engine MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 163 of 408

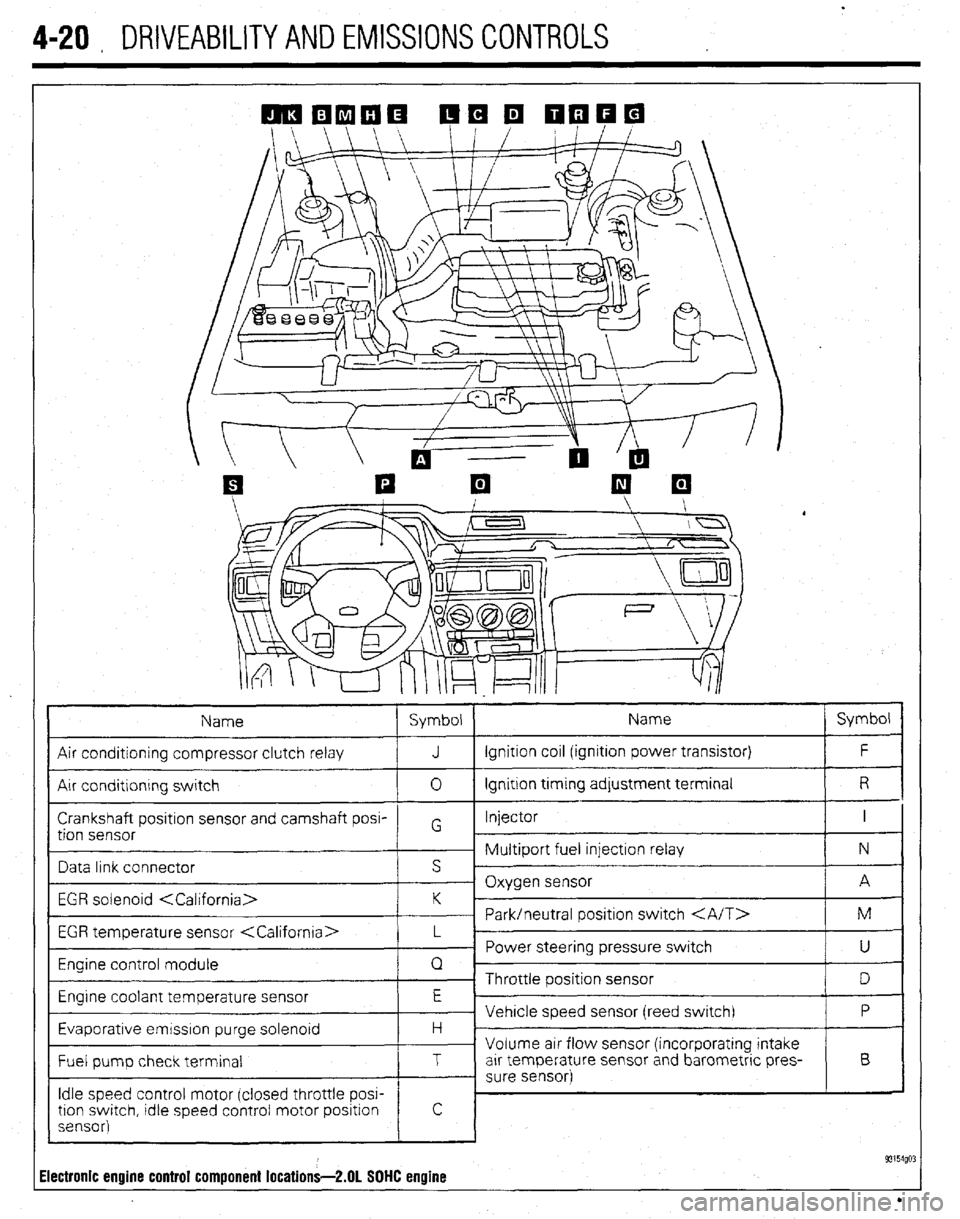

4-20 , DRIVEABILITYAND EMISSIONS CONTROLS

Name Symbol Name Symbol

Air conditioning compressor clutch relay J Ignition coil (ignition power transistor) F

Air conditlonrng switch 0 Ignition trming adjustment terminal R

Crankshaft positron sensor and camshaft posi- Injector I

tion sensor G

~ Multiport fuel injection relay N

Data link connector s ’

- Oxygen sensor A

EGR solenoid

~ Park/neutral positron switch M

EGR temperature sensor

_ Power steering pressure switch

U

Engine control module Q

~ Throttle position sensor

D

Engrne coolant temperature sensor E

Vehicle speed sensor (reed switch) P

Evaporative emrsslon purge solenoid H -

Volume air flow sensor (incorporating intake

Fuel pump check terminal T arr temperature sensor and barometric pres- B

- sure sensor)

Idle speed control motor (closed throttle POW

tron swatch, tdle speed control motor positron

sensor)

! c

93154go: Electronic engine control component locations-2.01 SOHC engine

Page 164 of 408

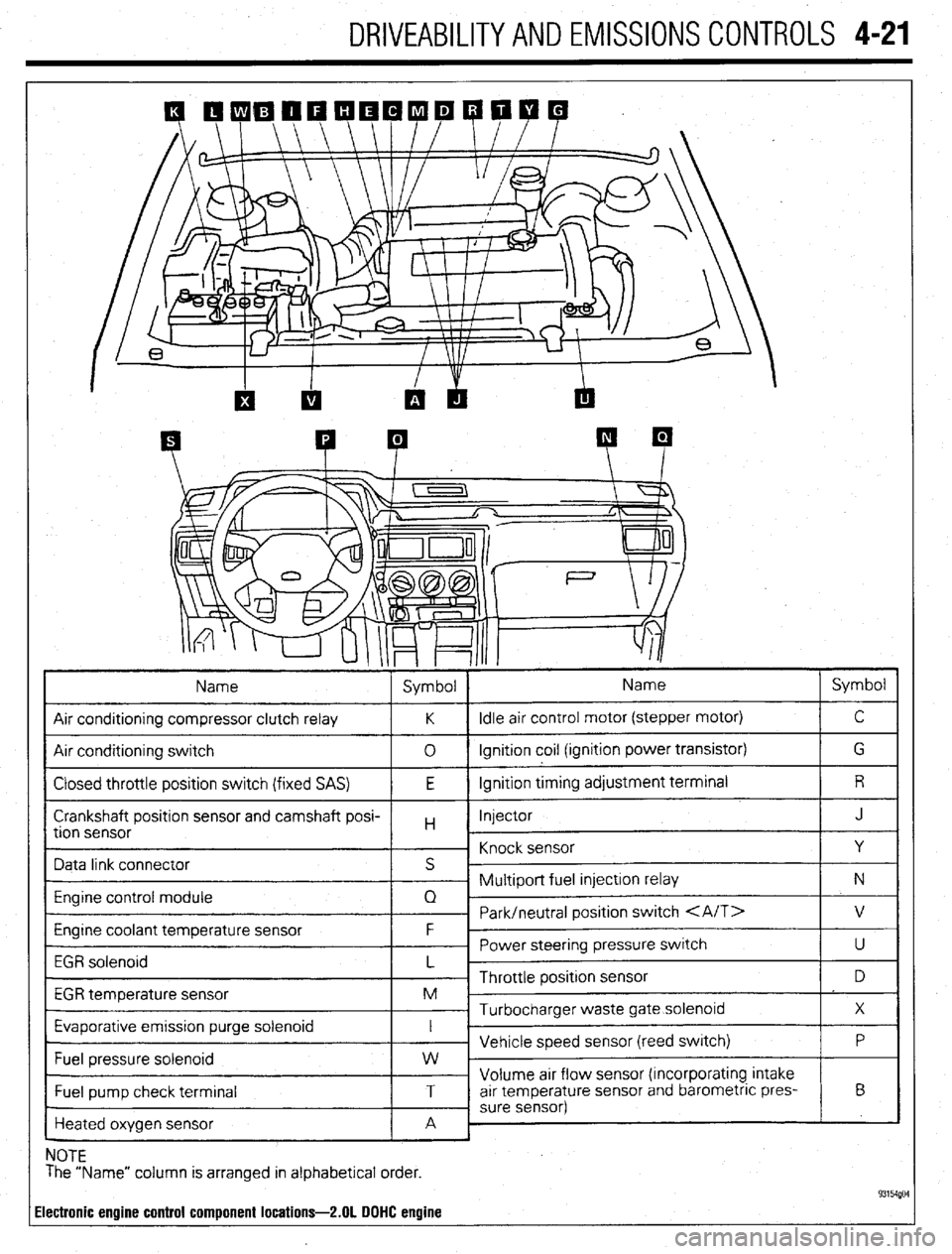

DRIVEABILITYAND EMISSIONS CONTROLS 4-21

Heated oxygen sensor

c

NOTE

The “Name” column is arranged in alphabetical order.

ilectronic engine control component locations-2.01 DOHC engine

Page 165 of 408

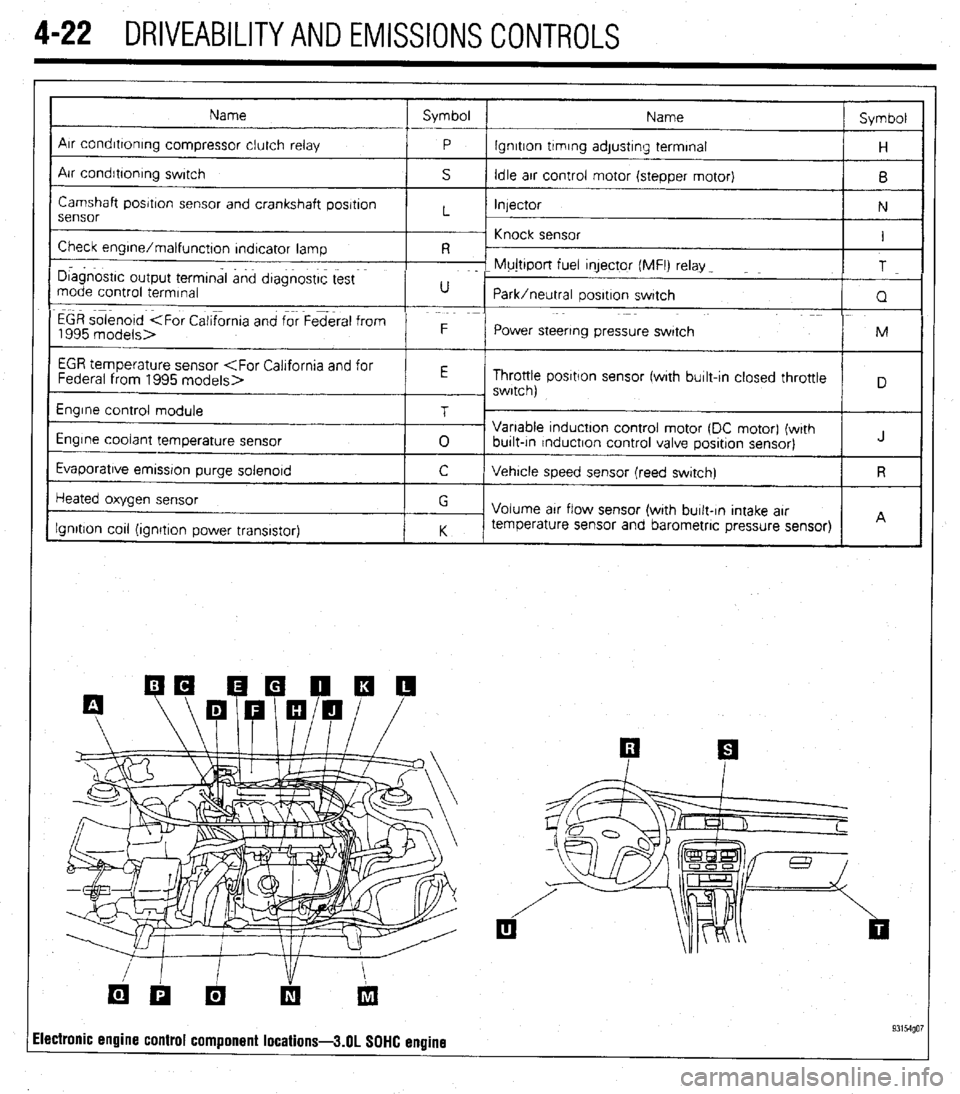

4-22 DRIVEABILITYAND EMISSIONS CONTROLS

Name Symbol

Name Symbol

I

Arr condrttontng compressor clutch relay

P lgnrtton trmrng adjustrng terminal

H

Air condrbonrng swrtch

S Idle arr control motor (stepper motor)

B

Camshaft posrtron sensor and crankshaft posrtron

Injector

N

sensor L

~ Knock sensor

Check engrne/malfunctton rndtcator lamp I

R -

I D~agnostrc output termtnal and dtagnostrc test F- Mujttport fuel qector (MFI) relay _

T

mode control termrnal U

Park/neutral oosrtron swatch

Q

EGR solenoid

1995 models> F

Power steering pressure swatch M

I

EGR temperature sensor

Throttle posrtlon sensor fwrth burlt-In closed throttle

, swrtch)

Engrne control module

Engine coolant temperature sensor

Evaporatrve emrssron purge solenord T

0 Variable tnductton control motor (DC motor) (wrth

burlt-tn rnductron control valve posrtron sensor) J

C Vehrcle speed sensor (reed swatch) R

Heated oxygen sensor

Ignition cot1 (ionrtron Dower transistor) G

Volume arr flow sensor (with burlt-In Intake arr

K temperature sensor and barometric pressure sensor)

I I A

ilectronic engine control component locations-3.01 SOHC engine 93154go7

Page 166 of 408

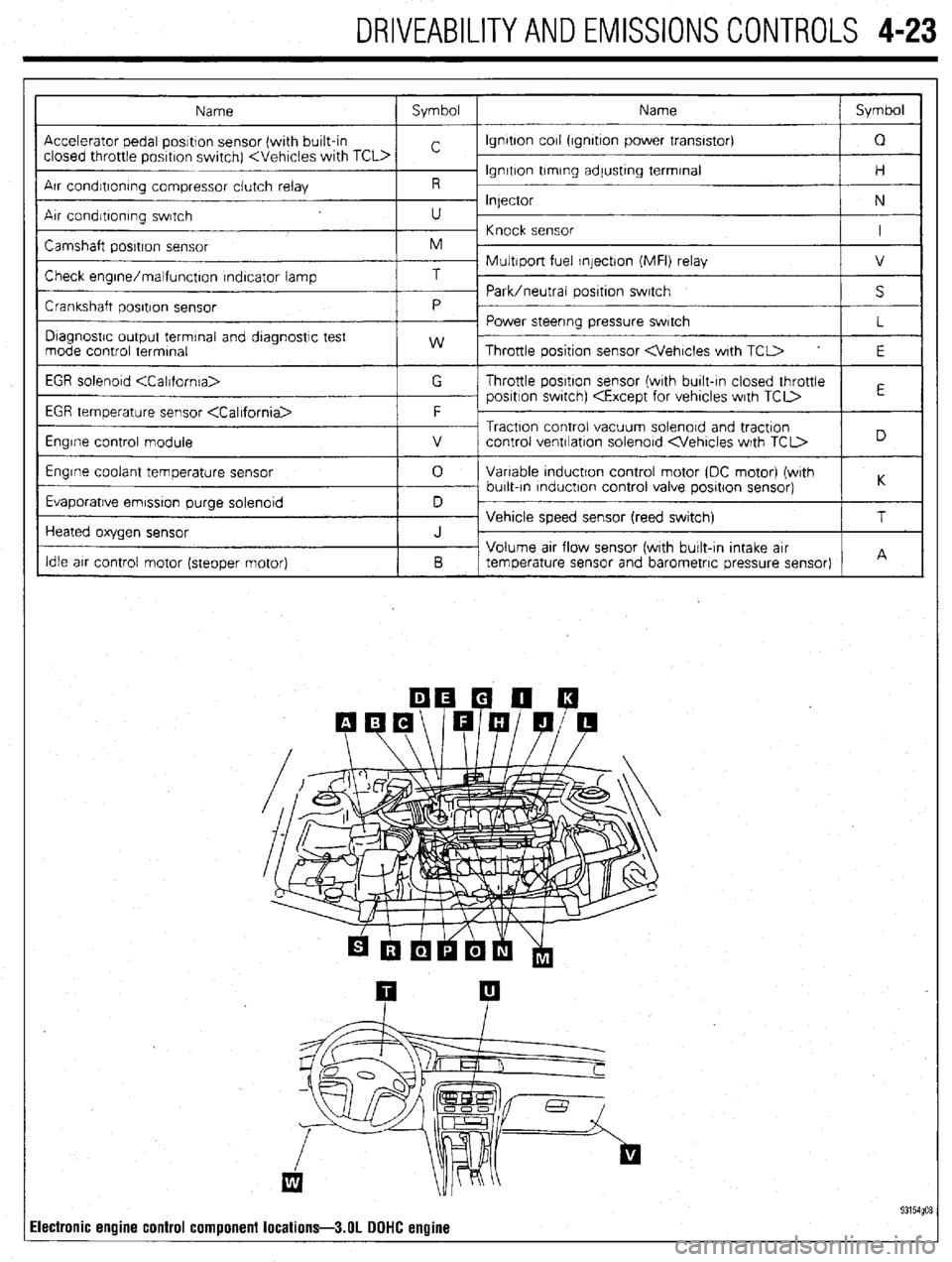

DRIVEABILITYAND EMISSIONS CONTROLS 4-23

Electronic engine

control component locations-3.01 DOHC engine

Page 167 of 408

.

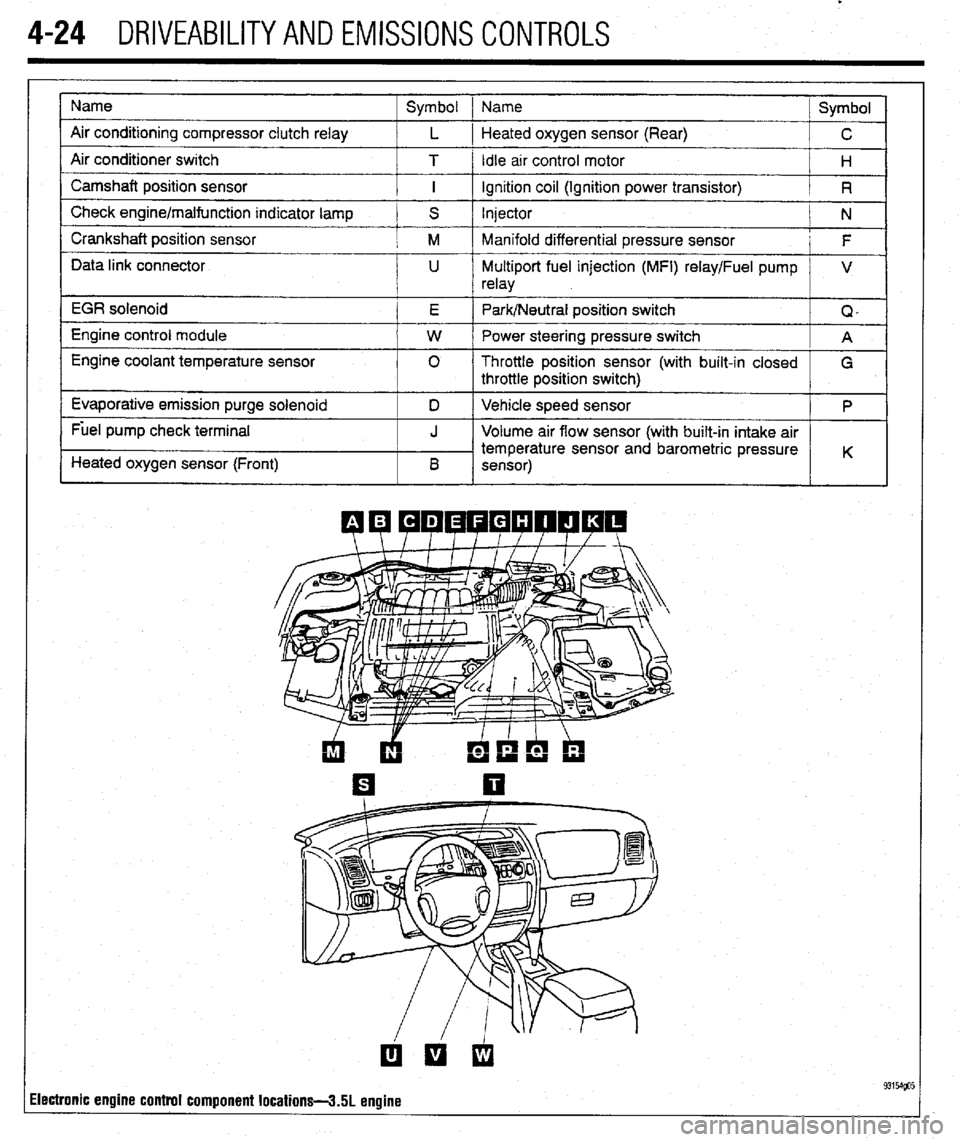

4-24 DRIVEABILITYAND EMISSIONS CONTROLS

Name

Air conditioning compressor clutch relay

Air conditioner switch

Camshaft position sensor

Check engine/malfunction indicator lamp

Crankshaft position sensor

Data link connector

EGR solenoid

Engine control module

Engine coolant temperature sensor

Evaporative emission purge solenoid

Fuel pump check terminal

Heated oxygen sensor (Front) Symbol 1 Name

Symbol

L 1 Heated oxygen sensor (Rear)

C

T / Idle arr control motor

H

I ignition coil (Ignition power transistor)

R

S Injector

N

M Manifold differential pressure sensor

F

U Multiport fuel injection (MFI) relay/Fuel pump V

relay

E Park/Neutral position switch

Q,

W Power steering pressure switch

A

0 Throttle position sensor (with built-in closed

G

throttle position switch)

D Vehicle speed sensor

P

J Volume air flow sensor (with built-in intake air

temperature sensor and barometric pressure

B K

sensor)

ilectronic engine control component locations-3.51 engine

Page 168 of 408

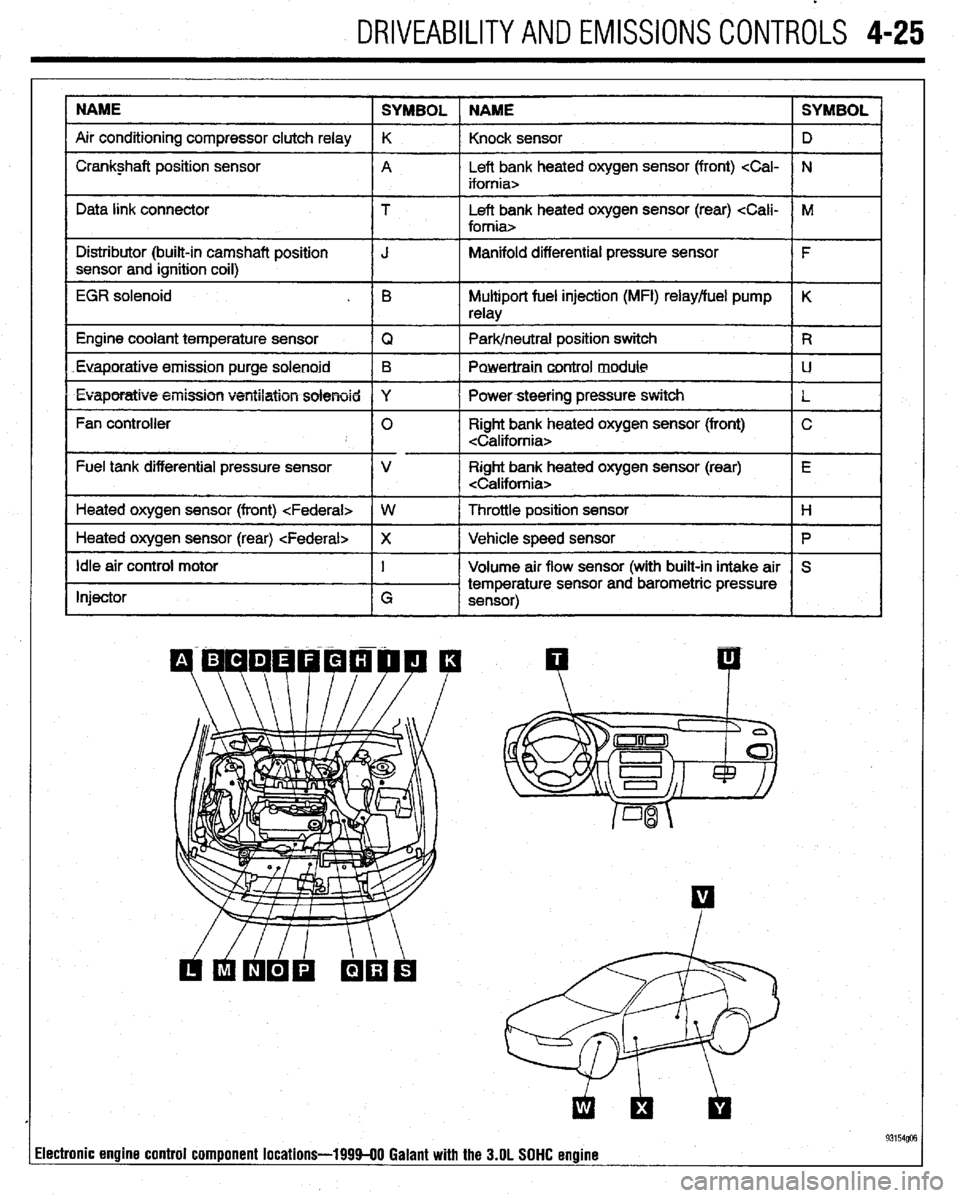

DRIVEABILITYAND EMISSIONS CONTROLS 4-25

NAME

SYMBOL NAME SYMBOL

Air conditioning compressor clutch relay K

Knock sensor D

I Crankshaft position sensor

A Left bank heated oxygen sensor (front)

I I

Data link connector T Left bank heated oxygen sensor (rear)

I Distributor (built-in camshaft position

I J Manifold differential pressure sensor

I F

sensor and ignition coil)

I

EGR solenoid . B Multiport fuel injection (MFI) relay/fuel pump K

relay

1 Engine coolant temperature sensor

IQ 1 Park/neutral position switch IR

Euaporatiue.emission purge solenoid B

Powertraincontrol module LJ

l Evaporatiw5+eiiission ventilation solenoid Y

I Powersteering pressure switch

L

Fan controller 0 Right bank heated oxygen sensor (front) C

Fuel tank differential pressure sensor V Right bank heated oxygen sensor (rear) E

Heated oxygen sensor (front)

I

1 Heated oxygen sensor (rear)

Ip I

Idle air control motor

Injector I

G Volume air flow sensor (with built-in intake air S

temperature sensor and barometric pressure

sensor)

I I

93154@3 lectronic engine control component locations-199940 Galant with the 3.OL SOHC engine

Page 169 of 408

4-26 DRIVEABILITYAND EMISSIONS CONTROLS

The Powertrain Control Module (PCM) monitors

the signals of input and output sensors, some all the

time and others at certain times and processes each

signal. When the PCM notices that an irregularity has

continued for a specified time or longer from when

the irregular signal was initially monitored, the PCM

judges that a malfunction has occurred and will

memorize the malfunction code. The code is then

stored in the memory of the PCM and is accessible

through the data link (diagnostic connector) with the

use of an electronic scan tool or a voltmeter.

CHECK ENGINE/MALFUNCTION

INDICATOR LIGHT

Among the on-board diagnostic items, a check

engine/malfunction indicator light comes on to notify

the driver of a emission control component irregular-

ity. If the irregularity detected returns to normal or the

PCM judges that the component has returned to nor-

mal, the check engine/malfunction indicator light will

be turned off Moreover, if the ignition is turned OFF

and then the engine is restarted, the check

engine/malfunction indicator light will not be turned

on unttl a malfunction is detected.

The check engine/malfunction indicator light will

come on immediately after the ignition switch is

turned ON. The light should stay lit for 5 seconds

and then will go off. This Indicates that the check en-

gine/malfunction indicator lamp is operating nor-

mally. This does not signify a problem with the sys-

tem.

*The check engine/malfunction indicator

lamp will come on when the terminal for the

ignition timing adjustment is shorted to

ground. Therefore, it is not abnormal that the

light comes on even when the terminal for ig-

nition timing is shorted at time of ignition

timing adjustment.

To test the light, perform the following:

1. Turn the ignition switch ON. Inspect the check

engine/malfunction indicator lamp for Illumination.

2. The light should be lit for 5 seconds and then

should go out.

3. If the lamp does not illuminate, check for open

circuit In the harness, blown fuse or blown bulb.

SERVICE PRECAUTIONS

l Before attachrng or detaching the PCM harness

connectors, make sure the ignition switch is OFF and

the negative battery cable is disconnected to avoid

the possibility of damage to the PCM.

l When performing PCM input/output signal di-

agnosis, remove the pin terminal retainer from the

connectors to make it easier to insert tester probes

into the connector.

l When attaching or detaching pin connectors ,

from the PCM, take care not to bend or break any pin

terminals. Check that there are no bends or breaks on

PCM pin terminals before attempting any connec-

tions.

l Before replacing any PCM, perform the PCM

input/output signal diagnosis to make sure the PCM

is functioning properly.

l When measuring supply voltage of PCM-con-

trolled components with a circuit tester, separate 1

tester probe from another. If the 2 tester probes acci-

dentally make contact with each other during mea-

surement, a short circuit WIII result and damage the

PCM.

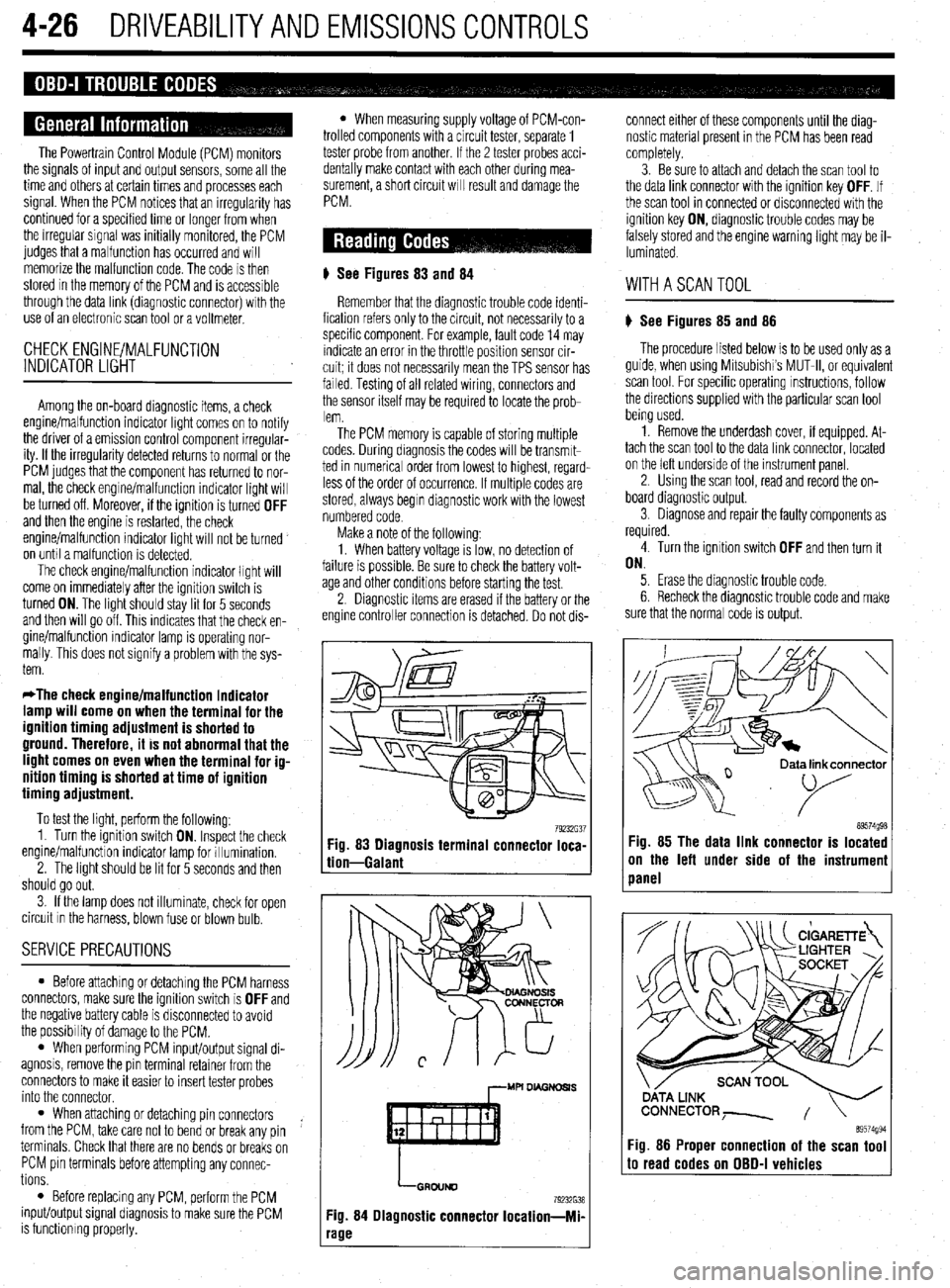

# See Figures 83

and 84

Remember that the diagnostic trouble code identi-

fication refers only to the circuit, not necessarily to a

specific component. For example, fault code 14 may

indicate an error in the throttle position sensor cir-

cuit; it does not necessarily mean the TPS sensor has

failed Testing of all related wiring, connectors and

the sensor itself may be required to locate the prob-

lem.

The PCM memory is capable of storing multiple

codes. During diagnosis the codes will be transmlt-

ted in numerical order from lowest to highest, regard-

less of the order of occurrence. If multiple codes are

stored, always begin diagnostic work with the lowest

numbered code

Make a note of the following:

1. When battery voltage IS low, no detection of

failure is possible. Be sure to check the battery volt-

age and other conditions before starting the test.

2. Diagnostic items are erased if the battery or the

engine controller connection is detached. Do not dis- connect either of these components until the diag-

nostic material present in the PCM has been read

completely.

3. Be sure to attach and detach the scan tool to

the data link connector with the ignition key OFF. If

the scan tool in connected or disconnected with the

ignition key ON, diagnostic trouble codes may be

falsely stored and the engine warning light may be il-

luminated. WITHASCANTOOL

) See Figures 85 and 86

The procedure listed below is to be used only as a

guide, when using Mitsubishi’s MUT-II, or equivalent

scan tool. For specific operating instructions, follow

the directions supplied with the particular scan tool

bemg used.

1. Remove the underdash cover, if equipped. At-

tach the scan tool to the data link connector, located

on the left underside of the instrument panel.

2. Using the scan tool, read and record the on-

board diagnostic output.

3. Diagnose and repair the faulty components as

required

4. Turn the ignition switch OFF and then turn it

ON.

5. Erase the diagnostic trouble code.

6 Recheck the diaanostic trouble code and make

sure that the normal &de is output.

79232G37 89574g98 Fig. 83 Diagnosis terminal connector loca-

tion-Galant Fig. 85 The data link connector is located

on the left under side of the instrumeni

panel

,--MU DL4GNDSl.S

LGRDIJND

79232638

Fig. 84 Diagnostic connector Iocation-Mi-

‘age

ata link connector

89574994 Fig. 86 Proper connection of the scan tool to read codes on OBD-I vehicles

Page 170 of 408

DRIVEABILITYAND EMISSIONS CONTROLS 4-27

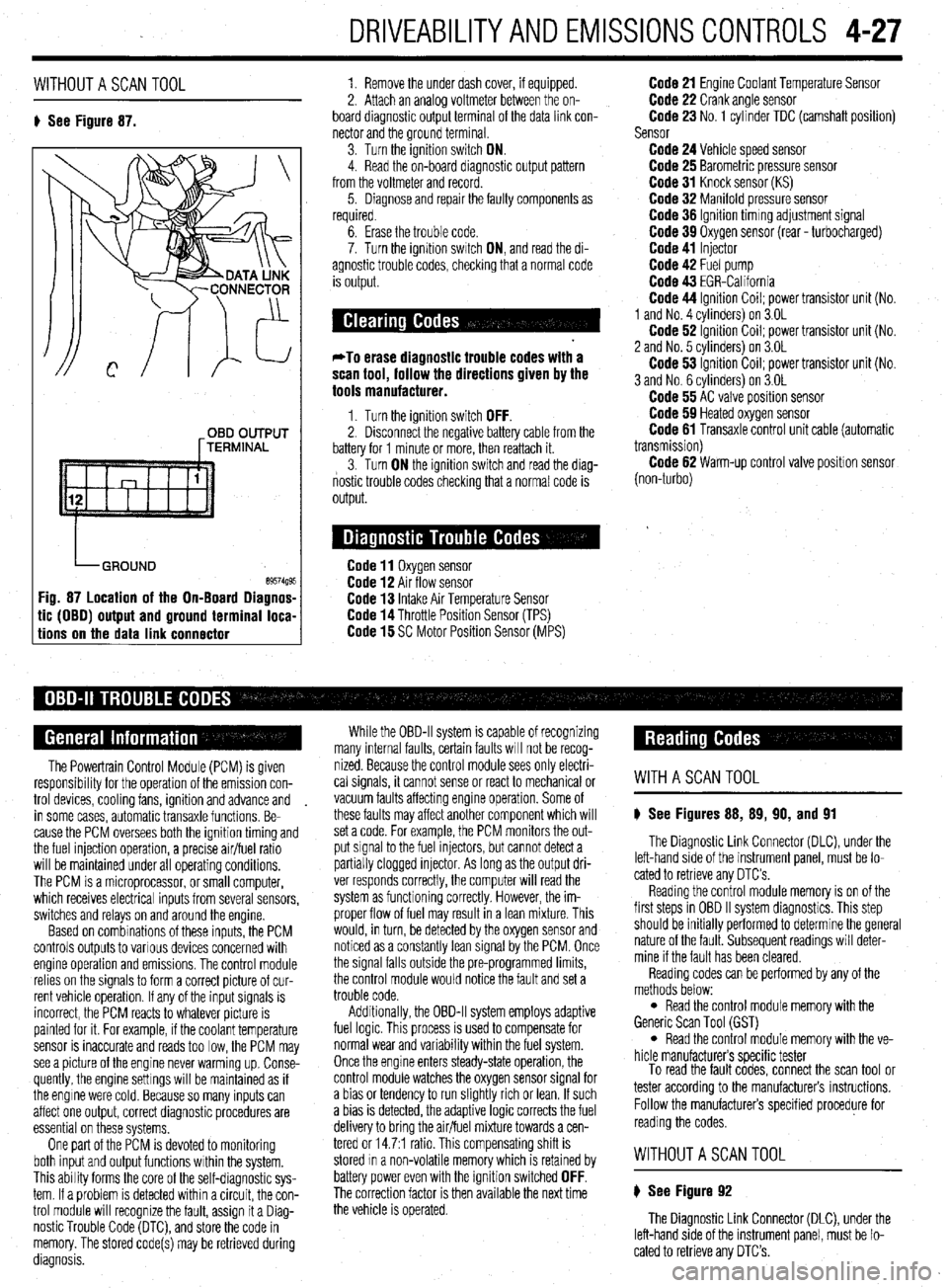

WITHOUTASCANTOOL

8 See Figure 87. 1. Remove the under dash cover, if equipped.

2. Attach an analoa voltmeter between the on-

board diagnostic outpit terminal of the data link con-

nector and the ground terminal

3. Turn the ignition switch ON.

4. Read the on-board diagnostic output pattern

from the voltmeter and record.

5. Diagnose and repair the faulty components as

required.

OBD OUTPUT

[TERMINAL

tic (OBO) output and ground terminal loca-

tions on the data link connector

6. Erase the trouble code.

7. Turn the ignition swatch ON, and read the di-

agnostic trouble codes, checking that a normal code

is output.

*To erase diagnostic trouble codes with a

scan tool, follow the directions given by the

tools manufacturer.

1. Turn the ignition switch OFF. 2. Disconnect the negative battery cable from the

battery for 1 minute or more, then reattach it.

3. Turn ON the ignition switch and read the diag-

nostic trouble codes checking that a normal code is

output.

Code 11 Oxygen sensor Code 12 Air flow sensor Code 13 Intake Air Temperature Sensor Code 14 Throttle Position Sensor (TPS) Code 15 SC Motor Position Sensor (MPS)

Code 21 Engine Coolant Temperature Sensor Code 22 Crank angle sensor Code 23 No. 1 cylinder TDC (camshaft position)

Sensor

Code 24 Vehicle speed sensor Code 25 Barometric pressure sensor Code 31 Knock sensor (KS) Code 32 Manifold pressure sensor Code 36 Ignition timmg adjustment signal Code 39 Oxygen sensor (rear - turbocharged) Code 41 Injector Code 42 Fuel pump Code 43 EGR-California Code 44 Ignition Coil; power transistor unit (No.

1 and No. 4 cvlinders) on 3.OL

Code 62 ignition Coil; power transistor unit (No.

2 and No. 5 cvlinders) on 3.OL

Code 53 ignition Coil; power transistor unit (No.

3 and No. 6 cylinders) on 3.OL

Code 55 AC valve position sensor Code 59 Heated oxygen sensor Code 61 Transaxle control unit cable (automatic

transmission)

Code 62 Warm-up control valve position sensor

(non-turbo)

The Powertrain Control Module (PCM) is given

responsibrlity for the operation of the emission con-

trol devices, cooling fans, ignition and advance and

in some cases, automatic transaxle functions. Be-

cause the PCM oversees both the ignition timing and

the fuel injection operation, a precise air/fuel ratio

will be maintained under all operating conditions,

The PCM is a microprocessor, or small computer,

which receives electrical inputs from several sensors,

switches and relays on and around the engine.

Based on combinations of these inputs, the PCM

controls outputs to various devices concerned with

engine operation and emissions. The control module

relies on the signals to form a correct picture of cur-

rent vehicle operation. If any of the input signals is

incorrect, the PCM reacts to whatever picture is

painted for it. For example, if the coolant temperature

sensor is inaccurate and reads too low, the PCM may

see a picture of the engine never warming up. Conse-

quently, the engine settings will be maintained as if

the engine were cold. Because so many inputs can

affect one output, correct diagnostic procedures are

essential on these systems,

One part of the PCM is devoted to monitoring

both input and output functions within the system.

This ability forms the core of the self-diagnostic sys-

tem. If a problem is detected within a circuit, the con-

trol module will recognize the fault, assign it a Diag-

nostic Trouble Code (DTC), and store the code in

memory. The stored code(s) may be retrieved during

diagnosis. While the OBD-II system is capable of recognizing

many internal faults, certain faults WIII not be recog-

nized. Because the control module sees only electri-

cal signals, it cannot sense or react to mechanical or

vacuum faults affecting engine operation. Some of

these faults may affect another component which will

set a code. For example, the PCM monitors the out-

put signal to the fuel injectors, but cannot detect a

partially clogged injector. As long as the output dri-

ver responds correctly, the computer will read the

system as functioning correctly. However, the im-

proper flow of fuel may result in a lean mixture. This

would, in turn, be detected by the oxygen sensor and

noticed as a constantly lean signal by the PCM. Once

the signal falls outside the pre-programmed limits,

the control module would notice the fault and set a

trouble code.

Additionally, the OBD-II system employs adaptive

fuel logic. This process is used to compensate for

normal wear and variability within the fuel system.

Once the engine enters steady-state operation, the

control module watches the oxygen sensor signal for

a bias or tendency to run slightly rich or lean. If such

a bias is detected, the adaptive logic corrects the fuel

delivery to bring the air/fuel mixture towards a cen-

tered or 14.7:1 ratio. This compensating shift is

stored In a non-volatile memory which is retained by

battery power even with the ignition switched

OFF. The correction factor is then available the next time

the vehicle is operated.

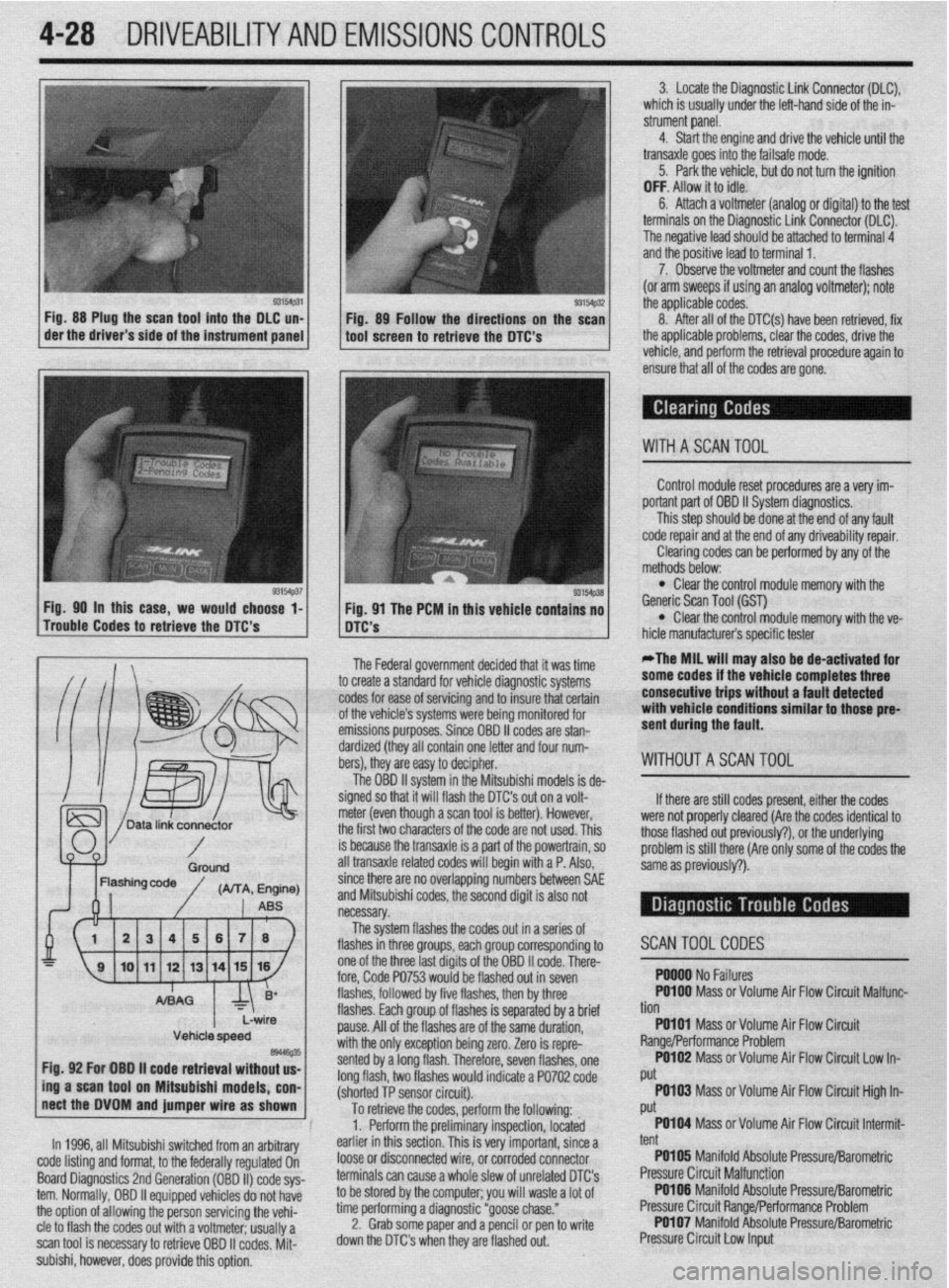

WITHASCANTOOL

8 See Figures 88, 89, 90, and 91

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any OTC’s

Reading the control module memory is on of the

first steps in OBD II system diagnostics. This step

should be initially performed to determine the general

nature of the fault. Subsequent readings will deter-

mine if the fault has been cleared.

Reading codes can be performed by any of the

methods below:

l Read the control module memory with the

Generic Scan Tool (GST)

l Read the control module memory with the ve-

hicle manufacturers specific tester

To read the fault codes, connect the scan tool or

tester according to the manufacturers instructions.

Follow the manufacturers specified procedure for

reading the codes.

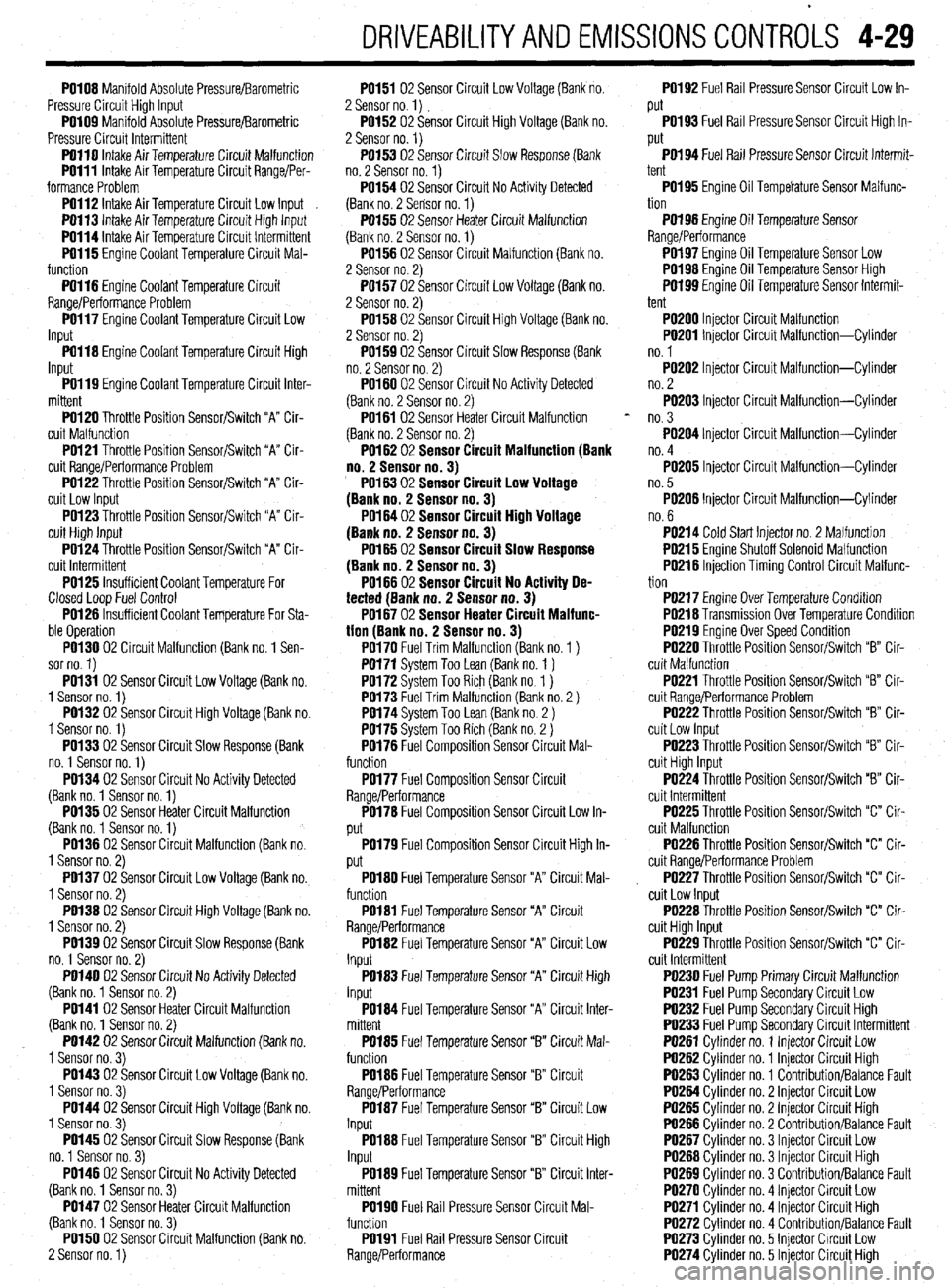

WITHOUTASCANTOOL

8 See Figure 92

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any DTC’s.

Page 171 of 408

4-28 DRIVEABILITYAND EMISSIONS CONTROLS

Fig. 88 Plug the scan tool into the DLC un-

Fig. 89 Follow the directions on the scan

der the driver’s side of the instrument panel

tool screen to retrieve the DTC’s 3. Locate the Diagnostic Link Connector (DLC),

which is usually under the left-hand side of the in-

strument panel.

4. Start the engine and drive the vehicle until the

transaxle goes into the failsafe mode.

5. Park the vehicle, but do not turn the ignition

OFF. Allow it to idle.

6. Attach a voltmeter (analog or digital) to the test

terminals on the Diagnostic Link Connector (DLC).

The negative lead should be attached to terminal 4

and the positive lead to terminal 1.

7. Observe the voltmeter and count the flashes

(or arm sweeps if using an analog voltmeter); note

the applicable codes.

- 8. After all of the DTC(s) have been retrieved, fix

the applicable problems, clear the codes, drive the

vehicle, and perform the retrieval procedure again to

ensure that all of the codes are gone.

WITHASCANTOOL

Control module reset procedures are a very im-

portant part of OBD II System diaqnostics.

This step should be done at the end of any fault

code repair and at the end of any driveability repair.

Clearing codes can be performed by any of the

Fig. 90 in this case, we would choor- A ’ ma*-. . . * .

Trouble Codes to retrieve the DTC’s

-.- -

A mere mar

. . methods below: l Clear the control module memory with the

se l-

I I ng. vi me rtim In mts venicie contains no Generic Scan Tool (GST) l DTC’S Clear the control module memory with the ve-

L’-‘m iufacturer’s specific tester

The Federal government decided that it was time

to create a standard for vehicle diagnostic systems

codes for ease of servicing and to insure that certain

of the vehicle’s systems were being monitored for

emissions purposes. Since OBD II codes are stan-

dardized (they all contain one letter and four num-

bers), they are easy to decipher.

The OBD II system in the Mitsubishi models is de-

signed so that it will flash the DTC’s out on a volt-

meter (even though a scan tool is better). However,

the first two characters of the code are not used. This

is because the transaxle is a part of the powertrain, so

all transaxle related codes will begin with a P. Also, *The MIL will may also be de-activated for

some codes if the vehicle completes three

consecutive trips without a fault detected

with vehicle conditions similar to those pre-

sent during the fault.

WITHOUTASCAN TOOL

If there are still codes p

resent, either the codes

were not properly cleared f

:Are the codes identical to

those flashed out previous

I$‘), or the underlying

problem is still there (Are I

only some of the codes the

same as oreviouslv?).

since there are no overlapping numbers between SAE

and Mitsubishi codes, the second digit is also not

necessary.

The system flashes the codes o

ut ma series of

flashes in

three nmm mh nrnlll -- J.-lr-, ---.. ~.--

p corresponding to

one of the

three last diaits of the OBD II code. There-

fore, Code WJJ wuuw UC:

IIKWAJ WI III XVWI flashes, followed by five flashes, then by three

flashes. Each group of flashes is se

pause. All of the flashes are of the (

witi the or$, nvrontinn hoinn mm sented by z

long flash,

(shorted Tt SWIWI LIIW. rparated by a brief

;ame duration,

88, “rw”I.‘L’“‘I uv,,,y LUI”.

Zero is repre-

1 long flash. Therefore, seven flashes, one

two flashes would indicate a PO702 code

3 nnmn^r ,.:*....:I I r

SCANTOOLCODES

. YYY” I ‘I” I cuI”I”.J PO100 Mass or Volume Air Flow Circuit Malfunc-

Lb

non

PO101 Mass orVolume Air Flow Circuit

Range/Performance Problem

PO102 Mass or Volume Air Flow Circuit Low In-

Put

.

To retrieve the codes, perform the following: PO103 Mass or Volume Air Flow Circuit High In-

i Put

1. Perform the preliminary inspection, located PO104 Mass or Volume Air Flow Circuit Intermit-

-;

Vehicle speed es446e35 Fig. 92 For OBO ii code retrieval without us-

ing a scan tool on Mitsubishi models, con-

nect the DVOM and jumper wire as shown

In 1996, all Mitsubishi switched from an arbitrary

code listing and format, to the federally regulated On

Board Diagnostics 2nd Generation (OBD II) code sys-

tern. Normally, OBD II equipped vehicles do not have

the option of allowing the person servicing the vehi-

cle to flash the codes out with a voltmeter; usually a

scan tool is necessary to retrieve OBD II codes. Mit-

subishi, however, does provide this option, earlier in this section. This is very important, since a

loose or disconnected wire, or corroded connector

terminals can cause a whole slew of unrelated DTC’s

to be stored by the computer; you will waste a lot of

time performing a diagnostic “goose chase.”

2. Grab some paper and a pencil or pen to write

down the DTC’s when they are flashed out. tent

PO105 Manifold Absolute Pressure/Barometric

Pressure Circuit Malfunction

PO106 Manifold Absolute Pressure/Barometric

Pressure Circuit Range/Performance Problem

PO107 Manifold Absolute Pressure/Barometric

Pressure Circuit Low Input

Page 172 of 408

DRIVEABILITYAND EMISSIONS CONTROLS 4-29

PO108 Manifold Absolute Pressure/Barometric

Pressure Circuit High Input

PO109 Manifold Absolute Pressure/Barometric

Pressure Circuit Intermittent

PO110 intake Air Temperature Circuit Malfunction

PO111 Intake Air Temperature Circuit Range/Per-

formance Problem

PO112 Intake Air Temperature Circuit Low Input

PO113 Intake Air Temoerature Circuit Hiah lnout

PO114 Intake Air Temberature Circuit lnt&miitent

PO115 Engine Coolant Temperature Circuit Mal-

function -

PO116 Engine Coolant Temperature Circuit

Range/Performance Problem

PO117 Engine Coolant Temperature Circuit Low

Input

PO118 Engine Coolant Temperature Circuit High

Input

PO119 Engine Coolant Temperature Circuit Inter-

mittent

PO120 Throttle Position Sensor/Switch “A” Cir-

cuit Malfunction

PO121 Throttle Position Sensor/Switch “A” Cir-

cuit Range/Performance Problem

PO122 Throttle Position Sensor/Switch “A” Cir-

cuit Low Input

PO123 Throttle Position Sensor/Switch “A” Cir-

cuit High Input

PO124 Throttle Position Sensor/Switch “A” Cir-

cuit Intermittent

PO125 Insufficient Coolant Temperature For

Closed Loop Fuel Control

PO126 Insufficient Coolant Temperature For Sta-

ble Operation

PO130 02 Circuit Malfunction (Bank no. 1 Sen-

sor no. 1)

PO131 02 Sensor Circuit Low Voltage (Bank no.

1 Sensor no. 1)

PO132 02 Sensor Circuit High Voltage (Bank no.

1 Sensor no. 1)

PO133 02 Sensor Circuit Slow Response (Bank

no. 1 Sensor no. 1)

PO134 02 Sensor Circuit No Activity Detected

(Bank no. 1 Sensor no. 1)

PO135 02 Sensor Heater Circuit Malfunction

(Bank no. 1 Sensor no. 1)

PO136 02 Sensor Circuit Malfunction (Bank no.

1 Sensor no. 2)

PO137 02 Sensor Circuit Low Voltage (Bank no.

1 Sensor no. 2)

PO138 02 Sensor Circuit High Voltage (Bank no.

1 Sensor no. 2)

PO139 02 Sensor Circuit Slow Response (Bank

no. 1 Sensor no. 2)

PO140 02 Sensor Circuit No Activity Detected

(Bank no. 1 Sensor no. 2)

PO141 02 Sensor Heater Circuit Malfunction

(Bank no. 1 Sensor no. 2)

PO142 02 Sensor Circuit Malfunction (Bank no.

1 Sensor no. 3)

PO143 02 Sensor Circuit Low Voltage (Bank no.

1 Sensor no. 3)

PO144 02 Sensor Circuit High Voltage (Bank no.

1 Sensor no. 3)

PO145 02 Sensor Circuit Slow Response (Bank

no. 1 Sensor no. 3)

PO146 02 Sensor Circuit No Activity Detected

(Bank no. 1 Sensor no. 3)

PO147 02 Sensor Heater Circuit Malfunction

(Bank no. 1 Sensor no. 3)

PO150 02 Sensor Circuit Malfunction (Bank no.

2 Sensor no. 1) PO151 02 Sensor Circuit Low Voltage (Bank no.

2 Sensor no. 1)

PO152 02 Sensor Circuit High Voltage (Bank no.

2 Sensor no. 1)

PO153 02 Sensor Circuit Slow Response (Bank

no. 2 Sensor no. 1)

PO154 02 Sensor Circuit No Activity Detected

(Bank no. 2 Sensor no. 1)

PO155 02 Sensor Heater Circuit Malfunction

(Bank no. 2 Sensor no. 1)

PO156 02 Sensor Circuit Malfunction (Bank no.

2 Sensor no. 2)

PO157 02 Sensor Circuit Low Voltage (Bank no.

2 Sensor no. 2)

PO158 02 Sensor Circuit High Voltage (Bank no.

2 Sensor no. 2)

PO159 02 Sensor Circuit Slow Response (Bank

no. 2 Sensor no. 2)

PO160 02 Sensor Circuit No Activity Detected

(Bank no. 2 Sensor no. 2)

PO161 02 Sensor Heater Circuit Malfunction

(Bank no. 2 Sensor no. 2)

PO162 02 Sensor CircuitMalfunction(8ank

no.2 Sensorno.3)

PO16302 Sensor Circuit Low Voltage

(Bankno. Sensorno.3)

PO16402 Sensor Circuit HighVoltage

(Bankno. Sensorno.3)

PO16502 Sensor Circuit Slow Response

(Bankno. Sensorno.3)

PO166 02 Sensor Circuit No Activity De-

tected(Bankno.2 Sensorno.3)

PO16702 SensorHeaterCircuitMalfunc-

tion(Bank no.2 Sensorno.3)

PO170 Fuel Trim Malfunction (Bank no. 1 )

PO171 System Too Lean (Bank no. 1 )

PO172 Svstem Too Rich (Bank no 1 )

PO173 F;el Trim Malfundtion (Bank io. 2 )

PO174 System Too Lean (Bank no 2 )

PO175 System Too Rich (Bank no. 2 )

PO176 Fuel Composition Sensor Circuit Mal-

function

PO177 Fuel Composition Sensor Circuit

Range/Performance

PO178 Fuel Composition Sensor Circuit Low In-

put

PO179 Fuel Composition Sensor Circuit High In-

put

PO180 Fuel Temperature Sensor “A” Circuit Mal-

function

PO181 Fuel Temperature Sensor “A” Circuit

Range/Performance

PO182 Fuel Temperature Sensor “A” Circuit Low

Input

PO183 Fuel Temperature Sensor “A” Circuit High

Input

PO184 Fuel Temperature Sensor “A” Circuit Inter-

mittent

PO185 Fuel Temperature Sensor “B” Circuit Mal-

function

PO186 Fuel Temperature Sensor “B” Circuit

Range/Performance

PO187 Fuel Temperature Sensor “B” Circuit Low

Input

PO188 Fuel Temperature Sensor “B” Circuit High

Input

PO189 Fuel Temperature Sensor “B” Circuit Inter-

mittent

PO190 Fuel Rail Pressure Sensor Circuit Mal-

funchon

PO191 Fuel Rail Pressure Sensor Circuit

Range/Performance PO192 Fuel Rail Pressure Sensor Circuit Low In-

put

PO193 Fuel Rail Pressure Sensor Circuit High In-

put

PO194 Fuel Rail Pressure Sensor Circuit Intermit-

tent

PO195 Engine Oil Tempetature Sensor Malfunc-

tion

PO198 Engine Oil Temperature Sensor

Range/Performance

PO197 Engine Oil Temperature Sensor Low

PO198 Engine Oil Temperature Sensor High

W199 Engine Oil Temperature Sensor Intermit-

tent

PO200 Injector Circuit Malfunction

PO201 Injector Circuit Malfunction-Cylinder

no. 1

PO202 Injector Circuit Malfunction-Cylinder

no. 2

PO203 Injector Circuit Malfunction-Cylinder

no. 3

PO204 Injector Circuit Malfunction-Cylinder

no. 4

PO205 Injector Circuit Malfunction-Cylinder

no. 5

PO206 Injector Circuit Malfunction-Cylinder

no. 6

PO214 Cold Start Injector no. 2 Malfunction

PO215 Engine Shutoff Solenoid Malfunction

PO218 Injection Timing Control Circuit Malfunc-

tion

PO217 Engine Over Temperature Condition

PO218 Transmission Over Temperature Condition

PO219 Engine Over Speed Condition

PO220 Throttle Position Sensor/Switch ‘9” Cir-

cuit Malfunction

PO221 Throttle Position Sensor/Switch “B” Cir-

cuit Range/Performance Problem

PO222 Throttle Position Sensor/Switch “B” Cir-

cuit Low Input

PO223 Throttle Position Sensor/Switch “B” Cir-

cuit High Input

PO224 Throttle Position Sensor/Switch “B” Cir-

cuit Intermittent

PO225 Throttle Position Sensor/Switch “C” Cir-

cuit Malfunction

PO226 Throttle Position Sensor/Switch “C” Cir-

cuit Range/Performance Problem

PO227 Throttle Position Sensor/Switch “c” Cir-

cuit Low Input

PO228 Throttle Position Sensor/Switch “C” Cir-

cuit High Input

PO229 Throttle Position Sensor/Switch “C” Cir-

cuit Intermittent

PO230 Fuel Pump Primary Circuit Malfunction

PO231 Fuel Pump Secondary Circuit Low

PO232 Fuel Pump Secondary Circuit High

PO233 Fuel Pump Secondary Circuit Intermittent

PO261 Cylinder no. 1 Injector Circuit Low

PO262 Cylinder no. 1 Injector Circuit High

PO263 Cylinder no. 1 Contribution/Balance Fault

PO264 Cvlinder no. 2 lniector Circuit Low

PO265 Cylinder no. 2 Injector Circuit High

PO266 Cylinder no. 2 Contribution/Balance Fault

PO267 Cylinder no. 3 Injector Circuit Low

PO268 Cylinder no. 3 Injector Circuit High

PO269 Cylinder no. 3 Contribution/Balance Fault

PO270 Cylinder no. 4 Injector Circuit Low

PO271 Cvlinder no. 4 lniector Circuit Hiah

PO272 Cylinder no. 4 CbntributionlBalaice Fault

PO273 Cylinder no. 5 Injector Circuit Low

PO274 Cylinder no. 5 Injector Circuit High