window MITSUBISHI 380 2005 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 639 of 1500

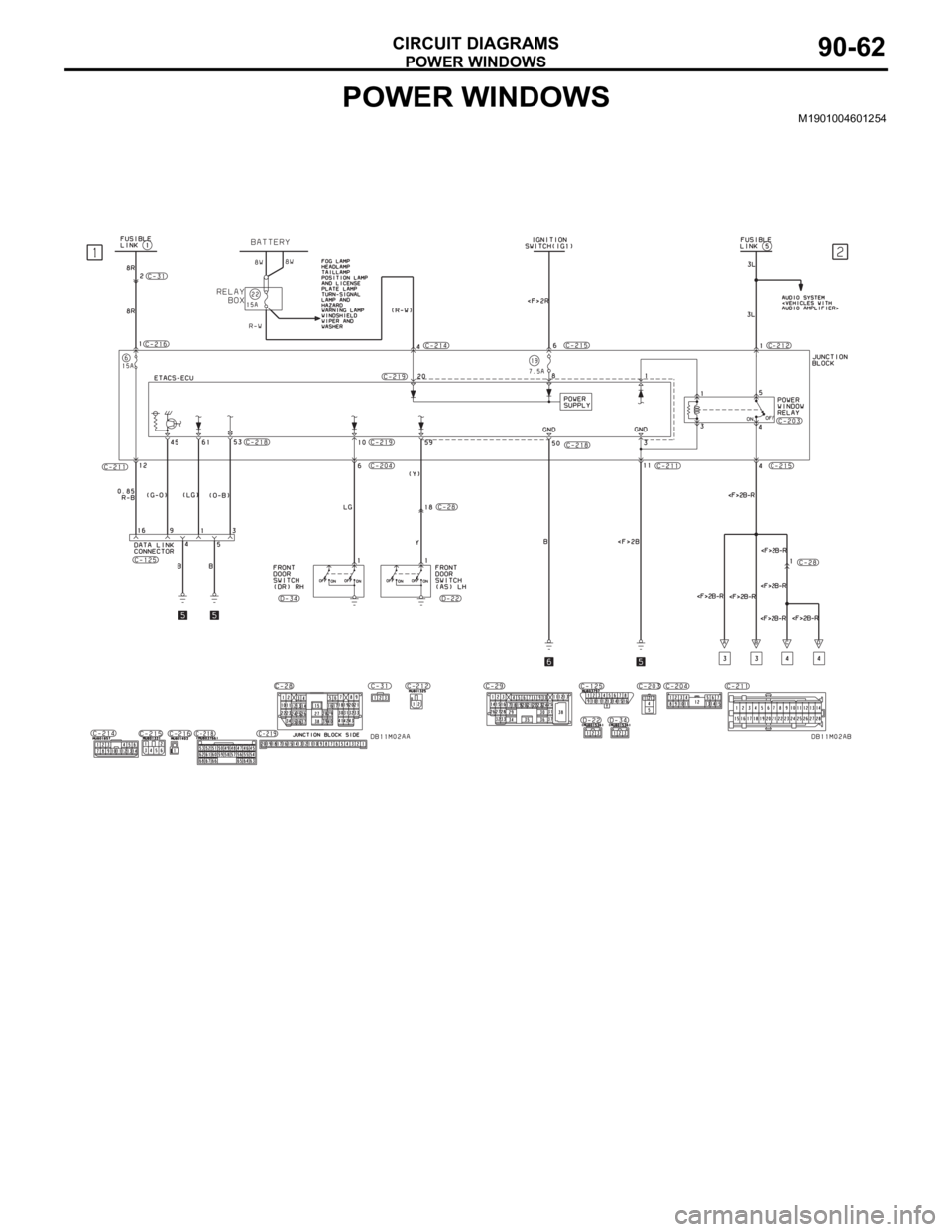

POWER WINDOWS

CIRCUIT DIAGRAMS90-62

POWER WINDOWSM1901004601254

Page 640 of 1500

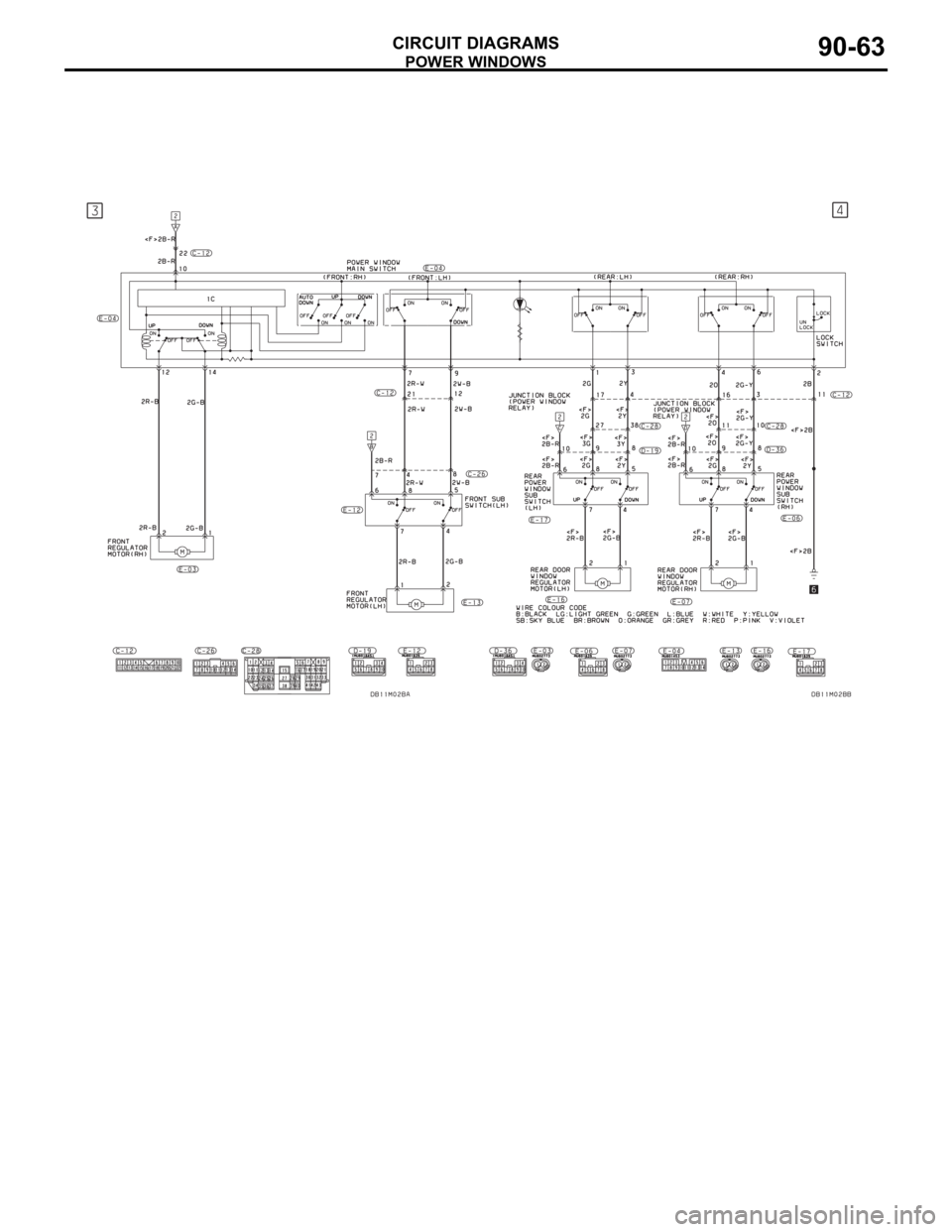

POWER WINDOWS

CIRCUIT DIAGRAMS90-63

Page 822 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-121

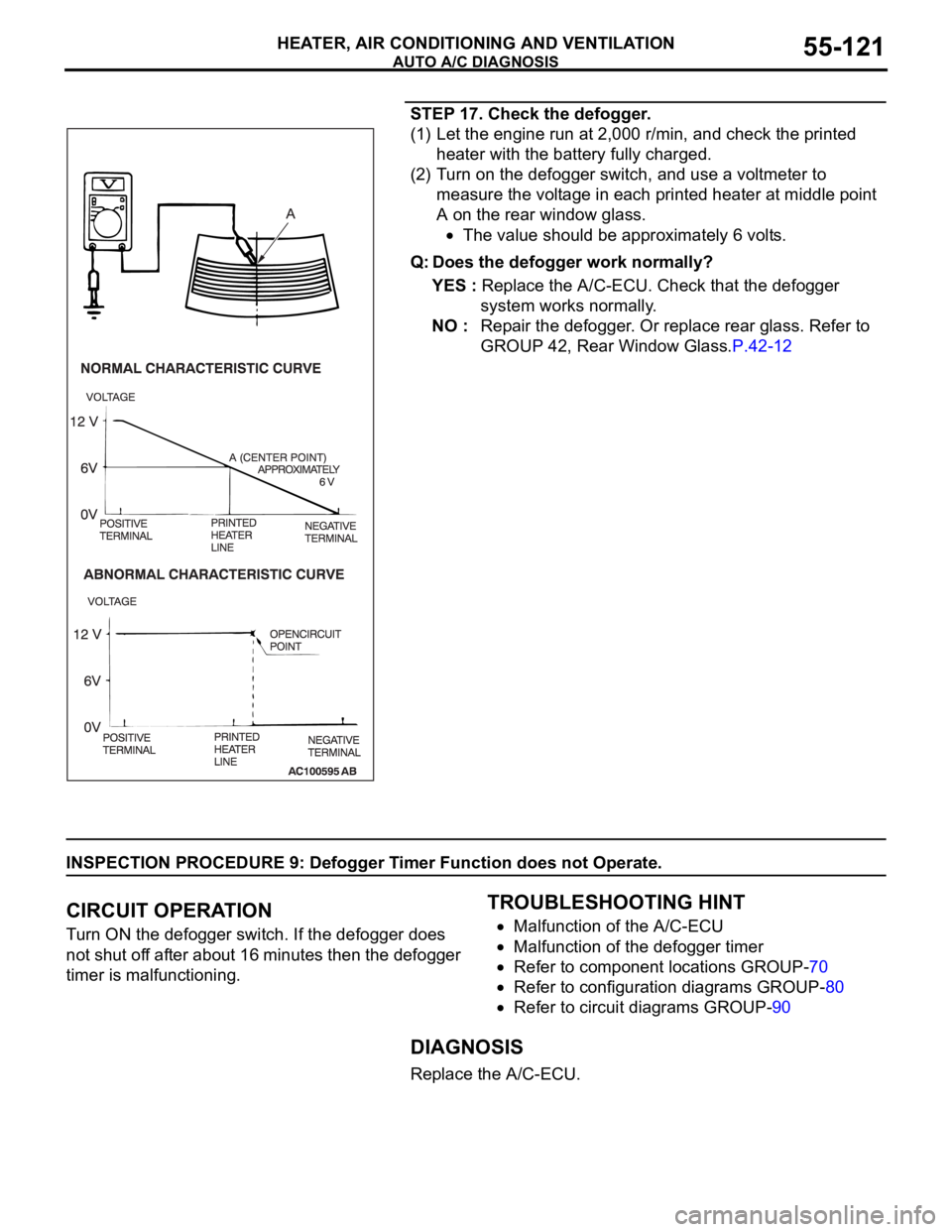

STEP 17. Check the defogger.

(1) Let the engine run at 2,000 r/min, and check the printed

heater with the battery fully charged.

(2) Turn on the defogger switch, and use a voltmeter to

measure the voltage in each printed heater at middle point

A on the rear window glass.

The value should be approximately 6 volts.

Q: Does the defogger work normally?

YES : Replace the A/C-ECU. Check that the defogger

system works normally.

NO : Repair the defogger. Or replace rear glass. Refer to

GROUP 42, Rear Window Glass.P.42-12

INSPECTION PROCEDURE 9: Defogger Timer Function does not Operate.

.

CIRCUIT OPERATION

Turn ON the defogger switch. If the defogger does

not shut off after about 16 minutes then the defogger

timer is malfunctioning.

.

TROUBLESHOOTING HINT

Malfunction of the A/C-ECU

Malfunction of the defogger timer

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Replace the A/C-ECU.

Page 835 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-134

Air outlet c/o

potentiometer55 Mode selection

damper control

motor potentiometerIgnition switch: ON Damper

positionOpening degree (V)

FA C E A p pr o x . 5

FOOT Approx. 3.75

FOOT/DEF. Approx. 2.5

DEF. Approx. 1.75

Air outlet c/o

potentiometer

(target)56 Target value for

mode selection

damper control

motor potentiometerIgnition switch: ON Damper

positionOpening degree (V)

FA C E A p pr o x . 5

FOOT Approx. 3.75

FOOT/DEF. Approx. 2.5

DEF. Approx. 1.75

In/out air

changeover

damper motor65 Outside/inside air

selection damper

control motorIgnition switch: ON Damper set

positionDamper position

Fresh air

positionFRESH

Air recirculation

positionRECIRC

Front blower fan 68 Blower motor Ignition switch: ON The actual air

volume (blower

motor speed)

corresponds to the

air volume shown on

the diagnostic tool.

Front blower

motor voltage 71 Blower motor Ignition switch: ON The air volume set

by the heater control

corresponds to the

value shown on the

diagnostic tool. (V)

Air conditioning

switch state1 Air conditioning

switchIgnition switch: ON Air conditioning

switch: ONDiagnostic tool

indication: "pressed"

Air conditioning

switch: OFFDiagnostic tool

indication: "release"

Rear defogger

switch state7 Rear window

defogger switchIgnition switch: ON Rear window

defogger

switch: ONDiagnostic tool

indication: "pressed"

Rear window

defogger

switch: OFFDiagnostic tool

indication: "release"

Refrigerant

pressure73 Refrigerant pressure Ignition switch: ON The diagnostic tool

indication is normal MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Page 837 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-136

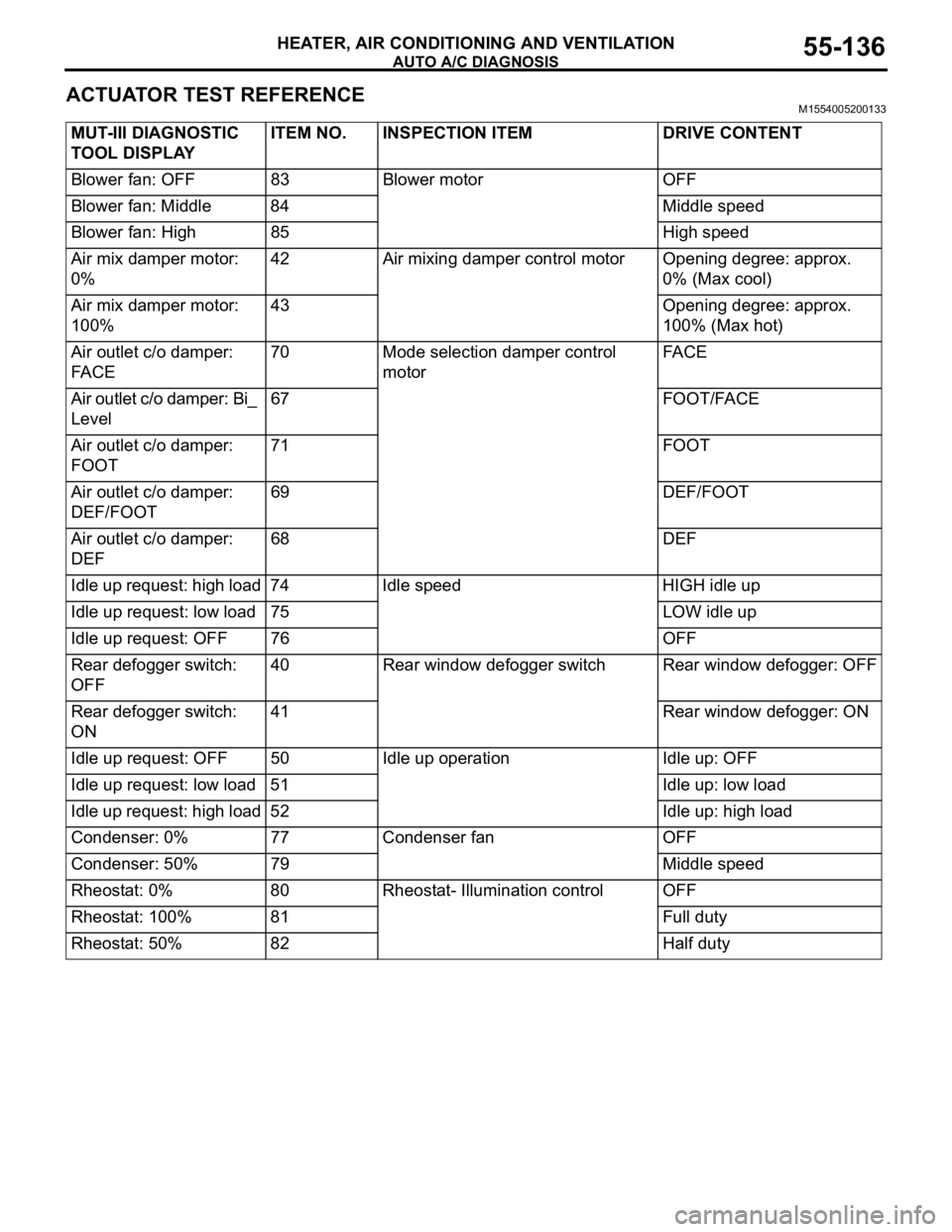

ACTUATOR TEST REFERENCEM1554005200133

MUT-III DIAGNOSTIC

TOOL DISPLAYITEM NO. INSPECTION ITEM DRIVE CONTENT

Blower fan: OFF 83 Blower motor OFF

Blower fan: Middle 84 Middle speed

Blower fan: High 85 High speed

Air mix damper motor:

0%42 Air mixing damper control motor Opening degree: approx.

0% (Max cool)

Air mix damper motor:

100%43 Opening degree: approx.

100% (Max hot)

Air outlet c/o damper:

FA C E70 Mode selection damper control

motorFA C E

Air outlet c/o damper: Bi_

Level67 FOOT/FACE

Air outlet c/o damper:

FOOT71 FOOT

Air outlet c/o damper:

DEF/FOOT69 DEF/FOOT

Air outlet c/o damper:

DEF68 DEF

Idle up request: high load 74 Idle speed HIGH idle up

Idle up request: low load 75 LOW idle up

Idle up request: OFF 76 OFF

Rear defogger switch:

OFF40 Rear window defogger switch Rear window defogger: OFF

Rear defogger switch:

ON41 Rear window defogger: ON

Idle up request: OFF 50 Idle up operation Idle up: OFF

Idle up request: low load 51 Idle up: low load

Idle up request: high load 52 Idle up: high load

Condenser: 0% 77 Condenser fan OFF

Condenser: 50% 79 Middle speed

Rheostat: 0% 80 Rheostat- Illumination control OFF

Rheostat: 100% 81 Full duty

Rheostat: 50% 82 Half duty

Page 844 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-143

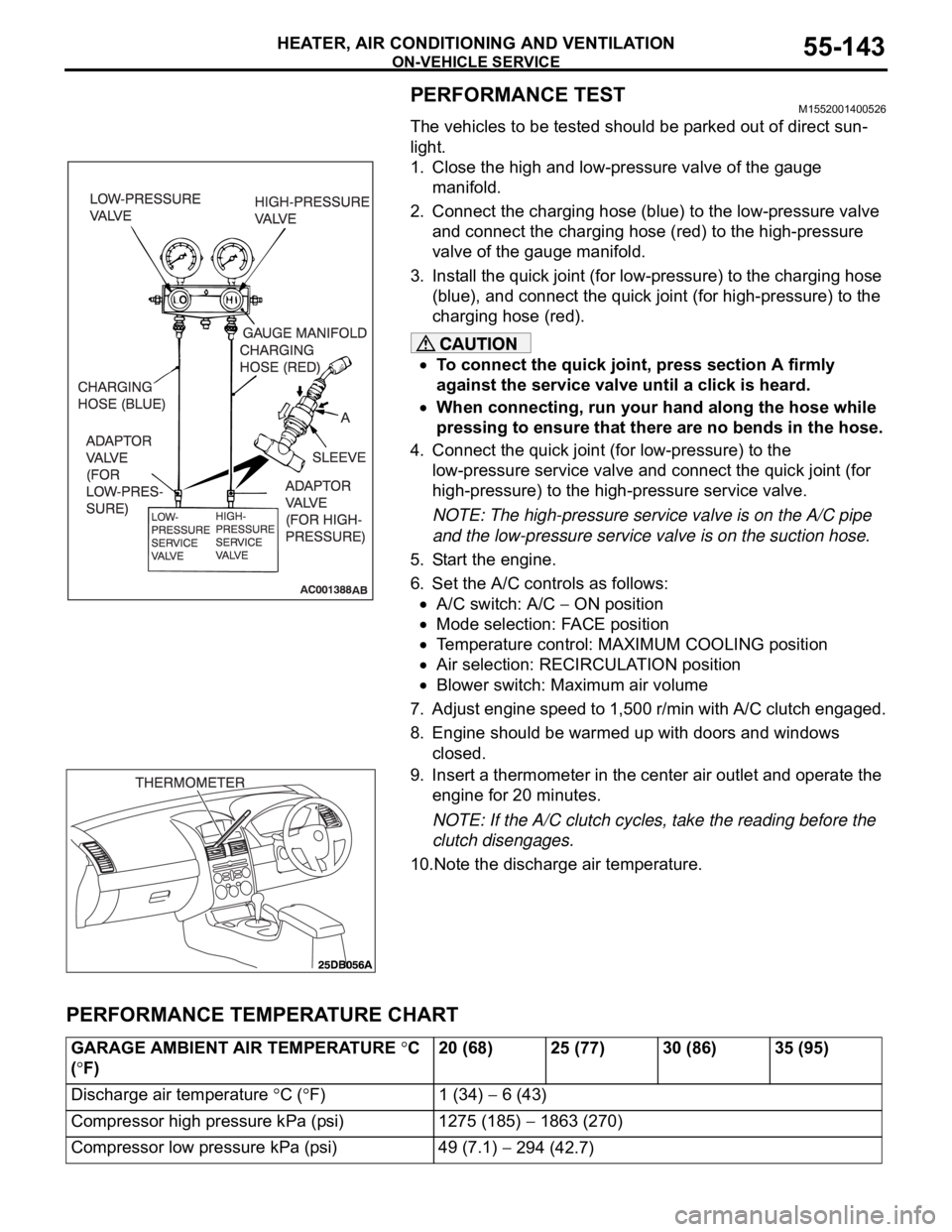

PERFORMANCE TEST M1552001400526

The vehicles to be tested should be parked out of direct sun-

light.

1. Close the high and low-pressure valve of the gauge

manifold.

2. Connect the charging hose (blue) to the low-pressure valve

and connect the charging hose (red) to the high-pressure

valve of the gauge manifold.

3. Install the quick joint (for low-pressure) to the charging hose

(blue), and connect the quick joint (for high-pressure) to the

charging hose (red).

To connect the quick joint, press section A firmly

against the service valve until a click is heard.

When connecting, run your hand along the hose while

pressing to ensure that there are no bends in the hose.

4. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick joint (for

high-pressure) to the high-pressure service valve.

NOTE: The high-pressure service valve is on the A/C pipe

and the low-pressure service valve is on the suction hose.

5. Start the engine.

6. Set the A/C controls as follows:

A/C switch: A/C ON position

Mode selection: FACE position

Temperature control: MAXIMUM COOLING position

Air selection: RECIRCULATION position

Blower switch: Maximum air volume

7. Adjust engine speed to 1,500 r/min with A/C clutch engaged.

8. Engine should be warmed up with doors and windows

closed.

9. Insert a thermometer in the center air outlet and operate the

engine for 20 minutes.

NOTE: If the A/C clutch cycles, take the reading before the

clutch disengages.

10.Note the discharge air temperature.

PERFORMANCE TEMPERATURE CHART

GARAGE AMBIENT AIR TEMPERATURE C

(

F)20 (68) 25 (77) 30 (86) 35 (95)

Discharge air temperature

C (F) 1 (34) 6 (43)

Compressor high pressure kPa (psi) 1275 (185)

1863 (270)

Compressor low pressure kPa (psi) 49 (7.1)

294 (42.7)

Page 885 of 1500

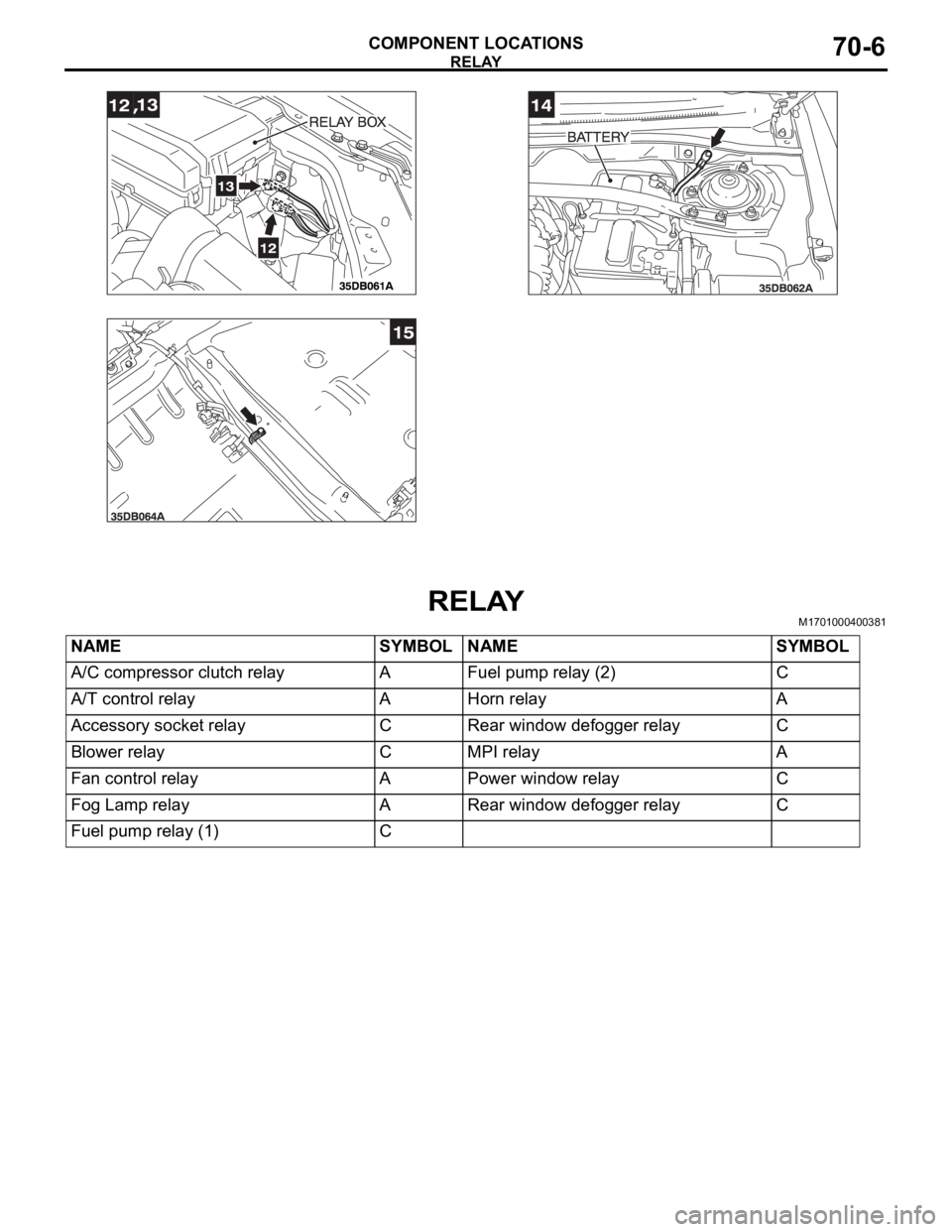

RELAY

COMPONENT LOCATIONS70-6

RELAYM1701000400381

NAME SYMBOL NAME SYMBOL

A/C compressor clutch relay A Fuel pump relay (2) C

A/T control relay A Horn relay A

Accessory socket relay C Rear window defogger relay C

Blower relay C MPI relay A

Fan control relay A Power window relay C

Fog Lamp relay A Rear window defogger relay C

Fuel pump relay (1) C

Page 893 of 1500

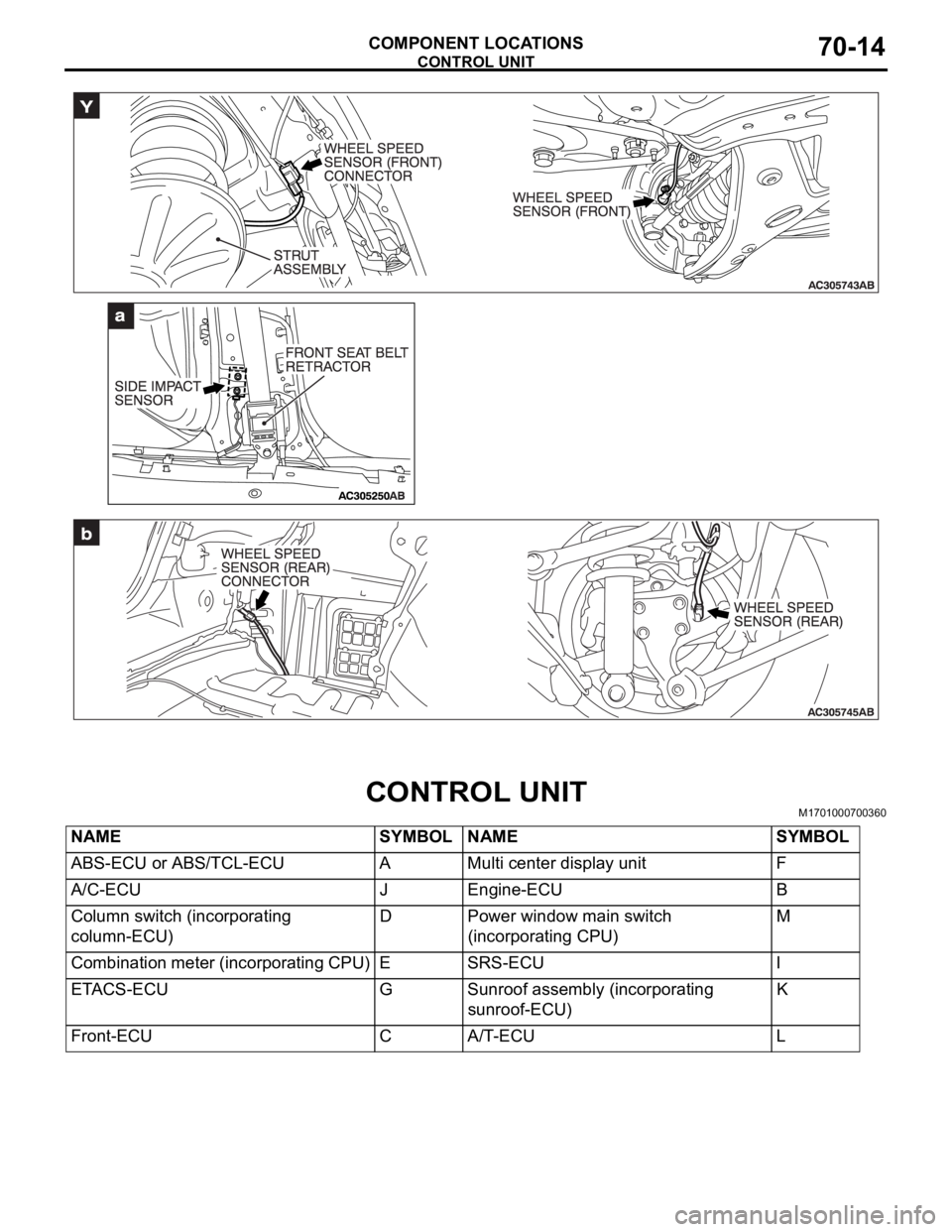

CONTROL UNIT

COMPONENT LOCATIONS70-14

CONTROL UNITM1701000700360

NAME SYMBOL NAME SYMBOL

ABS-ECU or ABS/TCL-ECU A Multi center display unit F

A/C-ECU J Engine-ECU B

Column switch (incorporating

column-ECU)D Power window main switch

(incorporating CPU)M

Combination meter (incorporating CPU) E SRS-ECU I

ETACS-ECU G Sunroof assembly (incorporating

sunroof-ECU)K

Front-ECU C A/T-ECU L

Page 1062 of 1500

DOOR MIRROR

EXTERIOR51-29

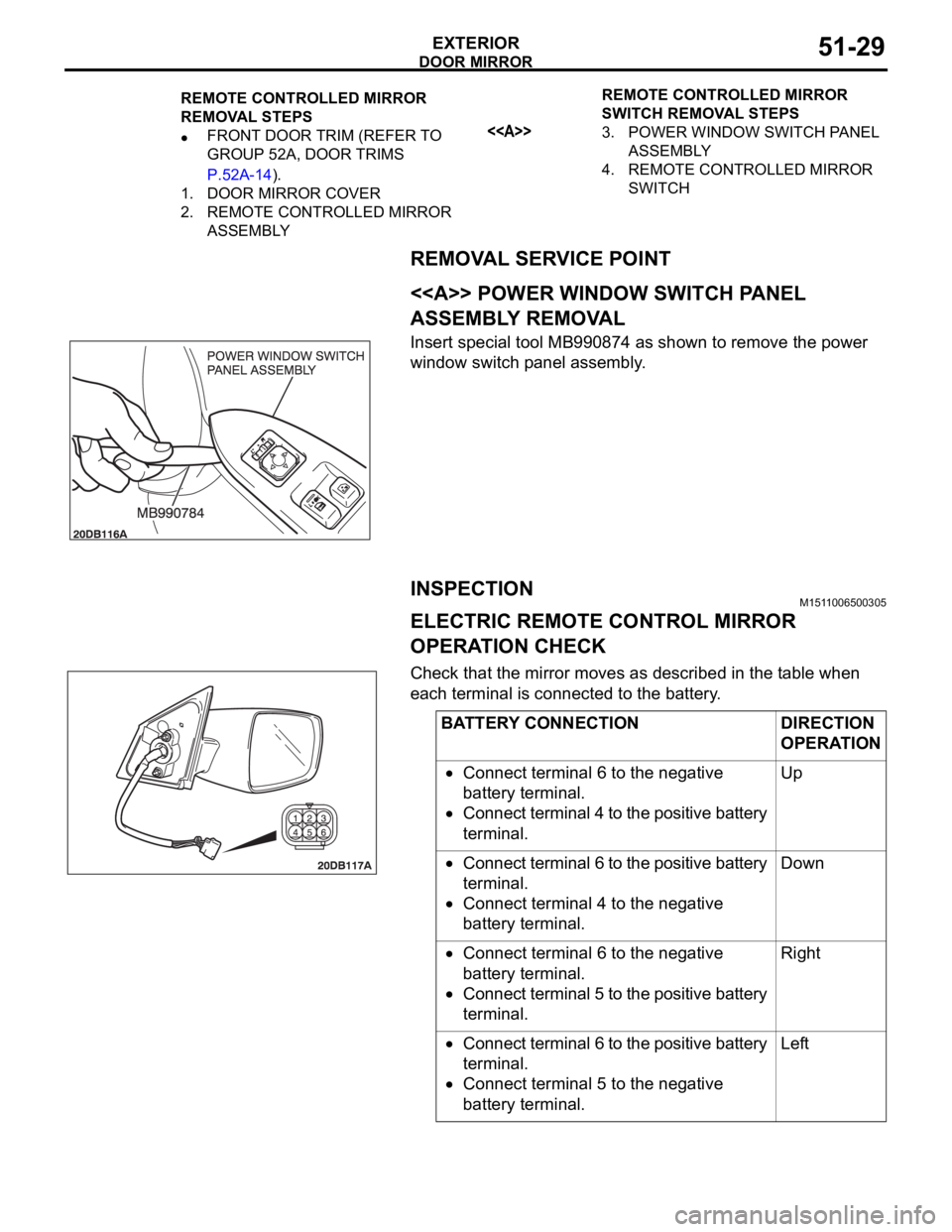

REMOVAL SERVICE POINT

.

<> POWER WINDOW SWITCH PANEL

ASSEMBLY REMOVAL

Insert special tool MB990874 as shown to remove the power

window switch panel assembly.

INSPECTIONM1511006500305

ELECTRIC REMOTE CONTROL MIRROR

OPERATION CHECK

Check that the mirror moves as described in the table when

each terminal is connected to the battery.

REMOTE CONTROLLED MIRROR

REMOVAL STEPS

FRONT DOOR TRIM (REFER TO

GROUP 52A, DOOR TRIMS

P.52A-14).

1. DOOR MIRROR COVER

2. REMOTE CONTROLLED MIRROR

ASSEMBLYREMOTE CONTROLLED MIRROR

SWITCH REMOVAL STEPS<>3. POWER WINDOW SWITCH PANEL

ASSEMBLY

4. REMOTE CONTROLLED MIRROR

SWITCH

BATTERY CONNECTION DIRECTION

OPERATION

Connect terminal 6 to the negative

battery terminal.

Connect terminal 4 to the positive battery

terminal.Up

Connect terminal 6 to the positive battery

terminal.

Connect terminal 4 to the negative

battery terminal.Down

Connect terminal 6 to the negative

battery terminal.

Connect terminal 5 to the positive battery

terminal.Right

Connect terminal 6 to the positive battery

terminal.

Connect terminal 5 to the negative

battery terminal.Left

Page 1068 of 1500

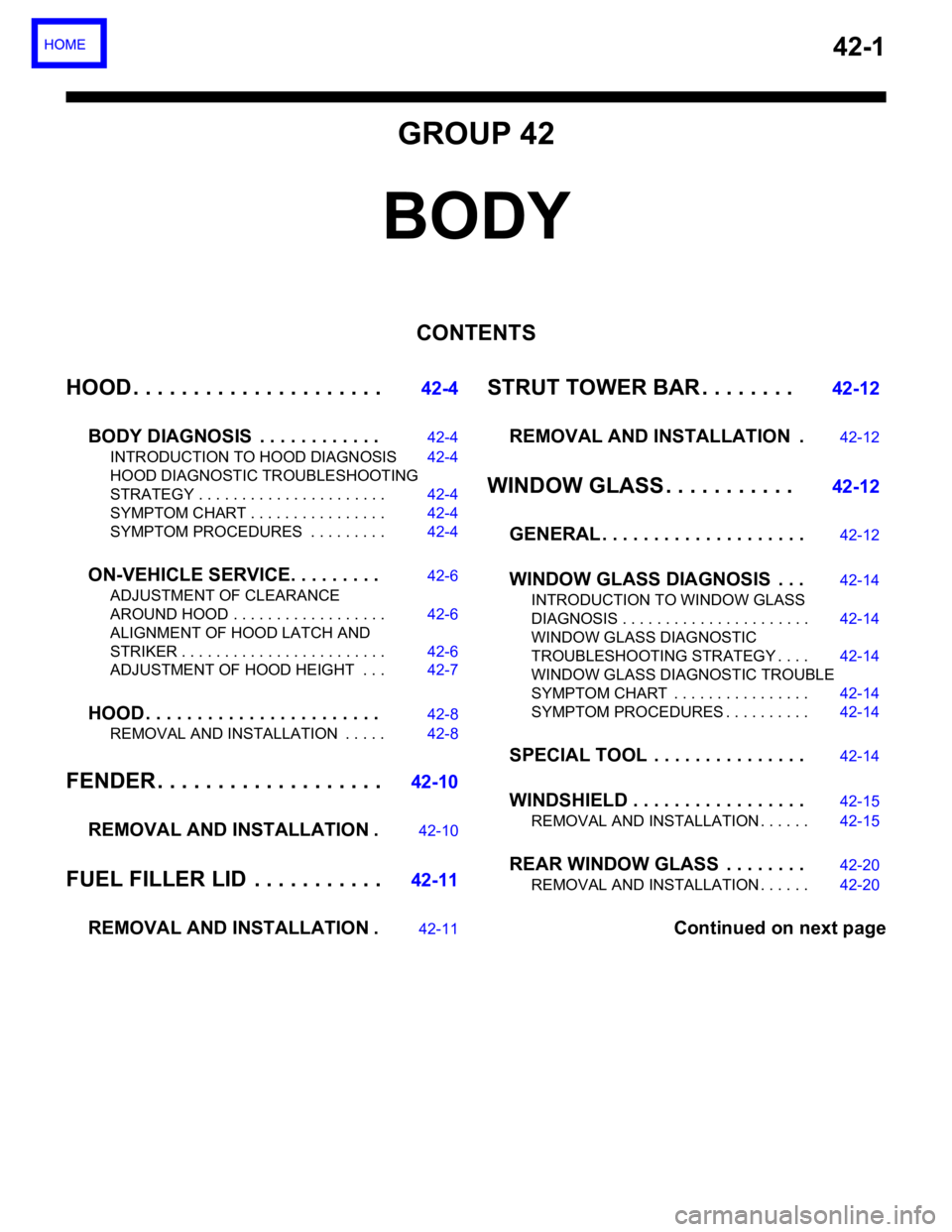

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .

42-4

BODY DIAGNOSIS . . . . . . . . . . . .

42-4

INTRODUCTION TO HOOD DIAGNOSIS42-4

HOOD DIAGNOSTIC TROUBLESHOOTING

STRATEGY . . . . . . . . . . . . . . . . . . . . . . 42-4

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-4

SYMPTOM PROCEDURES . . . . . . . . . 42-4

ON-VEHICLE SERVICE. . . . . . . . .42-6

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-6

ALIGNMENT OF HOOD LATCH AND

STRIKER . . . . . . . . . . . . . . . . . . . . . . . . 42-6

ADJUSTMENT OF HOOD HEIGHT . . . 42-7

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION . . . . . 42-8

FENDER . . . . . . . . . . . . . . . . . . .42-10

REMOVAL AND INSTALLATION .

42-10

FUEL FILLER LID . . . . . . . . . . .42-11

REMOVAL AND INSTALLATION .

42-11

STRUT TOWER BAR . . . . . . . . 42-12

REMOVAL AND INSTALLATION .

42-12

WINDOW GLASS . . . . . . . . . . . 42-12

GENERAL . . . . . . . . . . . . . . . . . . . .

42-12

WINDOW GLASS DIAGNOSIS . . .42-14

INTRODUCTION TO WINDOW GLASS

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-14

WINDOW GLASS DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-14

WINDOW GLASS DIAGNOSTIC TROUBLE

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-14

SYMPTOM PROCEDURES . . . . . . . . . . 42-14

SPECIAL TOOL . . . . . . . . . . . . . . .42-14

WINDSHIELD . . . . . . . . . . . . . . . . .42-15

REMOVAL AND INSTALLATION . . . . . . 42-15

REAR WINDOW GLASS . . . . . . . .42-20

REMOVAL AND INSTALLATION . . . . . . 42-20

Continued on next page