check engine MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 281 of 408

7-2 'DRIVETRAIN

Because of the way an internal combustron engine

breathes, it can produce torque, or twisting force,

only within a narrow speed range. Most modern,

overhead valve pushrod engines must turn at about

2500 rpm to produce their peak torque By 4500 rpm

they are producrng so lrttle torque that contrnued in-

creases in engine speed produce no power increases.

The torque peak on overhead camshaft engines IS

generally much higher, but much narrower.

The manual transaxle and clutch are employed to

vary the relationship between engine speed and the

speed of the wheels so that adequate engine power can

be produced under all crrcumstances. The clutch al-

lows engine torque to be applied to the transaxle input

shaft gradually, due to mechanical slippage. Conse-

quently, the vehicle may be started smoothly from a

full stop The transaxle changes the ratio between the

rotating speeds of the engine and the wheels by the

use of gears. The gear ratios allow full engine power to

be applied to the wheels during acceleration at low

speeds and at highway/passing speeds.

In a front wheel drive transaxle, power is usually

transmitted from the input shaft to a mainshaft or out-

put shaft located slightly beneath and to the side of

the input shaft. The gears of the mainshaft mesh with

gears on the input shaft, allowing power to be carried

from one to the other. All forward gears are in con-

stant mesh and are free from rotating with the shaft

unless the synchronizer and clutch IS engaged. Shaft-

ing from one gear to the next causes one of the gears

to be freed from rotating with the shaft and locks an-

other to it. Gears are locked and unlocked by internal

dog clutches which slide between the center of the

gear and the shaft. The forward gears employ syn-

chronizers; friction members which smoothly bring

gear and shaft to the same speed before the toothed

dog clutches are engaged.

SHIFT LINKAGE

1. Disconnect the shift linkage from the transaxle.

2. On the transaxle, put select lever in N and

move the shift lever in

4th gear. Depress the clutch,

if necessary, to shift.

3. Move the shift lever in the vehicle to the

4th gear position until it contacts the stop.

4. Turn the adjuster turnbuckle so the shift cable

eye aligns with the eye in the gear shift lever. When

installing the cable eye, make sure the flange side of

the plastic bushing at the shift cable end is on the

cotter pin side.

5 The cables should be adjusted so the clear-

ance between the shift lever and the 2 stoppers are

equal when the shift lever IS moved to 3rd and 4th

gear. Move the shift lever to each positron and check i

that the shifting is smooth

REMOVAL &INSTALLATION

1, Disconnect the negative battery cable 2. Remove any components necessary to access

the back-up light switch.

3. Unplug the back-up light switch connector.

4. Remove the switch from the case using the ap-

propriate size socket and drive tool.

To install: 5. Install the switch and tighten it to 22-25 ft. Ibs.

(30-35 Nm).

6. Attach the back-up light switch connector

7. Install any components removed to access the

back-up light switch

8. Connect the negative battery cable.

REMOVAL & INSTALLATION

Mirage

*If the vehicle is going to be roiled while the

halfshafts are out of the vehicle, obtain 2 outer

CV-joints or proper equivalent tools and install

to the hubs. If the vehicle is rolled without the

proper torque applied to the front wheel bear-

ings, the bearings will no longer be usable.

*The suspension components should not be

tightened until the vehicles weight is resting

on the ground.

1. Remove the battery and battery tray.

2. Remove the air cleaner assembly and vacuum

hoses.

3. Note the locations and disconnect the shifter

cables.

4. If equipped with 1.61 engine, remove the ten-

sion rod.

5. Detach the backup lamp switch connector,

speedometer cable connection and remove the starter

motor.

6. Raise the vehicle and support safely.

7. Remove the front wheels and the inner wheel

panels.

8. Remove the undercover and splash pan.

9. Drain the transaxle oil into a suitable con-

tainer

10. Support the engine and remove the cross-

member.

11. Remove the upper transaxle mounting bolt

and bracket.

12 Disconnect the stabilizer bar, tie rod ends and

the lower ball joint connections.

13 Remove the clutch release cylinder and clutch

oil line bracket. Do not disconnect the fluid lines and

secure the slave cylinder with wire.

14 Disconnect the clutch cable, if equipped with

cable controlled clutch system.

15. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle. Do not pull on the

driveshaft Doing so damages the inboard joint. Do

not insert the prybar so far the oil seal in the case is

damaged.

*It is not necessary to disconnect the half-

shafts from the steering knuckle. Remove the

shaft with the hub and knuckle as an assem-

bly. Tie the shafts aside. Note the circle clip

on the end of the inboard shafts should not

be reused.

16. Remove the bellhousing lower cover.

17 Remove the transaxle to engine bolts and

lower the transaxle from the vehrcle.

To install:

*When installing the transaxle, be sure to

align the splines of the transaxle with the

clutch disc.

18 Install the transaxle to the engine and install

the mounting bolts. Tighten the bolts to 31-40 ft. Ibs.

(43-55 Nm) on 1990-92 models and 35 ft. Ibs. (48

Nm) on 1993-00 models.

19 Install the bellhousing cover.

*When installing the halfshafts, use new

circlips on the axle ends. Care must be taken

to ensure that the oil seal lip of the transaxle

is not damaged by the serrated part of the

driveshaft.

20. Install and fully seat the halfshafts into the

transaxle.

21. Install the slave cylinder.

22. Connect the ball joints, tie rod ends and the

stabilizer bar connections.

23. Install the upper transaxle mounting bracket

and bolt.

24. Install the crossmember.

25. Install the undercover.

26. Install the upper transaxle-to-engine mount-

ing bolts, Tighten the bolts to 31-40 ft. Ibs. (43-55

Nm) on 199C-92 models and 35 ff. Ibs. (48 Nm) on

1993-00 models.

27. Install the starter motor.

28 Connect the backup light switch connector

and speedometer cable.

29 Connect and adjust the shifter cables.

30 Install the air cleaner assembly.

31. Install the front wheels.

32 Make sure the vehicle is level when refilling

the transaxle Use Hypoid gear oil or equivalent, GL-

4 or higher.

33. Connect the negative battery cable and check

the transaxle for proper operation. Make sure the re-

verse lights operate when in reverse.

Galant

1999-93 MODELS

rlf the vehicle is going to be rolled on its

wheels while the halfshafts are out of the ve-

hicle, obtain two outer CV-joints or proper

equivalent tools and install to the hubs. If the

vehicle is rolled without the proper torque

applied to the front wheel bearings, the bear-

ings will no longer be usable.

1. Remove the battery and the air intake hoses.

2. If equipped with Active-ECS, unplug the

compressor wiring.

3. Remove the auto-cruise actuator and under-

hood bracket, located on the passenger side inner

fender well.

4. Drain the transaxle and transfer case fluid, if

equipped, into a suitable waste container.

5. Remove the retainer bolt and pull the

speedometer cable from the transaxle assembly.

6. Remove the cotter pin securing the select and

shift cables and remove the cable ends from the

transaxle.

Page 282 of 408

DRIVETRAIN 7-3

7. Remove the connection for the clutch release

38. Install the battery.

bolt to 54 ft. Ibs. (73 Nm). Install the front engine roll

cylinder and without disconnecting the hydraulic line,

39. If equipped with Active-ECS, connect the air

stopper through-bolt and hand-tighten. Once the full

and secure it aside.

compressor.

weight of the engine is on the mounts, tighten the

8. Disconnect the backup light switch harness

40. Make sure the vehicle is level when refilling

bolt to 42 ft. Ibs. (57 Nm).

and position aside.

the transaxle. Use Hypoid gear oil or equivalent, GL-

30.

Install the triangular stay bracket and tighten

9. Detach the starter electrical connections, if

4 or higher.

the mounting bolts to 65 ft. Ibs. (88 Nm).

necessary, remove the starter motor and position

41. Check the transaxle and transfer case for

31. Connect the clutch release cylinder.

aside.

proper operation. Make sure the reverse lights come

32. Install the halfshafts, using new circlips on

10. Remove the transaxle mount bracket.

on when in reverse.

the axle ends.

11. Remove the upper transaxle mounting bolts.

12.

Raise the vehicle and support safely on jack-

1!I94-Ol? MODELS

stands.

13. Remove the undercover and the front wheels. 1. Disconnect the negative battery cable and When histalling the axleshaft, keep the in-

14.

Remove the cotter pin and disconnect the tie wait at least 90 seconds before performing any work. board joint straight in relation to the axle, so

rod end from the steering knuckle. 2. Remove the air cleaner and intake hoses. not to damage the oil seal lip of the

15. Remove the self-locking nut from the half- 3. Drain the transaxle into a suitable waste con- transaxle, with the serrated part of the half-

ShaftS. tainer. shaft.

16.

Disconnect the lower arm ball joint from the 4. Remove the cotter pins and clips securing the

steering knuckle. select and shift cables and remove the cable ends 33. Connect the tie rod and ball joints to the steer-

17. Remove the halfshafts from the transaxle. from the transaxle. ing knuckle. Tighten the ball joint self-locking nuts to

18. On AWD models, disconnect the front ex- 5. If equipped with Active-ECS, disconnect the 48 ft. Ibs. (65 Nm). Tighten the tie rod end nut to 21 ft.

haust pipe. air compressor. Ibs. (28 Nm) and secure with a new cotter pin.

19.

On AWD ‘models, remove the transfer case by 6. Disconnect the backup light switch harness 34.

Connect the damper fork to the lower control

removing the attaching bolts, moving the transfer and position aside. arm and tighten the through-bolt to 65 ft. Ibs. (88 Nm).

case to the left and lowering the front side. Remove it 7. Disconnect the speedometer electrical con- 35.

Connect the stabilizer link to the damper fork,

from the rear driveshaft. Be careful of the oil seal. Do nectar, from the transaxle assembly. and tighten the self-locking nut to 29 ft. Ibs. (39 Nm).

not allow the driveshaft to hang; once the front is re- 8. Remove the starter motor and position aside. 36. Install the underpan.

moved from the transfer, tie it up. Cover the transfer 9. Using special tool M2203827 or equivalent, 37. Install wheels and lower vehicle.

case openings to keep out dirt. support the engine assembly. 38. Install the transaxle mount bracket to the

20.

Remove the cover from the transaxle bell- 10. Remove the rear roll stopper mounting transaxle, and tighten the mounting nuts to 32 ft. Ibs.

housing. bracket. (43 Nm).

21. On AWD models, remove the crossmember 11. Remove the transaxle mount bracket. 39. install the rear roll stopper mounting bracket.

and the triangular gusset. 12. Remove the upper transaxle mounting bolts. 40.

Remove the engine support. Tighten the

22. Remove the transaxle lower coupling bolt. It 13. Raise and safely support the vehicle. transaxle mount through-bolt to 51 ft. Ibs. (69 Nm)

is just above the halfshaft opening on FWD or trans- 14. Remove the front wheel assemblies. and tighten the front engine roll stopper through-bolt.

fer case opening on AWD. 15. Remove the right hand undercover. 41. Install the upper transaxle mounting bolts

23.

Support the weight of the engine from above 16. Remove the cotter pin and disconnect the tie and tighten to 35 ft. Ibs. (48 Nm).

(chain hoist). Support the transaxle using a transmis- rod end, from the steering knuckle. 42. Install the starter motor.

sion jack and remove the remaining lower mounting 17. Disconnect the stabilizer bar link, from the 43. Attach the backup light switch and the

bolts. damper fork. speedometer connector.

24. On turbocharged vehicle, be careful not to 18. Disconnect the damper fork, from the lateral 44.

Connect the select and shift cables and install

damage the lower radiator hose with the transaxle lower control arm. new cotter pins.

housing during removal. Wrap tape on both the lower 19. Disconnect the later lower arm, and the com- 45.

Install the air cleaner and the air intake hose.

hose and the transaxle housing to prevent damage. pression arm, lower ball joints, from the steering 46. Connect the negative battery cable.

Move the transaxle assembly to the right and care- knuckle. 47. Make sure the vehicle is level, and refill the

fully lower it from the vehicle. 20. Pry the halfshafts from the transaxle, and se- transaxle.

To install: cure aside. 48.

Check the transaxle for proper operation. Make

25.

Install the transaxle to the engine and install 21. Remove the connection for the clutch release sure the reverse lights come on when in reverse.

the mounting bolts, Tighten the bolts to 35 ft. Ibs. (48 cylinder and without disconnecting the hydraulic line,

Nm). Install the transaxle lower coupling bolt. secure aside.

26.

Install the underpan, crossmember and the 22. Remove the cover from the transaxle bell-

triangular gusset. housing.

27.

Install the transfer case on AWD models and 23. Remove the engine front roll stopper REMOVAL&INSTALLATION

connect the exhaust pipe. through-bolt.

28.

Install the halfshafts, using new circlips on 24. Remove the crossmember and the triangular ) See Figures 1 thru 13

the axle ends. Try to keep the inboard joint straight in right hand stay.

relation to the axle. Be careful not to damage the oil 25. Support the transaxle, using a transmission

seal lip of the transaxle with the serrated part of the jack, and remove the transaxle lower coupling bolt.

halfshaft.

29. Connect the tie rod and ball joint to the steer- *The coupling bolt threads from the englne

side, into the transaxle, and is located just

ing knuckle.

30. Install the transaxle mount bracket. above the halfshaft opening.

31. Install wheels and lower vehicle. Retorque 26. Slide the transaxle rearward and carefully

axle shaft nuts to 145-188 ft. Ibs. (200-260 Nm). lower it from the vehicle.

32. Install the starter motor. To install:

33. Connect the backup light switch and the 27. Install the transaxle to the engine. Install the

speedometer cable. mounting bolts and tighten to 35 ft. Ibs. (48 Nm). In-

34. Install the clutch release cylinder. stall the transaxle lower coupling bolt and tighten to

35.

Connect the select and shift cables and install 22-25 ft. Ibs. (30-34 Nm).

new cotter pins. 28. Install the cover to the transaxle bellhousing

36. Install the air intake hose. and tighten the mounting bolts to 7 ft. Ibs. (9 Nm).

37. Install the auto-cruise actuator and bracket. 29. Install the crossmember and tighten the front

mounting bolts to 65 ft. Ibs. (88 Nm) and the rear

Page 284 of 408

DRIVETRAIN 7-5

1, While the vehicle is still on the ground, re- IO. Insert the halfshaft into the tram&e. Be sure cle is being serviced could make a difference in joint

move the cotter pin, and loosen the axle nut. it is fully seated. type. Be sure to properly identify the joint before at-

2. Raise the vehicle and support it safely. 1 I. Pull the strut assembly out and install the tempting joint or boot replacement. Look for identifi-

3. If equipped with ABS, remove the front wheel other end to the hub. cation numbers at the large end of the boots and/or

speed sensor. 12. Install the center bearing bracket bolts and on the end of the metal retainer bands.

4. If equipped with Active Electronic Control tighten to 33 ft. Ibs. (45 Nm). The 3 types of joints used are the Birfield Joint,

Suspension (Active-ECS), perform the following: 13. Install the washer on the axle shaft so the (B.J.), the Tripod Joint (T.J.) and the Double Offset

a. Loosen the nut that secures the air line to chamfered edge faces outward. Install the axle nut, Joint (D.O.J.).

the to the top of the strut and discard the O-ring.

b. Remove the bolts that secure the actuator but do not tighten it fully at this time.

14. Connect the ball joint to the steering knuckle. *Do not disassemble a Birfield joint. Ser-

to.the top of the strut and remove the compo-

Torque the new retaining nut to 43-52 ft. Ibs. (68-72 vice with a new joint or clean and repack us-

nent. Disconnect the wiring harness.

Nm) and secure with a new cotter pin. ing a new boot kit.

5. Disconnect the lower ball joint and the tie rod

15. Connect the tie rod end to the steering

The distance between the large and small boot

end from the steering knuckle.

knuckle. Torque the retaining nut to 21 ft. Ibs. (29

bands is important and should be checked prior to

6. Remove the axle nut and the washer.

Nm) and secure with a new cotter pin.

and after boot service. This is so the boot will not be

7. If removing the left side axle with an inner 16. If equipped with ABS, install the front wheel

installed either too loose or too tight, which could

shaft, remove the center support bearing bracket speed sensor.

cause early wear and cracking, allowing the grease to

bolts and washers. Then, remove the halfshaft by set-

17. If equipped with Active-KS, perform the fol- get out and water and dirt in, leading to early joint

ting up a puller on the outside wheel hub and push-

lowing:

failure.

ing the halfshaft from the front hub. Tap the shaft a. Install the air line with a new O-ring.

union at the joint case with a plastic hammer to re- b. Install the actuator to the top of the strut. *The drfveshaft joints use special grease;

move the halfshaft and inner shaft from the transaxle. Connect the wiring harness. do not add any grease other than that sup-

8. If removing right side axle shafts without an 18. Install the wheel and lower the vehicle to the plied with the kit.

inner shaft, remove the halfshaft by setting up a floor.

puller on the outside wheel hub and pushing the half- 19. Tighten the axle nut to 145-188 ft. Ibs.

Double Offset Joint

shaft from the front hub. After pressing the outer (200-260 Nm) and secure with a new cotter pin.

shaft, insert a prybar between the transaxle case and The Double Offset Joint (D.O.J.) is bigger than

the halfshaft and pry the shaft from the transaxle.

CV-JOINTS OVERHAUL other joints and, in these applications, is normally

*Do not pull on the shaft; doing so damages used as an inboard joint.

the inboard joint. b See Figures 14 thru 27 1. Remove the halfshaft from the vehicle.

2. Side cutter pliers can be used to cut the metal

To install: These vehicles use several different types of joints. retaining bands. Remove the boot from the joint outer

9. Replace the circlips on the ends of the half- Engine size, transaxle type, whether the joint is an in- race.

shafts. board or outboard joint, even which side of the vehi-

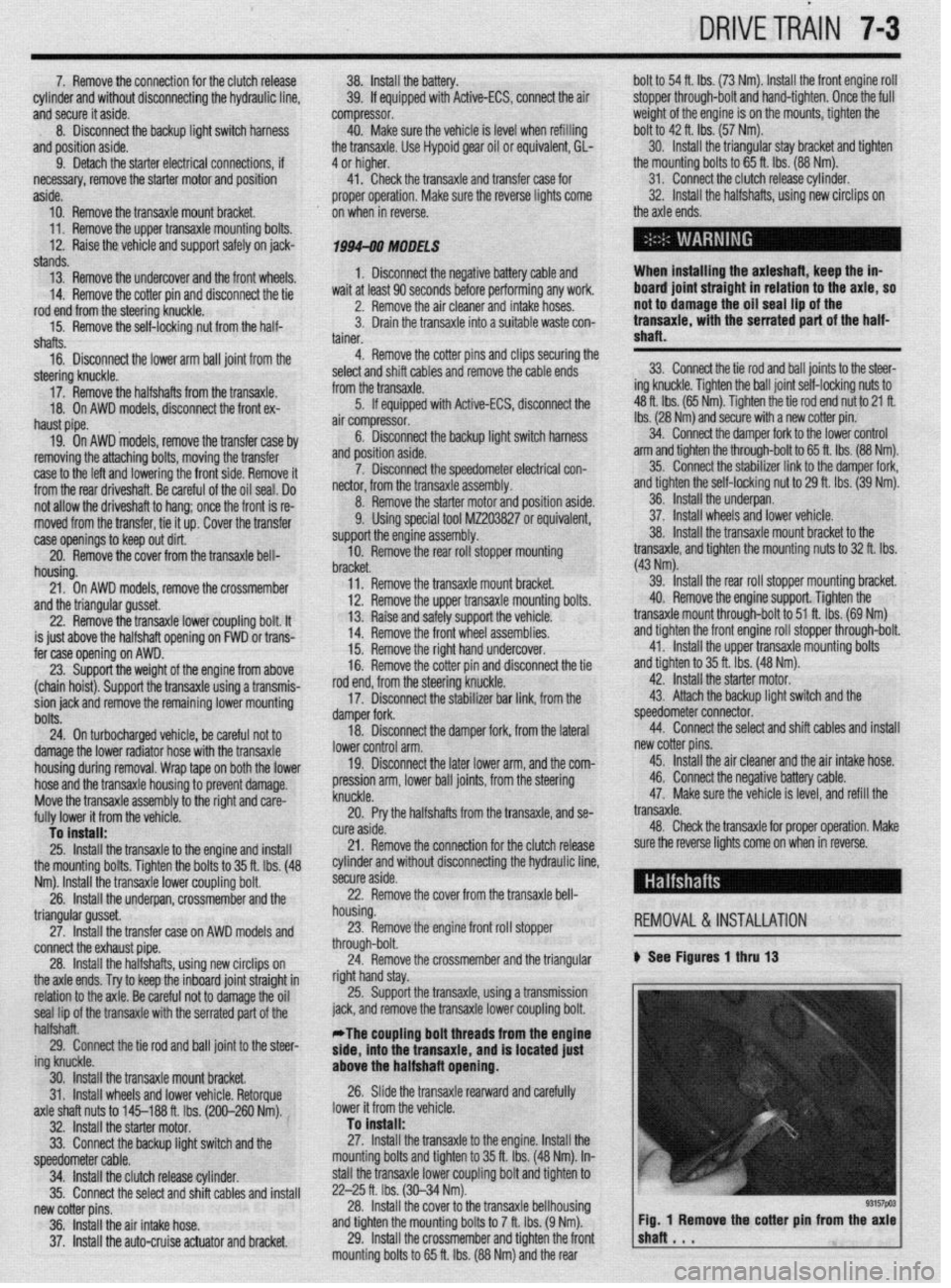

TCCS7030 TCCS7031

I I TCCS7032 Fig. 15 Removing the outer band from the

Fig. 16 Removing the inner band from the

Fig. 14 Check the CV-boot for wear

W-boot

lho~sing IFi7~ / Fig 17 Removing the CV-boot from the joint 1 1 CV-boot

TCCS7035 Fig 18 Clean the CV-joint housing prior to

removing boot Tccs7W 1 1 sembiy Fig 19 Removing the CV-joint housing as-

Page 288 of 408

DRIVETRAIN 7-9

*When adjusting the clutch pedal height or

the clutch pedal clevis pin play, be careful

not to push the pushrod toward the master

cylinder.

d. Check that when the clutch pedal is de-

pressed all the way, the interlock switch switches

over from ON to OFF.

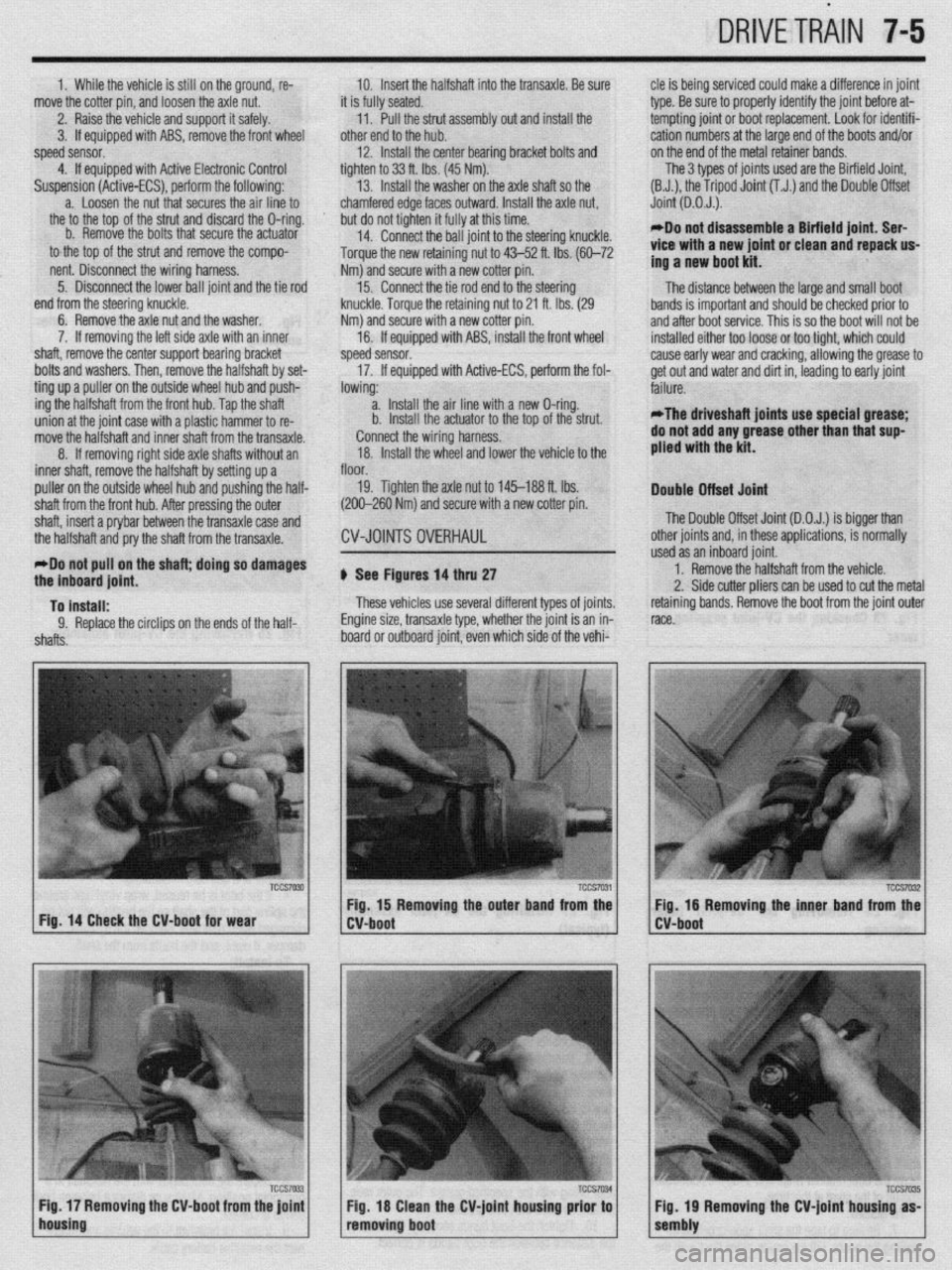

ADJUSTMENT

# See Figure 42

*The following adjustment is for the cable

actuated clutch system on the Mirage. The

Hydraulic systems on all other models are

self-adjusting.

1. Measure the clutch pedal height (measurement

A). The specificatron is 6.38-6.50 in.

(162-165mm).

*The clutch pedal height is not adjustable.

If not within specifications, part replacement

is required.

2. Depress clutch pedal several times and check

the pedal free-play (measurement B).

3. If measurement is not 0.67-0.87 in.

(17-22mm), adjustment is required.

4. To adjust, turn the outer cable adjusting nut,

located at the firewall, until free-play is within range.

5. Depress the clutch pedal several times and

recheck the measurement.

REMOVALANDINSTALLATION

1. Rotate the adjusting wheel counterclockwise to

loosen the cable.

2. Remove the cable retaining clamps.

3. Remove the cotter pin from the clutch actuat-

ing arm at the transaxle and disconnect the cable.

4. Disconnect the cable at the pedal and remove

the cable from the vehicle.

rln order to prevent cable binding or abra-

sion, be sure to take note of the cable rout-

ing, so that it can be reinstalled in the same

position.

To install:

5. Route the cable and make the connection at the

clutch pedal.

6. Make the connection at the transaxle and se-

cure the cable with the retaining clamp. Install a new

cotter pin.

7. Lubricate all pivot points.

8 Adjust the cable to achieve proper free-play.

REMOVAL &INSTALLATION

I

1. Disconnect the negative battery cable.

2. Remove necessary underhood components in

order to gain access to the clutch master cylinder.

Clutch pedal height

Fig. 42 Clutch pedal height (A) measure-

ment-Mirage

7923PGDl

3. Place a suitable drain pan under the vehicle to

catch the fluid once the line IS drsconnected, or place

a rag or shop towel under the fluid line of the master

cylinder.

4. Loosen the line at the cylinder and allow the

fluid to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a oainted surface; it will damage the paint.

5. Remove the clevis pin retainer at the clutch

pedal and remove the washer and clevis pm.

6. Remove the 2 nuts and pull the cylinder from

the firewall. A seal should be between the mounting

flange and firewall. This seal should be replaced.

7. The installation is the reverse of the removal

procedure.

8. Lubricate all pivot points with grease.

9. Bleed the system at the slave cylinder using

DOT 3 brake fluid and check the adjustment of the

clutch pedal.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable

2. Remove necessary underhood components in

order to gain access to the clutch release cylinder.

3. Place a suitable drain pan under the vehicle,

then remove the hydraulic line and allow the system

to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a uainted surface; it will damage the paint.

4. Remove the bolts and pull the cylinder from

the transaxle housing. On some 1.5L engines, in-

stead of a pushrod bearing against the clutch arm, a

clevis pin and yoke is used. Simply remove the cir-

clip, pull out the clevis pin and remove the cylinder.

5. The installation IS the reverse of the removal

procedure.

6. Lubricate all pivot points with grease.

7. Bleed the system using DOT 3 brake fluid.

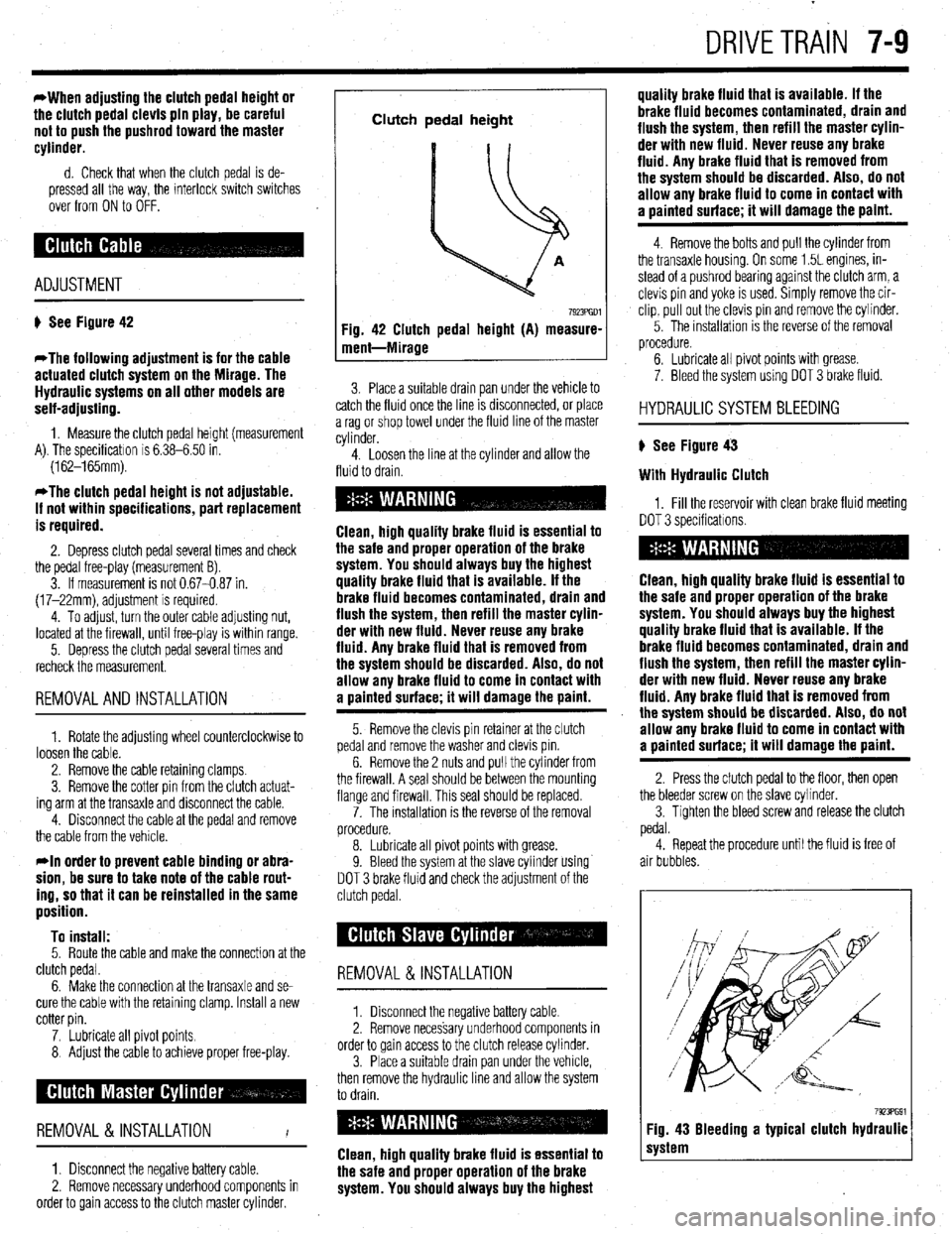

HYDRAULIC SYSTEM BLEEDING

) See Figure 43

With Hydraulic Clutch

1, Fill the reservoir with clean brake fluid meeting

DOT 3 specificatrons.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

2. Press the clutch pedal to the floor, then open

the bleeder screw on the slave cvlinder.

3. Tighten the bleed screw and release the clutch

pedal.

4. Repeat the procedure until the fluid is free of

air bubbles.

7923PG91 Fig. 43 Bleeding a typical clutch hydraulic

system

Page 289 of 408

7-10 DRIVETRAIN

The automatic transaxle allows engine torque and

power to be transmitted to the front wheels within a

narrow range of engine operating speeds. It will allow

the engine to turn fast enough to produce plenty of

power and torque at very low speeds, while keeping it

at a sensible rpm at high vehicle speeds (and it does

this job without driver assistance). The transaxle uses

a light fluid as the medium for the transmission of

power. This fluid also works in ths operation of vari-

ous hydraulic control circuits and as a lubricant. Be-

cause the transaxle fluid performs all of these func-

tions, trouble within the unit can easily travel from one

part to another For this reason, and because of the

complexity and unusual operating principles of the

transaxle, a very sound understanding of the basic

principles of operation will simplify troubleshooting

REMOVAL &INSTALLATION

Pan removal, fluid and filter

in Section 1 of this manual changes are covered

REMOVAL &INSTALLATION

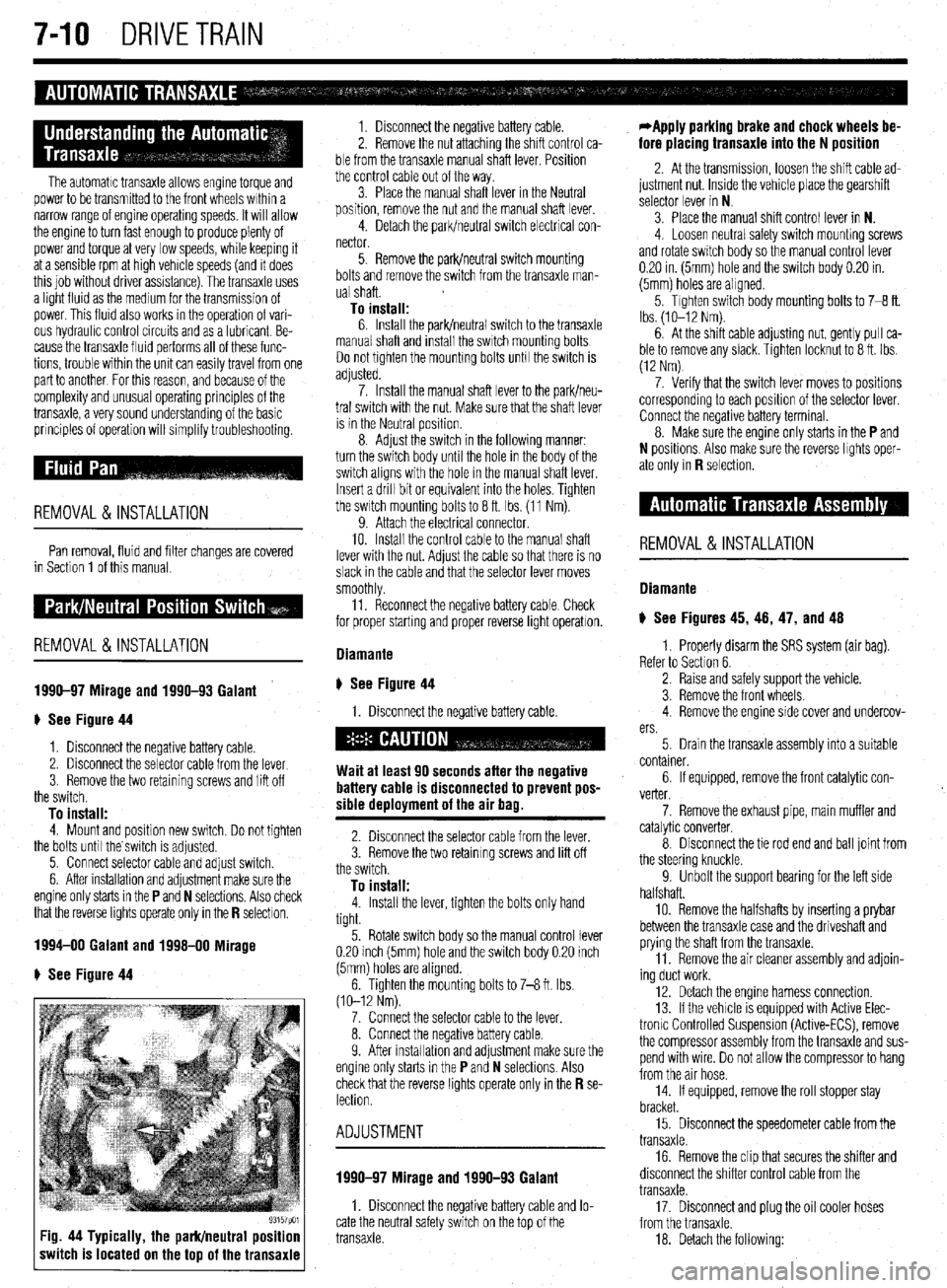

1990-97 Mirage and 1990-93 Galant

# See Figure 44

1. Disconnect the negative battery cable.

2. Disconnect the selector cable from the lever

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Mount and position new switch. Do not tighten

the bolts until the switch is adjusted.

5. Connect selector cable and adjust switch.

6. After installation and adjustment make sure the

engine only starts in the

P and N selections. Also check

that the reverse lights operate only in the R selectlon.

1994-00 Galant and 1998-00 Mirage

e See Figure 44

93157pm Fig. 44 Typically, the park/neutral position

switch is located on the top of the transaxle

1. Disconnect the negative battery cable.

2. Remove the nut attaching the shift control ca-

ble from the transaxle manual shaft lever. Position

the control cable out of the way.

3. Place the manual shaft lever in the Neutral

position, remove the nut and the manual shaft lever.

4. Detach the park/neutral switch electrical con-

nector.

5. Remove the park/neutral switch mounting

bolts and remove the switch from the transaxle man-

ual shaft.

To install: 6. Install the park/neutral switch to the transaxle

manual shaft and install the switch mounting bolts

Do not tighten the mounting bolts unh the switch is

adjusted.

7. Install the manual shaft lever to the park/neu-

tral switch with the nut. Make sure that the shaft lever

is in the Neutral position.

8. Adjust the switch in the following manner:

turn the switch body until the hole in the body of the

switch aligns with the hole in the manual shaft lever.

Insert a drill bit or equivalent into the holes. Tighten

the switch mounting bolts to 8 ft. Ibs. (11 Nm).

9. Attach the electrical connector.

10. Install the control cable to the manual shaft

lever with the nut. Adjust the cable so that there is no

slack in the cable and that the selector lever moves

smoothly

11. Reconnect the negative battery cable Check

for proper starting and proper reverse light operatron.

Diamante

ti See Figure 44

1. Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Disconnect the selector cable from the lever.

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Install the lever, tighten the bolts only hand

tight.

5. Rotate switch body so the manual control lever

0.20 inch (5mm) hole and the switch body 0.20 inch

(5mm) holes are aligned.

6. Tighten the mounting bolts to 7-8 ft. Ibs.

(10-12 Nm).

7. Connect the selector cable to the lever.

8. Connect the negative battery cable.

9. After installahon and adjustment make sure the

engine only starts in the

P and N selections. Also

check that the reverse lights operate only in the R se- lection.

ADJUSTMENT

1990-97 Mirage and 1990-93 Galant

1. Disconnect the negative battery cable and lo-

cate the neutral safety switch on the top of the

transaxle.

*Apply parking brake and chock wheels be-

fore placing transaxle into the N position

2. At the transmission, loosen the shift cable ad-

justment nut. Inside the vehicle place the gearshift

selector lever in N

3. Place the manual shift control lever in N.

4. Loosen neutral safety switch mounhng screws

and rotate switch body so the manual control lever

0.20 in. (5mm) hole and the switch body 0.20 in.

(5mm) holes are aligned.

5. Tighten switch body mounting bolts to 7-8 ft.

Ibs. (lo-12 Nm).

6. At the shift cable adjusting nut, gently pull ca-

ble to remove any slack. Tighten locknut to 8 ft. Ibs.

(12 Nm)

7. Verify that the switch lever moves to positions

corresponding to each position of the selector lever.

Connect the negative battery terminal.

8. Make sure the engine only starts in the

P and

N positions. Also make sure the reverse lights oper-

ate only in

R selection.

REMOVAL&INSTALLATION

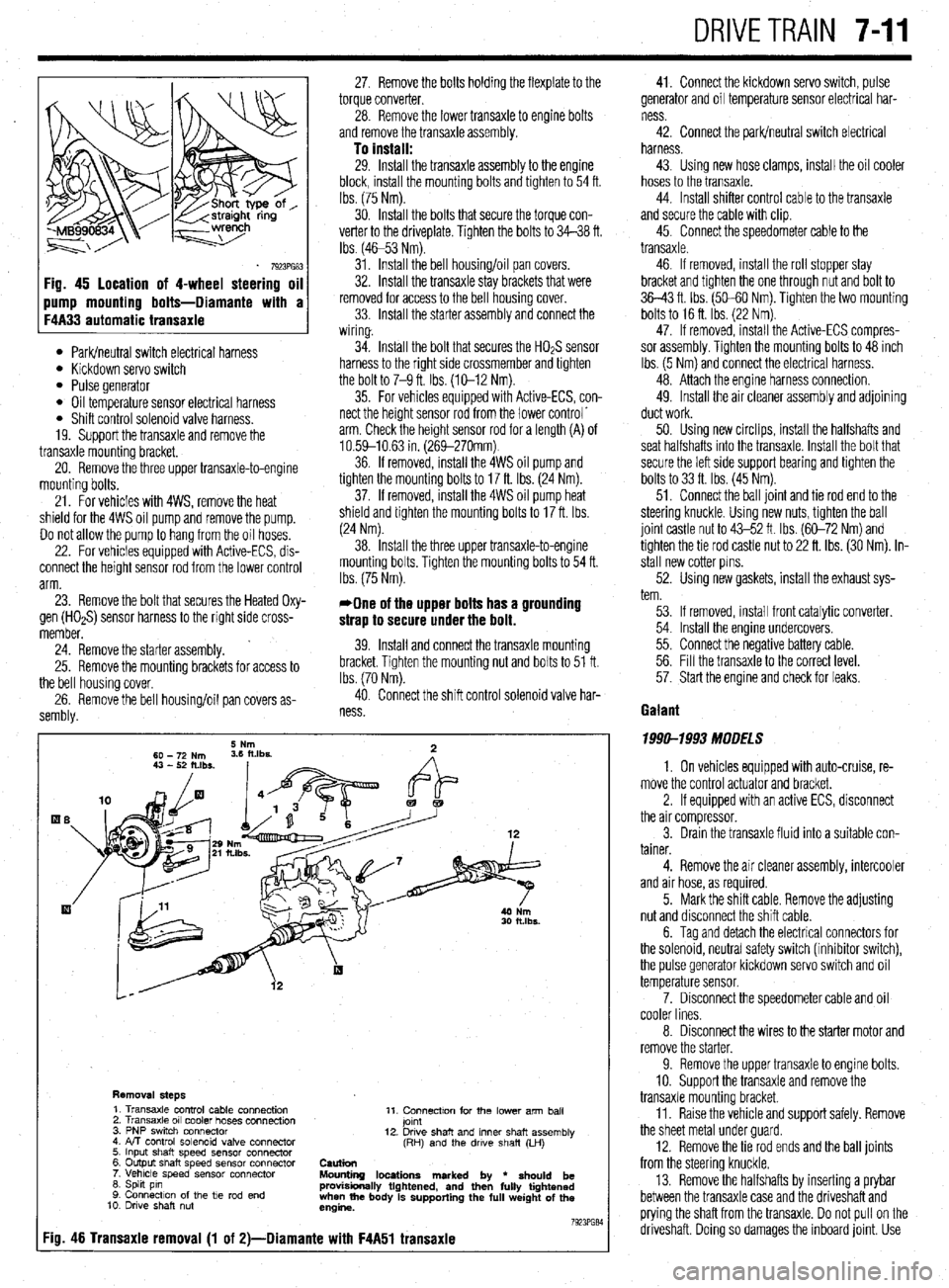

Diamante

) See Figures 45, 46, 47, and 48

1. Properly disarm the SRS system (air bag).

Refer to Section 6.

2. Raise and safely support the vehicle.

3. Remove the front wheels.

4. Remove the engine side cover and undercov-

ers.

5. Drain the transaxle assembly into a suitable

container.

6. If equipped, remove the front catalytic con-

verter.

7. Remove the exhaust pipe, main muffler and

catalytic converter.

8. Disconnect the tie rod end and ball joint from

the steering knuckle.

9. Unbolt the support bearing for the left side

halfshaft.

10. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle.

11. Remove the air cleaner assembly and adjoin-

ing duct work.

12. Detach the engine harness connection.

13. If the vehicle is equipped with Active Elec-

tronlc Controlled Suspension (Active-ECS), remove

the compressor assembly from the transaxle and sus-

pend with wire. Do not allow the compressor to hang

from the air hose.

14. If equipped, remove the roll stopper stay

bracket.

15. Disconnect the speedometer cable from the

transaxle.

16. Remove the clip that secures the shifter and

disconnect the shifter control cable from the

transaxle.

17. Disconnect and plug the oil cooler hoses

from the transaxle.

18. Detach the following:

Page 290 of 408

DRIVETRAIN 7-11

Fig. 45 location of 4-wheel steering oil

l Park/neutral switch electrical harness l Kickdown servo switch l Pulse generator l Oil temperature sensor electrical harness l Shift control solenoid valve harness.

19. Support the transaxle and remove the

transaxle mounting bracket.

20. Remove the three upper transaxle-to-engine

mounting bolts.

21. For vehicles with 4WS, remove the heat

shield for the 4WS oil pump and remove the pump.

Do not allow the pump to hang from the oil hoses.

22. For vehicles equipped with Active-ECS, dis-

connect the height sensor rod from the lower control

arm.

23. Remove the bolt that secures the Heated Oxy-

gen (HOaS) sensor harness to the right side cross-

member.

’ 24. Remove the starter assembly.

25. Remove the mounting brackets for access to

the bell housing cover,

26. Remove the bell housing/oil pan covers as-

sembly. 27. Remove the bolts holding the flexplate to the

torque converter.

28. Remove the lower transaxle to engine bolts

and remove the transaxle assembly.

To install: 29. Install the transaxle assembly to the engine

block, install the mounting bolts and tighten to 54 ft.

tbs. (75 Nm).

30. Install the bolts that secure the torque con-

verter to the driveplate. Tighten the bolts to 34-38 ft.

Ibs (4653 Nm).

31. Install the bell housing/oil pan covers.

32. Install the transaxle stay brackets that were

removed for access to the bell housing cover.

33. Install the starter assembly and connect the

wiring.

34. Install the bolt that secures the HO& sensor

harness to the right side crossmember and tighten

the bolt to 7-9 ft. Ibs. (X-12 Nm).

35. For vehicles equipped with Active-ECS, con-

nect the height sensor rod from the lower control’

arm. Check the height sensor rod for a length (A) of

10.59-10.63 in. (269-270mm)

36. If removed, install the 4WS oil pump and

tighten the mounting bolts to 17 ft. Ibs. (24 Nm).

37. If removed, install the 4WS oil pump heat

shield and tighten the mounting bolts to 17 ft. Ibs.

(24 Nm).

38. Install the three upper transaxle-to-engine

mounting bolts. Tighten the mounting bolts to 54 ft.

Ibs. (75 Nm).

*One of the upper bolts has a grounding

strap to secure under the bolt.

39. Install and connect the transaxle mounting

bracket. Tighten the mounting nut and bolts to 51 ft.

Ibs. (70 Nm).

40. Connect the shift control solenoid valve har-

ness

Removal steps 1. Transaxle control cable connection

2. Transaxle 011 cooler hoses connection

3. PNP swrtch connector

4. FvT control solenoid valve connector

5. Input shaft speed sensor connector

6. Output shaft speed sensor connector

7. Vehicle speed sensor connector

6. Spht pin

9. Connection of the tie rod end

10. Drwe shaft nut 11. Connectton for the lower arm ball

jomt

12. Drwe shaft and inner shaft assembly

(RH) and the drwe shaft (LH)

Caution

Mounting locations marked by

l should be

provisionally tightened, and then fully tightened

when the body is supporting the full weight of the

engine.

7923PG84

:io. 46 Transaxie removal (1 of 2)-Diamante with F4A51 transaxie

41. Connect the kickdown servo switch, pulse

generator and oil temperature sensor electrical har-

ness

42. Connect the park/neutral switch electrical

harness.

43. Using new hose clamps, install the oil cooler

hoses to the transaxle.

44. Install shifter control cable to the transaxle

and secure the cable with clip.

45. Connect the speedometer cable to the

transaxle.

46. If removed, install the roll stopper stay

bracket and tighten the one through nut and bolt to

36-43 ft. Ibs. (50-60 Nm). Tighten the two mounting

bolts to 16 ft. Ibs. (22 Nm).

47. If removed, install the Active-ECS compres-

sor assembly. Tighten the mounting bolts to 48 inch

Ibs. (5 Nm) and connect the electrical harness.

48. Attach the engine harness connection.

49. Install the air cleaner assembly and adjoining

duct work.

50. Using new circlips, install the halfshafts and

seat halfshafts into the transaxle. Install the bolt that

secure the left side support bearing and tighten the

bolts to 33 ft. Ibs. (45 Nm).

51. Connect the ball joint and tie rod end to the

steering knuckle. Using new nuts, tighten the ball

joint castle nut to 43-52 ft. Ibs. (60-72 Nm) and

tighten the tie rod castle nut to 22 ft. ibs. (30 Nm). in-

stall new cotter pins.

52. Using new gaskets, install the exhaust sys-

tem.

53. If removed, install front catalytic converter.

54. Install the engine undercovers.

55. Connect the negative battery cable.

56. Fill the transaxle to the correct level.

57. Start the engine and check for leaks.

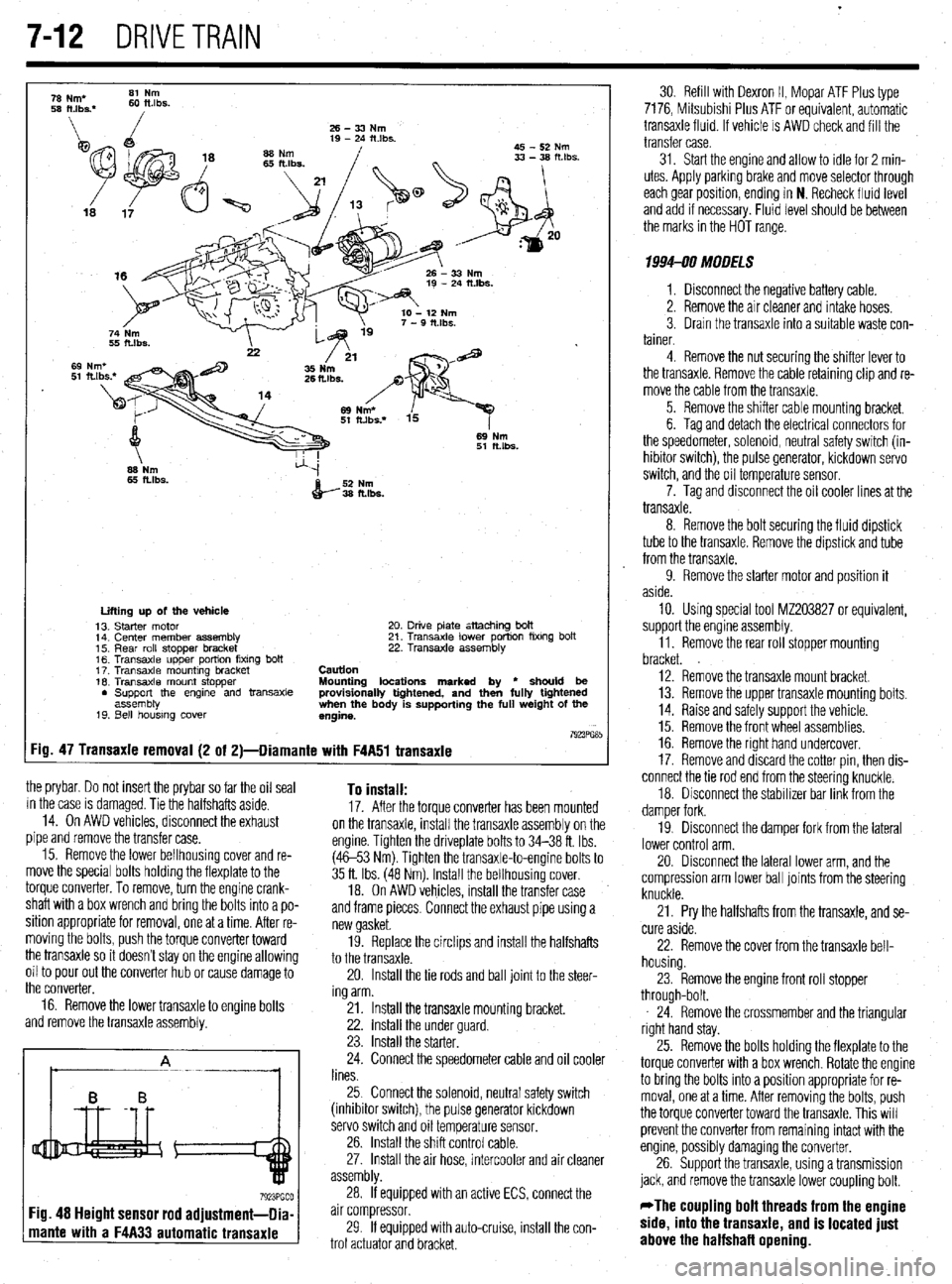

Gaiant

1999-1993 MODELS

1. On vehicles equipped with auto-cruise, re-

move the control actuator and bracket.

2. If equipped with an active ECS, disconnect

the air compressor.

3. Drain the transaxle fluid into a suitable con-

tainer.

4. Remove the air cleaner assembly, intercooler

and air hose, as required.

5. Mark the shift cable. Remove the adjusting

nut and disconnect the shift cable.

6. Tag and detach the electrical connectors for

the solenoid, neutral safety switch (inhibitor switch),

the pulse generator kickdown servo switch and oil

temperature sensor.

7. Disconnect the speedometer cable and oil

cooler lines.

8. Disconnect the wires to the starter motor and

remove the starter.

9. Remove the upper transaxle to engine bolts.

10. Support the transaxle and remove the

transaxle mounting bracket.

11. Raise the vehicle and support safely. Remove

the sheet metal under guard

12. Remove the tie rod ends and the bail joints

from the steering knuckle.

13. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle. Do not pull on the

driveshaft. Doing so damages the inboard joint. Use

Page 291 of 408

.

7-12 DRIVETRAIN

26-33Nm

19 - 24 itlbs.

45 - 52 Nm

69 Nm

51 ftlbs.

66 Nm

65 ftlbs.

52 Nm

36 fl.lbs.

:ig.

the prybar. Do not insert the prybar so far the oil seal

in the case is damaged. Tie the halfshafts aside.

14. On AWD vehicles, disconnect the exhaust

pipe and remove the transfer case.

15. Remove the lower bellhousing cover and re-

move the special bolts holding the flexplate to the

torque converter. To remove, turn the engine crank-

shaft with a box wrench and bring the bolts into a po-

sition appropriate for removal, one at a time. After re-

moving the bolts, push the torque converter toward

the transaxle so it doesn’t stay on the engine allowing

oil to pour out the converter hub or cause damage to

the converter,

16. Remove the lower transaxle to engine bolts

and remove the transaxle assembly. To install: 17. After the torque converter has been mounted

on the transaxle, install the transaxle assembly on the

engine. Tighten the driveplate bolts to 34-38 ft. Ibs.

(4653 Nm). Tighten the transaxle-to-engine bolts to

35 ft. Ibs. (48 Nm). Install the bellhousing cover.

18. On AWD vehicles, install the transfer case

and frame pieces. Connect the exhaust pipe using a

new gasket.

19. Replace the circlips and install the halfshafts

to the transaxle.

20. Install the tie rods and ball joint to the steer-

ing arm.

21. Install the transaxle mounting bracket.

22. install the under guard.

23. Install the starter.

24. Connect the speedometer cable and oil cooler

lines.

25 Connect the solenoid, neutral safety switch

(inhibitor switch), the pulse generator kickdown

servo switch and oil temperature sensor.

26. Install the shift control cable.

27. Install the air hose, intercooler and air cleaner

assembly.

If equipped with an active ECS, connect the

mante with a F4A33 automatic transaxle

30 Refill with Dexron II, Mopar ATF Plus type

7176, Mitsubishi Plus ATF or equivalent, automatic

transaxle fluid. If vehicle is AWD check and fill the

transfer case.

31. Start the engine and allow to idle for 2 min-

utes. Apply parkrng brake and move selector through

each gear posrtion, ending in N. Recheck fluid level

and add if necessary. Fluid level should be between

the marks in the HOT range.

1994-90 MODELS

1. Disconnect the negative battery cable.

2. Remove the air cleaner and intake hoses.

3. Drain the transaxle into a suitable waste con-

tainer.

4. Remove the nut securing the shifter lever to

the transaxle. Remove the cable retaining clip and re-

move the cable from the transaxle.

5. Remove the shifter cable mounting bracket,

6. Tag and detach the electrical connectors for

the speedometer, solenoid, neutral safety switch (in-

hibitor switch), the pulse generator, kickdown servo

switch, and the oil temperature sensor.

7. Tag and disconnect the oil cooler lines at the

transaxle.

8. Remove the bolt securing the fluid dipstick

tube to the transaxle. Remove the dipstrck and tube

from the transaxle.

9. Remove the starter motor and position it

aside.

10. Using special tool MZ203827 or equivalent,

support the engine assembly.

11. Remove the rear roll stopper mounting

bracket.

12. Remove the transaxle mount bracket.

13. Remove the upper transaxle mounting bolts.

14. Raise and safely support the vehicle.

15. Remove the front wheel assemblies.

16. Remove the right hand undercover.

17. Remove and discard the cotter pin, then dis-

connect the tie rod end from the steering knuckle,

18. Disconnect the stabilizer bar link from the

damper fork.

19. Disconnect the damper fork from the lateral

lower control arm.

20. Disconnect the lateral lower arm, and the

compression arm lower ball joints from the steering

knuckle.

21. Pry the halfshafts from the transaxle, and se-

cure aside.

22. Remove the cover from the transaxle bell-

housing.

23. Remove the engine front roll stopper

through-bolt.

24. Remove the crossmember and the triangular

right hand stay.

25. Remove the bolts holding the flexplate to the

torque converter with a box wrench Rotate the engine

to bring the bolts into a position appropriate for re-

moval, one at a time. After removing the bolts, push

the torque converter toward the transaxle. This will

prevent the converter from remaining intact with the

engine, possibly damaging the converter,

26. Support the transaxle, using a transmission

jack, and remove the transaxle lower coupling bolt.

*The coupling bolt threads from the engine

side, into the transaxle, and is located just

above the halfshafl opening.

Page 292 of 408

DRIVETRAIN 7-13

27. Shde the transaxle rearward and carefully

lower it from the vehicle.

To install: 28. After the torque converter has been mounted

on the transaxle, install the transaxle assembly to the

engine. Install the mounting bolts and tighten to 35

ft. Ibs. (48 Nm).

29. Install the transaxle lower coupling bolt and

tighten to 21-25 ft Ibs. (29-34 Nm).

30. Connect the torque converter to the flexplate

and tighten the bolts to 33-38 ft. Ibs. (45-52 Nm).

31. Install the cover to the transaxle bellhous-

ing and tighten the mounting bolts to 7 ft. Ibs. (9

Nm).

32 Install the crossmember and tighten the front

mounting bolts to 65 ft. Ibs (88 Nm) and the rear

bolt to 54 ft. Ibs. (73 Nm) Install the front engine roll

stopper through-bolt and lightly tighten. Once the full

weight of the engine is on the mounts, tighten the ’

bolt to 42 ft. Ibs. (57 Nm),

33. Install the triangular stay bracket and tighten

the mounting bolts to 65 ft. Ibs. (88 Nm).

34. Install the halfshafts, using new circlips on

the axle ends.

When installing the axleshaft, keep the in-

board joint straight in relation to the axle, so

as not to damage the oil seal lip of the

transaxle with the serrated part of the half-

shaft.

35. Connect the tie rod and ball joints to the

steering knuckle. Tighten the ball joint self-locking

nuts to 48 ft. Ibs. (65 Nm). Tighten the tie rod end nut

to 21 ft. Ibs. (28 Nm) and secure with a new cotter

pin.

36. Connect the damper fork to the lower control

arm and tighten the through-bolt to 65 ft Ibs. (88

Nm).

37. Connect the stabilizer link to the damper fork,

and tighten the self-locking nut to 29 ft. Ibs. (39 Nm).

38. Install the undercover.

39. Install the wheels and carefully lower the ve-

hicle

40. Install the transaxle mount bracket to the

transaxle, and tighten the mounting nuts to 32 ft. Ibs.

(43 Nm).

41. Install the rear roll stopper mounting bracket.

42. Remove the engine support. Tighten the

transaxle mount through-bolt to 51 ft. Ibs. (69 Nm)

and tighten the front engine roll stopper through-bolt.

43. Install the upper transaxle mounting bolts

and tighten to 35 fl. Ibs. (48 Nm).

44. Install the starter motor.

45. Install the dipstick tube and the dipstick

46. Install the shifter cable mounting bracket.

47. Connect the shifter lever and tighten the re-

taining nut to 14 ft. Ibs. (19 Nm).

48. Connect the oil cooler lines and secure with

clamps.

49. Attach the electrical connectors for the

speedometer, solenoid, neutral safety switch (in-,

hibitor switch), the pulse generator, kickdown servo

switch and oil temperature sensor.

50. Install the air cleaner and the air intake hose.

51. Connect the negative battery cable.

52. Make sure the vehicle is level, and refill the

transaxle. Start the engine and allow to idle for 2 minutes. Apply parking brake and move selector

through each gear position, ending in N. Recheck

fluid level and add if necessary. Fluid level should be

between the marks in the HOT range.

53. Check the transaxle for proper operation.

Make sure the reverse lights come on when in re-

verse and the engine starts only in

P or N.

Mirage

*If the vehicle is going to be rolled on its

wheels while the halfshafts are out of the ve-

hicle, obtain two outer CV-joints or proper

equivalent tools and install to the hubs. If the

vehicle is rolled without the proper torque

applied to the front wheel bearings, the bear-

ings will no longer be usable.

1. Disconnect the negative battery cable then

the positive battery cable.

2. Remove the battery and battery tray.

3. Remove the air hose and air cleaner assem-

bly.

4. Raise the vehicle and support safely.

5. Remove the under guard pan.

6. Drain the transaxle oil into a suitable con-

tainer.

7. If equipped with 1.6L engine, remove the ten-

sion rod.

8. Disconnect the control cable and cooler

lines.

9. On 3-speed transaxles, disconnect the throt-

tle control cable.

10. On 4-speed transaxles, perform the following:

a. Detach the shift control solenoid valve

connector.

b. Disconnect the inhibitor switch and kick-

down servo switch.

c. Disconnect the pulse generator and oil

temperature sensor.

11. Disconnect the speedometer cable and re-

move the starter.

12. Remove the transaxle mounting bolts and

bracket.

13. Disconnect the stabilizer bar from the lower

control arm.

14. Disconnect the steering tie rod end and the

ball joint from the steering arm.

15. Remove the halfshafts at the inboard side

from the transaxle. Tie the joint assembly aside.

*It is not necessary to disconnect the half-

shafts from the wheel hubs.

16. Support the engine and remove the center

member.

17. Remove the bellhousing cover and remove

the driveplate bolts.

18 Remove the transaxle assembly lower con-

necting bolt, located just over the halfshaft opening.

19. Properly support the transaxle assembly, then

lower it, moving it to the right for clearance.

To install: 20. After the torque converter has been mounted

on the transaxle, install the transaxle assembly on the

engine. Install the mounting bolts and tighten to

31-40 ft. Ibs. (43-55 Nm) on 1990-92 models and

35 ft. Ibs. (48 Nm) on 1993-00 models.

21. Tighten the driveplate bolts to 33-38 ft. Ibs.

(46-53 Nm). Install the bellhousing cover.

22. Install the center member. 23. Replace the circlips and install the halfshafts

to the transaxle.

24. Install the tie rods, ball joints and stabilizer

links to the steering arm

25. Install the transaxle mounting bracket and

bolts.

26. Install the starter.

27. Connect the speedometer cable.

28. Connect the inhibitor switch, kickdown servo

switch, the pulse generator and oil temperature sen-

sor, if disconnected.

29. Connect the shift control solenoid valve con-

nector.

30. Connect the control cables and oil cooler

lines.

31. Install the tension rod, if removed.

32. Install the air cleaner assembly.

33. Install the battery tray and battery.

34. Connect the positive then the negative termi-

nal.

35. Refill with Dexron@ II, Mopar ATF Plus type

7176 or equivalent, automatic transaxle fluid.

36. Start the engine and allow to idle for two min-

utes. Apply parking brake and move selector through

each gear position, ending in N. Recheck fluid level

and add if necessary. Fluid level should be between

the marks in the HOT range.

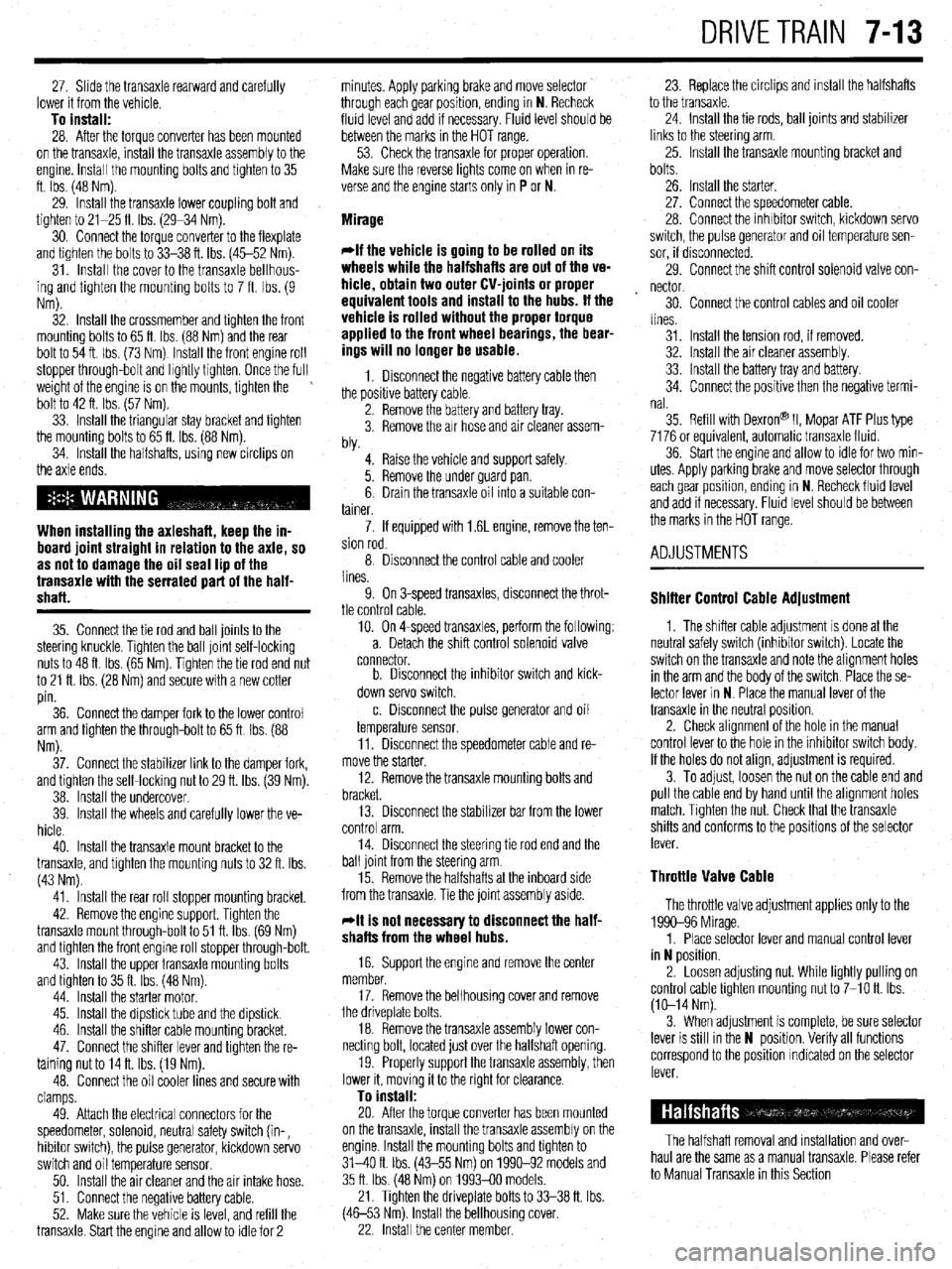

ADJUSTMENTS

Shifter Control Cable Adjustment

1. The shifter cable adjustment is done at the

neutral safety switch (inhibitor switch). Locate the

switch on the transaxle and note the alignment holes

in the arm and the body of the switch. Place the se-

lector lever in N. Place the manual lever of the

transaxle in the neutral position.

2. Check alignment of the hole in the manual

control lever to the hole in the inhibitor switch body.

If the holes do not align, adjustment is required.

3. To adjust, loosen the nut on the cable end and

pull the cable end by hand until the alignment holes

match. Tighten the nut. Check that the transaxle

shifts and conforms to the positions of the selector

lever.

Throttle Valve Cable

The throttle valve adjustment applies only to the

1990-96 Mirage.

1. Place selector lever and manual control lever

in N position.

2. Loosen adjusting nut. While lightly pulling on

control cable tighten mounting nut to 7-10 ft. Ibs.

(X-14 Nm).

3. When adjustment is complete, be sure selector

lever is still in the N position. Verify all functions

correspond to the position indicated on the selector

lever.

The halfshaft removal and installation and over-

haul are the same as a manual transaxle Please refer

to Manual Transaxle in this Section

Page 308 of 408

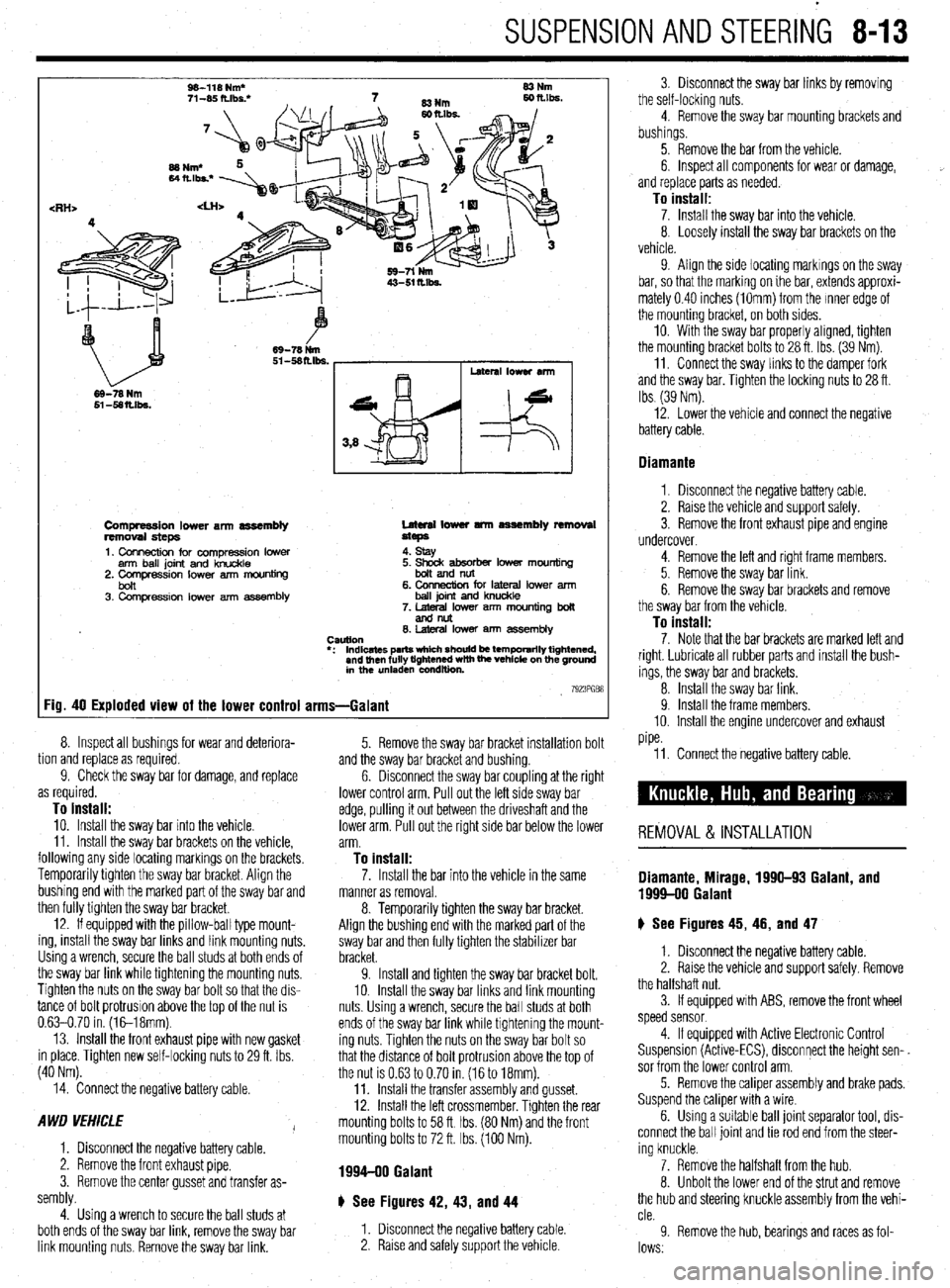

SUSPENSION AND STEERING 8-13

W-118 Nm*

71-W ft.lbs: 83Nm

69-78 Nm

Compression lower arm assembly

removal steps

1. Connection for compression lower

arm ball joint and knuckle

2. Comoression lower arm mouniina Lateral lower tmn assembly removal

steps

4. stay

bon ’ 3. Compression lower arm assembly 6. CMlnection for lateral lower arm

ball joint and knuckle

7. lateral lower arm mounting boll

andnllt

0. hleral lower am7 assembly

CWtlOtl

l : Indicates parts which should be temporarily tightened,

and then fully tightened with the vehicle on the ground

in the unladen condition

7923PGB8 Fig. 40 Exploded view of the lower control arms-Galant

tion and replace as required. 8.

9. Inspect all bushings for wear and deteriora-

Check the sway bar for damage, and replace

as required.

To install: 10. Install the sway bar into the vehicle.

11. Install the sway bar brackets on the vehicle,

following any side locating markings on the brackets.

Temporarily tighten the sway bar bracket. Align the

bushing end with the marked part of the sway bar and

then fully tighten the sway bar bracket.

12. If equipped with the pillow-ball type mount-

ing, install the sway bar links and link mounting nuts.

Using a wrench, secure the ball studs at both ends of

the sway bar link while tightening the mounting nuts.

Tighten the nuts on the sway bar bolt so that the dis-

tance of bolt protrusion above the top of the nut is

0.63-0.70 in. (1&18mm).

13. Install the front exhaust pipe with new gasket

in place. Tighten new self-locking nuts to 29 ft. Ibs.

(40 Nm). and the sway bar bracket and bushing.

6. 5. Remove the sway bar bracket installation bolt

Disconnect the sway bar coupling at the right

lower control arm. Pull out the left side sway bar

edge, pulling it out between the driveshaft and the

lower arm. Pull out the right side bar below the lower

arm.

To install:

14. Connect the negative battery cable.

A WD VEHICLE

I

1. Disconnect the negative battery cable.

2. Remove the front exhaust pipe.

3. Remove the center gusset and transfer as-

sembly.

4. Using a wrench to secure the ball studs at

both ends of the sway bar link, remove the sway bar

link mounting nuts. Remove the sway bar link. 11. Connect the negative battery cable.

REMOVAL & INSTALLATION

7. Install the bar into the vehicle in the same Diamante, Mirage, 1996-93 Galant, and manner as removal. 1999-00 Galant 8. Temporarily tighten the sway bar bracket.

Align the bushing end with the marked part of the

sway bar and then fully tighten the stabilizer bar

bracket.

9. Install and tighten the sway bar bracket bolt.

10. Install the sway bar links and link mounting

nuts Using a wrench, secure the ball studs at both

ends of the sway bar link while tightening the mount-

ing nuts. Tighten the nuts on the sway bar bolt so

that the distance of bolt protrusion above the top of

the nut is 0.63 to 0.70 in. (16 to 18mm).

11. Install the transfer assembly and gusset.

12. Install the left crossmember. Tighten the rear

mounting bolts to 58 ft Ibs. (80 Nm) and the front

mounting bolts to 72 ft. Ibs. (100 Nm). ) See Figures 45, 46, and 47

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely. Remove

the halfshaft nut.

3. If equipped with ABS, remove the front wheel

speed sensor

1994-90 Galant

4. If equipped with Active Electronic Control

Suspension (Active-ECS), disconnect the height sen-.

sor from the lower control arm.

5. Remove the caliper assembly and brake pads.

Suspend the caliper with a wire

6. Using a suitable ball joint separator tool, dis-

connect the ball joint and tie rod end from the steer-

ing knuckle.

7. Remove the halfshaft from the hub.

8. Unbolt the lower end of the strut and remove

the hub and steering knuckle assembly from the vehi-

cle.

9 Remove the hub, bearings and races as fol-

lows.

# See Figures 42, 43, and 44

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle 3. Disconnect the sway bar links by removing

the self-locking nuts.

4. Remove the sway bar mounting brackets and

bushings.

5. Remove the bar from the vehicle.

6. Inspect all components for wear or damage,

and replace parts as needed.

To install: 7. Install the sway bar into the vehicle.

8. Loosely install the sway bar brackets on the

vehicle.

9. Align the side locating markings on the sway

bar, so that the marking on ihe bar, extends approxi-

mately 0.40 inches (1Omm) from the Inner edge of

the mounting bracket, on both sides.

10. With the sway bar properly aligned, tighten

the mounting bracket bolts to 28 ft. Ibs. (39 Nm).

11. Connect the sway links to the damper fork

and the sway bar. Tighten the locking nuts to 28 ft.

Ibs (39 Nm).

12. Lower the vehicle and connect the negative

battery cable.

Diamante

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the front exhaust pipe and engine

undercover.

4. Remove the left and right frame members.

5. Remove the sway bar link.

6. Remove the sway bar brackets and remove

the sway bar from the vehicle.

To install: 7. Note that the bar brackets are marked left and

right. Lubricate all rubber parts and install the bush-

ings, the sway bar and brackets.

8. Install the sway bar link.

9. Install the frame members.

10. Install the engine undercover and exhaust

pipe.

Page 328 of 408

.

8132 SUSPENSION AND STEERING

(42 Nm) on Mirage and 36-39 ft. tbs. (49-53 Nm)

on Galant and Diamante models.

19. Have the front end alignment checked, and

adjusted if necessary.

Inner Tie Rods

11. Loosen the inner tie rod end nut from the

steering gear and remove the inner tie rod end.

To install: 12. Using a new lock plate, install the tie rod end

and tighten the tie rod to 65 ft. Ibs. (90 Nm). REMOVAL &INSTALLATION 13. Bend the tabs of the new lock plate to secure

1. Raise the front of the vehicle and support it

on jackstands.

2. Remove the wheel.

3. Remove the cotter pin and the outer tie rod

ball joint stud nut. Note the position of the steering

linkage.

4. Wire brush the threads on the tie rod shaft

and lubricate with penetrating oil.

5. Using a suitable ball joint separator tool, re-

move the tie rod ball joint from the steering knuckle.

6. Loosen the locknut and remove the tie rod

end from the tie rod. Count the number of complete

turns it takes to completely remove it.

7. Remove the tie rod-to-steering gear locknut.

8. Remove the clamps that secure the flexible

boot to the steering gear.

9. Slide the boot from the inner tie rod and re-

move the boot.

IO. Bend the lock plate tabs from the inner tie rod

end nut. the inner tie rod end.

14. Slide the boot onto the steering gear and se-

cure it with new clamps.

15. Install the outer tie rod end to the steering

gear locknut.

16. Install the outer tie rod end, turning it in ex-

actly as many turns as it was to remove the old one.

Make sure it is correctly positioned in relationship to

the steering linkage.

22. Have a front end alignment performed. 17. Connect the outer tie rod end to the steering

knuckle and install the castle nut. Tighten the nut to

25 ft. Ibs. (34 Nm,) on the Mirage and 21 ft. Ibs. (29

Nm) on the Galant and Diamante models.

18. Install a new cotter pin to the castle nut.

19. Tighten the tie rod end locking nut to 30 ft.

Ibs. (42 Nm) on the Mirage and 36-39 ft. Ibs. (49-53

Nm) on the Galant and Diamante models.

20. Install the wheel and tire assembly.

21. Lower the vehicle.

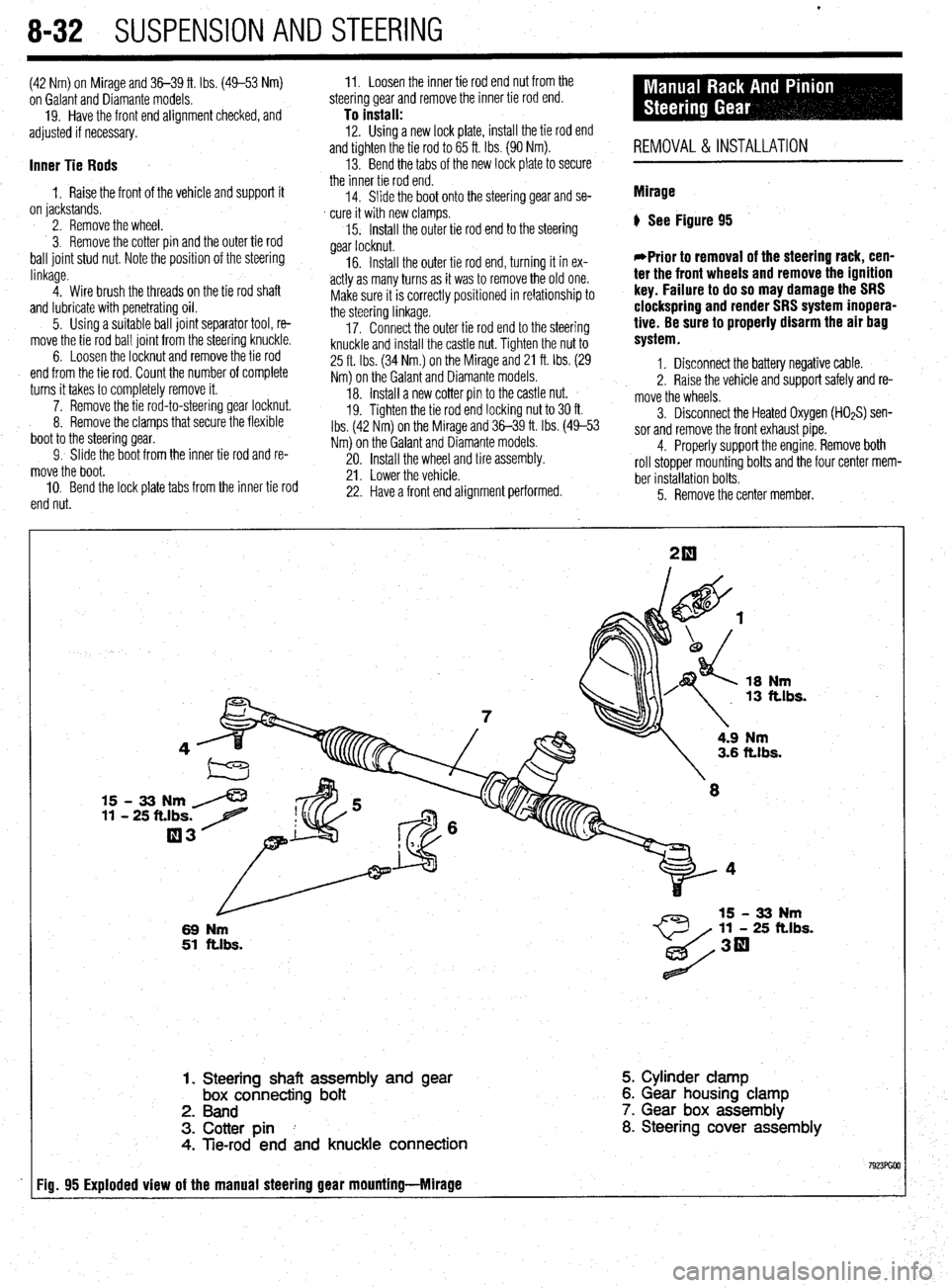

Mirage

) See Figure 95

*Prior to removal of the steering rack, cen-

ter the front wheels and remove the ignition

key. Failure to do so may damage the SRS

clockspring and render SRS system inopera-

tive. Be sure to properly disarm the air bag

system.

1. Disconnect the battery negative cable.

2. Raise the vehicle and support safely and re-

move the wheels.

5. Remove the center member. 3. Disconnect the Heated Oxygen (HOzS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine. Remove both

roll stopper mounting bolts and the four center mem-

ber installation bolts.

18

Nm 13 ft.lbs.

15 - 33 Nm /

11 - 25 ft.lbs. 7

03

L

69 Nm

51 ftlbs.

4.9 Nm 3.6 ft.lbs.

11 - 25 ft.lbs.

1. Steering shaft assembly and

gear box connecting bolt

2. Band

3. Cotter pin I

4. Tie-rod end and knuckle connection 5. Cylinder clamp

6. Gear housing clamp

7. Gear box assembly

8. Steering cover assembly

Fig. 95 Exploded view of the manual steering gear mounting-Mlrage