check engine MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 165 of 408

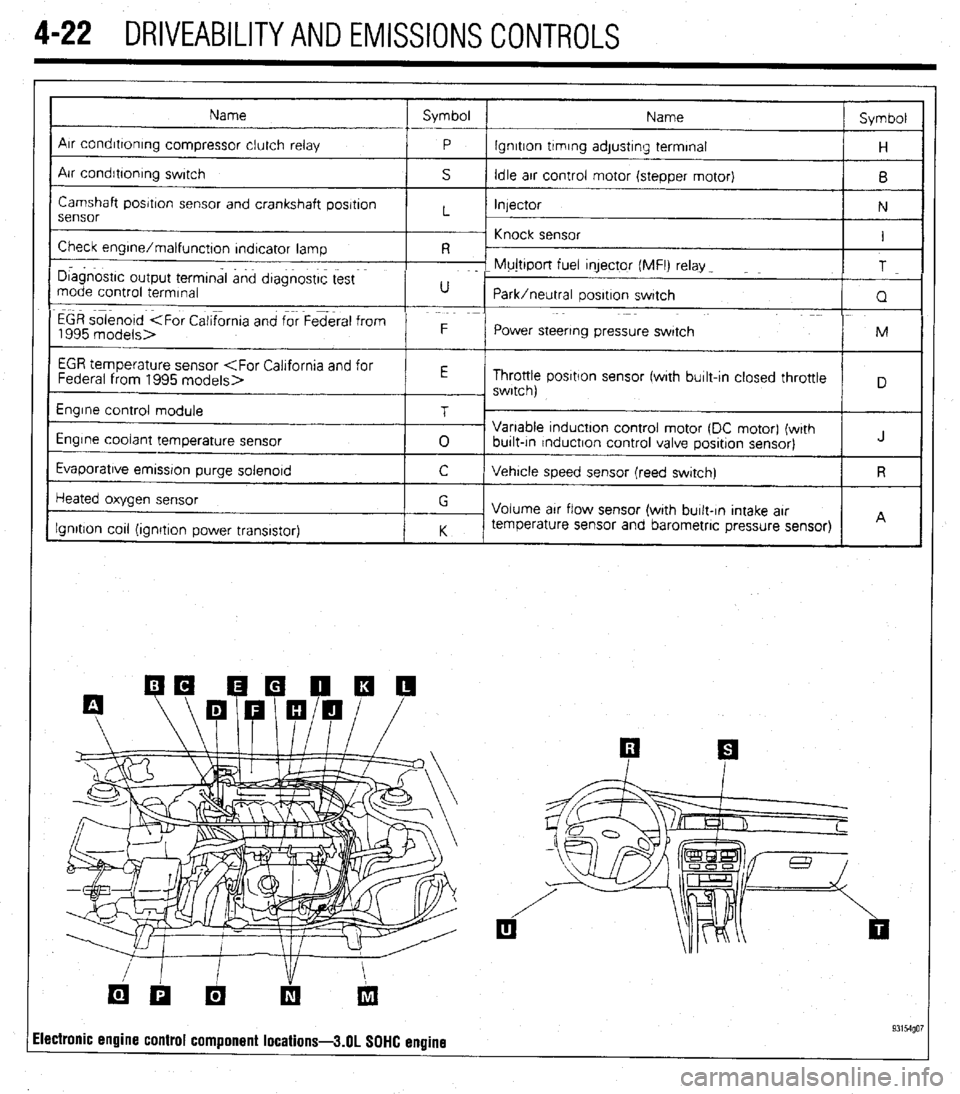

4-22 DRIVEABILITYAND EMISSIONS CONTROLS

Name Symbol

Name Symbol

I

Arr condrttontng compressor clutch relay

P lgnrtton trmrng adjustrng terminal

H

Air condrbonrng swrtch

S Idle arr control motor (stepper motor)

B

Camshaft posrtron sensor and crankshaft posrtron

Injector

N

sensor L

~ Knock sensor

Check engrne/malfunctton rndtcator lamp I

R -

I D~agnostrc output termtnal and dtagnostrc test F- Mujttport fuel qector (MFI) relay _

T

mode control termrnal U

Park/neutral oosrtron swatch

Q

EGR solenoid

1995 models> F

Power steering pressure swatch M

I

EGR temperature sensor

Throttle posrtlon sensor fwrth burlt-In closed throttle

, swrtch)

Engrne control module

Engine coolant temperature sensor

Evaporatrve emrssron purge solenord T

0 Variable tnductton control motor (DC motor) (wrth

burlt-tn rnductron control valve posrtron sensor) J

C Vehrcle speed sensor (reed swatch) R

Heated oxygen sensor

Ignition cot1 (ionrtron Dower transistor) G

Volume arr flow sensor (with burlt-In Intake arr

K temperature sensor and barometric pressure sensor)

I I A

ilectronic engine control component locations-3.01 SOHC engine 93154go7

Page 167 of 408

.

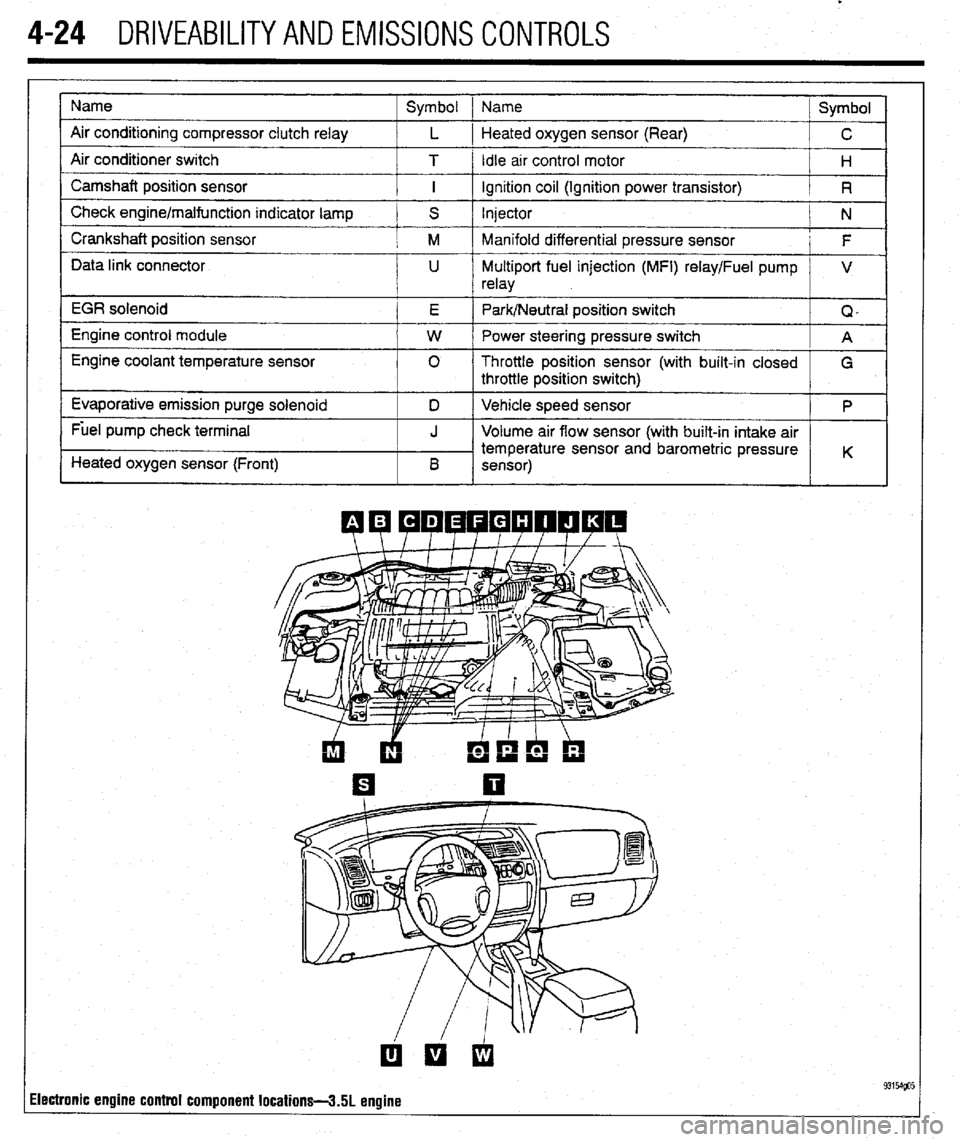

4-24 DRIVEABILITYAND EMISSIONS CONTROLS

Name

Air conditioning compressor clutch relay

Air conditioner switch

Camshaft position sensor

Check engine/malfunction indicator lamp

Crankshaft position sensor

Data link connector

EGR solenoid

Engine control module

Engine coolant temperature sensor

Evaporative emission purge solenoid

Fuel pump check terminal

Heated oxygen sensor (Front) Symbol 1 Name

Symbol

L 1 Heated oxygen sensor (Rear)

C

T / Idle arr control motor

H

I ignition coil (Ignition power transistor)

R

S Injector

N

M Manifold differential pressure sensor

F

U Multiport fuel injection (MFI) relay/Fuel pump V

relay

E Park/Neutral position switch

Q,

W Power steering pressure switch

A

0 Throttle position sensor (with built-in closed

G

throttle position switch)

D Vehicle speed sensor

P

J Volume air flow sensor (with built-in intake air

temperature sensor and barometric pressure

B K

sensor)

ilectronic engine control component locations-3.51 engine

Page 169 of 408

4-26 DRIVEABILITYAND EMISSIONS CONTROLS

The Powertrain Control Module (PCM) monitors

the signals of input and output sensors, some all the

time and others at certain times and processes each

signal. When the PCM notices that an irregularity has

continued for a specified time or longer from when

the irregular signal was initially monitored, the PCM

judges that a malfunction has occurred and will

memorize the malfunction code. The code is then

stored in the memory of the PCM and is accessible

through the data link (diagnostic connector) with the

use of an electronic scan tool or a voltmeter.

CHECK ENGINE/MALFUNCTION

INDICATOR LIGHT

Among the on-board diagnostic items, a check

engine/malfunction indicator light comes on to notify

the driver of a emission control component irregular-

ity. If the irregularity detected returns to normal or the

PCM judges that the component has returned to nor-

mal, the check engine/malfunction indicator light will

be turned off Moreover, if the ignition is turned OFF

and then the engine is restarted, the check

engine/malfunction indicator light will not be turned

on unttl a malfunction is detected.

The check engine/malfunction indicator light will

come on immediately after the ignition switch is

turned ON. The light should stay lit for 5 seconds

and then will go off. This Indicates that the check en-

gine/malfunction indicator lamp is operating nor-

mally. This does not signify a problem with the sys-

tem.

*The check engine/malfunction indicator

lamp will come on when the terminal for the

ignition timing adjustment is shorted to

ground. Therefore, it is not abnormal that the

light comes on even when the terminal for ig-

nition timing is shorted at time of ignition

timing adjustment.

To test the light, perform the following:

1. Turn the ignition switch ON. Inspect the check

engine/malfunction indicator lamp for Illumination.

2. The light should be lit for 5 seconds and then

should go out.

3. If the lamp does not illuminate, check for open

circuit In the harness, blown fuse or blown bulb.

SERVICE PRECAUTIONS

l Before attachrng or detaching the PCM harness

connectors, make sure the ignition switch is OFF and

the negative battery cable is disconnected to avoid

the possibility of damage to the PCM.

l When performing PCM input/output signal di-

agnosis, remove the pin terminal retainer from the

connectors to make it easier to insert tester probes

into the connector.

l When attaching or detaching pin connectors ,

from the PCM, take care not to bend or break any pin

terminals. Check that there are no bends or breaks on

PCM pin terminals before attempting any connec-

tions.

l Before replacing any PCM, perform the PCM

input/output signal diagnosis to make sure the PCM

is functioning properly.

l When measuring supply voltage of PCM-con-

trolled components with a circuit tester, separate 1

tester probe from another. If the 2 tester probes acci-

dentally make contact with each other during mea-

surement, a short circuit WIII result and damage the

PCM.

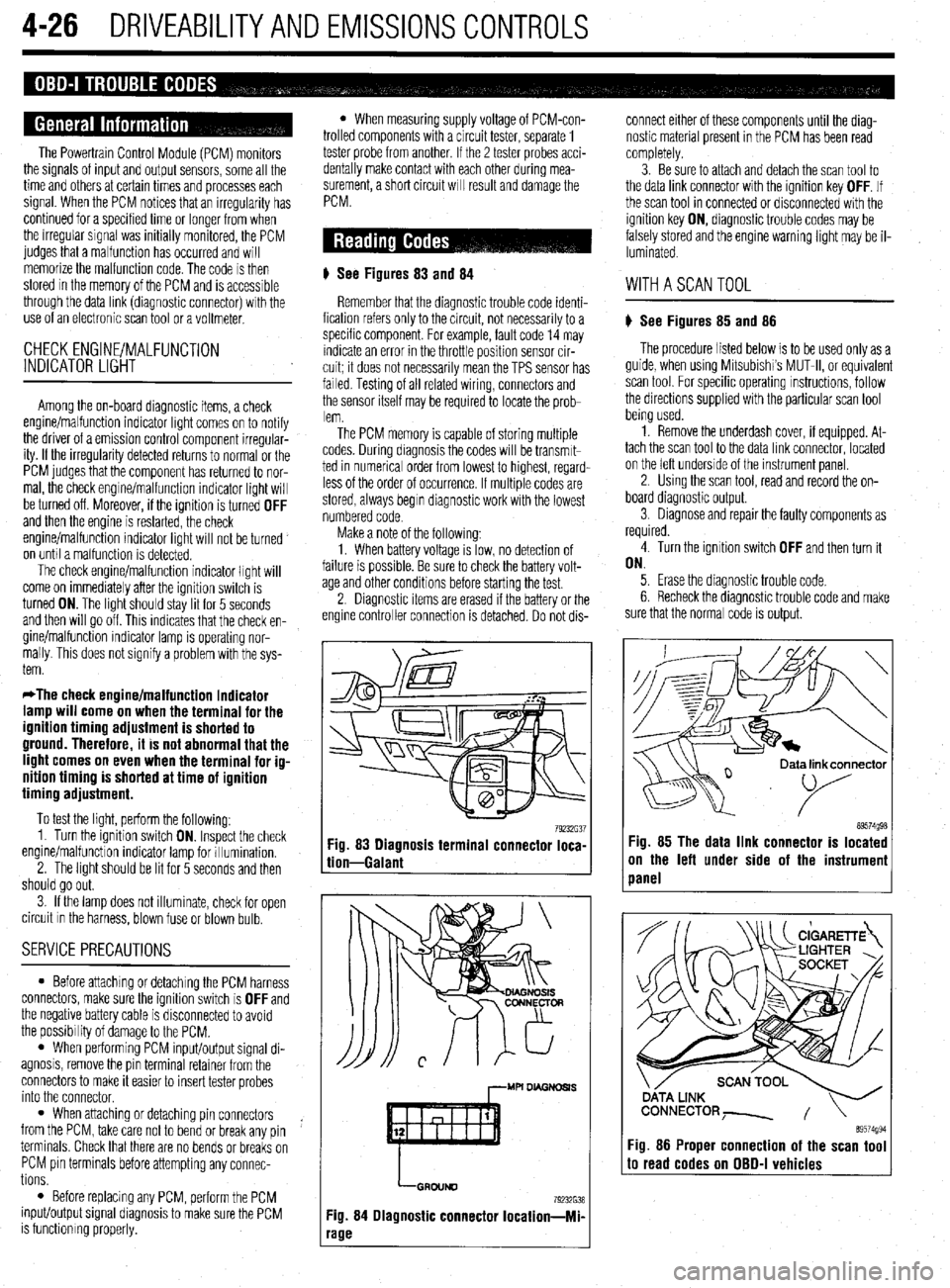

# See Figures 83

and 84

Remember that the diagnostic trouble code identi-

fication refers only to the circuit, not necessarily to a

specific component. For example, fault code 14 may

indicate an error in the throttle position sensor cir-

cuit; it does not necessarily mean the TPS sensor has

failed Testing of all related wiring, connectors and

the sensor itself may be required to locate the prob-

lem.

The PCM memory is capable of storing multiple

codes. During diagnosis the codes will be transmlt-

ted in numerical order from lowest to highest, regard-

less of the order of occurrence. If multiple codes are

stored, always begin diagnostic work with the lowest

numbered code

Make a note of the following:

1. When battery voltage IS low, no detection of

failure is possible. Be sure to check the battery volt-

age and other conditions before starting the test.

2. Diagnostic items are erased if the battery or the

engine controller connection is detached. Do not dis- connect either of these components until the diag-

nostic material present in the PCM has been read

completely.

3. Be sure to attach and detach the scan tool to

the data link connector with the ignition key OFF. If

the scan tool in connected or disconnected with the

ignition key ON, diagnostic trouble codes may be

falsely stored and the engine warning light may be il-

luminated. WITHASCANTOOL

) See Figures 85 and 86

The procedure listed below is to be used only as a

guide, when using Mitsubishi’s MUT-II, or equivalent

scan tool. For specific operating instructions, follow

the directions supplied with the particular scan tool

bemg used.

1. Remove the underdash cover, if equipped. At-

tach the scan tool to the data link connector, located

on the left underside of the instrument panel.

2. Using the scan tool, read and record the on-

board diagnostic output.

3. Diagnose and repair the faulty components as

required

4. Turn the ignition switch OFF and then turn it

ON.

5. Erase the diagnostic trouble code.

6 Recheck the diaanostic trouble code and make

sure that the normal &de is output.

79232G37 89574g98 Fig. 83 Diagnosis terminal connector loca-

tion-Galant Fig. 85 The data link connector is located

on the left under side of the instrumeni

panel

,--MU DL4GNDSl.S

LGRDIJND

79232638

Fig. 84 Diagnostic connector Iocation-Mi-

‘age

ata link connector

89574994 Fig. 86 Proper connection of the scan tool to read codes on OBD-I vehicles

Page 170 of 408

DRIVEABILITYAND EMISSIONS CONTROLS 4-27

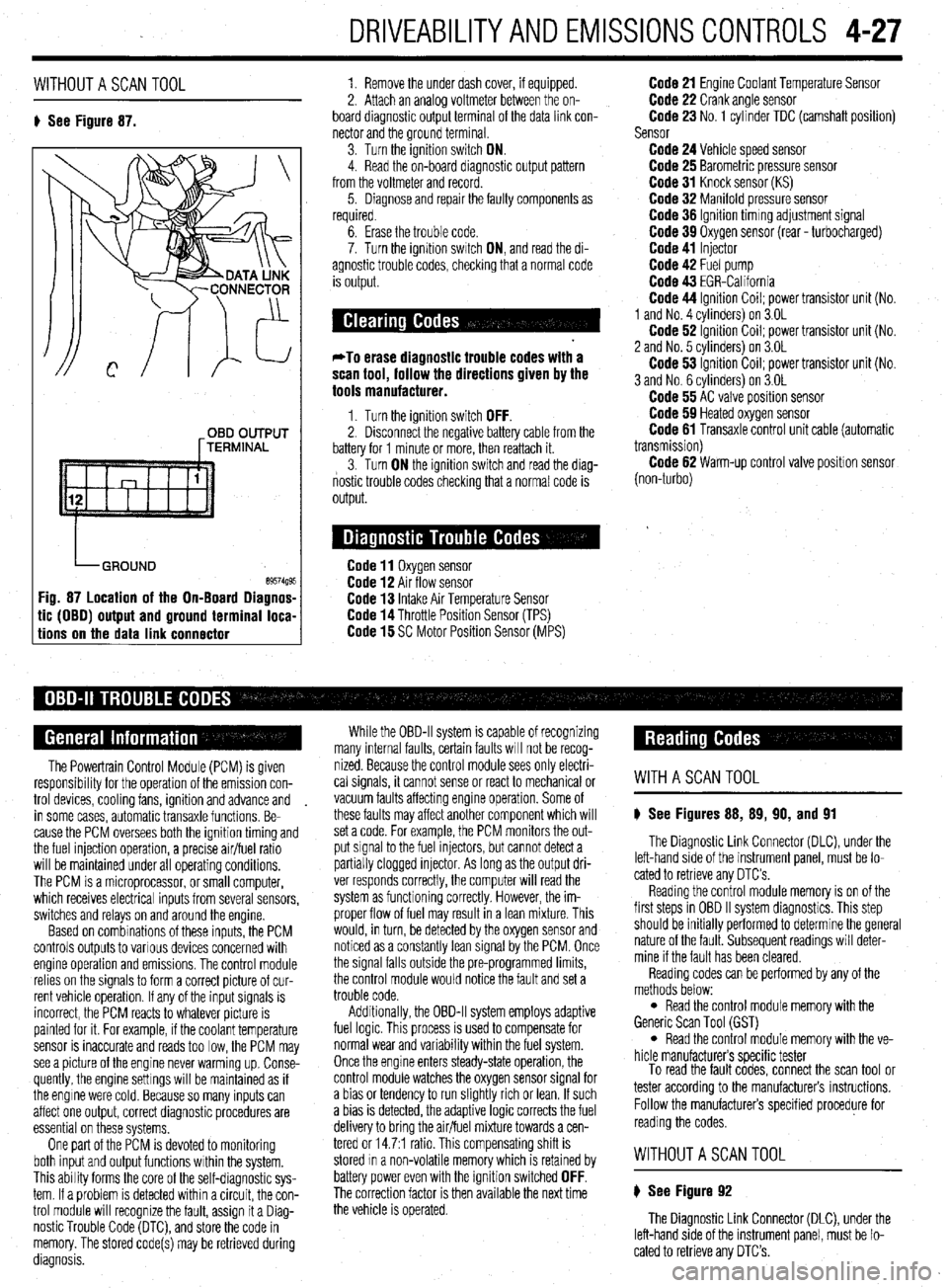

WITHOUTASCANTOOL

8 See Figure 87. 1. Remove the under dash cover, if equipped.

2. Attach an analoa voltmeter between the on-

board diagnostic outpit terminal of the data link con-

nector and the ground terminal

3. Turn the ignition switch ON.

4. Read the on-board diagnostic output pattern

from the voltmeter and record.

5. Diagnose and repair the faulty components as

required.

OBD OUTPUT

[TERMINAL

tic (OBO) output and ground terminal loca-

tions on the data link connector

6. Erase the trouble code.

7. Turn the ignition swatch ON, and read the di-

agnostic trouble codes, checking that a normal code

is output.

*To erase diagnostic trouble codes with a

scan tool, follow the directions given by the

tools manufacturer.

1. Turn the ignition switch OFF. 2. Disconnect the negative battery cable from the

battery for 1 minute or more, then reattach it.

3. Turn ON the ignition switch and read the diag-

nostic trouble codes checking that a normal code is

output.

Code 11 Oxygen sensor Code 12 Air flow sensor Code 13 Intake Air Temperature Sensor Code 14 Throttle Position Sensor (TPS) Code 15 SC Motor Position Sensor (MPS)

Code 21 Engine Coolant Temperature Sensor Code 22 Crank angle sensor Code 23 No. 1 cylinder TDC (camshaft position)

Sensor

Code 24 Vehicle speed sensor Code 25 Barometric pressure sensor Code 31 Knock sensor (KS) Code 32 Manifold pressure sensor Code 36 Ignition timmg adjustment signal Code 39 Oxygen sensor (rear - turbocharged) Code 41 Injector Code 42 Fuel pump Code 43 EGR-California Code 44 Ignition Coil; power transistor unit (No.

1 and No. 4 cvlinders) on 3.OL

Code 62 ignition Coil; power transistor unit (No.

2 and No. 5 cvlinders) on 3.OL

Code 53 ignition Coil; power transistor unit (No.

3 and No. 6 cylinders) on 3.OL

Code 55 AC valve position sensor Code 59 Heated oxygen sensor Code 61 Transaxle control unit cable (automatic

transmission)

Code 62 Warm-up control valve position sensor

(non-turbo)

The Powertrain Control Module (PCM) is given

responsibrlity for the operation of the emission con-

trol devices, cooling fans, ignition and advance and

in some cases, automatic transaxle functions. Be-

cause the PCM oversees both the ignition timing and

the fuel injection operation, a precise air/fuel ratio

will be maintained under all operating conditions,

The PCM is a microprocessor, or small computer,

which receives electrical inputs from several sensors,

switches and relays on and around the engine.

Based on combinations of these inputs, the PCM

controls outputs to various devices concerned with

engine operation and emissions. The control module

relies on the signals to form a correct picture of cur-

rent vehicle operation. If any of the input signals is

incorrect, the PCM reacts to whatever picture is

painted for it. For example, if the coolant temperature

sensor is inaccurate and reads too low, the PCM may

see a picture of the engine never warming up. Conse-

quently, the engine settings will be maintained as if

the engine were cold. Because so many inputs can

affect one output, correct diagnostic procedures are

essential on these systems,

One part of the PCM is devoted to monitoring

both input and output functions within the system.

This ability forms the core of the self-diagnostic sys-

tem. If a problem is detected within a circuit, the con-

trol module will recognize the fault, assign it a Diag-

nostic Trouble Code (DTC), and store the code in

memory. The stored code(s) may be retrieved during

diagnosis. While the OBD-II system is capable of recognizing

many internal faults, certain faults WIII not be recog-

nized. Because the control module sees only electri-

cal signals, it cannot sense or react to mechanical or

vacuum faults affecting engine operation. Some of

these faults may affect another component which will

set a code. For example, the PCM monitors the out-

put signal to the fuel injectors, but cannot detect a

partially clogged injector. As long as the output dri-

ver responds correctly, the computer will read the

system as functioning correctly. However, the im-

proper flow of fuel may result in a lean mixture. This

would, in turn, be detected by the oxygen sensor and

noticed as a constantly lean signal by the PCM. Once

the signal falls outside the pre-programmed limits,

the control module would notice the fault and set a

trouble code.

Additionally, the OBD-II system employs adaptive

fuel logic. This process is used to compensate for

normal wear and variability within the fuel system.

Once the engine enters steady-state operation, the

control module watches the oxygen sensor signal for

a bias or tendency to run slightly rich or lean. If such

a bias is detected, the adaptive logic corrects the fuel

delivery to bring the air/fuel mixture towards a cen-

tered or 14.7:1 ratio. This compensating shift is

stored In a non-volatile memory which is retained by

battery power even with the ignition switched

OFF. The correction factor is then available the next time

the vehicle is operated.

WITHASCANTOOL

8 See Figures 88, 89, 90, and 91

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any OTC’s

Reading the control module memory is on of the

first steps in OBD II system diagnostics. This step

should be initially performed to determine the general

nature of the fault. Subsequent readings will deter-

mine if the fault has been cleared.

Reading codes can be performed by any of the

methods below:

l Read the control module memory with the

Generic Scan Tool (GST)

l Read the control module memory with the ve-

hicle manufacturers specific tester

To read the fault codes, connect the scan tool or

tester according to the manufacturers instructions.

Follow the manufacturers specified procedure for

reading the codes.

WITHOUTASCANTOOL

8 See Figure 92

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any DTC’s.

Page 174 of 408

DRIVEABILITYAND EMISSIONSCONTROL-S 4-31

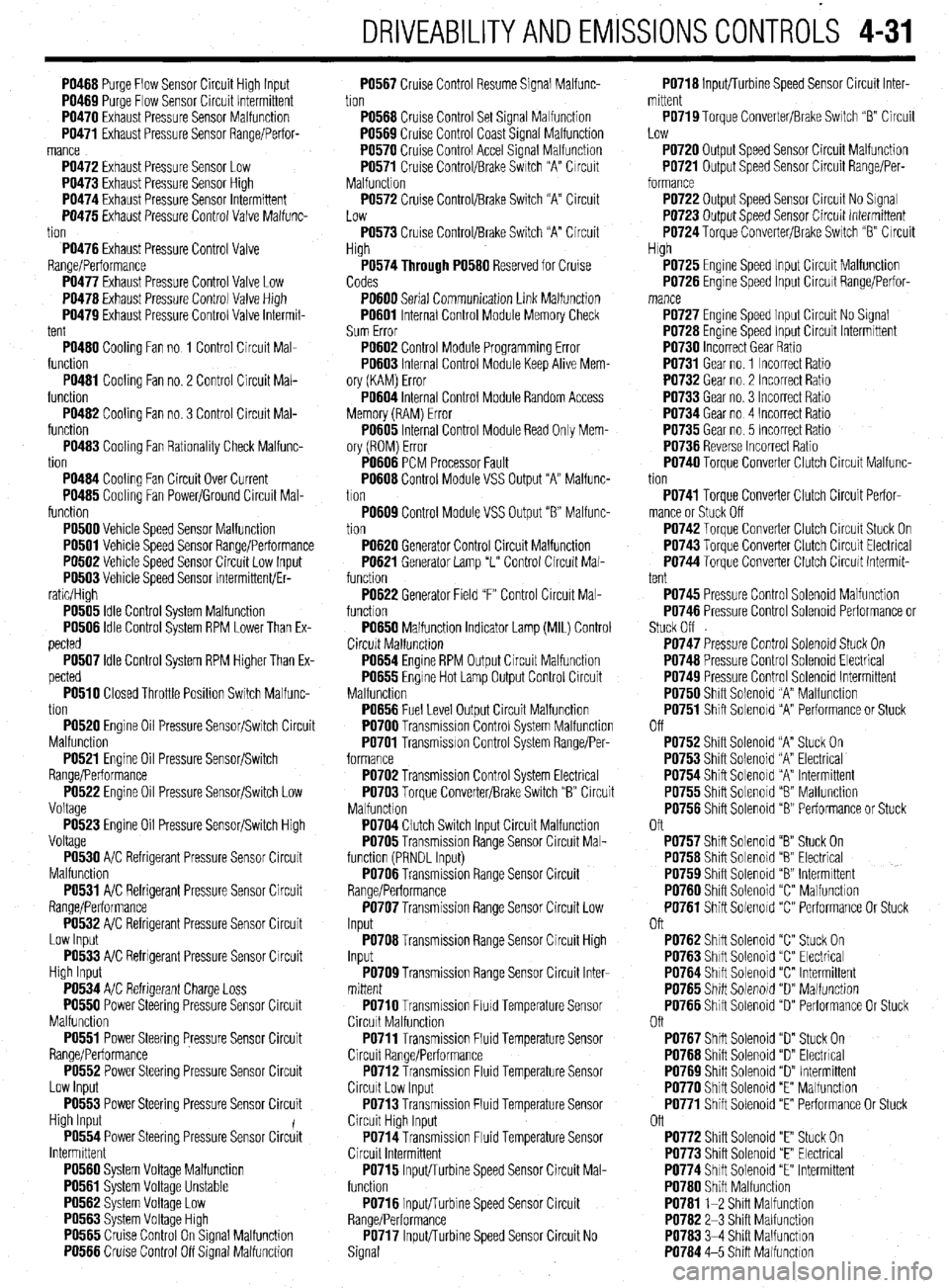

PO466 Purge Flow Sensor Circuit High Input

PO469 Purqe Flow Sensor Circuit Intermittent

PO470 Exhaust Pressure Sensor Malfunction

PO471 Exhaust Pressure Sensor Range/Perfor-

mance

PO472 Exhaust Pressure Sensor Low

PO473 Exhaust Pressure Sensor Hiah

PO474 Exhaust Pressure Sensor lnirmittent

PO475 Exhaust Pressure Control Valve Malfunc-

tion

PO476 Exhaust Pressure Control Valve

Range/Performance

PO477 Exhaust Pressure Control Valve Low

PO476 Exhaust Pressure Control Valve High

PO479 Exhaust Pressure Control Valve Intermit-

tent

PO460 Cooling Fan no 1 Control Circuit Mal-

function

PO461 Cooling Fan no. 2 Control Circuit Mal-

function

PO462 Cooling Fan no. 3 Control Circuit Mal-

function

PO463 Cooling Fan Rationality Check Malfunc-

tion

PO464 Cooling Fan Circuit Over Current

PO465 Cooling Fan Power/Ground Circuit Mal-

function

PO500 Vehicle Speed Sensor Malfunction

PO501 Vehicle Speed Sensor Range/Performance

PO502 Vehicle Speed Sensor Circuit Low Input

PO503 Vehicle Speed Sensor Intermittent/Er-

ratic/High

PO505 Idle Control System Malfunction

PO506 Idle Control System RPM Lower Than Ex-

pected

PO507 Idle Control System RPM Higher Than Ex-

pected

PO510 Closed Throttle Position Switch Malfunc-

tion

PO520 Engine Oil Pressure Sensor/Switch Circuit

Malfunction

PO521 Engine Oil Pressure Sensor/Switch

Range/Performance

PO522 Engine Oil Pressure Sensor/Switch Low

Voltage

PO523 Engine Oil Pressure Sensor/Switch High

Voltage

PO530 A/C Refrigerant Pressure Sensor Circuit

Malfunction

PO531 A/C Refrigerant Pressure Sensor Circuit

Range/Performance

PO532 A/C Refrigerant Pressure Sensor Circuit

Low Input

PO533 A/C Refrigerant Pressure Sensor Circuit

High Input

PO534 A/C Refrigerant Charge Loss

PO550 Power Steering Pressure Sensor Circuit

Malfunction

PO551 Power Steering Pressure Sensor Circuit

Range/Performance

PO552 Power Steering Pressure Sensor Circuit

Low Input

PO553 Power Steering Pressure Sensor Circuit

High Input

PO554 Power Steering Pressure Sensor Circiit

Intermittent

PO560 System Voltage Malfunction

PO561 System Voltage Unstable

PO562 System Voltage Low

PO563 Svstem Voltaoe Hlah

PO565 Ciuise Control On%ignal Malfunction

PO566 Cruise Control Off Signal Malfunction PO567 Cruise Control Resume Signal Malfunc-

tion

PO566 Cruise Control Set Signal Malfunction

PO569 Cruise Control Coast Signal Malfunction

PO570 Cruise Control Accel Signal Malfunction

PO571 Cruise Control/Brake Switch “A” Circuit

Malfunction

PO572 Cruise Control/Brake Switch “A” Circuit

Low

PO573 Cruise Control/Brake Switch “A” Circuit

High

P0574Through PO560 Reserved for Cruise

Codes

PO600 Serial Communication Link Malfunction

PO601 Internal Control Module Memory Check

Sum Error

PO602 Control Module Programming Error

PO603 Internal Control Module Keep Alive Mem-

ory (KAM) Error

PO604 Internal Control Module Random Access

Memory (RAM) Error

PO605 Internal Control Module Read Only Mem-

ory (ROM) Error

PO606 PCM Processor Fault

PO606 Control Module VSS Output “A” Malfunc-

tion

PO609 Control Module VSS Output “6” Malfunc-

tion

PO620 Generator Control Circuit Malfunction

PO621 Generator Lamp “L” Control Circuit Mal-

function

PO622 Generator Field “F” Control Circuit Mal-

function

PO650 Malfunction Indicator Lamp (MIL) Control

Circuit Malfunctron

PO654 Engine RPM Output Circuit Malfunction

PO655 Engine Hot Lamp Output Control Circuit

Malfunction

PO656 Fuel Level Output Circuit Malfunction

PO700 Transmission Control System Malfunction

PO701 Transmission Control System Range/Per-

formance

PO702 Transmission Control System Electrical

PO703 Torque Converter/Brake Switch “B” Circuit

Malfunction

PO704 Clutch Switch Input Circuit Malfunction

PO705 Transmission Range Sensor Circuit Mal-

function (PRNDL Input)

PO706 Transmission Range Sensor Circuit

Range/Performance

PO707 Transmission Range Sensor Circuit Low

Input

PO706 Transmission Range Sensor Circuit High

Input

PO709 Transmission Range Sensor Circuit Inter-

mittent

PO710 Transmission FluId Temperature Sensor

Circuit Malfunction

PO711 Transmission Fluid Temperature Sensor

Circuit Range/Performance

PO712 Transmission Fluid Temperature Sensor

Circuit Low Input

PO713 Transmission Fluid Temperature Sensor

Circuit High Input

PO714 Transmission Fluid Temperature Sensor

Circuit Intermittent

PO715 Input/Turbine Speed Sensor Circuit Mal-

function

PO716 Input/Turbine Speed Sensor Circuit

Range/Performance

PO717 InpWurbine Speed Sensor Circuit No

Signal PO716 Inputflurbine Speed Sensor Circuit Inter-

mittent

PO719 Torque Converter/Brake Switch “B” Circuit

Low

PO720 Output Speed Sensor Circuit Malfunction

PO721 Output Speed Sensor Circuit Range/Per-

formance

PO722 Output Speed Sensor Circuit No Signal

PO723 Output Speed Sensor Circuit Intermittent

PO724 Toraue Converter/Brake Switch “B” Circuit

High

PO725 Engine Speed Input Circuit Malfunction

PO726 Engine Speed Input Circuit Range/Perfor-

PO727 Engine Speed Input Circuit No Signal

PO726 Engine Speed Input Circuit Intermittent

PO730 Incorrect Gear Ratio

PO731 Gear no. 1 Incorrect Ratio

PO732 Gear no. 2 Incorrect Ratio

PO733 Gear no. 3 Incorrect Ratio

PO734 Gear no 4 Incorrect Ratio

PO735 Gear no. 5 Incorrect Ratio

PO736 Reverse Incorrect Ratio

PO740 Torque Converter Clutch Circuit Malfunc-

tion

PO741 Torque Converter Clutch Circuit Perfor-

mance or Stuck Off

PO742 Torque Converter Clutch Circuit Stuck On

PO743 Torque Converter Clutch Circuit Electrical

PO744 Torque Converter Clutch Circuit Intermit-

tent

PO745 Pressure Control Solenoid Malfunction

PO746 Pressure Control Solenoid Performance or

Stuck Off

PO747 Pressure Control Solenoid Stuck On

PO746 Pressure Control Solenoid Electrical

PO749 Pressure Control Solenoid Intermittent

PO750 Shift Solenoid “A” Malfunction

PO751 Shift Solenoid “A” Performance or Stuck

Off

PO752 Shift Solenoid “A” Stuck On

PO753 Shift Solenoid “A” Electrical

PO754 Shift Solenoid “A” Intermittent

PO755 Shift Solenoid “8 Malfunction

PO756 Shift Solenoid “B” Performance or Stuck

Oft

PO757 Shift Solenoid “B” Stuck On

PO756 Shift Solenoid “6” Electrical

PO759 Shift Solenoid “8” Intermittent

PO760 Shift Solenoid “C” Malfunction

PO761 Shift Solenoid “C” Performance Or Stuck

Oft

PO762 Shift Solenoid “C” Stuck On

PO763 Shift Solenoid “C” Electrical

PO764 Shift Solenoid “C” Intermittent

PO765 Shift Solenoid “D” Malfunction

PO766 Shift Solenoid “D” Performance Or Stuck

Oft

PO767 Shift Solenoid “D” Stuck On

PO766 Shift Solenoid “D” Electrical

PO769 Shift Solenoid “D” Intermittent

PO770 Shift Solenoid “E” Malfunction

PO771 Shift Solenoid “E” Performance Or Stuck

Off

PO772 Shift Solenoid “E” Stuck On

PO773 Shift Solenoid “E” Electrical

PO774 Shift Solenoid “E” Intermittent

PO760 Shift Malfunction

PO761 l-2 Shift Malfunction

PO762 2-3 Shift Malfunction

PO763 3-4 Shift Malfunction

PO764 4-5 Shift Malfunction

Page 177 of 408

.

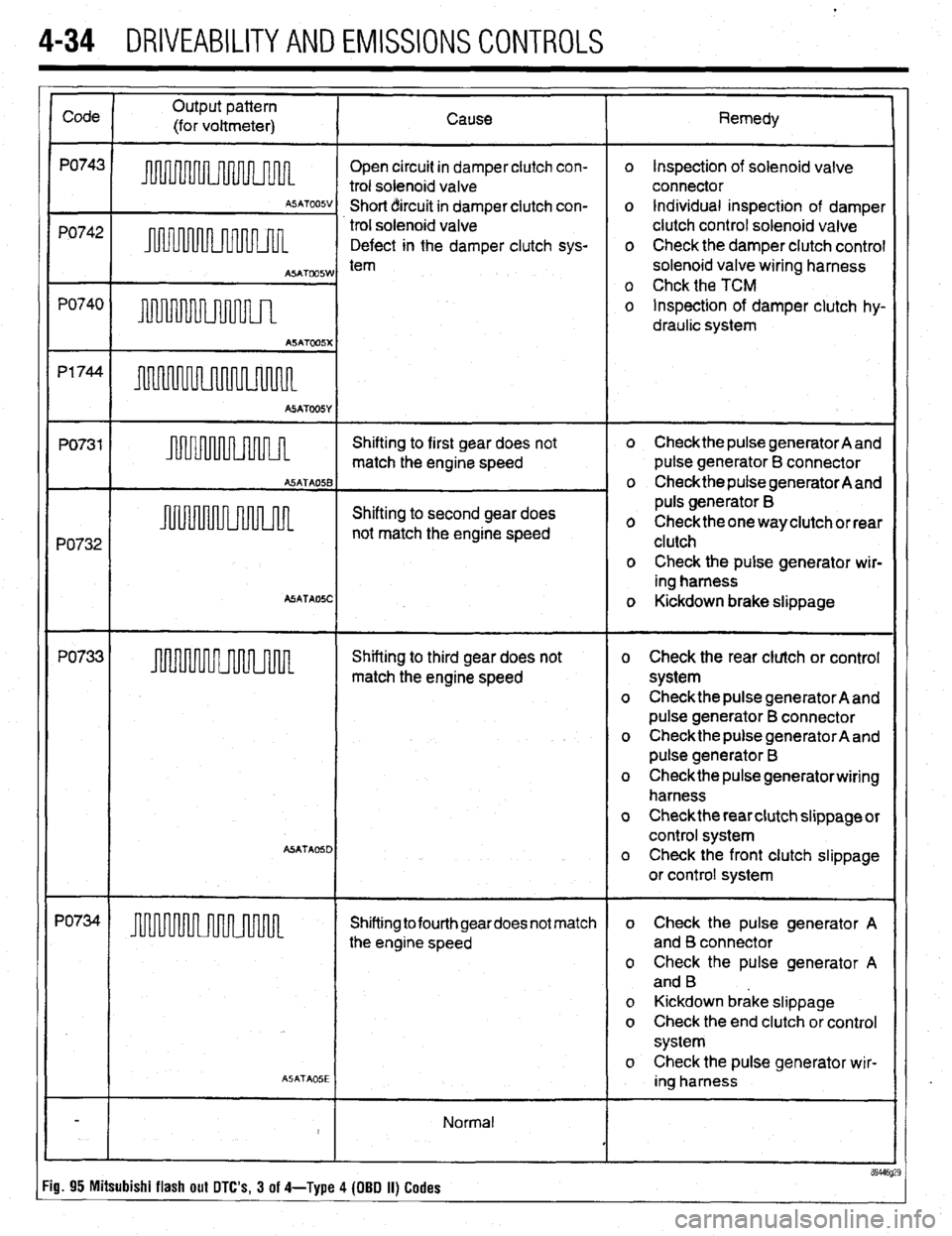

4-34 DRIVEABILITYAND EMISSIONS CONTROLS

Open circuit in damper clutch con-

trol solenoid valve

Short circuit in damper clutch con-

trol solenoid valve

Defect in the damper clutch sys- o Inspection of solenoid valve

connector

o Individual inspection of damper

clutch control solenoid valve

o Check the damper clutch control

solenoid valve wiring harness

o Chck the TCM

o Inspection of damper clutch hy-

draulic system

PO732 Shifting to first gear does not heckthe pulse generator A and

match the engine speed pulse generator B connector

o Check the pulse generator A and

Shifting to second gear does puls generator B

not match the engine speed o Checkthe one way clutch or rear

clutch

o Check the pulse generator wir-

ing harness

ASATAOSC o Kickdown brake slippage

PO733 Shifting to third gear does not o Check the rear clutch or control

match the engine speed system

o Check the pulse generator A and

pulse generator B connector

o Check the pulse generator A and

pulse generator B

o Checkthe pulse generatorwiring

harness

o Check the rear clutch slippage or

control system

A5ATA05D o Check the front clutch slippage

or control system

PO734

Shifting to fourth geardoes not match o Check the pulse generator A

the engine speed and B connector

o Check the pulse generator A

and B

o Kickdown brake slippage

o Check the end clutch or control

system

o Check the pulse generator wir-

ASATA05E ing harness

Normal

J

89446 :ig. 95 Mitsubishi flash out DTC’s, 3 of 4-Type 4 (OBD II) Codes

Page 189 of 408

I

5-2, FUELSYSTEM

When there is a problem starting or driving a vehi-

“is there fuel? will often lead to solving most basic

cle, two of the most important checks involve the ig- problems. For ignition system diagnosis and testing,

nition and the fuel systems. The questions most me-

please refer to the information on engine electrical

chanics attempt to answer first, “is there spark?” and

components and ignition systems found earlier in this manual. If the ignition system checks out (there

is spark), then you must determine if the fuel system

is operating properly (is there fuel?).

REMOVAL&INSTALLATION

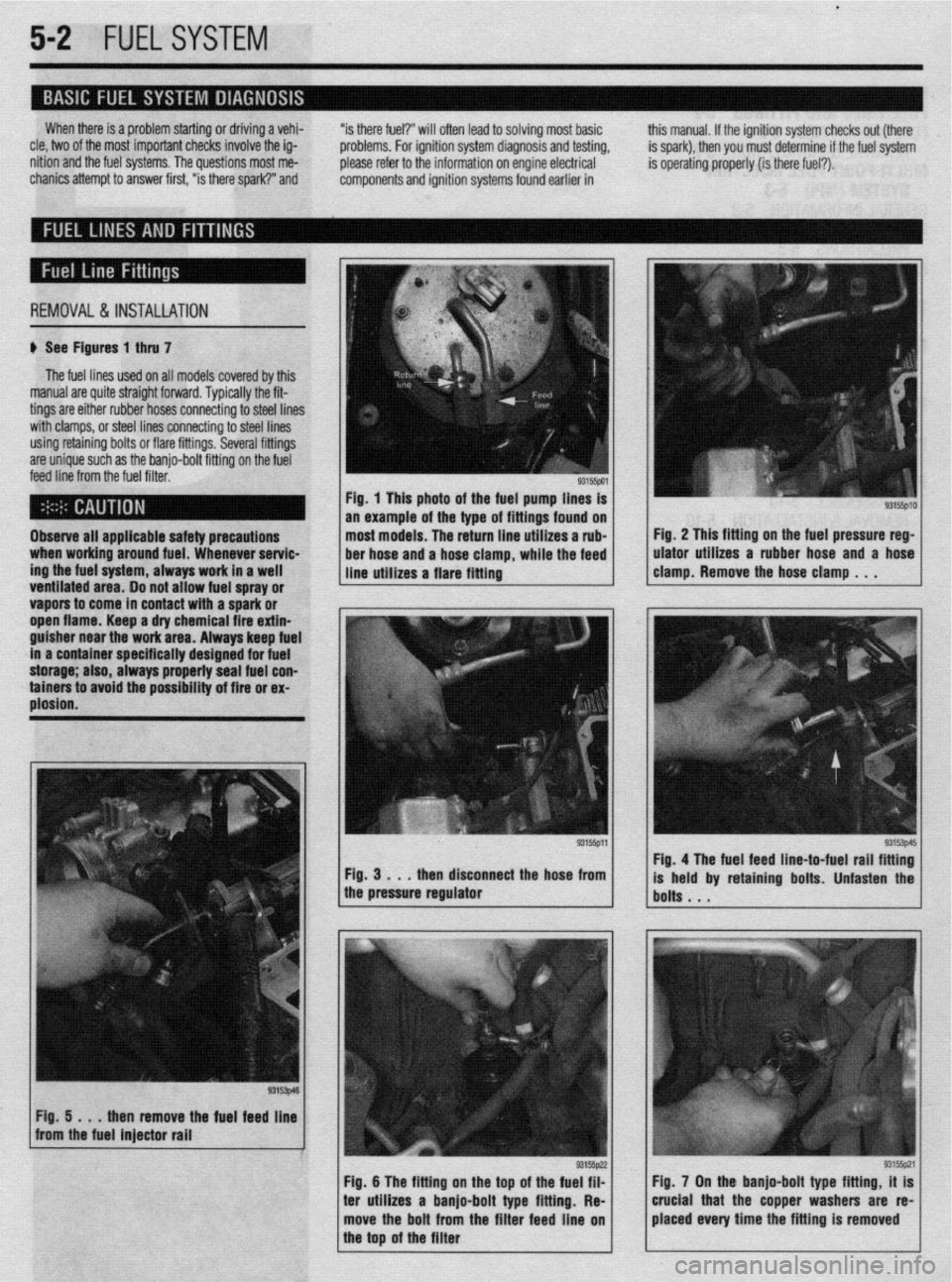

# See Figures 1 thru 7

The fuel lines used on all models covered by this

manual are quite straight forward. Typically the fit-

tings are either rubber hoses connecting to steel lines

with clamps, or steel lines connecting to steel lines

using retaining bolts or flare fittings. Several fittings

are unique such as the banjo-bolt fitting on the fuel

feed line from the fuel filter.

ventitateu area. Do not allow fuel spray or

vapors to come in contact with a spark or

ooen flame. Keen a drv chemical fire extin- Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

___ _ . . . _

guisher near the’work &ea. Always keep fuel

in a container specifically designed for fuel

storage; also, always pmperly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion. Fig. 1 This photo of the fuel pump lines is

an example of the type of fittings found on

most models. The return line utilizes a rub-

ber hose and a hose clamp, while the feed

line utilizes a flare fitting

ren disconnect the hose from

1 the pressure regulator Fig. 2 This fitting on the fuel pressure reg-

ulator utilizes a rubber hose and a hose

clamp. Remove the hose clamp . . .

93153p45 Fig. 4 The fuel feed line-to-fuel rail fitting

is held by retaining bolts. Unfasten the

bolts . . .

Fig. 5 . . .

then remove the fuel feed line

from the fuel injector rail

I

1 Fig. 6 The fitting on the too of the fueg;?lz

I I

93155pzl Fig. 7 On the banjo-bolt type fitting, it is

ter utilizes a banjo-bolt type fitting. Re-

I I crucial that the copper washers are re-

move the bolt from the filter feed line on placed every time the fitting is removed

the top of the filter

Page 191 of 408

5-4 FUELSYSTEM

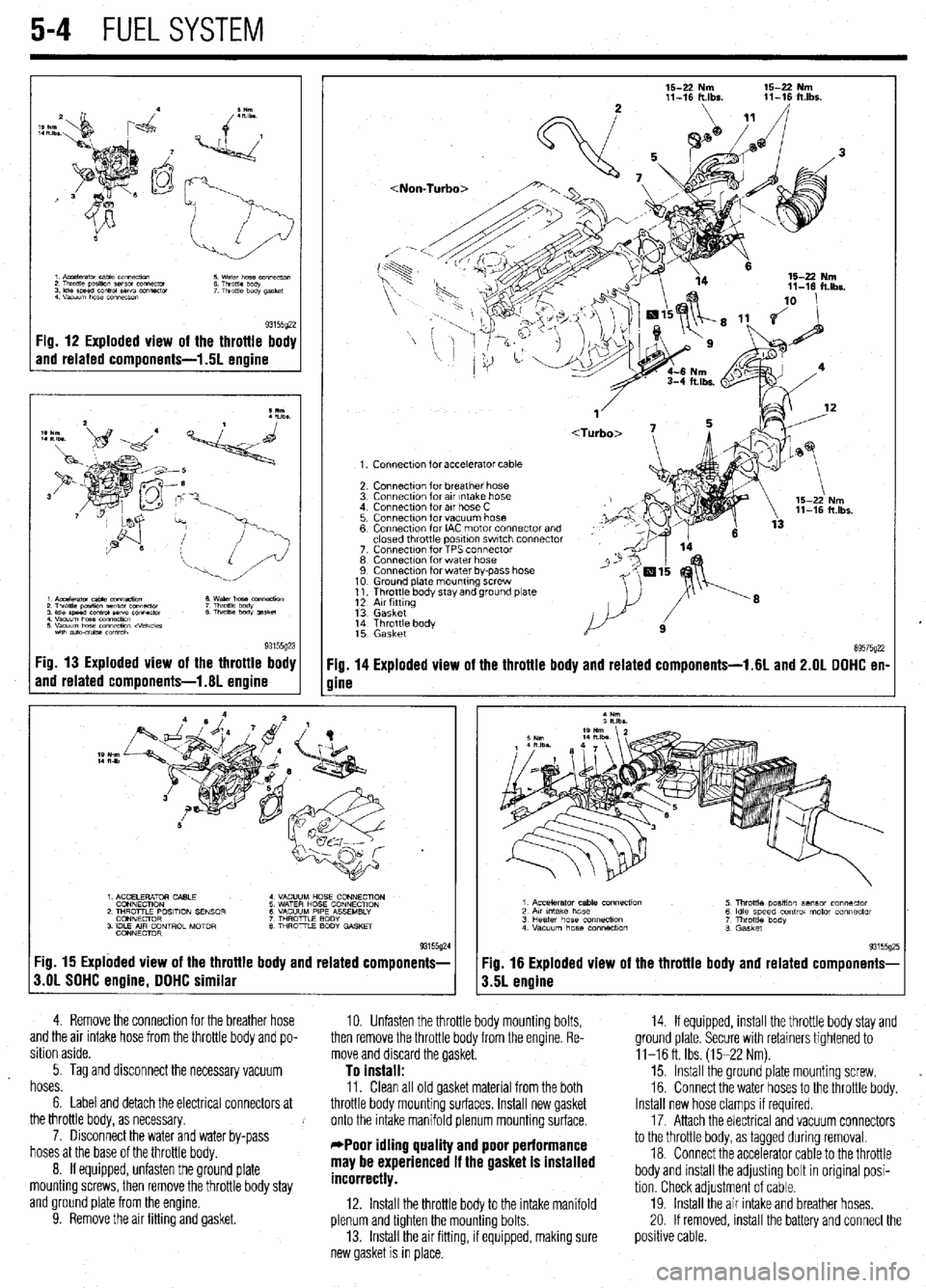

93155422 Fig. 12 Exploded view of the throttle body

and related components-l .5L engine

15-Z Nm

11-16 lt.lbs. 15-22 Nm 11-16 ft.lbr.

1. Connectnn for accelerator cable

2. Connection for breather hose

3 Connection for au intake hose

4 Connectton for au hose C

5. Connectton for vacuum hose

6 Connectton for IAC motor connector and

closed throttle posItIon swtch connector

7 ConnectIon for TPS connector

8 Connectton for water hose

9 Connectnon for water by-pass hose

10 Ground plate mounting screw

11. Throttle body stay and ground plate

12 Au flttlng

13 Gasket

14 Throttle body

15 Gasket ’

89575422 :ig. 14 Exploded view of the throttle body and related components-l.61 and 2.OL DOHC en-

line

93155g24 Yg. 15 Exploded view of the throttle body and related components- :ig. 16 Exploded view of the throttle body and related components-

1.OL SOHC engine, DOHC similar

1.5L engine

4. Remove the connection for the breather hose

10. Unfasten the throttle body mounting bolts, 14. If equipped, install the throttle body stay and

and the air intake hose from the throttle body and po-

then remove the throttle body from the engine. Re- QrOUnd plate. Secure with retainers tightened to

sition aside.

move and discard the gasket. 11-16 ft. Ibs. (15-22 Nm).

5. Tag and disconnect the necessary vacuum

To install: 15. Install the ground plate mounting screw.

hoses.

11. Clean all old gasket material from the both 16. Connect the water hoses to the throttle body.

6. Label and detach the electrical connectors at throttle body mounting surfaces. Install new gasket Install new hose clamps if required.

the throttle body, as necessary.

1 onto the intake manifold plenum mounting surface. 17. Attach the electrical and vacuum connectors

7. Disconnect the water and water by-pass

*Poor idling quality and poor performance to the throttle body, as tagged during removal.

hoses at the base of the throttle body.

may be experienced if the gasket is installed 18 Connect the accelerator cable to the throttle

8. If equipped, unfasten the ground plate

incorrectly. body and install the adjusting bolt in original posi-

mounting screws, then remove the throttle body stay

tion. Check adjustment of cable.

and QrOUnd plate from the engine.

12. Install the throttle body to the intake manifold 19 Install the air intake and breather hoses.

9. Remove the air fitting and

gasket. plenum and tighten the mounting bolts. 20. If removed, install the battery and connect the

13. Install the air fitting, if equipped, making sure positive cable.

new gasket iS in place.

Page 192 of 408

FUEL SYSTEM 5-5,

21. Connect the negative battery cable. Refill the

cooling system.

REMOVAL & INSTALLATION

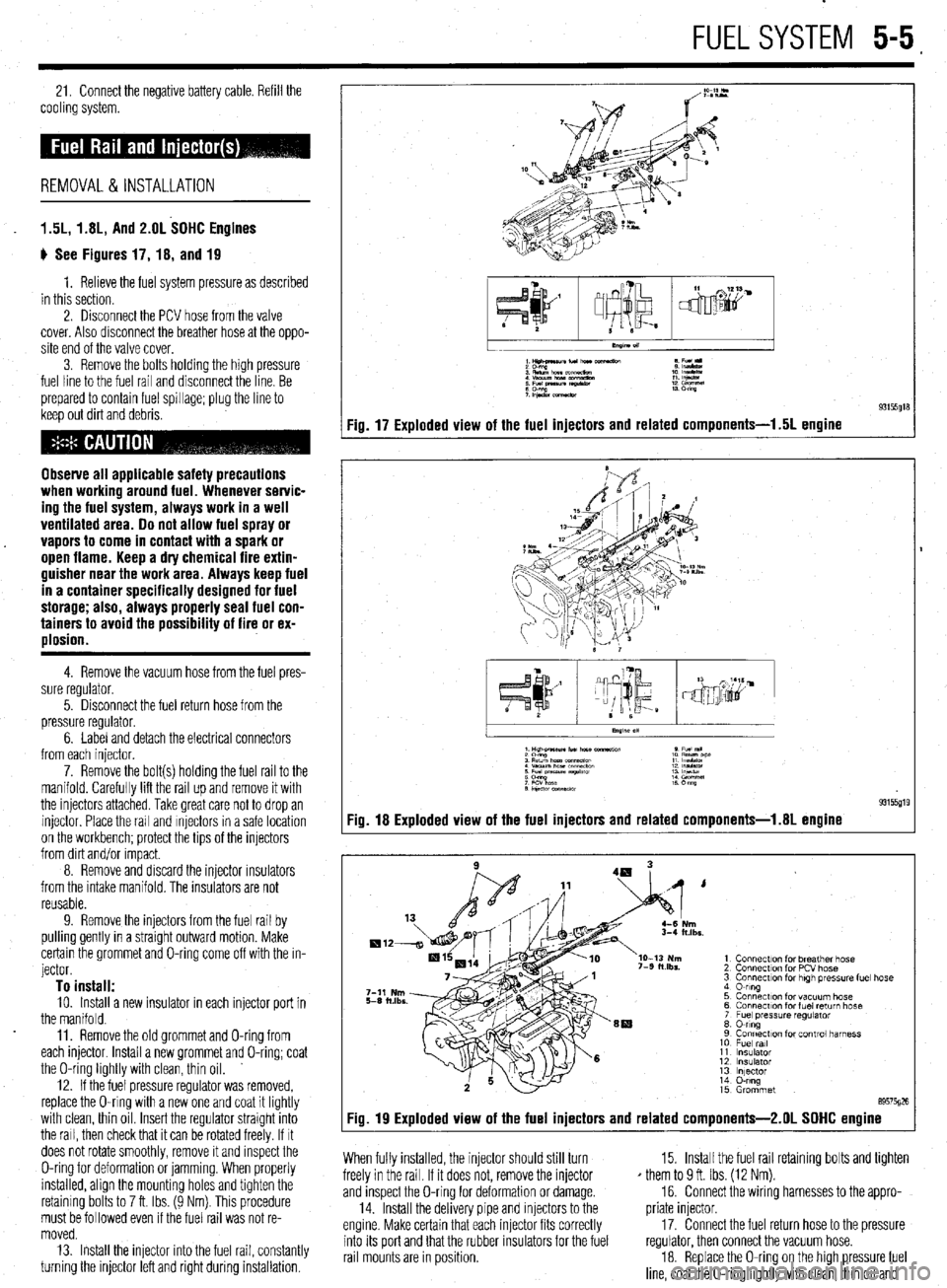

1.5L, 1.8L, And 2.OL SOHC Engines

ti See Figures 17, 18, and 19

1. Relieve the fuel system pressure as described

in this section.

2. Disconnect the PCV hose from the valve

cover. Also disconnect the breather hose at the oppo-

site end of the valve cover.

3. Remove the bolts holding the high pressure

fuel line to the fuel rail and disconnect the line. Be

prepared to contain fuel spillage; plug the line to

keep out dirt and debris.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. 00 not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

4. Remove the vacuum hose from the fuel pres-

sure regulator.

5. Disconnect the fuel return hose from the

pressure regulator.

6. Label and detach the electrical connectors

from each injector.

7. Remove the bolt(s) holding the fuel rail to the

manifold. Carefully lift the rail up and remove it with

the injectors attached. Take great care not to drop an

injector Place the rail and Injectors in a safe location

on the workbench; protect the tips of the injectors

from dirt and/or Impact.

8. Remove and discard the injector rnsulators

from the intake manifold. The insulators are not

reusable.

9. Remove the injectors from the fuel rail by

pulling gently in a straight outward motion. Make

certain the grommet and O-ring come off with the in-

jector.

To install: 10. Install a new insulator in each injector port in

the manifold.

11. Remove the old grommet and O-ring from

each injector Install a new grommet and O-ring; coat

the O-ring lightly with clean, thin oil.

12. If the fuel pressure regulator was removed,

replace the O-ring with a new one and coat it lightly

with clean, thin oil Insert the regulator straight into

the rail, then check that it can be rotated freely. If It

does not rotate smoothly, remove it and inspect the

O-ring for deformation or jamming. When properly

installed, align the mounting holes and tighten the

retaining bolts to 7 ft. Ibs. (9 Nm). This procedure

must be followed even if the fuel rail was not re-

moved.

13. Install the injector into the fuel rail, constantly

turning the injector left and right during installation.

1Hilt4naunfu(norc e Fu(l

:E%!,,.,.- 1: IEE

: Efgz tz!z? :: %%I

;P&.xmeaw 13 m

Fig. 17 Exploded view of the fuel injectors and related components-l .5L engine

I

.xs.

1 Connection for breather hose

2 Connection for PCV hose

3 Connection for high tm?ss”re fuel hose

4 0-ring

5 Connection for vacuum hose

6 Connecr~on for fuel return hose

7 Fuel pressure regulator

8 0-ring

9 Connection for control harness

10 Fuel ml

11 Insulator

12 insulator

13 lnlector

14 O-ring

15 Grommet

89575026

Fig. 19 Exploded view of the fuel injectors and related components-2.01 SOHC engine

When fully installed, the injector should still turn

freely in the rail. If it does not, remove the injector

and inspect the O-ring for deformation or damage.

14. Install the delivery pipe and injectors to the

engine. Make certain that each injector fits correctly

into its port and that the rubber insulators for the fuel

rail mounts are in position. 15. Install the fuel rail retaining bolts and tighten

* them to 9 ft. Ibs. (12 Nm).

16. Connect the wiring harnesses to the appro-

priate injector.

17. Connect the fuel return hose to the pressure

regulator, then connect the vacuum hose.

18. Replace the O-ring on the high pressure fuel

line, coat the O-ring lightly with clean, thin oil and

Page 193 of 408

install the line to the fuel rail. Tighten the mounting

bolts,

19. Attach the PCV hose and the breather hose if

thev were disconnected.

20. Connect the negative battery cable. Pressur-

ize the fuel system and inspect all connections for

I

leaks.

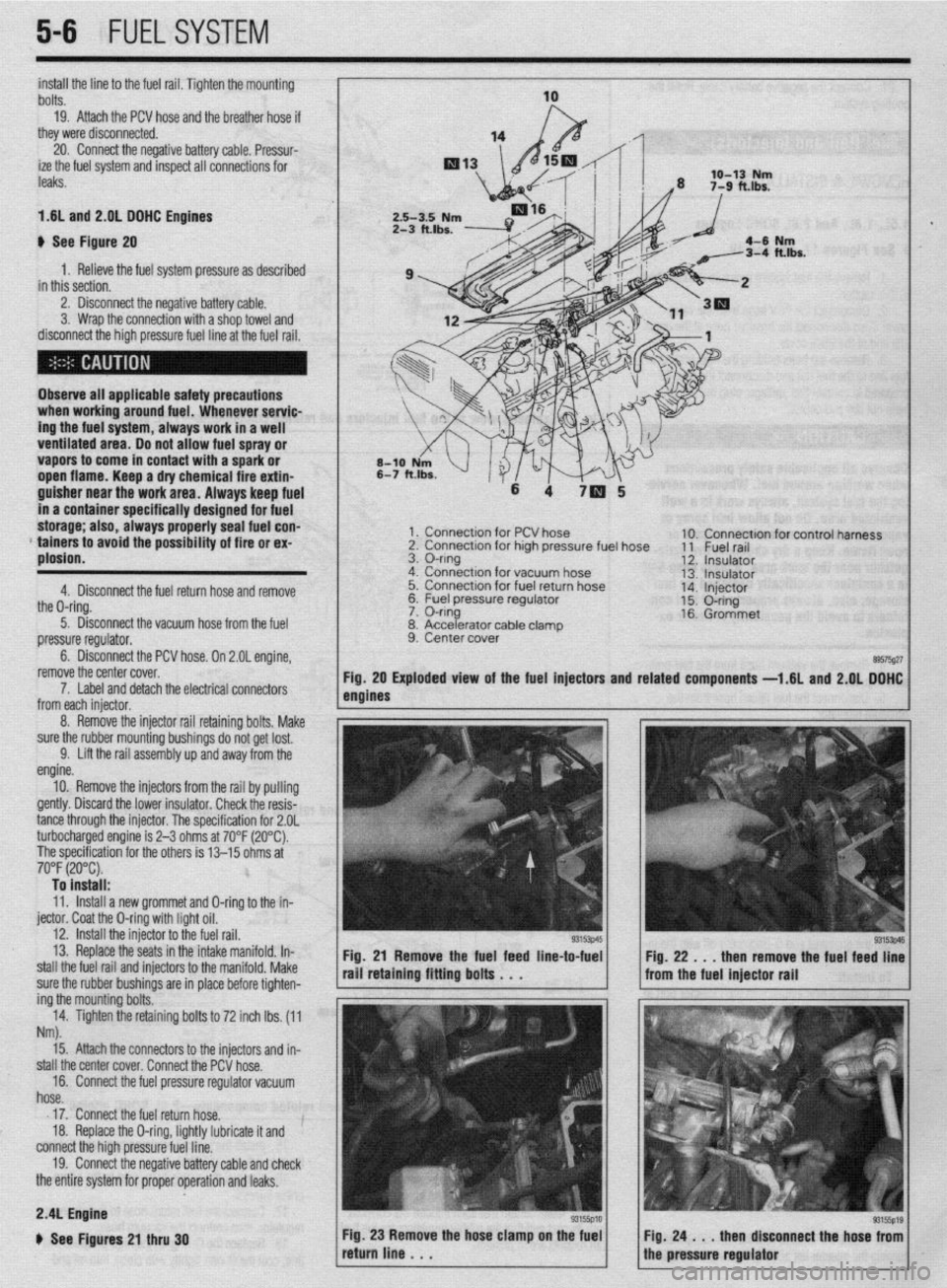

1.6L and 2.01 DOHC Engines

b See Figure 20

1. Relieve the fuel system pressure as described

in this section.

2. Disconnect the negative battery cable.

3. Wrap the connection with a shop towel and

disconnect the high pressure fuel line at the fuel rail.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

* tainers to avoid the possibility of fire or ex-

plosion.

4. Disconnect the fuel return hose and remove

the O-ring.

5. Disconnect the vacuum hose from the fuel

pressure regulator.

6. Disconnect the PCV hose. On 2.OL engine,

remove the center cover.

1 x Connection for PCV hose

2. Connection for high pressure fuel hose

3. O-ring

4. Connection for vacuum hose

5. Connection for fuel return hose

&2 I=, 1c.1 nrncc*.ra regu,ator

lble clamD

7. Label and detach the electrical connectors

from each iniector.

8. Accelerator ca

9. Center cover . 10. Connection for control harness

11 Fuel rail

12. Insulator

13. Insulator

14. Injector

15. O-ring

16. Grommet

89575g27 Exploded view of the fuel injectors and related

components -1.6L and 2.QL DOHC

5-6 FUELSYSTEM

8. Remove the injector rail retaining bolts, Make

sure the rubber mounting bushings do not get lost.

9. Lift the rail assembly up and away from the

engine.

10. Remove the injectors from the rail by pulling

gently. Discard the lower insulator. Check the resis-

tance through the injector. The specification for 2.OL

turbocharged engine is 2-3 ohms at 70°F (20°C).

The specification for the others is 13-15 ohms at

70°F (20°C). To install:

11. Install a new grommet and O-ring to the in-

jector. Coat the O-ring with light oil.

12. install the injector to the fuel rail.

13. Replace the seats in the intake manifold. In-

stall the fuel rail and injectors to the manifold. Make

sure the rubber bushings are in place before tighten-

ing the mounting bolts.

14. Tighten the retaining bolts to 72 inch lbs. (11

Nm).

Fig. 21 Remove the fuel feed line-to-fuel

rail retaining fitting bolts . . .

15. Attach the connectors to the injectors and in-

stall the center cover. Connect the PCV hose.

16. Connect the fuel pressure regulator vacuum

hose.

17. Connect the fuel return hose.

18. Replace the O-ring, lightly lubricate it and

connect the high pressure fuel line.

19. Connect the negative battery cable and check

the entire system for proper operation and leaks. Fig. 22 . . . then remove the fuel feed line

from the fuel injector rail

2.4L Engine

b See Figures 21 thru 30