Start system MITSUBISHI 380 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1265 of 1500

MAINTENANCE SERVICE

GENERAL00-44

8. EXHAUST SYSTEM (CONNECTIONS PORTION

OF MUFFLER, MUFFLER PIPES AND

CONVERTER HEAT SHIELDS) (CHECK AND

SERVICE AS REQUIRED)

M1001005800299

1. Check for holes and exhaust gas leaks due to damage,

corrosion, etc.

2. Check the joints and connections for looseness and exhaust

gas leaks.

3. Check the rubber hangers and brackets for damage.

9. ENGINE OIL (CHANGE)M1001002600360

Use the specified oil. (Refer to P.00-35.)

Use care as oil could be hot.

1. After warming up the engine, remove the oil filler cap.

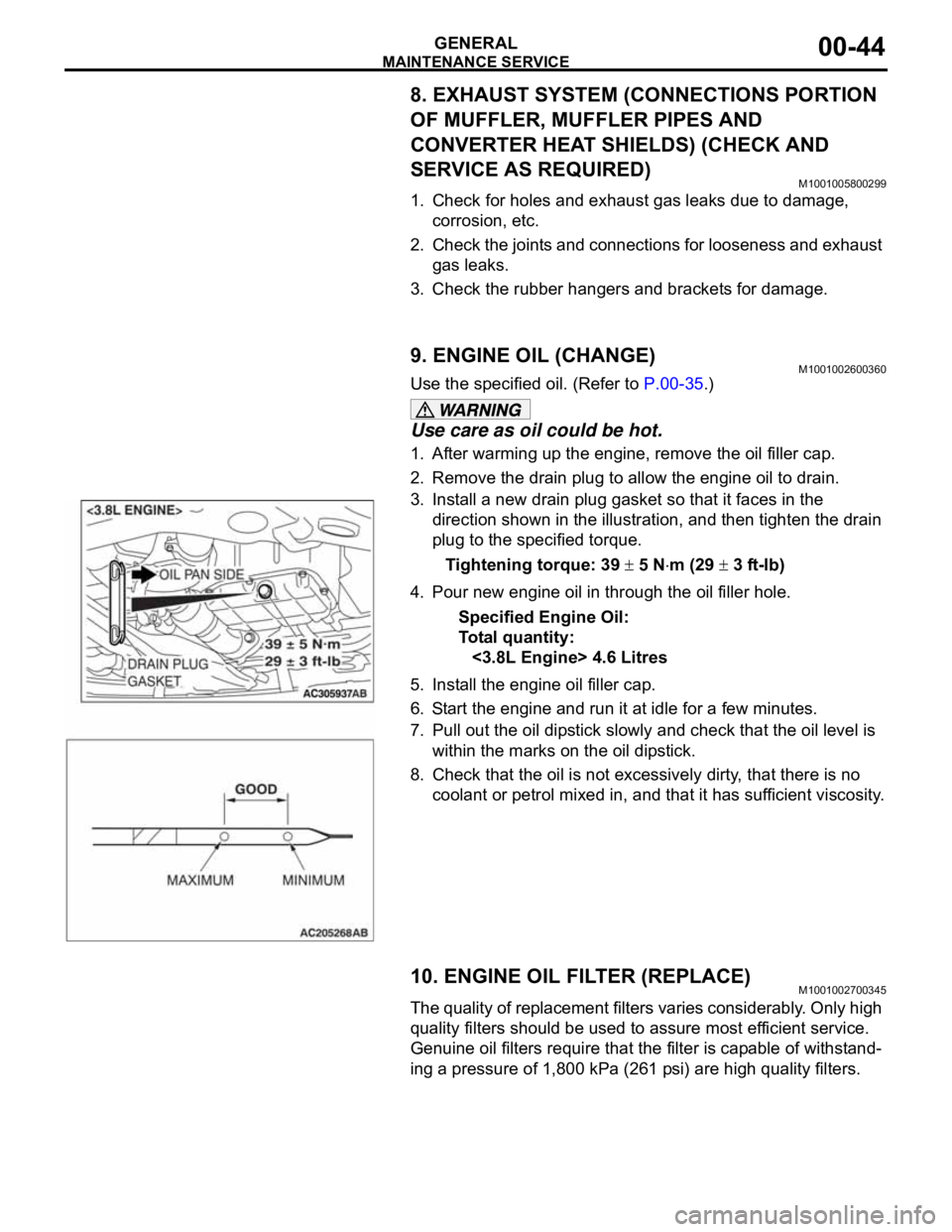

2. Remove the drain plug to allow the engine oil to drain.

3. Install a new drain plug gasket so that it faces in the

direction shown in the illustration, and then tighten the drain

plug to the specified torque.

Tightening torque: 39

5 Nm (29 3 ft-lb)

4. Pour new engine oil in through the oil filler hole.

Specified Engine Oil:

To ta l q u a n t i t y :

<3.8L Engine> 4.6 Litres

5. Install the engine oil filler cap.

6. Start the engine and run it at idle for a few minutes.

7. Pull out the oil dipstick slowly and check that the oil level is

within the marks on the oil dipstick.

8. Check that the oil is not excessively dirty, that there is no

coolant or petrol mixed in, and that it has sufficient viscosity.

10. ENGINE OIL FILTER (REPLACE)M1001002700345

The quality of replacement filters varies considerably. Only high

quality filters should be used to assure most efficient service.

Genuine oil filters require that the filter is capable of withstand-

ing a pressure of 1,800 kPa (261 psi) are high quality filters.

.

Page 1282 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-3

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

INTRODUCTION TO TRACTION CONTROL SYSTEM (TCL) DIAGNOSISM1136004600026

TCL Diagnostic Trouble Code Detection

Conditions

TCL diagnostic trouble codes (TCL DTCs) are set

under different conditions, depending on the mal-

function detected. Most TCL DTCs will only be set

during vehicle operation. Some TCL DTCs will also

be set during the TCL self-check immediately after

the engine is started. When you check if an TCL DTC will be displayed again after the DTC has been

erased, you should recreate the TCL DTC set condi-

tions. Depending on the detection timing and set

conditions for the specific TCL DTC, you must either

drive the vehicle or turn the engine off and restart it.

To set the proper conditions for that DTC again, refer

to "TCL DTC SET CONDITIONS" for each TCL DTC

that you are trying to reset.

TROUBLESHOOTING STRATEGYM1136003100062

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will check most of the

possible causes of a TCL problem.

1. Gather information from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any TCL DTC. (Refer to

P.13C-3, Diagnosis Function

How to Read and

Erase Diagnostic Trouble Codes).

4. If you can verify the condition but no TCL DTCs

are set, and the malfunction may be intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunctions P.00-14).

5. If you can verify the condition but there is no TCL

DTCs, or the system cannot communicate with

diagnostic tool MB991958 (MUT-III sub

assembly), and find the fault. (Refer to P.13C-23,

Symptom Chart).6. If there is a TCL DTC, record the number of the

code, then erase the code from vehicle memory

using the diagnostic tool MB991958 (MUT-III sub

assembly). (Refer to P.13C-3, Diagnosis Function

How to Read and Erase Diagnostic Trouble

Codes).

7. Re-create the TCL DTC set conditions to see if

the same TCL DTC will set again. (Refer to

P.13C-3, Diagnosis Function

How to Read and

Erase Diagnostic Trouble Codes).

If the same TCL DTC sets again, perform the

diagnostic procedures for the set code. (Refer to

P.13C-8, Diagnostic Trouble Code Chart).

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wir-

ing is an open/ short circuit, the ABS 8 ECU

will shut off power supply to the respective

wheel speed sensor. All other wheel speed

sensors will operate normally. To restore the

power supply, the ignition switch must be

turned to the "OFF" position then to the "ON"

position again.

DIAGNOSIS FUNCTIONM1136003200025

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1283 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-4

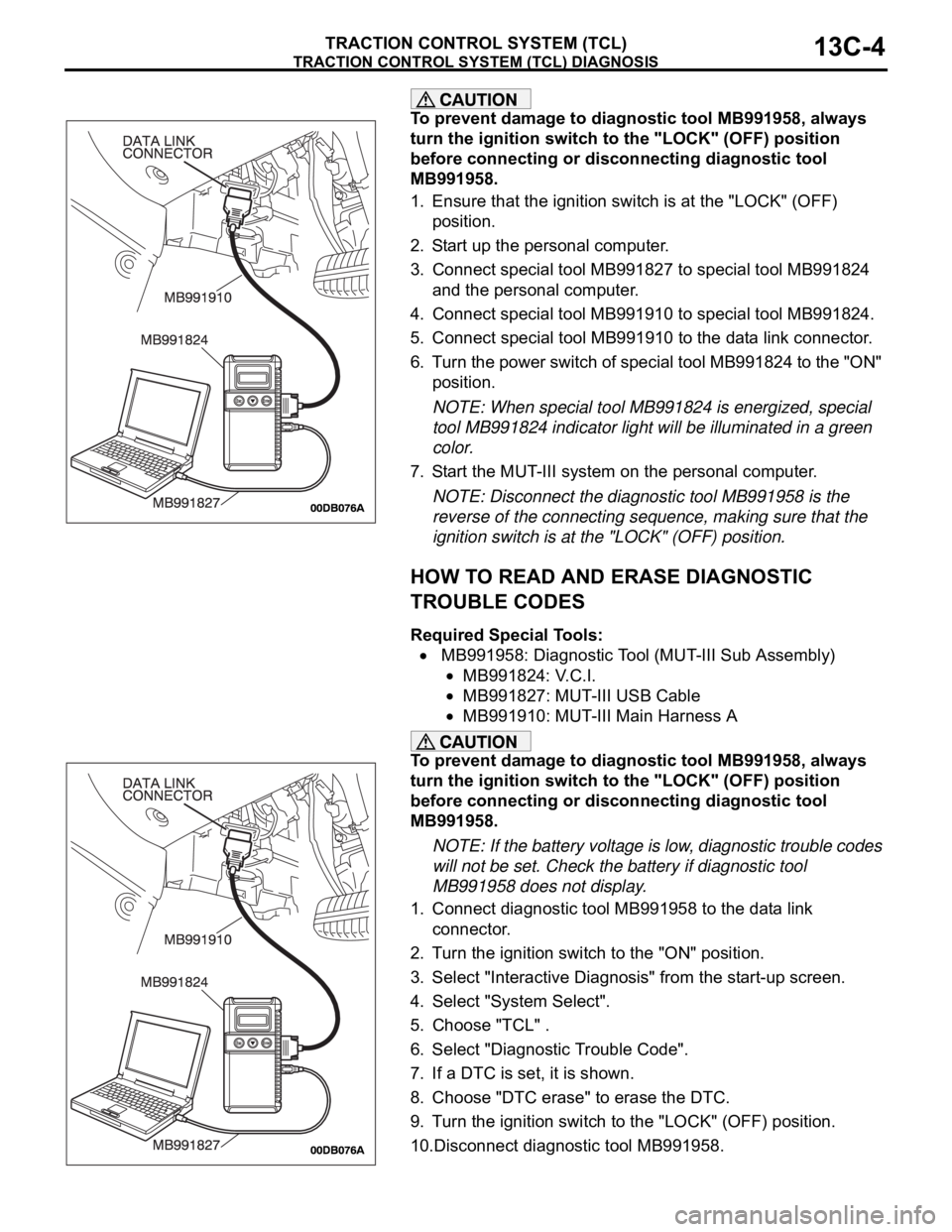

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824.

5. Connect special tool MB991910 to the data link connector.

6. Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When special tool MB991824 is energized, special

tool MB991824 indicator light will be illuminated in a green

color.

7. Start the MUT-III system on the personal computer.

NOTE: Disconnect the diagnostic tool MB991958 is the

reverse of the connecting sequence, making sure that the

ignition switch is at the "LOCK" (OFF) position.

HOW TO READ AND ERASE DIAGNOSTIC

TROUBLE CODES

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

NOTE: If the battery voltage is low, diagnostic trouble codes

will not be set. Check the battery if diagnostic tool

MB991958 does not display.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System Select".

5. Choose "TCL" .

6. Select "Diagnostic Trouble Code".

7. If a DTC is set, it is shown.

8. Choose "DTC erase" to erase the DTC.

9. Turn the ignition switch to the "LOCK" (OFF) position.

10.Disconnect diagnostic tool MB991958.

Page 1284 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-5

HOW TO READ DATA LIST

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System Select."

5. Choose "TCL" .

6. Select "Data List."

7. Choose an appropriate item.

8. Turn the ignition switch to the "LOCK" (OFF) position.

9. Disconnect diagnostic tool MB991958.

Page 1285 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-6

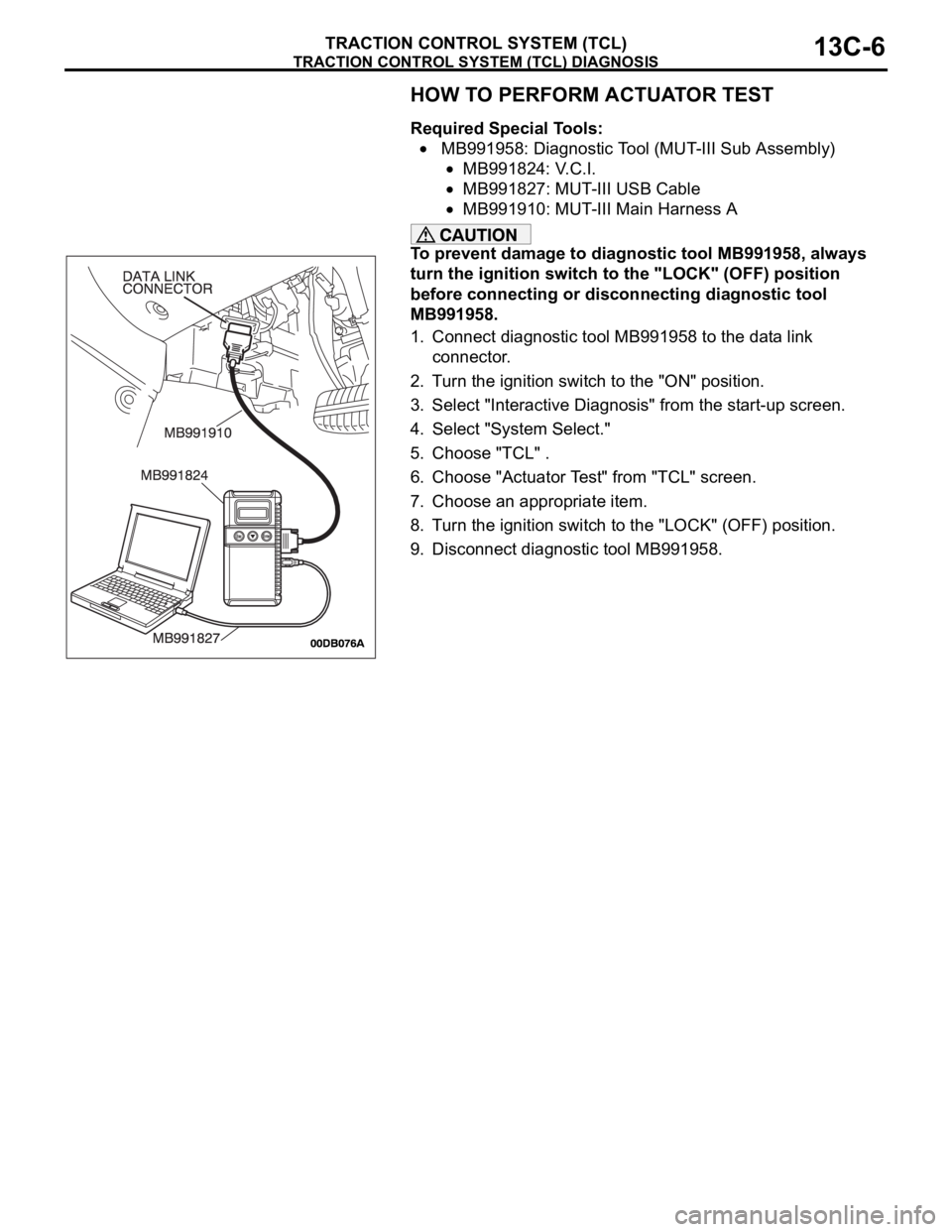

HOW TO PERFORM ACTUATOR TEST

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System Select."

5. Choose "TCL" .

6. Choose "Actuator Test" from "TCL" screen.

7. Choose an appropriate item.

8. Turn the ignition switch to the "LOCK" (OFF) position.

9. Disconnect diagnostic tool MB991958.

Page 1286 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-7

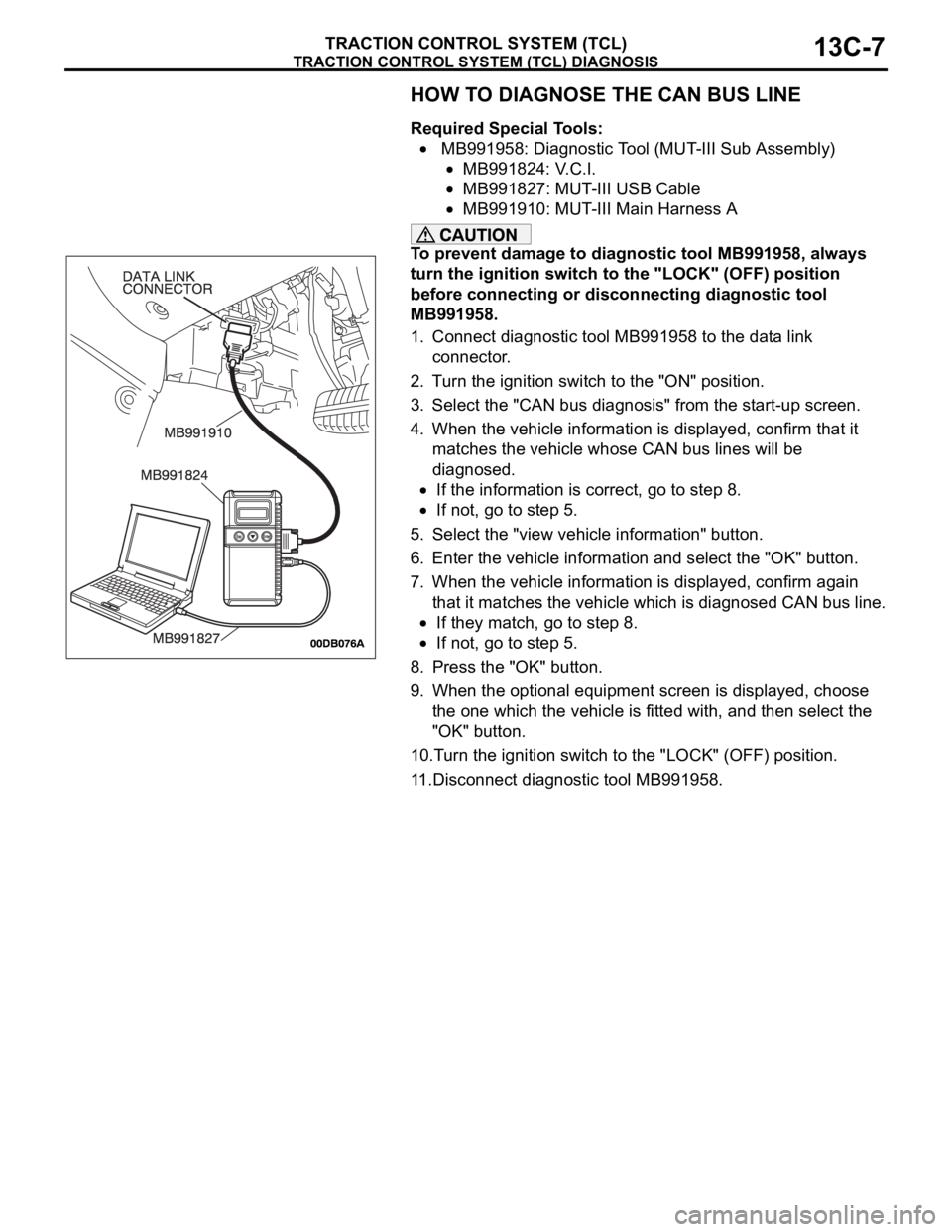

HOW TO DIAGNOSE THE CAN BUS LINE

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select the "CAN bus diagnosis" from the start-up screen.

4. When the vehicle information is displayed, confirm that it

matches the vehicle whose CAN bus lines will be

diagnosed.

If the information is correct, go to step 8.

If not, go to step 5.

5. Select the "view vehicle information" button.

6. Enter the vehicle information and select the "OK" button.

7. When the vehicle information is displayed, confirm again

that it matches the vehicle which is diagnosed CAN bus line.

If they match, go to step 8.

If not, go to step 5.

8. Press the "OK" button.

9. When the optional equipment screen is displayed, choose

the one which the vehicle is fitted with, and then select the

"OK" button.

10.Turn the ignition switch to the "LOCK" (OFF) position.

11.Disconnect diagnostic tool MB991958.

Page 1302 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-23

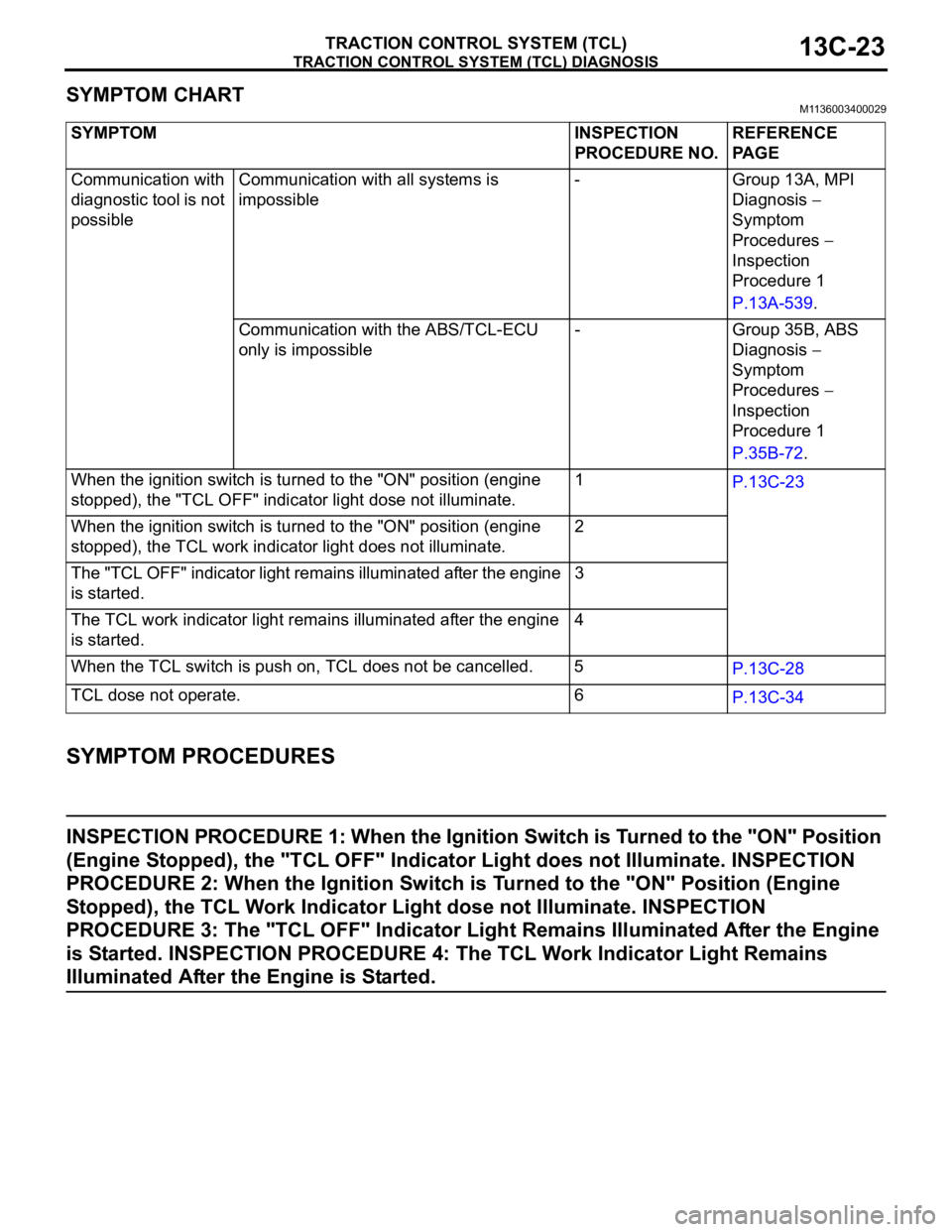

SYMPTOM CHARTM1136003400029

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: When the Ignition Switch is Turned to the "ON" Position

(Engine Stopped), the "TCL OFF" Indicator Light does not Illuminate. INSPECTION

PROCEDURE 2: When the Ignition Switch is Turned to the "ON" Position (Engine

Stopped), the TCL Work Indicator Light dose not Illuminate. INSPECTION

PROCEDURE 3: The "TCL OFF" Indicator Light Remains Illuminated After the Engine

is Started. INSPECTION PROCEDURE 4: The TCL Work Indicator Light Remains

Illuminated After the Engine is Started.

SYMPTOM INSPECTION

PROCEDURE NO.REFERENCE

PA G E

Communication with

diagnostic tool is not

possibleCommunication with all systems is

impossible- Group 13A, MPI

Diagnosis

Symptom

Procedures

Inspection

Procedure 1

P.13A-539.

Communication with the ABS/TCL-ECU

only is impossible- Group 35B, ABS

Diagnosis

Symptom

Procedures

Inspection

Procedure 1

P.35B-72.

When the ignition switch is turned to the "ON" position (engine

stopped), the "TCL OFF" indicator light dose not illuminate.1

P.13C-23

When the ignition switch is turned to the "ON" position (engine

stopped), the TCL work indicator light does not illuminate.2

The "TCL OFF" indicator light remains illuminated after the engine

is started.3

The TCL work indicator light remains illuminated after the engine

is started.4

When the TCL switch is push on, TCL does not be cancelled. 5

P.13C-28

TCL dose not operate. 6

P.13C-34

Page 1307 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-28

STEP 4. Retest the system

Q: Turn the ignition switch to the "ON" position. Do the

"TCL OFF" indicator light and the TCL work indicator

light illuminate for three seconds, and then go out after

the engine starts?

YES : The procedure is complete.

NO : . Return to Step 1.

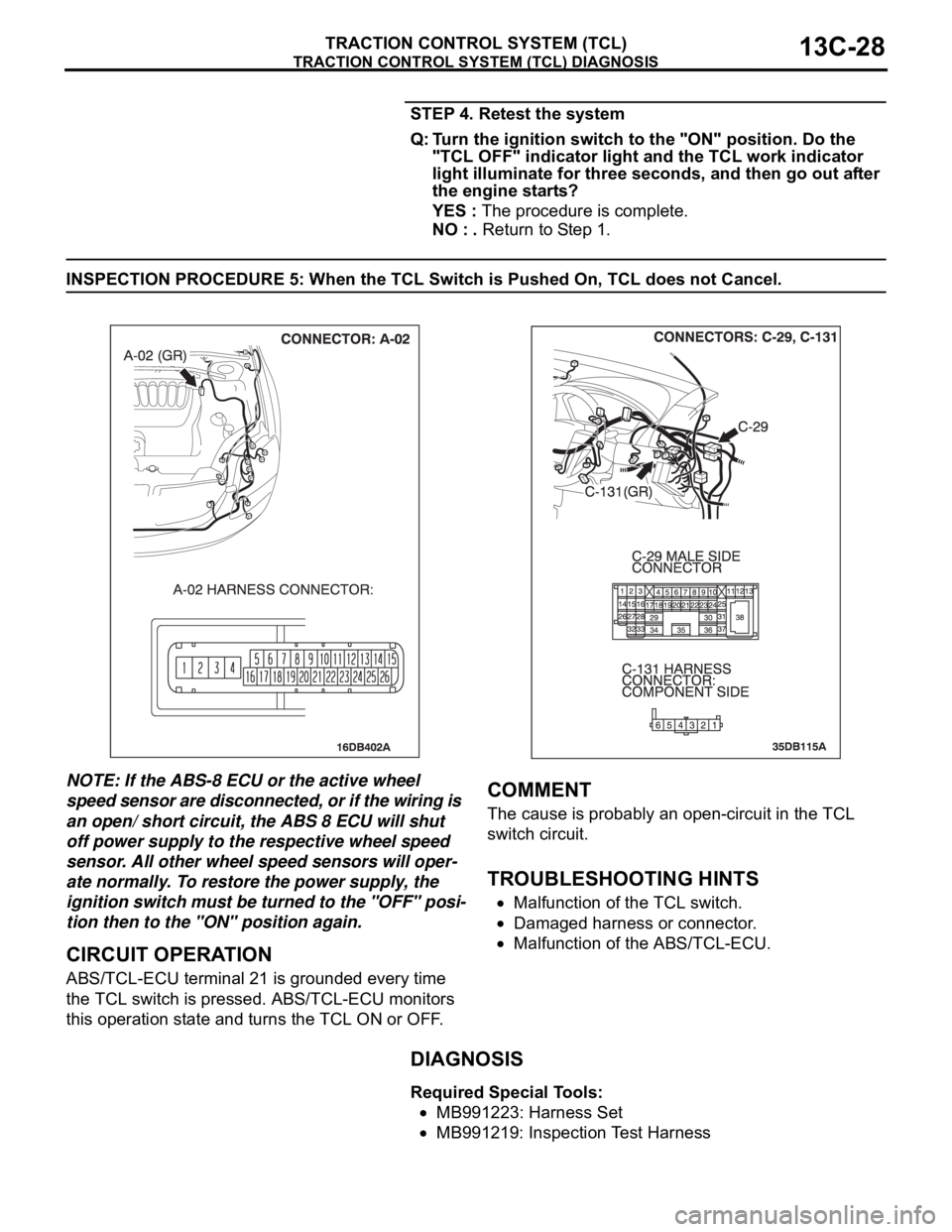

INSPECTION PROCEDURE 5: When the TCL Switch is Pushed On, TCL does not Cancel.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.

.

CIRCUIT OPERATION

ABS/TCL-ECU terminal 21 is grounded every time

the TCL switch is pressed. ABS/TCL-ECU monitors

this operation state and turns the TCL ON or OFF.

.

COMMENT

The cause is probably an open-circuit in the TCL

switch circuit.

.

TROUBLESHOOTING HINTS

Malfunction of the TCL switch.

Damaged harness or connector.

Malfunction of the ABS/TCL-ECU.

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991219: Inspection Test Harness

Page 1317 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-38

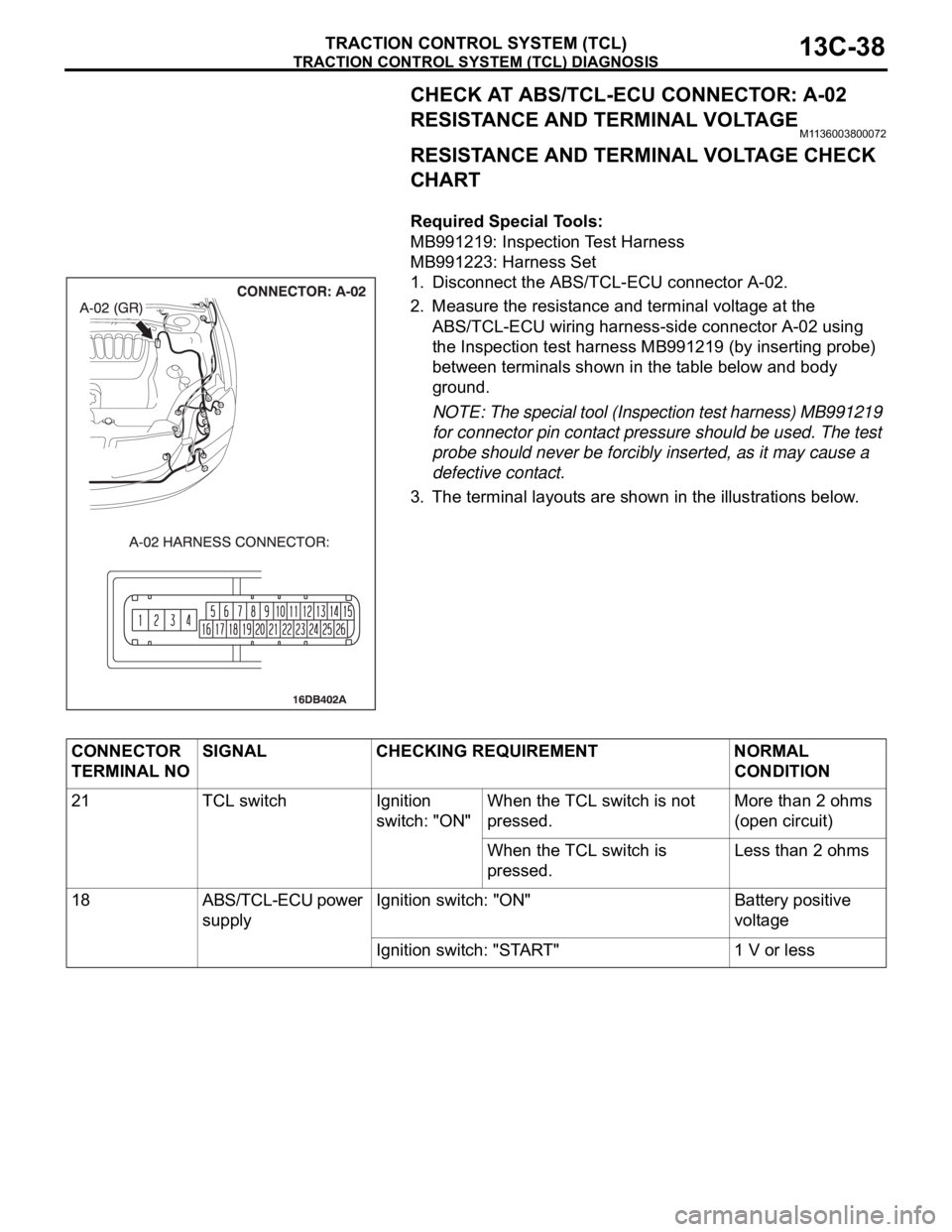

CHECK AT ABS/TCL-ECU CONNECTOR: A-02

RESISTANCE AND TERMINAL VOLTAGE

M1136003800072

RESISTANCE AND TERMINAL VOLTAGE CHECK

CHART

.

Required Special Tools:

MB991219: Inspection Test Harness

MB991223: Harness Set

1. Disconnect the ABS/TCL-ECU connector A-02.

2. Measure the resistance and terminal voltage at the

ABS/TCL-ECU wiring harness-side connector A-02 using

the Inspection test harness MB991219 (by inserting probe)

between terminals shown in the table below and body

ground.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

3. The terminal layouts are shown in the illustrations below.

CONNECTOR

TERMINAL NOSIGNAL CHECKING REQUIREMENT NORMAL

CONDITION

21 TCL switch Ignition

switch: "ON" When the TCL switch is not

pressed.More than 2 ohms

(open circuit)

When the TCL switch is

pressed.Less than 2 ohms

18 ABS/TCL-ECU power

supplyIgnition switch: "ON" Battery positive

voltage

Ignition switch: "START" 1 V or less

Page 1326 of 1500

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-47

ON-VEHICLE SERVICE

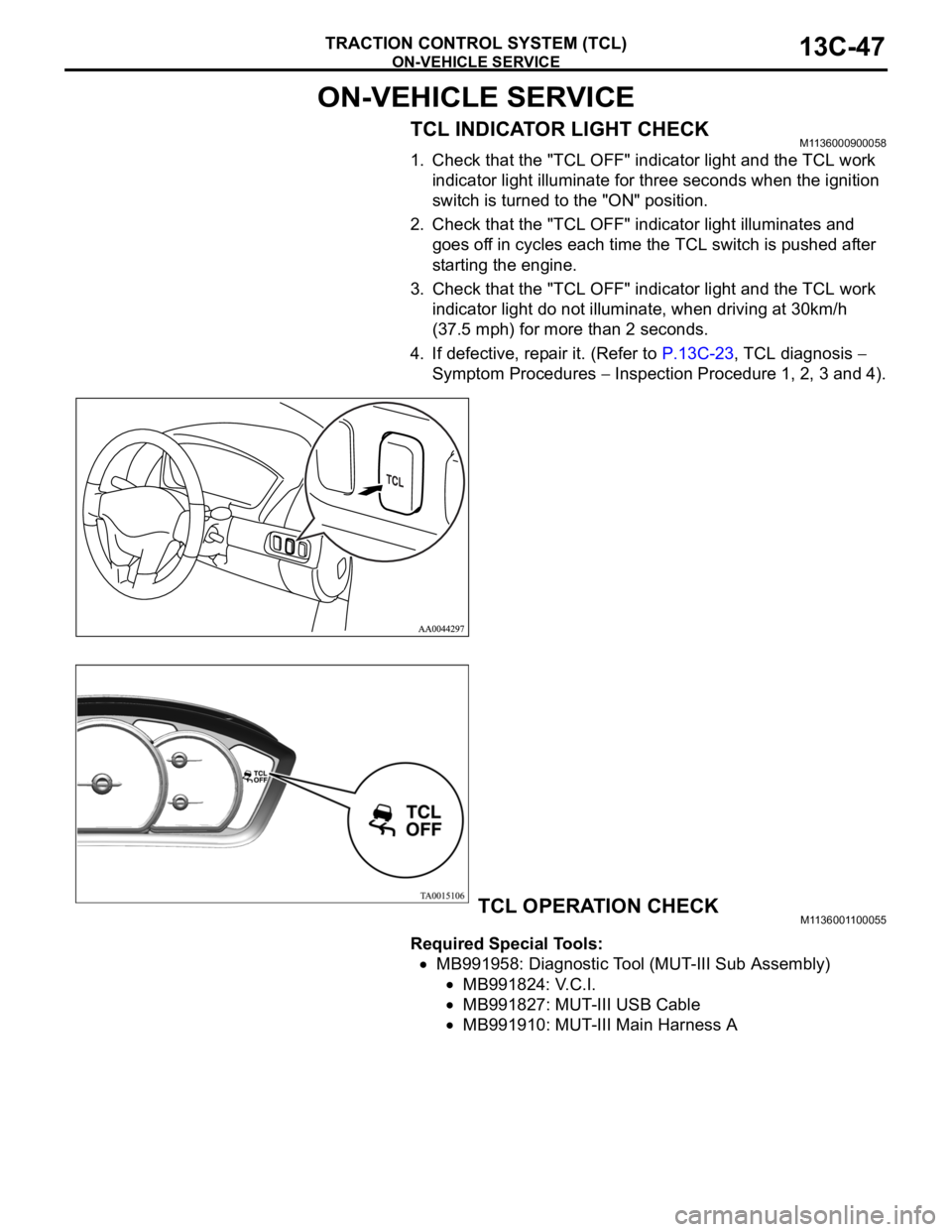

TCL INDICATOR LIGHT CHECKM1136000900058

1. Check that the "TCL OFF" indicator light and the TCL work

indicator light illuminate for three seconds when the ignition

switch is turned to the "ON" position.

2. Check that the "TCL OFF" indicator light illuminates and

goes off in cycles each time the TCL switch is pushed after

starting the engine.

3. Check that the "TCL OFF" indicator light and the TCL work

indicator light do not illuminate, when driving at 30km/h

(37.5 mph) for more than 2 seconds.

4. If defective, repair it. (Refer to P.13C-23, TCL diagnosis

Symptom Procedures

Inspection Procedure 1, 2, 3 and 4).

TCL OPERATION CHECKM1136001100055

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A