ESP MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 114 of 408

ENGINEANDENGINEOVERHAUL 3-53

16. Torque the bearing cap bolts in the following

sequence: No. 3, No. 2, No. 1 and No. 4 to 85 inch

Ibs. (10 Nm).

17. Repeat the sequence increasing the torque to

14 ft. Ibs. (20 Nm).

18. Remove the auto lash adjuster retainer tools

from the rocker arms.

19. Install the camshaft sprocket and bolt.

20. Using camshaft sprocket holding tool

MB9g67 and MD998719 or equivalent, hold the

sprocket and tighten the bolt to 65 ft. Ibs. (90 Nm).

21. Install the timing belt and valve covers.

22. Using a new O-ring, install the distributor ex-

tension housing.

23. Install the intake manifold plenum stay

bracket.

24. Install the distributor assembly Be sure to

align the rotor and distributor housing matchmarks.

25. Connect the negative battery cable and check

for leaks.

3.5L Engine

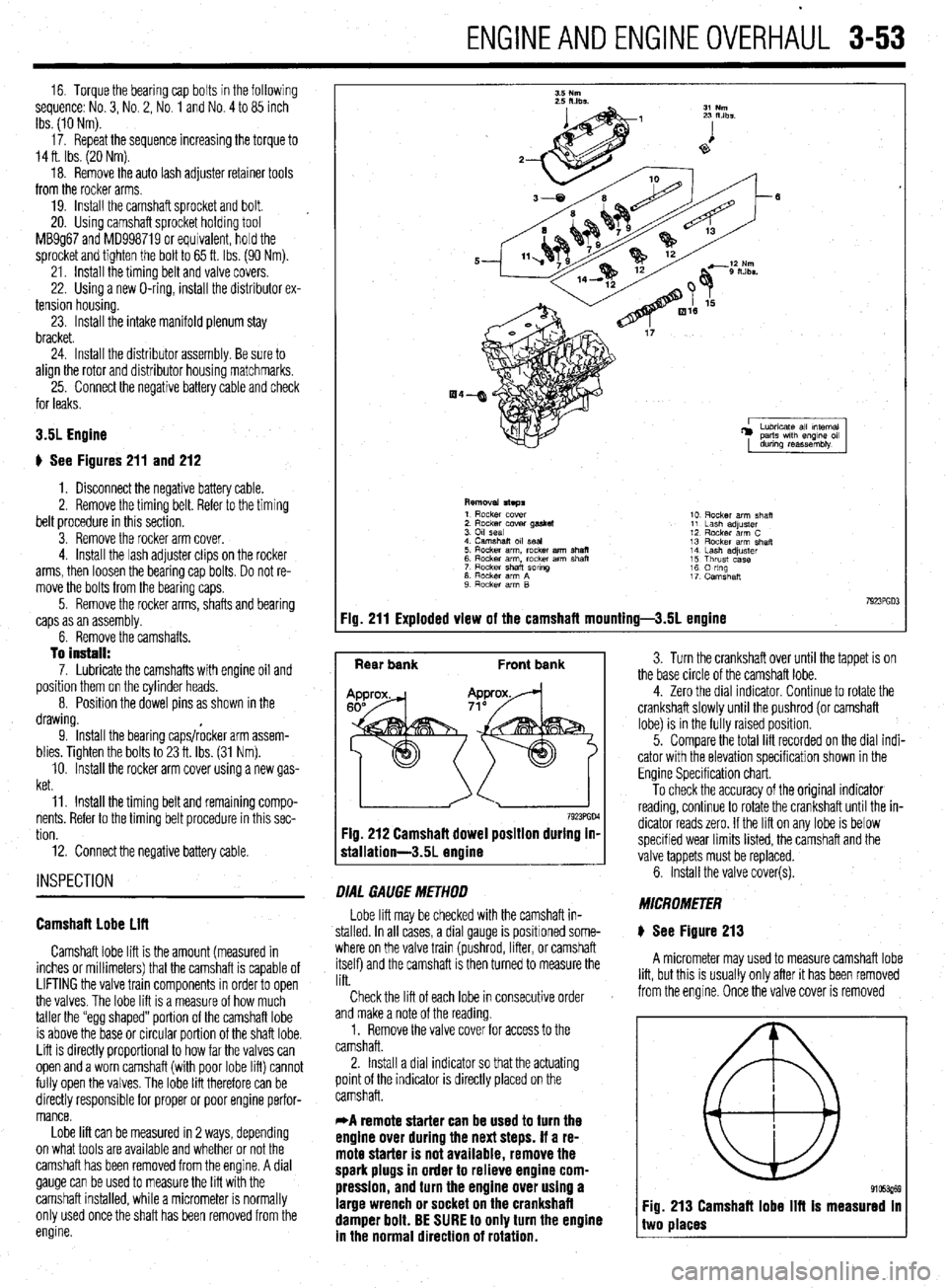

+ See Figures 211 and 212

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to the timing

belt procedure in this section.

3. Remove the rocker arm cover.

4. Install the lash adjuster clips on the rocker

arms, then loosen the bearing cap bolts. Do not re-

move the bolts from the bearing caps.

5. Remove the rocker arms, shafts and bearing

caps as an assembly.

6. Remove the camshafts.

To install: 7. Lubricate the camshafts with engine oil and

position them on the cylinder heads.

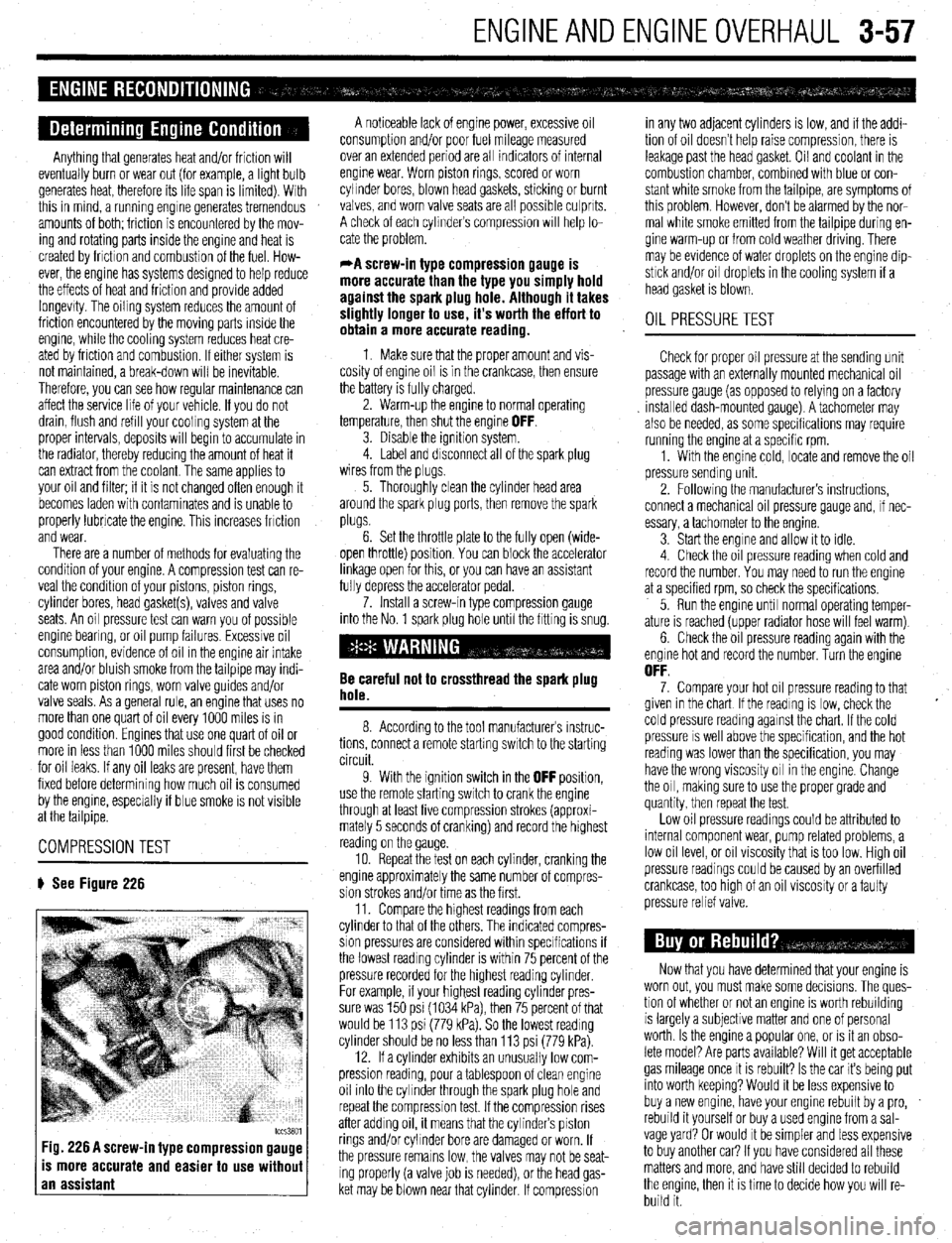

8. Position the dowel Dins as shown in the

drawing.

9. Install the bearing caps/rocker arm assem-

blies. Tighten the bolts to 23 ft. Ibs. (31 Nm).

10. hstall the rocker arm cover using a new gas-

ket.

11. Install the timing belt and remaining compo-

nents Refer to the timing belt procedure in this sec-

tion.

12. Connect the negative battery cable.

INSPECTION

Camshaft Lobe Liff

Camshaft lobe lift is the amount (measured in

inches or millimeters) that the camshaft is capable of

LIFTING the valve train components in order to open

the valves. The lobe lift is a measure of how much

taller the “egg shaped” portion of the camshaft lobe

is above the base or circular portion of the shaft lobe.

Lift is directly proportional to how far the valves can

open and a worn camshaft (with poor lobe lift) cannot

fully open the valves. The lobe lift therefore can be

directly responsible for proper or poor engine perfor-

mance.

Lobe lift can be measured in 2 ways, depending

on what tools are available and whether or not the

camshaft has been removed from the engine. A dial

gauge can be used to measure the lift with the

camshaft installed, while a micrometer is normally

only used once the shaft has been removed from the

engine.

10 Rocker arm shaft

11 Lash ad,uster

12 Rocker arm C

13 Rocker arm six,,

14 Lash adluster

15 Thrust case

16 orng

17 Camshan

:ig. 211 Exploded view of the camshaft mounting-3.51 engine 1923PGD

Rear bank Front bank

7923PGD4 Fig. 212 Camshaft dowel position during in-

stallation-3.51 engine

DIAL GAUGE METHOD

Lobe lift may be checked with the camshaft in-

stalled. In all cases, a dial gauge is positroned some-

where on the valve train (pushrod, lifter, or camshaft

itself) and the camshaft is then turned to measure the

lift.

Check the lift of each lobe in consecutive order

and make a note of the reading.

1. Remove the valve cover for access to the

camshaft.

2. Install a dial indicator so that the actuating

point of the indicator is directly placed on the

camshaft.

*A remote starter can be used to turn the

engine over during the next steps. If a re-

mote starter is not available, remove the

spark plugs in order to relieve engine com-

pression, and turn the engine over using a

large wrench or socket on the crankshaft

damper bolt. BE SURE to only turn the engine

in the normal direction of rotation.

3. Turn the crankshaft over until the tappet is on

the base circle of the camshaft lobe.

4. Zero the dial indicator. Continue to rotate the

crankshaft slowly until the pushrod (or camshaft

lobe) is in the fully raised position.

5. Compare the total lift recorded on the dial indi-

cator with the elevation specification shown in the

Engine Specification chart.

To check the accuracy of the original indicator

reading, continue to rotate the crankshaft until the in-

dicator reads zero. If the lift on any lobe is below

specified wear limits listed, the camshaft and the

valve tappets must be replaced.

6. Install the valve cover(s).

MICROMETER

) See Figure 213

A micrometer may used to measure camshaft lobe

lift, but this is usually only after it has been removed

from the engine. Once the valve cover is removed

I

@

Fig. 213 Camshaff lobe IIR Is measured In

Page 118 of 408

ENGINEANDENGINEOVERHAUL 3-57

Anything that generates heat and/or friction WIII

eventually burn or wear out (for example, a light bulb

generates heat, therefore its life span is limited). With

this in mind, a running engine generates tremendous

amounts of both; friction is encountered by the mov-

ing and rotating parts inside the engine and heat is

created by friction and combustion of the fuel How-

ever, the engine has systems designed to help reduce

the effects of heat and friction and provide added

longevrty. The oiling system reduces the amount of

friction encountered by the moving parts inside the

engine, while the cooling system reduces heat cre-

ated by friction and combustion If either system is

not maintained, a break-down will be inevitable.

Therefore, you can see how regular maintenance can

affect the service life of your vehicle, If you do not

drain, flush and refill your cooling system at the

proper intervals, deposits WIII begin to accumulate in

the radiator, thereby reducing the amount of heat it

can extract from the coolant The same applies to

your oil and filter; If it is not changed often enough it

becomes laden with contaminates and is unable to

properly lubricate the engine. This increases friction

and wear.

There are a number of methods for evaluating the

condition of your engine. A compression test can re-

veal the condition of your pistons, piston rings,

cylinder bores, head gasket(s), valves and valve

seats. An oil pressure test can warn you of possible

engine bearing, or oil pump failures. Excessrve oil

consumption, evidence of oil in the engine air intake

area and/or bluish smoke from the tailpipe may indi-

cate worn piston rings, worn valve guides and/or

valve seals. As a general rule, an engine that uses no

more than one quart of oil every 1000 miles is in

good condition. Engines that use one quart of oil or

more in less than 1000 miles should first be checked

for oil leaks. If any oil leaks are present, have them

fixed before determining how much oil is consumed

by the engine, especrally if blue smoke is not visible

at the tailpipe

COMPRESSION TEST

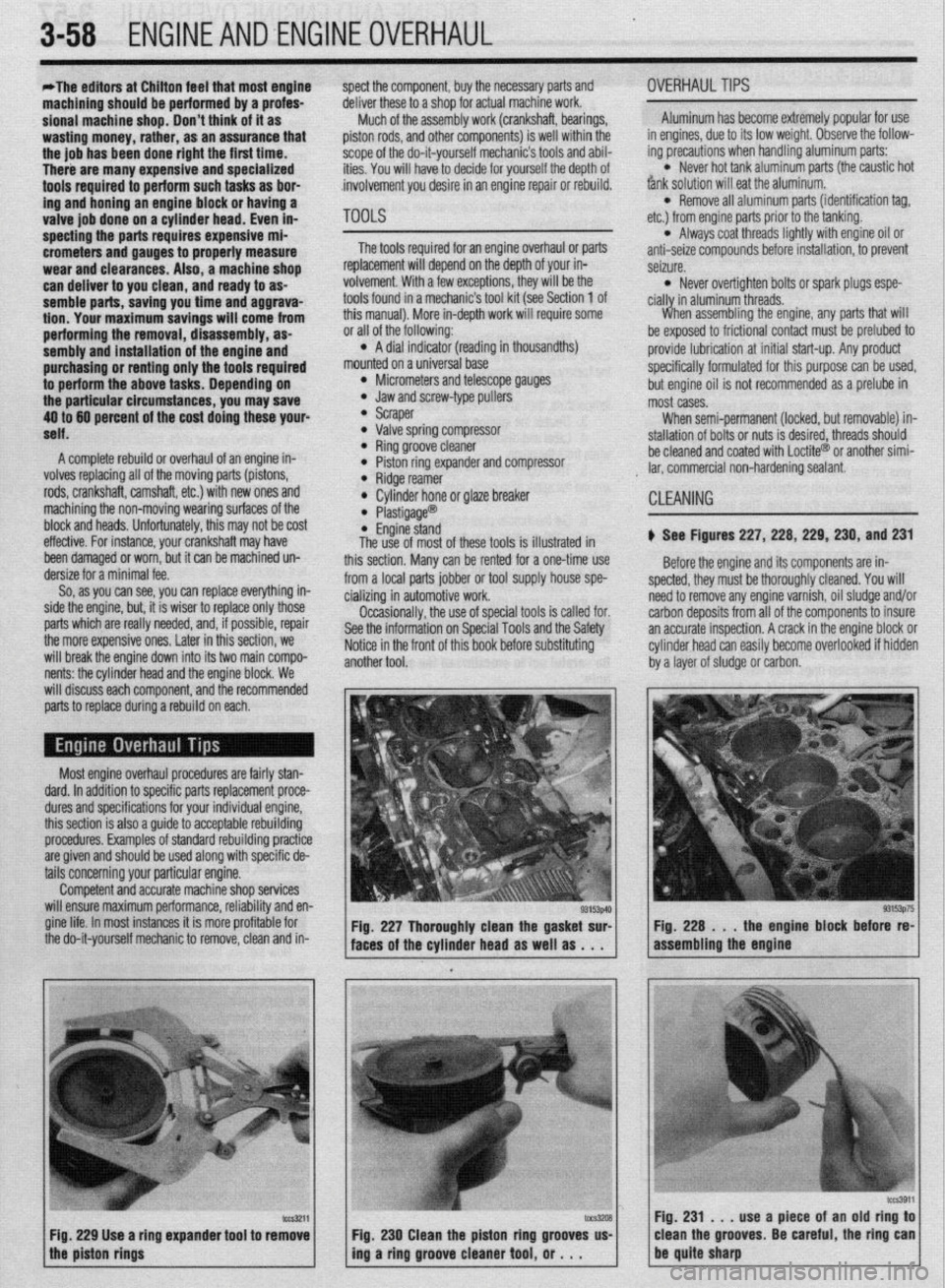

# See Figure 226

tccs3801 Fig. 226 A screw-in type compression gauge

is more accurate and easier to use without

an assistant

A noticeable lack of engine power, excessive oil

consumption and/or poor fuel mileage measured

over an extended period are all indicators of internal

engine wear. Worn piston rings, scored or worn

cylinder bores, blown head gaskets, sticking or burnt

valves, and worn valve seats are all possible culprits.

A check of each cylinders compression WIII help lo-

cate the problem.

*A screw-in type compression gauge is

more accurate than the type you simply hold

against the spark plug hole. Although it takes

slightly longer to use, it’s worth the effort to

obtain a more accurate reading.

1 Make sure that the proper amount and vis-

cosity of engine oil is in the crankcase, then ensure

the battery is fully charged.

2. Warm-up the engine to normal operating

temperature, then shut the engine

OFF. 3. Disable the ignition system.

4. Label and disconnect all of the spark plug

wires from the plugs,

5. Thoroughly clean the cylinder head area

around the spark plug ports, then remove the spark

plugs.

6. Set the throttle plate to the fully open (wide-

open throttle) position You can block the accelerator

linkage open for this, or you can have an assistant

fully depress the accelerator pedal.

7. Install a screw-in type compression gauge

into the No. 1 spark plug hole until the fitting is snug.

Be careful not to crossthread the spark plug

hole.

8. According to the tool manufacturers instruc-

tions, connect a remote starting switch to the starting

circuit.

9. With the ignition switch in the

OFF position,

use the remote starting switch to crank the engine

through at least five compression strokes (approxi-

mately 5 seconds of cranking) and record the highest

reading on the gauge

10. Repeat the test on each cylinder, cranking the

engine approximately the same number of compres-

sion strokes and/or time as the first.

11. Compare the hrghest readings from each

cylinder to that of the others. The indicated compres-

sion pressures are considered within specifications if

the lowest reading cylinder is within 75 percent of the

pressure recorded for the highest reading cylinder

For example, if your highest reading cylinder pres-

sure was 150 psi (1034 kPa), then 75 percent of that

would be 113 psi (779 kPa). So the lowest reading

cylinder should be no less than 113 psi (779 kPa).

12. If a cylinder exhibits an unusually low com-

pression reading, pour a tablespoon of clean engine

oil into the cylinder through the spark plug hole and

repeat the compression test. If the compression rises

after adding oil, it means that the cylinder’s piston

rings and/or cylinder bore are damaged or worn, If

the pressure remains low, the valves may not be seat-

ing properly (a valve job is needed), or the head gas-

ket may be blown near that cylinder. If compression in any two adjacent cylinders is low, and if the addi-

tion of oil doesn’t help raise compression, there is

leakage past the head gasket. Oil and coolant in the

combustion chamber, combined with blue or con-

stant white smoke from the tailpipe, are symptoms of

this problem. However, don’t be alarmed by the nor-

mal white smoke emitted from the tailpipe during en-

gine warm-up or from cold weather driving. There

may be evidence of water droplets on the engine dip-

stick and/or oil droplets in the cooling system if a

head gasket is blown.

OIL PRESSURETEST

Check for proper oil pressure at the sending unit

passage with an externally mounted mechanical oil

pressure gauge (as opposed to relying on a factory

Installed dash-mounted gauge). A tachometer may

also be needed, as some specifications may require

running the engine at a specific rpm.

1. With the engine cold, locate and remove the oil

pressure sending unit.

2. Followrng the manufacturers instructions,

connect a mechanical oil pressure gauge and, if nec-

essary, a tachometer to the engine.

3 Start the engine and allow it to idle.

4 Check the oil pressure reading when cold and

record the number. You may need to run the engine

at a specified rpm, so check the specifications,

5. Run the engine until normal operating temper-

ature is reached (upper radiator hose will feel warm)

6. Check the oil pressure reading again with the

engine hot and record the number. Turn the engine

OFF. 7. Compare your hot oil pressure reading to that

given in the chart If the reading is low, check the

cold pressure reading against the chart. If the cold

pressure IS well above the specification, and the hot

reading was lower than the specification, you may

have the wrong viscosity oil in the engine. Change

the oil, making sure to use the proper grade and

quantity, then repeat the test.

Low oil pressure readings could be attributed to

internal component wear, pump related problems, a

low oil level, or oil viscosity that is too low. High oil

pressure readings could be caused by an overfilled

crankcase, too htgh of an oil viscosity or a faulty

pressure relief valve.

Now that you have determined that your engine is

worn out, you must make some decisions. The ques-

tion of whether or not an engine IS worth rebuilding

is largely a subjective matter and one of personal

worth. Is the engine a popular one, or IS it an obso-

lete model? Are parts available? Will it get acceptable

gas mileage once It is rebuilt? Is the car its being put

into worth keeping? Would it be less expensive to

buy a new engine, have your engine rebuilt by a pro,

rebuild it yourself or buy a used engine from a sal-

vage yard? Or would It be simpler and less expensive

to buy another car? If you have considered all these

matters and more, and have still decided to rebuild

the engine, then it is time to decide how you will re-

build it.

Page 119 of 408

3-58 ENGINEANDENGINEOVERHAUL '

*The editors at Chilton feel that most engine

machining should be performed by a profes-

sional machine shop. Don’t think of it as

wasting money, rather, as an assurance that

the job has been done right the first time.

There are many expensive and specialized

tools required to perform such tasks as bor-

ing and honing an engine block or having a

valve job done on a cylinder head. Even in-

specting the parts requires expensive mi-

crometers and gauges to properly measure

wear and clearances. Also, a machine shop

can deliver to you clean, and ready to as-

semble parts, saving you time and aggrava-

tion. Your maximum savings will come from

performing the removal, disassembly, as-

sembly and installation of the engine and

purchasing or renting only the tools required

to perform the above tasks. Depending on

the particular circumstances, you may save

40 to 60 percent of the cost doing these your-

self.

A complete rebuild or overhaul of an engine in-

volves replacing all of the moving parts (pistons,

rods, crankshaft, camshaft, etc.) with new ones and

machining the non-moving wearing surfaces of the

block and heads. Unfortunately, this may not be cost

effective. For instance, your crankshaft may have

been damaged or worn, but it can be machined un-

dersize for a minimal fee.

So, as you can see, you can replace everything in-

side the engine, but, it is wiser to replace only those

parts which are really needed, and, if possible, repair

the more expensive ones. Later in this section, we

will break the engine down into its two main compo-

nents: the cylinder head and the engine block. We

will discuss each component, and the recommended

parts to replace during a rebuild on each. spect the component, buy the necessary parts and OVERHAULTIPS

deliver these to a shop for actual machine work.

Much of the assembly work (crankshaft, bearings, Aluminum has become extremely popular for use

piston rods, and other components) is well within the in engines, due to its low weight. Observe the follow-

scope of the do-it-yourself mechanic’s tools and abil- ing precautions when handling aluminum parts:

ities. You will have to decide for yourself the depth of

l Never hot tank aluminum parts (the caustic hot

involvement you desire in an engine repair or rebuild. 6nk solution will eat the aluminum.

l Remove all aluminum parts (identification tag,

TOOLS etc.) from engine parts prior to the tanking.

l Always coat threads lightly with engine oil or

The tools required for an engine overhaul or parts

anti-seize compounds before installation, to prevent

replacement will depend on the depth of your in-

seizure.

volvement. With a few exceptions, they will be the

l Never overtighten bolts or spark plugs espe-

tools found in a mechanic’s tool kit (see Section 1 of

this manual). More in-depth work will require some cially in aluminum threads.

When assembling the engine, any parts that will

or all of the following:

be exposed to frictional contact must be prelubed to

l A dial indicator (reading in thousandths)

provide lubrication at initial start-up. Any product

mounted on a universal base

specifically formulated for this purpose can be used,

l Micrometers and telescope gauges

* Jaw and screw-type pullers but engine oil is not recommended as a prelube in

most cases.

‘ Scraper

When semi-permanent (locked, but removable) in-

l Valve spring compressor

stallation of bolts or nuts is desired, threads should l Ring groove cleaner l Piston ring expander and compressor be cleaned and coated with Loctite@ or another simi- l Ridge reamer , lar, commercial non-hardening sealant. l Cylinder hone or glaze breaker l Plastigage@ l Engine stand

The use of most of these tools is illustrated in

this section. Many can be rented for a one-time use

from a local parts jobber or tool supply house spe-

cializing in automotive work.

Occasionally, the use of special tools is called for.

See the information on Special Tools and the Safety

Notice in the front of this book before substituting

another tool. CLEANING

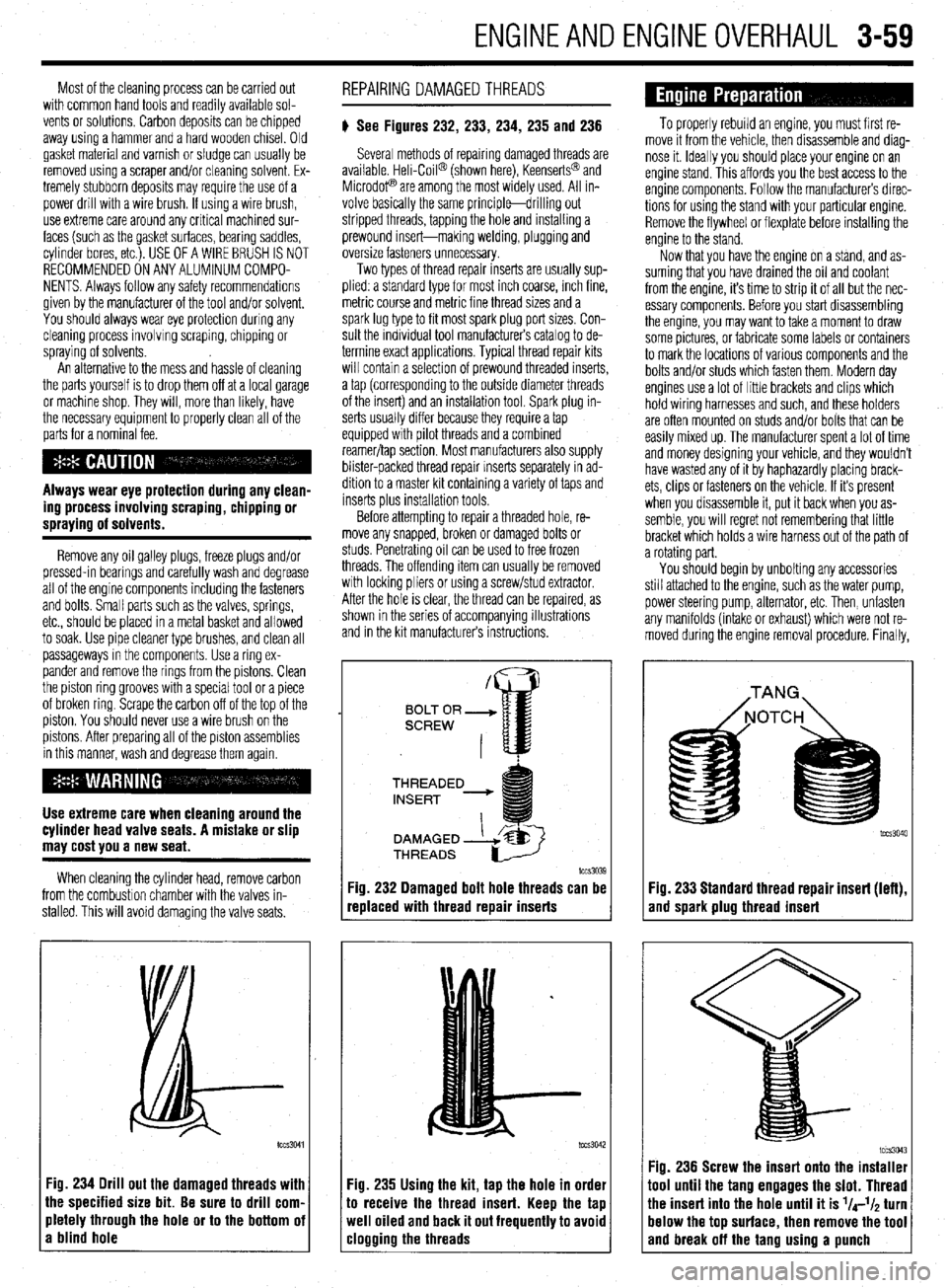

) See Figures 227, 228, 229, 230, and 231

Before the engine and its components are in-

spected, they must be thoroughly cleaned. You will

need to remove anv enaine varnish, oil sludoe and/or

c arbon deposits from ail of the componentsio insure

a In accurate inspection. A crack in the engine block or

c :ylinder head can easily become overlooked if hidden

t ry a layer of sludge or carbon.

Most engine overhaul procedures are fairly stan-

dard. In addition to specific parts replacement proce-

dures and specifications for your individual engine,

this section is also a guide to acceptable rebuilding

procedures. Examples of standard rebuilding practice

are given and should be used along with specific de-

tails concerning your particular engine.

Competent and accurate machine shop services

will ensure maximum performance, reliability and en-

gine life. In most instances it is more profitable for

the do-it-yourself mechanic to remove, clean and in- Fig. 227 Thoroughly clean the gasket sur-

faces of the cylinder head as well as . . .

Fig. 229 Use a ring expander tool to remove

the piston rings

fccs3911 ::“,z s,rpuse,a piece of fn old ring to 1

clean the grooves Be careful the ring can

230 Clean the piston ring grooves us-

ing a ring groove cleaner tool, or . . .

Page 120 of 408

ENGINEAND ENGINEOVERHAUL 3-59

Most of the cleaning process can be carried out

with common hand tools and readily available sol-

vents or solutions. Carbon deposits can be chipped

away using a hammer and a hard wooden chisel. Old

gasket material and varnish or sludge can usually be

removed using a scraper and/or cleaning solvent. Ex-

tremely stubborn deposits may require the use of a

power drill wrth a wire brush. If using a wire brush,

use extreme care around any critical machined sur-

faces (such as the gasket surfaces, bearing saddles,

cylinder bores, etc.). USE OF A WIRE BRUSH IS NOT

RECOMMENDED ON ANY ALUMINUM COMPO-

NENTS Always follow any safety recommendations

given by the manufacturer of the tool and/or solvent.

You should always wear eye protection during any

cleaning process involvrng scraping, chipping or

spraying of solvents.

An alternative to the mess and hassle of cleaning

the parts yourself is to drop them off at a local garage

or machine shop. They will, more than likely, have

the necessary equrpment to properly clean all of the

parts for a nominal fee.

Always wear eye protection during any clean-

ing process involving scraping, chipping or

spraying of solvents.

Remove any oil galley plugs, freeze plugs and/or

pressed-in bearings and carefully wash and degrease

all of the engine components including the fasteners

and bolts. Small parts such as the valves, springs,

etc., should be placed in a metal basket and allowed

to soak. Use pipe cleaner type brushes, and clean all

passageways in the components. Use a ring ex-

pander and remove the rings from the pistons. Clean

the piston ring grooves with a special tool or a piece

of broken ring Scrape the carbon off of the top of the

piston. You should never use a wire brush on the

pistons. After preparing all of the piston assemblies

in this manner, wash and degrease them again.

Use extreme care when cleaning around the

cylinder head valve seats. A mistake or slip

may cost you a new seat.

When cleaning the cylinder head, remove carbon

from the combustron chamber with the valves in-

stalled. This will avoid damaging the valve seats.

:ig. 234 Drill out the damaged threads with

he specified size bit. Be sure to drill corn.

rletely through the hole or to the bottom oi

I blind hole REPAIRING DAMAGEDTHREADS

# See Figures 232, 233, 234, 235 and 236

Several methods of repairing damaged threads are

available Heli-Coil@ (shown here), Keenserts@ and

Microdop are among the most widely used. All in-

volve basically the same principle-drilling out

stripped threads, tapping the hole and installing a

prewound insert-making welding, plugging and

oversize fasteners unnecessary.

Two types of thread repair inserts are usually sup-

plied: a standard type for most inch coarse, rnch fine,

metric course and metrrc fine thread sizes and a

spark lug type to fit most spark plug port sizes. Con-

sult the individual tool manufacturers catalog to de-

termine exact applications. Typical thread repair kits

will contain a selection of prewound threaded inserts,

a tap (corresponding to the outside diameter threads

of the insert) and an installation tool. Spark plug in-

serts usually differ because they require a tap

equipped wrth pilot threads and a combined

reamer/tap section. Most manufacturers also supply

blister-packed thread repair Inserts separately in ad-

dition to a master kit containing a variety of taps and

inserts plus installation tools

Before attempting to repair a threaded hole, re-

move any snapped, broken or damaged bolts or

studs. Penetrating oil can be used to free frozen

threads. The offending item can usually be removed

with locking pliers or using a screw/stud extractor.

After the hole is clear, the thread can be reparred, as

shown in the series of accompanying illustrations

and in the krt manufacturers instructions.

THREADED

lCCS3039

replaced with thread repair inserts

:ig. 235 Using the kit, tap the hole in order

o receive the thread insert. Keep the tap

veil oiled and back it out frequently to avoid

:logging the threads

To properly rebuild an engine, you must first re-

move it from the vehicle, then disassemble and diag-

nose it. Ideally you should place your engine on an

engine stand. This affords you the best access to the

engine components. Follow the manufacturers direc-

tions for using the stand with your particular engine.

Remove the flywheel or flexplate before installing the

engine to the stand.

Now that you have the engine on a stand, and as-

suming that you have drained the oil and coolant

from the engine, it’s time to strip it of all but the nec-

essary components. Before you start disassembling

the engine, you may want to take a moment to draw

some pictures, or fabricate some labels or containers

to mark the locations of various components and the

bolts and/or studs which fasten them. Modern day

engines use a lot of little brackets and clips which

hold wiring harnesses and such, and these holders

are often mounted on studs and/or bolts that can be

easily mixed up. The manufacturer spent a lot of time

and money designing your vehicle, and they wouldn’t

have wasted any of it by haphazardly placing brack-

ets, clips or fasteners on the vehicle. If it’s present

when you disassemble it, put it back when you as-

semble, you will regret not remembering that little

bracket which holds a wire harness out of the path of

a rotating part.

You should begin by unbolting any accessories

still attached to the engine, such as the water pump,

power steering pump, alternator, etc. Then, unfasten

any manifolds (intake or exhaust) which were not re-

moved during the engine removal procedure. Finally,

Fig. 233 Standard thread repair insert (left),

and spark plug thread insert

im3043 Fig. 236 Screw the insert onto the installer

1001 until the tang engages the slot. Thread

‘he insert into the hole until it is l/4-l/~ turn

lelow the top surface, then remove the tool

and break off the tano usina a uunch

Page 123 of 408

.

3-62 ENGINEANDENGINEOVERHAUL

lge. To accurately inspect them, you will need some

,pecialized tools:

l A O-l in. micrometer for the valves l A dial indicator or inside diameter gauge for

he valve guides

l A spring ressure test gau e

If you do no P Yl have access to t e proper tools,

‘ou may want to bring the components to a shop

hat does.

lalves

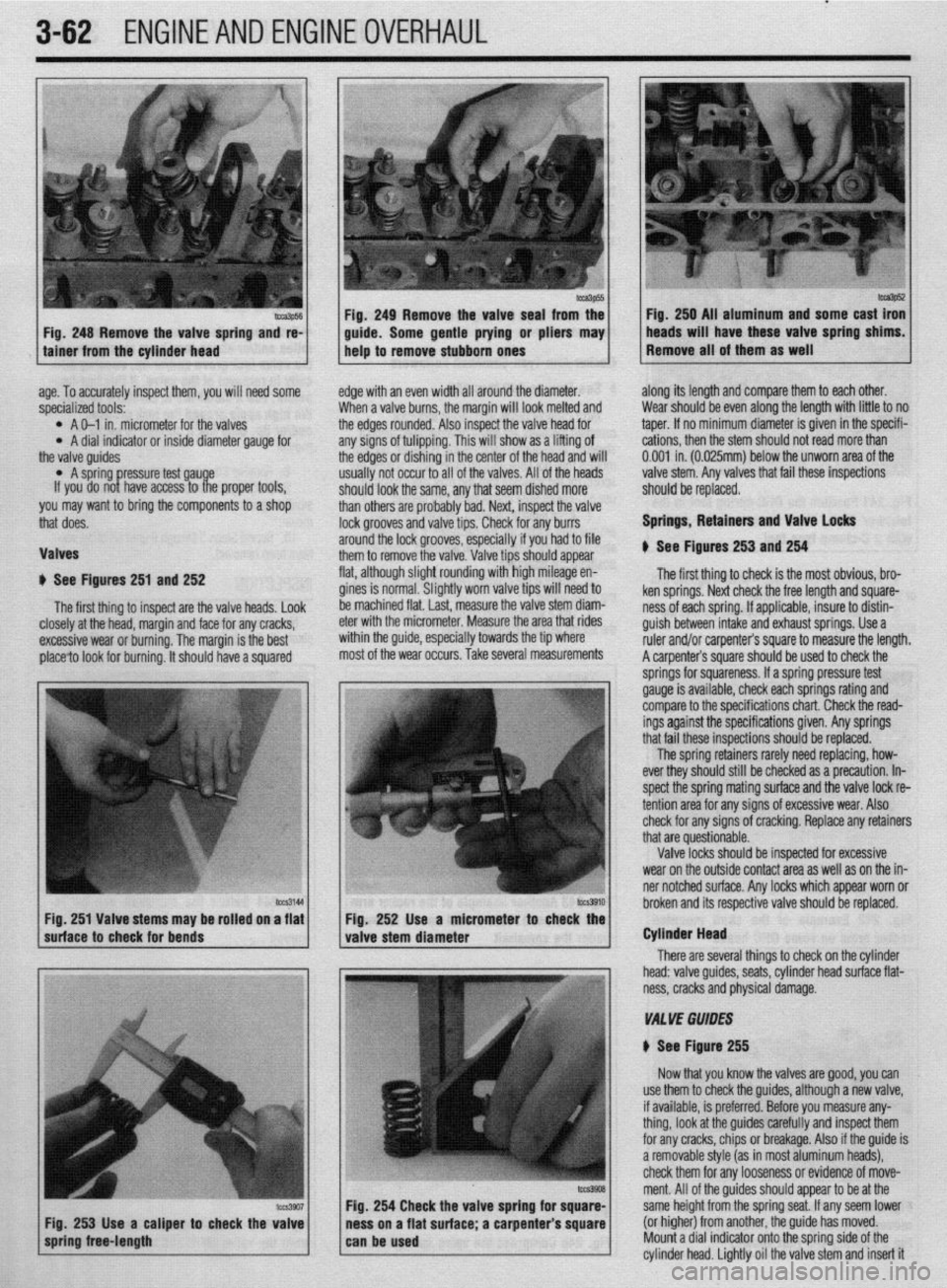

1 See Figures 251 and 252

The first thing to inspect are the valve heads. Look

E :losely at the head, margin and face for any cracks,

rxcessive wear or burning. The margin is the best

)lace?o look for burning. It should have a squared E

c

edge with an even width all around the diameter.

When a valve burns, the margin will look melted and

the edges rounded. Also inspect the valve head for

any signs of tulipping. This will show as a lifting of

the edges or dishing in the center of the head and will

usually not occur to all of the valves. All of the heads

should look the same, any that seem dished more

than others are probably bad. Next, inspect the valve

lock grooves and valve tips. Check for any burrs

around the lock grooves, especially if you had to file

them to remove the valve. Valve tips should appear

flat, although slight rounding with high mileage en-

gines is normal. Slightly worn valve tips will need to

be machined flat. last, measure the valve stem diam-

eter with the micrometer. Measure the area that rides

within the guide, especially towards the tip where

most of the wear occurs. Take several measurements along its length and compare them to each other.

Wear should be even along the length with little to no

taper. If no minimum diameter is given in the specifi-

cations, then the stem should not read more than

0.001 in. (0.025mm) below the unworn area of the

valve stem. Any valves that fail these inspections

should be replaced.

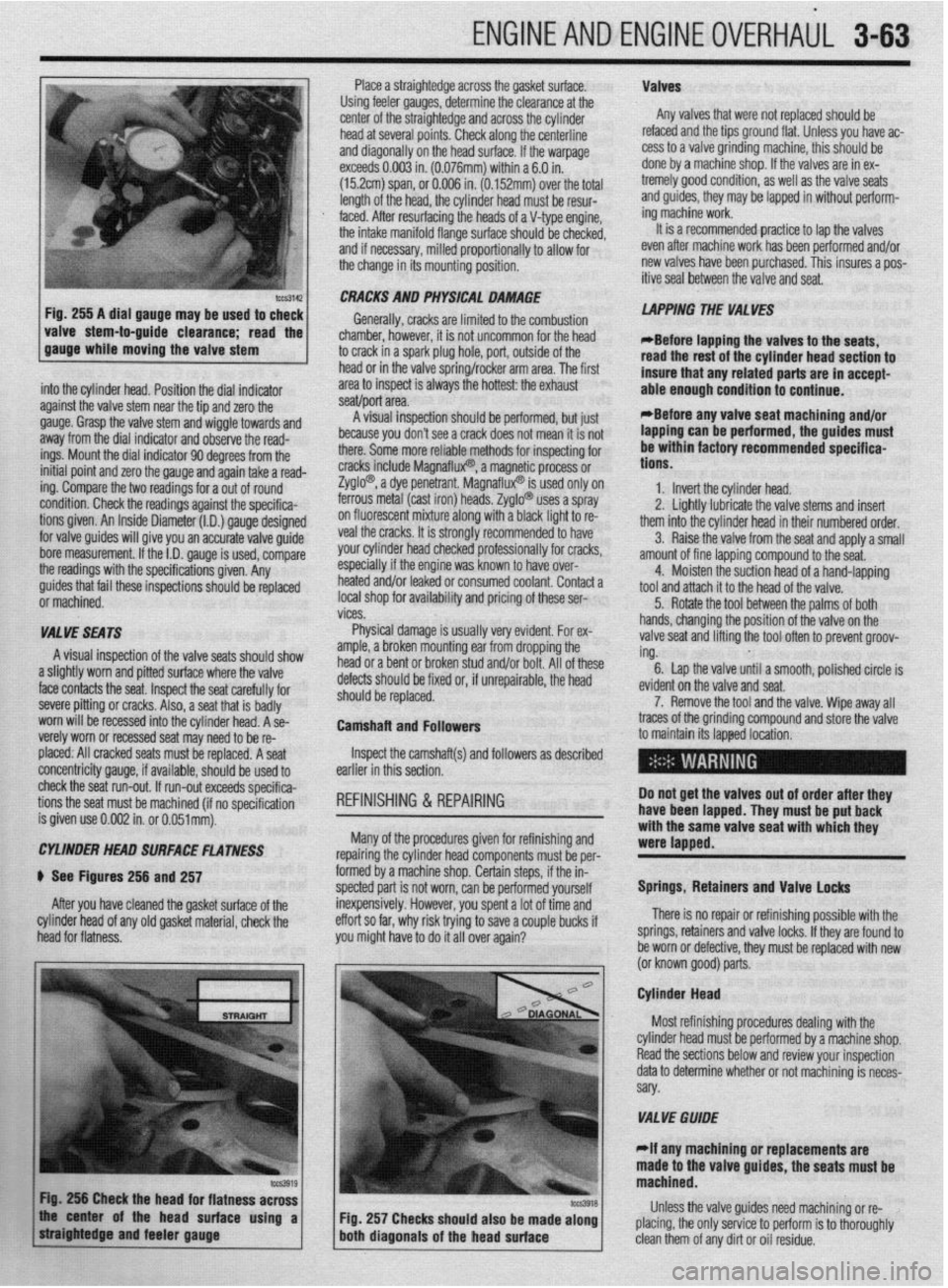

Springs, Retainers and Valve Locks

$ See Figures 253 and 254

The first thing to check is the most obvious, bro-

ken springs. Next check the free length and square-

ness of each spring. If applicable, insure to distin-

guish between intake and exhaust springs. Use a

ruler and/or carpenter’s square to measure the length.

A carpenter’s square should be used to check the

lCZS3144

I I hrnknn itc Fig. 251 Valve stems may be rolled on a flat Fio. 252 Use a micrometer

suhace to check for bends

valve stem diameter r to check the

I

There are seve Cylinder Head

ral things to check on the cylinder

head: valve guides, seats, cylinder head surface flat-

ness, cracks and physical damage.

VA1 YE GUIDES

N See Figure 255

Now that you know the valves are good, you can

254 Check the valve spring fo

s on a flat surface; a carpenter use them to check the guides, although a new valve,

if available, is preferred. Before you measure any-

thing, look at the guides carefully and inspect them

for any cracks, chips or breakage. Also if the guide is

a removable style (as in most aluminum heads),

check them for any looseness or evidence of move-

ment. All of the guides should appear to be at the

same height from the spring seat. If any seem lower

(or higher) from another, the guide has moved.

Mount a dial indicator onto the sorina side of the

cylinder head. Lightly oil the valve stem and insert it

Page 124 of 408

ENGINEANDENGINEOVERHAUL 3-63

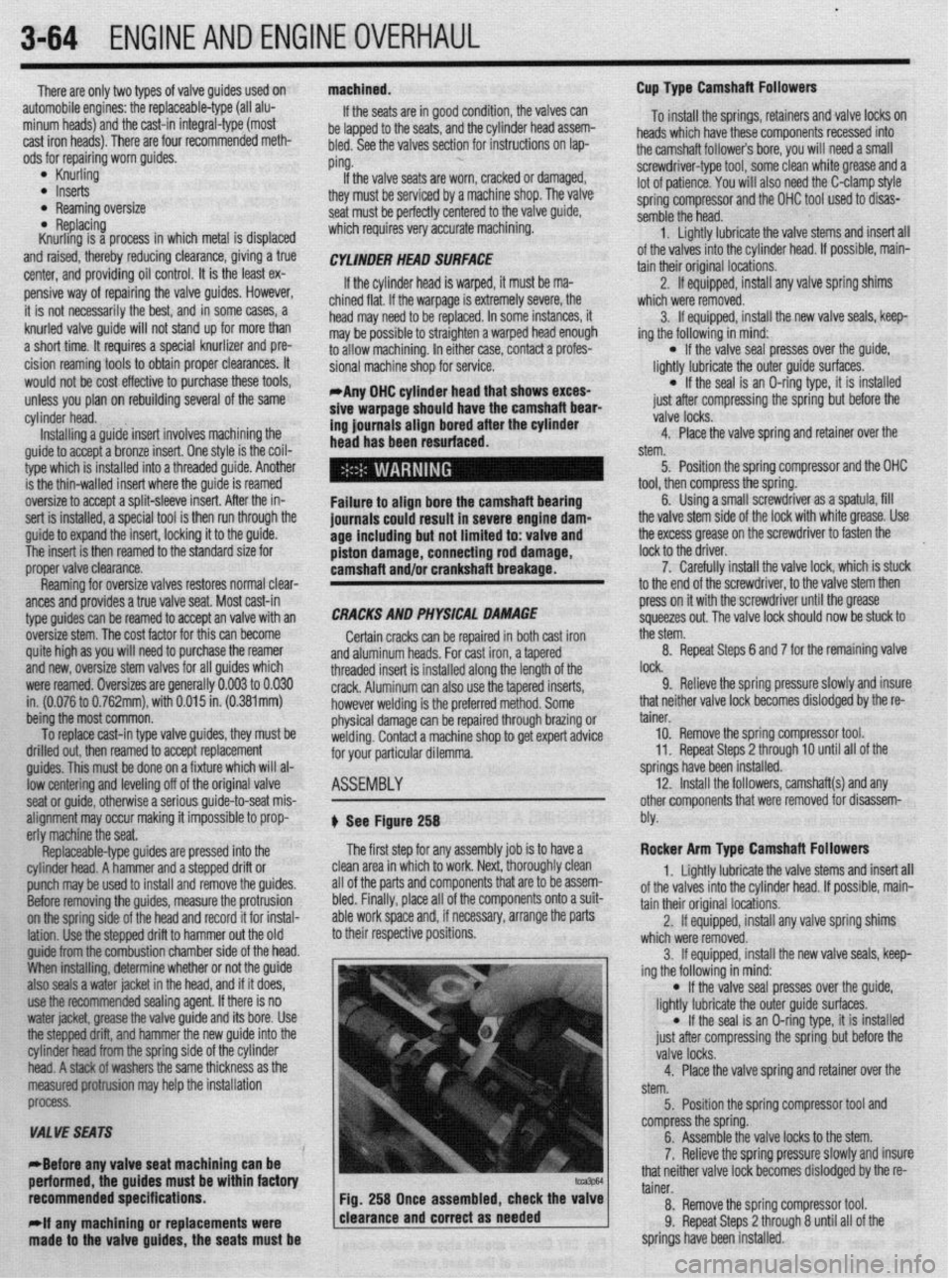

Place a straightedge across the gasket surface. Valves

Using feeler gauges, determine the clearance at the

center of the straightedge and across the cylinder Any valves that were not replaced should be

head at several points. Check along the centerline refaced and the tips ground flat. Unless you have ac-

and diagonally on the head surface. If the warpage cess to a valve grinding machine, this should be

exceeds 0.003 in. (0.076mm) within a 6.0 in. done by a machine shop. If the valves are in ex-

(152cm) span, or 0.006 in. (0.152mm) over the total tremely good condition, as well as the valve seats

length of the head, the cylinder head must be resur- and guides, they may be lapped in without petform-

,

I mg macnme worK.

4

It is a recnmmended practice to lap the valves faced. After resurfacing the heads of a V-type engine

the intake manifold flange surface should be checker,

and if necessary, milled proportionally to allow for

the change in its mounting position. _ - _ _ _ .- - - _

even after machine work has been p&formed and/or

new valves have been purchased. This insures a pos-

itive seal between the valve and seat.

-guide clearance; the 1

read

. .

into the cylinder head. Position the dial indicator

against the valve stem near the tie and zero the

gauge. Grasp the valve stem and’wiggle towards and

away from the dial indicator and observe the read-

ings. Mount the dial indicator 90 degrees from the

initial point and zero the gauge and again take a read-

ing. Compare the two readings for a out of round

condition. Check the readings against the specifica-

tions given. An Inside Diameter (I.D.) gauge designed

for valve guides will give you an accurate valve guide

bore measurement. If the I.D. gauge is used, compare

the readings with the specifications given. Any CRACKS AND PHYSICAL DAMAGE

Generally, cracks are limited to the combustion

chamber, hbwever, it is not uncommon for the head

to crack in a spark plug hole, port, outside of the

head or in the valve spring/rocker arm area. The first

area to inspect is always the hottest: the exhaust

.I *

seawpon area.

8 I .,“““I llly”Lv”l~ .ml”“l” - plr”llll”“, ““I ,“a’

because you don’t see a crack does not mean it is not

there. Some more reliable methods for inspecting for

cracks include Magnaflux? a magn$i,c process or

Zyglo? a dye penetrant. Ma{ -’

InatluxW IS used only on

ferrous metal (cast iron) heat Is. Zyglo@ uses a spray

on fluorescent mixture along with a black light to re-

veal the cracks. It is strongly recommended to have

your cylinder head checked professionally for cracks,

especially if the engine was known to have over-

I .* I,. ..^.. LAPPING THE VALVES

*Before iaoaino the valves to the seats,

read the rest of the cylinder head section to

insure that any related parts are in accept-

able enough condition to continue.

*Before anv valve seat machining and/or

lapping can be performed, the guides must

be within factory recommended specifica-

tions.

1. Invert the cylinder head.

2. Linhtlv Iuhrir;rB the valve stems and insert

-. _ ~ . . . . . .--.._-._

them into the cylinder head in their numbered order.

3. Raise the valve from the seat and apply a small

amount of fine lanninn compound to the seat.

4.

i guides that fail these inspections should be replaced nearea analor ieaKea or consumea coolant. Contact a Moisten the suction head of a hand-lapping

tool and attach it to the head of the valve.

i or machined. local shop for availability and pricing of these ser-

5. Rotate the tool between the palms of both

I vices.

I

VALVE SEATS Physical damage is usually very evident. For ex- hands, changing the position of the valve on the

valve seat and lifting the tool often to prevent groov-

A visual inspection of the valve seats should show

amnb P hrnbn mntlntinn ear from dropping the I and/or bolt. All of these ing.

.a,... . 6. Lap the valve until a smooth, polished circle is

a slightly worn and pitted surface where the valve

face contacts the seat. Inspect the seat carefully for

severe pitting or cracks. Also, a seat that is badly

worn will be recessed into the cylinder head. A se-

verely worn or recessed seat may need to be re- uetecIs SIIOUIO oe nxea or, IT unrepairaole, me neaa

should be replaced.

Camshaft and Followers evid

7

traces of the grinding corn

to maintain its lapped loca lent on the valve and seat.

‘. Remove the tool and the valve. Wipe away all

pound and store the valve

placed: All cracked seats must be replaced. A seat

concentricity gauge, if available, should be used to

check the seat run-out. If run-out exceeds specifica-

tions the seat must be machined (if no soecification

is given use 0.002 in. or O.O51mt$. Inspect the camshaft(s) and followers as described

earlier in this section.

REFINISHING & REPAIRING Do not get the valves out of order after they

have been lapped. They must be put back

: ..^^ I... --I:^:-L!-- --A

Many of the procedures gIveI

WI WIIIIISIIIIIIJ ~IIU repairing the cylinder head components must be per-

formed by a machine shop. Certain steps, if the in-

spected part is not worn, can be performed yourself

inexpensively. However, you spent a lot of time and

effort so far, why risk trying to save a couple bucks if

you might have to do it all over again?

I- with the same valve seat with which they

were lapped.

Springs, Retainers and Valve locks

There is no repair or refinishing possible with the

springs, retainers and valve locks. If they are found to

be worn or defective, they must be replaced with new

lor known nnod narts CYLtNDEt? HEAD SURFACE FLATNESS

) See Figures 256 and 257

After you have cleaned the gasket surface of the

cylinder head of any old gasket material, check the

head for flatness.

\- - a---r r- .-.

Cylinder Head

Most refinishing procedures dealing with the

VALVE GWDE

elf any machining or replacements are

e valve guides, the seats must be

Fig. 257 Checks should also be made along Unless the valve guides need machining or re-

placing, the only service to perform is to thoroughly‘

clean them of any dirt or oil residue.

Page 125 of 408

.

3-64 ENGINEANDENGINEOVERHAUL

There are only two types of valve guides used on

automobile engines: the replaceable-type (all alu-

minum heads) and the cast-in integral-type (most

cast iron heads). There are four recommended meth-

ods for repairing worn guides.

. Knurling

l Inserts l Reaming oversize l Replacing

Knurling is a process in which metal is displaced

and raised, thereby reducing clearance, giving a true

center, and providing oil control. It is the least ex-

pensive way of repairing the valve guides. However,

it is not necessarily the best, and in some cases, a

knurled valve guide will not stand up for more than

a short time. It requires a special knurlizer and pre-

cision reaming tools to obtain proper clearances. It

would not be cost effective to purchase these tools,

unless you plan on rebuilding several of the same

cylinder head.

Installing a guide insert involves machining the

guide to accept a bronze insert. One style is the coil-

type which is installed into a threaded guide. Another

is the thin-walled insert where the guide is reamed machined.

If the seats are in good condition, the valves can

be lapped to the seats, and the cylinder head assem-

bled. See the valves section for instructions on lap-

ping.

If the valve seats are worn, cracked or damaged,

they must be serviced by a machine shop. The valve

seat must be perfectly centered to the valve guide,

which requires very accurate machining.

CYLINDER HEAD SURFACE

If the cylinder head is warped, it must be ma-

chined flat. If the warpage is extremely severe, the

head may need to be replaced. In some instances, it

may be possible to straighten a warped head enough

to allow machining. In either case, contact a profes-

sional machine sh& for service. Cup Type Camshafl Followers

To install the springs, retainers and valve locks on

heads which have these components recessed into

the camshaft followers bore, you will need a small

I” .1.1.“1.“”

., ,, just after compressing the spring but before the *Any OHC cylinder head that shows exces-

sive warpage should have the camshaft bear-

ing journals align bored after the cylinder

head has been resurfaced. screwdriver-type tool, some clean white grease and a

lot of patience. You will also need the C-clamp style

spring compressor and the OHC tool used to disas-

semble the head.

1. Lightly lubricate the valve stems and insert all

of the valves into the cylinder head. If possible, main-

tain their original locations.

2. If equipped, install any valve spring shims

which were removed.

3. If equipped, install the new valve seals, keep-

ing the following in mind:

l If the valve seal presses over the guide,

lightly lubricate the outer guide surfaces.

l If the seal is an 0-rina tvoe. it rc rn+#fld

valve locks.

4. Place thevalve spring and retainer over the

stem.

5. Position the spring compressor and the OHC

tool, then compress the spring.

6. Using a small screwdriver as a spatula, fill

the valve stem side of the lock with white grease. Use

the excess grease on the screwdriver to fasten the

lock to the driver.

7. Carefully install the valve lock, which is stuck

to the end of the screwdriver, to the valve stem then

press on it with the screwdriver until the grease

squeezes out. The valve lock should now be stuck to

the stem.

8. Repeat Steps 6 and 7 for the remaining valve

lock. :

oversize to accept a split-sleeve insert. After the in-

sert is installed, a special tool is then run through the

guide to expand the insert, locking it to the guide.

The insert is then reamed to the standard size for

proper valve clearance.

Reamina for oversize valves restores normal clear- Failure to align bore the camshaft bearing

journals could result in severe engine dam-

age including but not limited to: valve and

oiston damage. connectinu rod damaoe,

iamshaft and/or crankshaft breakage,

antes and provides a true valve seat. Most cast-in

i tvpe guides can be reamed to accept an valve with an CRACKS AND PHYSICAL DAMAGE

oversize stem. The cost factor for this can become

quite high as you will need to purchase the reamer

and new, oversize stem valves for all guides which

were reamed. Oversizes are generally 0.003 to 0.030

in. (0.076 to 0.762mm), with 0.015 in. (0.381mm)

being the most common.

To replace cast-in type valve guides, they must be

drilled out, then reamed to accept replacement

guides, This must be done on a fixture which will al-

low centering and leveling off of the original valve

seat or quide, otherwise a serious guide-to-seat mis-

alignment may occur making it impossible to prop-

erly machine the seat.

Replaceable-type guides are pressed into the

cylinder head. A hammer and a stepped drift or

punch may be used to install and remove the guides.

Before removing the guides, measure the protrusion

on the spring side of the head and record it for instal-

tation. Use the stepped drift to hammer out the old

guide from the combustion chamber side of the head.

when in~llfng, determine whether or not the guide

also seals a water jacket in the head, and if it does,

use the ~o~ended sealing agent. If there is no

water jacket grease the valve guide and its bore. Use

the stepped drift, and hammer the new guide into the

cylinder head from the spring side of the cylinder

head. A stack af washers the same thickness as the

measured Eaton may help the installation Certain cracks can be repaired in both cast iron

and aluminum heads. For cast iron, a tapered

threaded insert is installed along the length of the

crack. Aluminum can also use the tapered inserts,

however welding is the preferred method. Some

physical damage can be repaired through brazing or

welding. Contact a machine shop to get expert advict

for your particular dilemma.

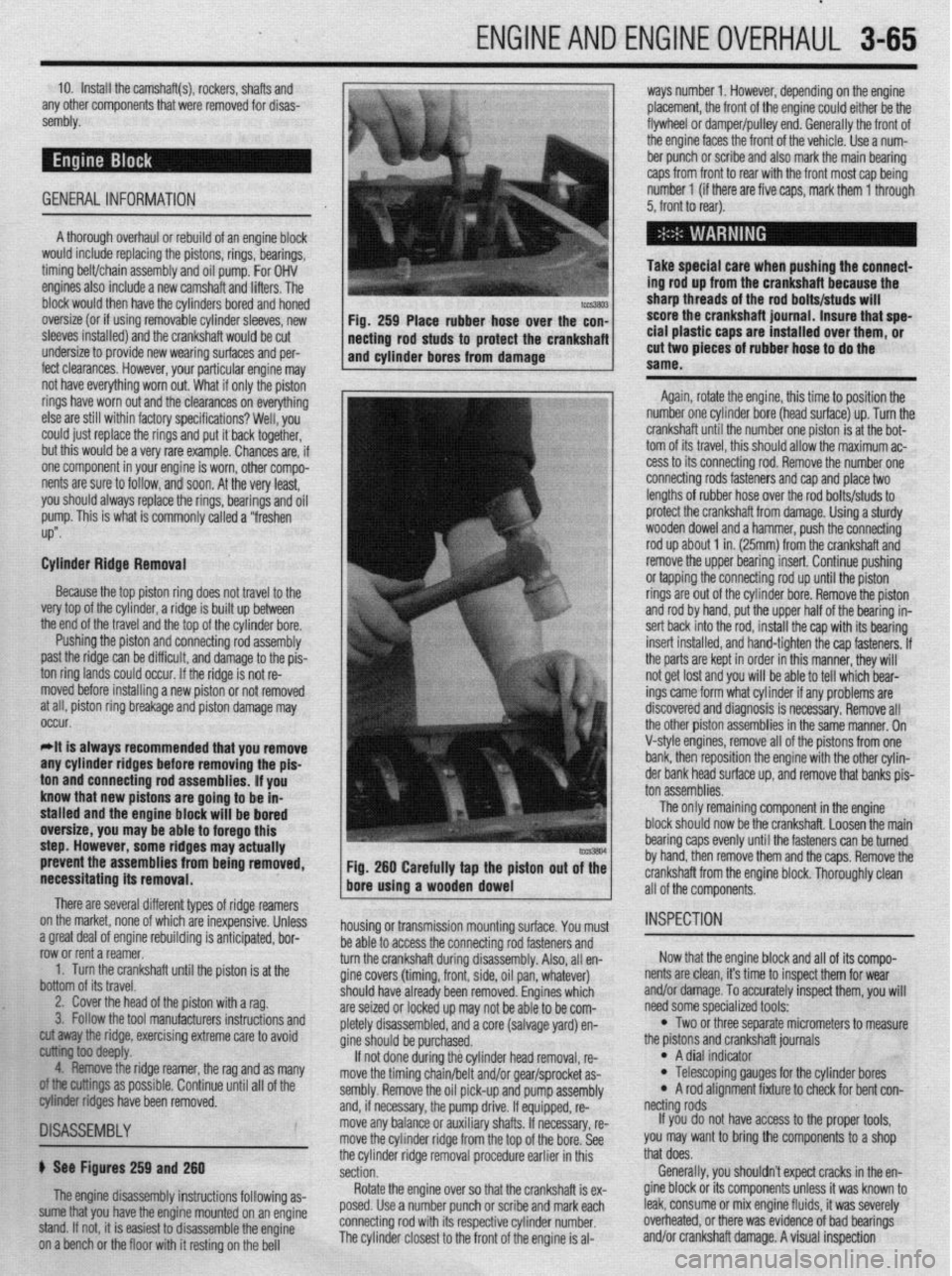

ASSEMBLY

+ See Figure 258

The first step for any assembly job is to have a

clean area in which to work. Next, thoroughly clean

all of the parts and components that are to be assem-

bled. Finally, place all of the components onto a suit-

able work space and, if necessary, arrange the parts

to their respective positions.

process.

VALVE SEATS

*Before any valve seat maChining can be

aerformed. the guides must be within factory

recommended specifications.

-

1 Fig. 258 Once assembled, check the valve

;

rlf any machtning or replacements were 1 clearance and correct as needed

I

made to the valve guides, the seats must be 9. Relieve the spring pressure slowly and insure

that neither valve lock becomes dislodged by the re-

tainer.

10. Remove the spring compressor tool.

11. Repeat Steps 2 through 10 until all of the

springs have been installed.

12. Install the followers, camshaft(s) and any

other components that were removed for disassem-

bly.

Rocker Arm Type Camshaft Followers

1. Lightly lubricate the valve stems and insert all

of the valves into the cylinder head. If possible, main-

tain their original locations.

2. If equipped, install any valve spring shims

which were removed.

3. If equipped, install the new valve seals, keep-

ing the following in mind:

l If the valve seal presses over the guide,

lightly lubricate the outer guide surfaces.

l If the seal is an O-ring type, it is installed

just after compressing the spring but before the

valve locks.

4. Place the valve spring and retainer over the

stem.

5. Position the spring compressor tool and

compress the spring.

6. Assemble the valve locks to the stem.

7. Relieve the spring pressure slowly and insure

that neither valve lock becomes dislodged by the re-

tainer.

8. Remove the spring compressor tool.

9. Repeat Steps 2 through 8 until all of the

springs have been installed.

Page 126 of 408

I)

ENGINEANDENGINEOVERHAUL 3-65

10. Install the camshaft(s), rockers, shafts and

any other components that were removed for disas-

sembly.

GENERAL INFORMATION ways number 1. However, depending on the engine

placement, the front of the engine could either be the

flywheel or damper/pulley end. Generally the front of

the engine faces the front of the vehicle. Use a num-

ber punch or scribe and also mark the main bearing

caps from front to rear with the front most cap being

number 1 (if there are five caps, mark them 1 through

5, front to rear).

A thorough overhaul or rebuild of an engine block

would include replacing the pistons, rings, bearings,

timing belt/chain assembly and oil pump. For OHV

engines also include a new camshaft and lifters. The

block would then have the cylinders bored and honed

oversize (or if using removable cylinder sleeves, new

sleeves installed) and the crankshaft would be cut

undersize to provide new wearing surfaces and per-

feet clearances. However, your particular engine may Take special care when pushing the connect-

ing rod up from the crankshaft because the

sharp threads of the rod bolts/studs will

score the crankshaft journal. Insure that spe-

cial plastic caps are installed over them, or

cut two pieces of rubber hose to do the

same.

Again, rotate the engine, this time to position the

number one cylinder bore (head surface) up. Turn the

crankshaft until the number one piston is at the bot-

tom of its travel, this should allow the maximum ac-

cess to its connecting rod. Remove the number one

connecting rods fasteners and cap and place two

lengths of rubber hose over the rod bolts/studs to

protect the crankshaft from damage. Using a sturdy

wooden dowel and a hammer, push the connecting

rod up about 1 in. (25mm) from the crankshaft and

remove the upper bearing insert. Continue pushing

or tapping the connecting rod up until the piston

rings are out of the cylinder bore. Remove the piston

and rod by hand, put the upper half of the bearing in-

sert back into the rod, install the cap with its bearing

insert installed, and hand-tighten the cap fasteners. If

the parts are kept in order in this manner, they will

not get lost and you will be able to tell which bear-

ings came form what cylinder if any problems are

discovered and diagnosis is necessary. Remove all

the other piston assemblies in the same manner. On

V-style engines, remove all of the pistons from one

bank, then reposition the engine with the other cylin-

der bank head surface up, and remove that banks nis-

prevent the assemblies from being removed,

necessitating its removal. Fig. 260 Carefully tap the piston out of the

bore using a wooden dowel

There are several different types of ridge reamers

on the market, none of which are inexpensive, Unless

.3 “me.+ ,-ins, rdnnn;nn mh~lil.-linn ;I nn+:n:nnL.* l.^W

a ylwx “Gal “I cllylllc Ir;““ll”llly 13 dllLILlpxC”, ““I- row or rent a reamer.

1. Turn the crankshaft until the piston is at the

bottom of its travel.

2. Cover the head of the piston with a rag.

3. Follow the tool manufacturers instructions and housing or transmission mounting surface. You must

1 as many

II of the

~1SA~E~BLY

b See Figures 259 and 260

The engine disassembly instructions following as-

sume that you have the engine mounted on an engine

stand. If not, it is easiest to disassemble the engine

on a bench or the floor with it resting on the bell be able to access the connecting rod fasteners and

turn the crankshaft during disassembly. Also, all en-

gine covers (timing, front, side, oil pan, whatever)

should

are sei2

nletelv have already been removed. Engines which

,ed or locked up may not be able to be com-

r’-‘-‘, disassembled, and a core (salvage yard) en-

gine sh ould be purchased.

If no

t done during the cylinder head removal, re-

move the timing chain/belt and/or gear/sprocket as-

sembly. Remove the oil pick-up and pump assembly

and, if necessary, the pump drive. If equipped, re-

move any balance or auxiliary shafts. If necessary, re-

move the cylinder ridge from the top of the bore. See

the cylinder ridge removal procedure earlier in this

section.

Rotate the engine over so that the crankshaft is ex-

posed. Use a number punch or scribe and mark each

connecting rod with its respective cylinder number.

The cylinder closest to the front of the engine is al- cut away the ridge, exercising extreme care to avoid

~ ioo deepfy.

4. Remove the ridge reamer, the rag and

armings as possible. Continue until a

biter ridges have been removed. ton assemblies.

The only remaining component in the engine

block should now be the crankshaft. Loosen the main

bearing caps evenly until the fasteners can be turned

by hand, then remove them and the caps. Remove the

crankshaft from the engine block. Thoroughly clean

all of the components.

INSPECTION

Now that the engine block and all of its compo-

nents are clean, it’s time to inspect them for wear

and/or damage. To accurately inspect them, you will

need some specialized tools:

l Two or three separate micrometers to measure

the prstons and crankshaft journals

l A dial indicator l Telescoping gauges for the cylinder bores l A rod alignment fixture to check for bent con-

netting rods

If you do not have access to the proper tools,

you may want to bring the components to a shop

that does.

Generally, you shouldn’t expect cracks in the en-

gine block or its components unless it was known to

leak, consume or mix engine fluids, it was severely

overheated, or there was evidence of bad bearings

and/or crankshaft damage. A visual inspection

Page 127 of 408

3-66 ENGINEANDENGINEOVERHAUL

should be performed on all of the components, but

just because you don’t see a crack does not mean it

is not there. Some more reliable methods for inspect-

ing for cracks include Magnaflux? a magnetic

process or Zyglo@‘, a dye penetrant. Magnaflux@ is

used only on ferrous metal (cast iron). Zyglo@ uses a

spray on fluorescent mixture along with a black light

to reveal the cracks. It is strongly recommended to

have your engine block checked professionally for

cracks, especially if the engine was known to have

overheated and/or leaked or consumed coolant. Con-

tact a local shop for availability and pricing of these

services.

Engine Block

ENGINE BLOCK BEARING ALIGNMENT

Remove the main bearing caps and, if still in:

stalled, the main bearing inserts. Inspect all of the

main bearing saddles and caps for damage, burrs or

high spots. If damage is found, and it is caused from

a spun main bearing, the block will need to be align-

bored or, if severe enough, replacement. Any burrs or

high spots should be carefully removed with a metal

file.

Place a straightedge on the bearing saddles, in the

engine block, along the centerline of the crankshaft. If

any clearance exists between the straightedge and the

saddles, the block must be align-bored.

Align-boring consists of machining the main

bearing saddles and caps by means of a flycutter that

runs through the bearing saddles.

DECK FLATNESS

The top of the engine block where the cylinder

head mounts is called the deck. Insure that the deck

surface is clean of dirt, carbon deposits and old gas-

ket material. Place a straightedge across the surface

of the deck along its centerline and, using feeler

gauges, check the clearance along several points. Re-

peat the checking procedure with the straightedge

placed along both diagonals of the deck surface. If

the reading exceeds 0.003 in. (0.076mm) within a 6.0

in. (152cm) span, or 0.006 in. (0.152mm) over the

total length of the deck, it must be machined.

CYLINDER BORES

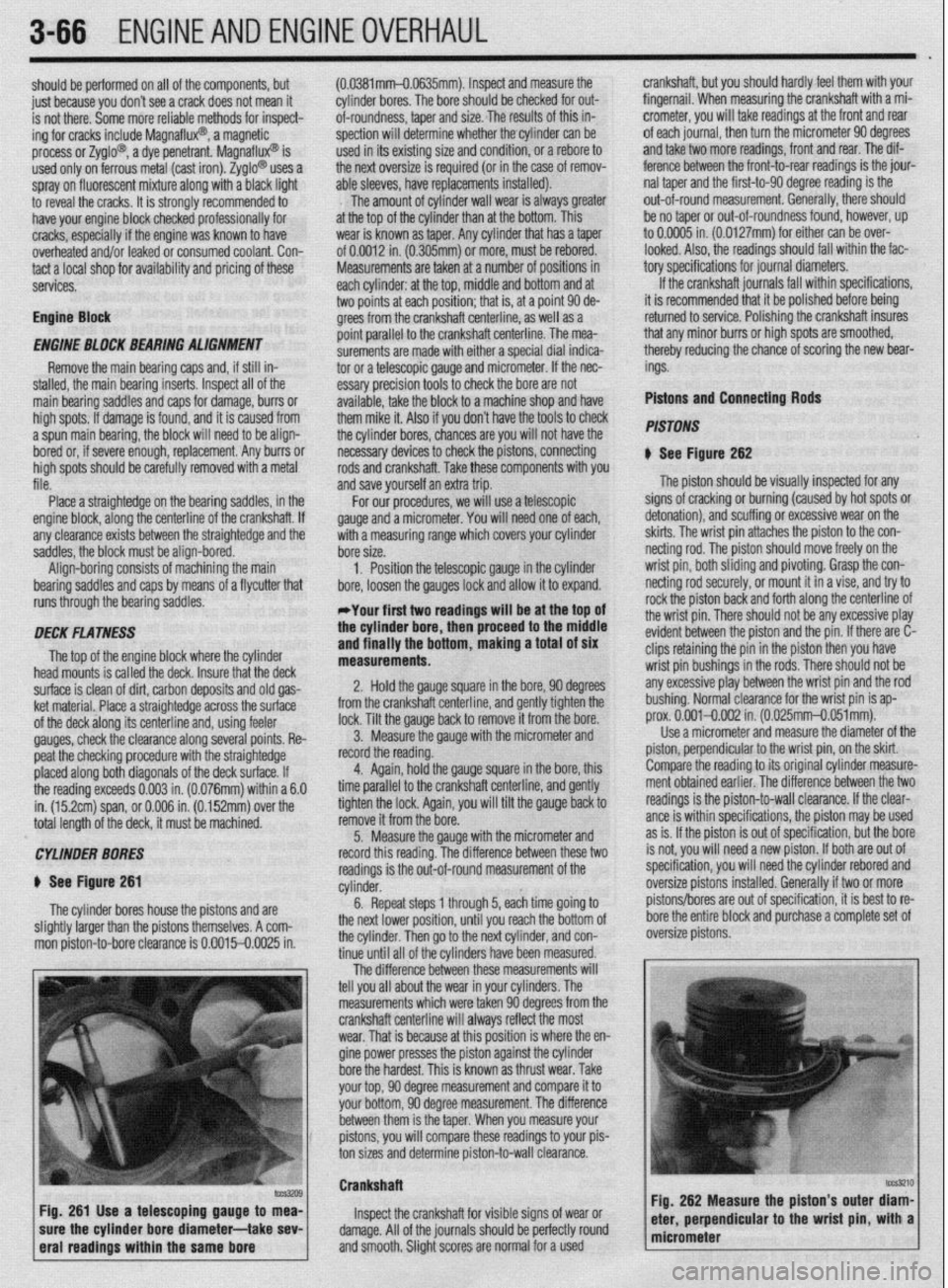

$ See Figure 261

The cylinder bores house the pistons and are

slightly larger than the pistons themselves. A com-

mon piston-to-bore clearance is 0.0015-0.0025 in. (0.0381mm-O.0635mm). Inspect and measure the

cylinder bores. The bore should be checked for out-

of-roundness, taper and size. The results of this in-

spection will determine whether thecylinder can be

used in its existing size and condition, or a rebore to

the next oversize is required (or in the case of remov-

able sleeves, have replacements installed).

The amount of cylinder wall wear is always greater

at the top of the cylinder than at the bottom. This

wear is known as taper. Any cylinder that has a taper

of 0.0012 in. (0.305mm) or more, must be rebored.

Measurements are taken at a number of positions in

each cylinder: at the top, middle and bottom and at

two points at each position; that is, at a point 90 de-

grees from the crankshaft centerline, as well as a

point parallel to the crankshaft centerline. The mea-

surements are made with either a special dial indica-

tor or a telescopic gauge and micrometer. If the nec-

essary precision tools to check the bore are not

available, take the block to a machine shop and have

them mike it. Also if you don’t have the tools to check

the cylinder bores, chances are you will not have the

necessary devices to check the pistons, connecting

rods and crankshaft. Take these components with you

and save yourself an extra trip.

For our procedures, we will use a telescopic

gauge and a micrometer. You will need one of each,’

with a measuring range which covers your cylinder

bore size.

1, Position the telescopic gauge in the cylinder

bore, loosen the gauges lock and allow it to expand.

*Your first two readings will be at the top of

the cylinder bore, then proceed to the middle

and finally the bottom, making a total of six

measurements.

2. Hold the gauge square in the bore, 90 degrees

from the crankshaft centerline, and gently tighten the

lock. Tilt the gauge back to remove it from the bore.

3. Measure the gauge with the micrometer and

record the reading.

4. Again, hold the gauge square in the bore, this

time parallel to the crankshaft centerline, and gently

tighten the lock. Again, you will tilt the gauge back to

remove it from the bore.

5. Measure the gauge with the micrometer and

record this reading. The difference between these two

readings is the out-of-round measurement of the

cylinder.

6. Repeat steps 1 through 5, each time going to

the next lower position, until you reach the bottom of

the cylinder. Then go to the next cylinder, and con-

tinue until all of the cylinders have been measured.

The difference between these measurements will

tell you all about the wear in your cylinders. The

measurements which were taken 90 degrees from the

crankshaft centerline will always reflect the most

wear.,That is because at this position is where the en-

gine power presses the piston against the cylinder

bore the hardest. This is known as thrust wear. Take

your top, 90 degree measurement and compare it to

your bottom, 90 degree measurement. The difference

between them is the taper. When you measure your

pistons, you will compare these readings to your pis-

ton sizes and determine piston-to-wall clearance. crankshaft, but you should hardly feel them with your

fingernail. When measuring the crankshaft with a mi-

crometer, you will take readings at the front and rear

of each journal, then turn the micrometer 90 degrees

and take two more readings, front and rear. The dif-

ference between the front-to-rear readings is the jour-

nal taper and the first-to-90 degree reading is the

out-of-round measurement. Generally, there should

be no taper or out-of-roundness found, however, up

to 0.0005 in. (0.0127mm) for either can be over-

looked. Also, the readings should fall within the fac-

tory specifications for journal diameters.

If the crankshaft journals fall within specifications,

it is recommended that it be polished before being

returned to service. Polishing the crankshaft insures

that any minor burrs or high spots are smoothed,

thereby reducing the chance of scoring the new bear-

ings.

Pistons and Connecting Rods

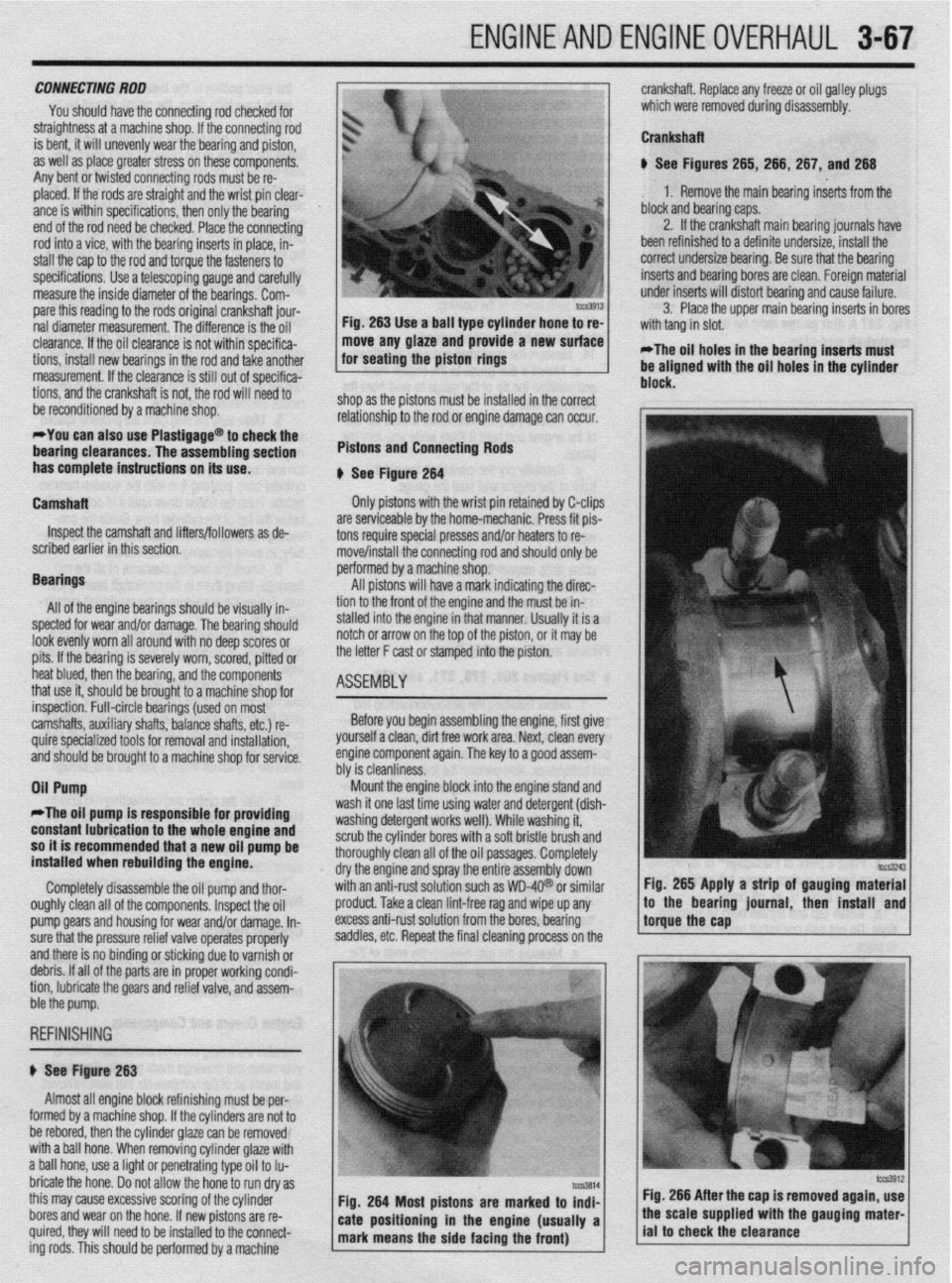

PISTONS

N See Figure 262

The piston should be visually inspected for any

signs of cracking or burning (caused by hot spots or

detonation), and scuffing or excessive wear on the

skirts. The wrist pin attaches the piston to the con-

netting rod. The piston should move freely on the

wrist pin, both sliding and pivoting. Grasp the con-

netting rod securely, or mount it in a vise, and try to

rock the piston back and forth along the centerline of

the wrist pin. There should not be any excessive play

evident between the piston and the pin. If there are C-

clips retaining the pin in the piston then you have

wrist pin bushings in the rods. There should not be

any excessive play between the wrist pin and the rod

bushing. Normal clearance for the wrist pin is ap-

prox. 0.001-0.002 in. (0.025mm-0.051mm).

Use a micrometer and measure the diameter of the

piston, perpendicular to the wrist pin, on the skirt.

Compare the reading to its original cylinder measure-

ment obtained earlier. The difference between the two

readings is the piston-to-wall clearance. If the clear-

ante is within specifications, the piston may be used

as is. If the piston is out of specification, but the bore

is not, you will need a new piston. If both are out of

specification, you will need the cylinder rebored and

oversize pistons installed. Generally if two or more

pistons/bores are out of specification, it is best to re-

bore the entire block and purchase a complete set of

oversize pistons.

Crankshaft

Inspect the crankshaft for visible signs of wear or

damage. All of the journals should be perfectly round

and smooth. Slight scores are normal for a used

Page 128 of 408

ENGINEANDENGINEOVERHAUL 3-67

CONNECTING ROD

You should have the connecting rod checked for

StraiQhtness at a machine shop. If the connecting rod

is bent, it will unevenly wear the bearing and piston,

as well as place greater stress on these components.

Any bent or twisted connecting rods must be re-

placed. If the rods are straight and the wrist pin clear-

ance is within specifications, then only the bearing

end of the rod need be checked. Place the connecting

rod into a vice, with the bearing inserts in place, in-

stall the cap to the rod and torque the fasteners to

specifications. Use a telescoping gauge and carefully

measure the inside diameter of the bearings. Com-

pare this reading to the rods original crankshaft jour-

nal diameter measurement. The difference is the oil

clearance. If the oil clearance is not within specifica-

tions, install new bearings in the rod and take another

.

specifica- L

need to

shop as the pistons must be installed in the con measurement. it the Clearance is still out of :

tions, and the crankshaft is not, the rod will

be reconditioned by a machine shop.

*You can also use Plastigage’

@to check the

bearing clearances. The assen- . ...= - _______

Mm sectinn has complete instructions on its use.

Camshaft

Inspect the camshaft and lifters/followers as de

scribed earlier in this section.

Bearings

All of the enaine bearinos should be visuallv in-

~~~ I~ .- - -- ..-_-..,

spected for we; and/or damage. The bearing should

look evenly worn all around with no deep scores or

pits. If the bearing is severely worn, scored, pitted or

heat blued, then the bearing, and the components

that use it, should be brought to a machine shop for

block. ,ect

relationshipto the rod or engine damage can occur,

Pistons and Connecting Rods

I

b See Fiaute 264 --- --*------

Only pistons with the wrist pin retained by C-clips

are serviceable by the home-mechanic. Press fit pis-

tons require special presses and/or heaters to re- I”

rr

rove/install the connecting rod and should only be

PC srformed by a machine shop.

All pistons will have a mark indicating the direc-

tir 9n to the front of the engine and the must be in-

stalled into the engine in that manner. Usually it is a

notch or arrow on the top of the piston, or it may be

the letter F cast or stamped into the piston.

ASEtiBlY

1

crankshaft. Replace any freeze or oil galley plugs

which were removed during disassembly.

Crankshaft

u See Figures 265, 266, 267, and 266

1. Remove the main bearing inserts from the

block and bearing caps.

2. If the crankshaft main bearing journals have

been refinished to a definite undersize, install the

correct undersize bearina. Be sure that the bearina

inserts and bearing bores are clean. Foreign mateiial

under inserts will distort bearinq and cause failure.

3. Place the upper main bearing inserts in bores

*The oil holes in the bearing inserts must

be aligned with the oil holes in the cylinder

. . .

inspection. Full-circle bearings (used on most

camshafts, auxiliary shafts, balance shafts, etc.) re-

quire specialized tools for removal and installation, ’

and should be brought to a machine shop for service.

Oil Pump Before you begin assembling the engine, first give

yourself a clean, dirt free work area. Next, clean every

engine component again. The key to a QOOd assem-

hhr io da~nlinmw “‘I Ia ~rGiOllll,lc7.Ja. Mount the engine block into the engine stand and

II

*The oil pump is responsible fo

r providing wasn It one last time usmg water and detergent (dish-

unrhinn rldarnant ~nrirc well), While washing it, with a soft bristle brush and

: oil oassaoes. Comoletelv constant lubrication to the whole engine and 1ILl.M 0, ,y “GSGl ycx II ““1 n

so it is recommended that a new oil pump be scrub the cylinder bore:

installed when rebuilding the engine. thoroughly clean all oft

dry the engine and spra

Completely disassemble the oil pump and thor- with an anti-rust solutio

oughly clean all of the components. Inspect the oil

pro

pump Qears and housing for wear and/or damage. In- exe

sure that the pressure relief valve operates properly sac

and there is no binding or sticking due to varnish or

debris. If all of the parts are in proper working condi-

tion, lubricate the gears and relief valve, and assem-

r

j ht

y the entire assembly down’

in such as WD-4Q@ or similar Fig. 265 Apply a strip of gauging material

Iduct. Take a clean lint-free rag and wipe up any

less anti-rust solution from the bores, bearing

Idles, etc. Repeat the final cleaning process on the !torguethe~~p * ,’ / to the bearmg lournal, then mstall and

ble the pump.

REFINISHING

# See Figure 263

Almost all engine block refinishing must be per-

I

IUIIII~U uy a macnme snap. ir me cynnoers are nor ro

be rebored, then the cylinder glaze can be removed

with a ball hone. When removing cylinder glaze with

a ball hone, use a light or penetrating type oil to Iu-

bricate the hone. Do not allow the hone to run dry as

this may cause excessive scoring of the cylinder

bores and wear on the hone. If new pistons are re-

quired, they will need to be installed to the connect-

ing rods. This should be oerformed bv a machine Fig. 266 After the cap is removed again, use