window MITSUBISHI 380 2005 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1069 of 1500

BODY42-2

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-23

GENERAL DESCRIPTION . . . . . .

42-23

CENTRAL DOOR LOCKING SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

POWER WINDOW DIAGNOSIS . . . . . . 42-23

DOOR DIAGNOSIS . . . . . . . . . . . . . . . . 42-23

INTRODUCTION TO GLASS AND DOOR

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

GLASS AND DOOR DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . 42-23

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-24

SYMPTOM PROCEDURES . . . . . . . . . 42-24

HOW TO LOCATE WIND NOISE . . . . . 42-27

SPECIAL TOOLS. . . . . . . . . . . . . .42-28

ON-VEHICLE SERVICE. . . . . . . . .42-30

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-30

DOOR WINDOW GLASS ADJUSTMENT42-31

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-32

POWER WINDOW TIMER FUNCTION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-32

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-33

POWER WINDOW RELAY CHECK . . . 42-33

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

POWER WINDOW CHECK . . . . . . . . . . 42-34

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR OUTSIDE HANDLE PLAY CHECK42-35

DOOR INSIDE HANDLE PLAY CHECK 42-35

DOOR ASSEMBLY . . . . . . . . . . . .42-37

REMOVAL AND INSTALLATION . . . . . 42-37

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-38

DOOR GLASS AND REGULATOR42-39

REMOVAL AND INSTALLATION . . . . . 42-39

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-43

DOOR HANDLE AND LATCH . . . .42-46

REMOVAL AND INSTALLATION . . . . . 42-46

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-49

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-52

REMOVAL AND INSTALLATION . . . . . . 42-52

TRUNK LID. . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSIS . . . . . . . .

42-60

INTRODUCTION TO TRUNK LID

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-60

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-60

SYMPTOM PROCEDURES . . . . . . . . . . 42-60

ON-VEHICLE SERVICE . . . . . . . . .42-61

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-61

TRUNK LID LATCH ADJUSTMENT. . . . 42-61

TRUNK LID HEIGHT ADJUSTMENT . . . 42-62

TRUNK LID . . . . . . . . . . . . . . . . . . .42-63

REMOVAL AND INSTALLATION . . . . . . 42-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-65

KEYLESS ENTRY SYSTEM 42-67

GENERAL DESCRIPTION . . . . . . .

42-67

KEYLESS ENTRY SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . .

42-68

SPECIAL TOOL . . . . . . . . . . . . . . .42-68

ON-VEHICLE SERVICE . . . . . . . . .42-69

TRANSMITTER BATTERY CHECK . . . . 42-69

HOW TO REPLACE THE TRANSMITTER

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . 42-70

KEYLESS ENTRY SYSTEM INSPECTION42-71

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION . . . . . . . . . . . 42-71

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-72

HOW TO REGISTER SECRET CODE . 42-73

Continued on next page

Page 1079 of 1500

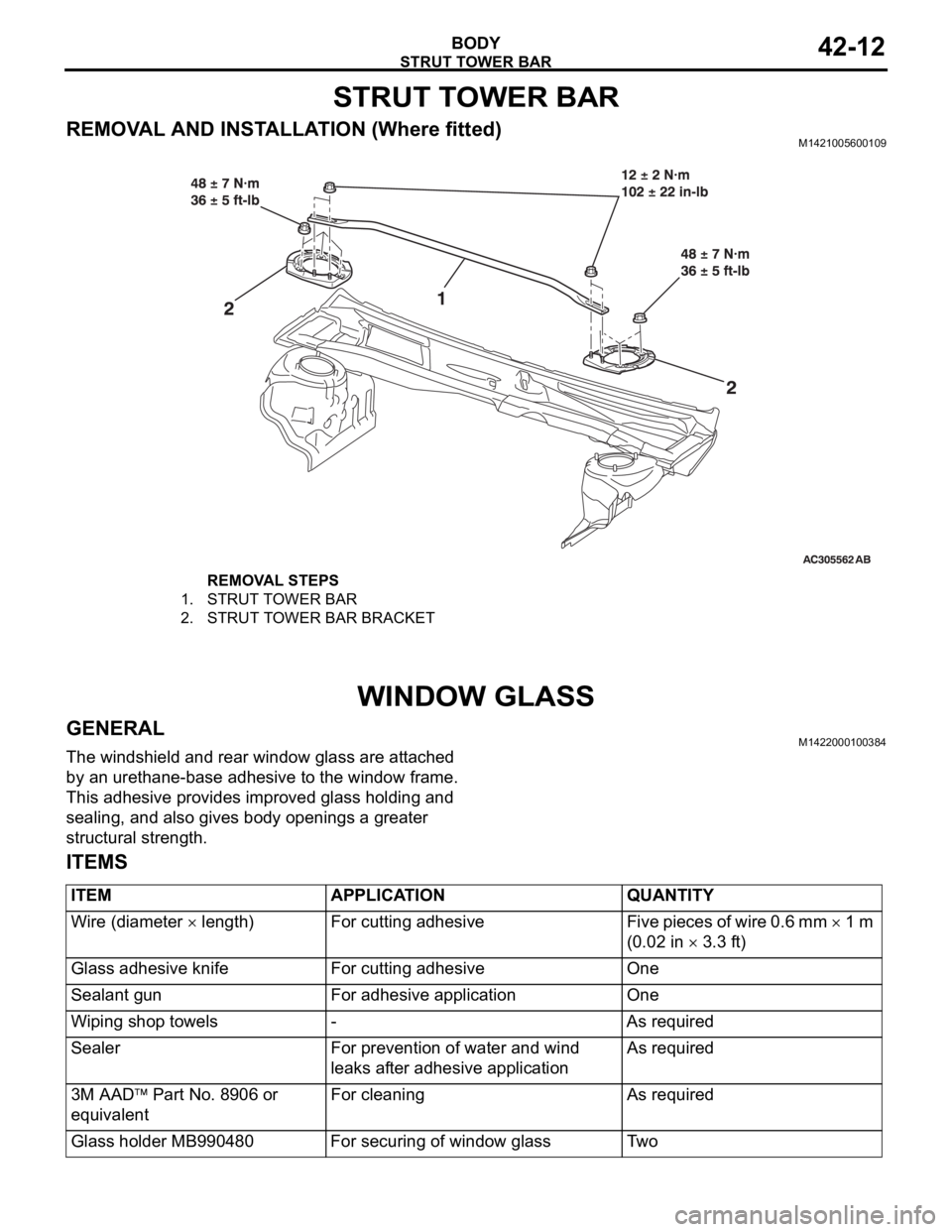

STRUT TOWER BAR

BODY42-12

STRUT TOWER BAR

REMOVAL AND INSTALLATION (Where fitted)M1421005600109

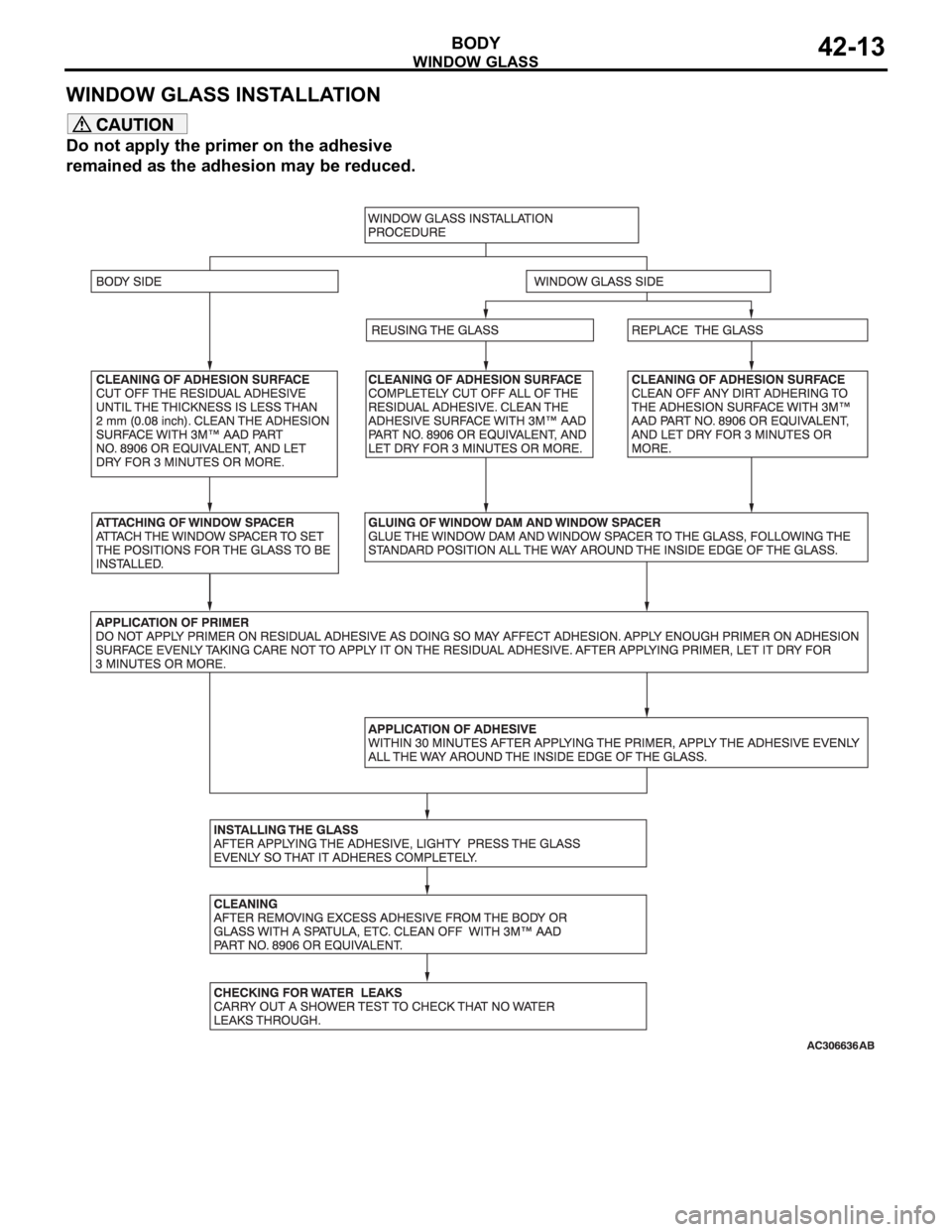

WINDOW GLASS

GENERALM1422000100384

The windshield and rear window glass are attached

by an urethane-base adhesive to the window frame.

This adhesive provides improved glass holding and

sealing, and also gives body openings a greater

structural strength.

ITEMS

REMOVAL STEPS

1. STRUT TOWER BAR

2. STRUT TOWER BAR BRACKET

ITEM APPLICATION QUANTITY

Wire (diameter

length) For cutting adhesive Five pieces of wire 0.6 mm 1 m

(0.02 in

3.3 ft)

Glass adhesive knife For cutting adhesive One

Sealant gun For adhesive application One

Wiping shop towels - As required

Sealer For prevention of water and wind

leaks after adhesive applicationAs required

3M AAD

Part No. 8906 or

equivalentFor cleaning As required

Glass holder MB990480 For securing of window glass Two

Page 1080 of 1500

WINDOW GLASS

BODY42-13

WINDOW GLASS INSTALLATION

Do not apply the primer on the adhesive

remained as the adhesion may be reduced.

Page 1081 of 1500

WINDOW GLASS

BODY42-14

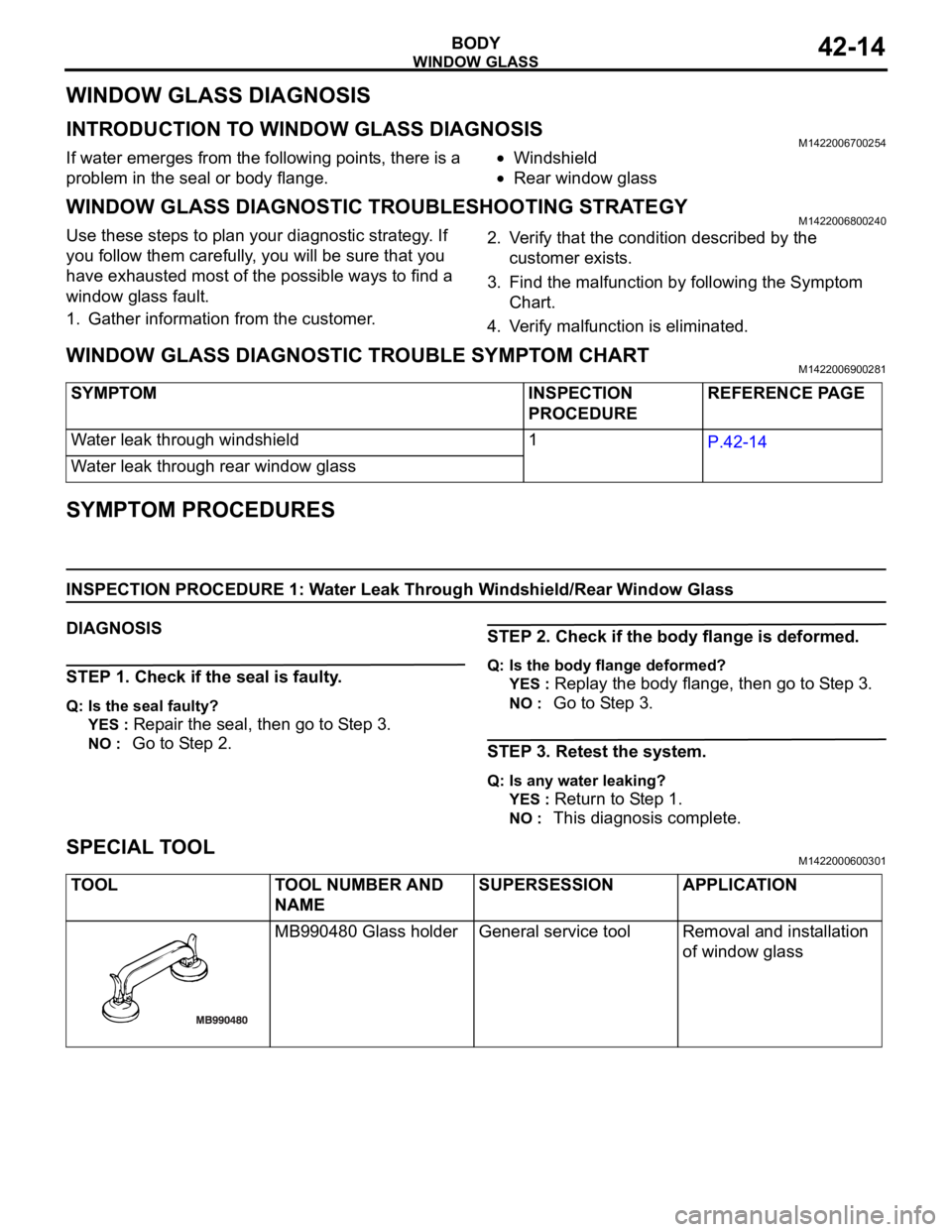

WINDOW GLASS DIAGNOSIS

INTRODUCTION TO WINDOW GLASS DIAGNOSISM1422006700254

If water emerges from the following points, there is a

problem in the seal or body flange.Windshield

Rear window glass

WINDOW GLASS DIAGNOSTIC TROUBLESHOOTING STRATEGYM1422006800240

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

window glass fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

WINDOW GLASS DIAGNOSTIC TROUBLE SYMPTOM CHARTM1422006900281

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Water Leak Through Windshield/Rear Window Glass

DIAGNOSIS

STEP 1. Check if the seal is faulty.

Q: Is the seal faulty?

YES :

Repair the seal, then go to Step 3.

NO : Go to Step 2.

STEP 2. Check if the body flange is deformed.

Q: Is the body flange deformed?

YES :

Replay the body flange, then go to Step 3.

NO : Go to Step 3.

STEP 3. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : This diagnosis complete.

SPECIAL TOOLM1422000600301

SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Water leak through windshield 1

P.42-14

Water leak through rear window glass

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB990480 Glass holder General service tool Removal and installation

of window glass

Page 1082 of 1500

WINDOW GLASS

BODY42-15

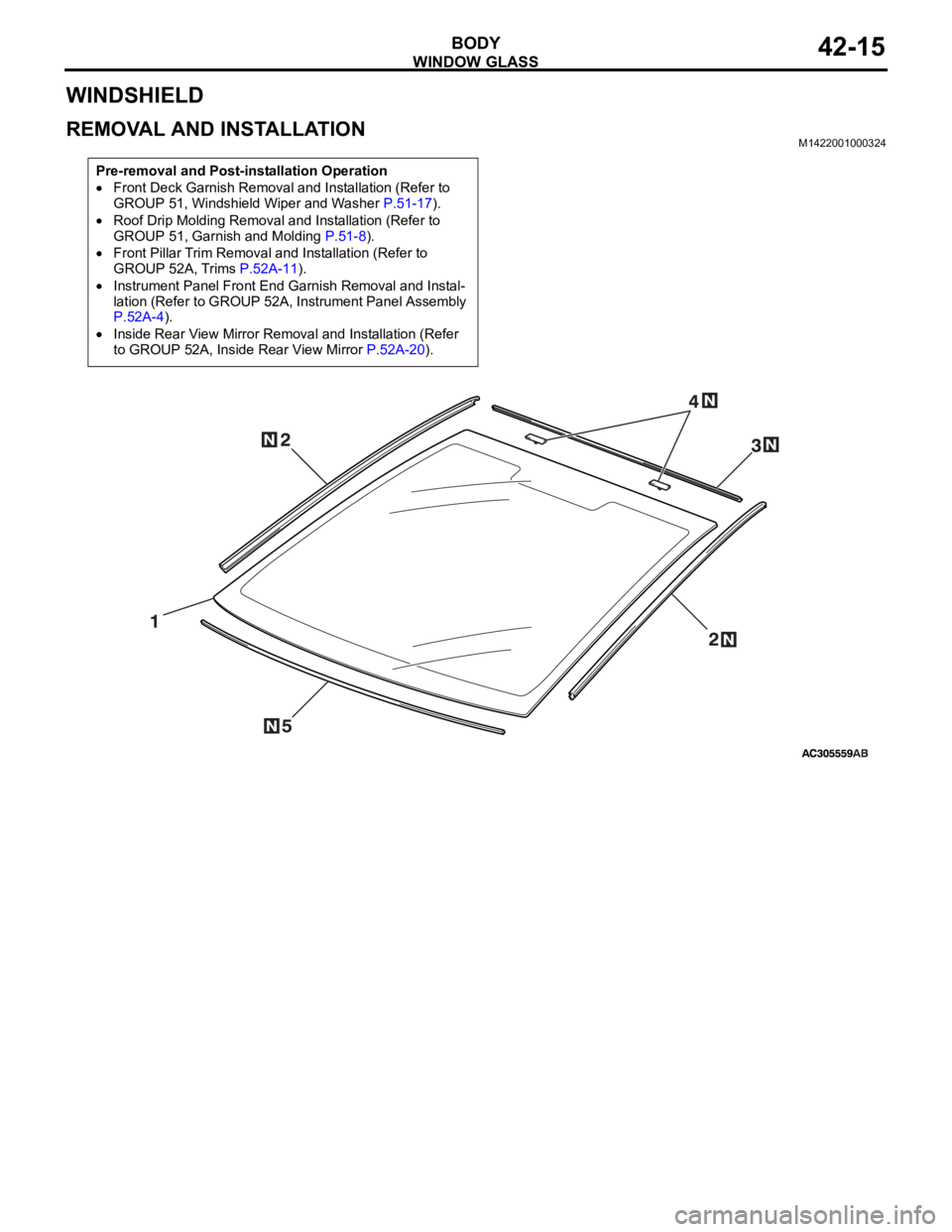

WINDSHIELD

REMOVAL AND INSTALLATIONM1422001000324

Pre-removal and Post-installation Operation

Front Deck Garnish Removal and Installation (Refer to

GROUP 51, Windshield Wiper and Washer P.51-17).

Roof Drip Molding Removal and Installation (Refer to

GROUP 51, Garnish and Molding P.51-8).

Front Pillar Trim Removal and Installation (Refer to

GROUP 52A, Trims P.52A-11).

Instrument Panel Front End Garnish Removal and Instal-

lation (Refer to GROUP 52A, Instrument Panel Assembly

P.52A-4).

Inside Rear View Mirror Removal and Installation (Refer

to GROUP 52A, Inside Rear View Mirror P.52A-20).

Page 1083 of 1500

WINDOW GLASS

BODY42-16

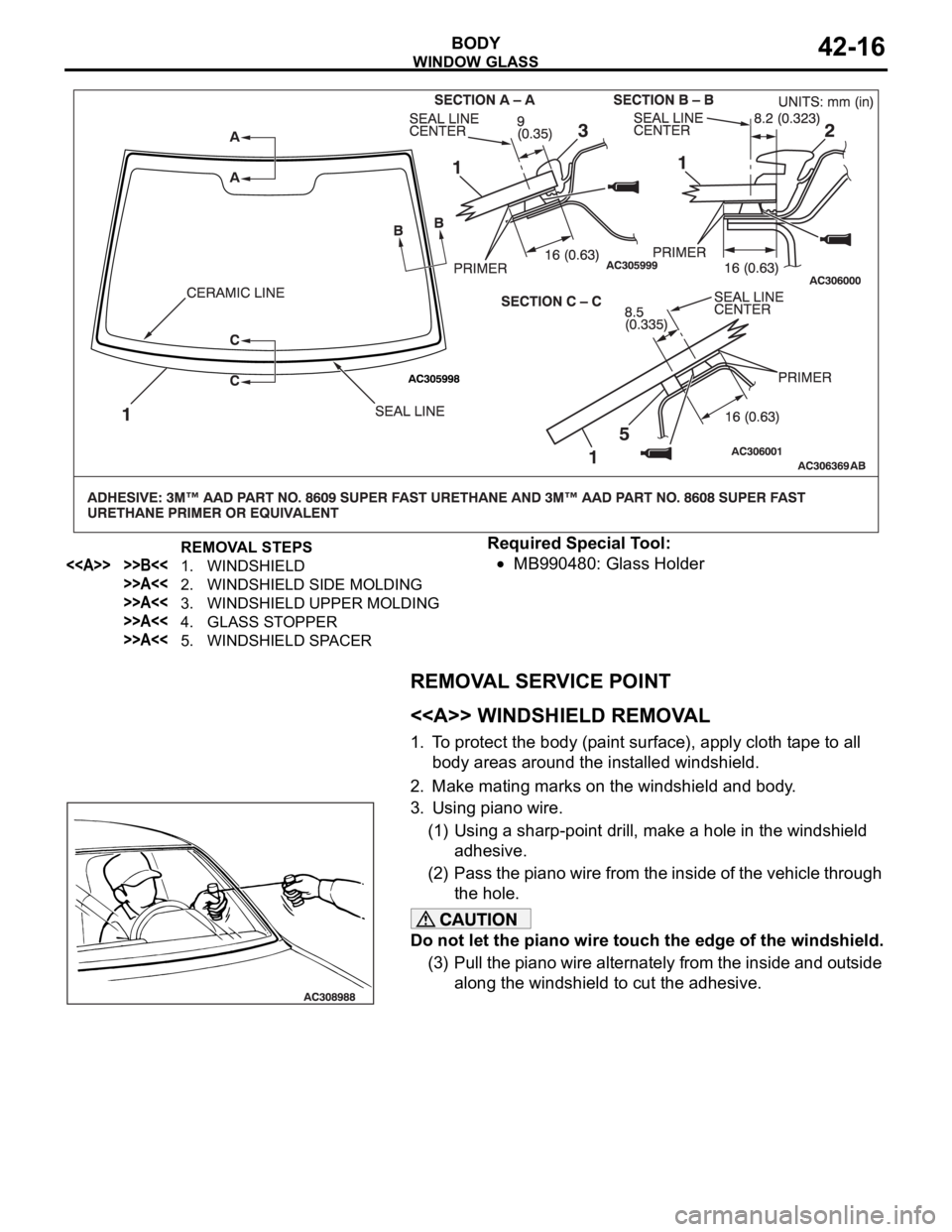

Required Special Tool:

MB990480: Glass Holder

REMOVAL SERVICE POINT

.

<> WINDSHIELD REMOVAL

1. To protect the body (paint surface), apply cloth tape to all

body areas around the installed windshield.

2. Make mating marks on the windshield and body.

3. Using piano wire.

(1) Using a sharp-point drill, make a hole in the windshield

adhesive.

(2) Pass the piano wire from the inside of the vehicle through

the hole.

Do not let the piano wire touch the edge of the windshield.

(3) Pull the piano wire alternately from the inside and outside

along the windshield to cut the adhesive.

REMOVAL STEPS

<> >>B<<1. WINDSHIELD

>>A<<2. WINDSHIELD SIDE MOLDING

>>A<<3. WINDSHIELD UPPER MOLDING

>>A<<4. GLASS STOPPER

>>A<<5. WINDSHIELD SPACER

Page 1084 of 1500

WINDOW GLASS

BODY42-17

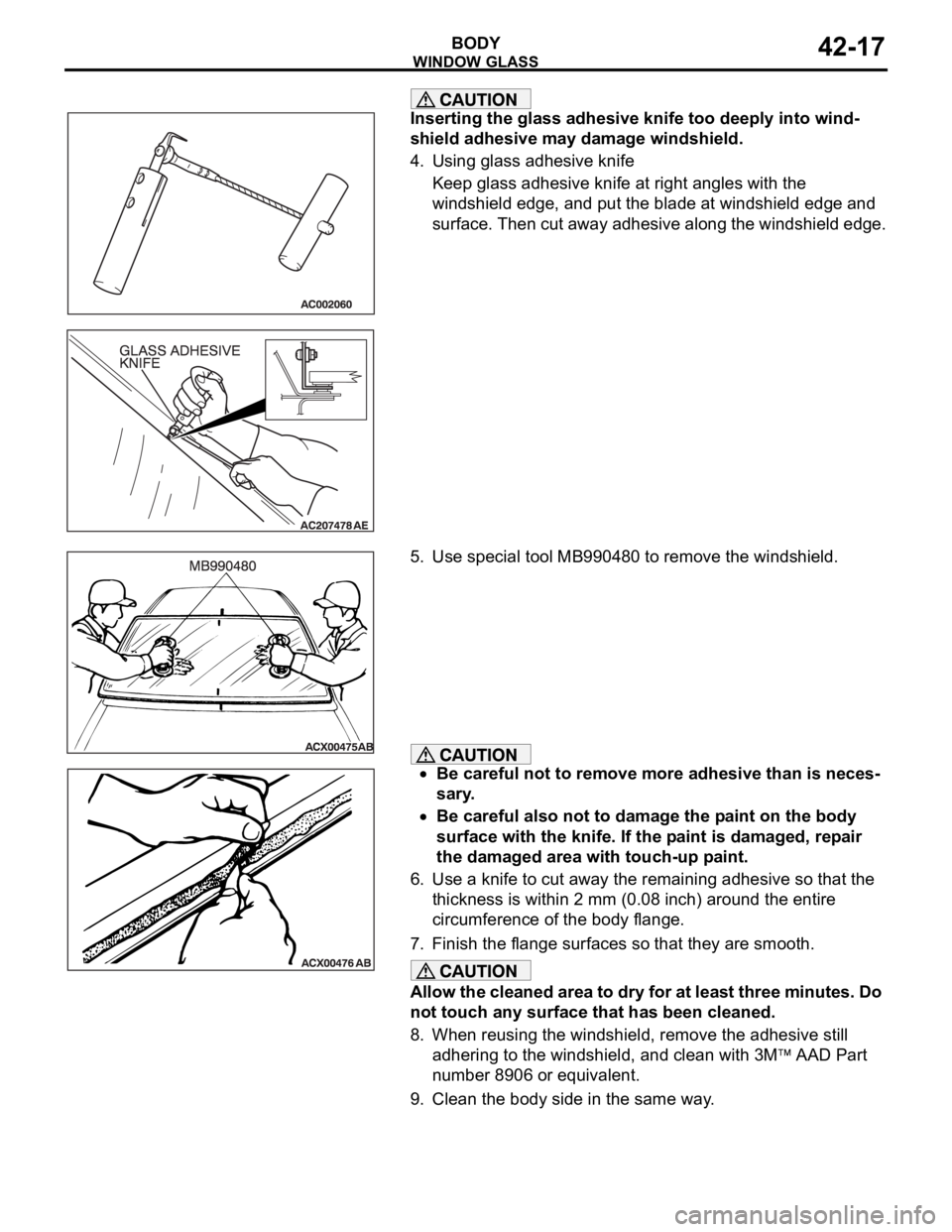

Inserting the glass adhesive knife too deeply into wind-

shield adhesive may damage windshield.

4. Using glass adhesive knife

Keep glass adhesive knife at right angles with the

windshield edge, and put the blade at windshield edge and

surface. Then cut away adhesive along the windshield edge.

5. Use special tool MB990480 to remove the windshield.

Be careful not to remove more adhesive than is neces-

sary.

Be careful also not to damage the paint on the body

surface with the knife. If the paint is damaged, repair

the damaged area with touch-up paint.

6. Use a knife to cut away the remaining adhesive so that the

thickness is within 2 mm (0.08 inch) around the entire

circumference of the body flange.

7. Finish the flange surfaces so that they are smooth.

Allow the cleaned area to dry for at least three minutes. Do

not touch any surface that has been cleaned.

8. When reusing the windshield, remove the adhesive still

adhering to the windshield, and clean with 3M

AAD Part

number 8906 or equivalent.

9. Clean the body side in the same way.

Page 1085 of 1500

WINDOW GLASS

BODY42-18

INSTALLATION SERVICE POINTS

.

>>A<< WINDSHIELD SPACER/GLASS STOP-

PER/WINDSHIELD UPPER MOLDING/WIND-

SHIELD SIDE MOLDING INSTALLATION

Leave the degreased parts for 3 or more minutes to dry

well, before starting on the next step. Do not touch the

degreased parts.

1. Use 3M

AAD Part number 8906 or equivalent to degrease

the inside and outside of the windshield and the body

flanges.

2. Install the windshield spacer and glass stoppers to the

specified positions so that there are no adrift or warped

surfaces inside the windshield.

3. Install the windshield upper and side moldings to the

windshield.

.

Page 1086 of 1500

WINDOW GLASS

BODY42-19

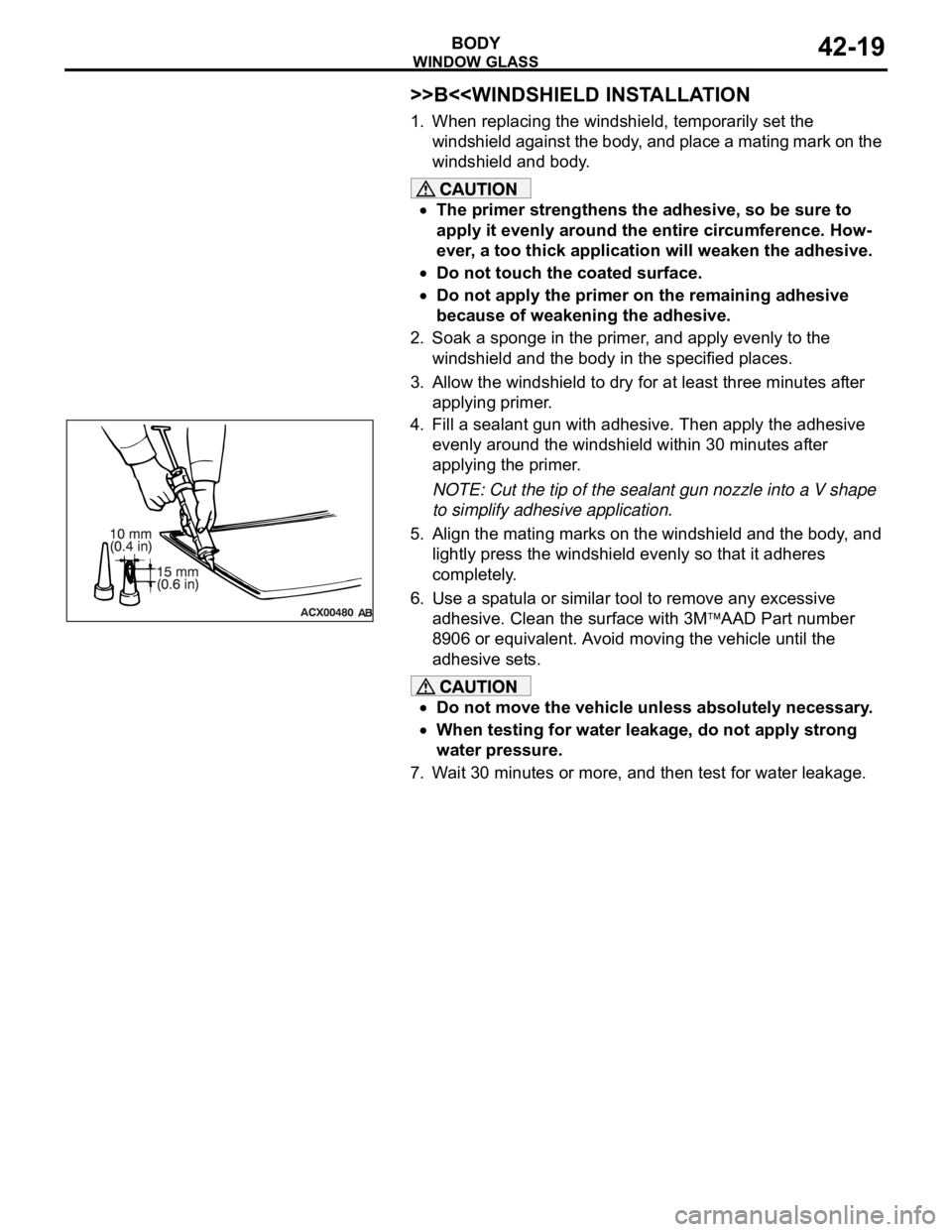

>>B<

windshield against the body, and place a mating mark on the

windshield and body.

The primer strengthens the adhesive, so be sure to

apply it evenly around the entire circumference. How-

ever, a too thick application will weaken the adhesive.

Do not touch the coated surface.

Do not apply the primer on the remaining adhesive

because of weakening the adhesive.

2. Soak a sponge in the primer, and apply evenly to the

windshield and the body in the specified places.

3. Allow the windshield to dry for at least three minutes after

applying primer.

4. Fill a sealant gun with adhesive. Then apply the adhesive

evenly around the windshield within 30 minutes after

applying the primer.

NOTE: Cut the tip of the sealant gun nozzle into a V shape

to simplify adhesive application.

5. Align the mating marks on the windshield and the body, and

lightly press the windshield evenly so that it adheres

completely.

6. Use a spatula or similar tool to remove any excessive

adhesive. Clean the surface with 3M

AAD Part number

8906 or equivalent. Avoid moving the vehicle until the

adhesive sets.

Do not move the vehicle unless absolutely necessary.

When testing for water leakage, do not apply strong

water pressure.

7. Wait 30 minutes or more, and then test for water leakage.

Page 1087 of 1500

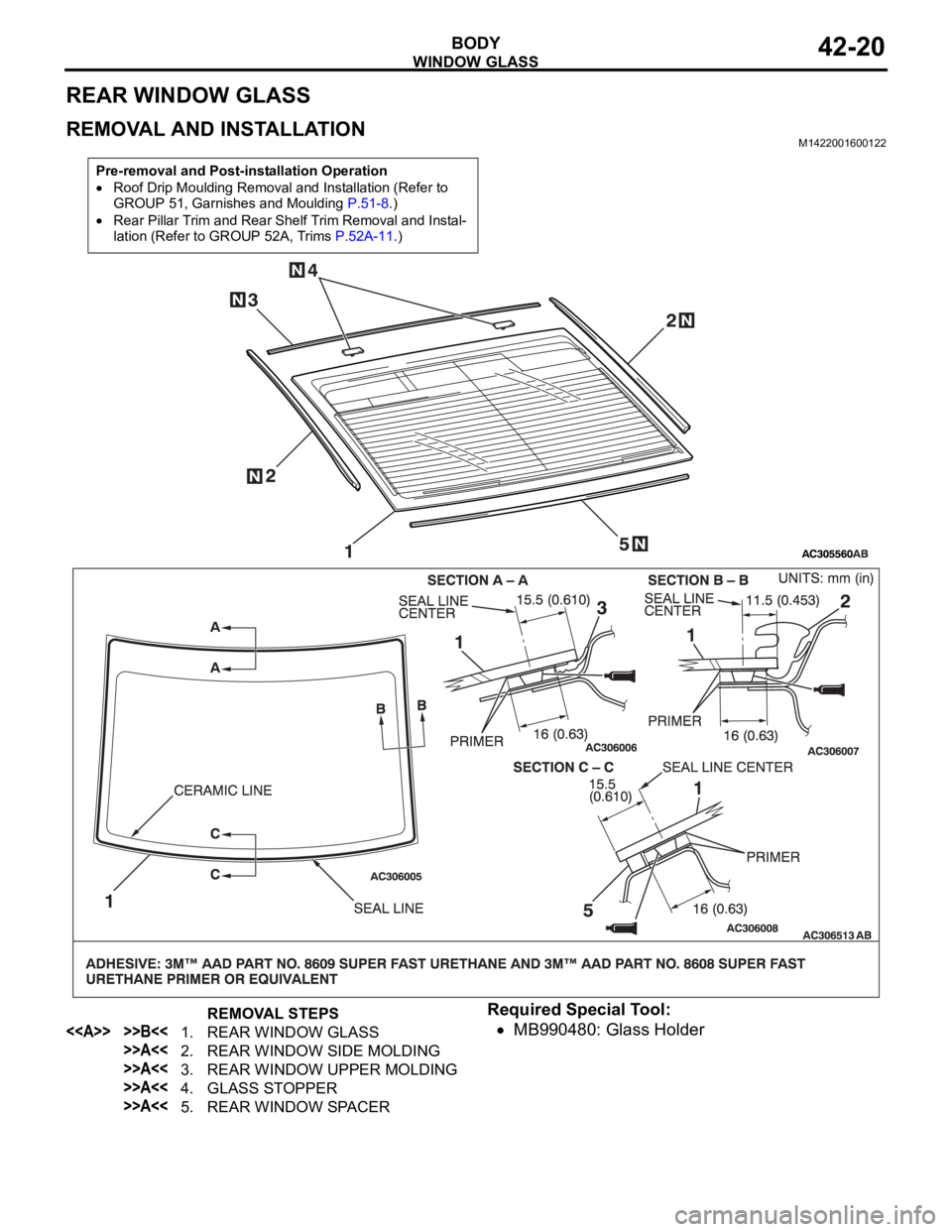

WINDOW GLASS

BODY42-20

REAR WINDOW GLASS

REMOVAL AND INSTALLATIONM1422001600122

Required Special Tool:

MB990480: Glass Holder

Pre-removal and Post-installation Operation

Roof Drip Moulding Removal and Installation (Refer to

GROUP 51, Garnishes and Moulding P.51-8.)

Rear Pillar Trim and Rear Shelf Trim Removal and Instal-

lation (Refer to GROUP 52A, Trims P.52A-11.)

REMOVAL STEPS

<> >>B<<1. REAR WINDOW GLASS

>>A<<2. REAR WINDOW SIDE MOLDING

>>A<<3. REAR WINDOW UPPER MOLDING

>>A<<4. GLASS STOPPER

>>A<<5. REAR WINDOW SPACER