engine MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1407 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-76

EMISSION CONTROL

GENERAL DESCRIPTIONM1173000100314

The emission control system consists of the fol-

lowing subsystems:

Positive crankcase ventilation system

Evaporative emission system

Exhaust emission control system

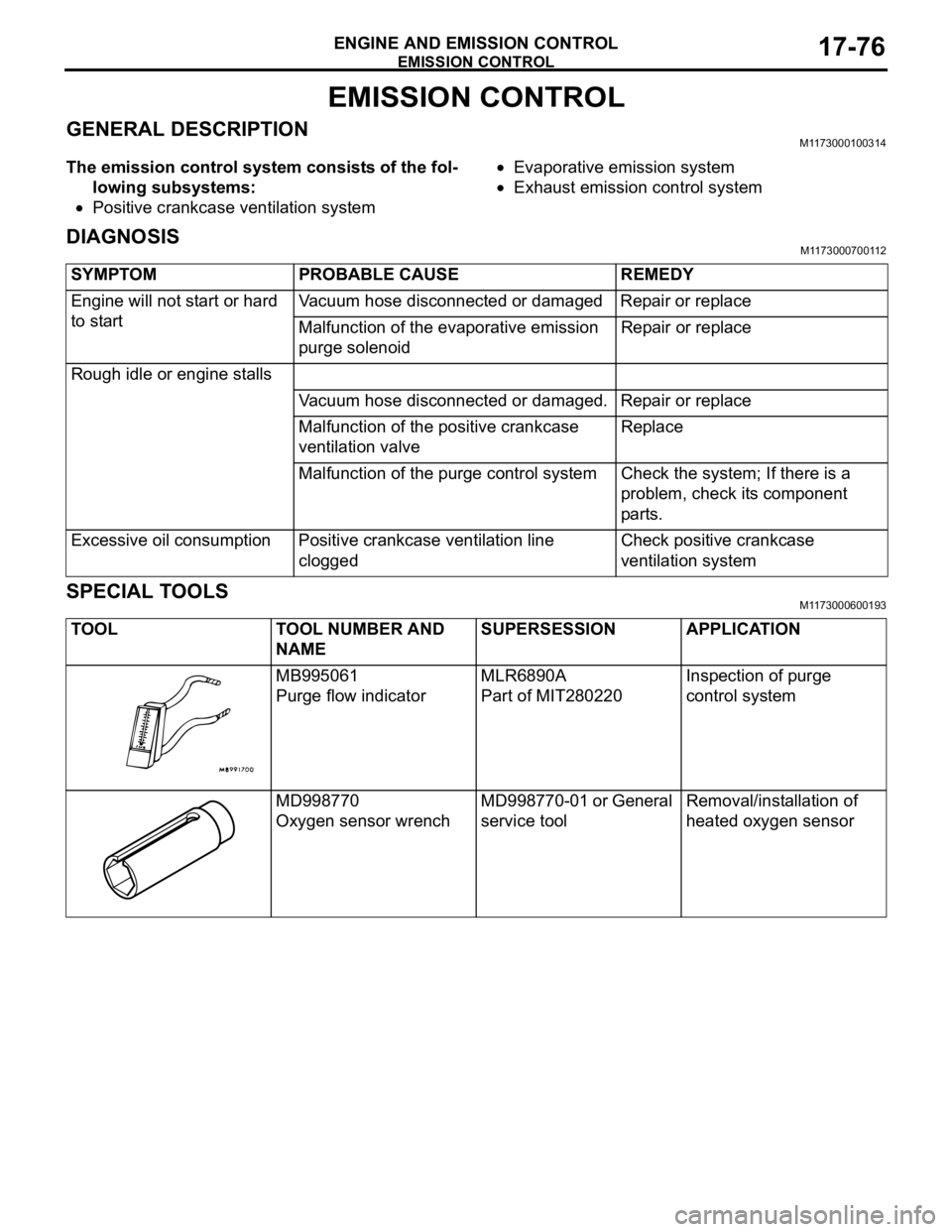

DIAGNOSISM1173000700112

SPECIAL TOOLSM1173000600193

SYMPTOM PROBABLE CAUSE REMEDY

Engine will not start or hard

to startVacuum hose disconnected or damaged Repair or replace

Malfunction of the evaporative emission

purge solenoidRepair or replace

Rough idle or engine stalls

Vacuum hose disconnected or damaged. Repair or replace

Malfunction of the positive crankcase

ventilation valveReplace

Malfunction of the purge control system Check the system; If there is a

problem, check its component

parts.

Excessive oil consumption Positive crankcase ventilation line

cloggedCheck positive crankcase

ventilation system

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB995061

Purge flow indicatorMLR6890A

Part of MIT280220Inspection of purge

control system

MD998770

Oxygen sensor wrenchMD998770-01 or General

service toolRemoval/installation of

heated oxygen sensor

Page 1408 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-77

VACUUM HOSES

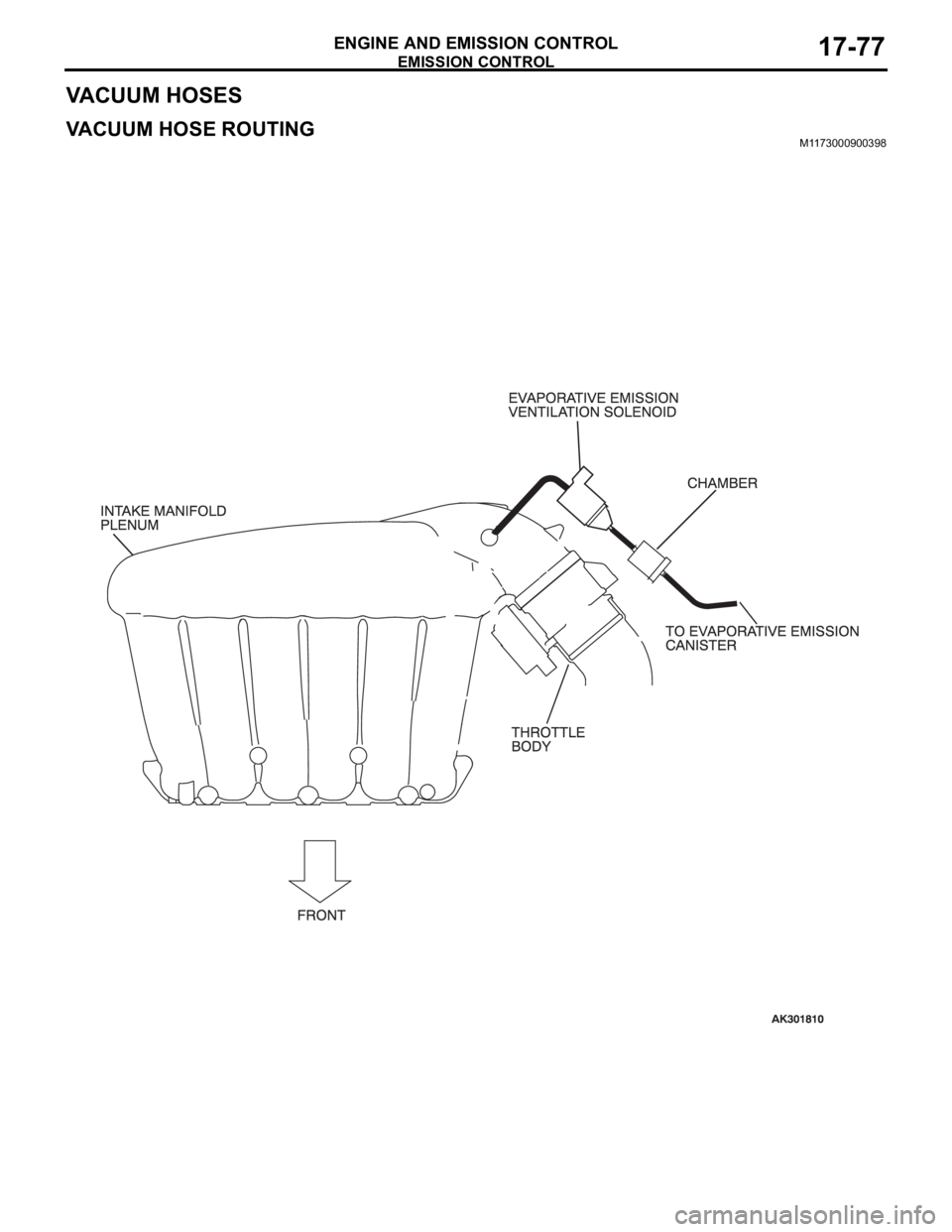

VACUUM HOSE ROUTINGM1173000900398

Page 1409 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-78

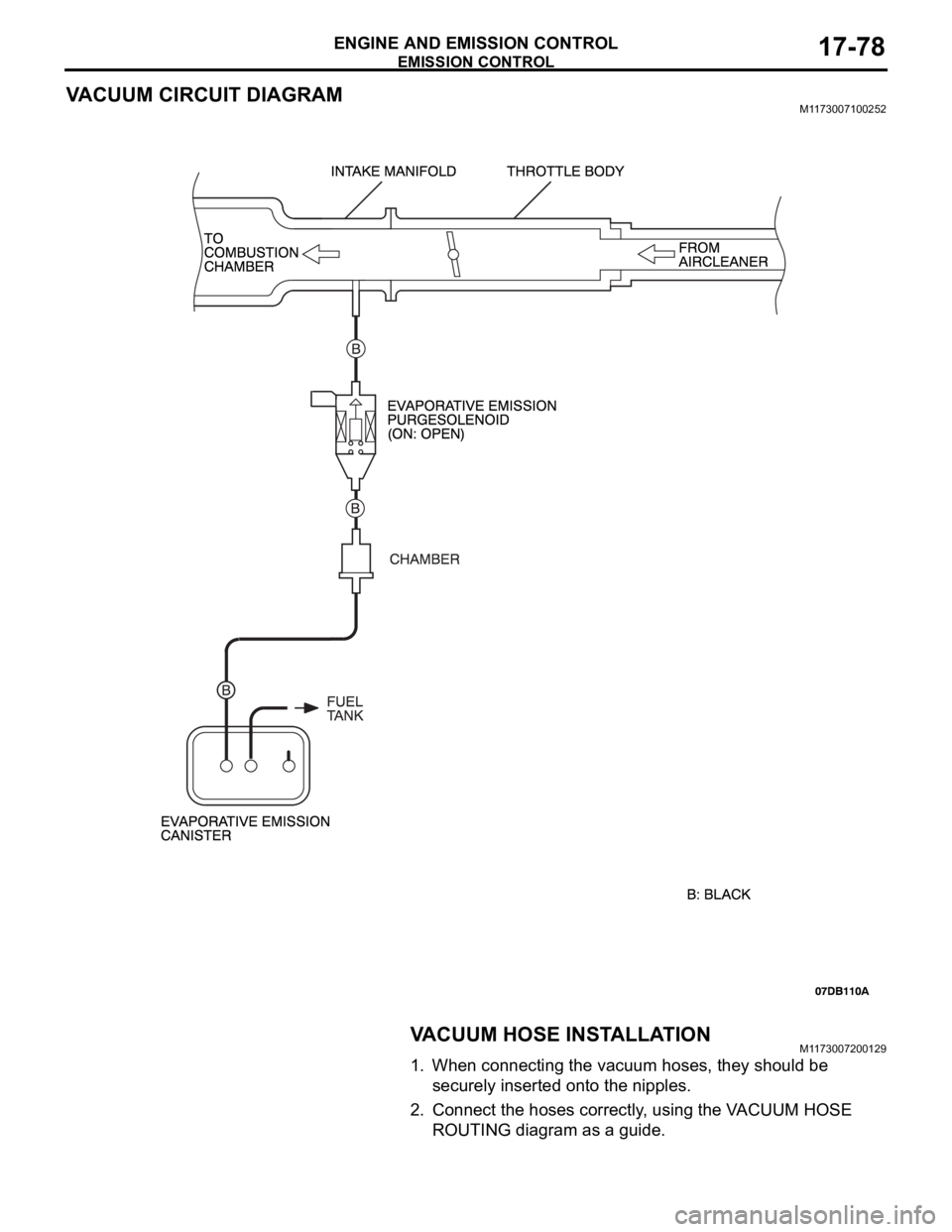

VACUUM CIRCUIT DIAGRAMM1173007100252

VACUUM HOSE INSTALLATIONM1173007200129

1. When connecting the vacuum hoses, they should be

securely inserted onto the nipples.

2. Connect the hoses correctly, using the VACUUM HOSE

ROUTING diagram as a guide.

Page 1410 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-79

VACUUM HOSE CHECKM1173007300171

1. Using the VACUUM HOSE ROUTING diagram as a guide,

check that the vacuum hoses are correctly connected.

2. Check the connection of the vacuum hoses, (removed,

loose, etc.) and confirm that there are no sharp bends or

damage.

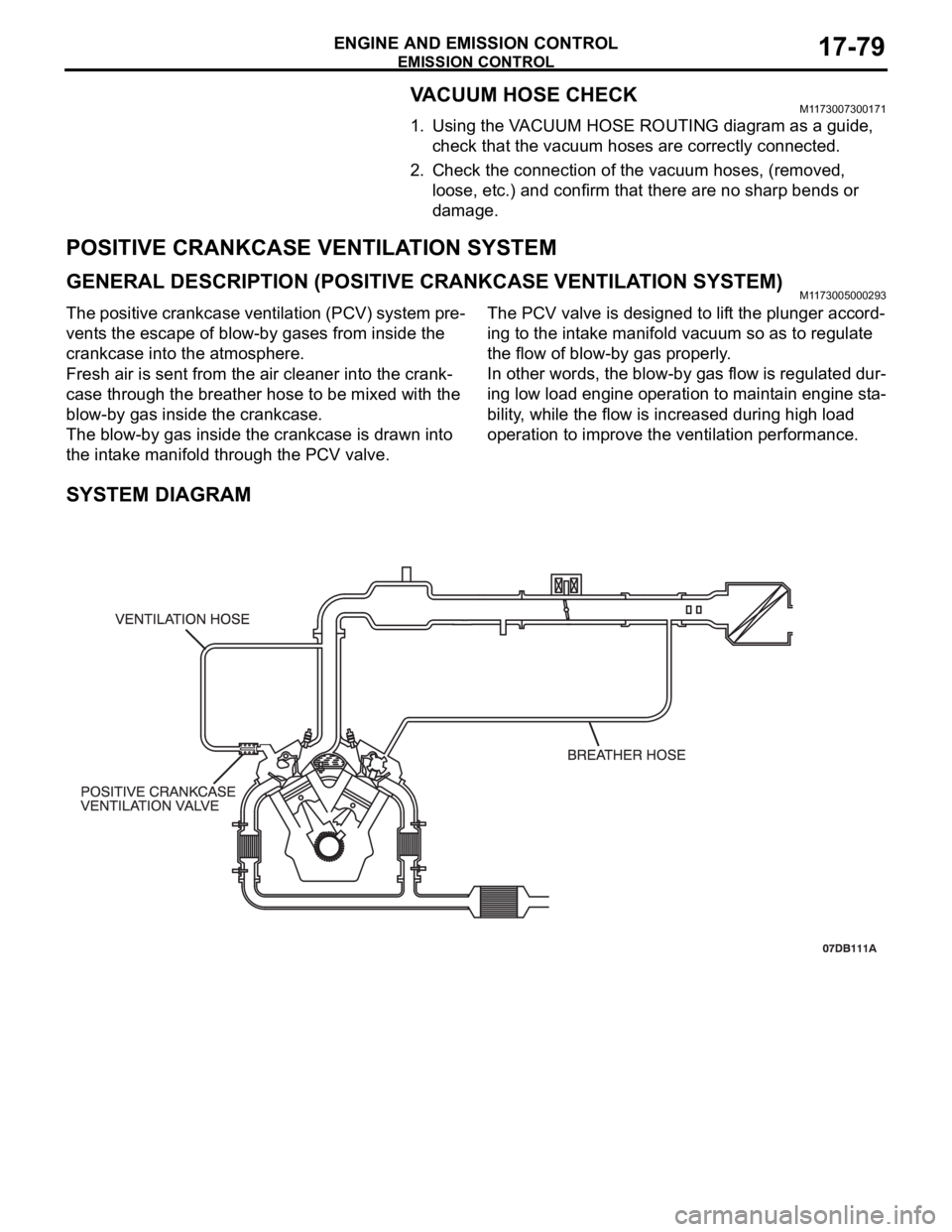

POSITIVE CRANKCASE VENTILATION SYSTEM

GENERAL DESCRIPTION (POSITIVE CRANKCASE VENTILATION SYSTEM)M1173005000293

The positive crankcase ventilation (PCV) system pre-

vents the escape of blow-by gases from inside the

crankcase into the atmosphere.

Fresh air is sent from the air cleaner into the crank-

case through the breather hose to be mixed with the

blow-by gas inside the crankcase.

The blow-by gas inside the crankcase is drawn into

the intake manifold through the PCV valve.The PCV valve is designed to lift the plunger accord-

ing to the intake manifold vacuum so as to regulate

the flow of blow-by gas properly.

In other words, the blow-by gas flow is regulated dur-

ing low load engine operation to maintain engine sta-

bility, while the flow is increased during high load

operation to improve the ventilation performance.

SYSTEM DIAGRAM

Page 1411 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-80

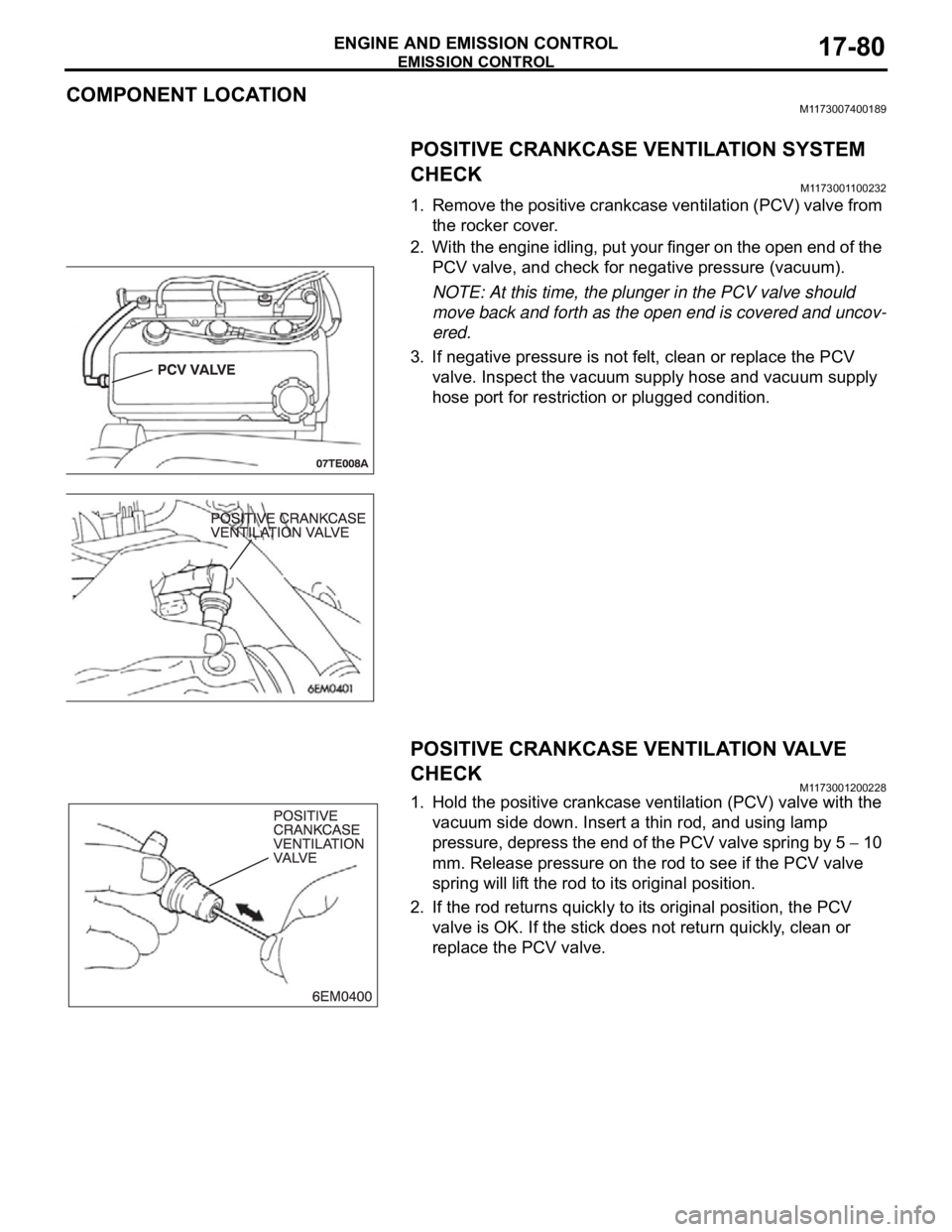

COMPONENT LOCATIONM1173007400189

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK

M1173001100232

1. Remove the positive crankcase ventilation (PCV) valve from

the rocker cover.

2. With the engine idling, put your finger on the open end of the

PCV valve, and check for negative pressure (vacuum).

NOTE: At this time, the plunger in the PCV valve should

move back and forth as the open end is covered and uncov-

ered.

3. If negative pressure is not felt, clean or replace the PCV

valve. Inspect the vacuum supply hose and vacuum supply

hose port for restriction or plugged condition.

POSITIVE CRANKCASE VENTILATION VALVE

CHECK

M1173001200228

1. Hold the positive crankcase ventilation (PCV) valve with the

vacuum side down. Insert a thin rod, and using lamp

pressure, depress the end of the PCV valve spring by 5

10

mm. Release pressure on the rod to see if the PCV valve

spring will lift the rod to its original position.

2. If the rod returns quickly to its original position, the PCV

valve is OK. If the stick does not return quickly, clean or

replace the PCV valve.

Page 1412 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-81

EVAPORATIVE EMISSION CONTROL SYSTEM

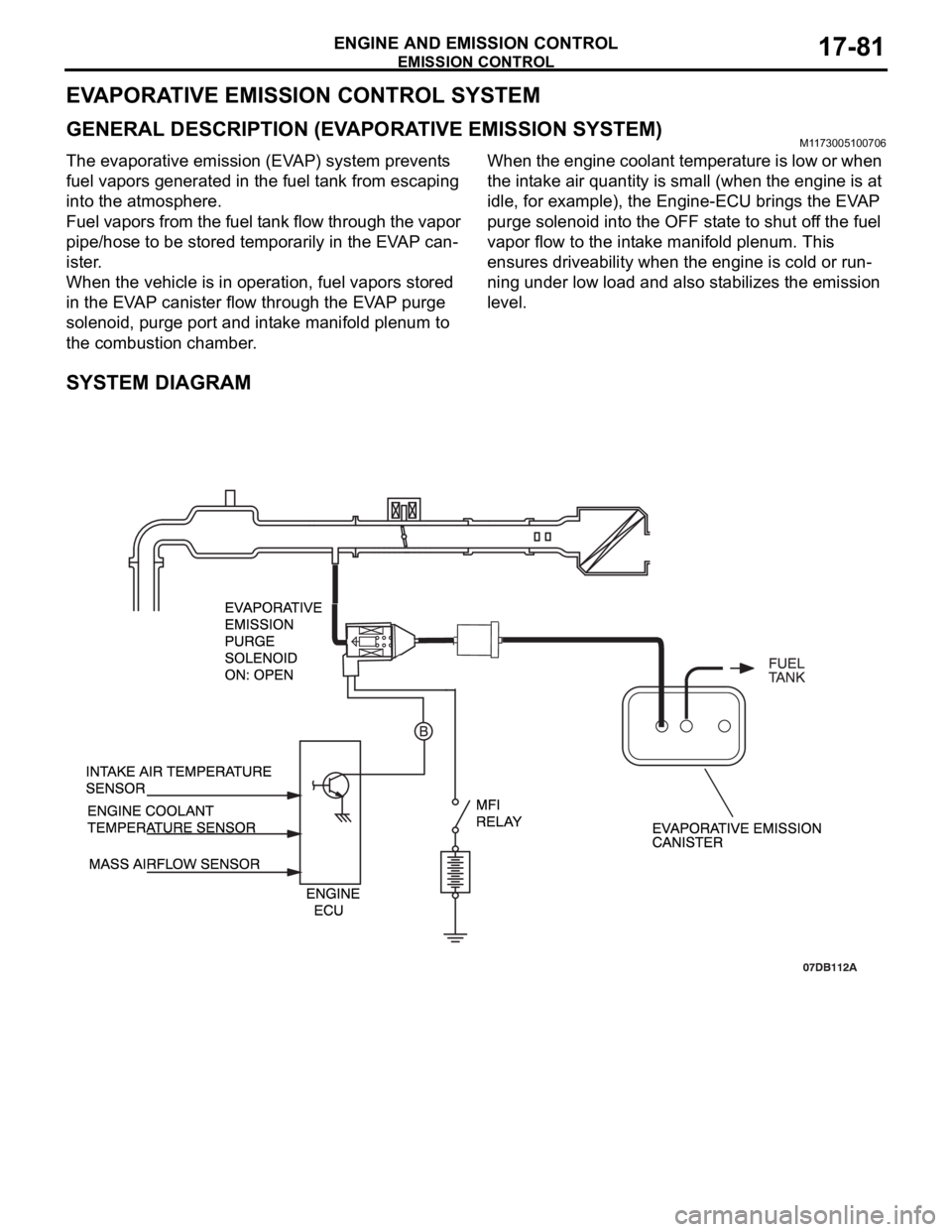

GENERAL DESCRIPTION (EVAPORATIVE EMISSION SYSTEM)M1173005100706

The evaporative emission (EVAP) system prevents

fuel vapors generated in the fuel tank from escaping

into the atmosphere.

Fuel vapors from the fuel tank flow through the vapor

pipe/hose to be stored temporarily in the EVAP can-

ister.

When the vehicle is in operation, fuel vapors stored

in the EVAP canister flow through the EVAP purge

solenoid, purge port and intake manifold plenum to

the combustion chamber.When the engine coolant temperature is low or when

the intake air quantity is small (when the engine is at

idle, for example), the Engine-ECU brings the EVAP

purge solenoid into the OFF state to shut off the fuel

vapor flow to the intake manifold plenum. This

ensures driveability when the engine is cold or run-

ning under low load and also stabilizes the emission

level.

SYSTEM DIAGRAM

Page 1413 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-82

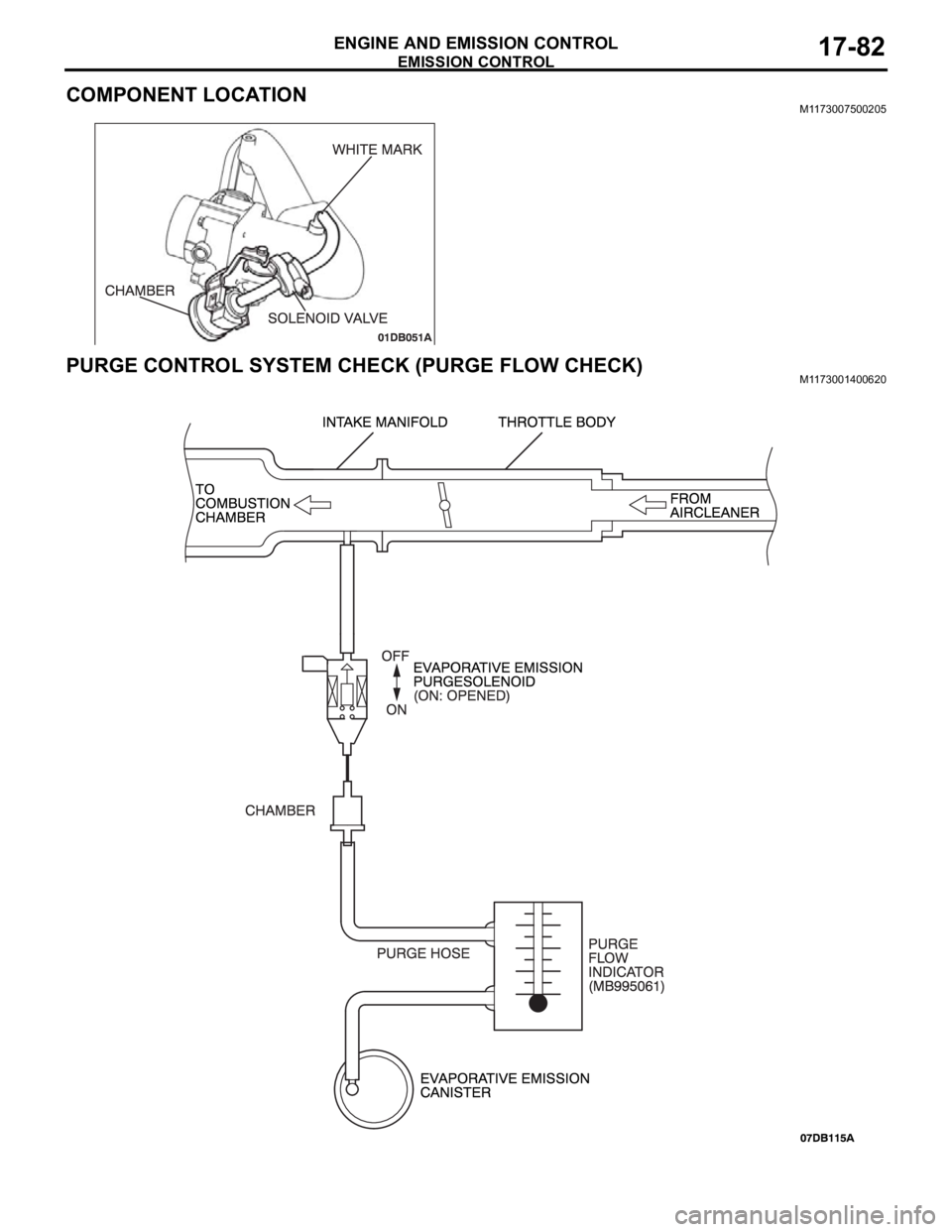

COMPONENT LOCATIONM1173007500205

PURGE CONTROL SYSTEM CHECK (PURGE FLOW CHECK)M1173001400620

Page 1414 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-83

Required Special Tool:

MB995061: Purge Flow Indicator

1. Disconnect the purge hose from the evaporative emission

(EVAP) purge solenoid, and connect special tool MB995061

between the EVAP purge solenoid and the purge hose.

2. Before inspection, set the vehicle in the following conditions:

Engine coolant temperature: 80 95C (176 203F)

Lights, electric cooling fan and accessories: OFF

Transaxle: P range

3. Run the engine at idle for more than four minutes.

4. Check the purge flow volume when engine is revved

suddenly several times.

Standard value: Momentarily 20 cm

3/s (2.5 SCFH) or

more.

5. If the purge flow volume is less than the standard value,

check it again with the vacuum hose disconnected from the

EVAP canister. If the purge flow volume is less than the

standard value, check the vacuum port and the vacuum

hose for clogging. Also check the EVAP purge solenoid. If

the purge flow volume is at the standard value, replace the

EVAP canister.

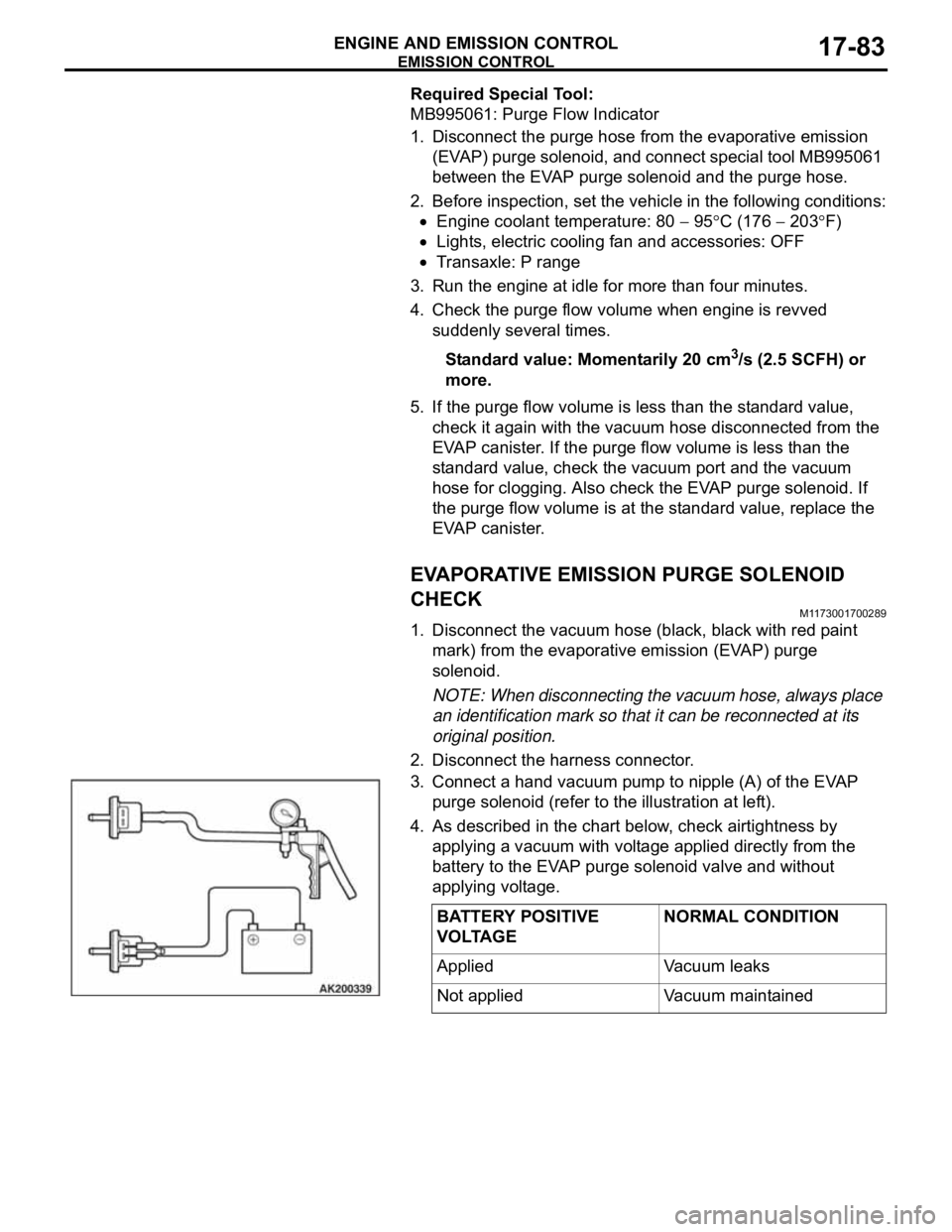

EVAPORATIVE EMISSION PURGE SOLENOID

CHECK

M1173001700289

1. Disconnect the vacuum hose (black, black with red paint

mark) from the evaporative emission (EVAP) purge

solenoid.

NOTE: When disconnecting the vacuum hose, always place

an identification mark so that it can be reconnected at its

original position.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the EVAP

purge solenoid (refer to the illustration at left).

4. As described in the chart below, check airtightness by

applying a vacuum with voltage applied directly from the

battery to the EVAP purge solenoid valve and without

applying voltage.

BATTERY POSITIVE

VOLTAGENORMAL CONDITION

Applied Vacuum leaks

Not applied Vacuum maintained

Page 1415 of 1500

![MITSUBISHI 380 2005 Workshop Manual EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-84

5. Measure the resistance between the terminals of the EVAP

purge solenoid.

Standard value: 16

[at 20C )]

6. Replace the solenoid if resistance is MITSUBISHI 380 2005 Workshop Manual EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-84

5. Measure the resistance between the terminals of the EVAP

purge solenoid.

Standard value: 16

[at 20C )]

6. Replace the solenoid if resistance is](/img/19/57086/w960_57086-1414.png)

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-84

5. Measure the resistance between the terminals of the EVAP

purge solenoid.

Standard value: 16

[at 20C )]

6. Replace the solenoid if resistance is out of specification.

MASS AIRFLOW SENSOR CHECKM1173050400053

To inspect these parts, refer to GROUP 13A, Multipoint Fuel

Injection (MPI)

Multipoint Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Chart 13A-17.

ENGINE COOLANT TEMPERATURE SENSOR

CHECK

M1173008100523

To inspect the sensor, refer to GROUP 13A, Multipoint Fuel

Injection (MPI)

Multipoint Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Chart 13A-17.

INTAKE AIR TEMPERATURE SENSOR CHECKM1173008200263

To inspect the sensor, refer to GROUP 13A, Multipoint Fuel

Injection (MPI)

Multipoint Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Chart 13A-17.

CATALYTIC CONVERTER

GENERAL DESCRIPTION (CATALYTIC CONVERTER)M1173005300131

The three way catalytic converter, together with the

closed loop air-fuel ratio control based on the oxygen

sensor signal, oxidizes carbon monoxides (CO) and

hydrocarbons (HC), also reduces nitrogen oxides

(NOx). When the mixture is controlled at stoichiometric

air-fuel ratio, the three way catalytic converter pro-

vides the highest purification against the three con-

stituents, namely, CO, HC and NOx.

Page 1416 of 1500

SPECIFICATIONS

ENGINE AND EMISSION CONTROL17-85

SPECIFICATIONS

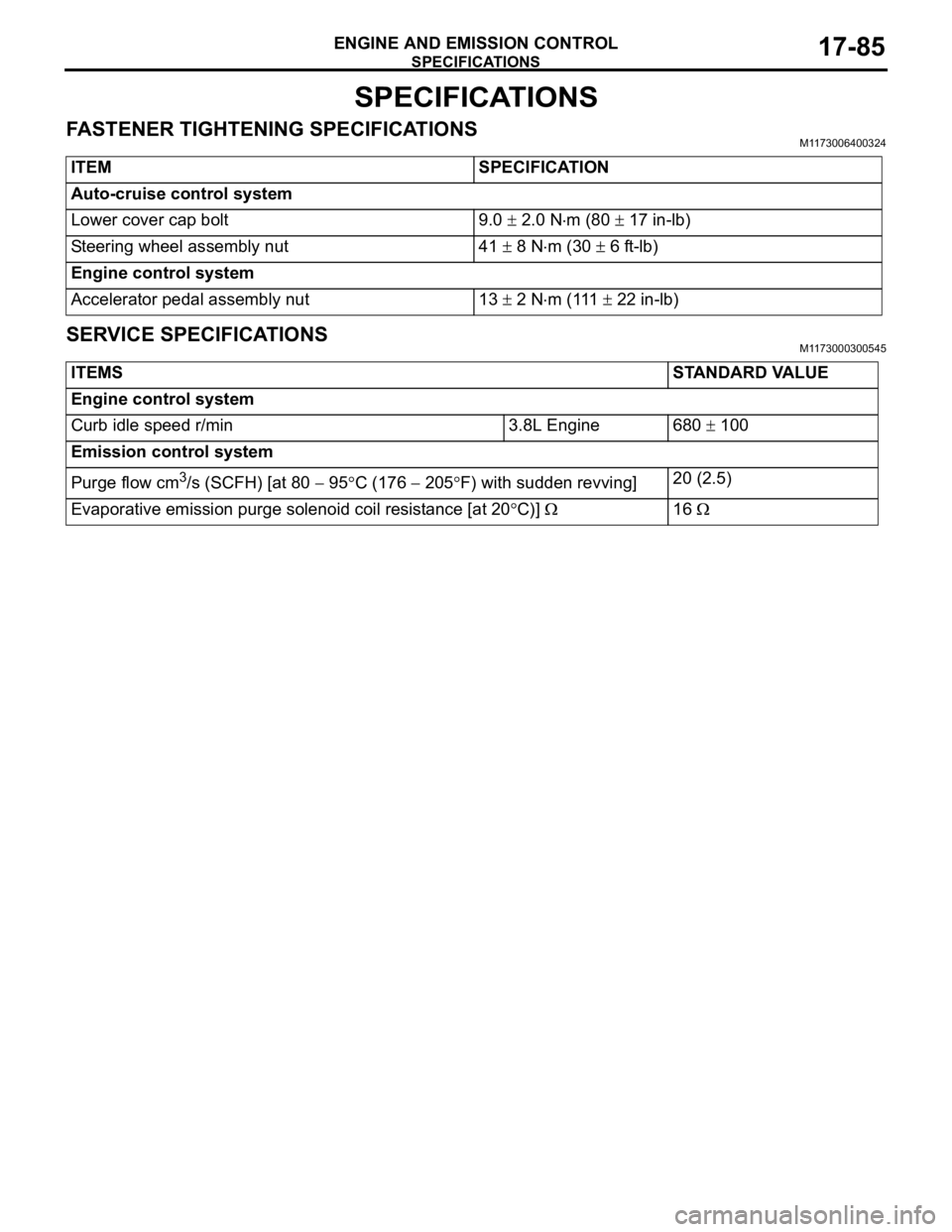

FASTENER TIGHTENING SPECIFICATIONSM1173006400324

SERVICE SPECIFICATIONSM1173000300545

ITEM SPECIFICATION

Auto-cruise control system

Lower cover cap bolt 9.0

2.0 Nm (80 17 in-lb)

Steering wheel assembly nut 41

8 Nm (30 6 ft-lb)

Engine control system

Accelerator pedal assembly nut 13

2 Nm ( 111 22 in-lb)

ITEMSSTANDARD VALUE

Engine control system

Curb idle speed r/min 3.8L Engine 680

100

Emission control system

Purge flow cm

3/s (SCFH) [at 80 95C (176 205F) with sudden revving]20 (2.5)

Evaporative emission purge solenoid coil resistance [at 20

C)] 16