window MITSUBISHI 380 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1088 of 1500

Page 1089 of 1500

WINDOW GLASS

BODY42-22

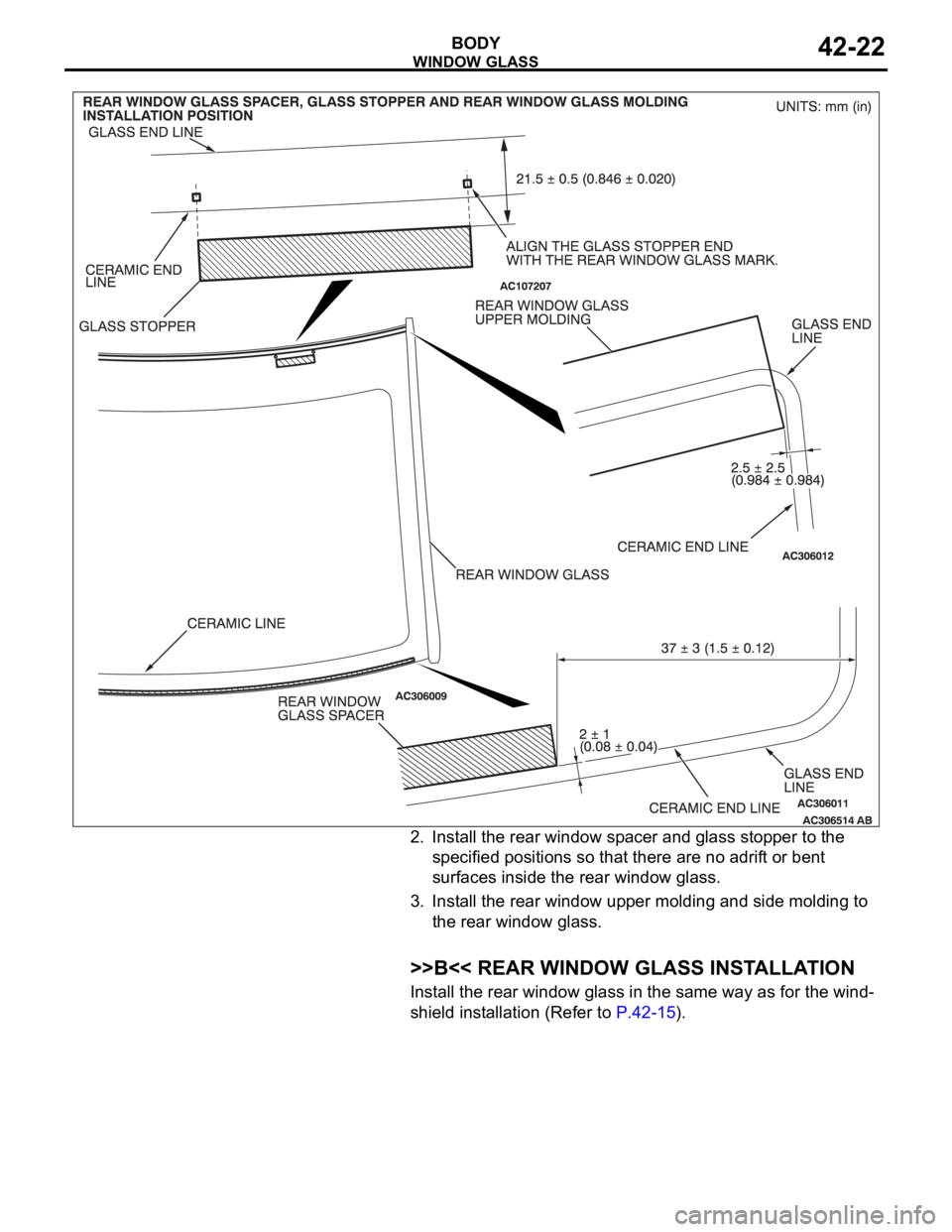

2. Install the rear window spacer and glass stopper to the

specified positions so that there are no adrift or bent

surfaces inside the rear window glass.

3. Install the rear window upper molding and side molding to

the rear window glass.

.

>>B<< REAR WINDOW GLASS INSTALLATION

Install the rear window glass in the same way as for the wind-

shield installation (Refer to P.42-15).

Page 1090 of 1500

DOOR

BODY42-23

DOOR

GENERAL DESCRIPTIONM1423000100246

OPERATION

.

CENTRAL DOOR LOCKING SYSTEM

The central door locking system operates the door

lock actuator to lock or unlock the doors and the fuel

lid door using the door lock switch built into the front

power window (main or sub) switch or key cylinder

built into the driver's side door outside handle. The

system has the following operations and features:

All doors and fuel lid door can be locked using the

door lock switch built into the front power window

(main or sub

Insert the key into the driver's key cylinder and

turn once to the unlock side to unlock the driver's

door and fuel lid door. Turn the key once again to

the unlock side to unlock all doors and fuel lid

door.

The key reminder function automatically unlocks

all doors when door lock operation is performed

and the front doors are opened while the key is

inserted into the ignition switch.

.

POWER WINDOWS

When the power window (main or sub) switch is

operated, the door windows will open or close. This

system has the following operations and features:

A power window lock switch on the power win-

dow main switch prevents the door window glass

from opening/closing with the front passenger's

and rear power window sub switch.

The power window of the door window glass can

be opened/closed for 30 seconds with the timer

function after the ignition switch is turned OFF.

(The timer expires if the front door

opened when the timer is in operation).

The power window main switch contains a

one-touch down switch that will automatically

open the driver's side door window only.

CENTRAL DOOR LOCKING SYSTEM DIAGNOSISM1427000700217

The central door locking system is controlled by the

simplified wiring system (SWS). Refer to GROUP

54B, SWS Diagnosis P.54B-57.

POWER WINDOW DIAGNOSISM1429000700224

The power window is controlled by the simplified wir-

ing system (SWS). Refer to GROUP 54B, SWS

Diagnosis P.54B-57.

DOOR DIAGNOSIS

INTRODUCTION TO GLASS AND DOOR DIAGNOSISM1423007300241

Glass and door faults include water leaks and

improper opening and closing. Causes for these

faults can include faults in the glass, weatherstrip,

drain hole, waterproof film or door installation.

GLASS AND DOOR DIAGNOSTIC TROUBLESHOOTING STRATEGYM1423006700246

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

glass and door fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

Page 1091 of 1500

DOOR

BODY42-24

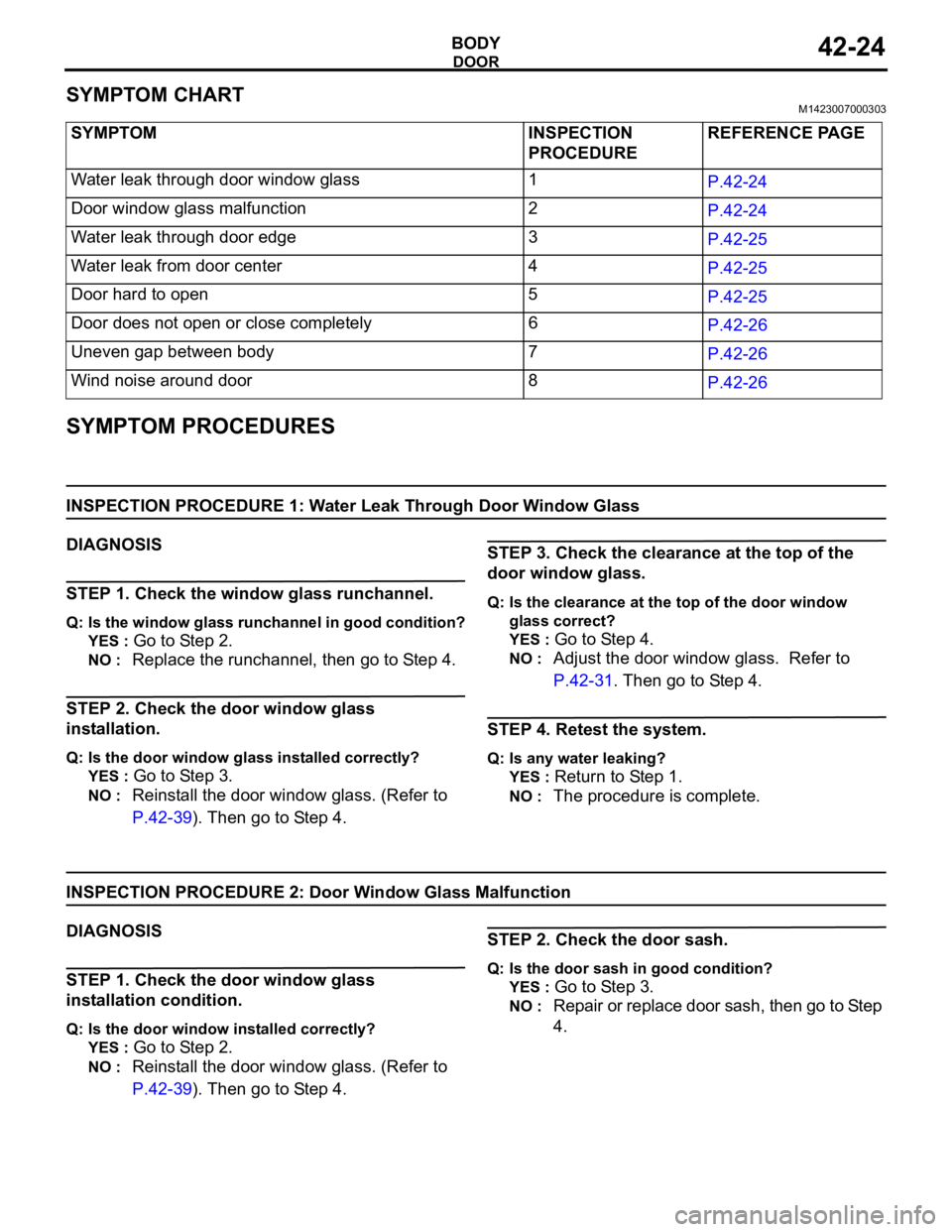

SYMPTOM CHARTM1423007000303

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Water Leak Through Door Window Glass

DIAGNOSIS

STEP 1. Check the window glass runchannel.

Q: Is the window glass runchannel in good condition?

YES :

Go to Step 2.

NO : Replace the runchannel, then go to Step 4.

STEP 2. Check the door window glass

installation.

Q: Is the door window glass installed correctly?

YES :

Go to Step 3.

NO : Reinstall the door window glass. (Refer to

P.42-39). Then go to Step 4.

STEP 3. Check the clearance at the top of the

door window glass.

Q: Is the clearance at the top of the door window

glass correct?

YES :

Go to Step 4.

NO : Adjust the door window glass. Refer to

P.42-31. Then go to Step 4.

STEP 4. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : The procedure is complete.

INSPECTION PROCEDURE 2: Door Window Glass Malfunction

DIAGNOSIS

STEP 1. Check the door window glass

installation condition.

Q: Is the door window installed correctly?

YES :

Go to Step 2.

NO : Reinstall the door window glass. (Refer to

P.42-39). Then go to Step 4.

STEP 2. Check the door sash.

Q: Is the door sash in good condition?

YES :

Go to Step 3.

NO : Repair or replace door sash, then go to Step

4. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Water leak through door window glass 1

P.42-24

Door window glass malfunction 2

P.42-24

Water leak through door edge 3

P.42-25

Water leak from door center 4

P.42-25

Door hard to open 5

P.42-25

Door does not open or close completely 6

P.42-26

Uneven gap between body 7

P.42-26

Wind noise around door 8

P.42-26

Page 1092 of 1500

DOOR

BODY42-25

STEP 3. Inspect the window regulator assembly.

Q: Is the window regulator assembly in good

condition?

YES :

Go to Step 4.

NO : Repair or replace the window regulator

assembly, then go to Step 4.

STEP 4. Retest the system.

Q: Does the door window operate correctly?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 3: Water Leak Through Door Edge

DIAGNOSIS

STEP 1. Check the weatherstrip.

Q: Is the weatherstrip in good condition?

YES :

Go to Step 2.

NO : Replace the weatherstrip, then go to Step 3.

STEP 2. Check the door fit (alignment).

Q: Is the door fit (alignment) correct?

YES :

Go to Step 3.

NO : Adjust the door fit (Refer to P.42-30). Then

go to Step 3.

STEP 3. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : The procedure is complete.

INSPECTION PROCEDURE 4: Water Leak from Door Center

DIAGNOSIS

STEP 1. Check the drain hole.

Q: Is the drain hole clogged?

YES :

Clean the drain hole, then go to Step 3.

NO : Go to Step 2.

STEP 2. Check the weatherstrip.

Q: Is the weatherstrip in good condition?

YES :

Go to Step 3.

NO : Repair or replace the weatherstrip, then go

to Step 3.

STEP 3. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : The procedure is complete.

INSPECTION PROCEDURE 5: Door Hard to Open

DIAGNOSIS

STEP 1. Adjust the latch and striker engagement.

Refer to P.42-30.

Q: Is the latch and striker engagement adjusted?

YES :

Go to Step 2.

NO : Adjust the latch and striker. (Refer to

P.42-30). Then go to Step 4.

STEP 2. Check for lock cable damage.

Q: Is the lock rod damaged?

YES :

Repair or replace the lock cable, then go to

St e p 4.

NO : Go to Step 3.

Page 1096 of 1500

DOOR

BODY42-29

MB990480 Glass holder General service tool Removal of power window

regulator assembly

MB991223 Harness set

A: MB991219 Test

harness

B: MB991220 LED

harness

C: MB991221 LED

harness adapter

D: MB991222 ProbeGeneral service tools Measurement of terminal

voltage

A: Connector pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection

MB990784 Ornament

removerGeneral service tool Removal of power window

switch panel assembly TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

Page 1098 of 1500

DOOR

BODY42-31

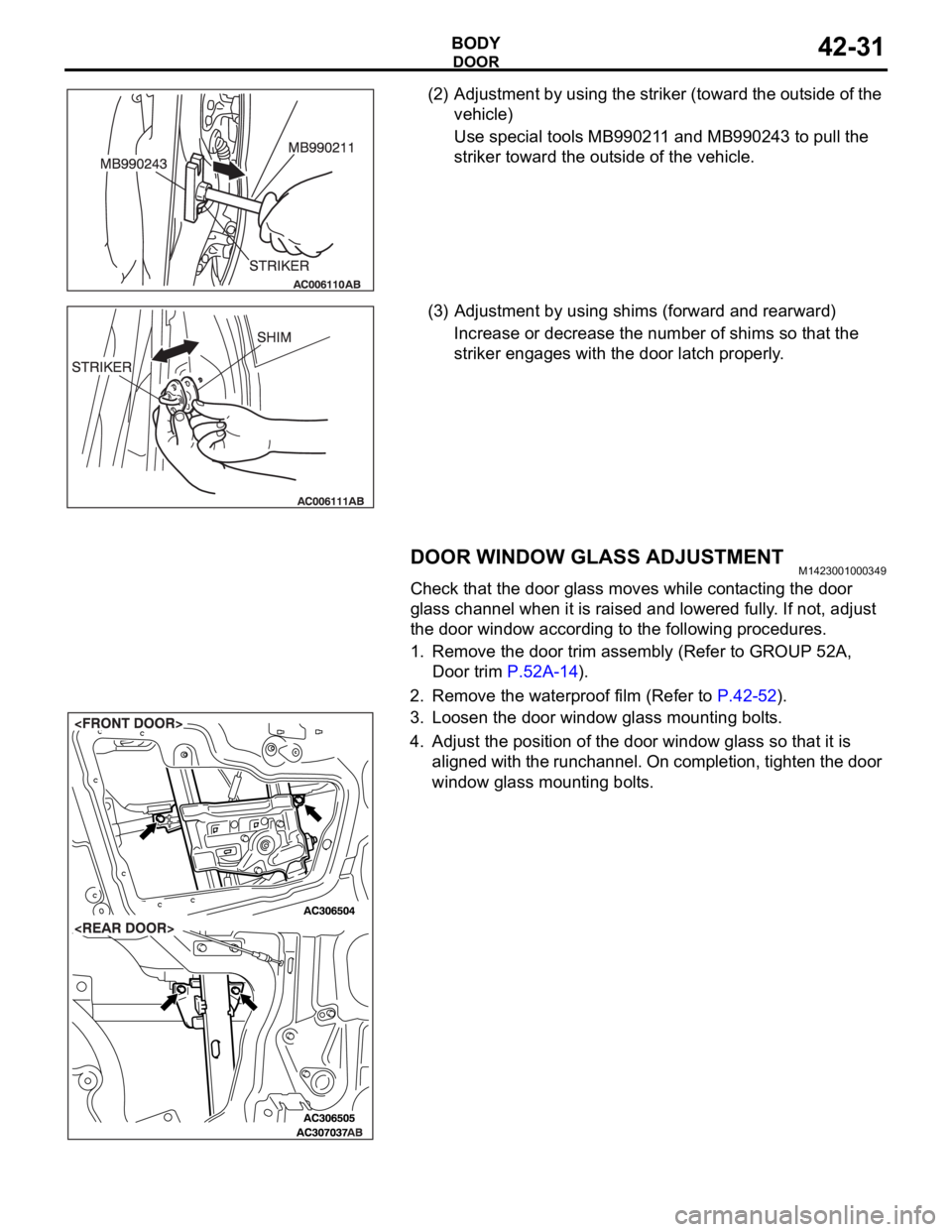

(2) Adjustment by using the striker (toward the outside of the

vehicle)

Use special tools MB990211 and MB990243 to pull the

striker toward the outside of the vehicle.

(3) Adjustment by using shims (forward and rearward)

Increase or decrease the number of shims so that the

striker engages with the door latch properly.

DOOR WINDOW GLASS ADJUSTMENTM1423001000349

Check that the door glass moves while contacting the door

glass channel when it is raised and lowered fully. If not, adjust

the door window according to the following procedures.

1. Remove the door trim assembly (Refer to GROUP 52A,

Door trim P.52A-14).

2. Remove the waterproof film (Refer to P.42-52).

3. Loosen the door window glass mounting bolts.

4. Adjust the position of the door window glass so that it is

aligned with the runchannel. On completion, tighten the door

window glass mounting bolts.

Page 1099 of 1500

DOOR

BODY42-32

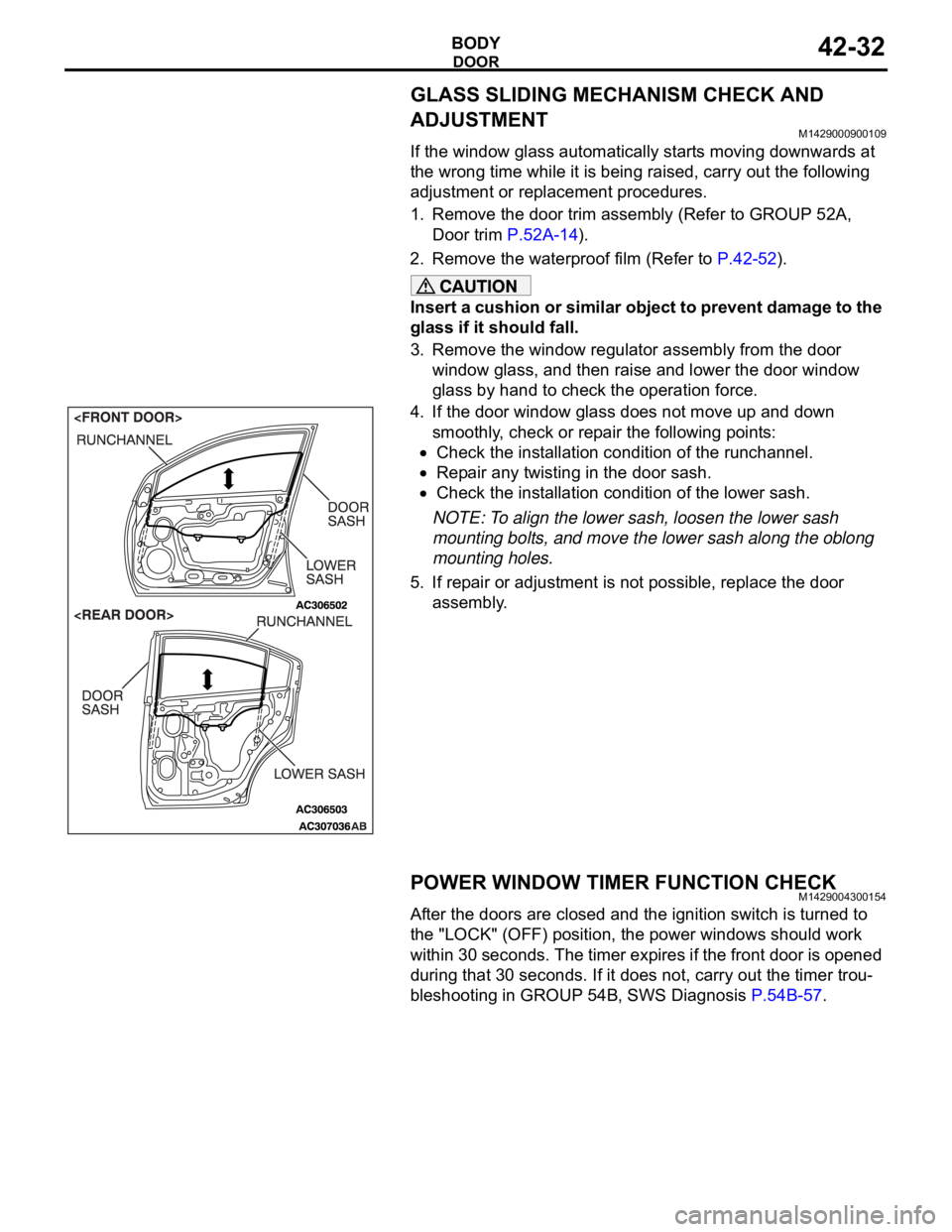

GLASS SLIDING MECHANISM CHECK AND

ADJUSTMENT

M1429000900109

If the window glass automatically starts moving downwards at

the wrong time while it is being raised, carry out the following

adjustment or replacement procedures.

1. Remove the door trim assembly (Refer to GROUP 52A,

Door trim P.52A-14).

2. Remove the waterproof film (Refer to P.42-52).

Insert a cushion or similar object to prevent damage to the

glass if it should fall.

3. Remove the window regulator assembly from the door

window glass, and then raise and lower the door window

glass by hand to check the operation force.

4. If the door window glass does not move up and down

smoothly, check or repair the following points:

Check the installation condition of the runchannel.

Repair any twisting in the door sash.

Check the installation condition of the lower sash.

NOTE: To align the lower sash, loosen the lower sash

mounting bolts, and move the lower sash along the oblong

mounting holes.

5. If repair or adjustment is not possible, replace the door

assembly.

POWER WINDOW TIMER FUNCTION CHECKM1429004300154

After the doors are closed and the ignition switch is turned to

the "LOCK" (OFF) position, the power windows should work

within 30 seconds. The timer expires if the front door is opened

during that 30 seconds. If it does not, carry out the timer trou-

bleshooting in GROUP 54B, SWS Diagnosis P.54B-57.

Page 1100 of 1500

DOOR

BODY42-33

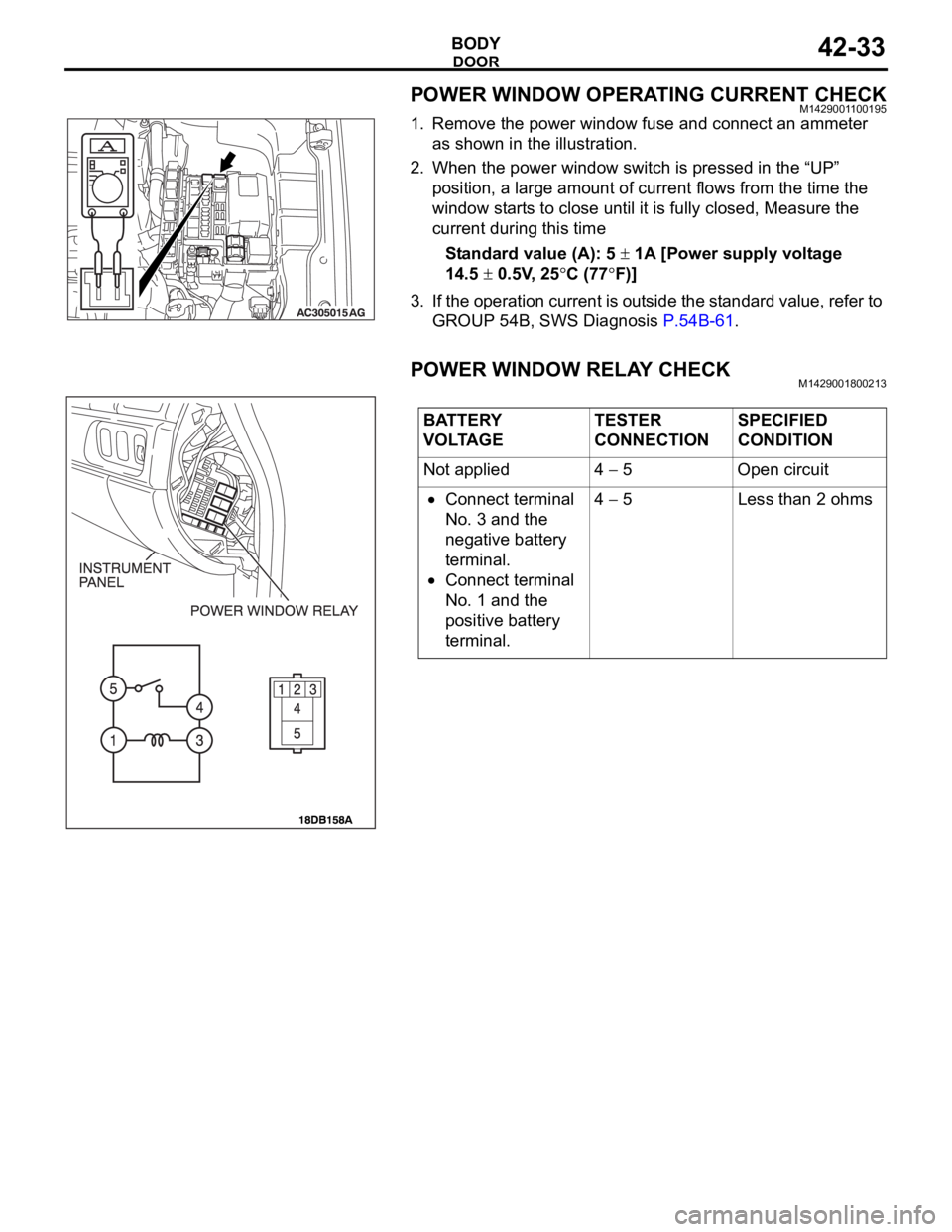

POWER WINDOW OPERATING CURRENT CHECKM1429001100195

1. Remove the power window fuse and connect an ammeter

as shown in the illustration.

2. When the power window switch is pressed in the “UP”

position, a large amount of current flows from the time the

window starts to close until it is fully closed, Measure the

current during this time

Standard value (A): 5

1A [Power supply voltage

14.5

0.5V, 25C (77F)]

3. If the operation current is outside the standard value, refer to

GROUP 54B, SWS Diagnosis P.54B-61.

POWER WINDOW RELAY CHECKM1429001800213

BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect terminal

No. 3 and the

negative battery

terminal.

Connect terminal

No. 1 and the

positive battery

terminal.4

5 Less than 2 ohms

Page 1101 of 1500

DOOR

BODY42-34

CIRCUIT BREAKER (INCORPORATED IN THE

POWER WINDOW MOTOR) INSPECTION

M1429001000284

1. Pull the power window switch to the UP position to fully

close the door window glass, and keep pulling the switch for

an additional ten seconds.

2. Release the power window switch from the UP position and

immediately press it to the DOWN position. The condition of

the circuit breaker is good if the door window glass starts to

move downwards within about 60 seconds.

POWER WINDOW CHECKM1429004400214

1. Operate the power window switch of each door to verify that

the power windows operate properly. If they don't, then

troubleshoot as described in GROUP 54B, SWS Diagnosis

P.54B-57.

2. Turn ON the power window lock switch of the power window

main switch. Then operate the passenger's door and rear

door power window sub-switches to ensure that they do not

operate. If they do, replace the power window main switch

(Refer to P.42-39).

CENTRAL DOOR LOCKING SYSTEM

INSPECTION

M1427001100144

Check the following. Troubleshoot if operations malfunction

(Refer to GROUP 54B, SWS Diagnosis P.54B-57).

Insert the key into the driver's key cylinder and turn once to

the unlock side to unlock the driver's door and fuel lid door.

Turn the key once again to the unlock side to unlock all

doors and fuel lid door.

All doors and fuel lid door can be locked using the door lock

switch built into the front power window (main or sub

switch.