 to read the TCL diagnostic

trouble codes. (Refer to P.13C-3).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect diagnostic tool MB991958.

Q: Is DTC U1120 set?

YES : Replace the hydraulic unit (integrated with

ABS/TCL-ECU). (Refer to GROUP 35B

Hydraulic

Unit P.35B-93). Then go to Step 6.

NO : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

Page 1302 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-23

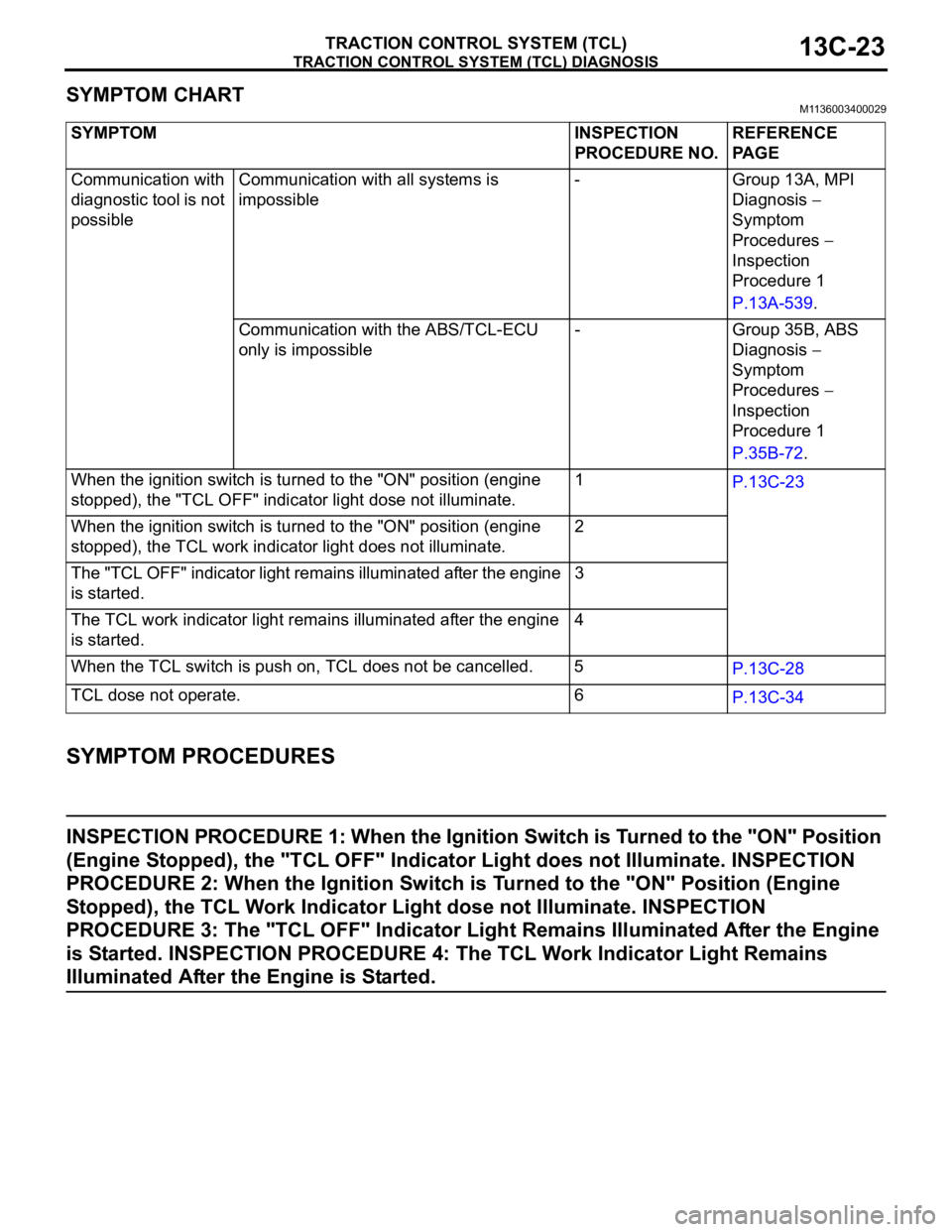

SYMPTOM CHARTM1136003400029

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: When the Ignition Switch is Turned to the "ON" Position

(Engine Stopped), the "TCL OFF" Indicator Light does not Illuminate. INSPECTION

PROCEDURE 2: When the Ignition Switch is Turned to the "ON" Position (Engine

Stopped), the TCL Work Indicator Light dose not Illuminate. INSPECTION

PROCEDURE 3: The "TCL OFF" Indicator Light Remains Illuminated After the Engine

is Started. INSPECTION PROCEDURE 4: The TCL Work Indicator Light Remains

Illuminated After the Engine is Started.

SYMPTOM INSPECTION

PROCEDURE NO.REFERENCE

PA G E

Communication with

diagnostic tool is not

possibleCommunication with all systems is

impossible- Group 13A, MPI

Diagnosis

Symptom

Procedures

Inspection

Procedure 1

P.13A-539.

Communication with the ABS/TCL-ECU

only is impossible- Group 35B, ABS

Diagnosis

Symptom

Procedures

Inspection

Procedure 1

P.35B-72.

When the ignition switch is turned to the "ON" position (engine

stopped), the "TCL OFF" indicator light dose not illuminate.1

P.13C-23

When the ignition switch is turned to the "ON" position (engine

stopped), the TCL work indicator light does not illuminate.2

The "TCL OFF" indicator light remains illuminated after the engine

is started.3

The TCL work indicator light remains illuminated after the engine

is started.4

When the TCL switch is push on, TCL does not be cancelled. 5

P.13C-28

TCL dose not operate. 6

P.13C-34