ESP MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 187 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-187

INSPECTION PROCEDURE D-5: Power Window: Front or rear passenger's power windows do not

work at all by operating the power window main switch.

.

CIRCUIT OPERATION

When you operate each power window switch for

front or rear passengers (incorporated in the power

window main switch), the corresponding power win-

dow motor operates, opening or closing each power

window.

.

TECHNICAL DESCRIPTION (COMMENT)

If the corresponding power window opens and closes

normally when each power window sub-switch is

operated, the power window main switch may be

defective.

.

TROUBLESHOOTING HINT

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The power window main switch may be defective

DIAGNOSIS

Check that power window sub switches operate normally.

Q: A power window cannot work by using the power

window main switch. Can you operate the power

window by using the corresponding power window sub

switch?

YES : Replace the power window main switch. Check that

the front or rear passenger's power window can work

normally by means of power window main switch.

NO : Refer to Symptom Chart P.54B-57 before resolving

this trouble.

KEYLESS ENTRY SYSTEM

GENERAL DESCRIPTION CONCERNING THE KEYLESS ENTRY SYSTEMM1549022000255

The following ECUs affect the functions and control

of the keyless entry system.

FUNCTIONCONTROL

ECU

All door lock function Pressing the transmitter lock button ETACS-ECU

Driver’s door unlock function Pressing the transmitter unlock button once ETACS-ECU

All door unlock function Pressing the transmitter unlock button twice ETACS-ECU

Trunk unlock function Pressing the transmitter trunk button twice ETACS-ECU

Keyless entry hazard answerback and horn answerback function ETACS-ECU

Timed locking mechanism ETACS-ECU

Page 704 of 1500

GENERAL DESCRIPTION

HEATER, AIR CONDITIONING AND VENTILATION55-3

GENERAL DESCRIPTIONM1552000100351

The heater and cooling units are combined in a sin-

gle unit, which, with the mode film damper and flow

rate control valve in the heater unit, reduces ventila-

tion resistance, increases fan power, and decreases

noise.

SAFETY PRECAUTIONS

Wear safety goggles and gloves when servic-

ing the refrigeration system to prevent

severe damage to eyes and hands.

Because R-134a refrigerant is a hydro fluorocarbon

(HFC) which contains hydrogen atoms in place of

chlorine atoms, it will not cause damage to the ozone

layer.

Ozone filters out harmful radiation from the sun. To

assist in protecting the ozone layer, Mitsubishi

Motors Corporation recommends an R-134a refriger-

ant recycling device.

Refrigerant R-134a is transparent and colorless in

both the liquid and vapor state. Since it has a boiling

point of

29.8C (21.64F) at atmospheric pressure,

it will be a vapor at all normal temperatures and pres-

sures. The vapor is heavier than air, non-flammable,

and non-explosive. The following precautions must

be observed when handling R-134a.

Do not heat R-134a above 40C (104.0F) or it

may catch fire and explode.

R-134a evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigeration

part of the A/C system. Keep a bottle of sterile min-

eral oil handy when working on the refrigeration sys-

tem.1. If any liquid refrigerant gets into your eyes, use a

few drops of mineral oil to wash them out. R-134a

is rapidly absorbed by the oil.

2. Next, splash your eyes with plenty of cold water.

3. Call your doctor immediately even if irritation has

ceased.

Keep R-134a containers upright when charging

the system.

In most instances, moderate heat is required to bring

the pressure of the refrigerant in its container above

the pressure of the system when charging or adding

refrigerant.

A bucket or large pan of hot water not over 40

C

(104.0

F) is all the heat required for this purpose. Do

not heat the refrigerant container with a blow torch or

any other means that would raise temperature and

pressure above this temperature. Do not weld or

steam-clean on or near the system components or

refrigerant lines.

A leak detector for R-134a should be used to

check for refrigerant gas leaks.

Do not allow liquid refrigerant to touch bright

metal or it will be stained.

When metering R-134a into the refrigeration system,

keep the supply tank or cans in an upright position. If

the refrigerant container is on its side or upside

down, liquid refrigerant will enter the system and

damage the compressor.

Refrigerant will tarnish bright metal and chrome sur-

faces, and in combination with moisture can severely

corrode all metal surfaces. ITEM SPECIFICATION

Heater control assembly Dial type

Compressor 10S17

Compressor Model Swashplate type

Refrigerant and quantity (g) R-134a (HFC-134a), 435

475

Page 772 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-71

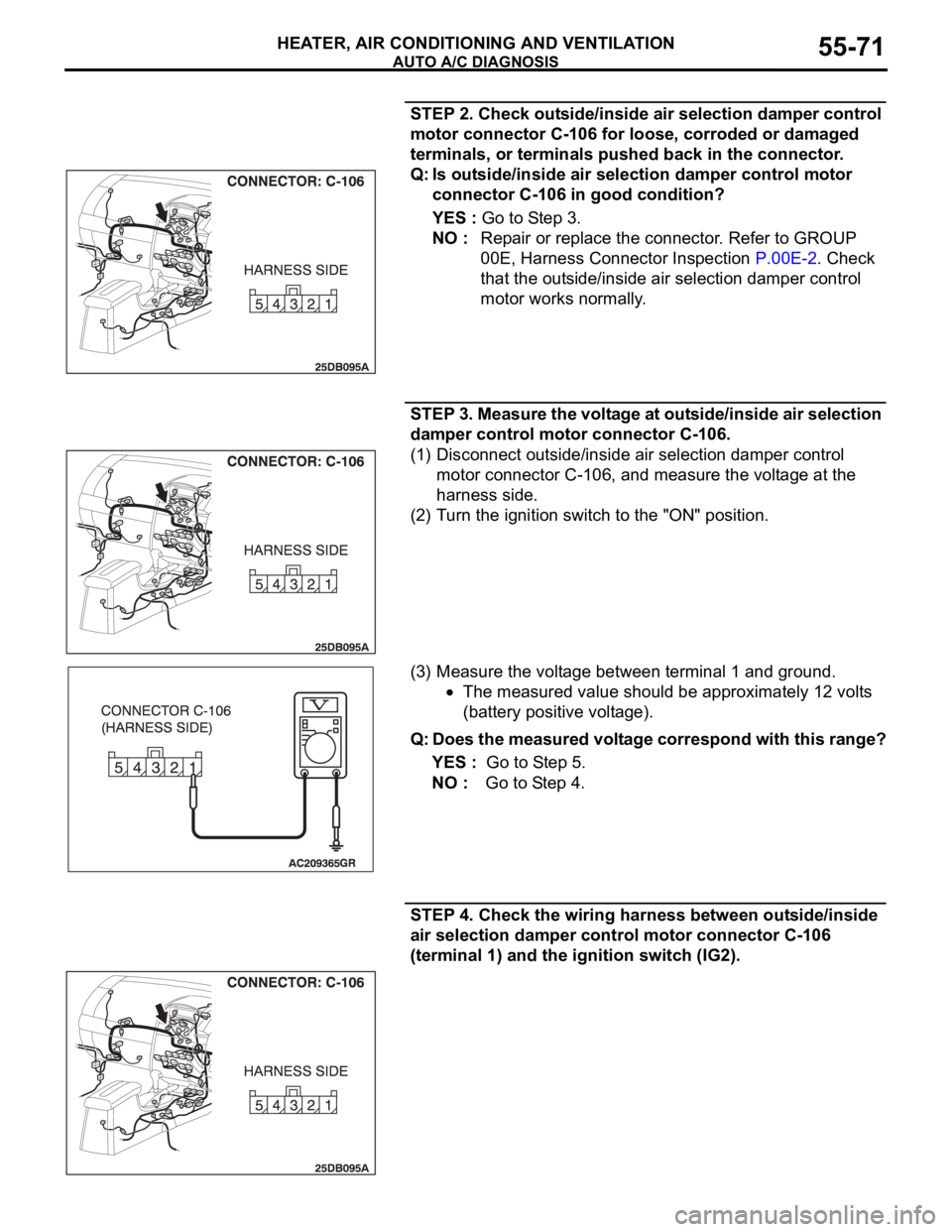

STEP 2. Check outside/inside air selection damper control

motor connector C-106 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Is outside/inside air selection damper control motor

connector C-106 in good condition?

YES : Go to Step 3.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Check

that the outside/inside air selection damper control

motor works normally.

STEP 3. Measure the voltage at outside/inside air selection

damper control motor connector C-106.

(1) Disconnect outside/inside air selection damper control

motor connector C-106, and measure the voltage at the

harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 1 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Does the measured voltage correspond with this range?

YES : Go to Step 5.

NO : Go to Step 4.

STEP 4. Check the wiring harness between outside/inside

air selection damper control motor connector C-106

(terminal 1) and the ignition switch (IG2).

Page 786 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-85

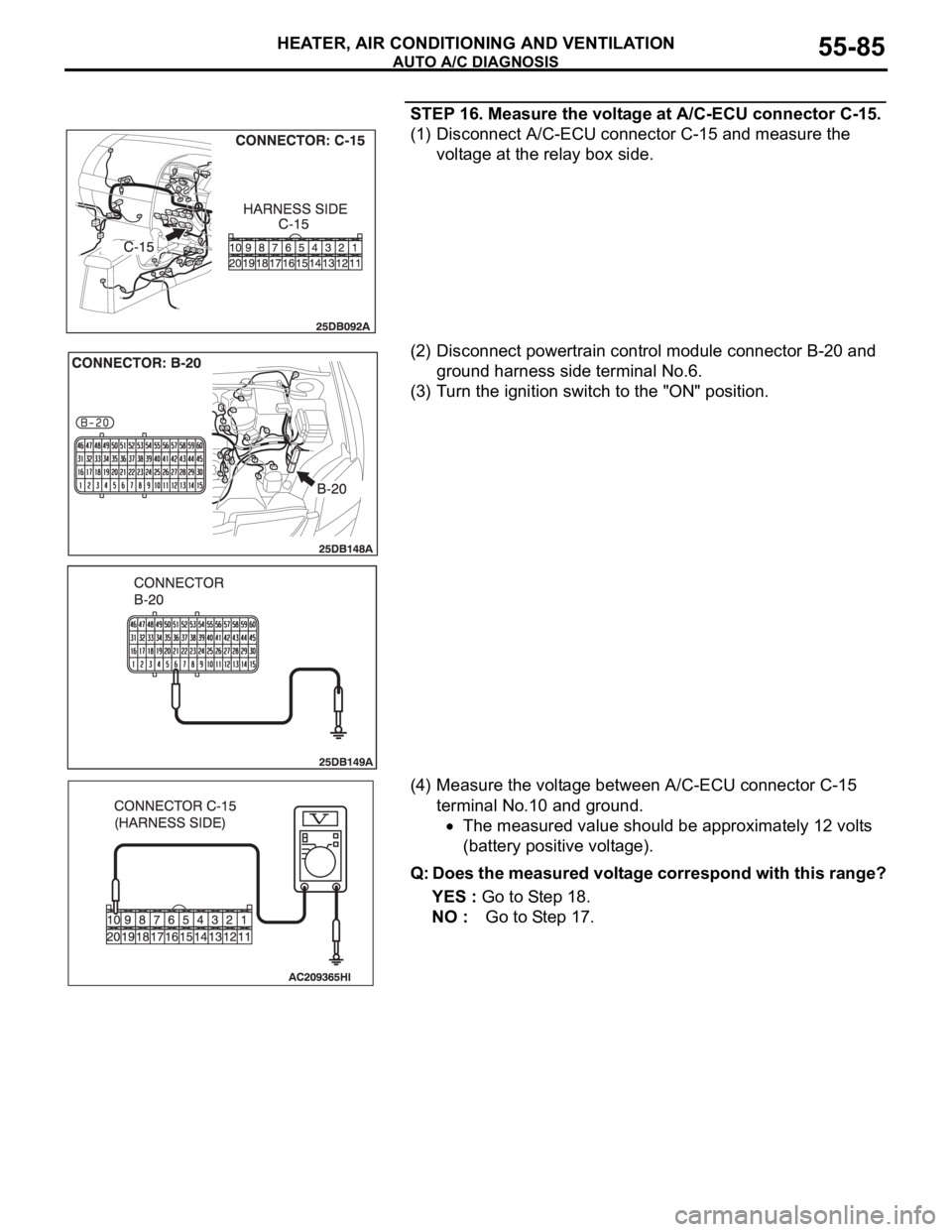

STEP 16. Measure the voltage at A/C-ECU connector C-15.

(1) Disconnect A/C-ECU connector C-15 and measure the

voltage at the relay box side.

(2) Disconnect powertrain control module connector B-20 and

ground harness side terminal No.6.

(3) Turn the ignition switch to the "ON" position.

(4) Measure the voltage between A/C-ECU connector C-15

terminal No.10 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Does the measured voltage correspond with this range?

YES : Go to Step 18.

NO : Go to Step 17.

Page 799 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-98

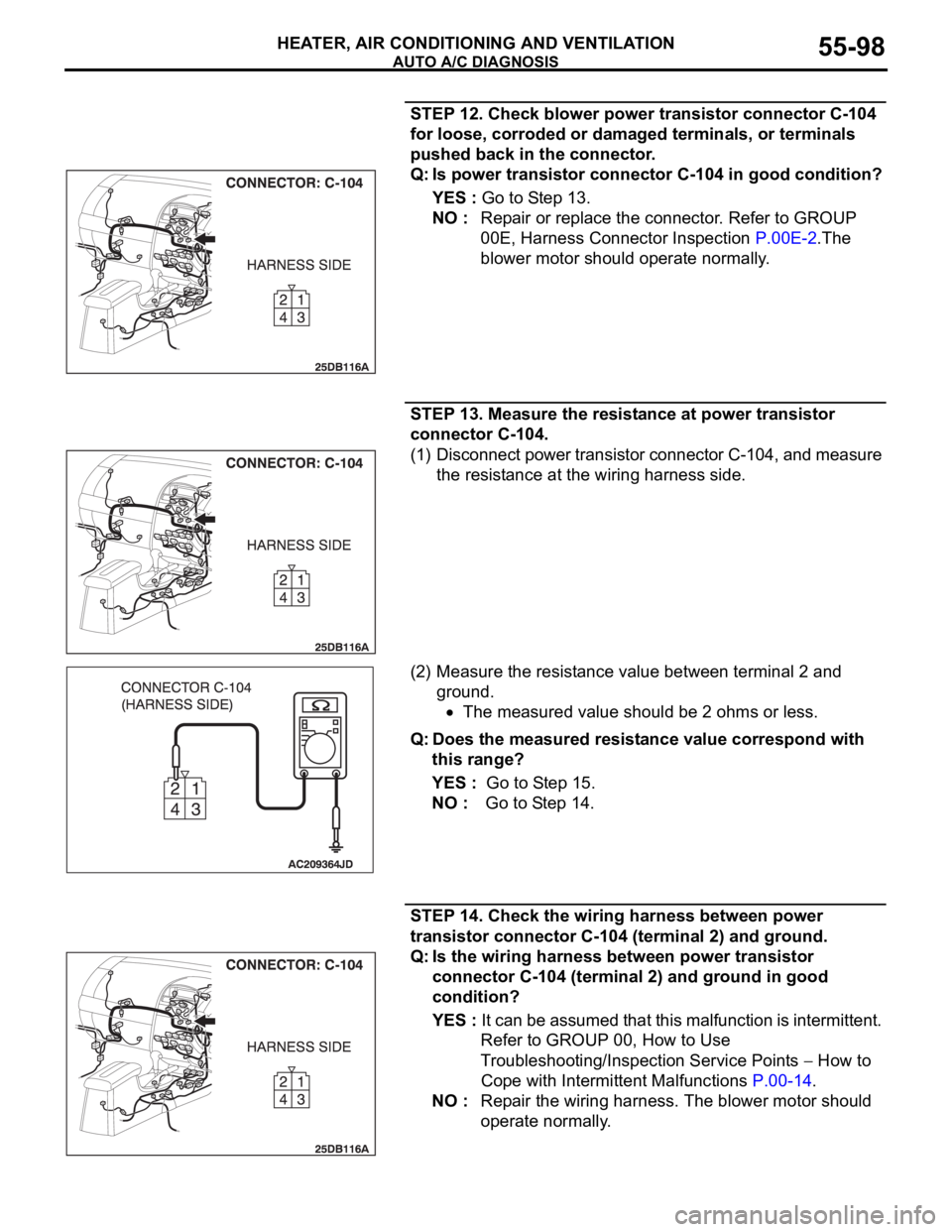

STEP 12. Check blower power transistor connector C-104

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power transistor connector C-104 in good condition?

YES : Go to Step 13.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2.The

blower motor should operate normally.

STEP 13. Measure the resistance at power transistor

connector C-104.

(1) Disconnect power transistor connector C-104, and measure

the resistance at the wiring harness side.

(2) Measure the resistance value between terminal 2 and

ground.

The measured value should be 2 ohms or less.

Q: Does the measured resistance value correspond with

this range?

YES : Go to Step 15.

NO : Go to Step 14.

STEP 14. Check the wiring harness between power

transistor connector C-104 (terminal 2) and ground.

Q: Is the wiring harness between power transistor

connector C-104 (terminal 2) and ground in good

condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. The blower motor should

operate normally.

Page 802 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-101

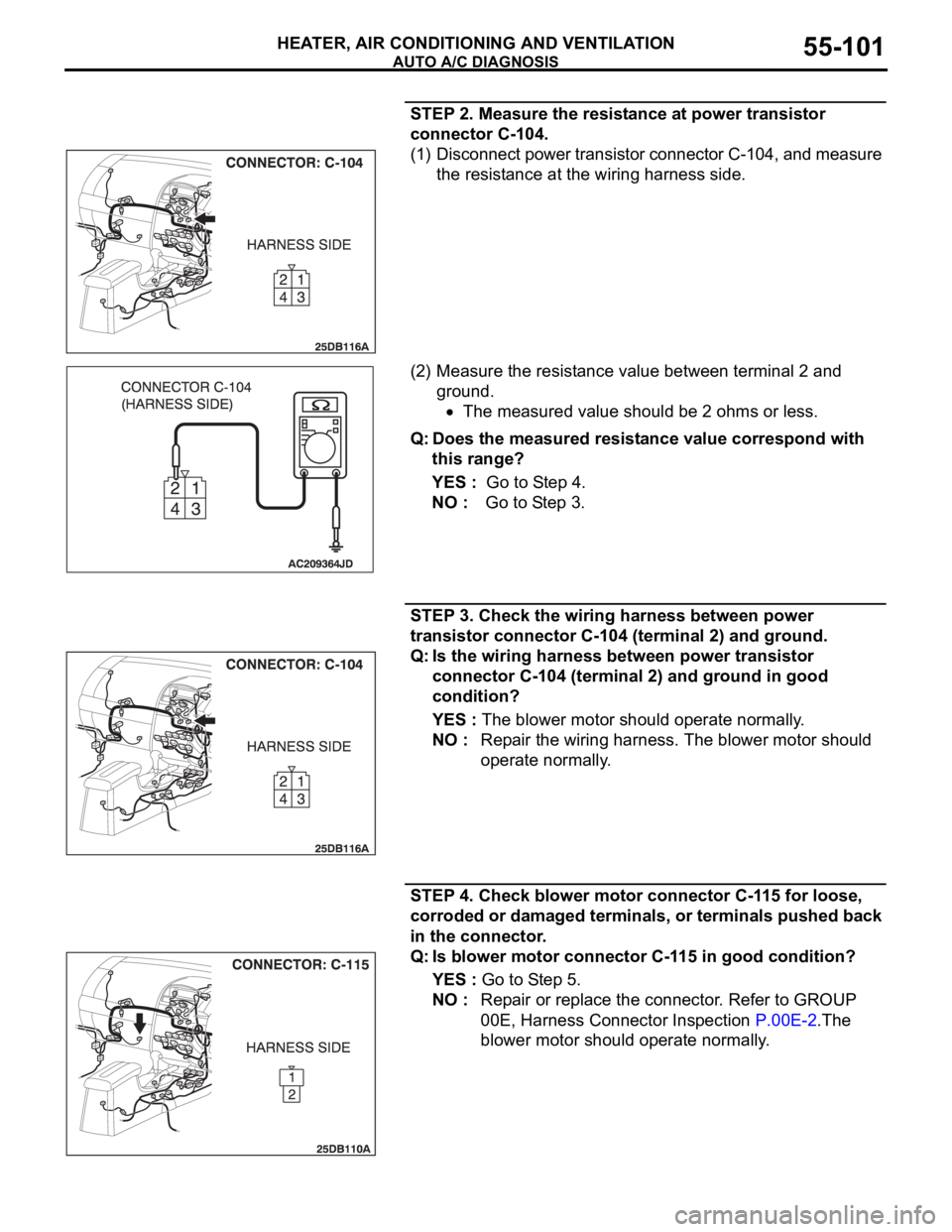

STEP 2. Measure the resistance at power transistor

connector C-104.

(1) Disconnect power transistor connector C-104, and measure

the resistance at the wiring harness side.

(2) Measure the resistance value between terminal 2 and

ground.

The measured value should be 2 ohms or less.

Q: Does the measured resistance value correspond with

this range?

YES : Go to Step 4.

NO : Go to Step 3.

STEP 3. Check the wiring harness between power

transistor connector C-104 (terminal 2) and ground.

Q: Is the wiring harness between power transistor

connector C-104 (terminal 2) and ground in good

condition?

YES : The blower motor should operate normally.

NO : Repair the wiring harness. The blower motor should

operate normally.

STEP 4. Check blower motor connector C-115 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is blower motor connector C-115 in good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2.The

blower motor should operate normally.

Page 828 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-127

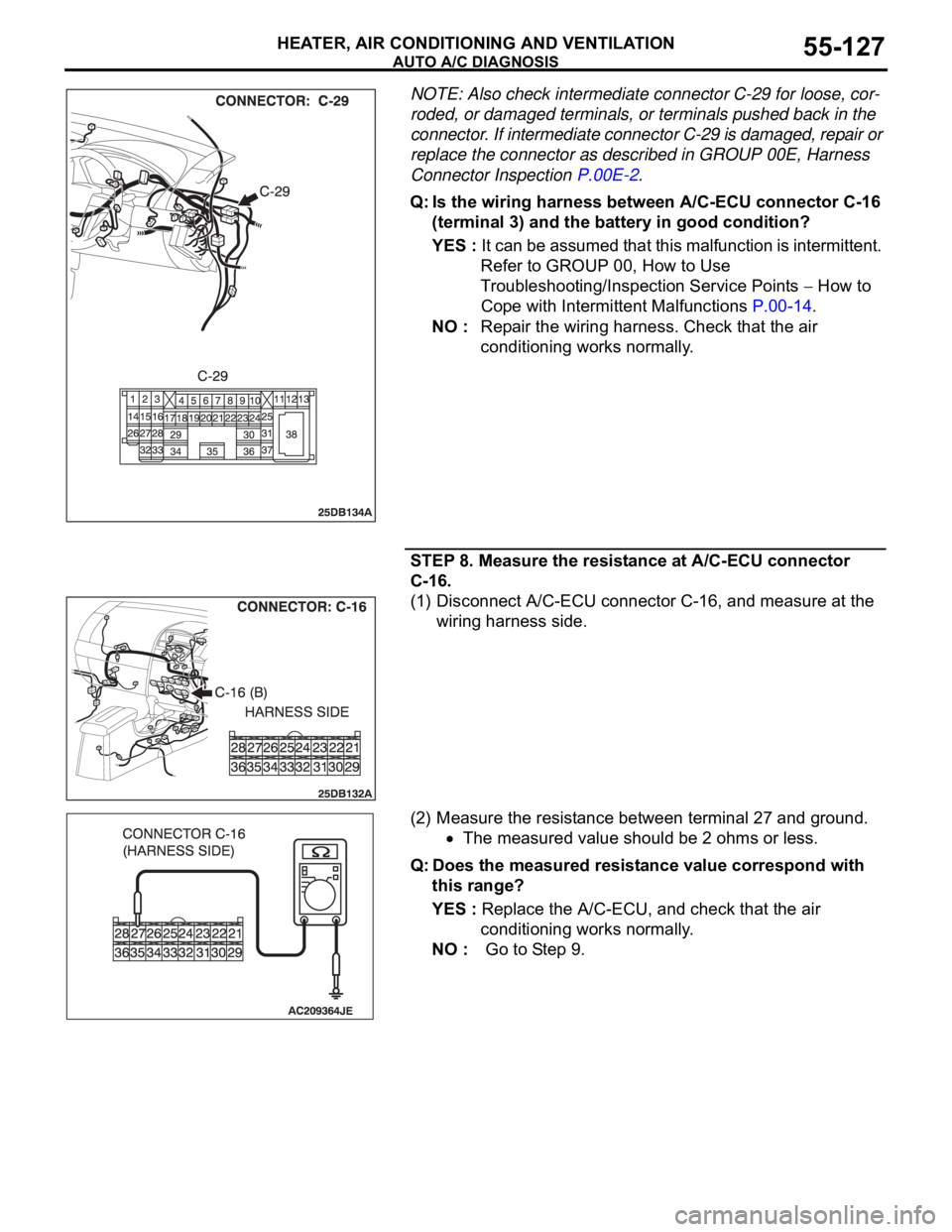

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C-ECU connector C-16

(terminal 3) and the battery in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 8. Measure the resistance at A/C-ECU connector

C-16.

(1) Disconnect A/C-ECU connector C-16, and measure at the

wiring harness side.

(2) Measure the resistance between terminal 27 and ground.

The measured value should be 2 ohms or less.

Q: Does the measured resistance value correspond with

this range?

YES : Replace the A/C-ECU, and check that the air

conditioning works normally.

NO : Go to Step 9.

Page 835 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-134

Air outlet c/o

potentiometer55 Mode selection

damper control

motor potentiometerIgnition switch: ON Damper

positionOpening degree (V)

FA C E A p pr o x . 5

FOOT Approx. 3.75

FOOT/DEF. Approx. 2.5

DEF. Approx. 1.75

Air outlet c/o

potentiometer

(target)56 Target value for

mode selection

damper control

motor potentiometerIgnition switch: ON Damper

positionOpening degree (V)

FA C E A p pr o x . 5

FOOT Approx. 3.75

FOOT/DEF. Approx. 2.5

DEF. Approx. 1.75

In/out air

changeover

damper motor65 Outside/inside air

selection damper

control motorIgnition switch: ON Damper set

positionDamper position

Fresh air

positionFRESH

Air recirculation

positionRECIRC

Front blower fan 68 Blower motor Ignition switch: ON The actual air

volume (blower

motor speed)

corresponds to the

air volume shown on

the diagnostic tool.

Front blower

motor voltage 71 Blower motor Ignition switch: ON The air volume set

by the heater control

corresponds to the

value shown on the

diagnostic tool. (V)

Air conditioning

switch state1 Air conditioning

switchIgnition switch: ON Air conditioning

switch: ONDiagnostic tool

indication: "pressed"

Air conditioning

switch: OFFDiagnostic tool

indication: "release"

Rear defogger

switch state7 Rear window

defogger switchIgnition switch: ON Rear window

defogger

switch: ONDiagnostic tool

indication: "pressed"

Rear window

defogger

switch: OFFDiagnostic tool

indication: "release"

Refrigerant

pressure73 Refrigerant pressure Ignition switch: ON The diagnostic tool

indication is normal MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Page 836 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-135

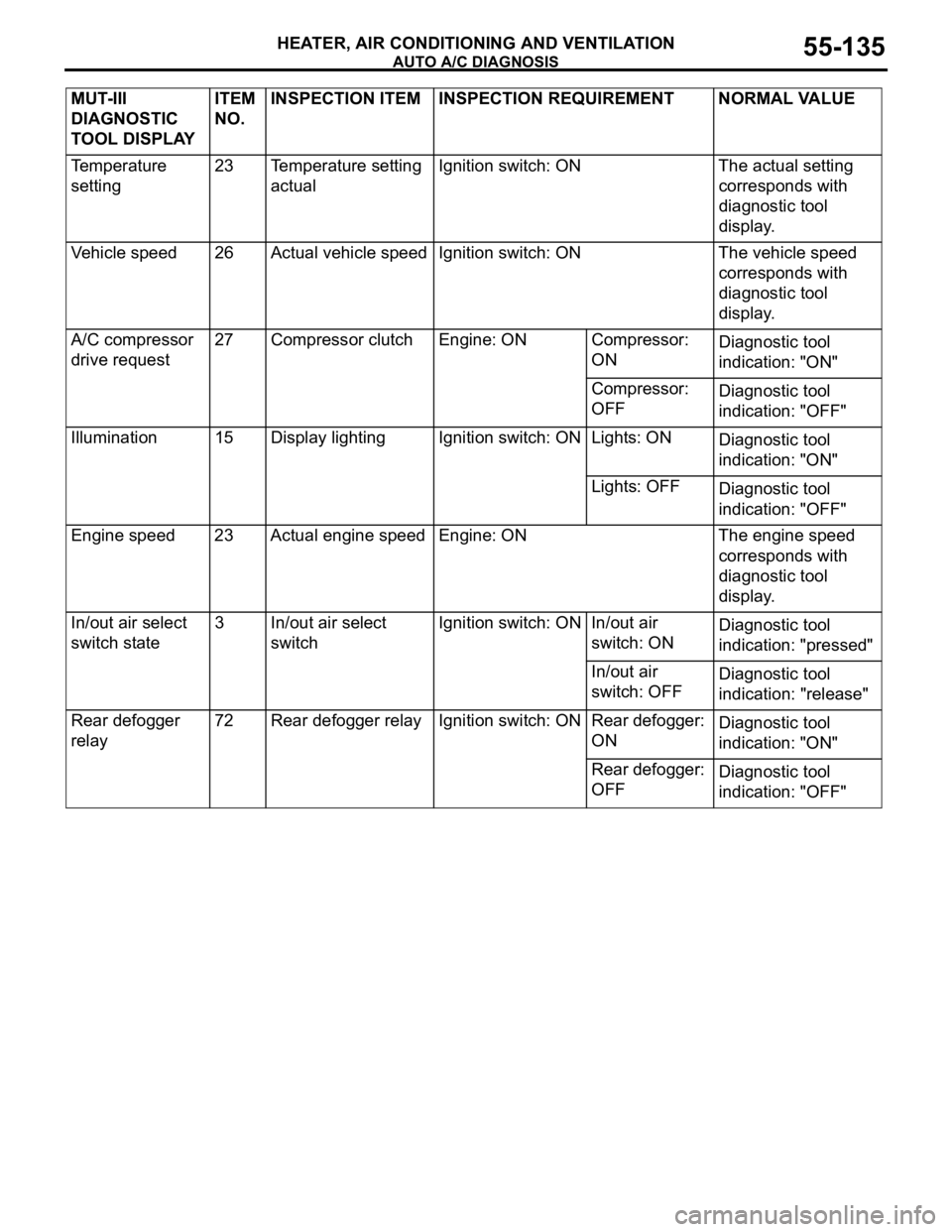

Temperature

setting23 Temperature setting

actualIgnition switch: ON The actual setting

corresponds with

diagnostic tool

display.

Vehicle speed 26 Actual vehicle speed Ignition switch: ON The vehicle speed

corresponds with

diagnostic tool

display.

A/C compressor

drive request27 Compressor clutch Engine: ON

Compressor:

ONDiagnostic tool

indication: "ON"

Compressor:

OFFDiagnostic tool

indication: "OFF"

Illumination 15 Display lighting Ignition switch: ON

Lights: ON

Diagnostic tool

indication: "ON"

Lights: OFF

Diagnostic tool

indication: "OFF"

Engine speed 23 Actual engine speed Engine: ON The engine speed

corresponds with

diagnostic tool

display.

In/out air select

switch state3 In/out air select

switch Ignition switch: ON In/out air

switch: ONDiagnostic tool

indication: "pressed"

In/out air

switch: OFFDiagnostic tool

indication: "release"

Rear defogger

relay72 Rear defogger relay Ignition switch: ON

Rear defogger:

ONDiagnostic tool

indication: "ON"

Rear defogger:

OFFDiagnostic tool

indication: "OFF" MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Page 846 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-145

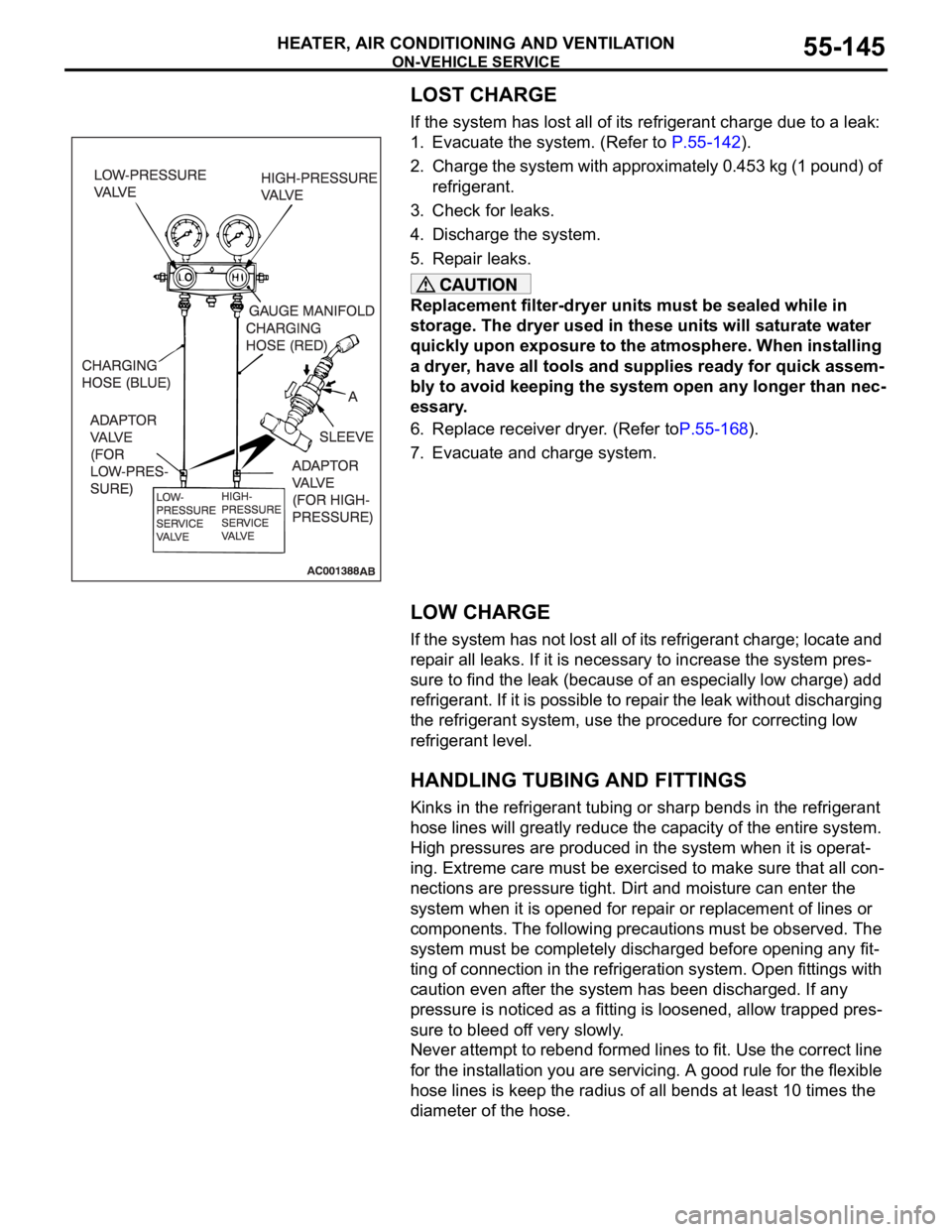

LOST CHARGE

If the system has lost all of its refrigerant charge due to a leak:

1. Evacuate the system. (Refer to P.55-142).

2. Charge the system with approximately 0.453 kg (1 pound) of

refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

Replacement filter-dryer units must be sealed while in

storage. The dryer used in these units will saturate water

quickly upon exposure to the atmosphere. When installing

a dryer, have all tools and supplies ready for quick assem-

bly to avoid keeping the system open any longer than nec-

essary.

6. Replace receiver dryer. (Refer toP.55-168).

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge; locate and

repair all leaks. If it is necessary to increase the system pres-

sure to find the leak (because of an especially low charge) add

refrigerant. If it is possible to repair the leak without discharging

the refrigerant system, use the procedure for correcting low

refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the refrigerant

hose lines will greatly reduce the capacity of the entire system.

High pressures are produced in the system when it is operat-

ing. Extreme care must be exercised to make sure that all con-

nections are pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of lines or

components. The following precautions must be observed. The

system must be completely discharged before opening any fit-

ting of connection in the refrigeration system. Open fittings with

caution even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow trapped pres-

sure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the correct line

for the installation you are servicing. A good rule for the flexible

hose lines is keep the radius of all bends at least 10 times the

diameter of the hose.