MITSUBISHI COLT 2006 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 341 of 364

GROUP 35A

BASIC BRAKE SYSTEM

CONTENTS

GENERAL INFORMATIO N . . . . . . . .35A-2

CONSTRUCTION DESCRIPTION . . .35A-5

MASTER CYLINDER . . . . . . . . . . . . . . . . . 35A-5

BRAKE BOOSTER . . . . . . . . . . . . . . . . . . . 35A-5

BRAKE PEDAL . . . . . . . . . . . . . . . . . . . . . . 35A-6

FRONT BRAKE . . . . . . . . . . . . . . . . . . . . . . 35A-7

REAR BRAKE . . . . . . . . . . . . . . . . . . . . . . . 35A-8

Page 342 of 364

GENERAL INFORMATION

BASIC BRAKE SYSTEM35A-2

GENERAL INFORMATION

M2350000100848

FEATURES

Brake system with high reliability and durability have

achieved distinguished braking performance.

BRAKING PERFORMANCE

•Brake booster with 9-inch variable amplification

ratio mechanism by which greater braking force

can be obtained with a less pedal pressure has

been installed (with brake assist function).

•14-inch disc brake is installed on the front

wheels.

•15-inch disc brake is installed on the front

wheels.

•8-inch leading trailing type drum brake is installed

on the rear wheels.

•14-inch disc brake is installed on the rear wheels.

STABILITY

•4-wheel anti-lock braking system (4ABS) is

adopted to prevent slipping caused by the vehicle

wheels locking up, in order to maintain appropri

-

ate braking distance, and also to maintain vehicle

stability and steering function.

•Electronic brake-force distribution (EBD) is

adopted to maintain the maximum amount of rear

braking force even when the vehicle's load is var

-

ied.

•Diagonal split (X-type) brake fluid line is adopted.

•Ventilated discs have been adopted to front

brakes to improve anti-fading performance.

•A brake pedal retraction suppression structure

that restrains the retraction of the brake pedal

and reduces the shock to the feet of the driver in

the event of a frontal collision has been adopted.

SERVICEABILITY

•Diagnosis function is adopted for the ABS system

in order to make inspection easier.

•For the front disc brakes, brake disc separated

front hub is adapted to make removal and instal

-

lation easier.

•ABS-ECU and hydraulic unit have been inte-

grated to make them more compact and lighter.

Page 343 of 364

GENERAL INFORMATION

BASIC BRAKE SYSTEM35A-3

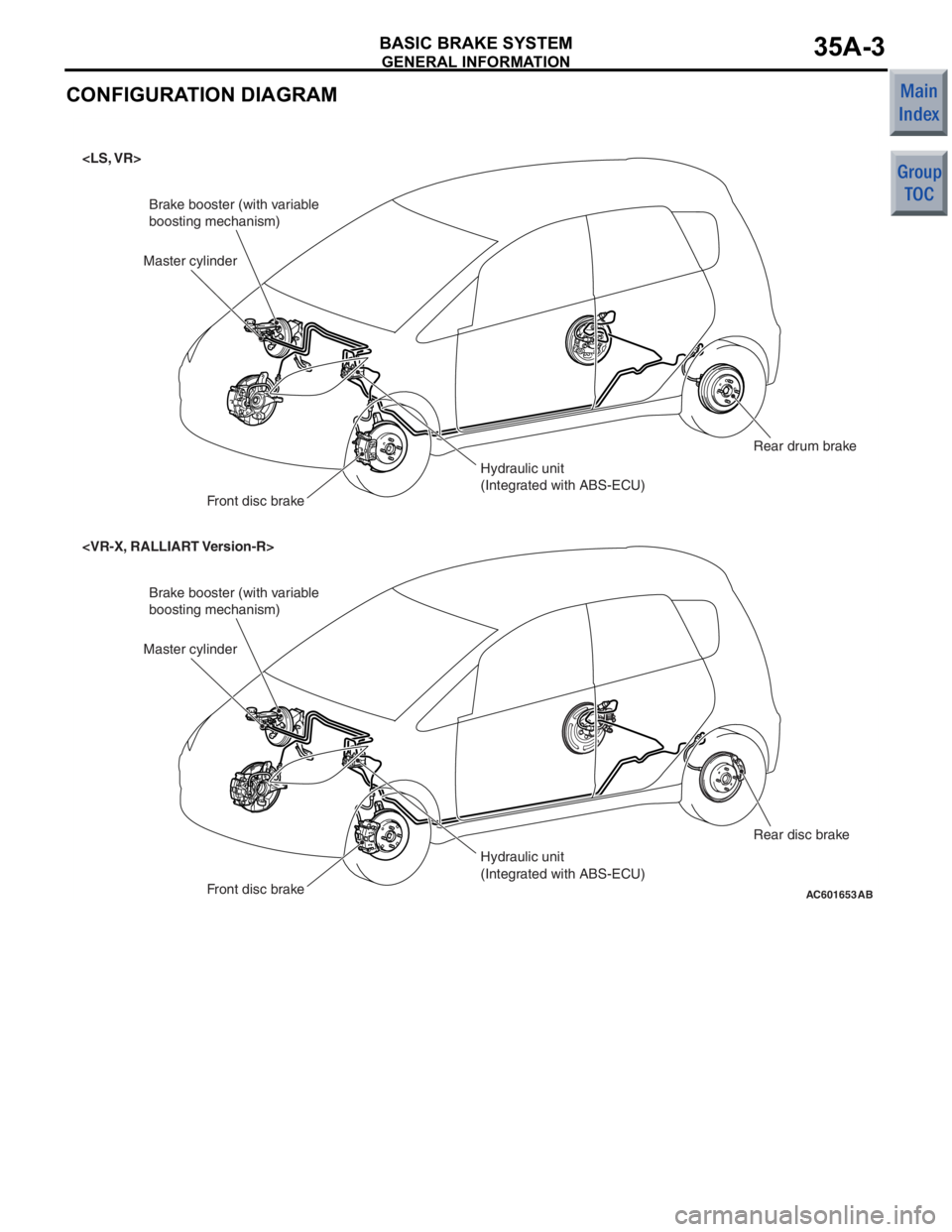

CONFIGURATION DIAGRAM

AC601653

Brake booster (with variable

boosting mechanism)

Hydraulic unit

(Integrated with ABS-ECU)

Master cylinder

Front disc brake Rear drum brake

Brake booster (with variable

boosting mechanism)

Hydraulic unit

(Integrated with ABS-ECU)

Master cylinder

Front disc brake Rear disc brake

AB

Page 344 of 364

GENERAL INFORMATION

BASIC BRAKE SYSTEM35A-4

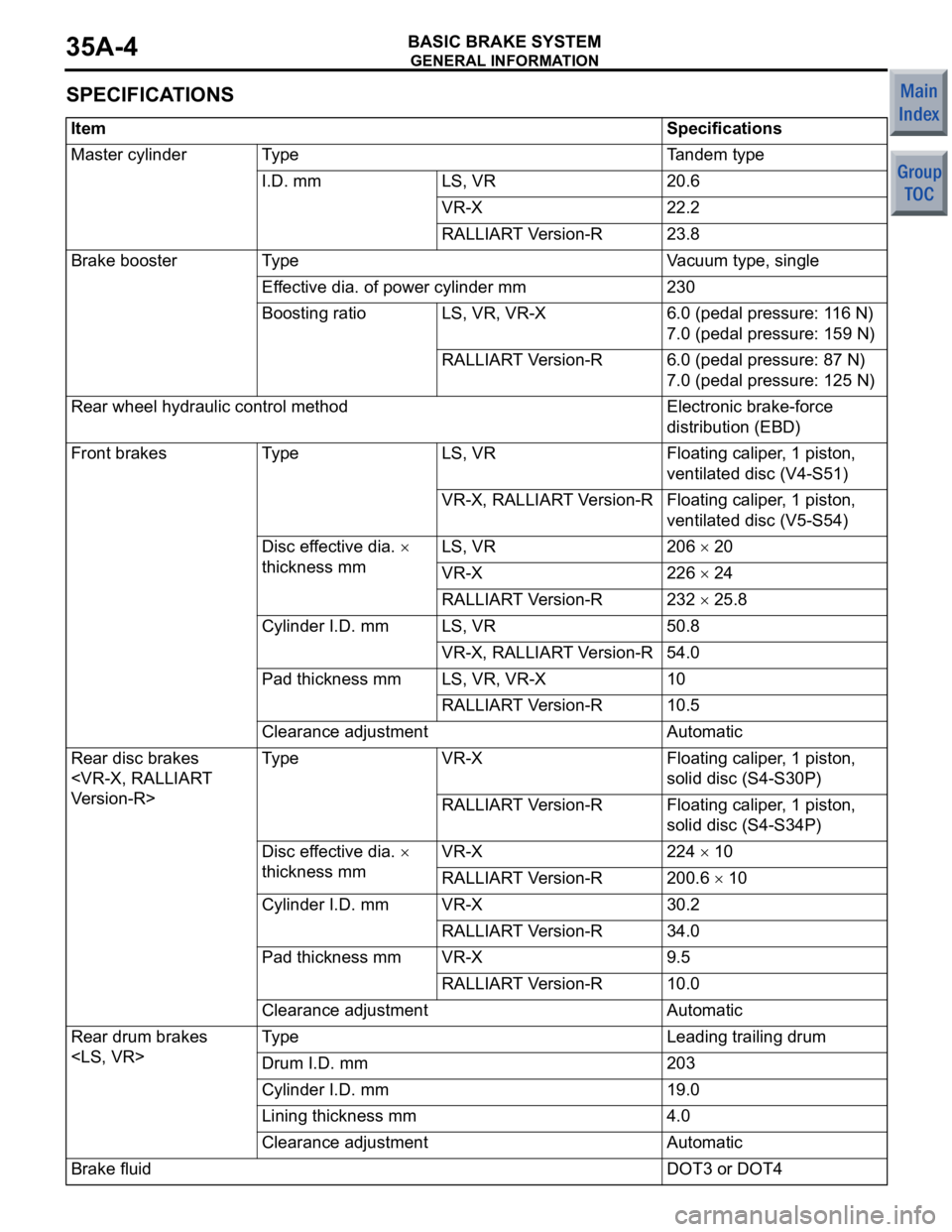

SPECIFICATIONS

ItemSpecifications

Master cylinderTy p eTandem type

I.D. mmLS, VR20.6

VR-X22.2

RALLIART Version-R23.8

Brake boosterTy p eVacuum type, single

Effective dia. of power cylinder mm230

Boosting ratioLS, VR, VR-X6.0 (pedal pressure: 116 N)

7.0 (pedal pressure: 159 N)

RALLIART Version-R6.0 (pedal pressure: 87 N)

7.0 (pedal pressure: 125 N)

Rear wheel hydraulic control methodElectronic brake-force

distribution (EBD)

Front brakesTy p eLS, VRFloating caliper, 1 piston,

ventilated disc (V4-S51)

VR-X, RALLIART Version-RFloating caliper, 1 piston,

ventilated disc (V5-S54)

Disc effective dia. ×

thickness mmLS, VR206 × 20

VR-X226 × 24

RALLIART Version-R232 × 25.8

Cylinder I.D. mmLS, VR50.8

VR-X, RALLIART Version-R54.0

Pad thickness mmLS, VR, VR-X10

RALLIART Version-R10.5

Clearance adjustmentAutomatic

Rear disc brakes

Ty p eVR-XFloating caliper, 1 piston,

solid disc (S4-S30P)

RALLIART Version-RFloating caliper, 1 piston,

solid disc (S4-S34P)

Disc effective dia. ×

thickness mmVR-X224 × 10

RALLIART Version-R200.6 × 10

Cylinder I.D. mmVR-X30.2

RALLIART Version-R34.0

Pad thickness mmVR-X9.5

RALLIART Version-R10.0

Clearance adjustmentAutomatic

Rear drum brakes

Ty p eLeading trailing drum

Drum I.D. mm203

Cylinder I.D. mm19.0

Lining thickness mm4.0

Clearance adjustmentAutomatic

Brake fluidDOT3 or DOT4

Page 345 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-5

CONSTRUCTION DESCRIPTION

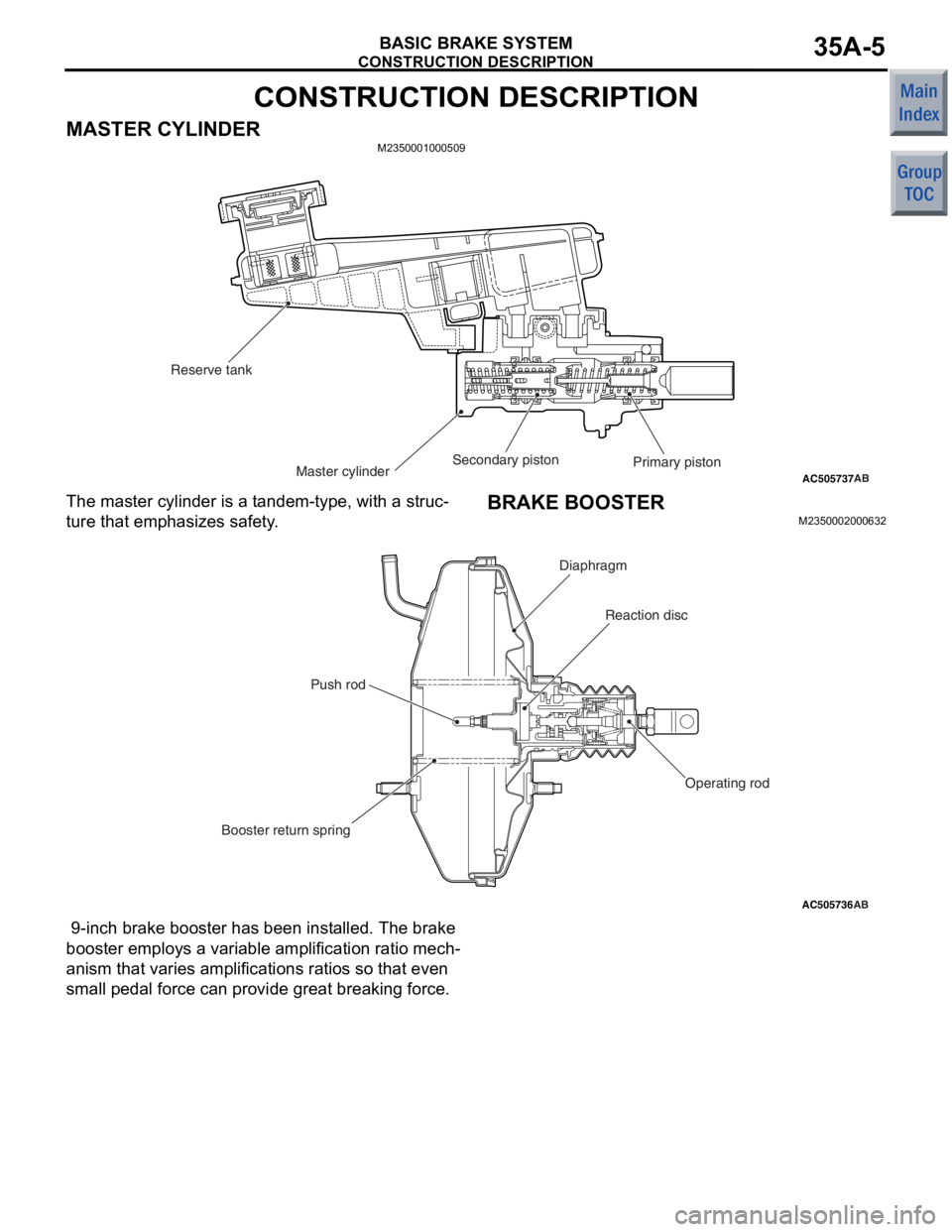

MASTER CYLINDERM2350001000509

AC505737ABMaster cylinder

Reserve tank

Primary piston

Secondary piston

The master

cylind e r is a t andem-typ e, with a stru c-

ture that emp hasizes sa fety .

BRAKE BOOSTER

M23500020 0063 2

AC505736AB

Reaction disc

Booster return spring Push rod

Diaphragm

Operating rod

9-inch brake booste r has been inst alled. T he brake

booster employs a

variable amplification ratio mech

-

anism that va ries amplifications ratios so that e v en

sma

ll p edal force can provide gre a t brea kin g force.

Page 346 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-6

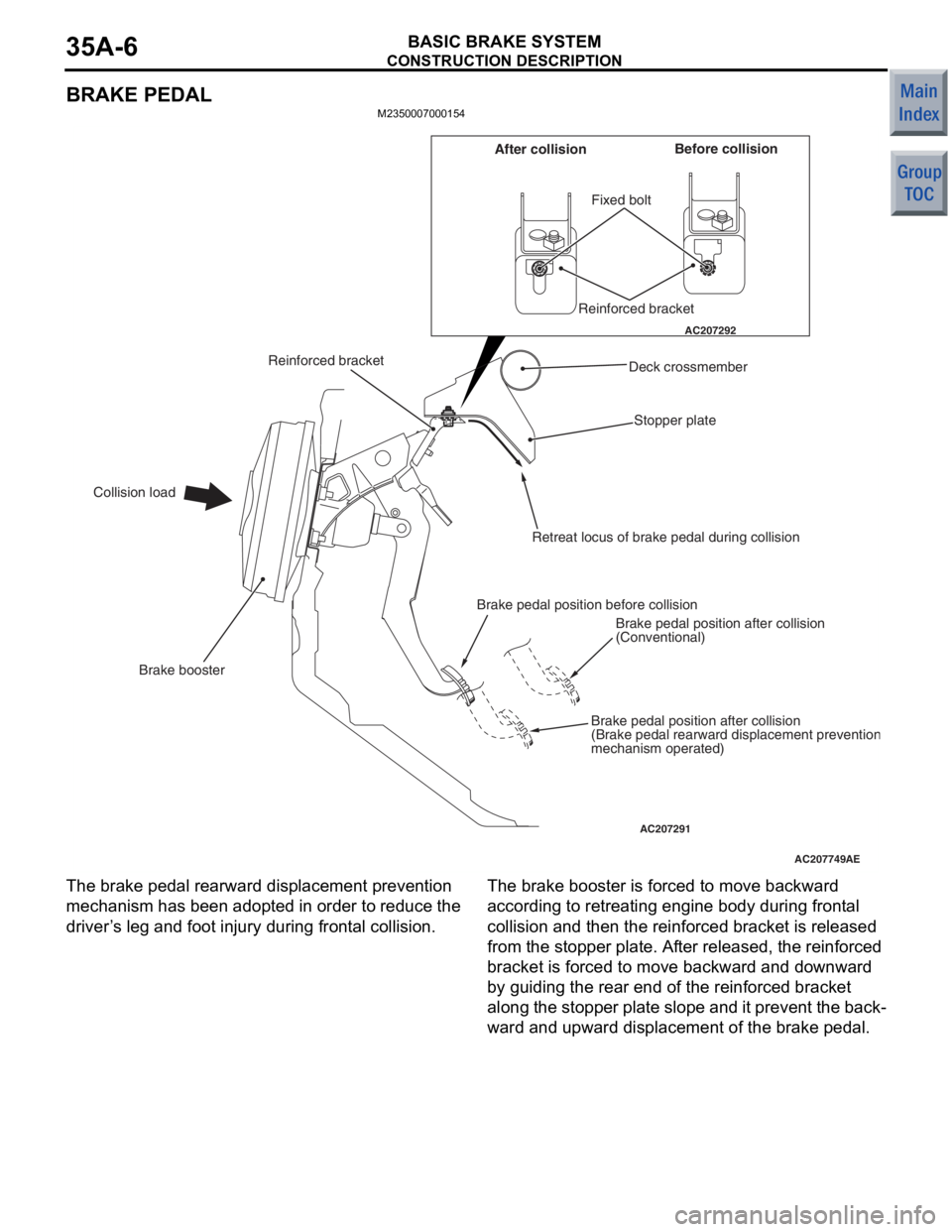

BRAKE PEDAL

M2350007000154

AC207749

AC207292

AC207291AE

Fixed bolt

Stopper plate

Brake booster

Collision load Before collision

After collision

Reinforced bracket

Deck crossmember

Retreat locus of brake pedal during collision

Brake pedal position before collision Brake pedal position after collision

(Conventional)

Brake pedal position after collision

(Brake pedal rearward displacement preventio

nmechanism operated)

Reinforced bracket

The bra

k e pe dal re arward displacement preve n tion

mechanism

has been adop ted in ord e r to reduce the

driver

’ s le g and foot injury during fron t a l co llisio n .The brak e bo oste r is force d to move backward

accordin

g to ret r eatin g engine bo dy d u ring front al

collision a

nd the n the r e info rced b r acket is release d

from

the stopper plat e. Af ter release d , the reinf o rced

bracket is forced to

move backward and do wn wa rd

by gu

iding the rear end of the reinf o rced bracket

along

the stoppe r plate slo pe and it preve n t the back

-

ward and upward displace ment of the b r ake pedal.

Page 347 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-7

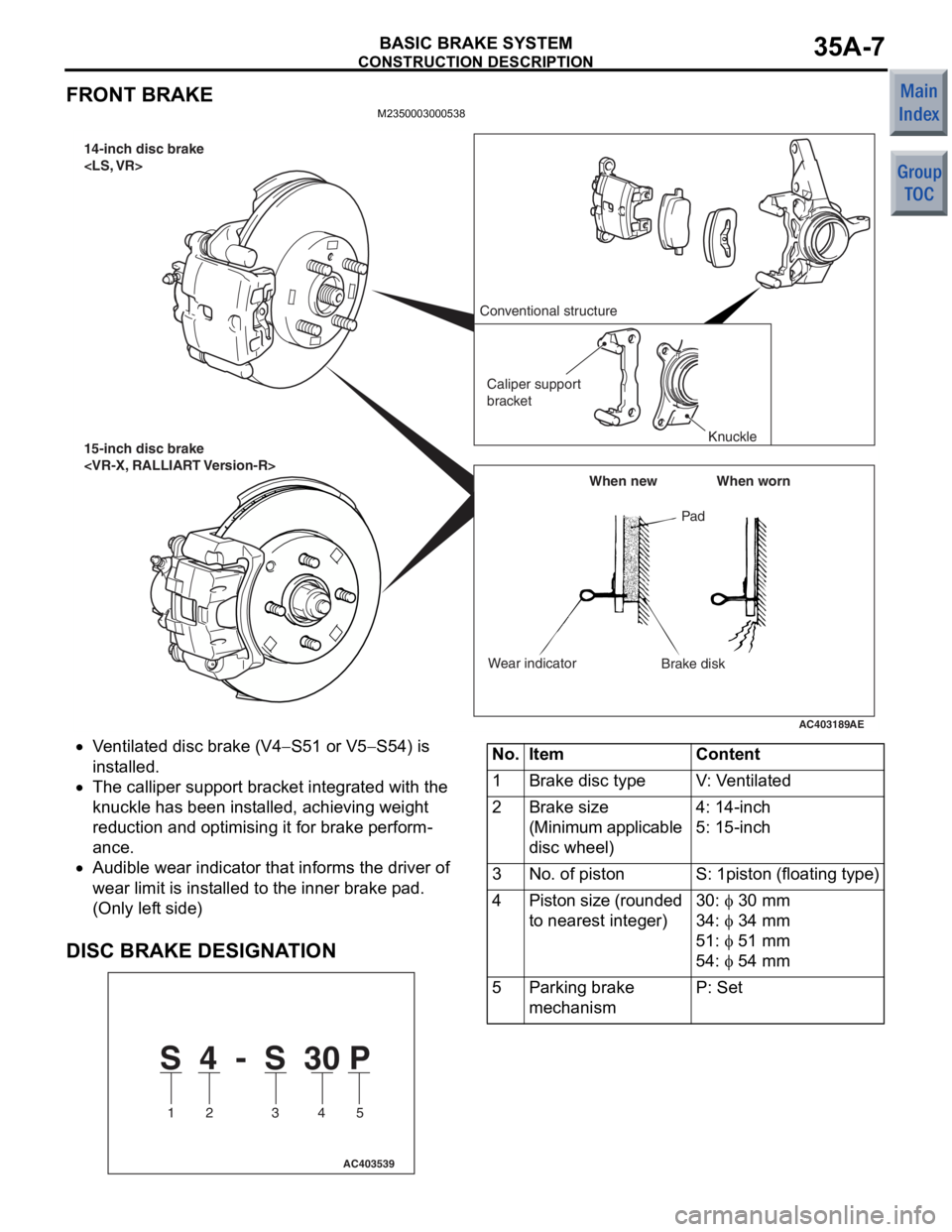

FRONT BRAKE

M2350003000538

AC403189AE

14-inch disc brake

15-inch disc brake

Brake disk

Wear indicator When new When worn

Conventional structure

Caliper support

bracket Knuckle

•Ventilate d disc b r ake (V4−S51 or V5−S54) is

in

st

alled.

•The callipe r sup port bra c ket int egrated with the

kn

uckle h a s be en in st alled, achie v in g weigh t

redu

ction and optimising it for b r ake perform

-

ance.

•Audible wear indicat o r that informs th e driver of

wear limit is inst

alle d to th e inn e r brake p ad.

(Only lef

t side)

DISC BRAKE DESIGNA T ION

S 4 - S 30 P

1 2 3 4 5

AC403539

No.ItemContent

1Brake disc typeV: Ventilated

2Brake size

(Minimum applicable

disc wheel)4: 14-inch

5: 15-inch

3No. of pistonS: 1piston (floating type)

4Piston size (rounded

to nearest integer)30: φ 30 mm

34: φ 34 mm

51: φ 51 mm

54: φ 54 mm

5Parking brake

mechanismP: Set

Page 348 of 364

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-8

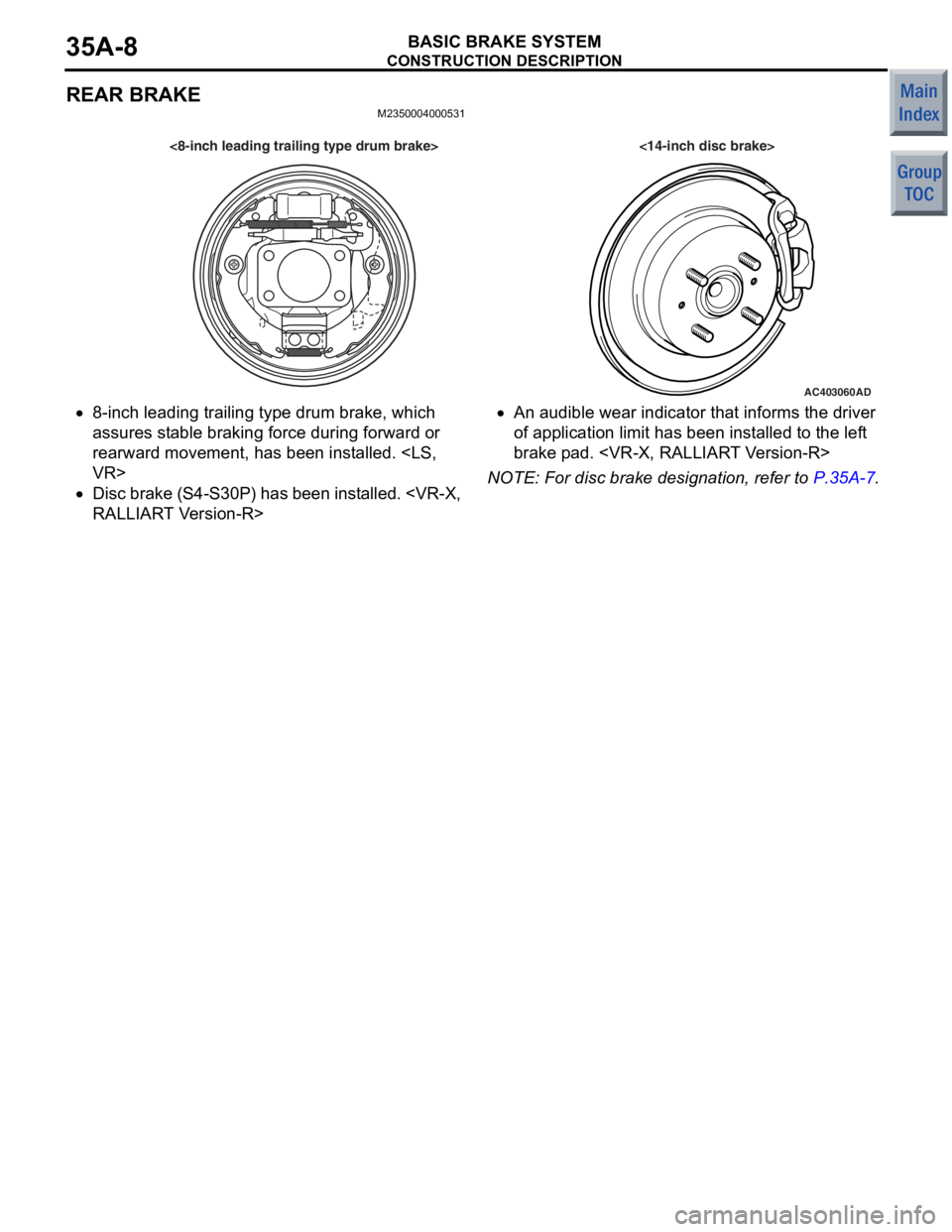

REAR BRAKE

M2350004000531

AC403060AD

<8-inch leading trailing type drum brake> <14-inch disc brake>

•8-inch leading tra iling type drum brake, which

assure

s st ab le bra k in g force during forward or

rearward

movement, ha s bee n inst alle d.

•Disc brake (S4 - S3 0 P ) ha s be en in st a l le d.

T V e rsion - R>

•An audible wear indicator th at in forms the d r ive r

of a

pplication limit has been inst a lled to the lef t

brake p

ad.

NOTE: For d i sc brake de sign ation , refer t o P.35A-7.

Page 349 of 364

GROUP 23

CONTINUOUSLY VARIABLE

TRANSMISSION (CVT)

CONTENTS

CVT. . . . . . . . . . . . . . . . . . . . . . . . . . .23-2

GENERAL INFORMATION . . . . . . . . . . . . . 23-2

ELECTRONIC CONTROL SYSTEM. . . . . . 23-3

EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . 23-3

CONTROLLER AREA NETWORK (CAN)

COMMUNICATION . . . . . . . . . . . . . . . . . . . 23-3

RATIO PATTERN . . . . . . . . . . . . . . . . . . . . 23-3

DIAGNOSIS CLASSIFICA TION TABLE . . . 23-4

ATF WARMER (ATF COOLER) . . . . . . . . . 23-5

TRANSMISSION CONTROL . . . . . . .23-6

GENERAL INFORMATION . . . . . . . . . . . . . 23-6

SELECTOR LEVER ASSEMBLY . . . . . . . . 23-7

CVT ERRONEOUS OPERATION

PREVENTION MECHANISMS . . . . . . . . . . 23-8

Page 350 of 364

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)23-2

CVT

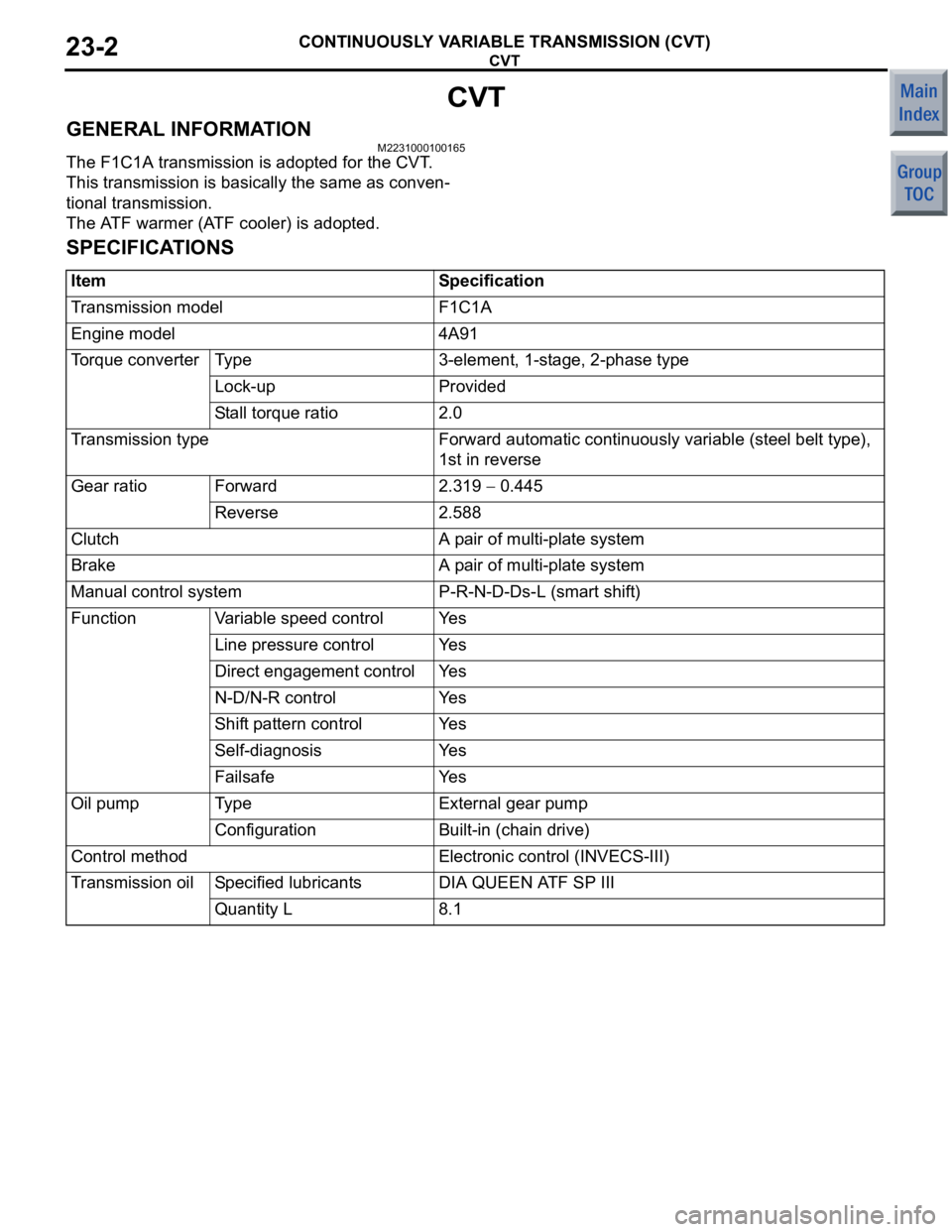

GENERAL INFORMATIONM2231000100165

The F1C1A transmission is adopted for the CVT.

This transmission is basically the same as conven

-

tional transmission.

The ATF warmer (ATF cooler) is adopted.

SPECIFICATIONS

ItemSpecification

Transmission modelF1C1A

Engine model4A91

Torque converterTy p e3-element, 1-stage, 2-phase type

Lock-upProvided

Stall torque ratio2.0

Transmission typeForward automatic continuously variable (steel belt type),

1st in reverse

Gear ratioForward2.319 − 0.445

Reverse2.588

ClutchA pair of multi-plate system

BrakeA pair of multi-plate system

Manual control systemP-R-N-D-Ds-L (smart shift)

FunctionVariable speed controlYe s

Line pressure controlYe s

Direct engagement controlYe s

N-D/N-R controlYe s

Shift pattern controlYe s

Self-diagnosisYe s

FailsafeYe s

Oil pumpTy p eExternal gear pump

ConfigurationBuilt-in (chain drive)

Control methodElectronic control (INVECS-III)

Transmission oilSpecified lubricantsDIA QUEEN ATF SP III

Quantity L8.1