Battery MITSUBISHI 380 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 263 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-263

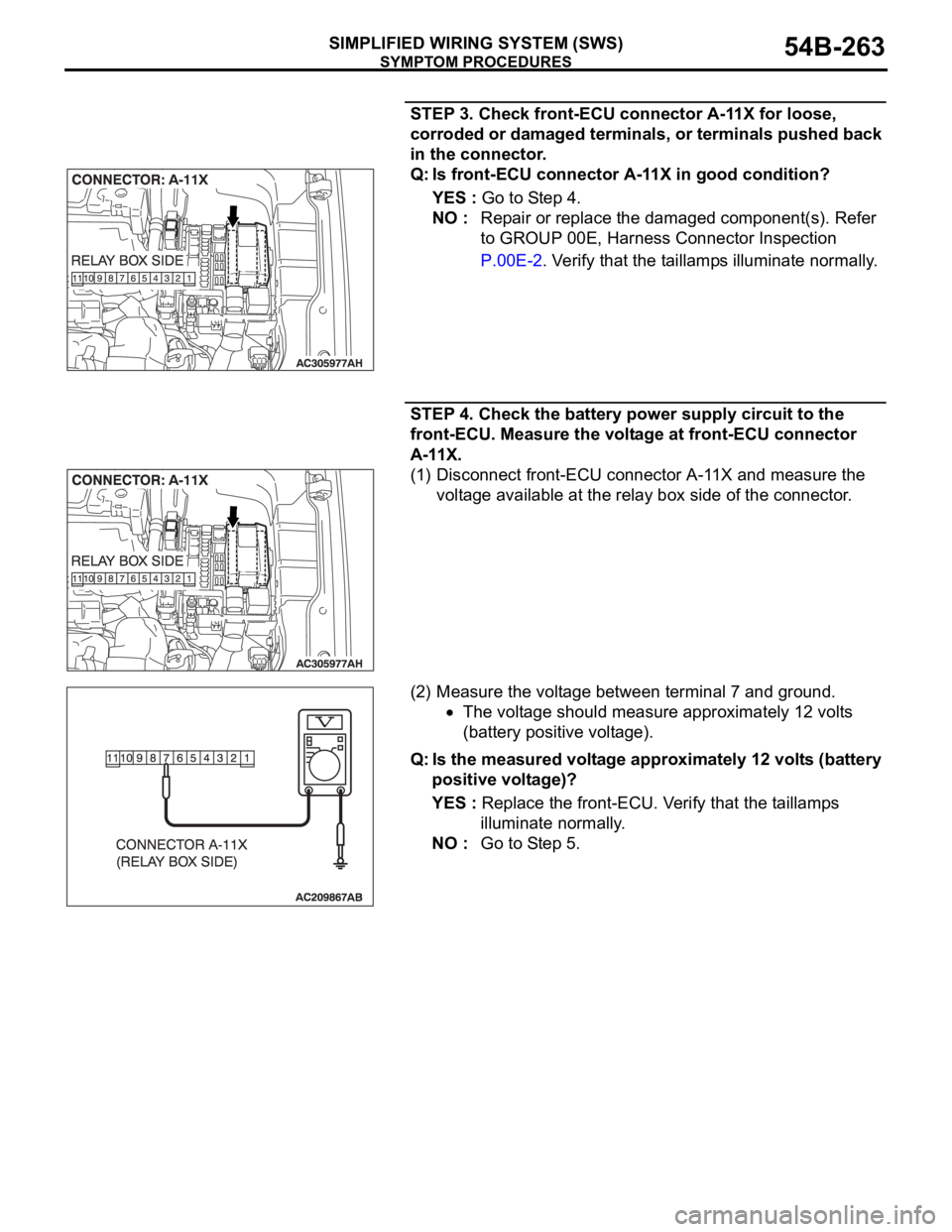

STEP 3. Check front-ECU connector A-11X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-11X in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the taillamps illuminate normally.

STEP 4. Check the battery power supply circuit to the

front-ECU. Measure the voltage at front-ECU connector

A-11X.

(1) Disconnect front-ECU connector A-11X and measure the

voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 7 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Replace the front-ECU. Verify that the taillamps

illuminate normally.

NO : Go to Step 5.

Page 264 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-264

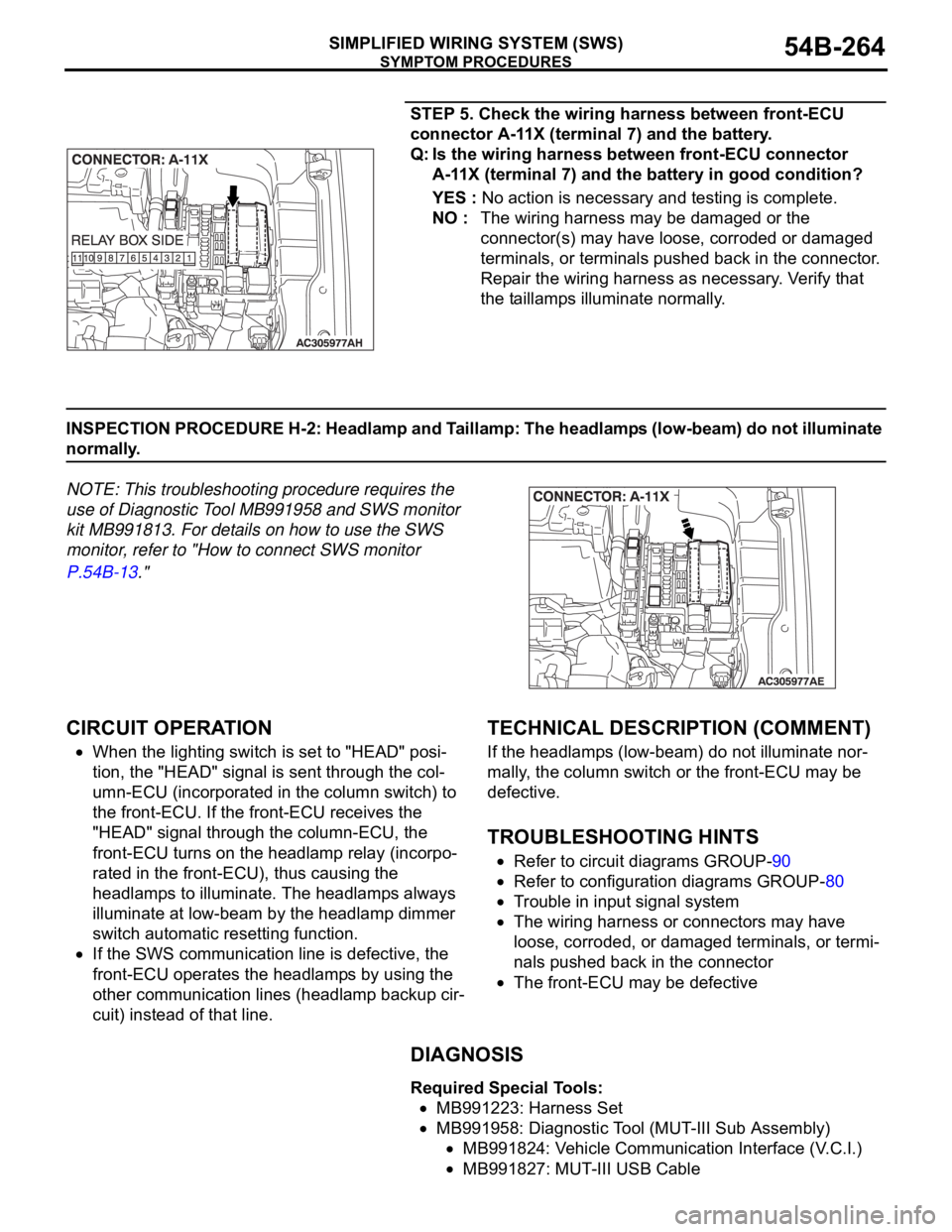

STEP 5. Check the wiring harness between front-ECU

connector A-11X (terminal 7) and the battery.

Q: Is the wiring harness between front-ECU connector

A-11X (terminal 7) and the battery in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the taillamps illuminate normally.

INSPECTION PROCEDURE H-2: Headlamp and Taillamp: The headlamps (low-beam) do not illuminate

normally.

NOTE: This troubleshooting procedure requires the

use of Diagnostic Tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

When the lighting switch is set to "HEAD" posi-

tion, the "HEAD" signal is sent through the col-

umn-ECU (incorporated in the column switch) to

the front-ECU. If the front-ECU receives the

"HEAD" signal through the column-ECU, the

front-ECU turns on the headlamp relay (incorpo-

rated in the front-ECU), thus causing the

headlamps to illuminate. The headlamps always

illuminate at low-beam by the headlamp dimmer

switch automatic resetting function.

If the SWS communication line is defective, the

front-ECU operates the headlamps by using the

other communication lines (headlamp backup cir-

cuit) instead of that line.

.

TECHNICAL DESCRIPTION (COMMENT)

If the headlamps (low-beam) do not illuminate nor-

mally, the column switch or the front-ECU may be

defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The front-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

Page 267 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-267

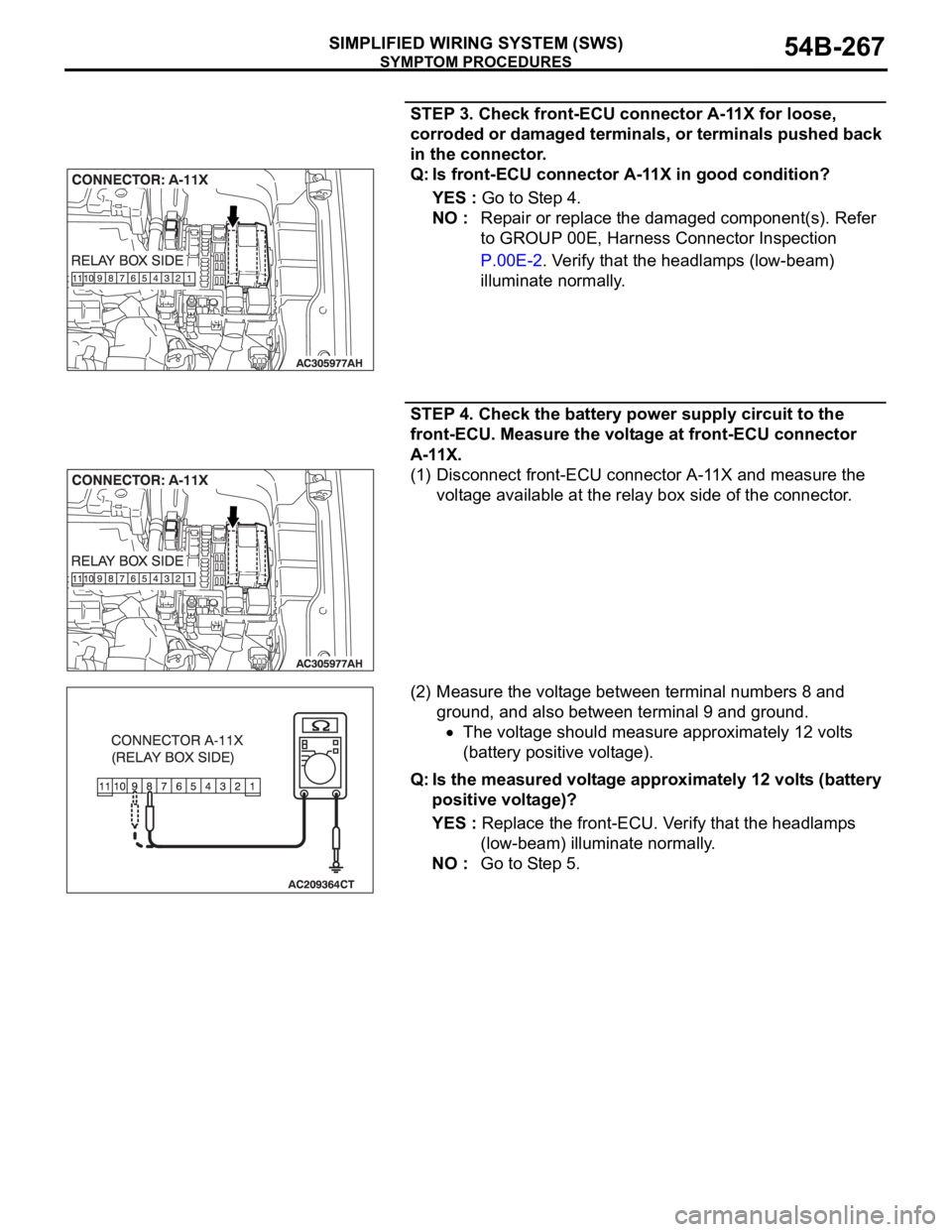

STEP 3. Check front-ECU connector A-11X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is front-ECU connector A-11X in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the headlamps (low-beam)

illuminate normally.

STEP 4. Check the battery power supply circuit to the

front-ECU. Measure the voltage at front-ECU connector

A-11X.

(1) Disconnect front-ECU connector A-11X and measure the

voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal numbers 8 and

ground, and also between terminal 9 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Replace the front-ECU. Verify that the headlamps

(low-beam) illuminate normally.

NO : Go to Step 5.

Page 268 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-268

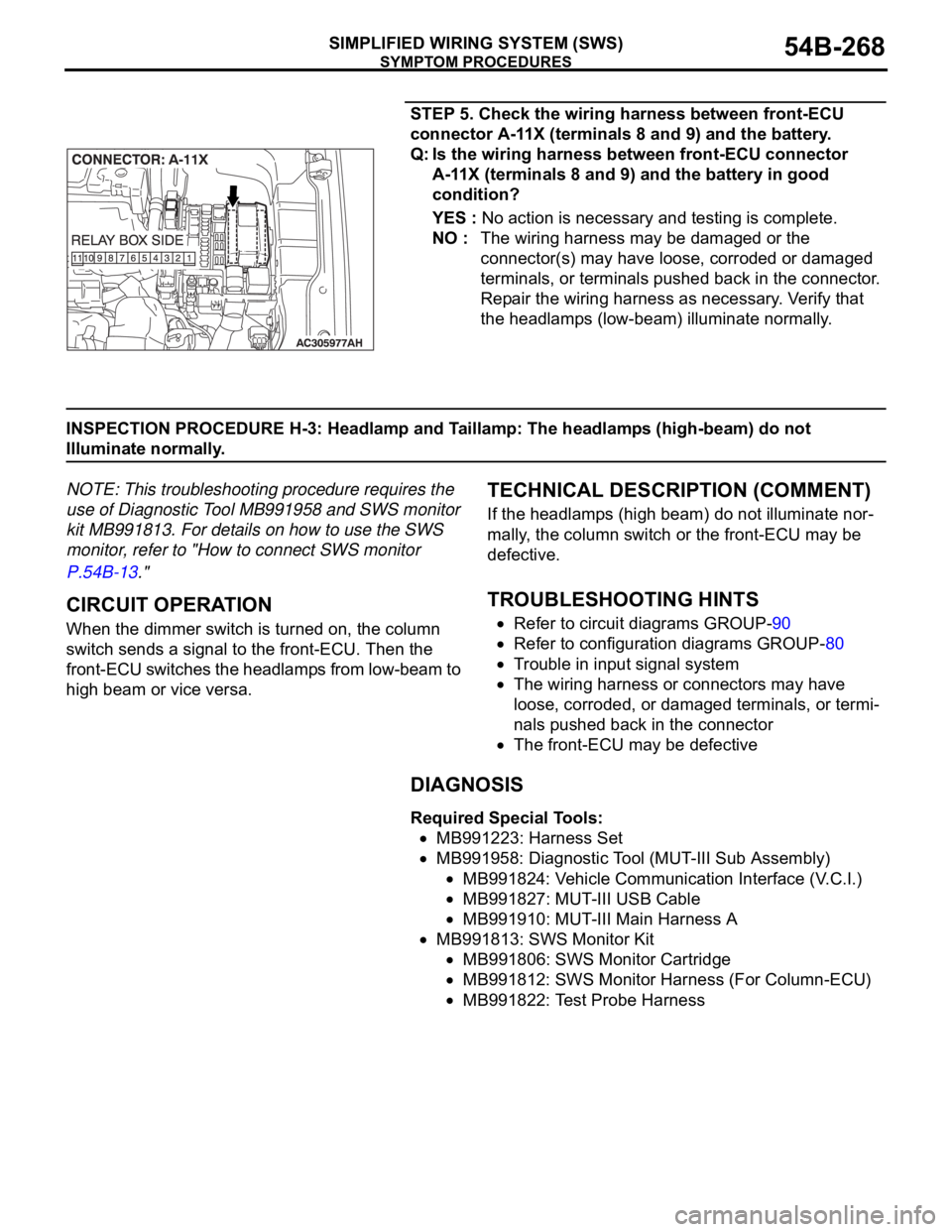

STEP 5. Check the wiring harness between front-ECU

connector A-11X (terminals 8 and 9) and the battery.

Q: Is the wiring harness between front-ECU connector

A-11X (terminals 8 and 9) and the battery in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps (low-beam) illuminate normally.

INSPECTION PROCEDURE H-3: Headlamp and Taillamp: The headlamps (high-beam) do not

Illuminate normally.

NOTE: This troubleshooting procedure requires the

use of Diagnostic Tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

When the dimmer switch is turned on, the column

switch sends a signal to the front-ECU. Then the

front-ECU switches the headlamps from low-beam to

high beam or vice versa.

.

TECHNICAL DESCRIPTION (COMMENT)

If the headlamps (high beam) do not illuminate nor-

mally, the column switch or the front-ECU may be

defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The front-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness

Page 312 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-312

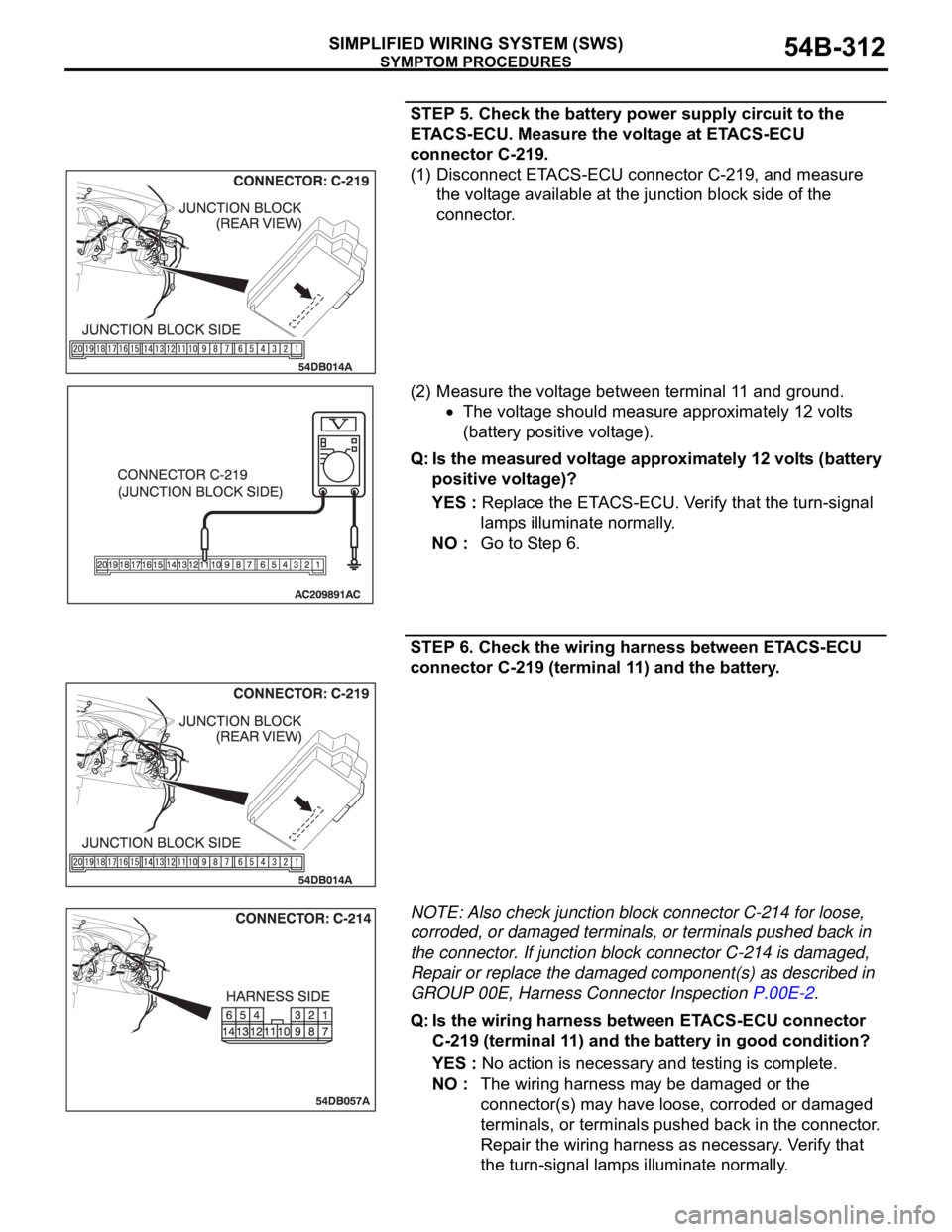

STEP 5. Check the battery power supply circuit to the

ETACS-ECU. Measure the voltage at ETACS-ECU

connector C-219.

(1) Disconnect ETACS-ECU connector C-219, and measure

the voltage available at the junction block side of the

connector.

(2) Measure the voltage between terminal 11 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Replace the ETACS-ECU. Verify that the turn-signal

lamps illuminate normally.

NO : Go to Step 6.

STEP 6. Check the wiring harness between ETACS-ECU

connector C-219 (terminal 11) and the battery.

NOTE: Also check junction block connector C-214 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-214 is damaged,

Repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-219 (terminal 11) and the battery in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the turn-signal lamps illuminate normally.

Page 342 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-342

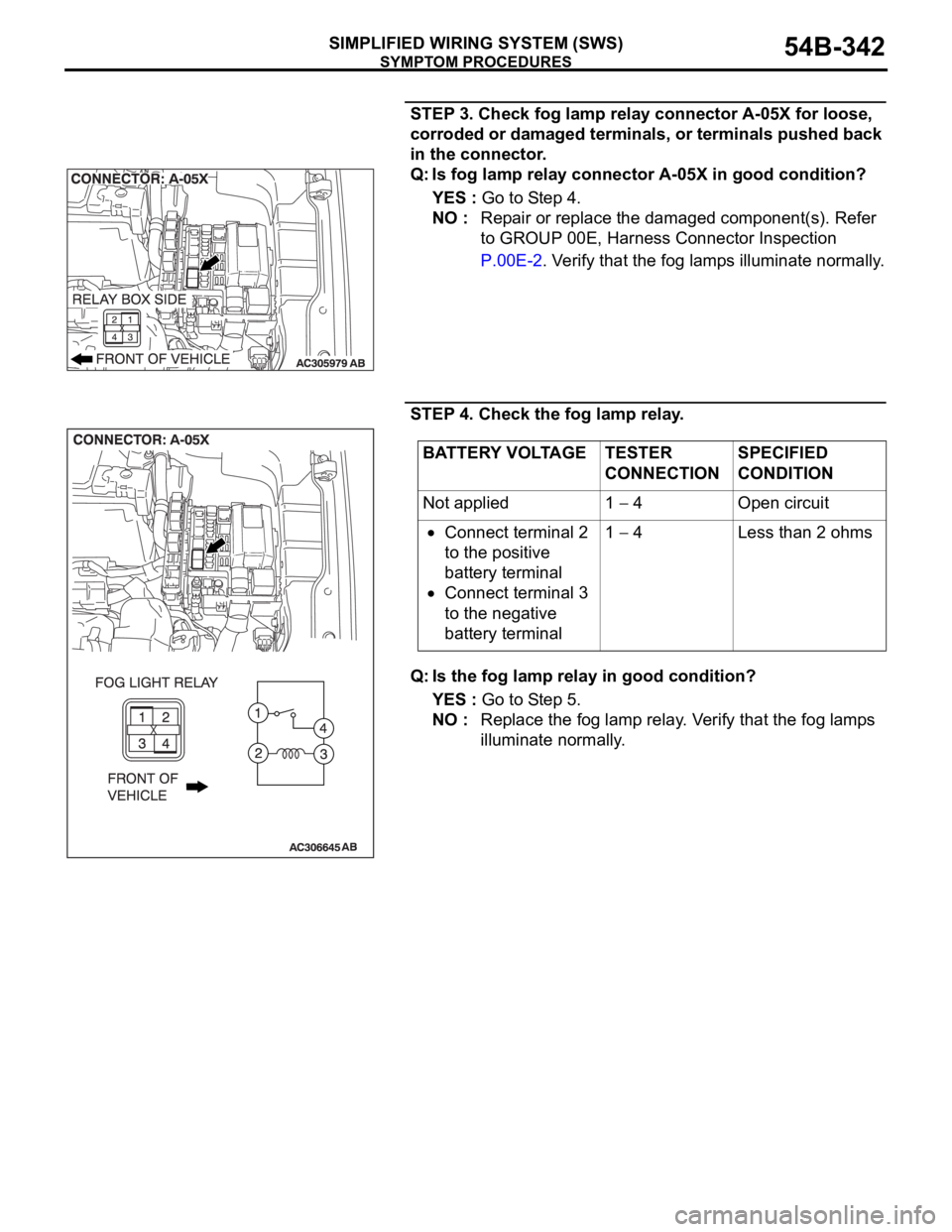

STEP 3. Check fog lamp relay connector A-05X for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp relay connector A-05X in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the fog lamps illuminate normally.

STEP 4. Check the fog lamp relay.

Q: Is the fog lamp relay in good condition?

YES : Go to Step 5.

NO : Replace the fog lamp relay. Verify that the fog lamps

illuminate normally.

BATTERY VOLTAGE TESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect terminal 2

to the positive

battery terminal

Connect terminal 3

to the negative

battery terminal1

4 Less than 2 ohms

Page 343 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-343

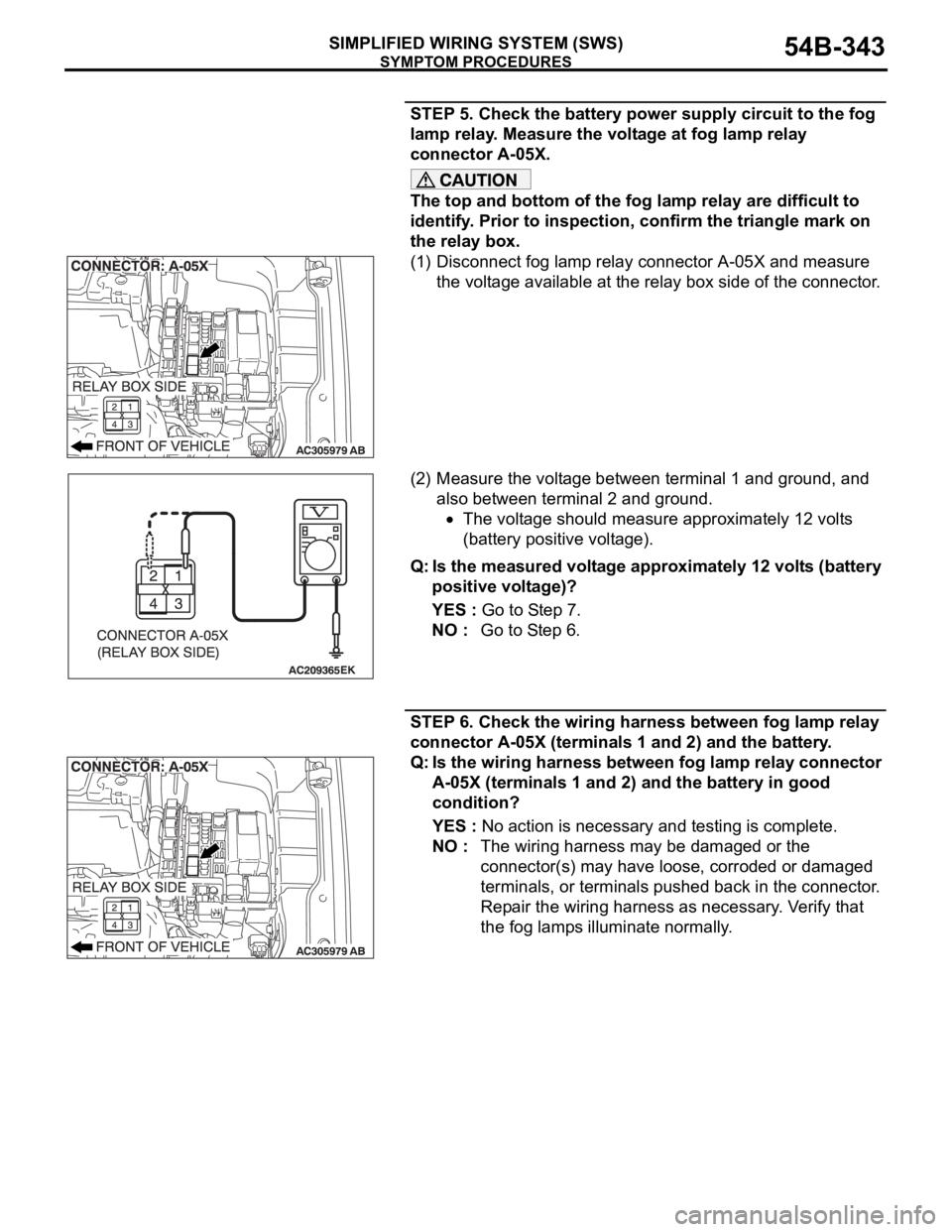

STEP 5. Check the battery power supply circuit to the fog

lamp relay. Measure the voltage at fog lamp relay

connector A-05X.

The top and bottom of the fog lamp relay are difficult to

identify. Prior to inspection, confirm the triangle mark on

the relay box.

(1) Disconnect fog lamp relay connector A-05X and measure

the voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 1 and ground, and

also between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 7.

NO : Go to Step 6.

STEP 6. Check the wiring harness between fog lamp relay

connector A-05X (terminals 1 and 2) and the battery.

Q: Is the wiring harness between fog lamp relay connector

A-05X (terminals 1 and 2) and the battery in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

Page 356 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-356

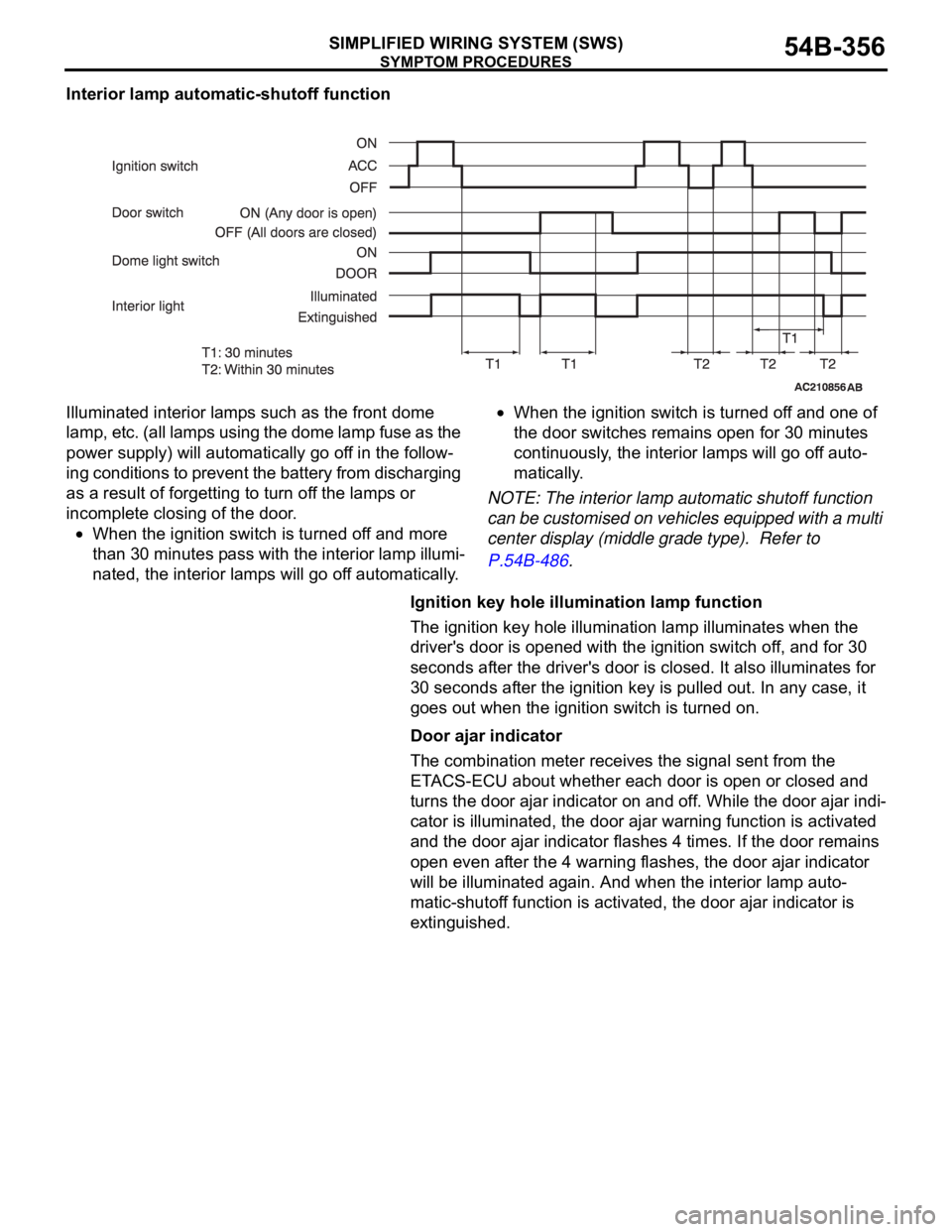

Interior lamp automatic-shutoff function

Illuminated interior lamps such as the front dome

lamp, etc. (all lamps using the dome lamp fuse as the

power supply) will automatically go off in the follow-

ing conditions to prevent the battery from discharging

as a result of forgetting to turn off the lamps or

incomplete closing of the door.

When the ignition switch is turned off and more

than 30 minutes pass with the interior lamp illumi-

nated, the interior lamps will go off automatically.

When the ignition switch is turned off and one of

the door switches remains open for 30 minutes

continuously, the interior lamps will go off auto-

matically.

NOTE: The interior lamp automatic shutoff function

can be customised on vehicles equipped with a multi

center display (middle grade type). Refer to

P.54B-486.

Ignition key hole illumination lamp function

The ignition key hole illumination lamp illuminates when the

driver's door is opened with the ignition switch off, and for 30

seconds after the driver's door is closed. It also illuminates for

30 seconds after the ignition key is pulled out. In any case, it

goes out when the ignition switch is turned on.

Door ajar indicator

The combination meter receives the signal sent from the

ETACS-ECU about whether each door is open or closed and

turns the door ajar indicator on and off. While the door ajar indi-

cator is illuminated, the door ajar warning function is activated

and the door ajar indicator flashes 4 times. If the door remains

open even after the 4 warning flashes, the door ajar indicator

will be illuminated again. And when the interior lamp auto-

matic-shutoff function is activated, the door ajar indicator is

extinguished.

Page 387 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-387

STEP 8. Check the key reminder switch (ignition key hole

illumination).

(1) Disconnect key reminder switch connector C-310.

(2) Remove the ignition key hole illumination lamp bulb. Then

measure the resistance value between the bulb terminals.

(3) Install a bulb to the key remainder switch, and measure the

resistance between connector C-310 terminals 1 and 2. The

measured resistance value should be roughly the same as

the value measured in Step (2).

Q: Are these two resistance values extremely different?

YES : Replace the key reminder switch. Verify that the

ignition key hole illumination lamp illuminates

normally.

NO :

STEP 9. Check the battery power supply circuit to the key

reminder switch circuit. Measure the voltage at key

reminder switch connector C-310.

(1) Disconnect key reminder switch connector C-310, and

measure the voltage available at the wiring harness side of

the connector.

(2) Measure the voltage between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 11.

NO : Go to Step 10.

Page 388 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-388

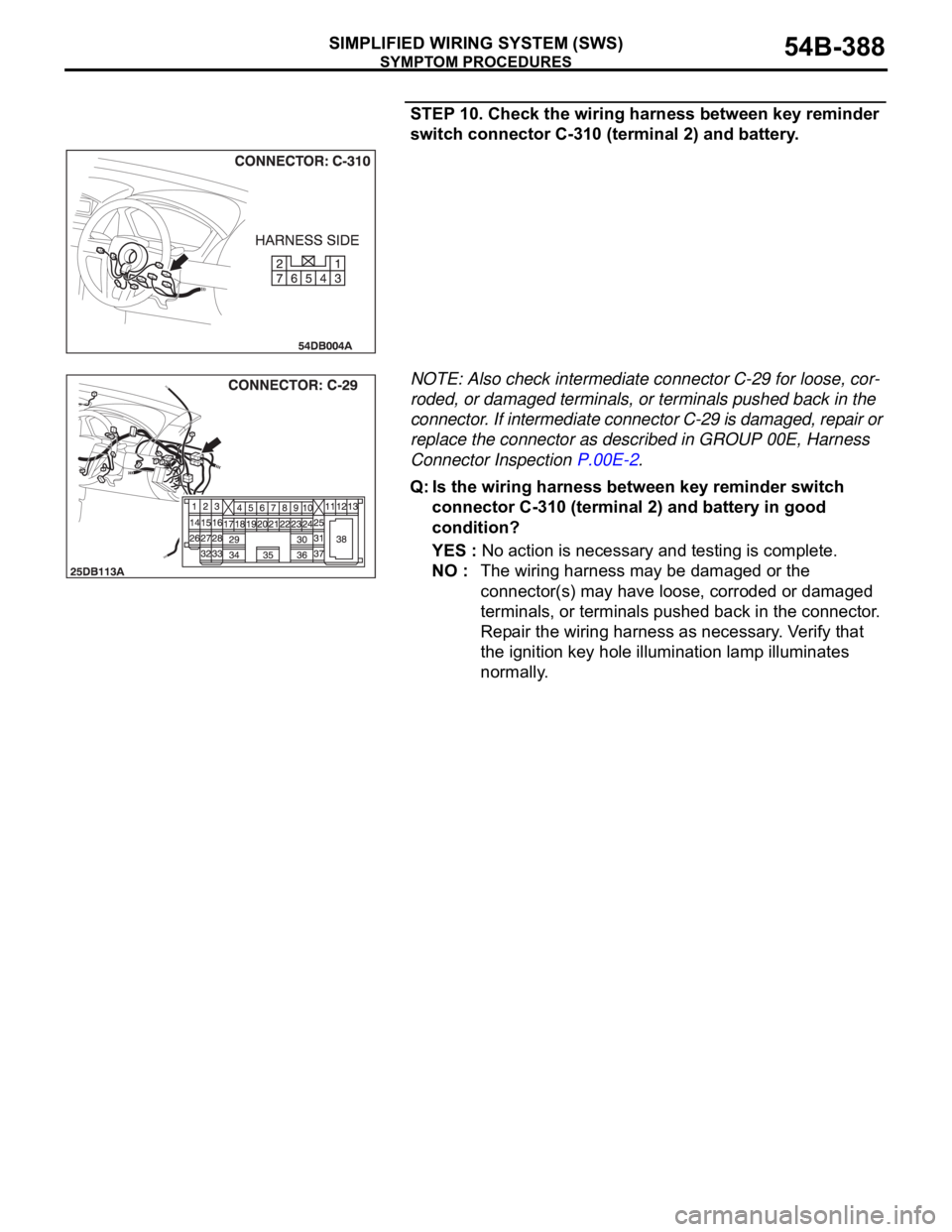

STEP 10. Check the wiring harness between key reminder

switch connector C-310 (terminal 2) and battery.

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between key reminder switch

connector C-310 (terminal 2) and battery in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the ignition key hole illumination lamp illuminates

normally.