check engine MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 194 of 408

FUELSYSTEM 5-7

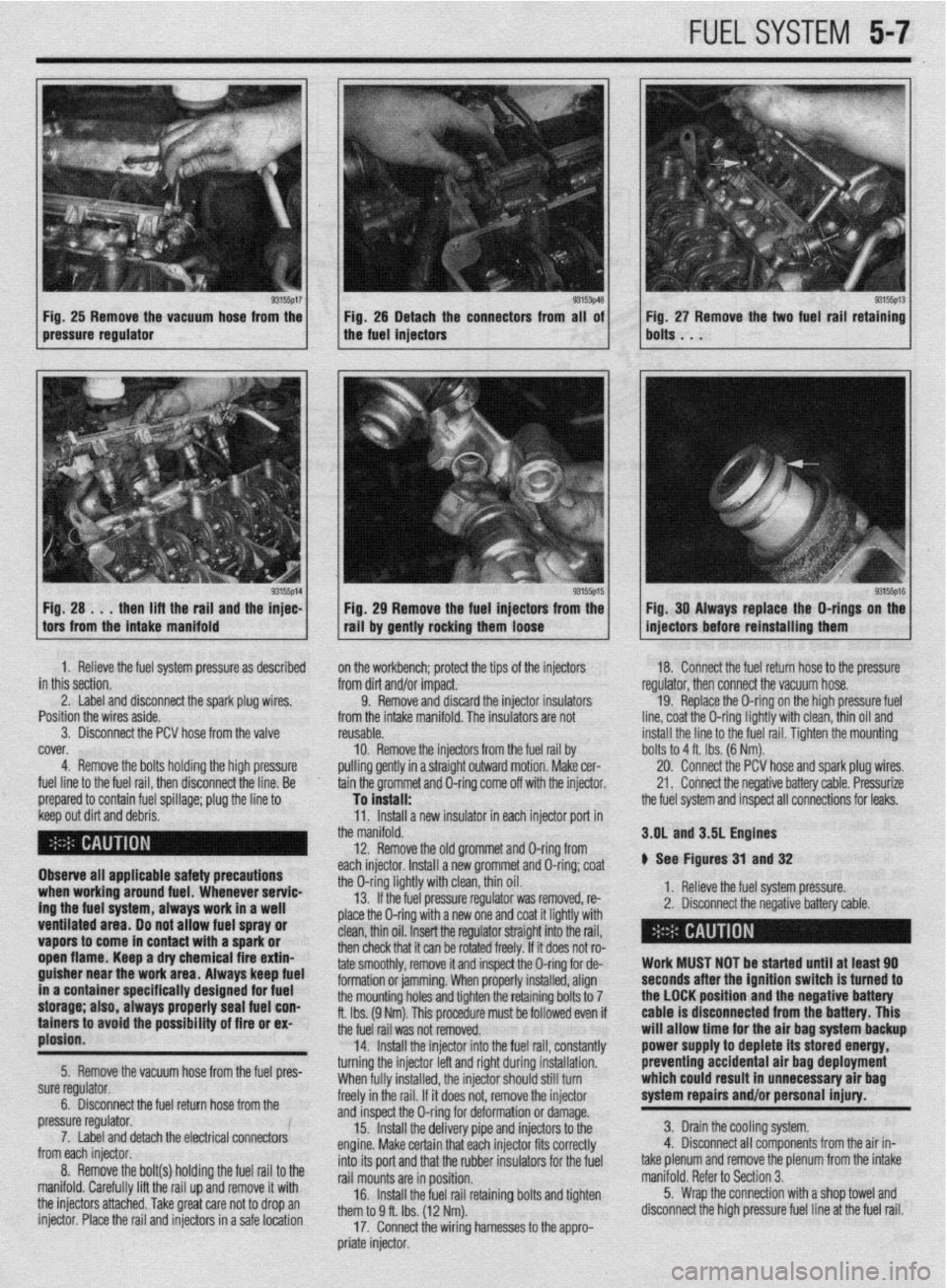

Fig, 25 Remove the vacuum hose from the Fig. 25 Detach the connectors from all of

pressure regulator the fuel injectors

1 H; :A ..;lt;;aft~rgi,i~;yl the ;F: 1 / . 93155p15 1 Fig 29 Remove the fuel injectors from the

tall by gently rocking them loose Fig. 27 Remove the two fuel rail retaining

bolts . . .

93155ps Fig. 30 Always replace the O-rings on the

injectors before reinstalling them

1. Relieve the fuel system pressure as described

in this section.

2. Label and disconnect the spark plug wires. ’

Position the wires aside.

3. Disconnect the PCV hose from the valve

cover,

4. Remove the bolts holding the high pressure

fuel line to the fuel rail, then disconnect the line. Be

prepared to contain fuel spillage; plug the line to on the workbench; protect the tips of the injectors

from dirt and/or impact.

9. Remove and discard the injector insulators

from the intake manifold. The insulators are not

reusable.

10. Remove the injectors from

pulling gently in a straight outwarc the fuel rail by

I motion. Make cer-

tain the grommet and O-ring come off with the injector. 18. Connect the fuel return hose to the pressure

regulator, then connect the vacuum hose.

19. Replace the O-ring on the high pressure fuel

line, coat the O-ring lightly with clean, thin oil and

install the line to the fuel rail. Tiahten the mountina

To install: -

the fuel system and inspect all connections for leaks. bolts to 4 ft. Ibs. (6 Nm).

20. Connect the PCV hose and spark plug wires.

21. Connect the negative battery cable. Pressurize

1. neneve me rueI system pressure.

2. Disconnect the negative battery cable. 3.OL and 3.5L Engines

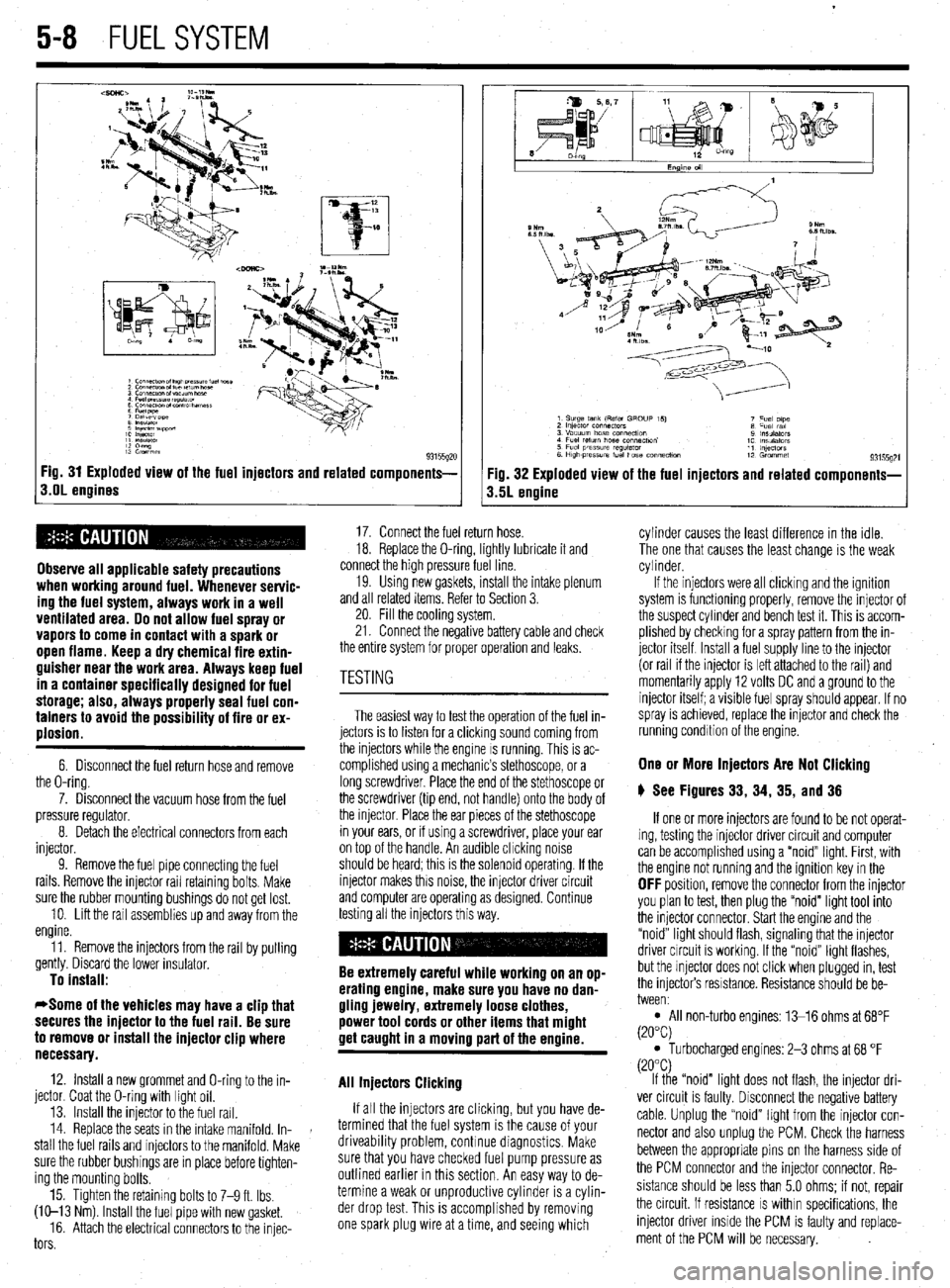

# See Figures 31 and 32

> - ,. .* , ,

I

I

Work MUST NOT be started until at least 90

seconds after the ignition switch is turned to

the LOCK position and the negative battery

cable is disconnected from the battery. This

will allow time for the air bag system backup

power supply to deplete its stored energy,

preventing accidental air bag deployment

which could result in unnecessary air bag

system repairs and/or personal injury.

3. Drain the cooling system.

4. Disconnect all components from the air in-

take plenum and remove the plenum from the intake

manifold. Refer to Section 3.

5. Wrap the connection with a shop towel and

disconnect the high pressure fuel line at the fuel rail. keep out dirt and debris.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possfbility of fire or ex-

plosion.

5. Remove the vacuum hose from the fuel pres-

sure regulator.

6. Disconnect the fuel return hose from the

pressure regulator.

7. Label and detach the electrical connectors

from each injector.

8. Remove the bolt(s) holding the fuel rail to the

manifold. Carefully lift the rail up and remove it with

the injectors attached. Take great care not to drop an

injector. Place the rail and injectors in a safe location 11. Install a new insulator in each injector port in

the manifold.

12. Remove the old grommet and D-ring from

each injector. Install a new grommet and O-ring; coat

the O-ring lightly with clean, thin oil.

13. If the fuel pressure regulator was removed, re-

place the O-ring with a new one and coat it lightly with

clean, thin oil. Insert the regulator straight into the rail,

then check that it can be rotated freely. If it does not ro-

tate smoothly, remove it and inspect the O-ring for de-

formation or jamming. When properly installed, align

the mounting holes and tighten the retaining bolts to 7

ft. Ibs. (9 Nm). This procedure must be followed even if

the fuel rail was not removed.

14. Install the injector into the fuel rail, constantly

turning the injector left and right during installation.

When fully installed, the injector should still turn

freely in the rail. If it does not, remove the injector

and inspect the O-ring for deformation or damage.

15. Install the delivery pipe and injectors to the

engine. Make certain that each injector fits correctly

into its port and that the rubber insulators for the fuel

rail mounts are in position.

16. Install the fuel rail retaining bolts and tighten

them to 9 ff. Ibs. (12 Nm).

17. Connect the wiring harnesses to the appro-

priate injector.

Page 195 of 408

5-8 FUELSYSTEM

9 ,npimr w1m.m

1: i”“L,

1: 82”w

93155gx Fig. 31 Exploded view of the fuel injectors and related components-

s.OL engines

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

6. Disconnect the fuel return hose and remove

the O-ring.

7. Disconnect the vacuum hose from the fuel

pressure regulator.

8. Detach the electrical connectors from each

injector.

9. Remove the fuel pipe connectmg the fuel

rails. Remove the injector rail retaining bolts. Make

sure the rubber mounting bushings do not get lost.

10. Lift the rail assemblies up and away from the

engine.

11. Remove the injectors from the rail by pulling

gently. Discard the lower insulator.

To install:

*Some of the vehicles may have a clip that

secures the injector to the fuel rail. Be sure

to remove or install the injector clip where

necessary.

12. Install a new grommet and O-ring to the in-

jector. Coat the O-ring with light oil.

13. Install the injector to the fuel rail.

14. Replace the seats in the intake manifold. In-

stall the fuel rails and injectors to the manifold. Make

sure the rubber bushings are in place before tighten-

ing the mounting bolts.

15. Tighten the retaining bolts to 7-9 ft. Ibs.

(W-13 Nm) Install the fuel pipe with new gasket.

16. Attach the electrical connectors to the injec-

tors

Fig. 32 Exploded view of the fuel injectors and related components-

3.5L engine

17. Connect the fuel return hose.

18. Replace the O-ring, lightly lubricate it and

connect the high pressure fuel line.

19. Usmg new gaskets, install the intake plenum

and all related items. Refer to Section 3.

20. Fill the cooling system.

21. Connect the negative battery cable and check

the entire system for proper operation and leaks.

The easiest way to test the operation of the fuel in-

jectors is to listen for a clicking sound coming from

the injectors while the engine IS running. This is ac-

complished using a mechanic’s stethoscope, or a

long screwdriver. Place the end of the stethoscope or

the screwdriver (tip end, not handle) onto the body of

the injector. Place the ear pieces of the stethoscope

in your ears, or if using a screwdriver, place your ear

on top of the handle. An audible chcking noise

should be heard; this is the solenoid operating. If the

injector makes this noise, the injector driver circuit

and computer are operating as designed. Continue

testing all the injectors this way.

Be extremely careful while working on an op-

erating engine, make sure you have no dan-

gling jewelry, extremely loose clothes,

power tool cords or other items that might

get caught in a moving part of the ermine.

All Injectors Clicking

If all the injectors are clicking, but you have de-

termined that the fuel system is the cause of your

driveability problem, continue diagnostics. Make

sure that you have checked fuel pump pressure as

outlined earlier in this section. An easy way to de-

termine a weak or unproductive cylinder is a cylin-

der drop test. This is accomplished by removing

one spark plug wire at a time, and seeing which cylinder causes the least difference in the idle.

The one that causes the least change is the weak

cylinder.

If the injectors were all clicking and the ignition

system is functioning properly, remove the injector of

the suspect cylinder and bench test it. This is accom-

plished by checking for a spray pattern from the in-

jector itself Install a fuel supply line to the injector

(or rail if the injector is left attached to the rail) and

momentarily apply 12 volts DC and a ground to the

injector itself; a visible fuel spray should appear. If no

spray is achieved, replace the injector and check the

running condition of the engine.

One or More Injectors Are Not Clicking

6 See Figures 33, 34, 35, and 36

If one or more injectors are found to be not operat-

ing, testing the injector driver circuit and computer

can be accomplished using a “noid” light. First, with

the engine not running and the ignition key in the

OFF position, remove the connector from the injector

you plan to test, then plug the “noid” light tool into

the injector connector. Start the engine and the

“noid” light should flash, signaling that the injector

driver circuit is working. If the “noid” light flashes,

but the injector does not click when plugged in, test

the injectors resistance. Resistance should be be-

tween:

l All non-turbo engines: 13-16 ohms at 68°F

(20°C)

l Turbocharged engines: 2-3 ohms at 68 “F

(20°C)

If the “noid” light does not flash, the injector dri-

ver circuit is faulty. Disconnect the negative battery

cable. Unplug the “noid” light from the injector con-

nector and also unplug the PCM. Check the harness

between the appropriate pins on the harness side of

the PCM connector and the injector connector. Re-

sistance should be less than 5.0 ohms; if not, repair

the circuit. If resistance

IS within specifications, the

injector driver inside the PCM is faulty and replace-

ment of the PCM will be necessary.

Page 200 of 408

FUELSYSTiM 5-13

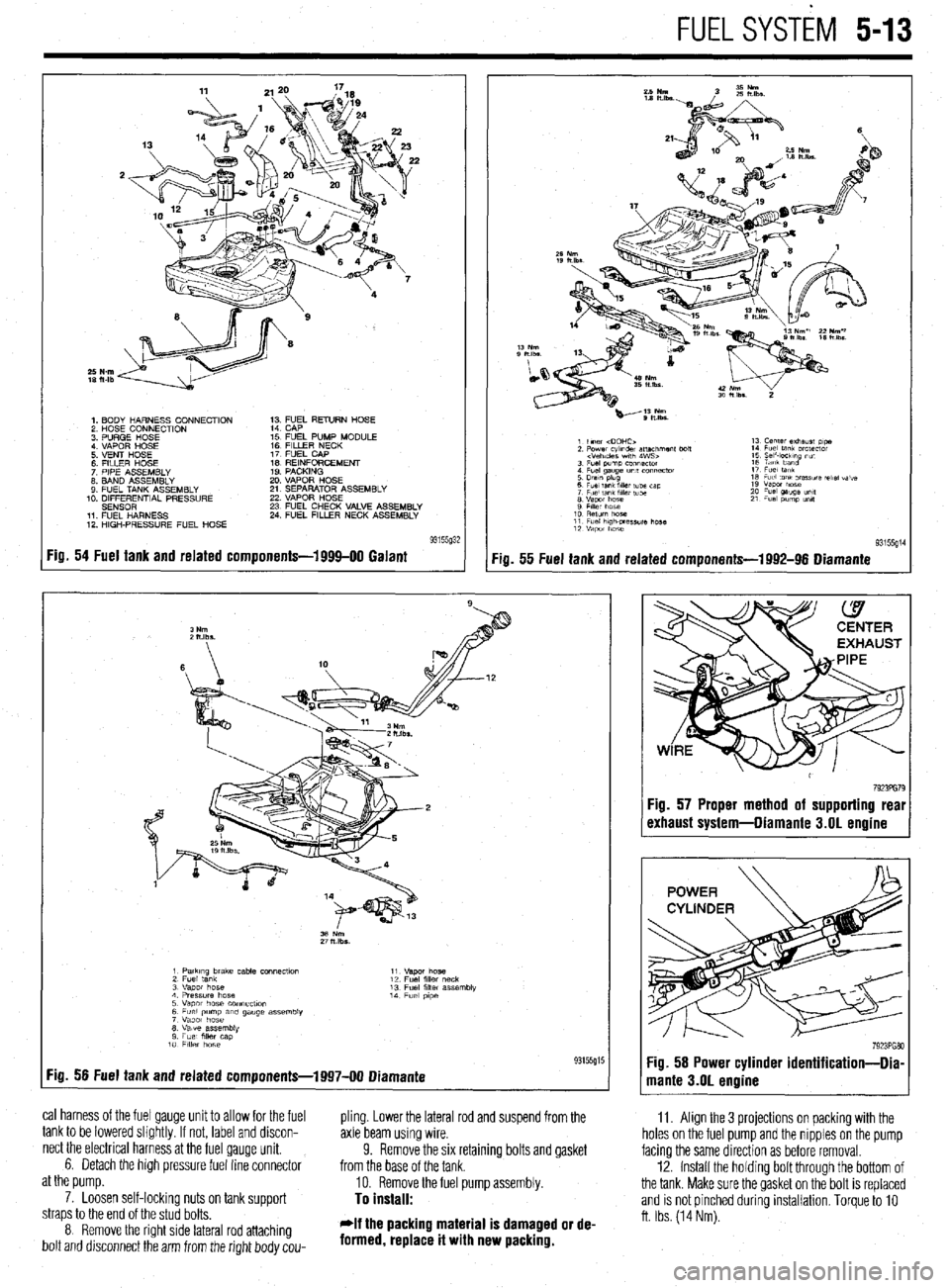

1. BODY HARNESS CONNECTION

2 HOSE CONNECTION

3 PURGE HOSE

4 VAPOR HOSE

5 VENT HOSE

6 FllLER HOSE

7 PIPE ASSEMBLY

8. BAND ASSEMBLY

9 FUEL TANK ASSEMBLY

10. DIFFERENTIAL PRESSURE

SENSOR

11 FUEL HARNESS

12 HIGH-PRESSURE FUEL HOSE 1; ;;JL RETURN HOSE

15 FUEL PUMP MODULE

16 FILLER NECK

17 FUEL CAP

IS REINFORCEMENT

19 PACKING

20 VAPOR HOSE

21 SEPARATOR ASSEMBLY

22 VAPOR HOSE

23 FUEL CHECK VALVE ASSEMBLY

24 FUEL FILLER NECK ASSEMBLY

Fig. 54 Fuel tank and related components-1999-00 Galant

:ia. 55 Fuel tank and related components-1992-96 Diamante

11. Align the 3 projections on packing with the

holes on the fuel pump and the nipples on the pump

facing the same direction as before removal.

12. Install the holdrng bolt through the bottom of

the tank. Make sure the gasket on the bolt is replaced

and is not pinched during installation. Torque to 10

ft. Ibs. (14 Nm).

1 PatkIng brake cable COnneCtlo” 11

2 Fuel tank “.qm hose

12 Fuel fllk, neck

3 “apot hose 13 Fuel filler assembly

4 Pressure hose 14

5 Vapor hose COnneCflOn Fuel p,pe

6 Fuel pump am gauge assembly

7 Vapor hose

8 Valve assembly

9 Fuel mer cap

10 FllkY hose

:ig. 56 Fuel tank and related components-1997-00 Diamante 93155g15

cal harness of the fuel gauge unit to allow for the fuel

pling. Lower the lateral rod and suspend from the

tank to be lowered slightly. If not, label and discon-

axle beam using wire.

nect the electrical harness at the fuel gauge unit.

6. Detach the high pressure fuel line connector 9. Remove the six retaining bolts and gasket

from the base of the tank.

at the pump.

10. Remove the fuel pump assembly.

7. Loosen self-lockinq nuts on tank suooort

To install: straps to the end of the stud bolts.

8 Remove the right side lateral rod attaching

bolt and drsconnect the arm from the right body cou- *If the packing material is damaged or de-

formed, replace it with new packing.

7923PG79 :ig. 57 Proper method of supporting real

rxhaust system-Diamante 3.01 engine

Page 203 of 408

.

5-16 FUELSYSTEM

6. Disconnect the return hose and the high

pressure fuel hose.

7. Using special tool MB991480 or equivalent,

remove the fuel pump retaining cap and remove the

pump assembly.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

To install:

*If the packing material is damaged or de-

formed, replace it with new packing.

8. Install the packing to the fuel tank.

9. Install the fuel pump assembly to the tank

and align the mating marks on the pump and the

floorpan.

10. Tighten the fuel pump retaining cap using

tool MB991480 or equrvalent.

11. Connect the high pressure hose, return hose

and the fuel tank wirmg.

12. Connect the negative battery cable.

13. Check the fuel pump for proper pressure and

inspect the entire system for leaks.

14. Apply sealant to the access cover and install

the cover.

15. Install the rear seat cushion.

TESTING

1. Relieve fuel system pressure.

2. Disconnect the battery negative cable.

3. Disconnect the fuel hrgh pressure hose at the

delivery pipe side.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

alosion.

4. Connect a fuel pressure gauge to tools

MD998709 and MD998742 or exact equivalent, with

appropriate adapters, seals and/or gaskets to prevent

leaks during the test. Install the gauge and adapter

between the delivery pipe and high pressure hose. In-

stall carefully to prevent leaks.

5. Connect the negative battery cable.

6. Apply battery voltage to the terminal for fuel

pump activation (located in the engine compartment)

to run the fuel pump, and check for leaks.

7. Start the engine and run at curb idle speed.

8. Measure the fuel pressure and compare to

the specifications listed in the chart in Section 1.

9. Locate and disconnect the vacuum hose run-

ning to the fuel pressure regulator. Plug the end of

the hose and record the fuel pressure again. The fuel

pressure should have increased approximately IO

psi. 10. Reconnect the vacuum hose the fuel pressure

regulator. After the fuel pressure stabilizes, race the

engine 2-3 times and check that the fuel pressure

does not fall when the engine is running at idle.

il. Check to be sure there is fuel pressure in the

return hose by gently pressing the fuel return hose

with fingers while racing the engine. There will be no

fuel pressure in the return hose when the volume of

fuel flow is low.

12. If fuel pressure is too low, check for a

clogged fuel filter, a defective fuel pressure regulator

or a defective fuel pump, any of which will require re-

placement.

13. If fuel pressure is too high, the fuel pressure

regulator is defective and will have to be replaced or

the fuel return is bent or clogged. If the fuel pressure

readmg does not change when the vacuum hose is

disconnected, the hose is clogged or the valve is

stuck in the fuel pressure regulator and it will have to

be replaced.

14. Stop the engine and check for changes in the

fuel pressure gauge. It should not drop. If the gauge

reading does drop, watch the rate of drop. If fuel

pressure drops slowly, the likely cause is a leaking

injector which will require replacement. If the fuel

pressure drops immediately after the engine is

stopped, the check valve in the fuel pump isn’t clos-

ing and the fuel pump will have to be replaced.

15. Relieve fuel system pressure.

16. Disconnect the high pressure hose and re-

move the fuel pressure gauge from the delivery pipe.

17. Install a new O-ring in the groove of the high

pressure hose. Connect the hose to the delivery pipe

and tighten the screws. After Installation, apply bat-

tery voltage to the terminal for fuel pump activation to

run the fuel pump. Check for leaks.

Page 211 of 408

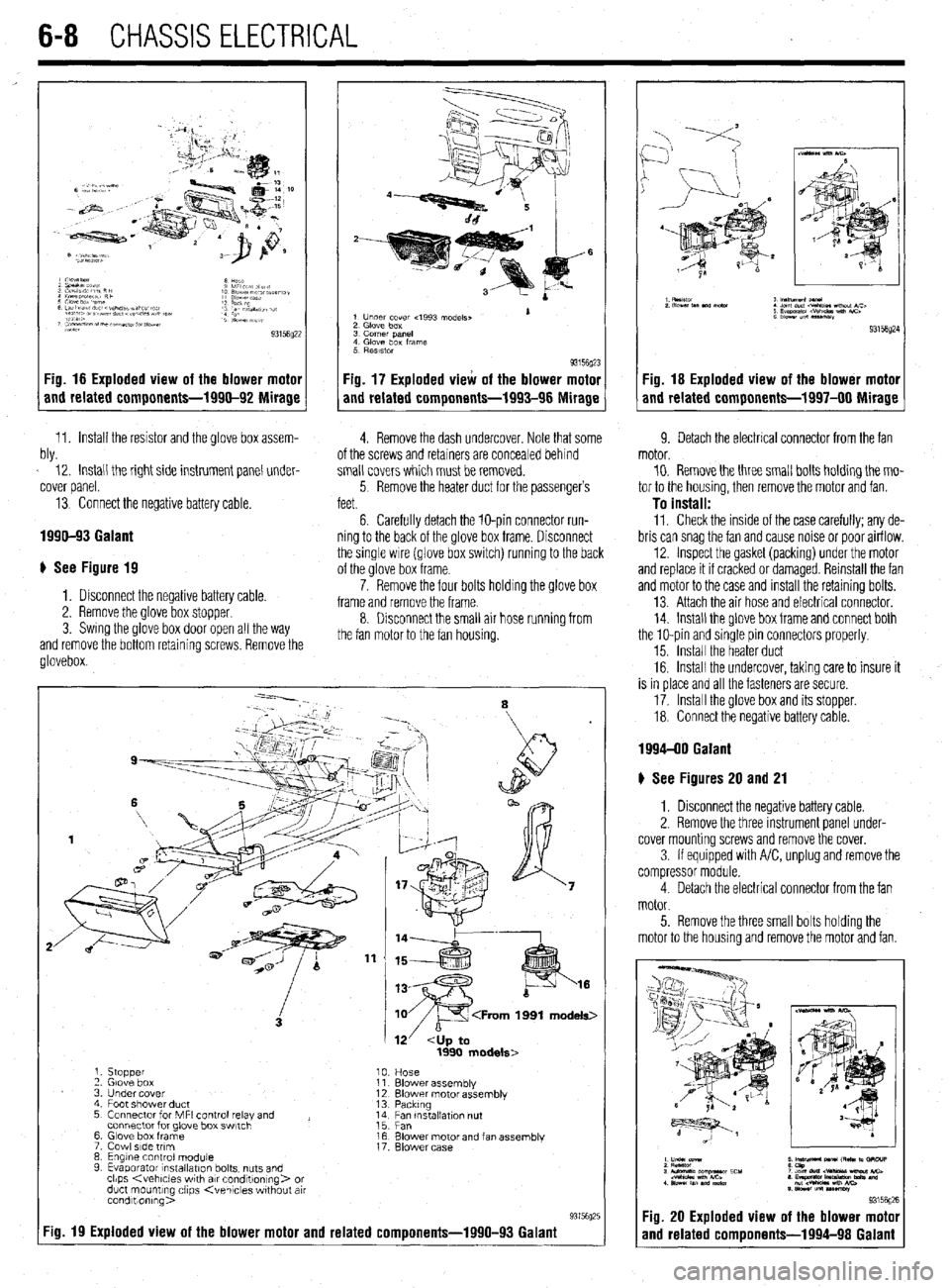

6-8 CHASSIS ELECTRICAL

Fig. 16 Exploded view of the blower motor

and related components-1990-92 Mirage

11. Install the resistor and the glove box assem- W 12. Install the right side instrument panel under-

cover panel.

13. Connect the negative battery cable.

1990-93 Galant

# See Figure 19

1. Disconnect the negative battery cable.

2. Remove the glove box stopper.

3. Swing the glove box door open all the way

and remove the bottom retainina screws. Remove the

glovebox

1 Under cover 4993 models, 1

2 Glove box

3 corner pane,

4 Glove box frame

5 RBSlStOr

93156~23

Fig. 17 Exploded view of the blower motor

and related components-1993-96 Mirage

4. Remove the dash undercover. Note that some 9. Detach the electrical connector from the fan

ot the screws and retainers are concealed behind

small covers which must be removed.

5 Remove the heater duct for the passenger’s

feet.

6. Carefully detach the lo-pin connector run-

ning to the back of the glove box frame. Disconnect

the single wire (glove box switch) running to the back

of the glove box frame.

7. Remove the four bolts holding the glove box

frame and remove the frame.

8. Disconnect the small air hose running from

the fan motor to the fan housing. motor.

10. Remove the three small bolts holding the mo-

tor to the housing, then remove the motor and fan.

To install: 11. Check the inside of the case carefully: any de-

bris can snag the fan and cause noise or poor airflow.

12. Inspect the gasket (packing) under the motor

and replace it if cracked or damaged. Reinstall the fan

and motor to the case and Install the retaining bolts.

13. Attach the air hose and electrical connector.

14. Install the glove box frame and connect both

the lo-pin and sinqle pin connectors properly.

15. Install the heater duct

16. Install the undercover, taking care to insure it

is in place and all the fasteners are secure.

17. Install the glove box and its stopper.

18. Connect the negative battery cable.

:ig. 19 Exploded view of the blower motor and related components-1990-93 Galant

1. stopper

‘2 Glove box

3 Under cover

4 Foot shower duct

5 Connector for MFI control relay and ,

connector for glove box swtch

6 Glove box frame

7 Cowl side trim

8 Engine control module

9 Evaporator lnstallatlon bolts, nuts and

clips

duct mounting clips Kvehlcles wthout air

condltionlng>

Fig. 18 Exploded view of the blower motor

and related components-1997-00 Mirage

--.

8

12’

Blower assemblv

Blower motor assembly

Packtng

;;c, tnstallatlon nut

Blower motor and fan assembly

Blower case

1994-00 Galant

) See Figures 20 and 21

1. Disconnect the negative battery cable.

2. Remove the three instrument panel under-

cover mounting screws and remove the cover.

3 If equipped with A/C, unplug and remove the

compressor module.

4. Detach the electrical connector from the fan

motor.

5. Remove the three small bolts holding the

motor to the housing and remove the motor and fan.

; y&M 5 m- M ,RC m .3RcuP

3 lulomafs corn-r ECU :2%brtr-Mbi&C>

.“eM *nn mi

1 slmhn.m”m,n 8 ~y~tipJ*-m-=%9 md

S sa*n”nlUSW

931561

Fig. 20 Exploded view of the blower mote

and related comoonents-1994-98 Galan

Page 213 of 408

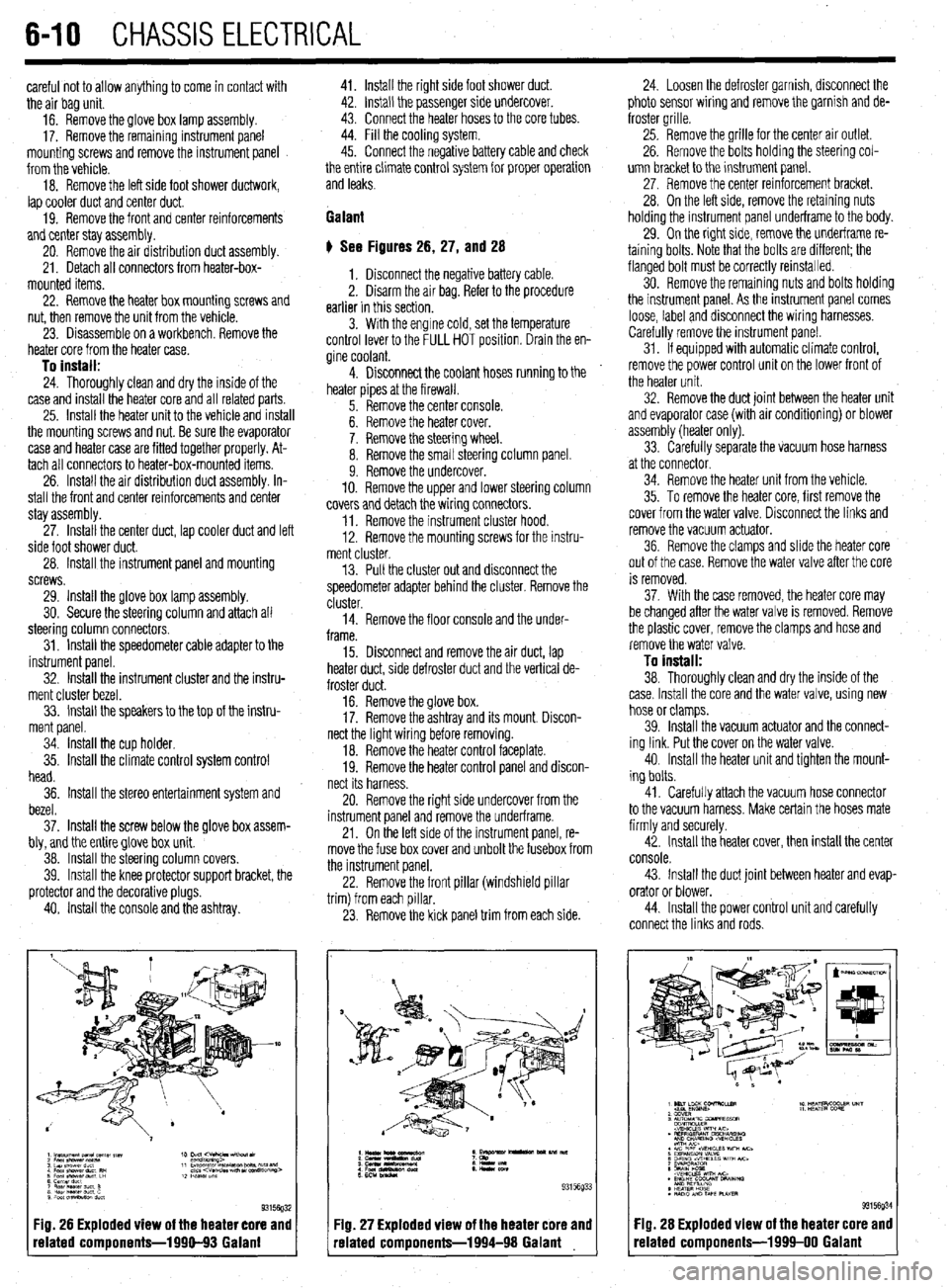

640 CHASSIS ELECTRICAL

careful not to allow anything to come in contact with

the air bag unit.

16. Remove the glove box lamp assembly.

17. Remove the remaining instrument panel

mounting screws and remove the instrument panel

from the vehicle.

18. Remove the left side foot shower ductwork,

lap cooler duct and center duct.

19. Remove the front and center reinforcements

and center stay assembly.

20. Remove the air distribution duct assembly.

21. Detach all connectors from heater-box-

mounted items.

22. Remove the heater box mounting screws and

nut, then remove the unit from the vehicle.

23. Disassemble on a workbench. Remove the

heater core from the heater case.

To install:

24. Thoroughly clean and dry the inside of the

case and install the heater core and all related parts.

25. Install the heater unit to the vehicle and install

the mounting screws and nut. Be sure the evaporator

case and heater case are fitted together properly. At-

tach all connectors to heater-box-mounted items.

26. Install the air distribution duct assembly. In-

stall the front and center reinforcements and center

stay assembly.

27. Install the center duct, lap cooler duct and left

side foot shower duct.

28. Install the instrument panel and mounting

screws.

29. Install the glove box lamp assembly.

30. Secure the steering column and attach all

steering column connectors.

31. Install the speedometer cable adapter to the

instrument panel.

32. Install the instrument cluster and the instru-

ment cluster bezel.

33. Install the speakers to the top of the instru-

ment panel.

34. Install the cup holder.

35. Install the climate control system control

head.

36. Install the stereo entertainment system and

bezel.

37. Install the screw below the glove box assem-

bly, and the entire glove box unit.

38. Install the steering column covers.

39. Install the knee protector support bracket, the

protector and the decorative plugs.

40. Install the console and the ashtray. 41. Install the right side foot shower duct.

42. Install the passenger side undercover.

43. Connect the heater hoses to the core tubes.

44. Fill the cooling system.

45. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Galant

# See Figures 26, 27, and 28

1. Disconnect the negative battery cable.

2. Disarm the air bag. Refer to the procedure

earlier in this section.

3. With the engine cold, set the temperature

control lever to the FULL HOT position. Drain the en-

gine coolant.

4. Disconnect the coolant hoses running to the

heater pipes at the firewall.

5. Remove the center console.

6. Remove the heater cover.

7. Remove the steering wheel.

8. Remove the small steering column panel.

9. Remove the undercover.

10. Remove the upper and lower steering column

covers and detach the wiring connectors.

11. Remove the instrument cluster hood.

12. Remove the mounting screws for the instru-

ment cluster.

13. Pull the cluster out and disconnect the

speedometer adapter behind the cluster. Remove the

cluster.

14. Remove the floor console and the under-

frame.

15. Disconnect and remove the air duct, lap

heater duct, side defroster duct and the vertical de-

froster duct.

16. Remove the glove box.

17. Remove the ashtray and its mount. Discon-

nect the light wiring before removing.

18. Remove the heater control faceplate.

19. Remove the heater control panel and discon-

nect its harness.

20. Remove the right side undercover from the

instrument panel and remove the underframe.

21. On the left side of the instrument panel, re-

move the fuse box cover and unbolt the fusebox from

the instrument panel.

22. Remove the front pillar (windshield pillar

trim) from each pillar.

23. Remove the kick panel trim from each side.

Fig. 26 Exploded view of the heater core and

related components-1990-93 Galant

:IQ. 27 Exploded view of the heater core and

-elated components-1994-98 Galant 24. Loosen the defroster garnish, disconnect the

photo sensor wiring and remove the garnish and de-

froster grille.

25. Remove the grille for the center air outlet.

26. Remove the bolts holding the steering col-

umn bracket to the instrument panel.

27, Remove the center reinforcement bracket.

28. On the left side, remove the retaining nuts

holding the instrument panel underframe to the body.

29. On the right side, remove the underframe re-

taining bolts. Note that the bolts are different; the

flanged bolt must be correctly reinstalled.

30. Remove the remaining nuts and bolts holding

the instrument panel. As the instrument panel comes

loose, label and disconnect the wiring harnesses.

Carefully remove the instrument panel.

31. If equipped with automatic climate control,

remove the power control unit on the lower front of

the heater unit.

32. Remove the duct joint between the heater unit

and evaporator case (with air conditioning) or blower

assembly (heater only).

33. Carefully separate the vacuum hose harness

at the connector.

34. Remove the heater unit from the vehicle.

35. To remove the heater core, first remove the

cover from the water valve. Disconnect the links and

remove the vacuum actuator.

36. Remove the clamps and slide the heater core

out of the case. Remove the water valve after the core

is removed.

37. With the case removed, the heater core may

be changed after the water valve is removed. Remove

the plastic cover, remove the clamps and hose and

remove the water valve.

To install:

38. Thoroughly clean and dry the inside of the

case. Install the core and the water valve, using new

hose or clamps.

39. Install the vacuum actuator and the connect-

ing link. Put the cover on the water valve.

40. Install the heater unit and tighten the mount-

ing bolts.

41. Carefully attach the vacuum hose connector

to the vacuum harness. Make certain the hoses mate

firmly and securely.

42. Install the heater cover, then install the center

console.

43. Install the duct joint between heater and evap-

orator or blower.

44. Install the power control unit and carefully

connect the links and rods.

Fig. 28 Exploded view of the heater core and

related components-1999-00 Galant

Page 230 of 408

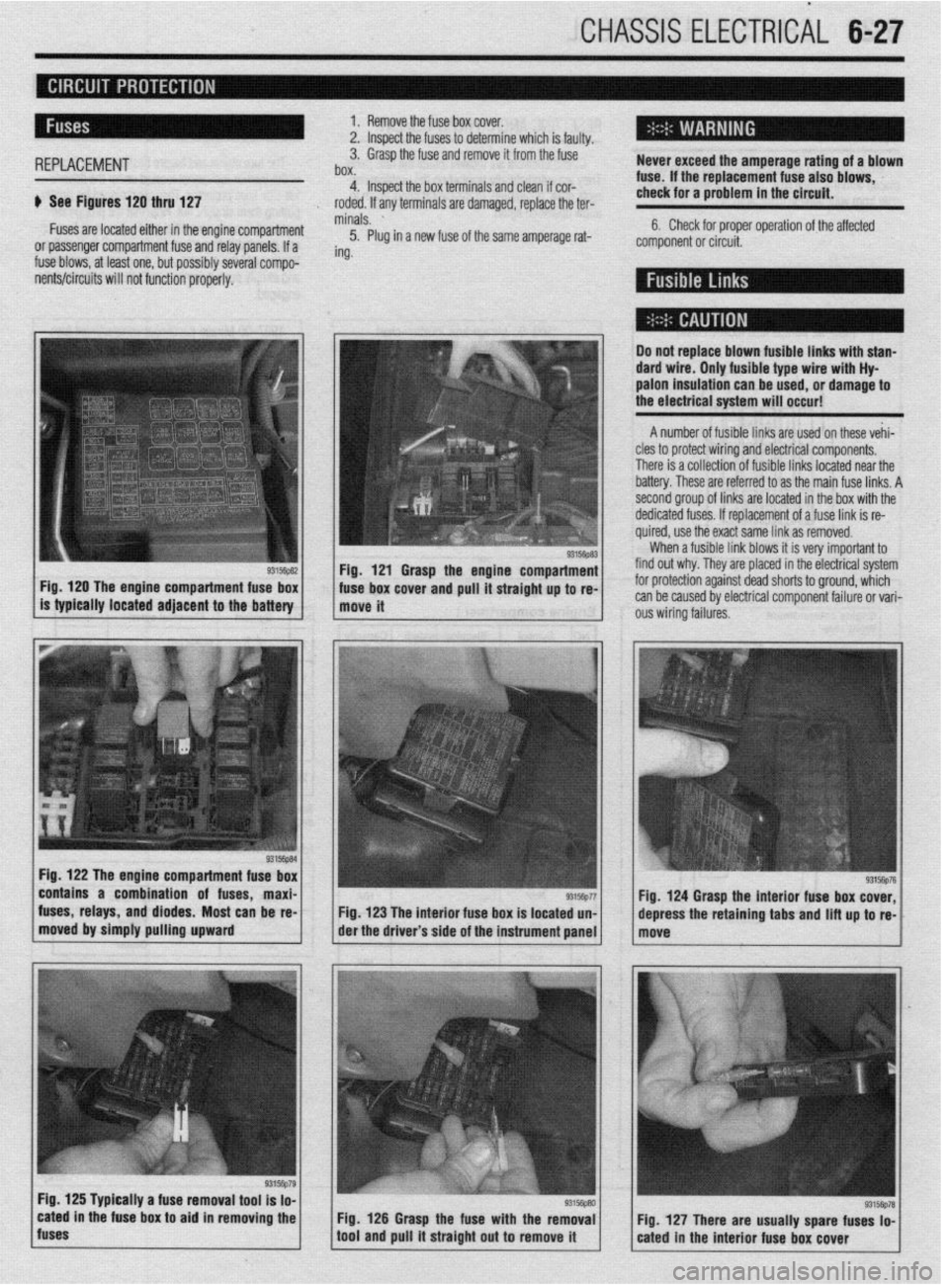

CHASSIS ELECTRICAL 6-27

1. Remove the fuse box cover.

2. lnsoect the fuses to determine which is faulty.

REPLACEMENT 3. Grasp the fuse and remove it from the fuse

box. Never exceed the amperage rating of a blown

4. Inspect the box terminals and clean if cor- fuse. If the replacement fuse also blows,

It See Figures 120 thru 127 check for a problem in the circuit.

roded. If any terminals are damaged, replace the ter-

Fuses are located either in the engine Compartment minals. ’

5. Plug in a new fuse of the same amperage rat- 6. Check for proper operation of the affected

or passenger compartment fuse and relay panels. If a component or circuit.

fuse blows, at least one, but possibly several compo- ing.

ients/circuits will not function properly.

Fig, 120 The engine compartment fuse box

is typically located adjacent to the

battery

Fig. 122 The engine compartment fuse box

contains a combination of fuses, maxi-

fuses, relays, and diodes. Most can be re-

moved by simply pulling upward

I Do not replace blown fusible links with stan-

dard wire. Only fusible type wire with Hy

palon insulation can be

used, or damage to

the electrical system will occur!

A number of fusible links are used on these vehi-

cles to protect wiring and electrical components.

There is a collection of fusible links located near the

battery. These are referred to as the main fuse links. A

second group of links are located in the box with the

dedicated fuses. If replacement of a fuse link is re-

quired, use the exact same link as removed.

When a fusible link blows it is very important to

Fig. 121 Grasp the engine compartment find out why. They are placed in the electrical system

. ’ ‘“‘,+“” 1 ous wiring failures. fuse box cover and pull It straight up to re- for protection against dead shorts to ground, which

move it can be caused by electrical component failure or vari-

Fig. 123 The interior fuse box is located un-

der the driver’s side of the instrument panel

Fig. 125 Typically a fuse removal tool is lo-

cated in the fuse box to aid in removing the

fuses Fig. 126 Grasp the fuse with the removal

tool and pull it straight out to remove it Fig. 124 Grasp the interior fuse box cover,

depress the retaining

tabs and lift up to re-

Page 239 of 408

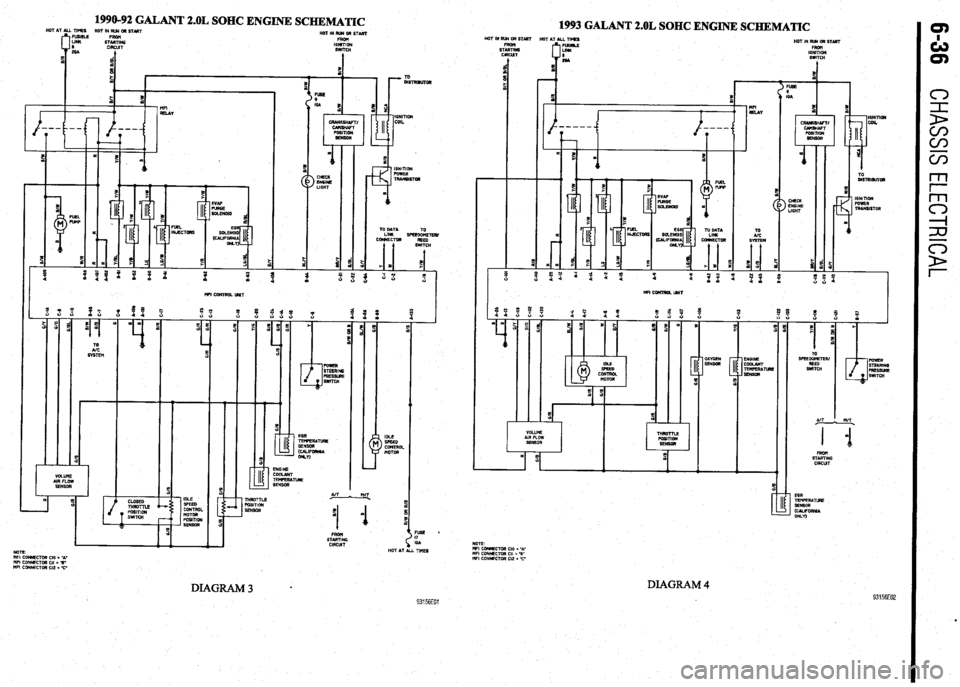

1990-92 GALANT 2.OL SOHC ENGINE SCHEMATIC

1993 GALANT 2.OL SOHC ENGINE SCHEMATIC HOT IN RIB aR START

STEki

CIRCUT HOTINRWORSTART

FROH

16NlTlON

SWITCH

t HOT IN RUR OR STlRT

HOT AT ALL TIMES

HOT IN RU4 DR START

FRDtl

IGNITION

SWITCH

I EEE LIGHT

! a

s ;

--

T m

> CHECK

EN6lNE

LIGHT

%

i E IGNITION

PDWER

4 ’

TRANSISTOR

D

4

&Rl,DR

s

ICNlTlOK

FUWER

TRARSlSTOR

m

TO OATA

LINK SPEED&TEfl/

CONRECTM

REED

( !iWlTCH TO

UC

WI CWJTROL UNIT

IDLE

> SFEED

CONTROL

MOTOR AIT

! n/T.

I 1 0

1

STEK

ClRCUT EGR

TEnFERA~

SENSOR

mLIFoRRlA

WLn

VOLUME

AIR FLOW

SENSOR

I

5

E

! %

FUSE *

I7

IOA

HOT AT ALL TIMES EGR

TEMFERATLRE

SERSDR

, (~~IFORR~A

ONLV) An L MT

.

B m

11

STARTING

CIRCUT NOTE

I’IFI CORRECTOR Cl0 = -A-

WI coRNEcmR CII - 3’

“FI CONNECTOR Cl2 I 77

DIAGRAM 4 93156E02

NOlE

MFI CCMECTOR Cl0 = ‘A-

WI CONNECTOR Cl, = %’

WI CDNNECTOR Cl2 = C

DIAGRAM3 l 93156EOl

Page 241 of 408

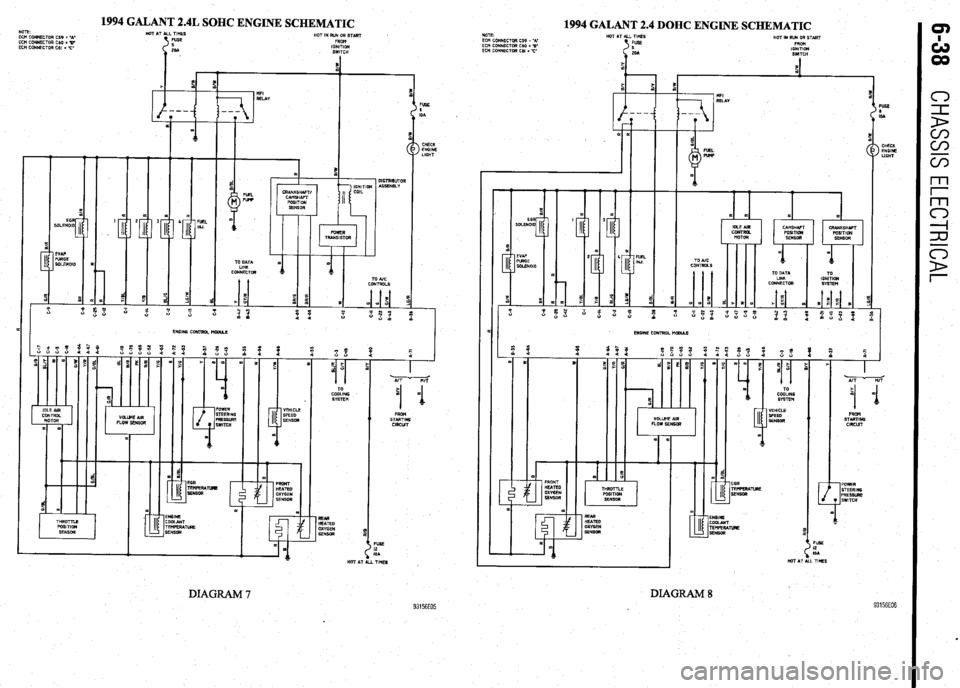

1994 GALANT 2.4L SOHC ENGINE SCHEMATIC

1994 GALANT 2.4 DOHC ENGINE SCHEMATIC NOTE

ECM CONNECTOR CS9 = ‘A’

ECH CONNECTOR C60 = B

ECH CONNECTOR Cti, = -I’ NOTE

ECH CONNECTOR C59 = ‘A-

ECH CONNECTOR C60 = ‘B

ECH CONNECTOR CM = -17 HOT AT ALL Tl?lES

FUSE

s

20A

s HQt IN RUN OR START

FRQ+l

IGNITION

SWITCH *

ON

:li IGI

SI

FVSE

0

IOA

> CHECK

ENGINE

LIGHT CHECU

/ ENOM

LIGHT

-T-T FUEL Pup

TO DATA

LINU

CONNECTOR I

CRANKSHAFT/

CAMSHAFT

POSITION

SENSOR

PQW2R

TRANSISTOR

m

(D

A

a

=

TO AK

CONTROLS

ENGINE CONTROL WCCU.2

m FRONT

H2AT2D

OXYGEN

SENSOR TO

CDDLING

SYSTEM

VEHICLE

SPEED

SENSOR

f FROM

START1116

CIRCWT

EGR

TEllPERATuRE

SENSOR

93156E05

HOT AT !NSlNE

3OLANT

rEMPERATu3E

ENSOR REAR

HEATED

OXYGEN

SENSOR REAR

HUTED

OXYGEN

SENSOA

TIM!3 vJ* HOT AT ALL TlblES

DIAGRAM 7

. DIAGRAM 8

Page 244 of 408

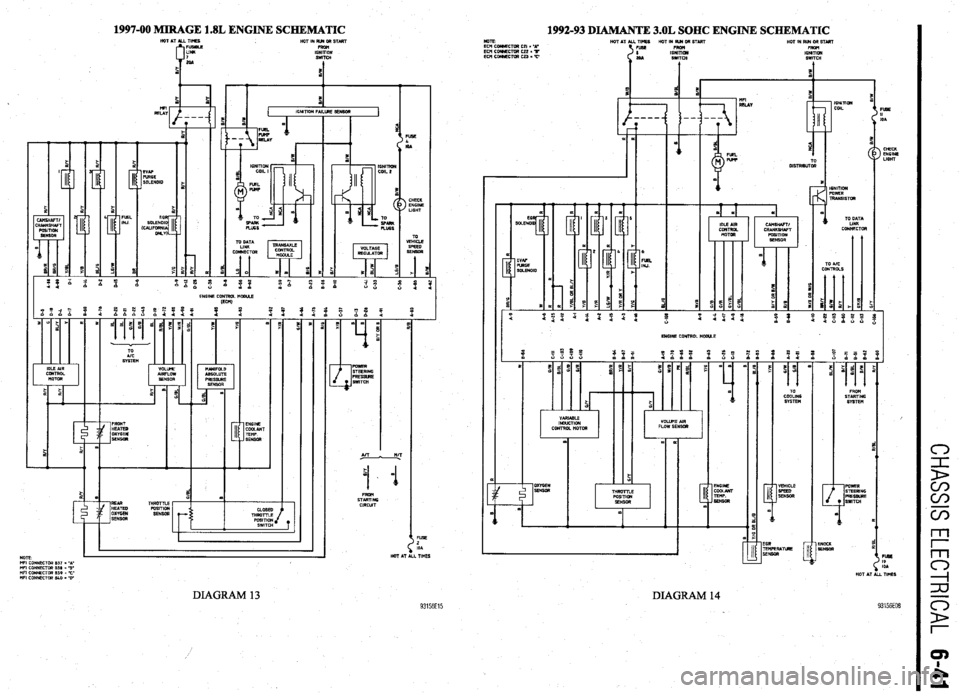

1997-00 MIRAGE 1.8L ENGINE SCHEMATIC

1992-93 DIAMANTE 3.OL SOHC ENGINE SCHEMATIC NOTE

HOT AT ML TIHGS

HOT IN R&S4 OR STbRT

HOT IM RUN OR START

ECM CGNNECTOR CZI = ‘4.

FUSS FROn

ECM COmECTOR CL2 = w

I IGNITIW

Et24 COtWECTOR CZ3 = ‘IT

zG4 SWITCH FROM

IGNlnON

SWITCH

4 HOT AT UL TIMES

HOT IN RiN GR START

FUSIRLE

FRW

LINK

IGNITION

:04 SWITCH

5

1

IGHlnON FAiLUlE SENSOR

FUSE

b

IO4

CHECK

ENGINE

LIGHT

TO

VEHICLG

ENGINE CONTROL MO4M.E

IECH)

II

ENGINE CONTROL MWUE

, 1 TO

COOLING

SYSTlw4

EGR

TEHFRR4TLtGE

SENSOR 1 POWER

STEERIMG

cI>

72

D

cn

c&n

.-

CD NT A NIT

.

5 (I)

I 4 FROM

STARTING

CIRCUT

HOT AT F!u3swE SWITCH

KNOCK

SENM

FLsC

I9

104 POSITION 6

SWITCH

FL&G

2

IOA

TIMES

hl

c3

-i

zu MFI CONNECTOR 8.37 = ‘4.

MFI CONNECTOR 811 - 3’

Hfl CONNECTOR 6.59 = ‘C’

WI CONNECTOR Sk0 g ‘D-

93156E15 DIAGRAM 13

DIAGRAM 14