check engine MITSUBISHI DIAMANTE 1900 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 148 of 408

,

DRIVEABILITYAND EMISSIONS CONTROLS 4-5

Fig. 16 Remove the canister retaining bolts

and remove the canister

Solenoid Valves

u See Figures 17 and 18

1 b Disconnect the negative battery cable.

2. Label and remove the vacuum and electrical

harness connections from the purge control solenoid.

3. Remove the solenoid and mounting bracket

from the engine compartment.

4. Installation is the reverse of the removal proce-

dure.

I

- EVAPORATIVE EMISSION

Fig. 18 location of the evaporative emis-

purge solenoid-1990-93 2.OL DDHC

Volume air flow seneftr I

I Manifold diierential pressure m

&a$34

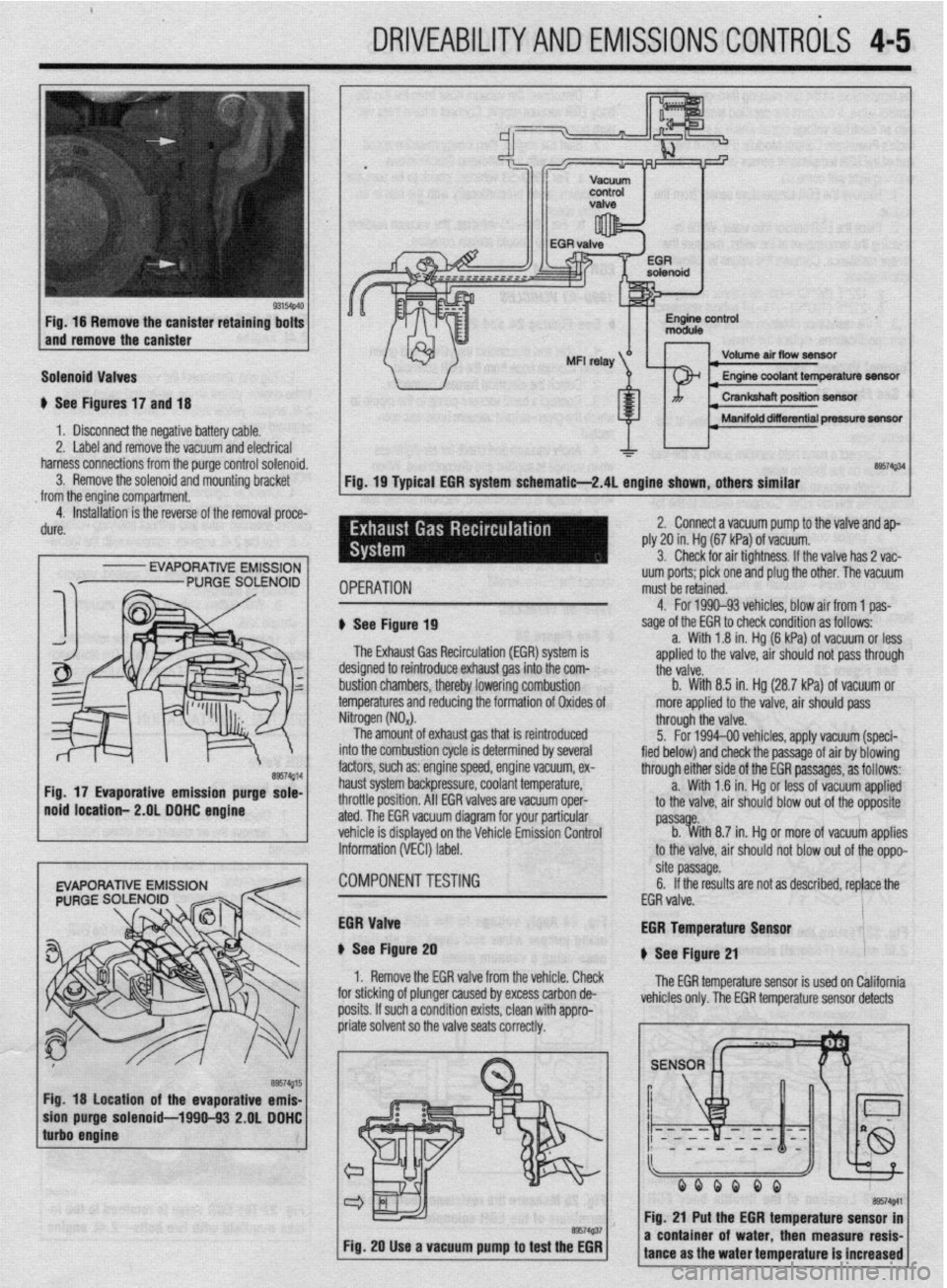

Fig. 19 Typical EGR system schematie-2.4L engine shown, others similar

IPERATION uum ports; pick one and plug the other. The vacuum

must be retained.

1 See Figure 19

The Exhaust Gas Recirculation (EM) system is

lesigned to reintroduce exhaust gas into the com-

ttii valve.

rustion chambers, thereby lowering combustion b. With 8.5 in. Hg (28.7 kPa) of vacuum or

emperatures and reducing the formation of Oxides of more applied to the valve, air should pass 4. For 1990-93 vehicles. blow air from 1 oas-

sage of the EGR to check condition as foffows--

a. With 1.8 in. Hg (6 kPa) of vacuum or less

aoolied to the valve. air should not oass throuah

litrogen (NO,).

The amount of exhaust gas that is reintroduced

Ito the combustion cycle is determined by several

actors, such as: engine speed, engine vacuum, ex-

raust system backpressure, coolant temperature,

Irottle position. All EGR valves are vacuum oper-

ted. The EGR vacuum diagram for your particular

chicle is displayed on the Vehicle Emission Control

iformation (VECI) label. through the valve.

5. For 1994-00 vehicles, apply vacuum (speci-

fied below) and check the passage of air by blowing

through either side of the EGR passages, as follows:

a. With 1 .?I in. Hg or less of vacuum applied

to the valve, air should blow out of the opposite

passa e.

b. %ith 8.7 in. Hg or more of vacuum applies

to the valve, air should not blow out of the oppo-

:OMPONENTTESTiNG site passage.

6. If the results are not as described, replace the

EGR valve.

iGR Valve

t See Figure 20

1. Remove the EGR valve from the vehicle. Check

I”..““.

:or sticking of plunger caused by excess carbon de-

losits. If such a condition exists, clean with appro- EGR Temperature Lan*nr

u See Figure 21

The EGR temperature sensor is used on California

vehicles only. The EGR temperature sensor detects

Fig. 20 Use a vacuum pump to test the EGR

I I

a coni tance i of water. then measure resis-

I ms the water temperature is increased

Page 149 of 408

the temperature of the gas passing through +h

control valve. It converts the detected temf

Ierature

into an electrical voltage signal which is sent the ve-

hicle’s Powertrain Control Module (PCM). If the cir-

cuit of the EGR temperature sensor is broken, the

warning light will come on.

1. Remove the EGR temperature sensor from the

engine.

2. Place the EGR sensor into water. While in-

creasing the temperature of the water, measure the

sensor resistance. Compare the values to following

specifications:

a. 122°F 50°C

b. 212°F 100” )-11-14 kohms resistance

t P O-83 kohms resistance

3. If the resistance obtained varies significantly ,

.,. . .

i, replace the sensor, nom specmcaoom

Thermal Vacuum Valva

therm0 valve.

2. Connect a hand held vacuum pump to the vac-

uum hose on the therm0 valve.

3. Apply vacuum and check the air passage

through the therm0 vOrL’n %ults to the fnrm

lowinq specifications:

ant temperature of 122°F

vacuum leaks

lant temoerature of 176’F 4 n;rm.nnnn+ +h.n s,r,,~,,,,rn hnm frnm ‘h.n +hrotle

body EGR vacuum nipple. Connect a hand-held

vac-

uum pump to the nipple.

2. Start the engine, then slowly raise the speed

and compare with the following specifications.

a. For 1990-93 vehides, check to be sure the

vacuum raised proportionally with the rise in en-

gine s eed.

b. Ior 199450 vehicles, the vacuum reading

on the pump should remain constant.

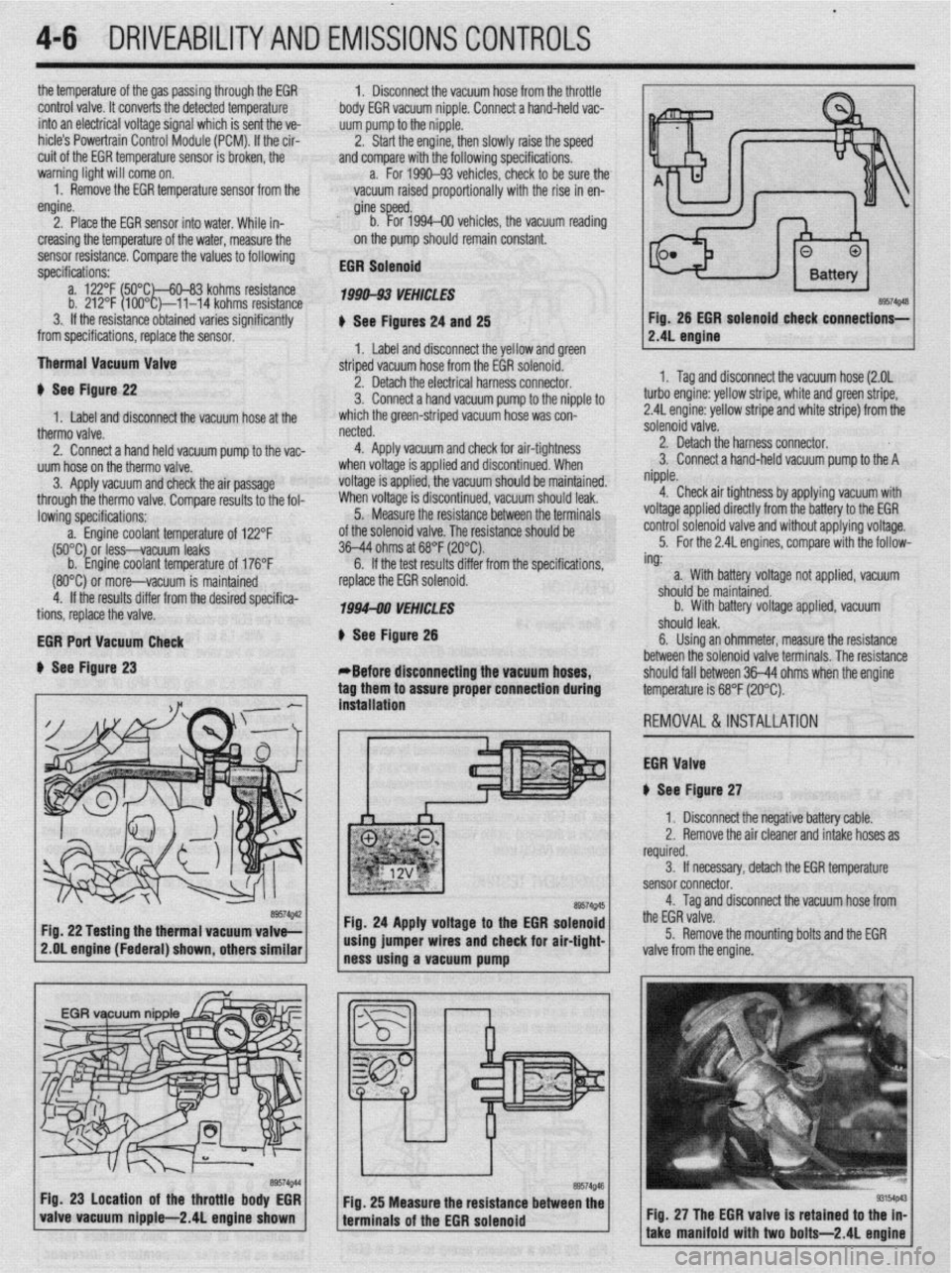

EGR Solenoid

1990-93 L’EHICL ES

# See Figures 24 and 25

1. Label and disconnect the yellow and green

striped vacuum hose from the EGR solenoid.

netted.

4. Apply vacuum and check for air-tightness

when voltage is applied and discontinued. When

voltage is applied, the vacuum should be maintained.

When voltage is discontinued, vacuum should leak.

5. Measure the resistance between the terminals

of the solenoid valve. The resistance should be

36-44 ohms at 68°F (20°C).

6. If the test results differ from the soecifications.

4-6 DRIVEABILITYAND EMISSIONSCONTROLS

Fig. 26 EGR solenoid

check connections-

# See Figure 22

1. Label and disconnect the vacuum hose at the 2. Detach the electrical harness connector.

3. Connect a hand vacuum pump to the nipple to

which the green-striped vacuum hose was con-

(80°C) 0; more-vacuum is maintained

4. If the results differ from the desired specifica-

tions, replace the valve.

EGR Port Vacuum Check

+ See Figure 23 replace the EGR solenoid.

1994-00 VEHICLES

# See Figure 26

*Before disconnecting the vacuum hoses,

tag them to assure proper connection during

. . ** *. 1. Tag and disconnect the vacuum hose (2.OL

turbo engine: yellow stripe, white and green stripe,

2.4L engine: yellow stripe and white stripe) from the

solenoid valve.

2. Detach the harness connector.

3. Connect a hand-held vacuum pump to the A

nipple.

4. Check air tightness by applying vacuum with

voltage applied directly from the battery to the EGR

control solenoid valve and without applying voltage.

5. For the 2.4L engines, compare with the follow-

ing:

. .

roltage not applied, vacuum a. With battery

should be maintainr

b. With battery

.I III I

snoura

iea~.

sd. -

/oltage applied, vacuum

6. Using an ohmmeter, measure the resistance

between the solenoid valve terminals. The resistance

should fall between 36-44 ohms when the enaine

temperature is 68°F (20°C).

REMOVAL&INSTALLATION

EGR Valve

iI See Figure 27 mslatlanon

1 I Disconnect the negative battery cable.

2. Remove the air cleaner and intake hoses as

required.

3. If necessary, detach the EGR temperature

sensor connector.

4. Tag and disconnect the vacuum hose from

the EGR valve.

5. Remove the mounting bolts and the EGR

2.OL engine (Federal) shown, others similar

valve from the engine.

Fig. 27 The EGR valve is retained to t

take manifold with two bolts-2.4L e

Page 152 of 408

DRIVEABILITYAND EMISSIOP JSCONTRiLS 4-9

3. Label and disconnect the H02S from the en-

gine control wiring harness.

*Lubricate the sensor with penetrating oil

prior to removal.

4. Remove the sensor using an oxygen sensor

I To install: - -v- -- ---- ..----. ----...= -..- r... *-

5. Install the sensor in the mounting boss and

hl-li)r\,,.l 0 ,.l.-.f.l, .T‘fi.LI wrench or another suitable tool.

tighten to 27-33 ft. Ibs. (37-45 Nm).

6. Connect the engine control wiring harness to 1 Fia. 43 IAC mntnr tnfitinn and nin Incations 1

KtMUVHL i% IN3 I ALLA I IUN

See Fiaurr! d4

1. Disconnect the negative battery cable.

2. Remove the air cleaner intake hose.

move the oxygen sensor. The socket con- 3. Remove any necessary hoses from the IAC

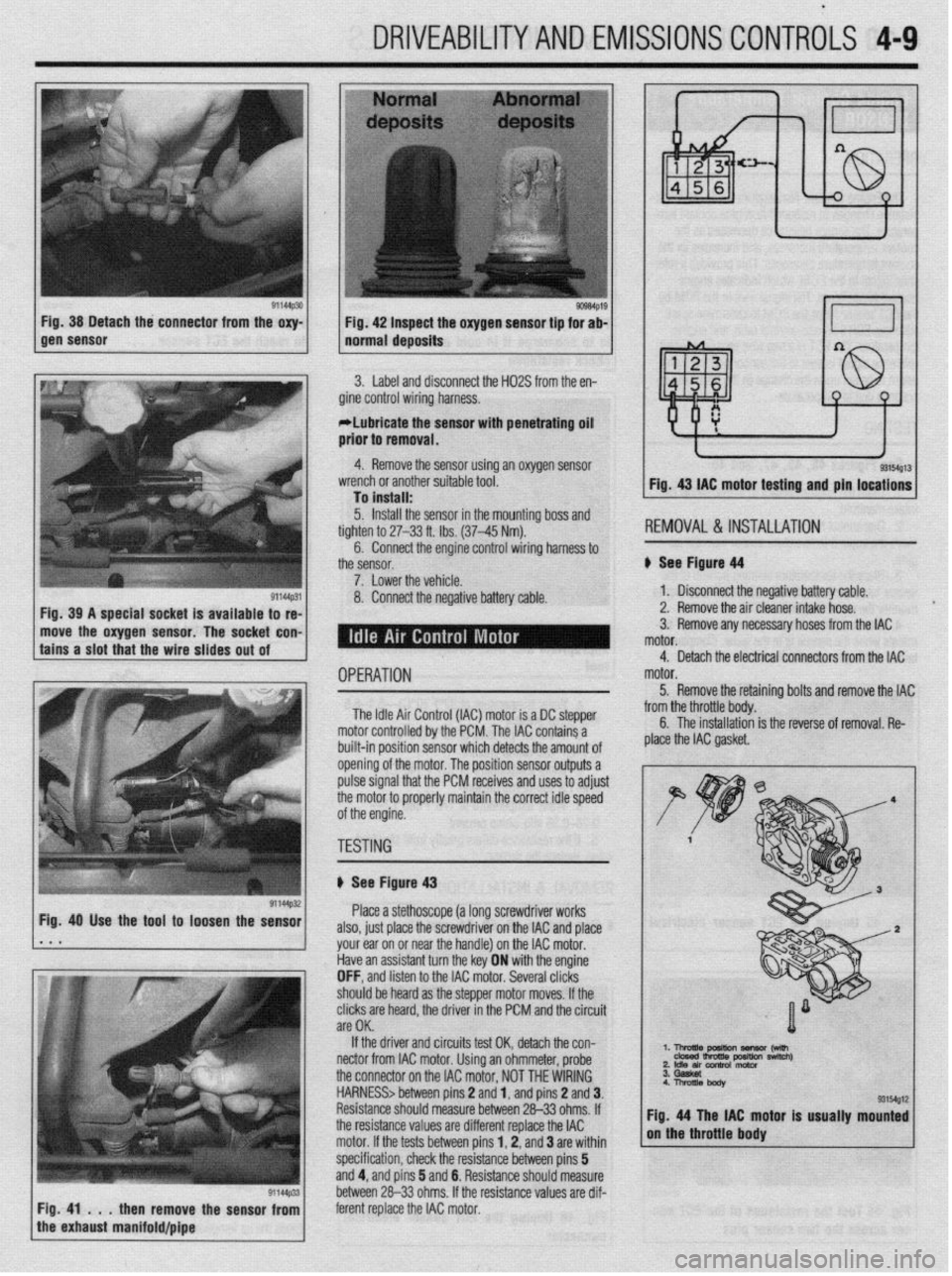

OPERATION

The Idle Air Control (IAC) motor is a DC stepper

motor controlled by the PCM. The IAC contains a

built-in position sensor which detects the amount of

opening of the motor. The position sensor outputs a

pulse signal that the PCM receives and uses to adjust

the motor to properly maintain the correct idle speed

of the engine. motor.

5. Remove the retainino bolts and remove the IAC

y -_.._ -..- ._... -._ . .._ ._ from the throttle body. C The inc.hllrrti~n a 11o IIIJL(IIIoLIuII is the reverse of removal. Re-

plaie the IAC gasket.

TESTING

I

ti See Figure 43

Place a stethoscope (a long screwdriver works

also, just place the screwdriver on the IAC and place

your ear on or near the handle) on the IAC motor.

Have an assistant turn the key ON with the engine

OFF, and listen to the IAC motor. Several clicks

should be heard as the steooer motor moves. If the

clicks are heard, the driver in the PCM and the circuit

are OK.

If the driver and circuits test OK, detach the con-

nectar from IAC motor. Using an ohmmeter, probe ‘. l-!AEz?rn~ -w

2 Idle an conh0l motor nswltch)

the connector on the IAC motor, NOT THE WIRING

HARNESS> between pins 2 and 1, and pins 2 and 3.

Resistance should measure between 26-33 ohms. If

the resistance values are different replace the IAC tor is usually mounted

motor. If the tests between pins 1,2, and 3 are within

specification, check the resistance between pins 5

and 4, and pins 5 and 6. Resistance should measure

between 26-33 ohms. If the resistance values are dif-

then remove the sensor from ferent replace the IAC motor.

Page 153 of 408

4-10 DRIVEABILITYAND EMISSIONS CONTROLS

I

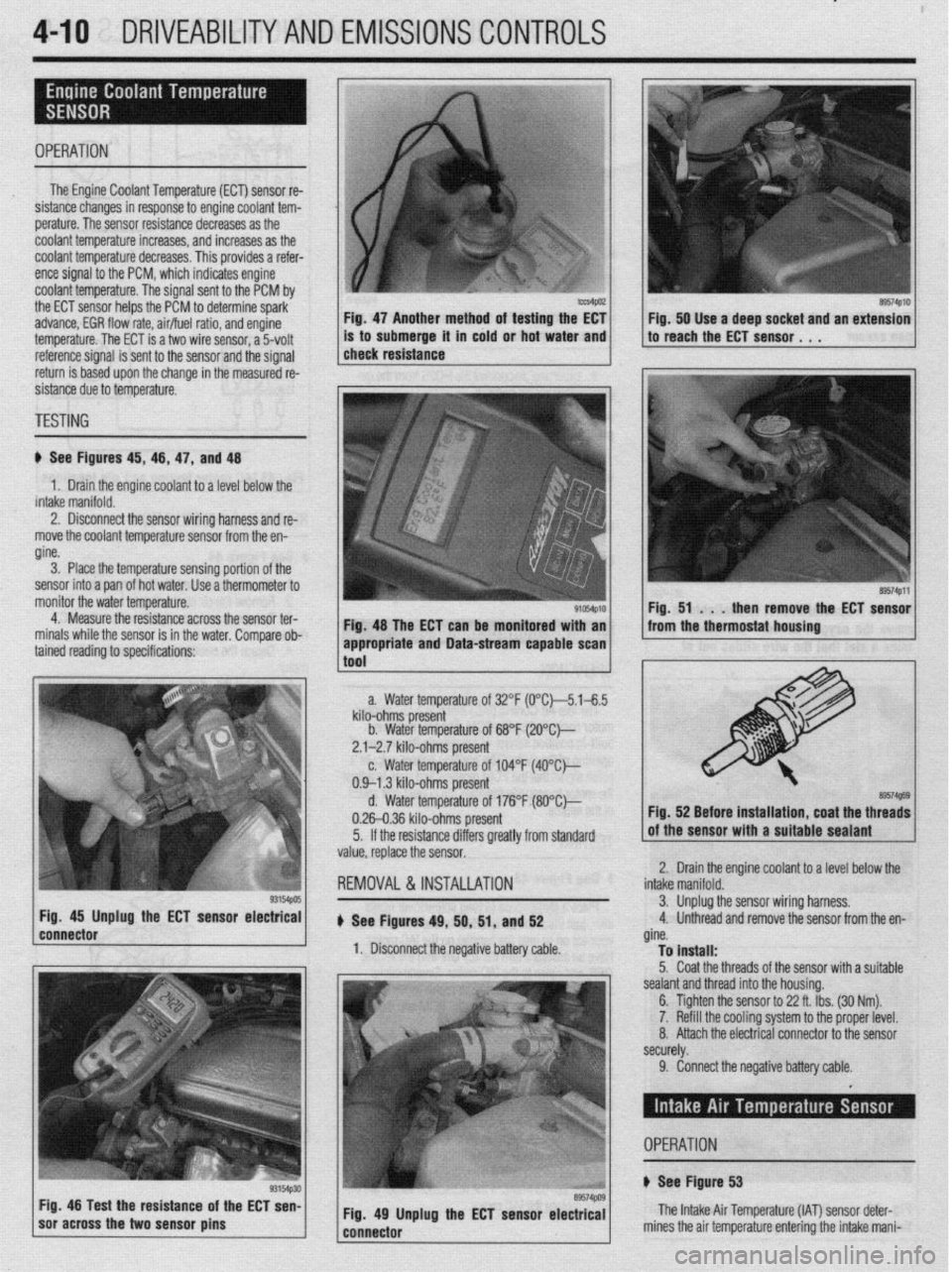

OPERATION

The Engine Coolant Temperature (ECT) sensor re-

sistance changes in response to engine coolant tem-

perature. The sensor resistance decreases as the

coolant temperature increases, and increases as the

coolant temperature decreases. This provides a refer-

ence signal to the PCM, which indicates engine

coolant temperature. The signal sent to the PCM by

the ECT sensor helps the PCM to determine spark-

advance, EGR flow rate, air/fuel ratio, and engine

temperature. The ECT is a two wire sensor, a 5volt

3. Place the temperature sensing portion of the

sensor into a pan of hot water. Use a thermometer to

monitor the water temperature.

4. Measure the resistance across the sensor ter-

minals while the sensor is in the water. Comoare ob- Fig. 47 Another method of testing the EC1 Fig. 50 Use a deep socket and an extension

is to submerge it in cold or hot water and to reach the ECT sensor. 1 ,

reference signal is sent to the sensor and the signal

return is based upon the change in the measured re-

sistance due to temperature. 1 check resistance

TESTING

ti See Figures 45, 46, 47, and 48

1. Drain the engine coolant to a level below the

intake manifold.

2. Disconnect the sensor wiring harness and re-

move the coolant temperature sensor from the en-

gine.

Fig. 48 The ECT can be monitored with an

tained reading to specifications: ’

93154pos Fig. 45 Unplug the ECT sensor electrical

connector

1 soracross the two sensor pins g3154p30 Fig 48 Test the resistance of the ECT sen-

89574PlO

89574Pll

Fig. 51 . . .

then remove the ECT sensor

from the thermostat housing

a. Water temperature of 32°F (0°C~5.1-6.5

kilo-ohms present

b. Water temperature of 68°F (2O”C)--

2.1-2.7 kilo-ohms present

c. Water temperature of 104°F (4O”C)---

0.9-l .3 kilo-ohms present

d. Water temperature of 176°F (8O”Ck,

0.26-0.36 kilo-ohms present

5. If the resistance differs greatly from standard

value, replace the sensor.

REMOVAL &INSTALLATION

u See Figures 49, 50, 51, and 52

1. Disconnect the negative battery cable. Fig. 52 Before installation, coat the threads

Iolant to a level below the 2. Drain the engine c(

intake manifold.

3. Unplug1 the sensor wiring harness,

4. Unthreac

d and remove the sensor from the en-

gine.

To install:

5. Coat the threads of the sensor with a suitable

sealant and thread into the housing.

6. Tighten the sensor to 22 ft. Ibs. (30 Nm).

7. Refill the cooling system to the proper level.

8. Attach the electrical connector to the sensor

securely. appropriate and Data-stream capable scan 1

1

tnnl

9. Connect the negative battery cable.

Fig. 49 Unplug the ECT sensor electrical

---..^-s-- The Intake Air Temperature (IAT) sensor det

mines the air temnerature enterinn the! intake n er-

- ._ r_ -.-._ _. ._. J . _ ..-. ._

iani- OPERATION

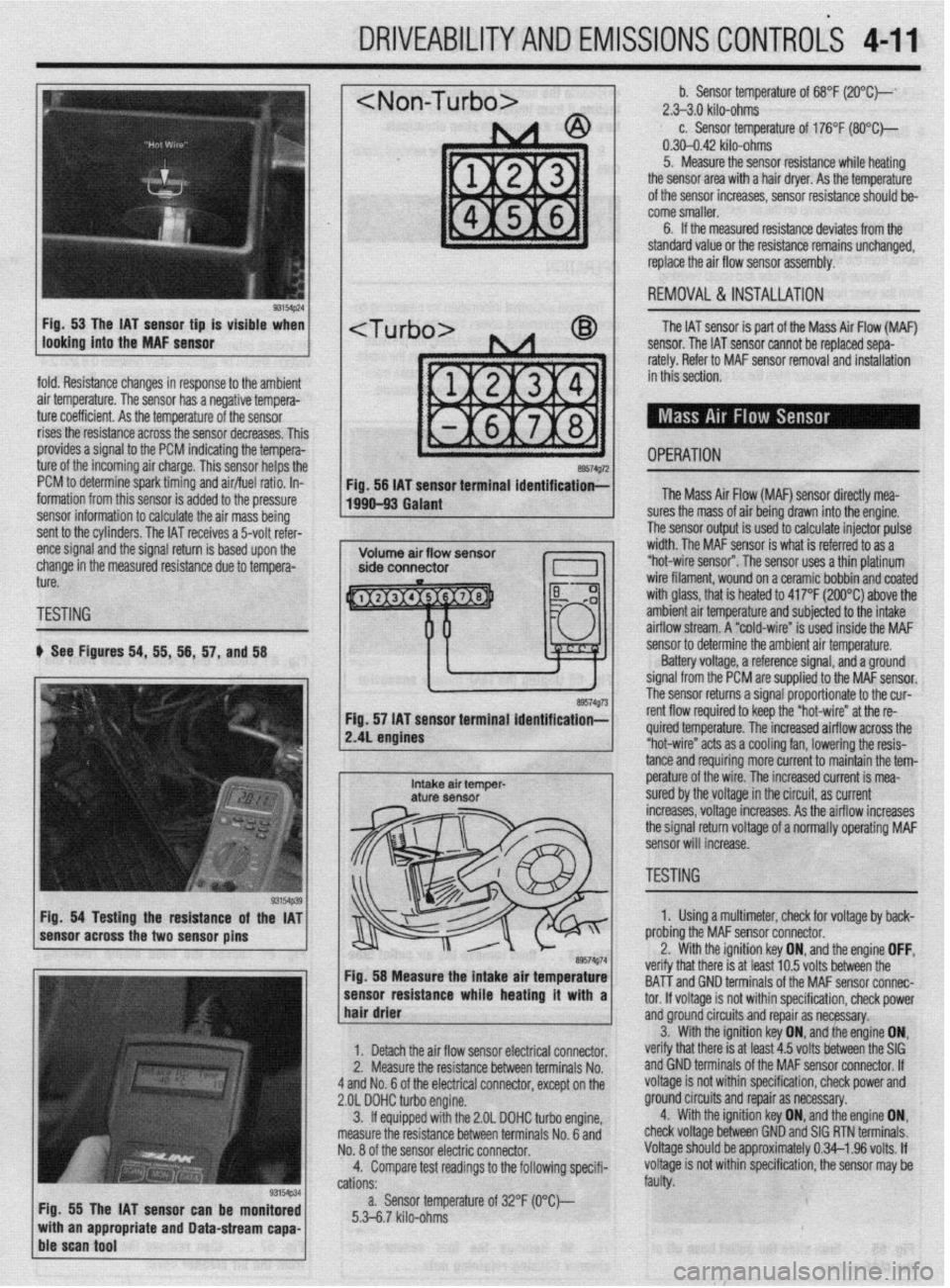

+ See Figure 53

Page 154 of 408

DRIVEABILITYAND EMISSIONS CONTROLi 4-11

fold. Resistance changes in response to the ambient

air temperature. The sensor has a negative tempera-

ture coefficient. As the temperature of the sensor

rises the resistance across the sensor decreases. Thil

provides a signal to the PCM indicating the tempera-

ture of the incoming air charge. This sensor helps the

PCM to determine spark timing and air/fuel ratio. In-

formation from this sensor is added to the pressure

sensor information to calculate the air mass being

sent to the cylinders. The IAT receives a 5-volt refer-

ence signal and the signal return is based upon the

change in the measured resistance due to tempera-

ture.

TESTING

b See Figures 54, 55, 56, 57, and 58

Fig. 54 Testing the resistance of the IAT

sensor across the two sensor pins

Fig. 55 The IAT sensor can be monitored

with an appropriate and Data-stream capa-

ble scan tool

~1 b. Sensor temperature of 68°F (2O”C)--‘ 2.>3.0 kilo-ohms c. Sensor temperature of 176°F (SO*C)-

0.30-0.42 kilo-ohms

5. Measure the sensor resistance while heating

the sensor area with a hair dryer. As the temperature

of the sensor increases, sensor resistance should be-

come smaller.

6. If the measured resistance deviates from the

standard value or the resistance remains unchanged,

replace the air flow sensor assembly.

1 REMOVAL&INSTALLATION

The IAT sensor is part of the Mass Air Flow (MAF)

sensor. The IAT sensor cannot be replaced sepa-

rately. Refer to MAF sensor removal and installation

in this section.

- OPERATION a9574g72 Fig. 56 IAT sensor terminal identification;-

1990-93 Galant The Mass Air Flow (MAF) sensor directly mea-

lres the mass of air being drawn into the engine.

I ?he sensor output is used to calculate injector pulse

width. The MAF sensor is what is referred to as a

“hot-wire sensor”. The sensor uses a thin platinum

wire filament, wound on a ceramic bobbin and coated

with glass, that is heated to 417°F (200°C) above the

amh+en+ nir +PmnPrfijre and subiected to the intake

..I._ ~ ..-.. .“..‘r-,u.. ai mow stream. A “cold-wire” is used inside the MAF

sensor resuirance wnoe nearmg ir wnn a 1

hair drier ‘hat melt: IS al I~“< ,“.., lvllQ UtiLnbtill ,,,=

tnd GND terminals of the MAF sensor connec-

tor. If voltaae is not within specification, check power

1. Detach the air flow sensor electrical connector.

2. Measure the resistance between terminals No.

4 and No. 6 of the electrical connector, except on the

2.OL DOHC turbo engine.

3. ff equipped with the 2.OL DOHC turbo engine,

measure the resistance between terminals No. 6 and

No. 8 of the sensor electric connector.

4. Compare test readings to the following specifi-

cations:

a. Sensor temperature of 32°F (O“C)--

5.3-6.7 kilo-ohms and groundcircuits and repair as necessary.

verify that there is at least 4.5 volts between the SIG 3. With the ignition key ON, and,the engine ON,

and GND terminals of the MAF sensor connector. If

voltage is not within specification, check power and

ground circuits and repair as necessary.

4. With the ignition key ON, and the engine ON,

check voltage between GND and SIG RTN terminals.

Voltage should be approximately 0.34-l .96 volts. If

voltage is not within specification, the sensor may be

faulty.

/ sensor to determine the ambient air temperature.

Battery voltage, a reference signal, and a ground

signal from the PCM are supplied to the MAF sensor.

rho ~pn**r rp+++rns a signal proportionate to the cur-

re. The increased airflow across the

s a cooling fan, lowering the resis-

mo more current to maintain the tem- tance and requir

e^-‘.._^ ^I LL^

I

Intake air temper- pe~a+ure UI me wire. The increased current is mea- aturf sensor sured by the voltage in the circuit, as current

increases, voltage increases. As the airflow increases

the signal return voltage of a normally operating MAF

sensor will increase.

, ~~1 TESTING - II ire” at the re-

89574g74 Fig. 58 Measure the intake air temperature

-----_ ---1-a---- L..- L--1. . . .*a 1. Using a multimeter, check for voltage by back-

nrr\hinn +hn MAF sensor connector.

the ignition key ON, and the engine OFF, .^-^ :- -’ ‘.txt In E; \mltr hahrman tha veriry t

BAT-T i

Page 155 of 408

4112 DRIVEABILITYAND EMISSIONS CONTROLS

.

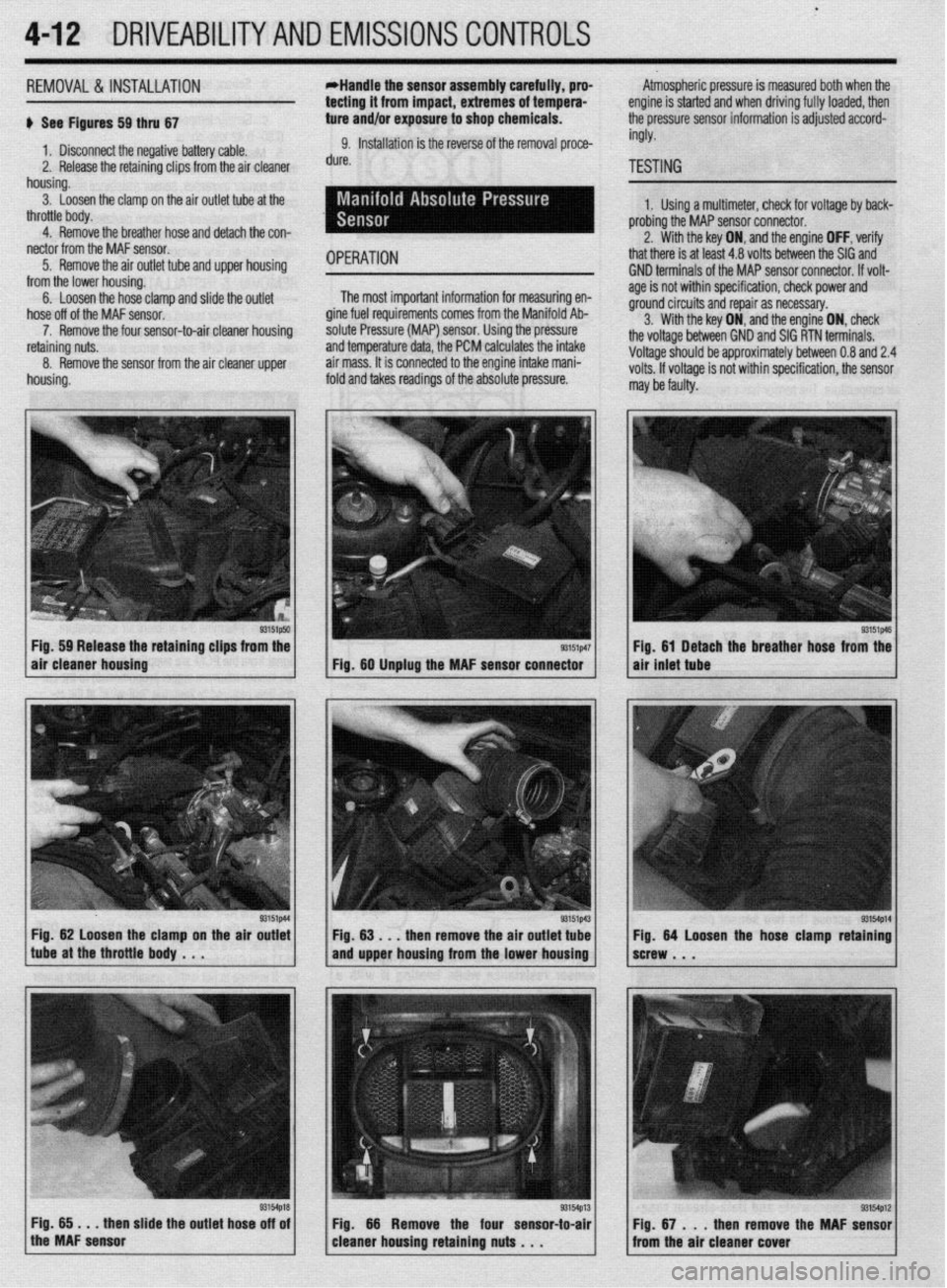

REMOVAL&INSTALLATION

+ See Figures 59 thru 67

1, Disconnect the negative battery cable.

2. Release the retaining clips from the air cleaner

housing.

3. Loosen the clamp on the air outlet tube at the

throttle body.

4. Remove the breather hose and detach the con-

nector from the MAF sensor.

5. Remove the air outlet tube and upper housing

from the lower housing.

6. Loosen the hose clamp and slide the outlet

hose off of the MAF sensor.

7. Remove the four sensor-to-air cleaner housing

retaining nuts.

8. Remove the sensor from the air cleaner upper

housing. Atmospheric pressure is measured both when the

engine is started and when driving fully loaded, then

the oressure sensor information is adiusted accord- *Handle the sensor assembly carefully, pro-

tecting it from impact, extremes of tempera-

ture and/or exposure to shop chemicals.

9. Installation is the reverse of the removal proce-

dure.

OPERATION

The most important information for measuring en-

gine fuel requirements comes from the Manifold Ab-

solute Pressure (MAP) sensor. Using the pressure

and temperature data, the PCM calculates the intake

air mass. It is connected to the engine intake mani-

fold and takes readings of the absolute pressure. ingly.

TESTING

1. Using a multimeter, check for voltage by back-

probing the MAP sensor connector.

2. With the key ON, and the engine OFF, verify

that there is at least 4.8 volts between the SIG and

GND terminals of the MAP sensor connector. If volt-

age is not within specification, check power and

ground circuits and repair as necessary.

3. With the key ON, and the engine ON, check

the voltage between GND and SIG RTN terminals.

Voltage should be approximately between 0.8 and 2.4

volts. If voltage is not within specification, the sensor

r nay be faulty.

Fig. 59 Release the retaining clips from the

air cleaner housing

Fig. 62 loosen the clamp on the air outlet

tube at the throttle body . . .

then slide the outlet hose off of Fig. 61 Detach the breather hose from the

air inlet tube

53154p12 Fig. 67 . . . then remove the MAF sensor

from the air cleaner cover

Page 156 of 408

DRIVEABILITYAND EMISSIONS CONTROiS 4-13

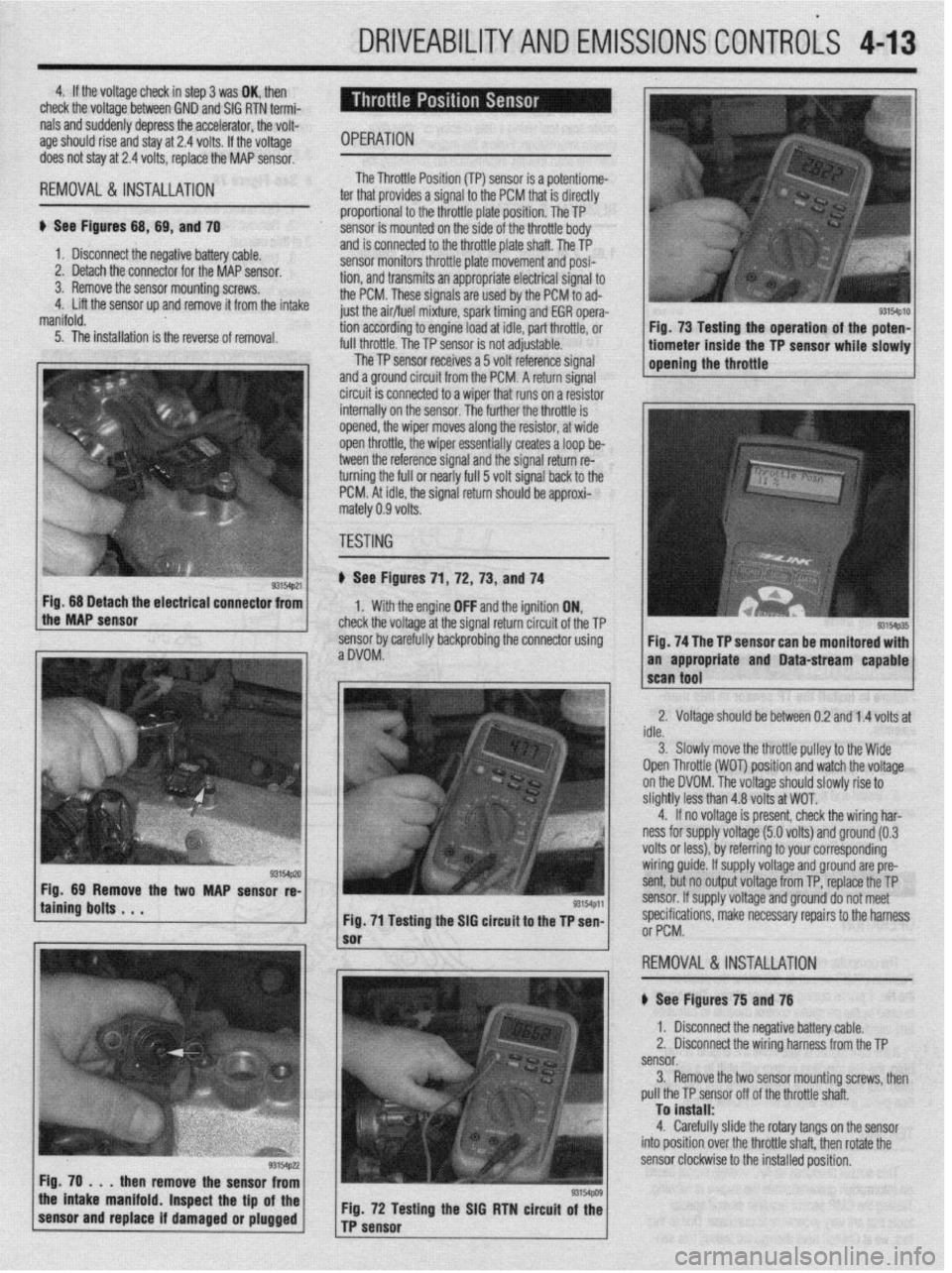

4. If the voltaoe check in sbo 3 was OK. then

check the voltage-between GND’and SIG RTN termi-

nals and suddenly depress the accelerator, the volt-

age should rise and stay at 2.4 volts. If the voltage

OPERATION does not stay at 2.4 volts, replace the MAP sensor.

REMOVAL&INSTALLATION '

ti See Figures 68, 69, and 70

1. Disconnect the negative bat lery cable.

2. Detach the connector for thl e MAP sensor.

3. Remove the sensor mountir ig screws.

4. Lift the sensor up and remove it from the intake

manifold. The Throttle Posii

ti-* \*. Inn ITPl smsnr is 8 Dotentiome- , WI...,". *., . ter that provides a si gnal to the PCM that is directly

proportion: il to the throttle plate position. The TP

sensor is rr iounted on the side of the throttle body

and is connected to the throttle plate shaft. The TP

sensor monitors throttle plate movement and posi-

tion, and transmits an appropriate electrical signal to

the PCM. These signals grp IIQX-I hv rho PCM to ad-

just the air/flnI mivtlI “-- ------li

5. The installation is the reverse of removal. WI I dLfUl U full throttle The TP c

UyI ,,,,,,,:re, spark timing and EGR opera-

ng to engine load at idle, part throttle, or

The TP sensor is not adjustable.

..-

lensor receives a 5 volt reference signal

and a ground circuit from the PCM. A return signal

circuit is connected to a wiper that runs on a resistor

internally on the sensnr ThP fmth@r rho throttle is

opined the winnr mr oP -*lY”, .I,” ..,y’V, 111 Jves along the resistor, at wide

en throttle, the wiper essentially creates a loop be-

tween the reference signal and the signal return re-

turning the full or nearly full 5 volt signal back to the

PCM. At idle, the signal return should be approxi-

rnz

rtely 0.9 volts.

TF

iSTING

) See Figures 71 ,72, 73, and 74

1. With the engine OFF and the ignition ON,

check the voltage at the signal return circuit of the TP

sensor bv carefullv backorobina the connector using

aDVOM: . ” Fig. 68 Detach the electrical connector from

the MAP sensor

taining bolts . . . WMp,l

Fig. 71 Testing the SIG circuit to the TP sen-

then remove the sensor from

the intake manifold. Inspect the tip of the

sensor and replace if damaged or plugged Fig. 72 Testing the SIG RTN circuit of the

TP sensor

sm4p10 I Fig. 73 Testing the operation of the poten- 1

tiometer inside the TP sensor while slowly 1

opening the throttle

Fig. 74 The TP sensor can be monitored with

an appropriate and Data-stream capable

2. Voltage should be between 0.2 and 1.4 volts at

idle.

3. Slowlv move the throttle oullev to the Wide

Open Throttle (WOT) position and watch the voltage

on the DVOM. The voltage should slowly rise to

slightly less than 4.8 volts at WOT.

4. If no voltage is present, check the wiring har-

ness for supply voltage (5.0 volts) and ground (0.3

volts or less), by referring to your corresponding

wiring guide. If supply voltage and ground are pre-

sent, but no output voltage from TP, replace the TP

sensor. If supply voltage and ground do not meet

specifications, make necessarv reoairs to the harness

or PCM.

,

REMOVAL&INSTALLATION

# See Figures 75 and 76

1. Disconnect the negative battery cable.

2. Disconnect the wiring harness from the TP

sensor.

3. Remove the two sensor mounting screws, then

pull the TP sensor off of the throttle shaft.

To install:

4. Carefully slide the rotary tangs on the sensor

into position over the throttle shaft. then rotate the

sensor clockwise to the installed position.

Page 161 of 408

.

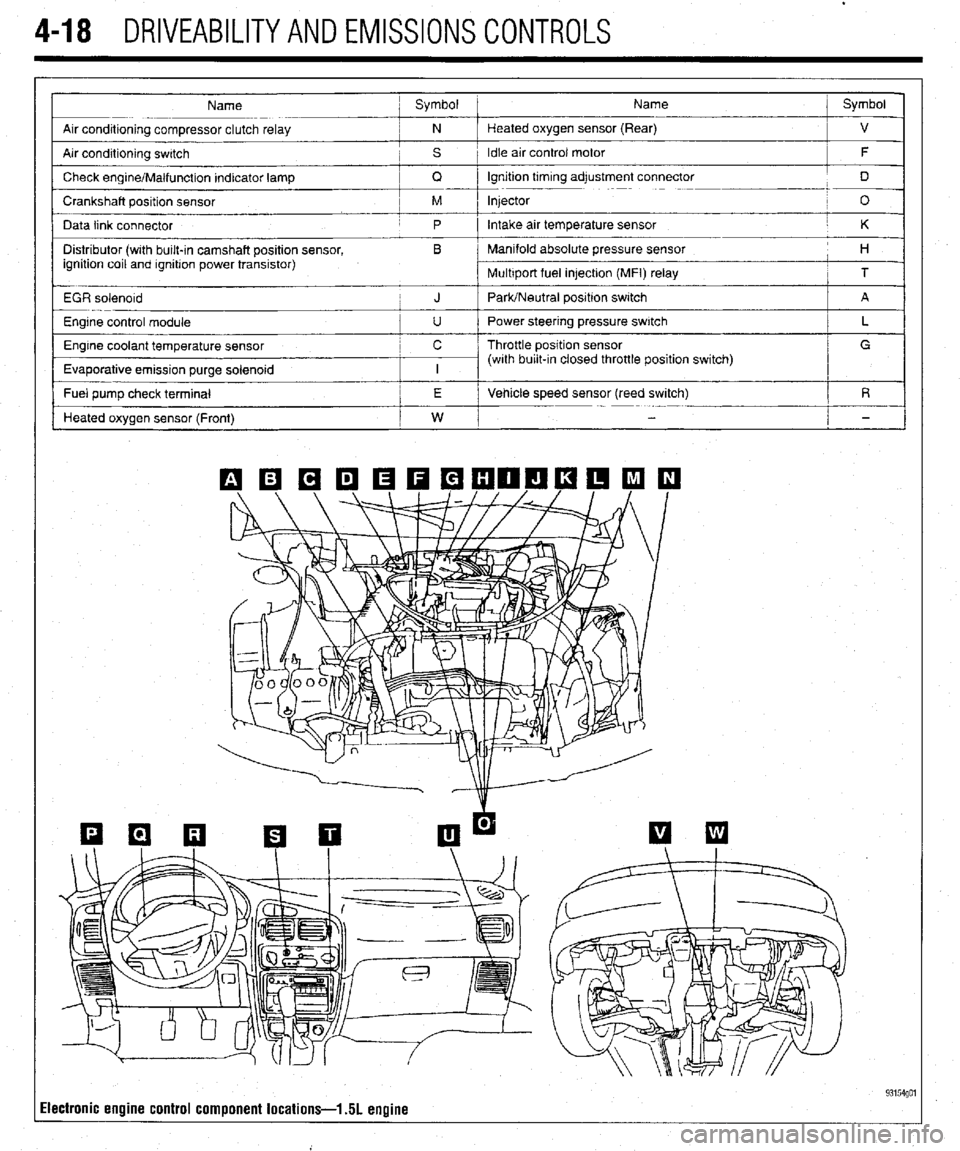

4-18 DRIVEABILITYAND EMISSIONS CONTROLS

Name ; Symbol Name j Symbol

I

Arr conditioning compressor clutch relay ; N Heated oxygen sensor (Rear)

j ”

Air condrtioning swatch , s 1 Idle air control motor

/ F

/

Check engrne/Malfunction Indicator lamp

/ Q lgnrtion trmrng adjustment connector

j D

Crankshaft position sensor / M Injector

! O

Data link connector

j p Intake air temperature sensor / K

Distributor (wrth bulk-in camshaft position sensor, , B Manifold absolute pressure sensor

ignition coil and rgnrtron power transistor) I 1 H

Multrport fuel in]ectron (MFI) relay

i T

EGR solenord

i J PaWNeutral positron switch j A

Engine control module

I u I Power steering pressure switch

Engine coolant temperature sensor c / Throttle position sensor

Evaporative emission purge solenoid

I I I (with burl&In closed throttle position switch) / L _

/ G

I

I

- Fuel pump check terminal /

I j E i Vehicle speed sensor (reed switch)

/ R

Heated oxygen sensor (Front)

I w I

i -

Ilectronic engine control component locations-l 51 engine 93154go1

Page 162 of 408

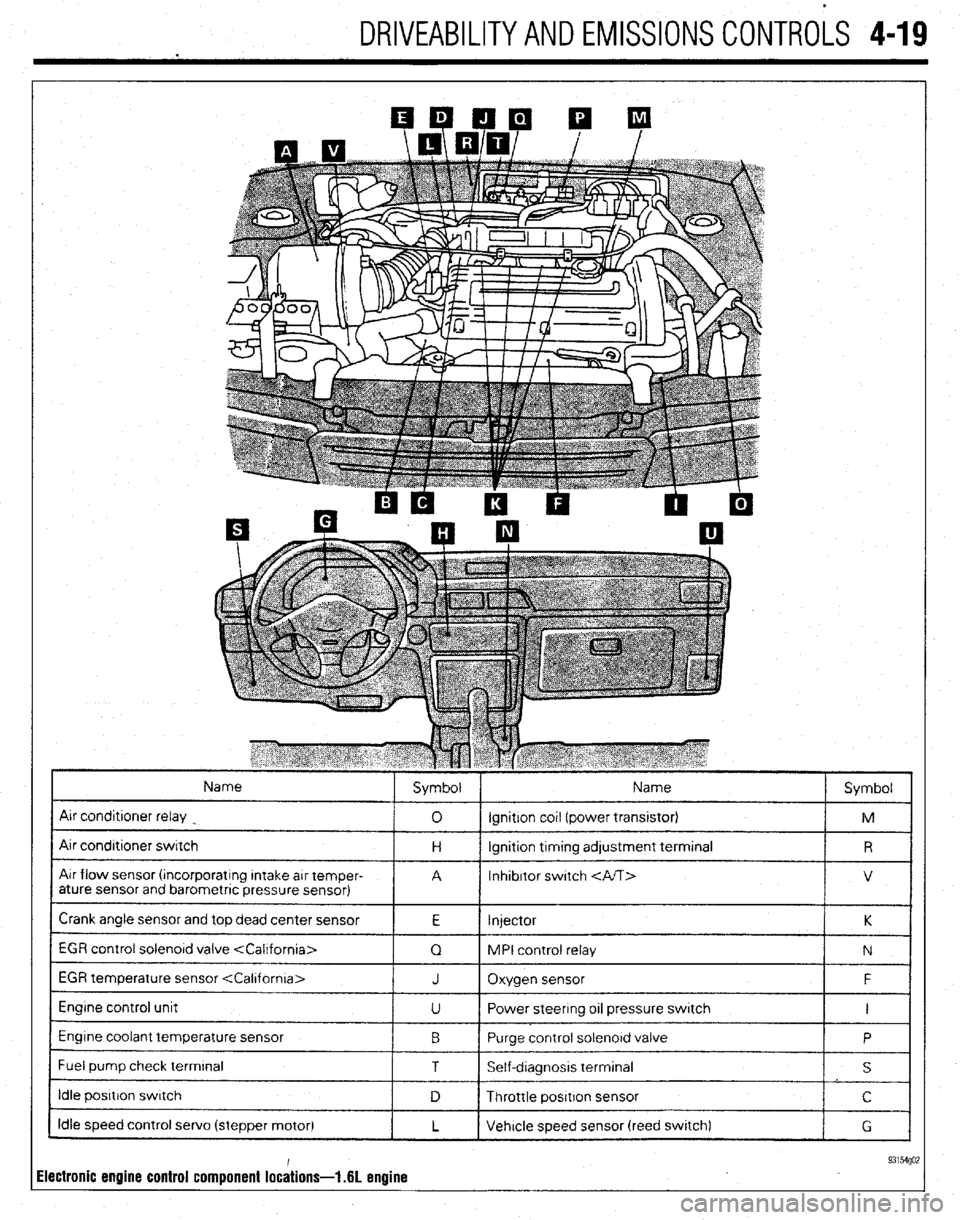

DRIVEABILITYAND EMISSIONS CONTROLS 4-19

Name

Air conditroner relay

Air condrtroner switch

Air flow sensor (rncorporatrng Intake arr temper-

ature sensor and barometric pressure sensor) Symbol Name

Symbol

0 ignition cot1 (power transrstor)

M

H lgnrtion trmtng adjustment terminal

R

A Inhibitor switch

V

Crank angle sensor and top dead center sensor

E Injector K

1 EGR control solenord valve

1 Q 1 MPI control relay

1 N 1

EGR temperature sensor

Engine control unit

Engine coolant temperature sensor

I Fuel pump check terminal J Oxygen sensor F

U Power steering 011 pressure switch I

0 Purge control solenord valve

P

1 T I Self-dragnosis terminal

I s I

I idle posrtron swatch

1 D 1 Throttle positron sensor I c I

Idle speed control servo (stepper motor)

L Vehicle speed sensor (reed swatch)

G

ilectronic engine control component lochions- .6L enuine 93154go;

Page 163 of 408

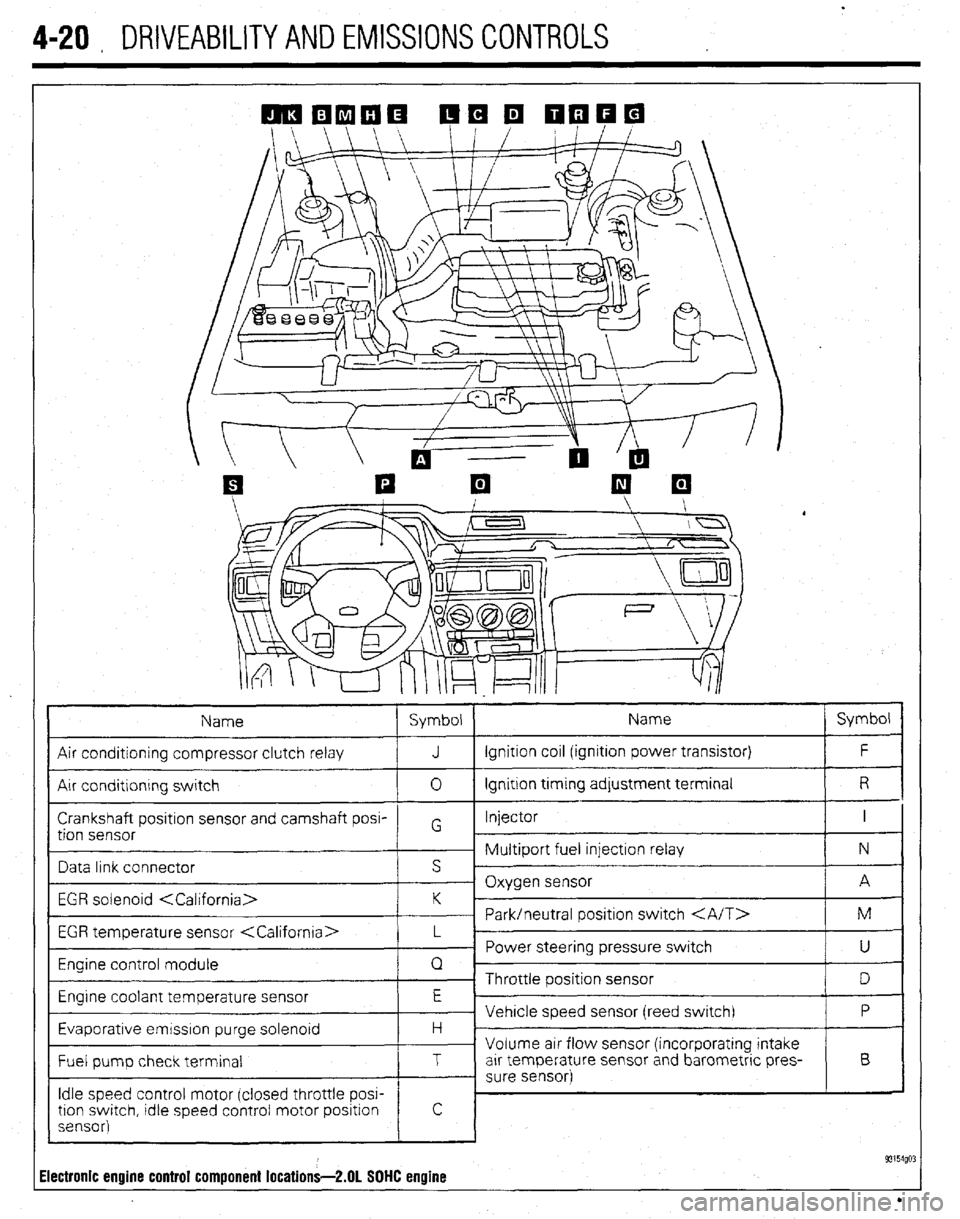

4-20 , DRIVEABILITYAND EMISSIONS CONTROLS

Name Symbol Name Symbol

Air conditioning compressor clutch relay J Ignition coil (ignition power transistor) F

Air conditlonrng switch 0 Ignition trming adjustment terminal R

Crankshaft positron sensor and camshaft posi- Injector I

tion sensor G

~ Multiport fuel injection relay N

Data link connector s ’

- Oxygen sensor A

EGR solenoid

~ Park/neutral positron switch M

EGR temperature sensor

_ Power steering pressure switch

U

Engine control module Q

~ Throttle position sensor

D

Engrne coolant temperature sensor E

Vehicle speed sensor (reed switch) P

Evaporative emrsslon purge solenoid H -

Volume air flow sensor (incorporating intake

Fuel pump check terminal T arr temperature sensor and barometric pres- B

- sure sensor)

Idle speed control motor (closed throttle POW

tron swatch, tdle speed control motor positron

sensor)

! c

93154go: Electronic engine control component locations-2.01 SOHC engine