engine MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 705 of 1500

GENERAL DESCRIPTION

HEATER, AIR CONDITIONING AND VENTILATION55-4

OPERATION

.

CONDENSER FAN AND RADIATOR FAN

CONTROL

The ECU judges the required revolution speed of

radiator fan motor and condenser fan motor using

the input signals transmitted from A/C switch, output

shaft speed sensor and engine coolant temperature

sensor. The ECU activates the fan control relays to

drive the radiator fan motor and condenser fan

motor.

.

COMPRESSOR CONTROL

When operating the air conditioning switch

The air thermo sensor, which senses the temper-

ature of the air flowing out of the evaporator,

deactivates the compressor at 3

C (37.4F) or

below.

The dual pressure switch turns OFF when the

refrigerant pressure becomes excessively high or

low, thus protecting the compressor circuit (See

Table below).

When the air thermo sensor is activated, and the

ignition switch, blower switch, and air condition-

ing switch are ON, the A/C compressor clutch

relay is energized.

When operating the mode selection dial

The air conditioning will work when the mode

selection dial is set to the "Defroster" or

"Defroster/foot" position, or the temperature con-

trol dial is set to the "MAX A/C" position. In other

dial positions, when the air conditioning switch is

turned on, the air conditioning will work.

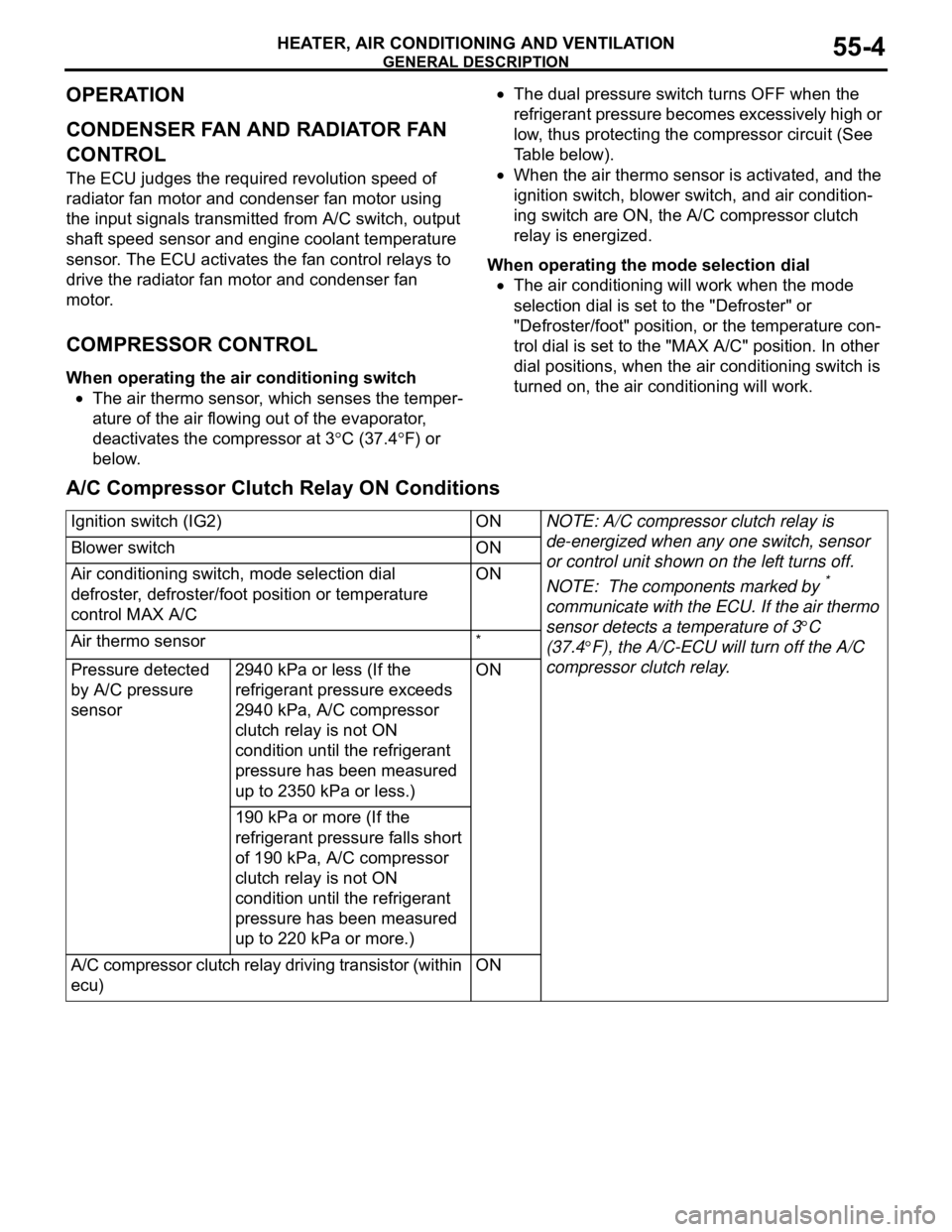

A/C Compressor Clutch Relay ON Conditions

Ignition switch (IG2) ONNOTE: A/C compressor clutch relay is

de-energized when any one switch, sensor

or control unit shown on the left turns off.

NOTE: The components marked by

*

communicate with the ECU. If the air thermo

sensor detects a temperature of 3

C

(37.4

F), the A/C-ECU will turn off the A/C

compressor clutch relay. Blower switch ON

Air conditioning switch, mode selection dial

defroster, defroster/foot position or temperature

control MAX A/CON

Air thermo sensor*

Pressure detected

by A/C pressure

sensor2940 kPa or less (If the

refrigerant pressure exceeds

2940 kPa, A/C compressor

clutch relay is not ON

condition until the refrigerant

pressure has been measured

up to 2350 kPa or less.)ON

190 kPa or more (If the

refrigerant pressure falls short

of 190 kPa, A/C compressor

clutch relay is not ON

condition until the refrigerant

pressure has been measured

up to 220 kPa or more.)

A/C compressor clutch relay driving transistor (within

ecu)ON

Page 710 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-9

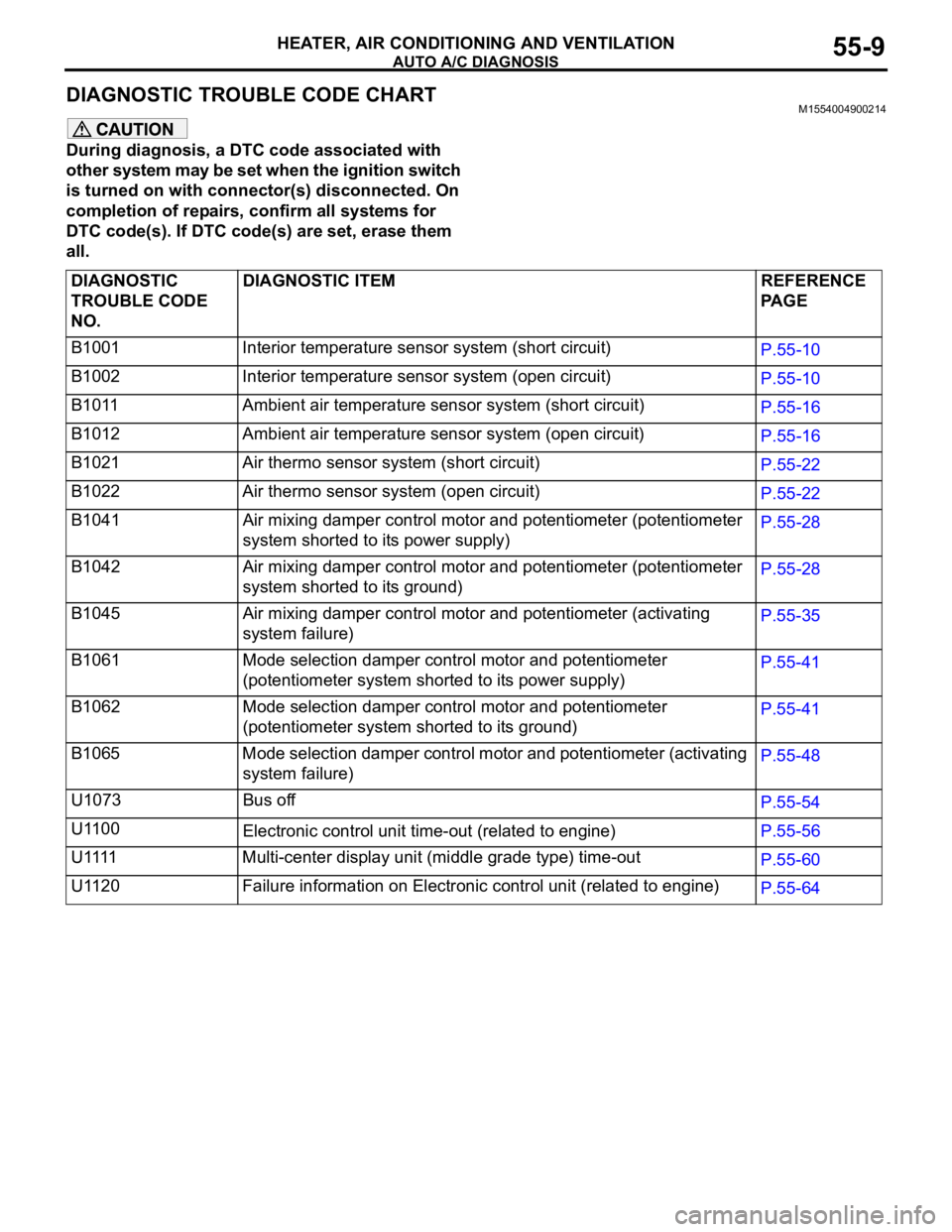

DIAGNOSTIC TROUBLE CODE CHART M1554004900214

During diagnosis, a DTC code associated with

other system may be set when the ignition switch

is turned on with connector(s) disconnected. On

completion of repairs, confirm all systems for

DTC code(s). If DTC code(s) are set, erase them

all.

DIAGNOSTIC

TROUBLE CODE

NO.DIAGNOSTIC ITEM REFERENCE

PA G E

B1001 Interior temperature sensor system (short circuit)

P.55-10

B1002 Interior temperature sensor system (open circuit)

P.55-10

B1011 Ambient air temperature sensor system (short circuit)

P.55-16

B1012 Ambient air temperature sensor system (open circuit)

P.55-16

B1021 Air thermo sensor system (short circuit)

P.55-22

B1022 Air thermo sensor system (open circuit)

P.55-22

B1041 Air mixing damper control motor and potentiometer (potentiometer

system shorted to its power supply)P.55-28

B1042 Air mixing damper control motor and potentiometer (potentiometer

system shorted to its ground)P.55-28

B1045 Air mixing damper control motor and potentiometer (activating

system failure)P.55-35

B1061 Mode selection damper control motor and potentiometer

(potentiometer system shorted to its power supply)P.55-41

B1062 Mode selection damper control motor and potentiometer

(potentiometer system shorted to its ground)P.55-41

B1065 Mode selection damper control motor and potentiometer (activating

system failure)P.55-48

U1073 Bus off

P.55-54

U1100

Electronic control unit time-out (related to engine)P.55-56

U 1111 M u l t i - c e n t e r d i s p l a y u n i t ( m i d d l e g r a d e t y p e ) t i m e - o u t

P.55-60

U1120 Failure information on Electronic control unit (related to engine)

P.55-64

Page 713 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-12

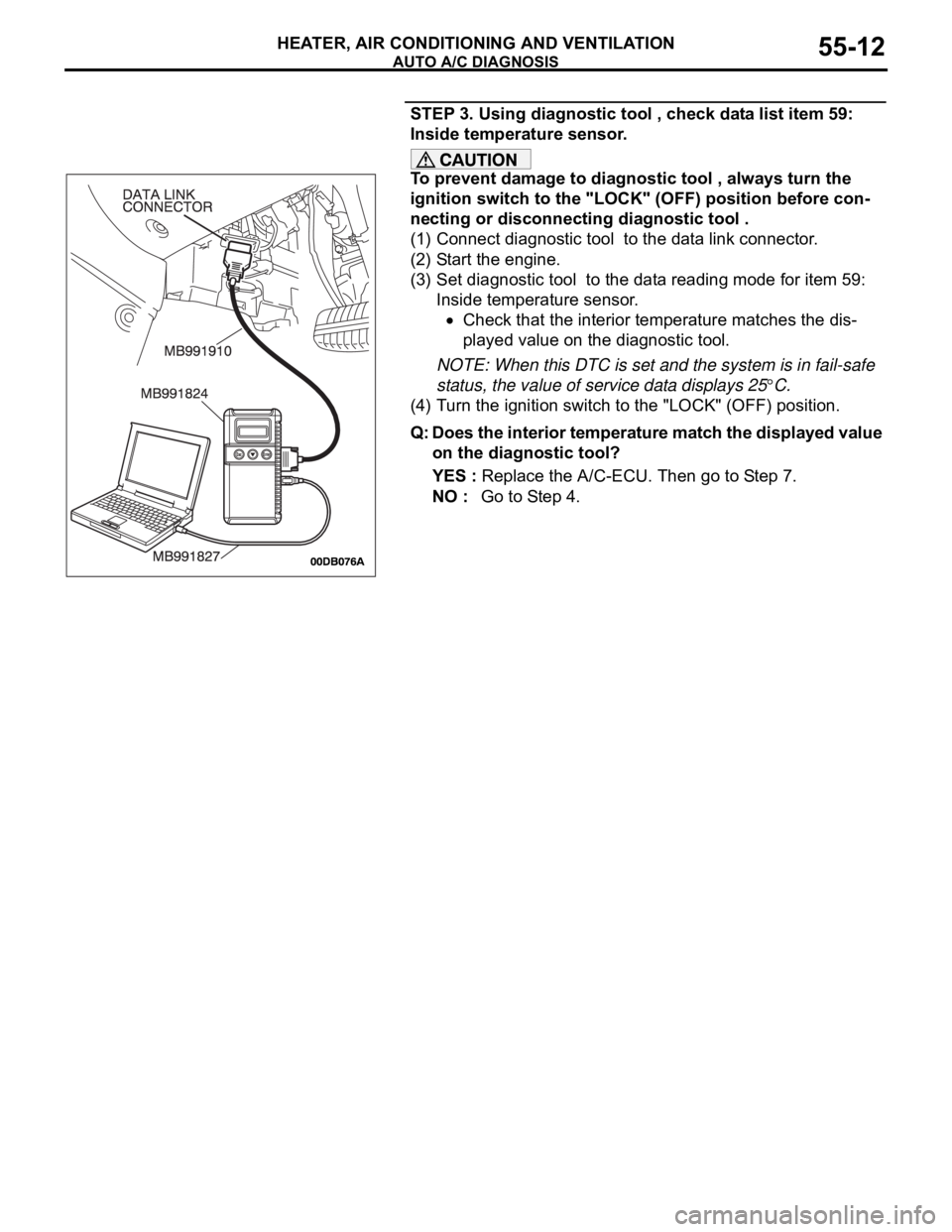

STEP 3. Using diagnostic tool , check data list item 59:

Inside temperature sensor.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine.

(3) Set diagnostic tool to the data reading mode for item 59:

Inside temperature sensor.

Check that the interior temperature matches the dis-

played value on the diagnostic tool.

NOTE: When this DTC is set and the system is in fail-safe

status, the value of service data displays 25

C.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Does the interior temperature match the displayed value

on the diagnostic tool?

YES : Replace the A/C-ECU. Then go to Step 7.

NO : Go to Step 4.

Page 719 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-18

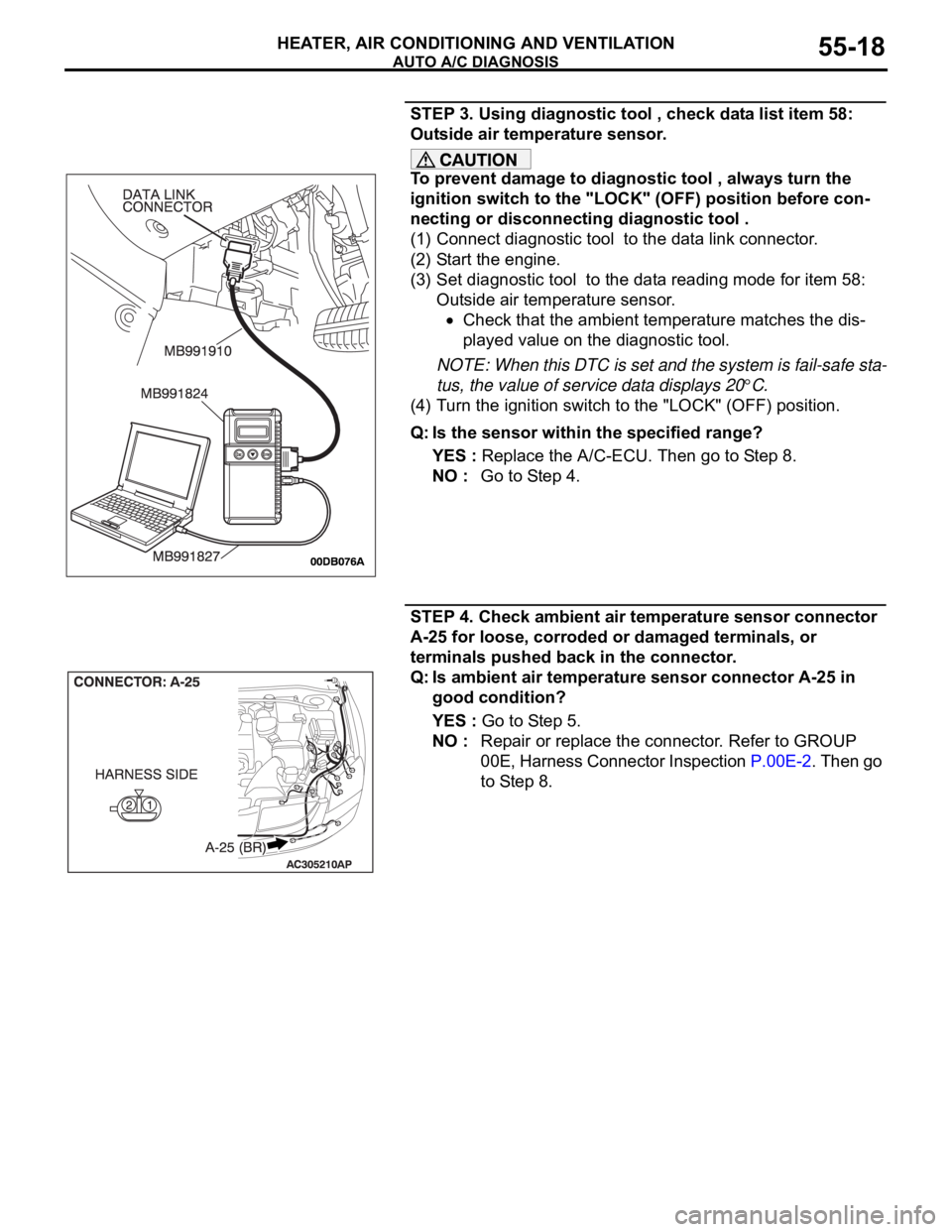

STEP 3. Using diagnostic tool , check data list item 58:

Outside air temperature sensor.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine.

(3) Set diagnostic tool to the data reading mode for item 58:

Outside air temperature sensor.

Check that the ambient temperature matches the dis-

played value on the diagnostic tool.

NOTE: When this DTC is set and the system is fail-safe sta-

tus, the value of service data displays 20

C.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor within the specified range?

YES : Replace the A/C-ECU. Then go to Step 8.

NO : Go to Step 4.

STEP 4. Check ambient air temperature sensor connector

A-25 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is ambient air temperature sensor connector A-25 in

good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Then go

to Step 8.

Page 725 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-24

STEP 3. Using diagnostic tool , check data list item 20: Air

thermo sensor.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Ignition switch: ON

(3) Set diagnostic tool to the data reading mode for item 20: Air

thermo sensor.

Check that the passenger room temperature matches

the displayed value on the diagnostic tool while the

engine is cold.

NOTE: When this DTC is set and the system is fail-safe sta-

tus, the value of service data displays

6C.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor within the specified range?

YES : Replace the A/C-ECU. Then go to Step 7.

NO : Go to Step 4.

Page 731 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-30

STEP 3. Using diagnostic tool , check data list item 63: Air

mix potentiometer.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine.

(3) Set diagnostic tool to the data reading mode for item 63: Air

mix potentiometer.

Check that the set position of the heater control matches

the displayed position on the diagnostic tool.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor within the specified range?

YES : Replace the A/C-ECU. Then go to Step 7.

NO : Go to Step 4.

Page 738 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-37

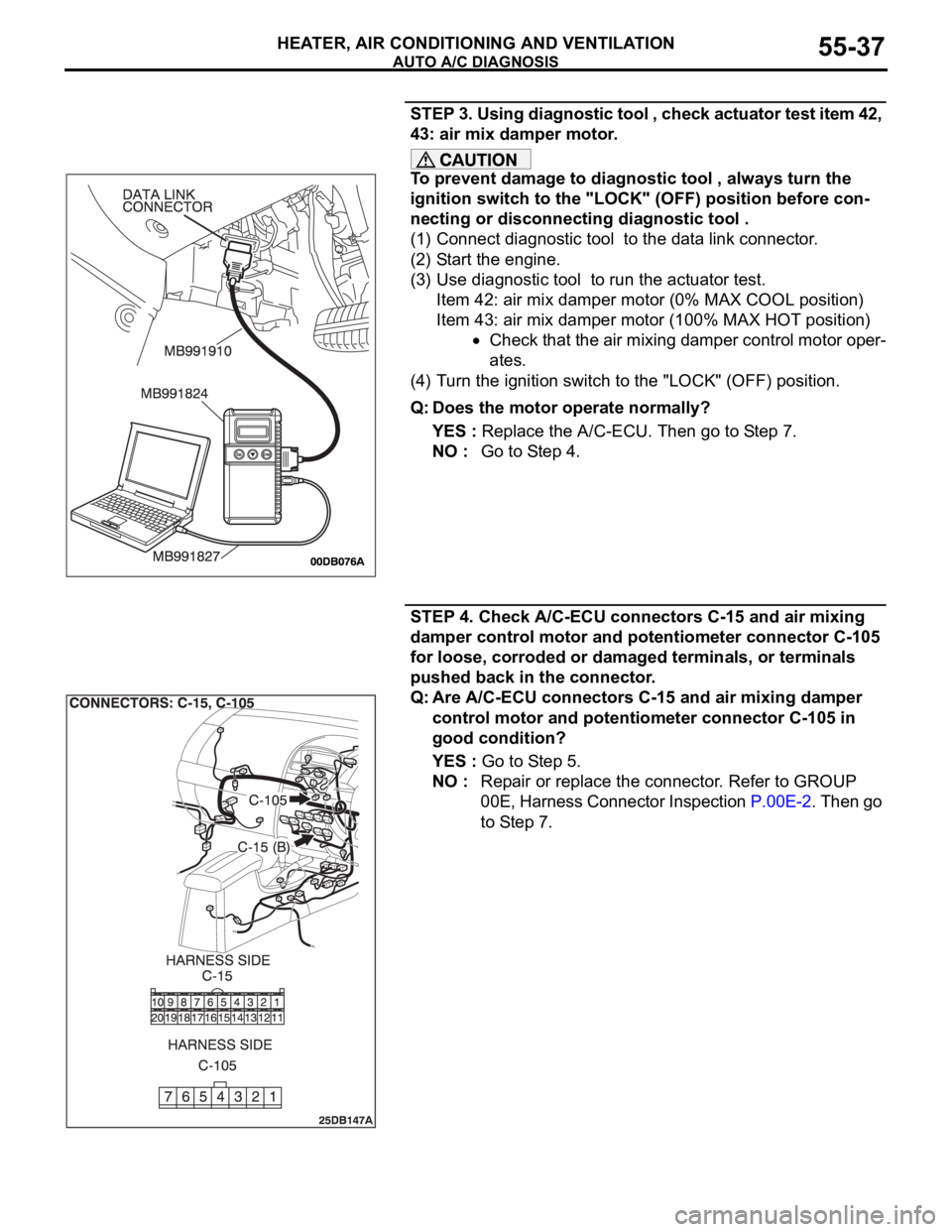

STEP 3. Using diagnostic tool , check actuator test item 42,

43: air mix damper motor.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine.

(3) Use diagnostic tool to run the actuator test.

Item 42: air mix damper motor (0% MAX COOL position)

Item 43: air mix damper motor (100% MAX HOT position)

Check that the air mixing damper control motor oper-

ates.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Does the motor operate normally?

YES : Replace the A/C-ECU. Then go to Step 7.

NO : Go to Step 4.

STEP 4. Check A/C-ECU connectors C-15 and air mixing

damper control motor and potentiometer connector C-105

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Are A/C-ECU connectors C-15 and air mixing damper

control motor and potentiometer connector C-105 in

good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Then go

to Step 7.

Page 744 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-43

STEP 3. Using diagnostic tool , check data list item 55: Air

outlet c/o potentiometer.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine.

(3) Set diagnostic tool to the data reading mode for item 55: Air

outlet c/o potentiometer.

Check that the set position of the heater control matches

the displayed position on the diagnostic tool.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor within the specified range?

YES : Replace the A/C-ECU. Then go to Step 7.

NO : Go to Step 4.

Page 751 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-50

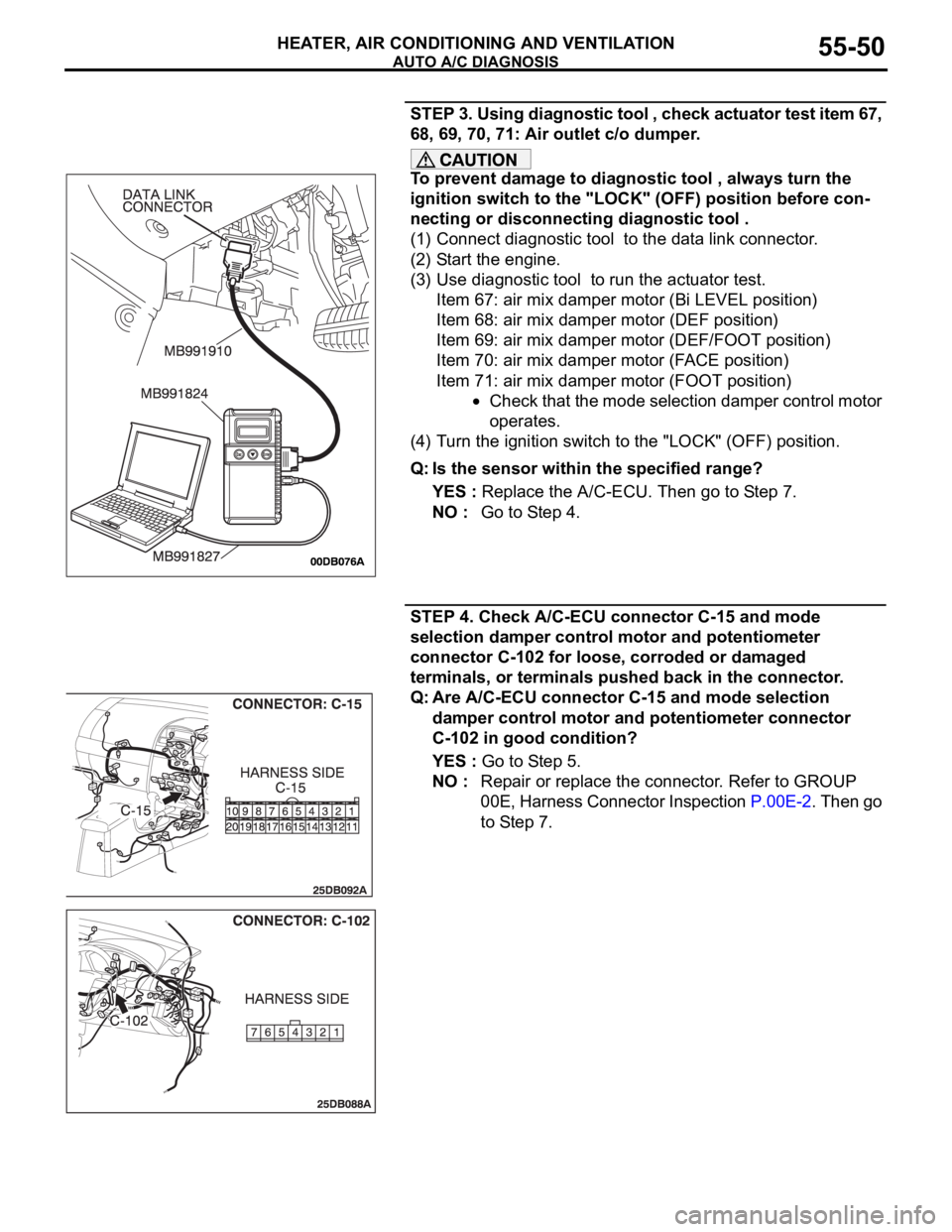

STEP 3. Using diagnostic tool , check actuator test item 67,

68, 69, 70, 71: Air outlet c/o dumper.

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine.

(3) Use diagnostic tool to run the actuator test.

Item 67: air mix damper motor (Bi LEVEL position)

Item 68: air mix damper motor (DEF position)

Item 69: air mix damper motor (DEF/FOOT position)

Item 70: air mix damper motor (FACE position)

Item 71: air mix damper motor (FOOT position)

Check that the mode selection damper control motor

operates.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor within the specified range?

YES : Replace the A/C-ECU. Then go to Step 7.

NO : Go to Step 4.

STEP 4. Check A/C-ECU connector C-15 and mode

selection damper control motor and potentiometer

connector C-102 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Are A/C-ECU connector C-15 and mode selection

damper control motor and potentiometer connector

C-102 in good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Then go

to Step 7.

Page 757 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-56

DTC U1100: Electronic control unit Time-out (Related to Engine)

If DTC U1100 is set in the A/C-ECU, diagnose the

CAN main bus line.

Whenever the ECU is replaced, ensure that the

communication circuit is normal.

.

TROUBLE JUDGMENT

The A/C-ECU receives engine control sys-

tem-related signal from the Electronic control unit. If

the ECU cannot receive the signal, DTC U1100 will

be set.

.

TECHNICAL DESCRIPTION (COMMENT)

Current trouble

Connector(s) or wiring harness in the CAN bus

lines between the Electronic control unit and the

A/C-ECU, the power supply system to the

Electronic control unit, the Electronic control unit

itself, or the A/C-ECU may be defective.Past trouble

If DTC U1100 is stored as a past trouble, carry

out diagnosis with particular emphasis on wiring

and connector(s) in the CAN bus line between

the A/C-ECU and the Electronic control unit, and

the power supply system to the Electronic control

unit. If the connectors and wiring are normal, and

obviously the ECU is the cause of the trouble,

replace the ECU. If in doubt, do not replace the

ECU.

NOTE: For a past trouble, you cannot find it by

the diagnostic tool CAN bus diagnostics even if

there is a failure in CAN bus lines. In this case,

refer to GROUP 00, How to Use Troubleshoot-

ing/Inspection Service Points

How to Cope with

Intermittent Malfunctions P.00-14) and check the

CAN bus lines. You can narrow down the possi-

ble cause of the trouble by referring to the DTC,

which is set regarding the CAN communica-

tion-linked ECUs (Refer to GROUP 54C, Expla-

nation about the scan too CAN bus diagnostics

P.54C-6).

.

TROUBLESHOOTING HINTS

Electronic control unit failed

Malfunction of the A/C-ECU

Damaged harness wires and connectors

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)