MITSUBISHI 380 2005 Repair Manual

380 2005

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57086/w960_57086-0.png

MITSUBISHI 380 2005 Repair Manual

Page 921 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-6

DIAGNOSIS

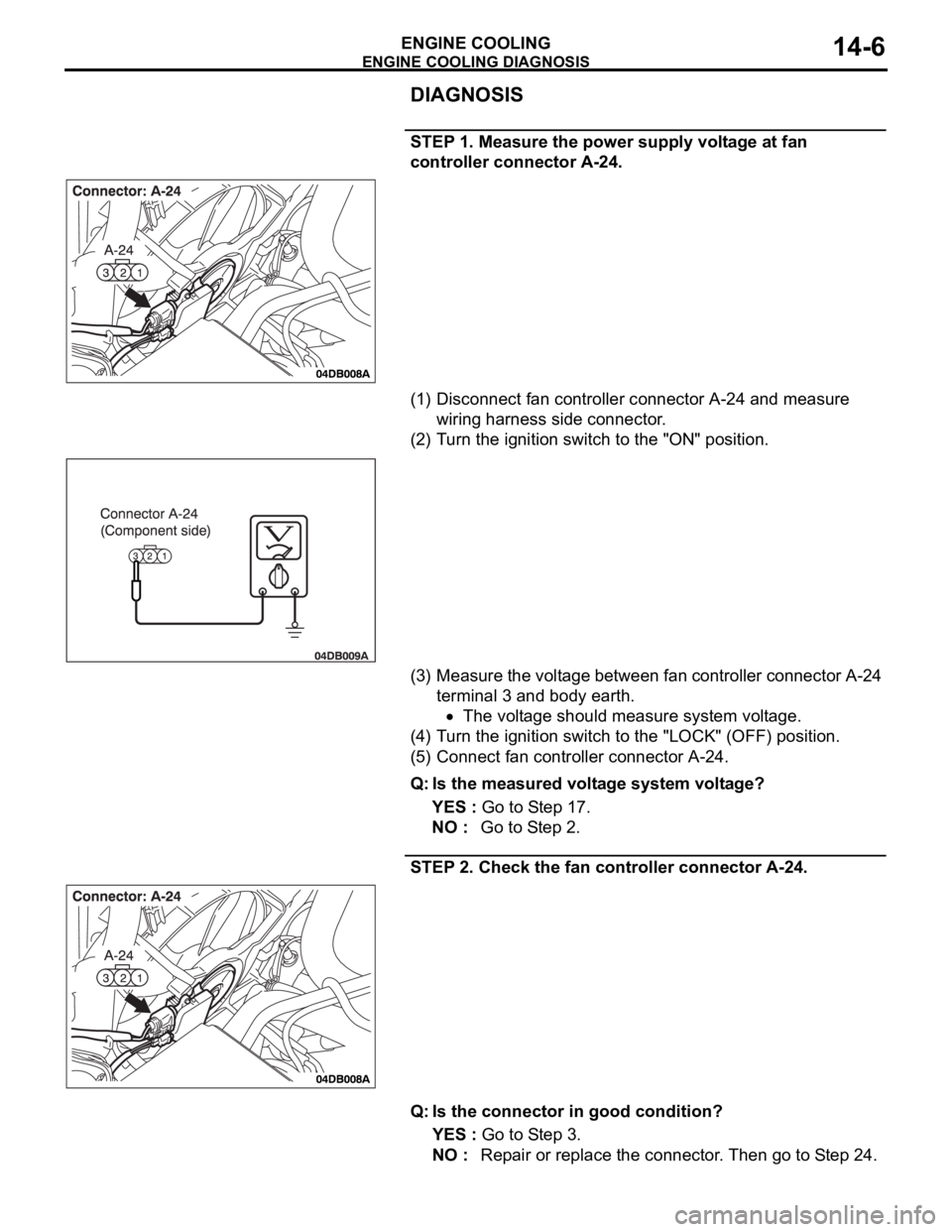

STEP 1. Measure the power supply voltage at fan

controller connector A-24.

(1) Disconnect fan controller connector A-24 and measure

wiring harness side connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between fan controller connector A-24

terminal 3 and body earth.

The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Connect fan controller connector A-24.

Q: Is the measured voltage system voltage?

YES : Go to Step 17.

NO : Go to Step 2.

STEP 2. Check the fan controller connector A-24.

Q: Is the connector in good condition?

YES : Go to Step 3.

NO : Repair or replace the connector. Then go to Step 24.

Page 922 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-7

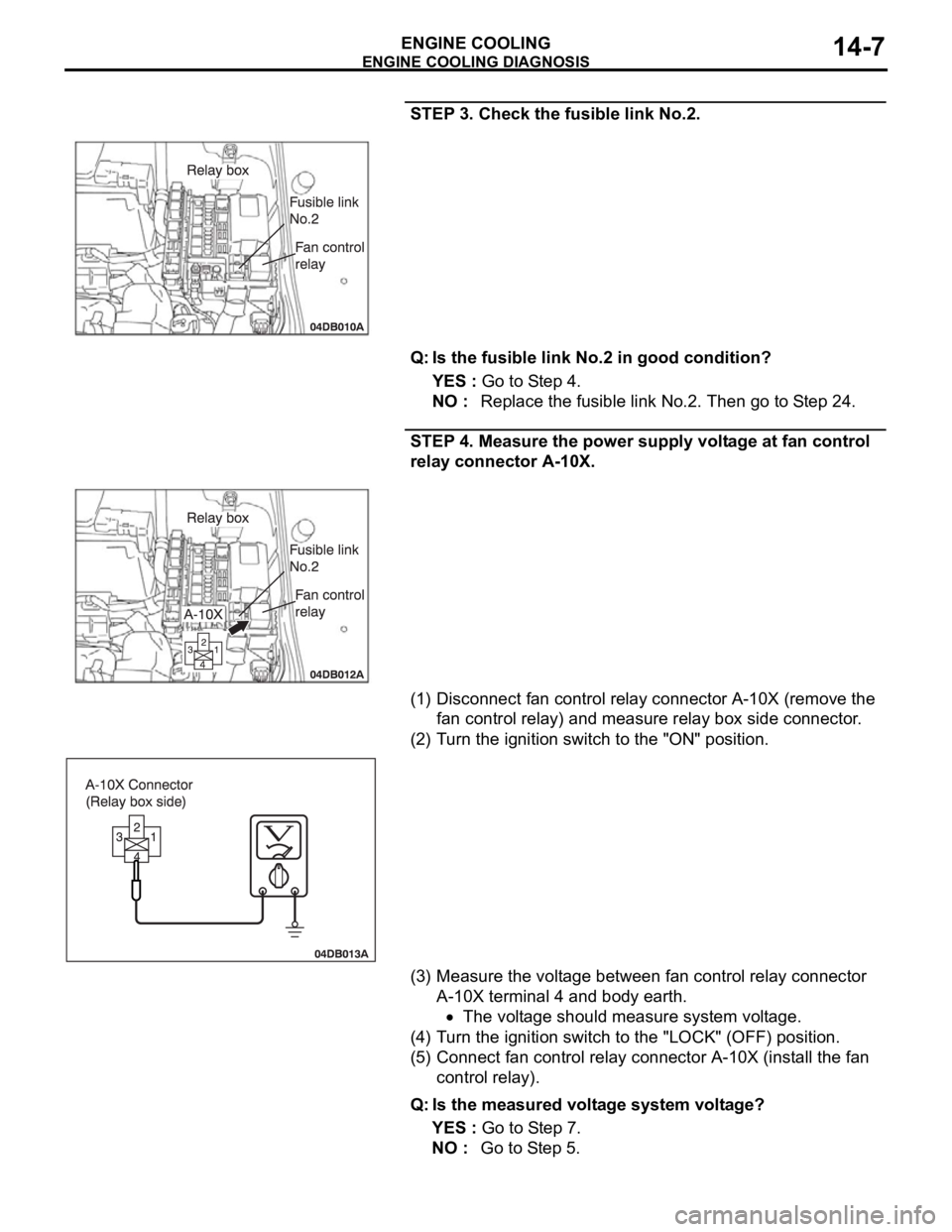

STEP 3. Check the fusible link No.2.

Q: Is the fusible link No.2 in good condition?

YES : Go to Step 4.

NO : Replace the fusible link No.2. Then go to Step 24.

STEP 4. Measure the power supply voltage at fan control

relay connector A-10X.

(1) Disconnect fan control relay connector A-10X (remove the

fan control relay) and measure relay box side connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between fan control relay connector

A-10X terminal 4 and body earth.

The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Connect fan control relay connector A-10X (install the fan

control relay).

Q: Is the measured voltage system voltage?

YES : Go to Step 7.

NO : Go to Step 5.

Page 923 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-8

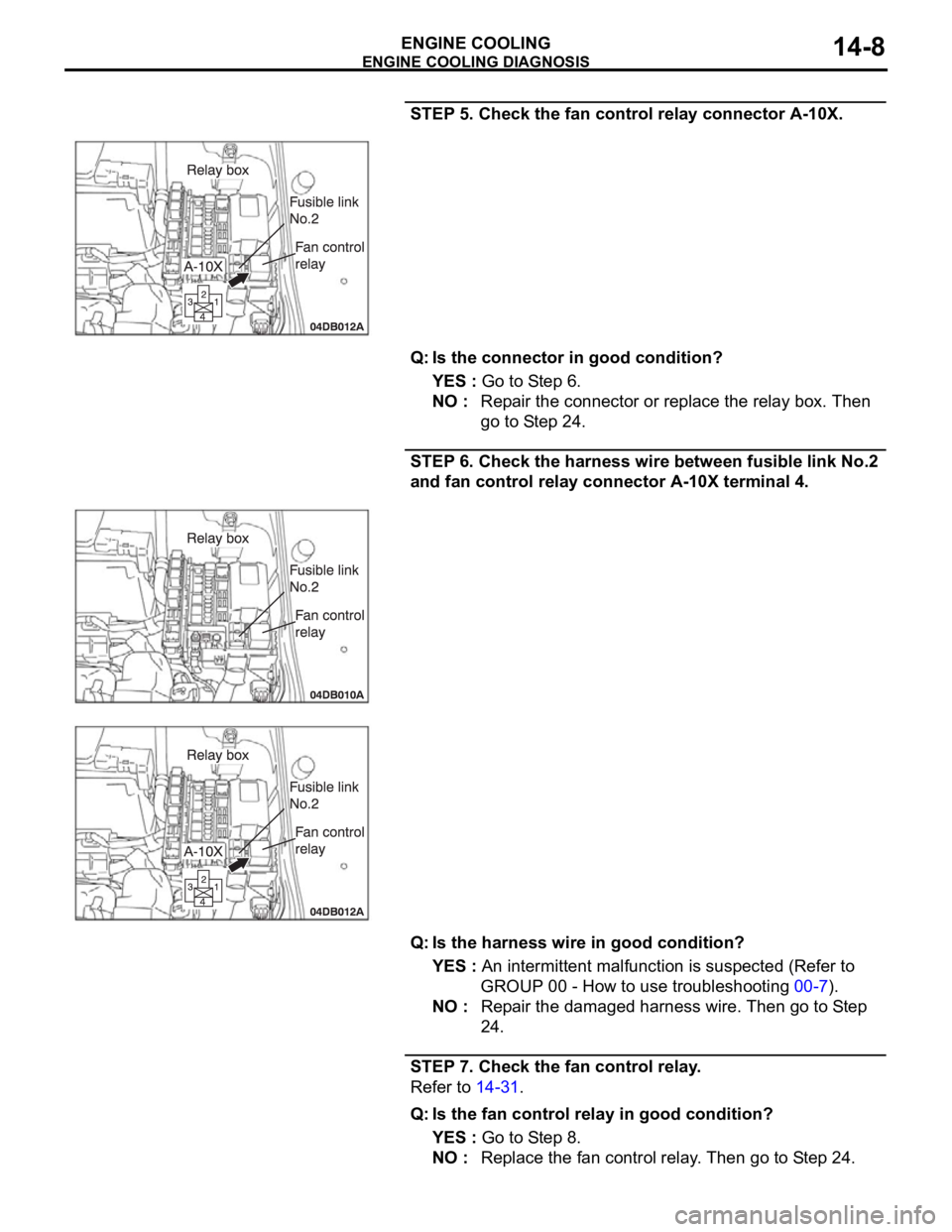

STEP 5. Check the fan control relay connector A-10X.

Q: Is the connector in good condition?

YES : Go to Step 6.

NO : Repair the connector or replace the relay box. Then

go to Step 24.

STEP 6. Check the harness wire between fusible link No.2

and fan control relay connector A-10X terminal 4.

Q: Is the harness wire in good condition?

YES : An intermittent malfunction is suspected (Refer to

GROUP 00 - How to use troubleshooting 00-7).

NO : Repair the damaged harness wire. Then go to Step

24.

STEP 7. Check the fan control relay.

Refer to 14-31.

Q: Is the fan control relay in good condition?

YES : Go to Step 8.

NO : Replace the fan control relay. Then go to Step 24.

Page 924 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-9

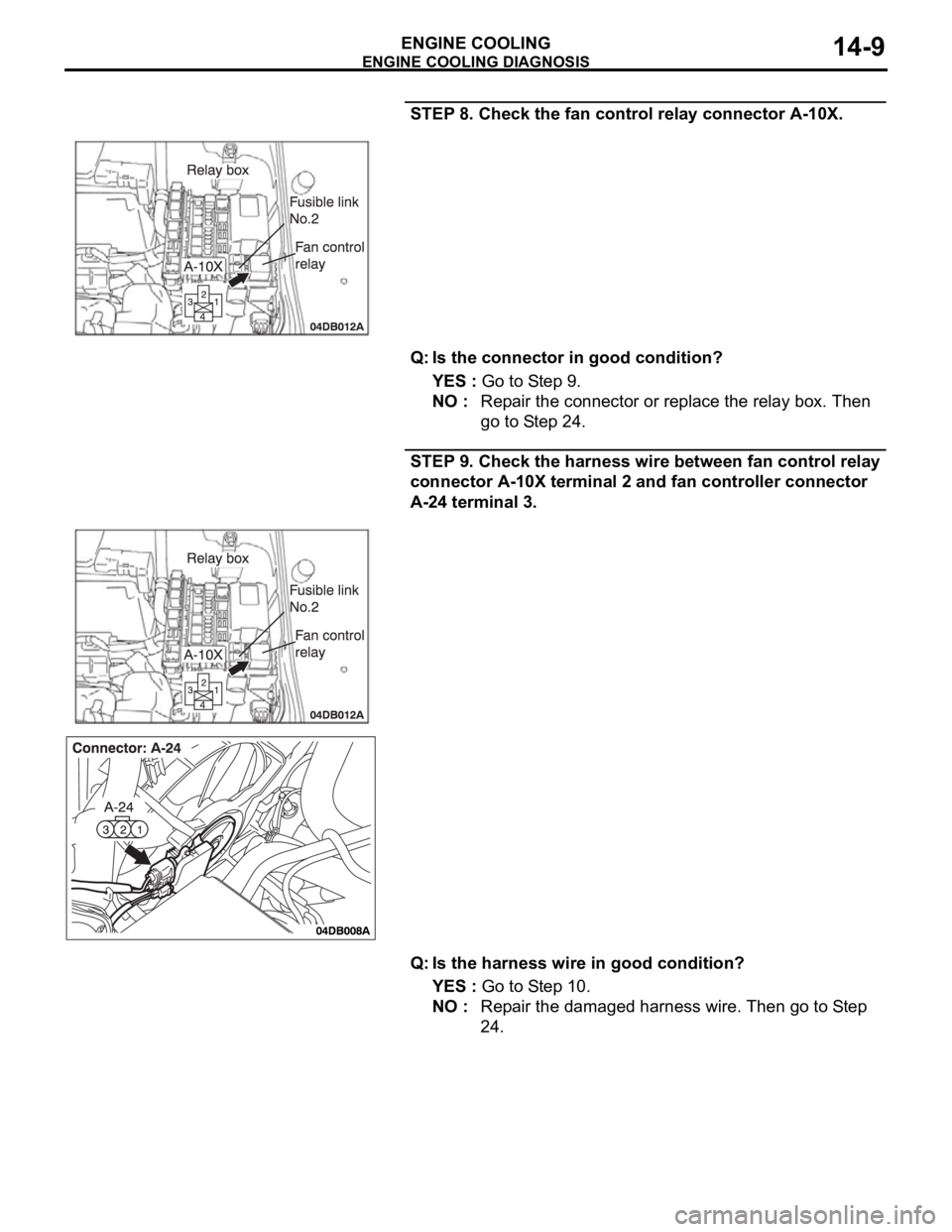

STEP 8. Check the fan control relay connector A-10X.

Q: Is the connector in good condition?

YES : Go to Step 9.

NO : Repair the connector or replace the relay box. Then

go to Step 24.

STEP 9. Check the harness wire between fan control relay

connector A-10X terminal 2 and fan controller connector

A-24 terminal 3.

Q: Is the harness wire in good condition?

YES : Go to Step 10.

NO : Repair the damaged harness wire. Then go to Step

24.

Page 925 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-10

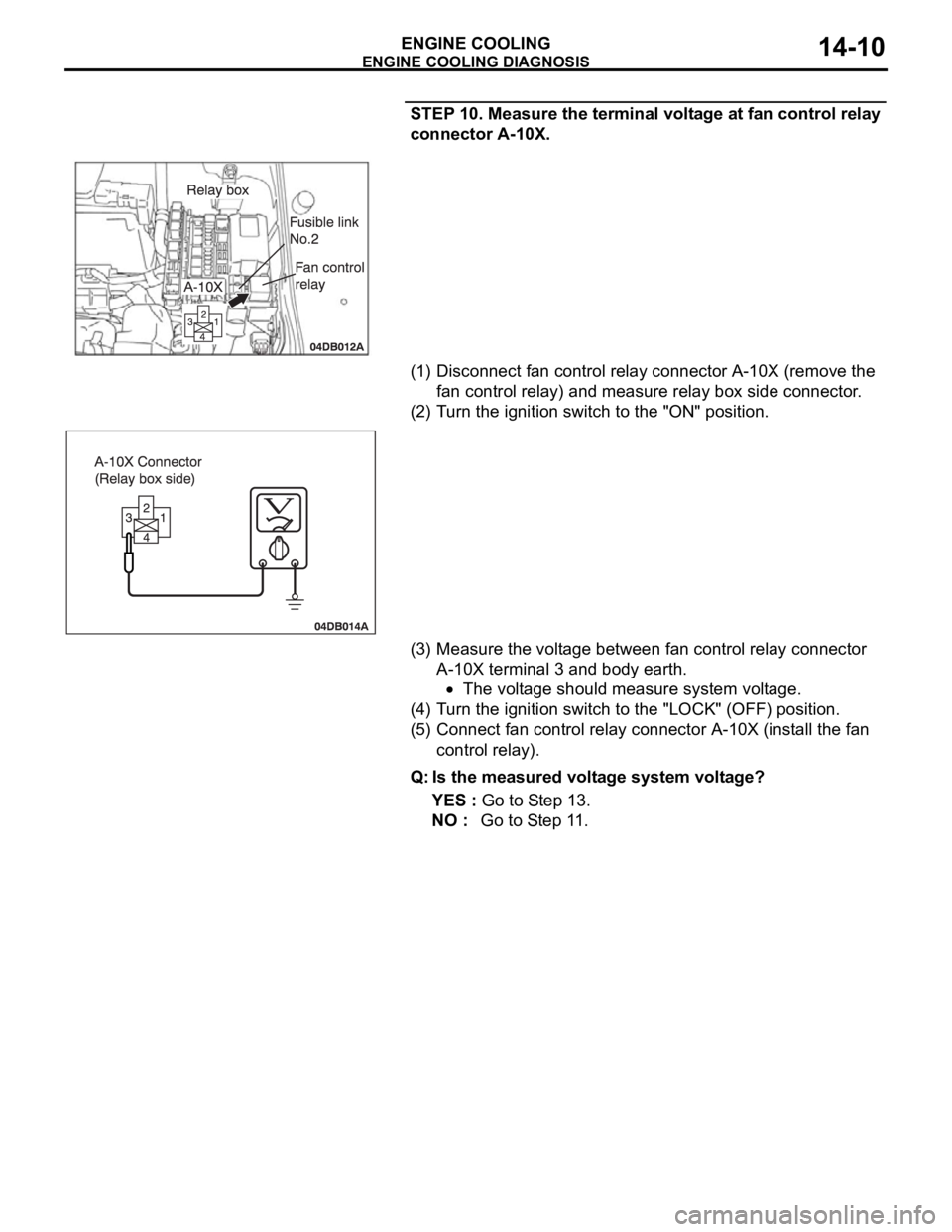

STEP 10. Measure the terminal voltage at fan control relay

connector A-10X.

(1) Disconnect fan control relay connector A-10X (remove the

fan control relay) and measure relay box side connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between fan control relay connector

A-10X terminal 3 and body earth.

The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Connect fan control relay connector A-10X (install the fan

control relay).

Q: Is the measured voltage system voltage?

YES : Go to Step 13.

NO : Go to Step 11.

Page 926 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-11

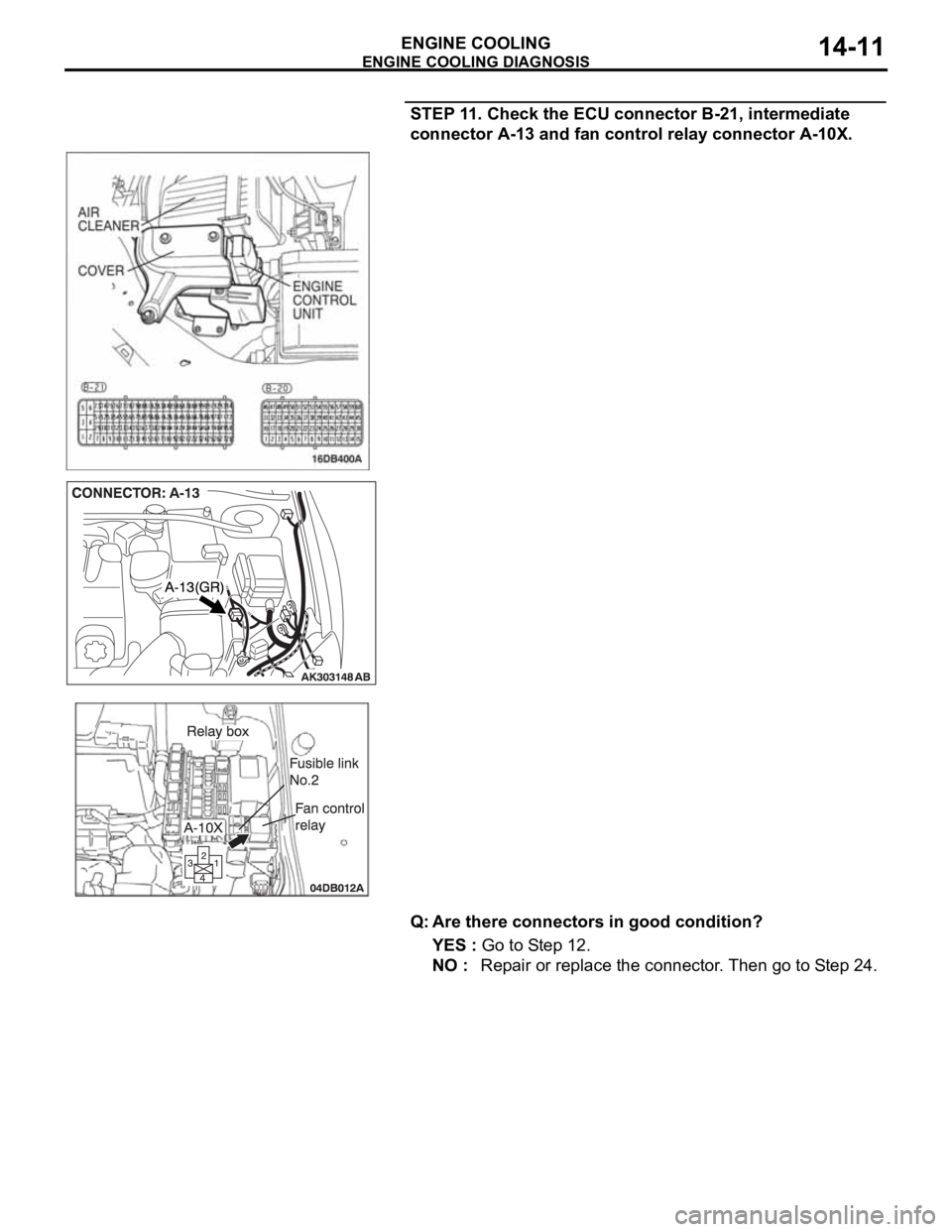

STEP 11. Check the ECU connector B-21, intermediate

connector A-13 and fan control relay connector A-10X.

Q: Are there connectors in good condition?

YES : Go to Step 12.

NO : Repair or replace the connector. Then go to Step 24.

Page 927 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-12

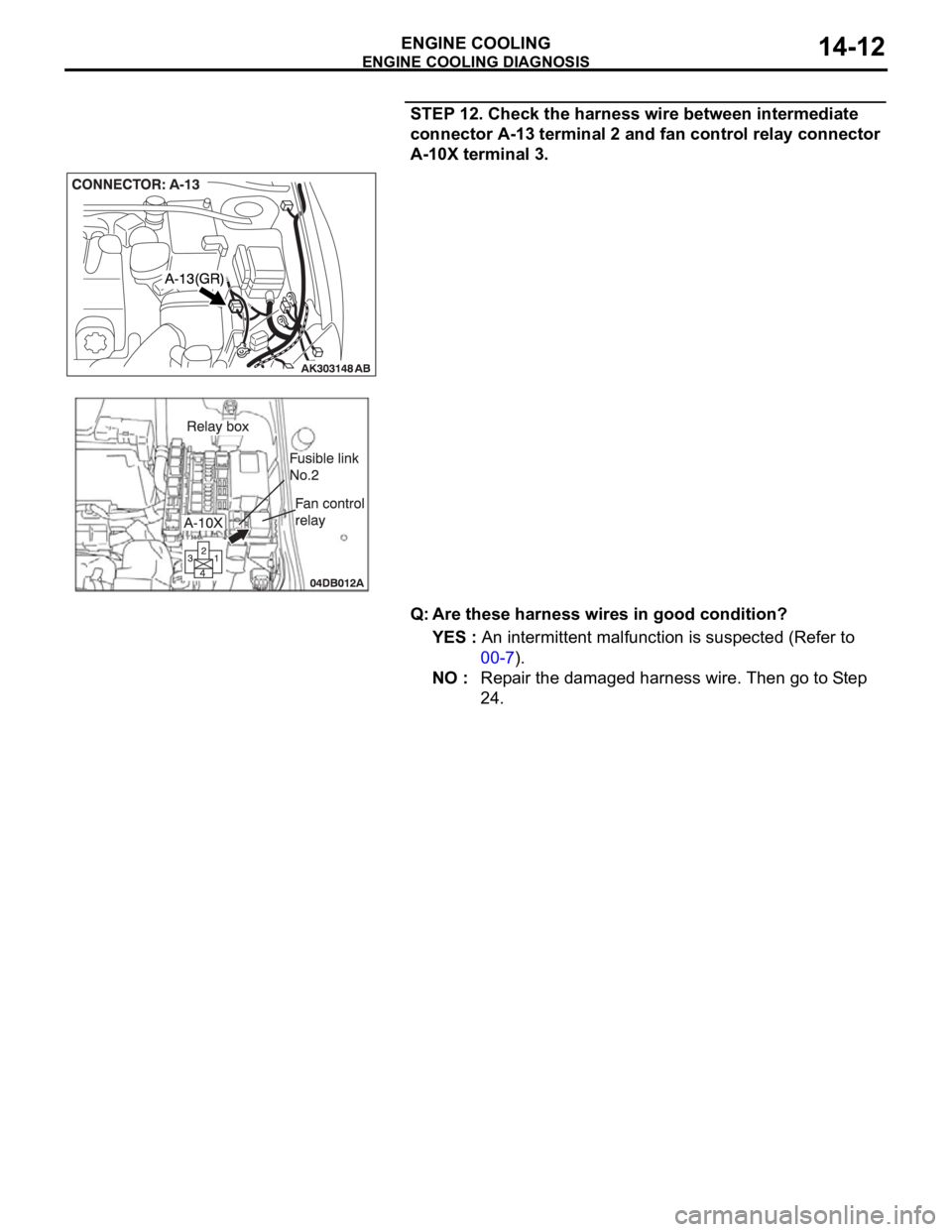

STEP 12. Check the harness wire between intermediate

connector A-13 terminal 2 and fan control relay connector

A-10X terminal 3.

Q: Are these harness wires in good condition?

YES : An intermittent malfunction is suspected (Refer to

00-7).

NO : Repair the damaged harness wire. Then go to Step

24.

Page 928 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-13

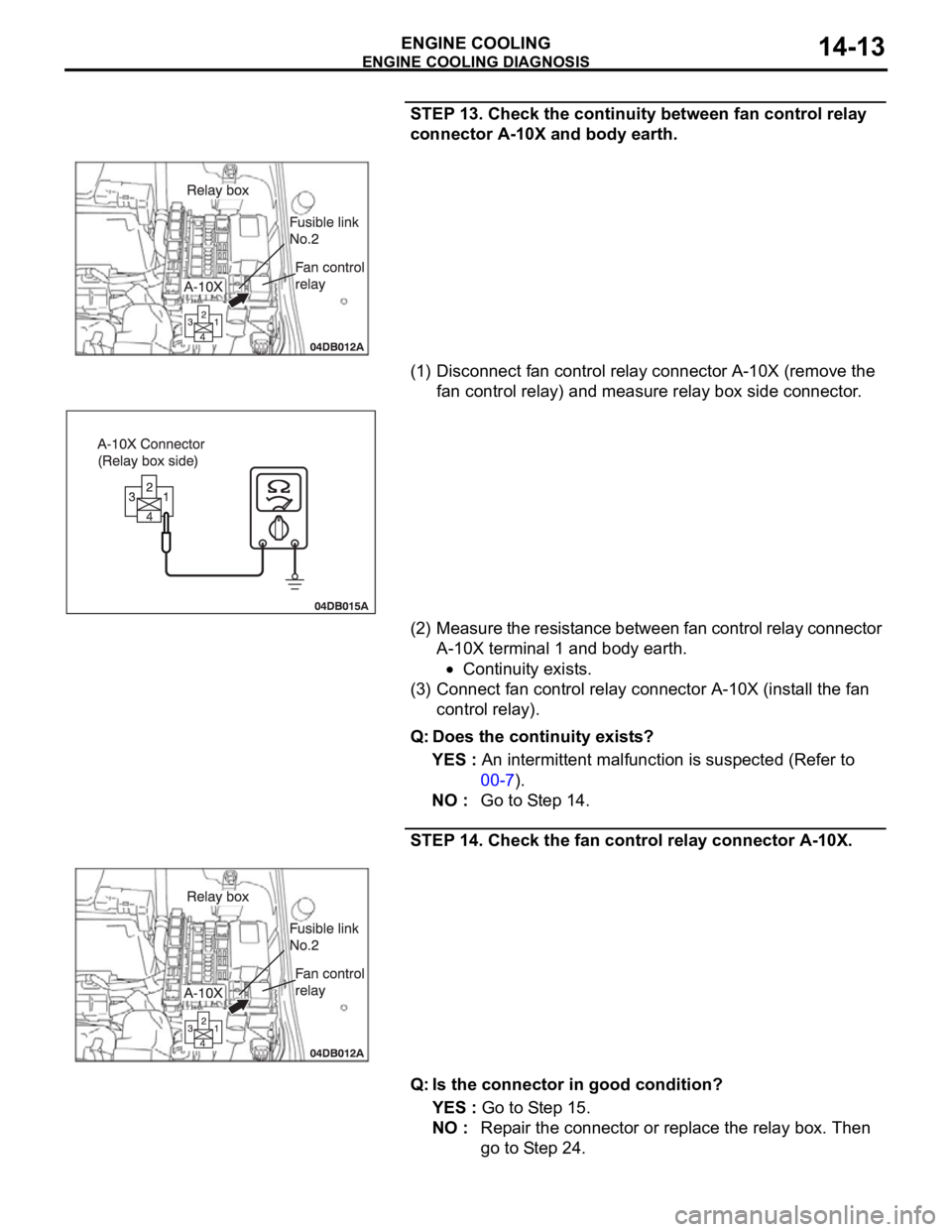

STEP 13. Check the continuity between fan control relay

connector A-10X and body earth.

(1) Disconnect fan control relay connector A-10X (remove the

fan control relay) and measure relay box side connector.

(2) Measure the resistance between fan control relay connector

A-10X terminal 1 and body earth.

Continuity exists.

(3) Connect fan control relay connector A-10X (install the fan

control relay).

Q: Does the continuity exists?

YES : An intermittent malfunction is suspected (Refer to

00-7).

NO : Go to Step 14.

STEP 14. Check the fan control relay connector A-10X.

Q: Is the connector in good condition?

YES : Go to Step 15.

NO : Repair the connector or replace the relay box. Then

go to Step 24.

Page 929 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-14

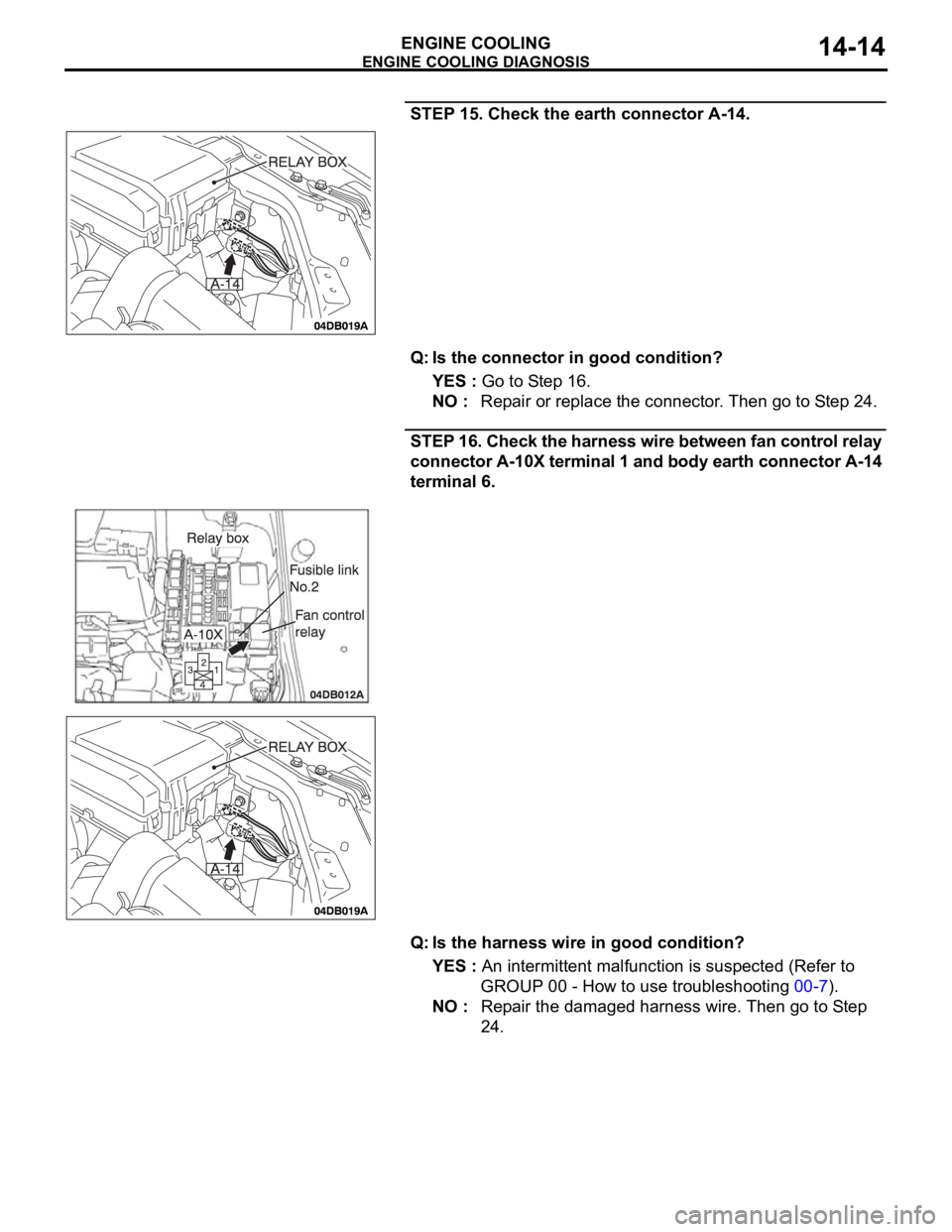

STEP 15. Check the earth connector A-14.

Q: Is the connector in good condition?

YES : Go to Step 16.

NO : Repair or replace the connector. Then go to Step 24.

STEP 16. Check the harness wire between fan control relay

connector A-10X terminal 1 and body earth connector A-14

terminal 6.

Q: Is the harness wire in good condition?

YES : An intermittent malfunction is suspected (Refer to

GROUP 00 - How to use troubleshooting 00-7).

NO : Repair the damaged harness wire. Then go to Step

24.

Page 930 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-15

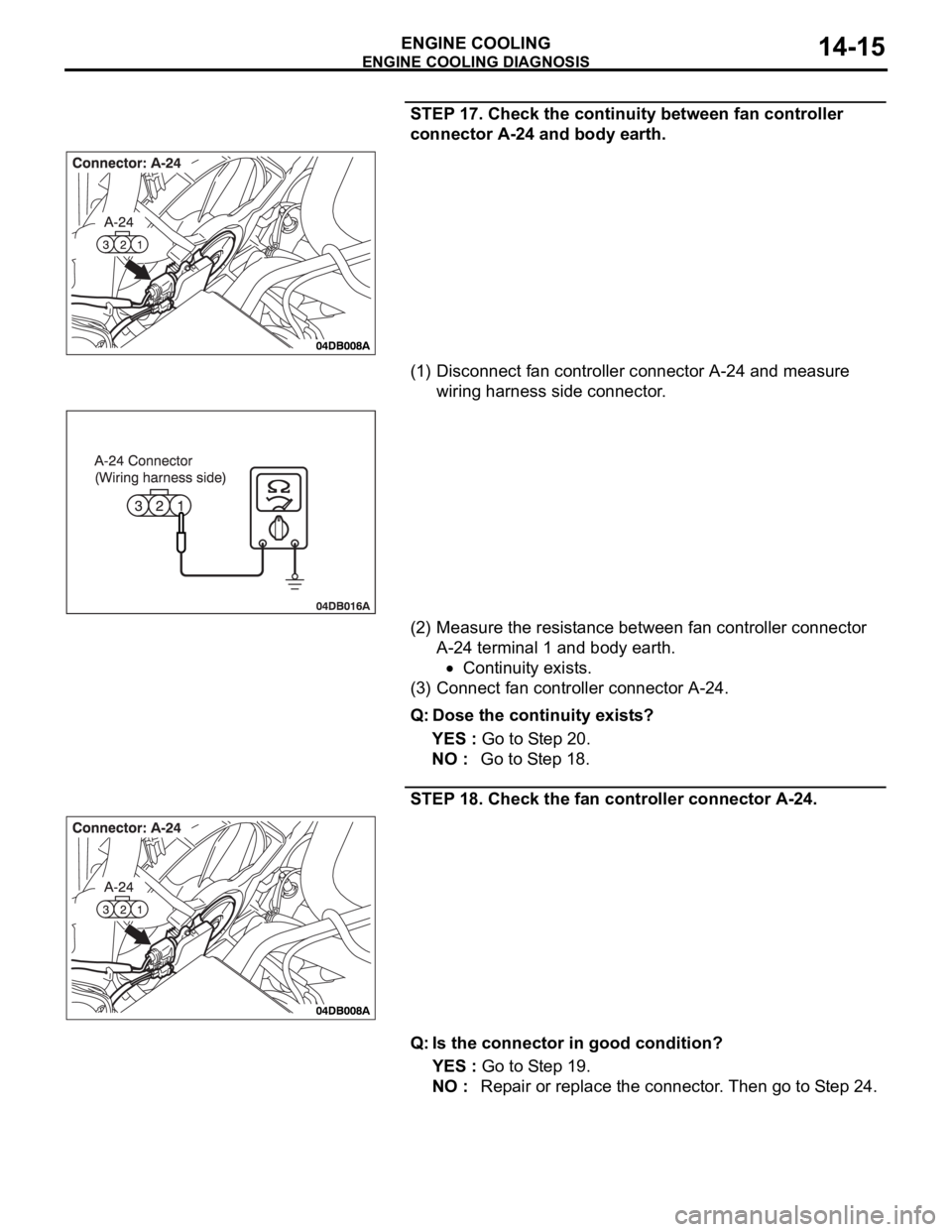

STEP 17. Check the continuity between fan controller

connector A-24 and body earth.

(1) Disconnect fan controller connector A-24 and measure

wiring harness side connector.

(2) Measure the resistance between fan controller connector

A-24 terminal 1 and body earth.

Continuity exists.

(3) Connect fan controller connector A-24.

Q: Dose the continuity exists?

YES : Go to Step 20.

NO : Go to Step 18.

STEP 18. Check the fan controller connector A-24.

Q: Is the connector in good condition?

YES : Go to Step 19.

NO : Repair or replace the connector. Then go to Step 24.