check transmission fluid MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 35 of 408

.

l-36 GENERALINFORMATIONAND MAINTENANCE

Install the drain plug and tighten to 22 ft. Ibs.

(304Nm)

5. Refill the transaxle to the proper level, as

shown in the Capacities chart, with the appropriate

fluid. The oil level should be at the bottom of the oil

filler hole. I

6. When the oil reaches the orooer level, install

the filler plug and tighten to 22 ft. Ibs. (30 Nm).

FLUID RECOMMENDATIONS

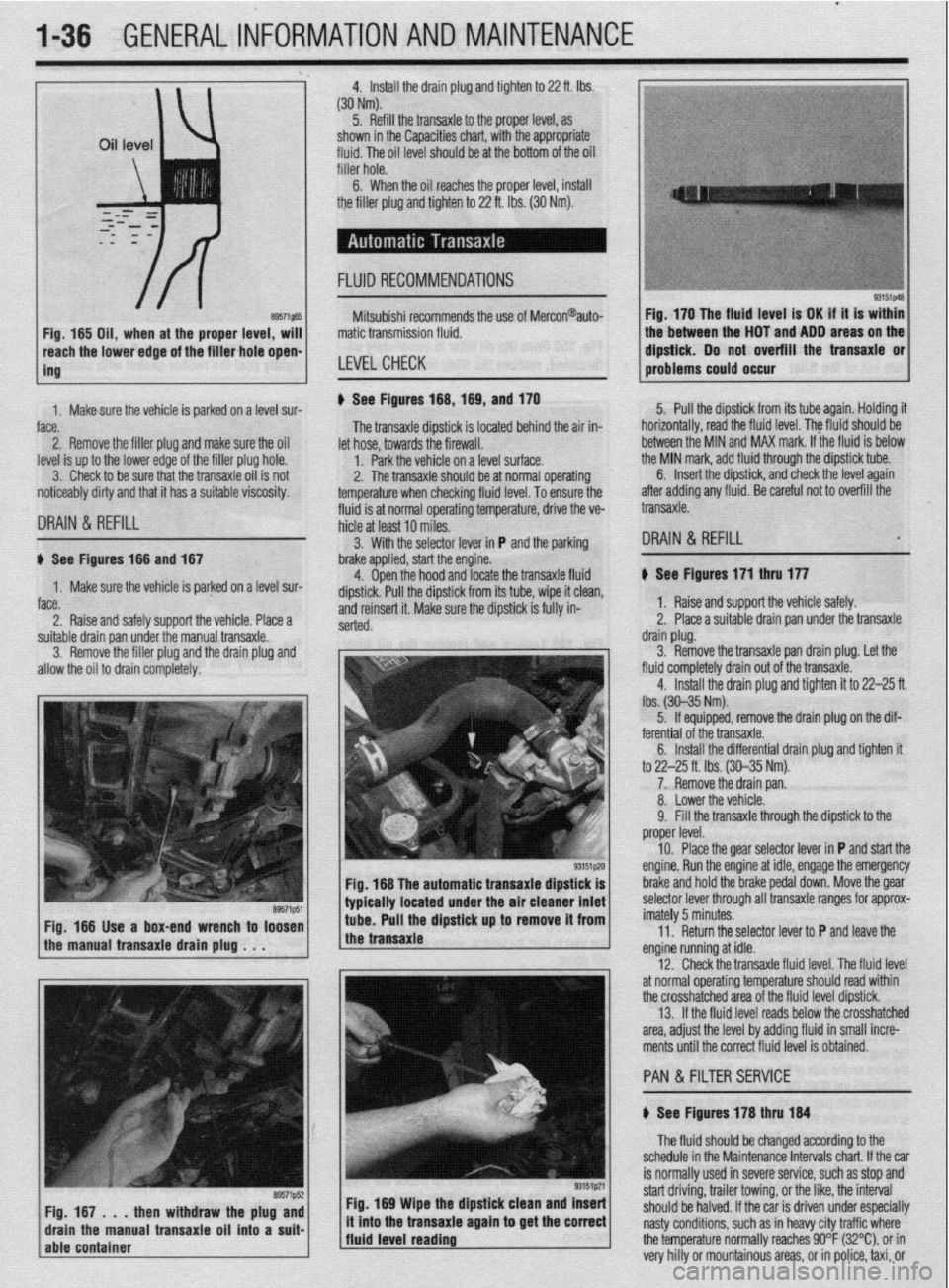

8957i565 Fig, 165 Oil, when at the proper level, will

reach the lower edge of tC=+ frfr*r u*rn -non-

ing Mitsubishi recommends the use of Mercon@auto-

matic transmission fluid.

LEVELCHECK

Fig. 170 The fluid level is OK if it is within

the between the HOT and ADD areas on the

&&i& Do not overfill the transaxle or

-.*".."... -- .*"- problems could o ccur

1. Makesure the vehicle is oarked on a level sur-

face.

2. Remove the filler plug and make sure the oil

level is up to the lower edge of the filler plug hole.

3. Check to be sure that the transaxle oil is not

noticeably dirty and that it has a suitable viscosity. u See Figures 168,169, and 170

fluid is at normal operating temperature, drive the ve- The transaxle dipstick is located behind the air in-

hicle at least 10 miles. let hose, towards the firewall.

1. Park the vehicle on a level surface.

2. The transaxle should be at normal operating

temperature when checking fluid level. To ensure the 5. Pull the dipstick from its tube again. Holding it

horizontally, road the fluid level. The fkrid should be

between the MIN and MAX mark. If the fluid is below

the MIN mark, add fluid through the dipstick tube.

DRAIN & REFILL

6. Insert the dipstick, and check the level again

after adding any fluid. Be careful not to overfill the

transaxle.

3. With the selector lever in P and the parking

DRAIN & REFILL u See Figures 166 and 167

1. Make sure the vehicle is parked on a level sur-

face.

2. Raise and safely support the vehicle. Place a brake applied, start the engine.

4. Open the hood and locate the transaxle fluid

dipstick. Pull the dipstick from its tube, wipe it clean,

and reinsert it. Make sure the dipstick is fully in-

serted.

suitable drain pan under the manual transaxle.

3. Remove the filler plug and the drain plug and

allow the oil to drain completely.

Fig. 166 The automatic transaxle dipstick is

typically located under the air cleaner inlet

Fig. 166 Use a box-end wrench to loosen

the manual transaxle drain plug . . . tube. Pull the dipstick up to remove it from

the transaxle

Fig. 169 Wipe the dipstick clean and Insert

/fluid level reading ., it mto the transaxle agam to get the correct

j The fluid should be changed according to the

schedule in the Maintenance Intervals chart. If the car

is normally used in severe service, such as stop and

start driving, trailer towing, or the like, the interval

should be halved. If the car is driven under especially

nasty conditions, such as in heavy city traffic where

the temperature normally reaches 90°F (32%), or in

very hilly or mountainous areas, or in police, taxi, or b See Figures 171 thru 177

1. Raise and support the vehicle safely.

2. Place a suitable drain pan under the transaxle

drain plug.

3. Remove the transaxle pan drain plug. Let the

fluid completely drain out of the transaxle.

4. Install the drain plug and tighten it to 22-25 ft.

lbs. (30-35 Nm).

5. If equipped, remove the drain plug on the dif-

ferential of the transaxle.

6. Install the differential drain plug and tighten ft

to 22-25 ft. Ibs. (30-35 Nm).

7. Remove the drain pan.

8. Lower the vehicle.

9. Fill the transaxle through the dipstick to the

proper level.

10. Place the gear selector lever in P and start the

engine. Run the engine at idle, engage the emergency

brake and hold the brake pedal down. Move the gear

selector lever through all transaxle ranges for approx-

imately 5 minutes.

11. Return the selector lever to P and leave the

engine running at idle.

12. Check the transaxle fluid level. The fluid level

at normal operating temperature should read within

the crosshatched area of the fluid level dipstick.

13. If the fluid level reads below the crosshatched

area, adjust the level by adding fluid in small incre-

ments until the correct fluid level is obtained.

PAN &FILTER SERVICE

b See Figures 178 thru 184

Page 41 of 408

1-42 GENERAL~INFORMATION AND MAINTENANCE

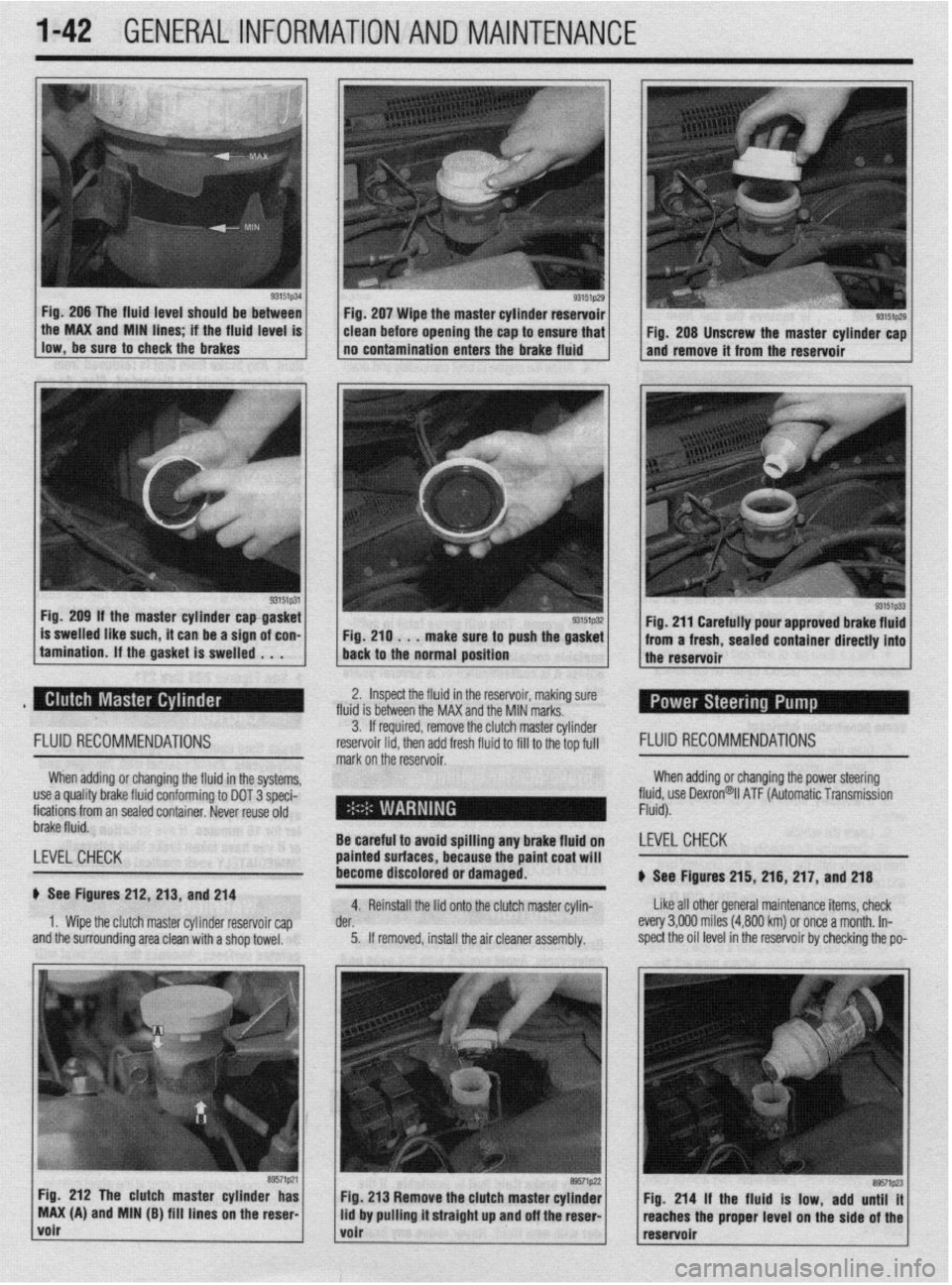

Fig. 206 The fluid level should be between

llow,be*“retoch~ckiebrake~ . the MAX and MIN hnes if the fhud level IS

93151p31 Fig. 209 If the master cylinder capgasket

is swelled like such, it can be a sign of con-

tamination. If the gasket is swelled . . . Fig. 207 Wipe the master cylinder reservoir

clean before opening the cap to ensure that

no contamination enters the brake fluid

Fig. 210 . . .

make sure to push the gasket

back to the normal position

93151p29 I Fig. 208 Unscrew the master cylinder cap

and remove it from the reservoir

Fig. 211 Carefully pour approved brake fluid

from a fresh, sealed container directly into

the reservoir

2. Inspect the fluid in the reservoir, making sure

fluid is between the MAX and the MIN marks.

FLUID RECOMMENDATIONS

When adding or changing the fluid in the systems,

use a quality brake fluid conforming to DOT 3 speci-

fications from an sealed container. Never reuse old

brake fluid.

LEVEL CHECK

b See Figures 212, 213, and 214

1. Wipe the clutch master cylinder reservoir cap

and the surrounding area clean with a shop towel. 3. If required, remove the clut ch master cylinder

reservoir lid. then add fresh fluid I FLUID RECOMMENDATIONS

mark on the’reservoir. to fill to the top full

When adding or changing the power steering

fll$,“” Dexron@il ATF (Automatic Transmission

-

- .

Be careful to avoid sf Billing any brake fluid on LEVELCHECK

painted surfaces, bet

:ause the paint coat will

become discolored or damaged.

b See Figures 215, 216, 217, and 218

4. Reinstall the lid onto the clutch master cylin- Like all other general maintenance items, check

der. every 3,OOfl miles (4,800 km) or once a month. In-

5. If removed, install the air cleaner assembly. spect the oil level in the reservoir by checking the po-

Fig. 212 The clutch master cylinder has

MAX (A) and MIN (B) fill lines on the reser

volr

Page 126 of 408

I)

ENGINEANDENGINEOVERHAUL 3-65

10. Install the camshaft(s), rockers, shafts and

any other components that were removed for disas-

sembly.

GENERAL INFORMATION ways number 1. However, depending on the engine

placement, the front of the engine could either be the

flywheel or damper/pulley end. Generally the front of

the engine faces the front of the vehicle. Use a num-

ber punch or scribe and also mark the main bearing

caps from front to rear with the front most cap being

number 1 (if there are five caps, mark them 1 through

5, front to rear).

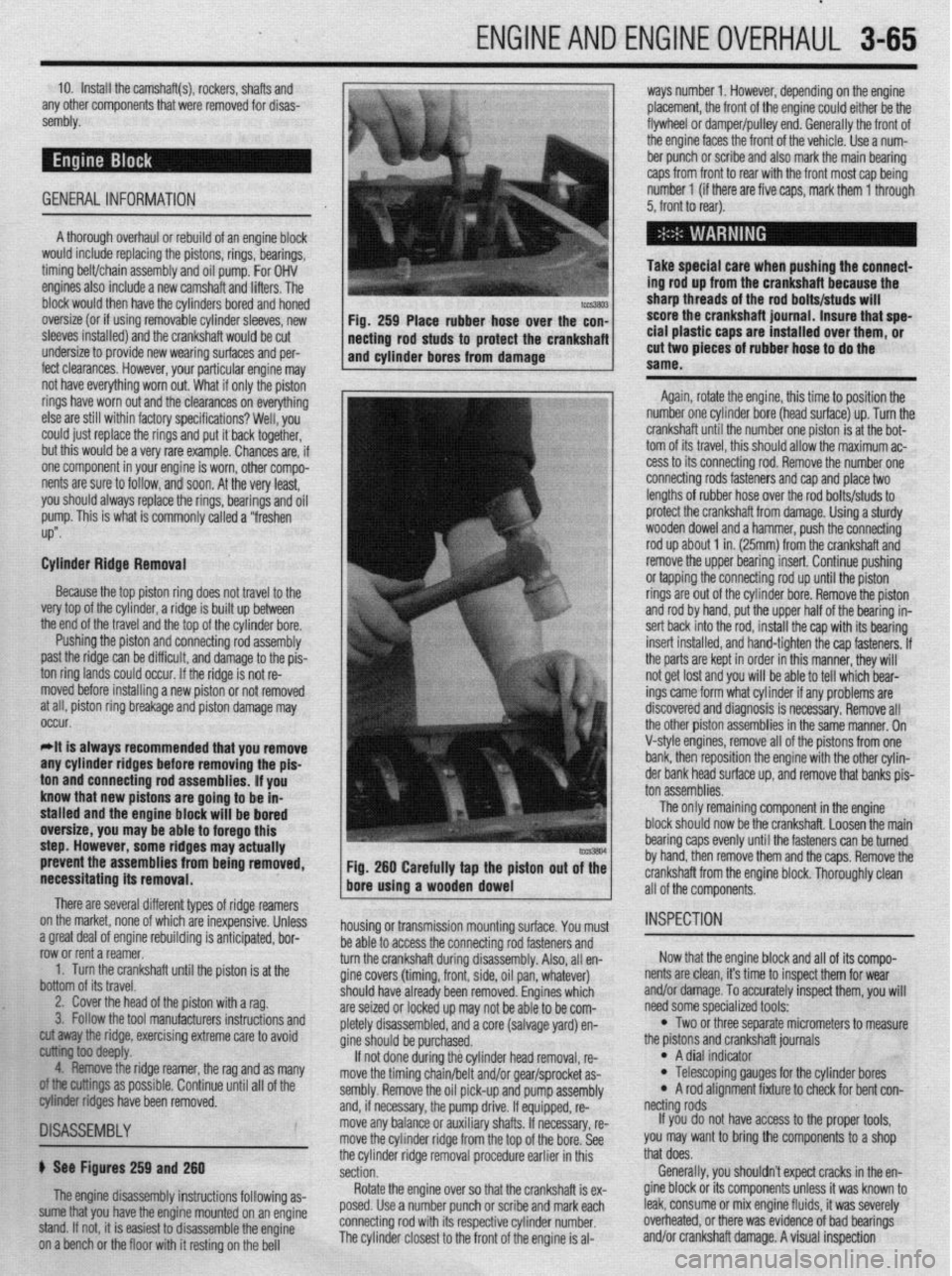

A thorough overhaul or rebuild of an engine block

would include replacing the pistons, rings, bearings,

timing belt/chain assembly and oil pump. For OHV

engines also include a new camshaft and lifters. The

block would then have the cylinders bored and honed

oversize (or if using removable cylinder sleeves, new

sleeves installed) and the crankshaft would be cut

undersize to provide new wearing surfaces and per-

feet clearances. However, your particular engine may Take special care when pushing the connect-

ing rod up from the crankshaft because the

sharp threads of the rod bolts/studs will

score the crankshaft journal. Insure that spe-

cial plastic caps are installed over them, or

cut two pieces of rubber hose to do the

same.

Again, rotate the engine, this time to position the

number one cylinder bore (head surface) up. Turn the

crankshaft until the number one piston is at the bot-

tom of its travel, this should allow the maximum ac-

cess to its connecting rod. Remove the number one

connecting rods fasteners and cap and place two

lengths of rubber hose over the rod bolts/studs to

protect the crankshaft from damage. Using a sturdy

wooden dowel and a hammer, push the connecting

rod up about 1 in. (25mm) from the crankshaft and

remove the upper bearing insert. Continue pushing

or tapping the connecting rod up until the piston

rings are out of the cylinder bore. Remove the piston

and rod by hand, put the upper half of the bearing in-

sert back into the rod, install the cap with its bearing

insert installed, and hand-tighten the cap fasteners. If

the parts are kept in order in this manner, they will

not get lost and you will be able to tell which bear-

ings came form what cylinder if any problems are

discovered and diagnosis is necessary. Remove all

the other piston assemblies in the same manner. On

V-style engines, remove all of the pistons from one

bank, then reposition the engine with the other cylin-

der bank head surface up, and remove that banks nis-

prevent the assemblies from being removed,

necessitating its removal. Fig. 260 Carefully tap the piston out of the

bore using a wooden dowel

There are several different types of ridge reamers

on the market, none of which are inexpensive, Unless

.3 “me.+ ,-ins, rdnnn;nn mh~lil.-linn ;I nn+:n:nnL.* l.^W

a ylwx “Gal “I cllylllc Ir;““ll”llly 13 dllLILlpxC”, ““I- row or rent a reamer.

1. Turn the crankshaft until the piston is at the

bottom of its travel.

2. Cover the head of the piston with a rag.

3. Follow the tool manufacturers instructions and housing or transmission mounting surface. You must

1 as many

II of the

~1SA~E~BLY

b See Figures 259 and 260

The engine disassembly instructions following as-

sume that you have the engine mounted on an engine

stand. If not, it is easiest to disassemble the engine

on a bench or the floor with it resting on the bell be able to access the connecting rod fasteners and

turn the crankshaft during disassembly. Also, all en-

gine covers (timing, front, side, oil pan, whatever)

should

are sei2

nletelv have already been removed. Engines which

,ed or locked up may not be able to be com-

r’-‘-‘, disassembled, and a core (salvage yard) en-

gine sh ould be purchased.

If no

t done during the cylinder head removal, re-

move the timing chain/belt and/or gear/sprocket as-

sembly. Remove the oil pick-up and pump assembly

and, if necessary, the pump drive. If equipped, re-

move any balance or auxiliary shafts. If necessary, re-

move the cylinder ridge from the top of the bore. See

the cylinder ridge removal procedure earlier in this

section.

Rotate the engine over so that the crankshaft is ex-

posed. Use a number punch or scribe and mark each

connecting rod with its respective cylinder number.

The cylinder closest to the front of the engine is al- cut away the ridge, exercising extreme care to avoid

~ ioo deepfy.

4. Remove the ridge reamer, the rag and

armings as possible. Continue until a

biter ridges have been removed. ton assemblies.

The only remaining component in the engine

block should now be the crankshaft. Loosen the main

bearing caps evenly until the fasteners can be turned

by hand, then remove them and the caps. Remove the

crankshaft from the engine block. Thoroughly clean

all of the components.

INSPECTION

Now that the engine block and all of its compo-

nents are clean, it’s time to inspect them for wear

and/or damage. To accurately inspect them, you will

need some specialized tools:

l Two or three separate micrometers to measure

the prstons and crankshaft journals

l A dial indicator l Telescoping gauges for the cylinder bores l A rod alignment fixture to check for bent con-

netting rods

If you do not have access to the proper tools,

you may want to bring the components to a shop

that does.

Generally, you shouldn’t expect cracks in the en-

gine block or its components unless it was known to

leak, consume or mix engine fluids, it was severely

overheated, or there was evidence of bad bearings

and/or crankshaft damage. A visual inspection

Page 174 of 408

DRIVEABILITYAND EMISSIONSCONTROL-S 4-31

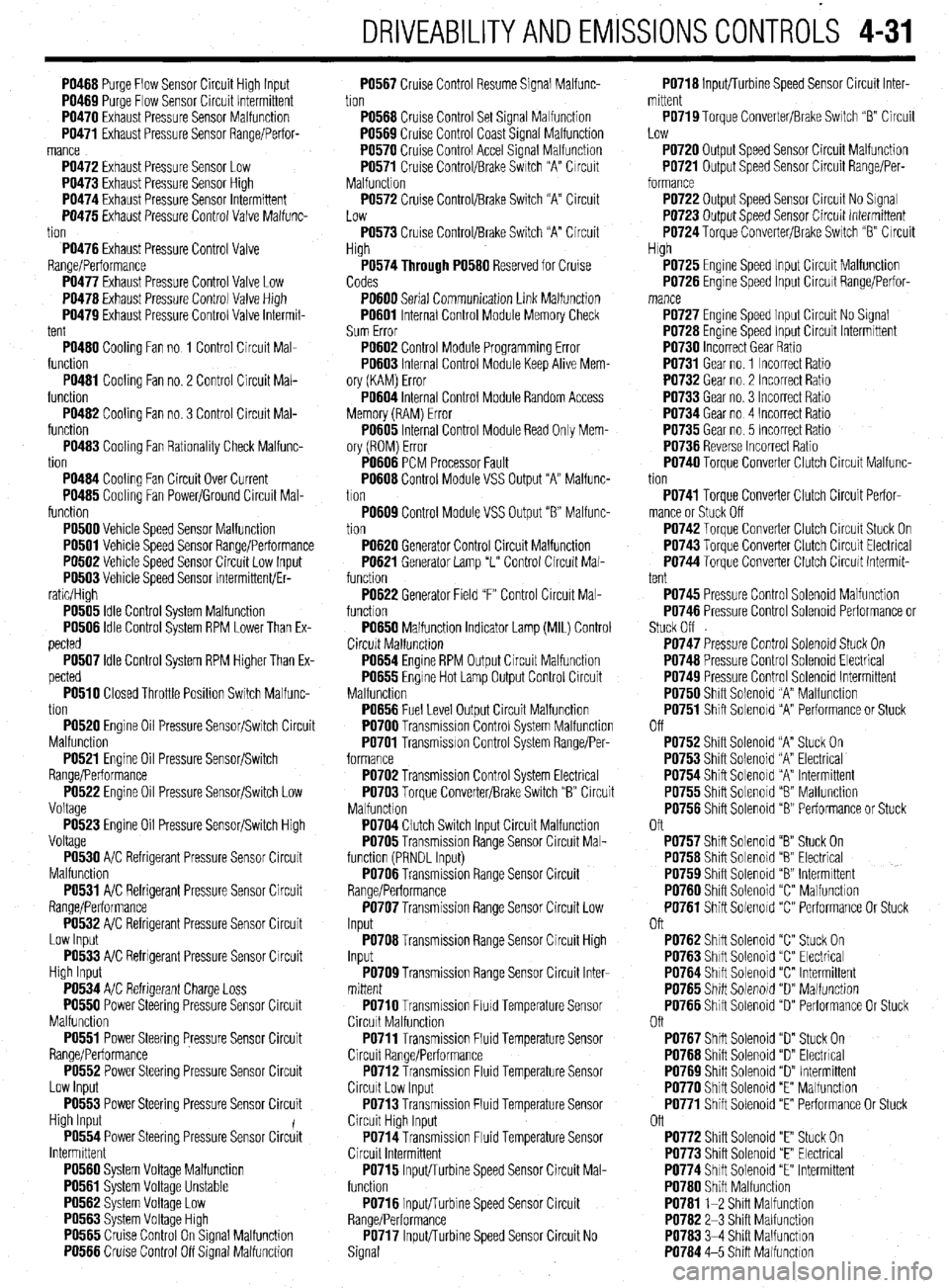

PO466 Purge Flow Sensor Circuit High Input

PO469 Purqe Flow Sensor Circuit Intermittent

PO470 Exhaust Pressure Sensor Malfunction

PO471 Exhaust Pressure Sensor Range/Perfor-

mance

PO472 Exhaust Pressure Sensor Low

PO473 Exhaust Pressure Sensor Hiah

PO474 Exhaust Pressure Sensor lnirmittent

PO475 Exhaust Pressure Control Valve Malfunc-

tion

PO476 Exhaust Pressure Control Valve

Range/Performance

PO477 Exhaust Pressure Control Valve Low

PO476 Exhaust Pressure Control Valve High

PO479 Exhaust Pressure Control Valve Intermit-

tent

PO460 Cooling Fan no 1 Control Circuit Mal-

function

PO461 Cooling Fan no. 2 Control Circuit Mal-

function

PO462 Cooling Fan no. 3 Control Circuit Mal-

function

PO463 Cooling Fan Rationality Check Malfunc-

tion

PO464 Cooling Fan Circuit Over Current

PO465 Cooling Fan Power/Ground Circuit Mal-

function

PO500 Vehicle Speed Sensor Malfunction

PO501 Vehicle Speed Sensor Range/Performance

PO502 Vehicle Speed Sensor Circuit Low Input

PO503 Vehicle Speed Sensor Intermittent/Er-

ratic/High

PO505 Idle Control System Malfunction

PO506 Idle Control System RPM Lower Than Ex-

pected

PO507 Idle Control System RPM Higher Than Ex-

pected

PO510 Closed Throttle Position Switch Malfunc-

tion

PO520 Engine Oil Pressure Sensor/Switch Circuit

Malfunction

PO521 Engine Oil Pressure Sensor/Switch

Range/Performance

PO522 Engine Oil Pressure Sensor/Switch Low

Voltage

PO523 Engine Oil Pressure Sensor/Switch High

Voltage

PO530 A/C Refrigerant Pressure Sensor Circuit

Malfunction

PO531 A/C Refrigerant Pressure Sensor Circuit

Range/Performance

PO532 A/C Refrigerant Pressure Sensor Circuit

Low Input

PO533 A/C Refrigerant Pressure Sensor Circuit

High Input

PO534 A/C Refrigerant Charge Loss

PO550 Power Steering Pressure Sensor Circuit

Malfunction

PO551 Power Steering Pressure Sensor Circuit

Range/Performance

PO552 Power Steering Pressure Sensor Circuit

Low Input

PO553 Power Steering Pressure Sensor Circuit

High Input

PO554 Power Steering Pressure Sensor Circiit

Intermittent

PO560 System Voltage Malfunction

PO561 System Voltage Unstable

PO562 System Voltage Low

PO563 Svstem Voltaoe Hlah

PO565 Ciuise Control On%ignal Malfunction

PO566 Cruise Control Off Signal Malfunction PO567 Cruise Control Resume Signal Malfunc-

tion

PO566 Cruise Control Set Signal Malfunction

PO569 Cruise Control Coast Signal Malfunction

PO570 Cruise Control Accel Signal Malfunction

PO571 Cruise Control/Brake Switch “A” Circuit

Malfunction

PO572 Cruise Control/Brake Switch “A” Circuit

Low

PO573 Cruise Control/Brake Switch “A” Circuit

High

P0574Through PO560 Reserved for Cruise

Codes

PO600 Serial Communication Link Malfunction

PO601 Internal Control Module Memory Check

Sum Error

PO602 Control Module Programming Error

PO603 Internal Control Module Keep Alive Mem-

ory (KAM) Error

PO604 Internal Control Module Random Access

Memory (RAM) Error

PO605 Internal Control Module Read Only Mem-

ory (ROM) Error

PO606 PCM Processor Fault

PO606 Control Module VSS Output “A” Malfunc-

tion

PO609 Control Module VSS Output “6” Malfunc-

tion

PO620 Generator Control Circuit Malfunction

PO621 Generator Lamp “L” Control Circuit Mal-

function

PO622 Generator Field “F” Control Circuit Mal-

function

PO650 Malfunction Indicator Lamp (MIL) Control

Circuit Malfunctron

PO654 Engine RPM Output Circuit Malfunction

PO655 Engine Hot Lamp Output Control Circuit

Malfunction

PO656 Fuel Level Output Circuit Malfunction

PO700 Transmission Control System Malfunction

PO701 Transmission Control System Range/Per-

formance

PO702 Transmission Control System Electrical

PO703 Torque Converter/Brake Switch “B” Circuit

Malfunction

PO704 Clutch Switch Input Circuit Malfunction

PO705 Transmission Range Sensor Circuit Mal-

function (PRNDL Input)

PO706 Transmission Range Sensor Circuit

Range/Performance

PO707 Transmission Range Sensor Circuit Low

Input

PO706 Transmission Range Sensor Circuit High

Input

PO709 Transmission Range Sensor Circuit Inter-

mittent

PO710 Transmission FluId Temperature Sensor

Circuit Malfunction

PO711 Transmission Fluid Temperature Sensor

Circuit Range/Performance

PO712 Transmission Fluid Temperature Sensor

Circuit Low Input

PO713 Transmission Fluid Temperature Sensor

Circuit High Input

PO714 Transmission Fluid Temperature Sensor

Circuit Intermittent

PO715 Input/Turbine Speed Sensor Circuit Mal-

function

PO716 Input/Turbine Speed Sensor Circuit

Range/Performance

PO717 InpWurbine Speed Sensor Circuit No

Signal PO716 Inputflurbine Speed Sensor Circuit Inter-

mittent

PO719 Torque Converter/Brake Switch “B” Circuit

Low

PO720 Output Speed Sensor Circuit Malfunction

PO721 Output Speed Sensor Circuit Range/Per-

formance

PO722 Output Speed Sensor Circuit No Signal

PO723 Output Speed Sensor Circuit Intermittent

PO724 Toraue Converter/Brake Switch “B” Circuit

High

PO725 Engine Speed Input Circuit Malfunction

PO726 Engine Speed Input Circuit Range/Perfor-

PO727 Engine Speed Input Circuit No Signal

PO726 Engine Speed Input Circuit Intermittent

PO730 Incorrect Gear Ratio

PO731 Gear no. 1 Incorrect Ratio

PO732 Gear no. 2 Incorrect Ratio

PO733 Gear no. 3 Incorrect Ratio

PO734 Gear no 4 Incorrect Ratio

PO735 Gear no. 5 Incorrect Ratio

PO736 Reverse Incorrect Ratio

PO740 Torque Converter Clutch Circuit Malfunc-

tion

PO741 Torque Converter Clutch Circuit Perfor-

mance or Stuck Off

PO742 Torque Converter Clutch Circuit Stuck On

PO743 Torque Converter Clutch Circuit Electrical

PO744 Torque Converter Clutch Circuit Intermit-

tent

PO745 Pressure Control Solenoid Malfunction

PO746 Pressure Control Solenoid Performance or

Stuck Off

PO747 Pressure Control Solenoid Stuck On

PO746 Pressure Control Solenoid Electrical

PO749 Pressure Control Solenoid Intermittent

PO750 Shift Solenoid “A” Malfunction

PO751 Shift Solenoid “A” Performance or Stuck

Off

PO752 Shift Solenoid “A” Stuck On

PO753 Shift Solenoid “A” Electrical

PO754 Shift Solenoid “A” Intermittent

PO755 Shift Solenoid “8 Malfunction

PO756 Shift Solenoid “B” Performance or Stuck

Oft

PO757 Shift Solenoid “B” Stuck On

PO756 Shift Solenoid “6” Electrical

PO759 Shift Solenoid “8” Intermittent

PO760 Shift Solenoid “C” Malfunction

PO761 Shift Solenoid “C” Performance Or Stuck

Oft

PO762 Shift Solenoid “C” Stuck On

PO763 Shift Solenoid “C” Electrical

PO764 Shift Solenoid “C” Intermittent

PO765 Shift Solenoid “D” Malfunction

PO766 Shift Solenoid “D” Performance Or Stuck

Oft

PO767 Shift Solenoid “D” Stuck On

PO766 Shift Solenoid “D” Electrical

PO769 Shift Solenoid “D” Intermittent

PO770 Shift Solenoid “E” Malfunction

PO771 Shift Solenoid “E” Performance Or Stuck

Off

PO772 Shift Solenoid “E” Stuck On

PO773 Shift Solenoid “E” Electrical

PO774 Shift Solenoid “E” Intermittent

PO760 Shift Malfunction

PO761 l-2 Shift Malfunction

PO762 2-3 Shift Malfunction

PO763 3-4 Shift Malfunction

PO764 4-5 Shift Malfunction

Page 289 of 408

7-10 DRIVETRAIN

The automatic transaxle allows engine torque and

power to be transmitted to the front wheels within a

narrow range of engine operating speeds. It will allow

the engine to turn fast enough to produce plenty of

power and torque at very low speeds, while keeping it

at a sensible rpm at high vehicle speeds (and it does

this job without driver assistance). The transaxle uses

a light fluid as the medium for the transmission of

power. This fluid also works in ths operation of vari-

ous hydraulic control circuits and as a lubricant. Be-

cause the transaxle fluid performs all of these func-

tions, trouble within the unit can easily travel from one

part to another For this reason, and because of the

complexity and unusual operating principles of the

transaxle, a very sound understanding of the basic

principles of operation will simplify troubleshooting

REMOVAL &INSTALLATION

Pan removal, fluid and filter

in Section 1 of this manual changes are covered

REMOVAL &INSTALLATION

1990-97 Mirage and 1990-93 Galant

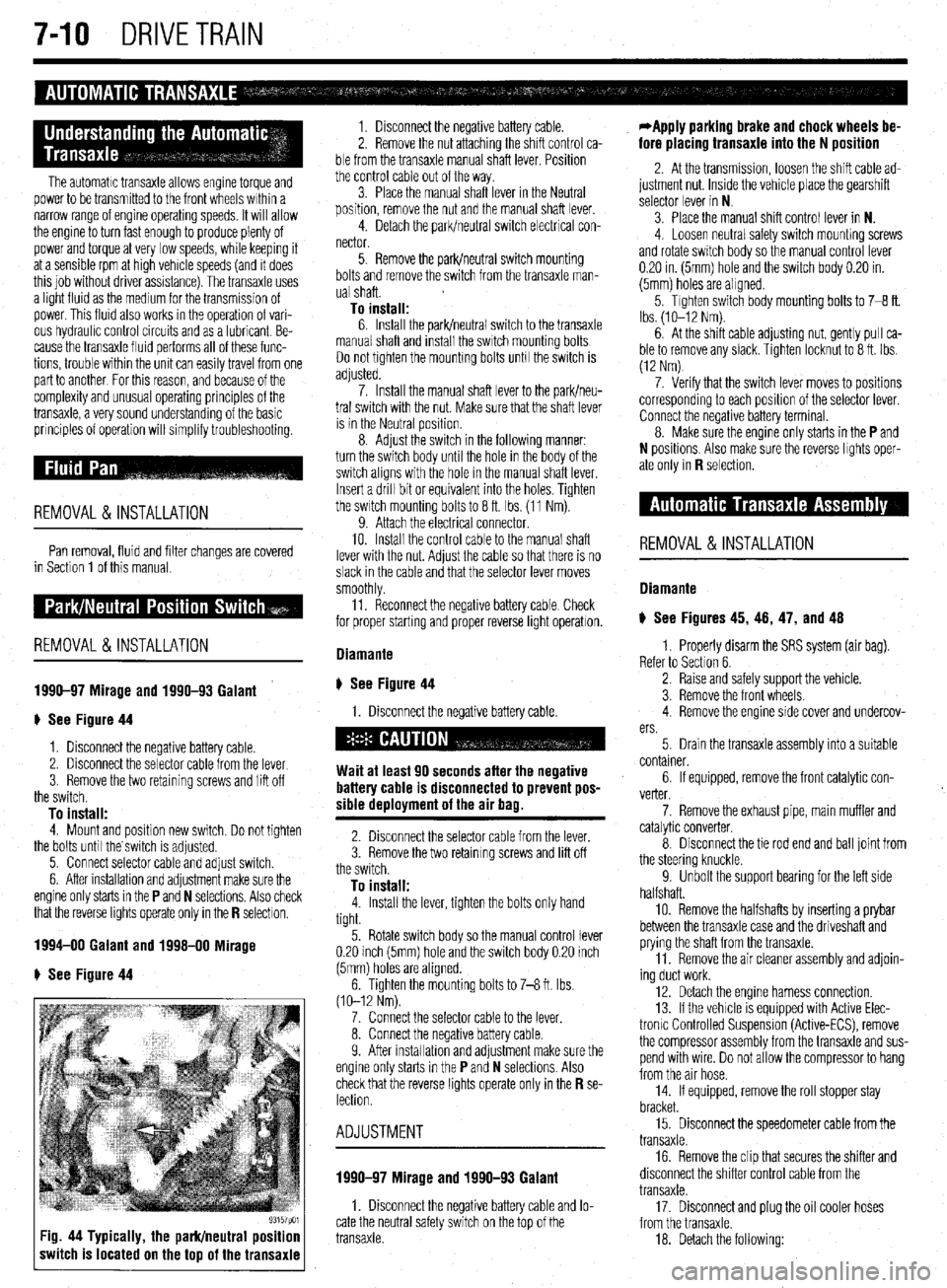

# See Figure 44

1. Disconnect the negative battery cable.

2. Disconnect the selector cable from the lever

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Mount and position new switch. Do not tighten

the bolts until the switch is adjusted.

5. Connect selector cable and adjust switch.

6. After installation and adjustment make sure the

engine only starts in the

P and N selections. Also check

that the reverse lights operate only in the R selectlon.

1994-00 Galant and 1998-00 Mirage

e See Figure 44

93157pm Fig. 44 Typically, the park/neutral position

switch is located on the top of the transaxle

1. Disconnect the negative battery cable.

2. Remove the nut attaching the shift control ca-

ble from the transaxle manual shaft lever. Position

the control cable out of the way.

3. Place the manual shaft lever in the Neutral

position, remove the nut and the manual shaft lever.

4. Detach the park/neutral switch electrical con-

nector.

5. Remove the park/neutral switch mounting

bolts and remove the switch from the transaxle man-

ual shaft.

To install: 6. Install the park/neutral switch to the transaxle

manual shaft and install the switch mounting bolts

Do not tighten the mounting bolts unh the switch is

adjusted.

7. Install the manual shaft lever to the park/neu-

tral switch with the nut. Make sure that the shaft lever

is in the Neutral position.

8. Adjust the switch in the following manner:

turn the switch body until the hole in the body of the

switch aligns with the hole in the manual shaft lever.

Insert a drill bit or equivalent into the holes. Tighten

the switch mounting bolts to 8 ft. Ibs. (11 Nm).

9. Attach the electrical connector.

10. Install the control cable to the manual shaft

lever with the nut. Adjust the cable so that there is no

slack in the cable and that the selector lever moves

smoothly

11. Reconnect the negative battery cable Check

for proper starting and proper reverse light operatron.

Diamante

ti See Figure 44

1. Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Disconnect the selector cable from the lever.

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Install the lever, tighten the bolts only hand

tight.

5. Rotate switch body so the manual control lever

0.20 inch (5mm) hole and the switch body 0.20 inch

(5mm) holes are aligned.

6. Tighten the mounting bolts to 7-8 ft. Ibs.

(10-12 Nm).

7. Connect the selector cable to the lever.

8. Connect the negative battery cable.

9. After installahon and adjustment make sure the

engine only starts in the

P and N selections. Also

check that the reverse lights operate only in the R se- lection.

ADJUSTMENT

1990-97 Mirage and 1990-93 Galant

1. Disconnect the negative battery cable and lo-

cate the neutral safety switch on the top of the

transaxle.

*Apply parking brake and chock wheels be-

fore placing transaxle into the N position

2. At the transmission, loosen the shift cable ad-

justment nut. Inside the vehicle place the gearshift

selector lever in N

3. Place the manual shift control lever in N.

4. Loosen neutral safety switch mounhng screws

and rotate switch body so the manual control lever

0.20 in. (5mm) hole and the switch body 0.20 in.

(5mm) holes are aligned.

5. Tighten switch body mounting bolts to 7-8 ft.

Ibs. (lo-12 Nm).

6. At the shift cable adjusting nut, gently pull ca-

ble to remove any slack. Tighten locknut to 8 ft. Ibs.

(12 Nm)

7. Verify that the switch lever moves to positions

corresponding to each position of the selector lever.

Connect the negative battery terminal.

8. Make sure the engine only starts in the

P and

N positions. Also make sure the reverse lights oper-

ate only in

R selection.

REMOVAL&INSTALLATION

Diamante

) See Figures 45, 46, 47, and 48

1. Properly disarm the SRS system (air bag).

Refer to Section 6.

2. Raise and safely support the vehicle.

3. Remove the front wheels.

4. Remove the engine side cover and undercov-

ers.

5. Drain the transaxle assembly into a suitable

container.

6. If equipped, remove the front catalytic con-

verter.

7. Remove the exhaust pipe, main muffler and

catalytic converter.

8. Disconnect the tie rod end and ball joint from

the steering knuckle.

9. Unbolt the support bearing for the left side

halfshaft.

10. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle.

11. Remove the air cleaner assembly and adjoin-

ing duct work.

12. Detach the engine harness connection.

13. If the vehicle is equipped with Active Elec-

tronlc Controlled Suspension (Active-ECS), remove

the compressor assembly from the transaxle and sus-

pend with wire. Do not allow the compressor to hang

from the air hose.

14. If equipped, remove the roll stopper stay

bracket.

15. Disconnect the speedometer cable from the

transaxle.

16. Remove the clip that secures the shifter and

disconnect the shifter control cable from the

transaxle.

17. Disconnect and plug the oil cooler hoses

from the transaxle.

18. Detach the following:

Page 291 of 408

.

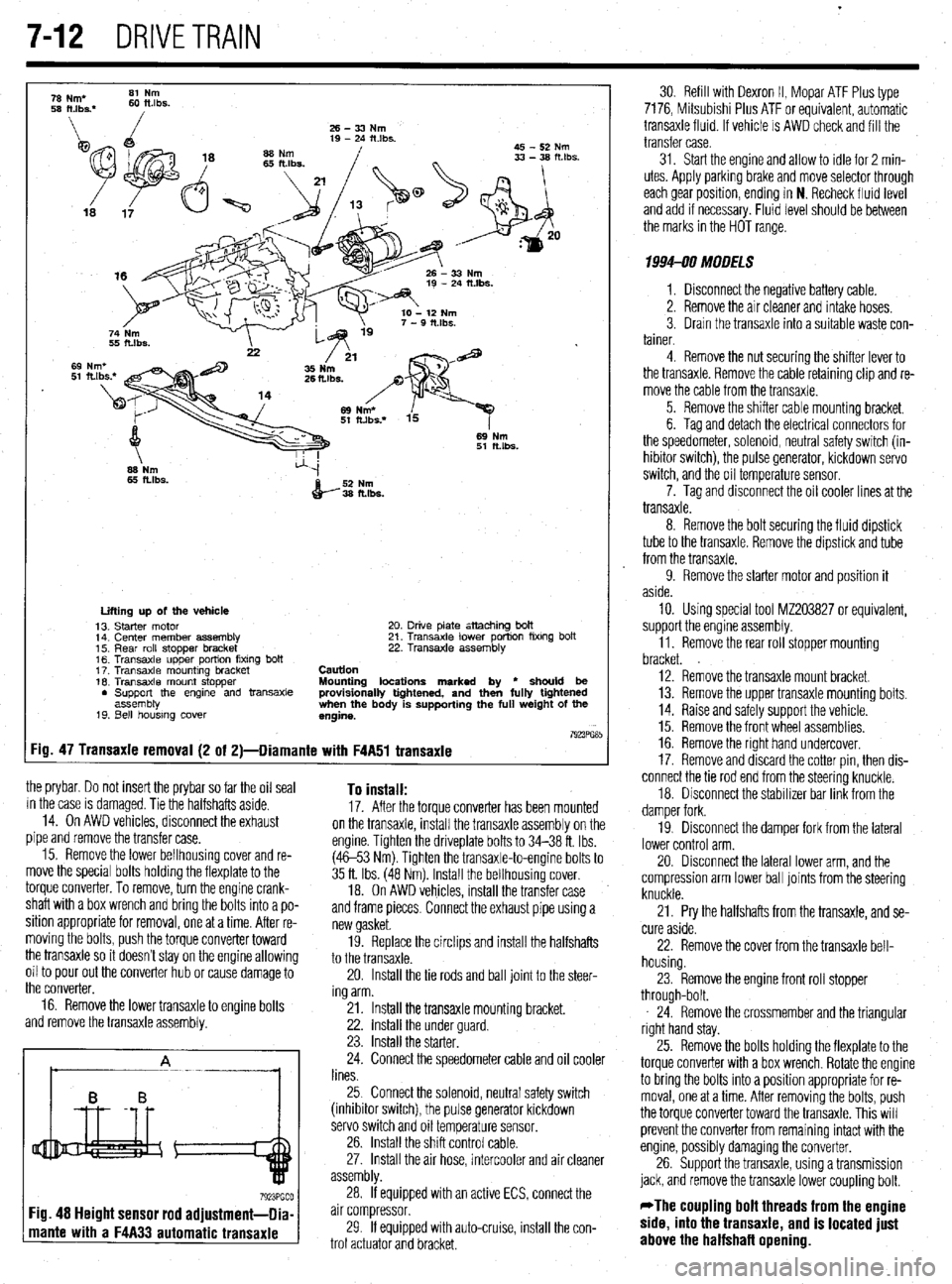

7-12 DRIVETRAIN

26-33Nm

19 - 24 itlbs.

45 - 52 Nm

69 Nm

51 ftlbs.

66 Nm

65 ftlbs.

52 Nm

36 fl.lbs.

:ig.

the prybar. Do not insert the prybar so far the oil seal

in the case is damaged. Tie the halfshafts aside.

14. On AWD vehicles, disconnect the exhaust

pipe and remove the transfer case.

15. Remove the lower bellhousing cover and re-

move the special bolts holding the flexplate to the

torque converter. To remove, turn the engine crank-

shaft with a box wrench and bring the bolts into a po-

sition appropriate for removal, one at a time. After re-

moving the bolts, push the torque converter toward

the transaxle so it doesn’t stay on the engine allowing

oil to pour out the converter hub or cause damage to

the converter,

16. Remove the lower transaxle to engine bolts

and remove the transaxle assembly. To install: 17. After the torque converter has been mounted

on the transaxle, install the transaxle assembly on the

engine. Tighten the driveplate bolts to 34-38 ft. Ibs.

(4653 Nm). Tighten the transaxle-to-engine bolts to

35 ft. Ibs. (48 Nm). Install the bellhousing cover.

18. On AWD vehicles, install the transfer case

and frame pieces. Connect the exhaust pipe using a

new gasket.

19. Replace the circlips and install the halfshafts

to the transaxle.

20. Install the tie rods and ball joint to the steer-

ing arm.

21. Install the transaxle mounting bracket.

22. install the under guard.

23. Install the starter.

24. Connect the speedometer cable and oil cooler

lines.

25 Connect the solenoid, neutral safety switch

(inhibitor switch), the pulse generator kickdown

servo switch and oil temperature sensor.

26. Install the shift control cable.

27. Install the air hose, intercooler and air cleaner

assembly.

If equipped with an active ECS, connect the

mante with a F4A33 automatic transaxle

30 Refill with Dexron II, Mopar ATF Plus type

7176, Mitsubishi Plus ATF or equivalent, automatic

transaxle fluid. If vehicle is AWD check and fill the

transfer case.

31. Start the engine and allow to idle for 2 min-

utes. Apply parkrng brake and move selector through

each gear posrtion, ending in N. Recheck fluid level

and add if necessary. Fluid level should be between

the marks in the HOT range.

1994-90 MODELS

1. Disconnect the negative battery cable.

2. Remove the air cleaner and intake hoses.

3. Drain the transaxle into a suitable waste con-

tainer.

4. Remove the nut securing the shifter lever to

the transaxle. Remove the cable retaining clip and re-

move the cable from the transaxle.

5. Remove the shifter cable mounting bracket,

6. Tag and detach the electrical connectors for

the speedometer, solenoid, neutral safety switch (in-

hibitor switch), the pulse generator, kickdown servo

switch, and the oil temperature sensor.

7. Tag and disconnect the oil cooler lines at the

transaxle.

8. Remove the bolt securing the fluid dipstick

tube to the transaxle. Remove the dipstrck and tube

from the transaxle.

9. Remove the starter motor and position it

aside.

10. Using special tool MZ203827 or equivalent,

support the engine assembly.

11. Remove the rear roll stopper mounting

bracket.

12. Remove the transaxle mount bracket.

13. Remove the upper transaxle mounting bolts.

14. Raise and safely support the vehicle.

15. Remove the front wheel assemblies.

16. Remove the right hand undercover.

17. Remove and discard the cotter pin, then dis-

connect the tie rod end from the steering knuckle,

18. Disconnect the stabilizer bar link from the

damper fork.

19. Disconnect the damper fork from the lateral

lower control arm.

20. Disconnect the lateral lower arm, and the

compression arm lower ball joints from the steering

knuckle.

21. Pry the halfshafts from the transaxle, and se-

cure aside.

22. Remove the cover from the transaxle bell-

housing.

23. Remove the engine front roll stopper

through-bolt.

24. Remove the crossmember and the triangular

right hand stay.

25. Remove the bolts holding the flexplate to the

torque converter with a box wrench Rotate the engine

to bring the bolts into a position appropriate for re-

moval, one at a time. After removing the bolts, push

the torque converter toward the transaxle. This will

prevent the converter from remaining intact with the

engine, possibly damaging the converter,

26. Support the transaxle, using a transmission

jack, and remove the transaxle lower coupling bolt.

*The coupling bolt threads from the engine

side, into the transaxle, and is located just

above the halfshafl opening.

Page 389 of 408

TROUBLESHOOiNG 11-7

4. Starter motor spins, but does not engage

a. Check the starter motor for a seized or binding pinion gear.

b. Remove the flywheel inspection plate and check for a damaged ring gear.

Gasoline Engines

1. Engine runs poor/y, hesiiates

a. Check the engine ignition system operation and adjust if possible, or replace defective

parts.

b. Check for restricted fuel injectors and replace as necessary.

c. Check the fuel pump output and delivery. Inspect fuel lines for restrictions. If the fuel

pump pressure is below specification, replace the fuel pump.

d. Check the operation of the engine management system and repair as necessary.

2. Enfline lacks power

a. Check the engine’s tune-up status. Note the tune-up specifications and check for items

such as severely worn spark plugs; adjust or replace as needed. On vehicles with

manually adjusted valve clearances, check for tight valves and adjust to specification.

b. Check the air filter and air intake system. Replace the air filter if it is dirty or contami-

nated. Check the fresh air intake system for restrictions or blockage.

c. Check the operation of the engine fuel and ignition management systems. Check the

sensor operation and wiring. Check for low fuel pump pressure and repair or replace

components as necessary.

d. Check the throttle linkage adjustments. Check to make sure the linkage is fully open-

ing the throttle. Replace any worn or defective bushings or linkages.

e. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

f. Check for a loose or defective knock sensor. A loose, improperly torqued or defective

knock sensor will decrease spark advance and reduce power. Replace defective knock

sensors and install using the recommended torque specification.

g. Check for engine mechanical conditions such as low compression, worn piston rings,

worn valves, worn camshafts and related parts. An engine which has severe mechani-

cal wear, or has suffered internal mechanical damage must be rebuilt or replaced to re-

store lost power.

h. Check the engine oil level for being overfilled. Adjust the engine’s oil level, or change

the engine oil and filter, and top off to the correct level.

i. Check for an intake manifold or vacuum hose leak. Replace leaking gaskets or worn

vacuum hoses.

j. Check for dragging brakes and replace or repair as necessary.

k. Check tire air pressure and tire wear. Adjust the pressure to the recommended set-

tings. Check the tire wear for possible alignment problems causing increased rolling

resistance, decreased acceleration and increased fuel usage.

I. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

3. Poor fuel economy

a. Inspect the air filter and check for any air restrictions going into the air filter housing.

Replace the air filter if it is dirty or contaminated.

b. Check the engine for tune-up and related adjustments. Replace worn ignition parts,

check the engine ignition timing and fuel mixture, and set to specifications if possible.

c. Check the tire size, tire wear, alignment and tire pressure. Large tires create more

rolling resistance, smaller tires require more engine speed to maintain a vehicle’s road

speed. Excessive tire wear can be caused by incorrect tire pressure, incorrect wheel

alignment or a suspension problem. All of these conditions create increased rolling

resistance, causing the engine to work harder to accelerate and maintain a vehicle’s

speed.

d. Inspect the brakes for binding or excessive drag. A sticking brake caliper, overly ad-

justed brake shoe, broken brake shoe return spring, or binding parking brake cable or

linkage can create a significant drag, brake wear and loss of fuel economy. Check the

brake system operation and repair as necessary.

4. Engine runs on (diesels) when turned off

a. Check for idle speed set too high and readjust to specification.

b. Check the operation of the idle control valve, and replace if defective.

c. Check the ignition timing and adjust to recommended settings.

Check for defective

sensors or related components and replace if defective.

d. Check for a vacuum leak at the intake manifold or vacuum hose

and replace defective

gaskets or hoses.

e. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

f. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

g. Check the engine operating temperature for overheating and repair as necessary. 5. Engine knocks and pinfls during heavy accele/ation, and on steep hills

a. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

b. Check the ignition timing and adjust to recommended settings. Check for defective

sensors or related components and replace if defective.

c. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

d. Check the spark plugs for the correct type, electrode gap and heat range. Replace worn

or damaged spark plugs. For severe or continuous high speed use, install a spark plug

that is one heat range colder.

e. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

f. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

6. Engine atxelerates, but vehicle does not gain speed

a. On manual transmission vehicles, check for causes of a slipping clutch. Refer to the

clutch troubleshooting section for additional information.

b. On automatic transmission vehicles, check for a slipping transmission” Check the

transmission fluid level and condition. If the fluid level is too high, adjust to the cor-

rect level. If the fluid level is low, top off using the recommended fluid type. If the fluid

exhibits a burning odor, the transmission has been slipping internally. Changing the

fluid and filter may help temporarily, however in this situation a transmission may re-

quire overhauling to ensure long-term reliability.

Diesel Engines

1. Engine runs pOOr!y a. Check the injection pump timing and adjust to specification.

b. Check for air in the fuel lines or leaks, and bleed the air from the fuel system.

c. Check the fuel filter, fuel feed and return lines for a restriction and repair as necessary.

d. Check the fuel for contamination, drain and flush the fuel tank and replenish with fresh

fuel.

2. Enfline lacks power

a. Inspect the air intake system and air filter for restrictions and, if necessary, replace the

air filter.

b. Verify the injection pump timing and reset if out of specification.

c. Check the exhaust for an internal restriction and replace failed parts.

d. Check for a restricted fuel filter and, if restricted, replace the filter.

e. Inspect the fuel filler cap vent. When removing the filler cap, listen for excessive hiss-

ing noises indicating a blockage in the fuel filler cap vents, If the filler cap vents are

blocked, replace the cap.

f. Check the fuel system for restrictions and repair as necessary.

g. Check for low engine compression and inspect for external leakage at the glow plugs

or nozzles. If no external leakage is noted, repair or replace the engine.

ENGINE PERFORMANCE TROUBLESHOOTING HINTS When troubleshooting an engine running or performance condition, the mechanical

condition of the engine should be determined before lengthy troubleshooting procedures

are performed.

The engine fuel management systems in fuel injected vehicles rely on electronic sen-

sors to provide information to the engine control unit for precise fuel metering. Unlike

carburetors, which use the incoming air speed to draw fuel through the fuel metering jets

in order to provide a proper fuel-to-air ratio, a fuel injection system provides a specific

amount of fuel which is introduced by the fuel injectors into the intake manifold or intake

port, based on the information provided by electronic sensors.

The sensors monitor the engine’s operating temperature, ambient temperature and the

amount of air entering the engine, engine speed and throttle position to provide informa-

tion to the engine control unit, which, in turn, operates the fuel injectors by electrical

pulses. The sensors provide information to the engine control unit using low voltage

electrical signals. As a result, an unplugged sensor or a poor electrical contact could

cause a poor running condition similar to a failed sensor.

When troubleshooting a fuel related engine condition on fuel injected vehicles, care-

fully inspect the wiring and electrical connectors to the related components. Make sure

the electrical connectors are fully connected, clean and not physically damaged. If neces-

sary, clean the electrical contacts using electrical contact cleaner. The use of cleaning

agents not specifically designed for electrical contacts should not be used, as they could

leave a surface film or damage the insulation of the wiring.

The engine electrical system provides the necessary electrical power to operate the ve-

hicle’s electrical accessories, electronic control units and sensors. Because engine man-

agement systems are sensitive to voltage changes, an alternator which over or under-

charges could cause engine running problems or component failure. Most alternators

utilize internal voltage regulators which cannot be adjusted and must be replaced indi-

vidually or as a unit with the alternator.

Page 390 of 408

11-8 TROUBLESHOOTING

Ignition systems may be controlled by, or linked to, the engine fuel management sys-

tem. Similar to the fuel injection system, these ignition systems rely on electronic sen-

sors for information to determine the optimum ignition timing for a given engine speed

and load. Some ignition systems no longer allow the ignition timing to be adjusted.

Feedback from low voltage electrical sensors provide information to the control unit to

determine the amount of ignition advance. On these systems, if a failure occurs the failed

component must be replaced. Before replacing suspected failed electrical components,

carefully inspect the wiring and electrical connectors to the related components. Make

sure the electrical connectors are fully connected, clean and not physically damaged. If

necessary, clean the electrical contacts using electrical contact cleaner. The use of clean-

ing agents not specifically designed for electrical contacts should be avoided, as they

could leave a surface film or damage the insulation of the wiring.

1. Engine makes a knocking or pinging noise when accelerating

a. Check the octane rating of the fuel being used. Depending on the type of driving or

driving conditions, it may be necessary to use a higher octane fuel.

b. Verify the ignition system settings and operation. Improperly adjusted ignition timing

or a failed component, such as a knock sensor, may cause the ignition timing to ad-

vance excessively or prematurely. Check the ignition system operation and adjust, or

replace components as needed.

c. Check the spark plug gap, heat range and condition. If the vehicle is operated in se-

vere operating conditions or at continuous high speeds, use a colder heat range spark

plug. Adjust the spark plug gap to the manufacturer’s recommended specification and

replace worn or damaged spark plugs.

2. Sfarter motor grinds when used

a. Examine the starter pinion gear and the engine ring gear for damage, and replace dam-

aged parts.

b. Check the starter mounting bolts and housing. If the housing is cracked or damaged

replace the starter motor and check the mounting bolts for tightness.

3. Engine makes a screeching noise

a. Check the accessory drive belts for looseness and adjust as necessary.

b. Check the accessory drive belt tensioners for seizing or excessive bearing noises and

replace if loose, binding, or excessively noisy.

c. Check for a seizing water pump. The pump may not be leaking; however, the bearing

may be faulty or the impeller loose and jammed. Replace the water pump.

4. Engine makes a growling noise

a. Check for a loose or failing water pump. Replace the pump and engine coolant.

b. Check the accessory drive belt tensioners for excessive bearing noises and replace if

loose or excessively noisy.

5. Engine makes a ticking or tapping noise

a. On vehicles with hydraulic lash adjusters, check for low or dirty engine oil and top off

or replace the engine oil and filter.

b. On vehicles with hydraulic lash adjusters, check for collapsed lifters and replace failed

components.

c. On vehicles with hydraulic lash adjusters, check for low oil pressure caused by a re-

stricted oil filter, worn engine oil pump, or oil pressure relief valve.

d. On vehicles with manually adjusted valves, check for excessive valve clearance or

worn valve train parts. Adjust the valves to specification or replace worn and defective

parts.

e. Check for a loose or improperly tensioned timing belt or timing chain and adjust or re-

place parts as necessary.

f. Check for a bent or sticking exhaust or intake valve. Remove the engine cylinder head

to access and replace.

6. Engine makes a heavy knocking noise

a. Check for a loose crankshaft pulley or flywheel; replace and torque the mounting

bolt(s) to specification.

b. Check for a bent connecting rod caused by a hydro-lock condition. Engine disassem-

bly is necessary to inspect for damaged and needed replacement parts.

c. Check for excessive engine rod bearing wear or damage. This condition is also asso-

ciated with low engine oil pressure and will require engine disassembly to inspect for

damaged and needed replacement parts,

7. Vehicle has a fuel odor when driven ’ a. Check the fuel gauge level. If the fuel gauge registers full, it is possible that the odor is

caused by being filled beyond capacity, or some spillage occurred during refueling.

The odor should clear after driving an hour, or twenty miles, allowing the vapor canis-

ter to purge.

b. Check the fuel filler cap for looseness or seepage. Check the cap tightness and, if

loose, properly secure. If seepage is noted, replace the filler cap.

c. Check for loose hose clamps, cracked or damaged fuel delivery and return lines, or

leaking components or seals, and replace or repair as necessary. d. Check the vehicle’s fuel economy. If fuel consumption has increased due to a failed

component, or if the fuel is not properly ignited due to an ignition related failure, the

catalytic converter may become contaminated. This condition may also trigger the

check engine warning light. Check the spark plugs for a dark, rich condition or verify

the condition by testing the vehicle’s emissions. Replace fuel fouled spark plugs, and

test and replace failed components as necessary.

5. Vehicle has a rotten egg odor when driven

a. Check for a leaking intake gasket or vacuum leak causing a lean running condition. A

lean mixture may result in increased exhaust temperatures, causing the catalytic con-

verter to run hotter than normal. This condition may also trigger the check engine

warning light. Check and repair the vacuum leaks as necessary.

b. Check the vehicle’s alternator and battery condition. If the alternator is overcharging,

the battery electrolyte can be boiled from the battery, and the battery casing may begin

to crack, swell or bulge, damaging or shorting the battery internally. If this has oc-

curred, neutralize the battery mounting area with a suitable baking soda and water

mixture or equivalent, and replace the alternator or voltage regulator. Inspect, service,

and load test the battery, and replace if necessary.

9. Vehicle has a sweet odor when driven

a. Check for an engine coolant leak caused by a seeping radiator cap, loose hose clamp,

weeping cooling system seal, gasket or cooling system hose and replace or repair as

needed.

b. Check for a coolant leak from the radiator, coolant reservoir, heater control valve or

under the dashboard from the heater core, and replace the failed part as necessary.

c. Check the engine’s exhaust for white smoke in addition to a sweet odor. The presence

of white, steamy smoke with a sweet odor indicates coolant leaking into the combus-

tion chamber. Possible causes include a failed head gasket, cracked engine block or

cylinder head. Other symptoms of this condition include a white paste build-up on the

inside of the oil filler cap, and softened, deformed or bulging radiator hoses.

19. Engine vibraies when idling

a. Check for loose, collapsed, or damaged engine or transmission mounts and repair or

replace as necessary.

b. Check for loose or damaged engine covers or shields and secure or replace as neces-

sary.

11. Engine vibrates during acceleration

a. Check for missing, loose or damaged exhaust system hangers and mounts; replace or

repair as necessary.

b. Check the exhaust system routing and fit for adequate clearance or potential rubbing;

repair or adjust as necessary.

7. Battery goes dead while driving

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test. If the battery loses fluid while driving, check for an overcharg-

ing condition. If the alternator is overcharging, replace the alternator or voltage regula-

tor. (A voltage regulator is typically built into the alternator, necessitating alternator re-

placement or overhaul.)

b. Check the battery cable condition. Clean or replace corroded cables and clean the bat-

tery terminals.

c. Check the alternator and voltage regulator operation. If the charging system is over or

undercharging, replace the alternator or voltage regulator, or both.

d. Inspect the wiring and wire connectors at the alternator for looseness, a missing .

ground or defective terminal, and repair as necessary.

e. Inspect the alternator drive belt tension, tensioners and condition. Properly tension the

drive belt, replace weak or broken tensioners, and replace the drive belt if worn or

cracked.

2. Battery goes dead overnight

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test.

b. Check for a voltage draw, such as a trunk light, interior light or glove box light staying

on. Check light switch position and operation, and replace if defective.

c. Check the alternator for an internally failed diode, and replace the alternator if defec-

tive.

1. Engine overheats

a. Check the coolant level. Set the heater temperature to full hot and check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture.

b. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.

Page 391 of 408

TROUBLESHOOTING 11-9

c. On vehicles with electrically controlled cooling fans, check the cooling fan operation.

Check for blown fuses or defective fan motors, temperature sensors and relays, and

replace failed components.

d. Check for a coolant leak caused by a failed head gasket, or a porous water jacket cast-

ing in the cylinder head or engine block. Replace defective parts as necessary.

e. Check for an internally restricted radiator. Flush the radiator or replace if the blockage

is too severe for flushing.

f. Check for a damaged water pump. If coolant circulation is poor, check for a loose wa-

ter pump impeller. If the impeller is loose, replace the water pump.

2. Engine loses coolant

a. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.

b. Check for a coolant leak caused by a failed head gasket, or a porous water jacket cast-

ing in the cylinder head or engine block. Replace defective parts as necessary.

3. Engine temperature remains co/d when driving

a. Check the thermostat operation. Replace the thermostat if it sticks in the open posi-

tion.

b. On vehicles with electrically controlled cooling fans, check the cooling fan operation.

Check for defective temperature sensors and stuck relays, and replace failed compo-

nents.

c. Check temperature gauge operation if equipped to verify proper operation of the

gauge. Check the sensors and wiring for defects, and repair or replace defective com-

ponents.

4. Engine runs hot

a. Check for an internally restricted radiator. Flush the radiator or replace if the blockage

is too severe for flushing.

b. Check for a loose or slipping water pump drive belt. Inspect the drive belt condition.

Replace the belt if brittle, cracked or damaged. Check the pulley condition and prop-

erly tension the belt.

c. Check the cooling fan operation. Replace defective fan motors, sensors or relays as

necessary.

d. Check temperature gauge operation if equipped to verify proper operation of the

gauge. Check the sensors and wiring for defects, and repair or replace defective com-

ponents.

e. Check the coolant level. Set the heater temperature to full hot, check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture. Once the engine is cool, recheck the fluid level and

top off as needed.

NOTE: The engine cooling system can also be affected by an engine’s me-

chanical condition. A failed head gasket or a porous casting in the engine

block or cylinder head could cause a loss of coolant and result in engine

overheating.

Some cooling systems rely on electrically driven cooling fans to cool the radiator and

use electrical temperature sensors and relays to operate the cooling fan. When diagnos-

ing these systems, check for blown fuses, damaged wires and verify that the electrical

connections are fully connected, clean and not physically damaged. If necessary, clean

the electrical contacts using electrical contact cleaner. The use of cleaning igents not specifically designed for electrical contacts could leave a film or damage the insulation of

the wiring.

1. Exhaust rattles at idle speed

a. Check the engine and transmission mounts and replace mounts showing signs of

damage or wear.

b. Check the exhaust hangers, brackets and mounts. Replace broken, missing or dam-

aged mounts.

c. Check for internal damage to mufflers and catalytic converters. The broken pieces from

the defective component may travel in the direction of the exhaust flow and collect

and/or create a blockage in a component other than the one which failed, causing en-

gine running and stalling problems. Another symptom of a restricted exhaust is low

engine manifold vacuum. Remove the exhaust system and carefully remove any loose

or broken pieces, then replace any failed or damaged parts as necessary.

d. Check the exhaust system clearance, routing and alignment. If the exhaust is making

contact with the vehicle in any manner, loosen and reposition the exhaust system.

2. Exhaust system vibrates when driving

a. Check the exhaust hangers, brackets and mounts. Replace broken, missing or dam-

aged mounts.

b. Check the exhaust system clearance, routing and alignment. If the exhaust is making

contact with the vehicle in any manner, check for bent or damaged components and

replace, then loosen and reposition the exhaust system.

c. Check for internal damage to mufflers and catalytic converters. The broken pieces from

the defective component may travel in the direction of the exhaust flow and collect

and/or create a blockage in a component other than the one which failed, causing en-

gine running and stalling problems. Another symptom of a restricted exhaust is low

engine manifold vacuum. Remove the exhaust system and carefully remove any loose

or broken pieces, then replace any failed or damaged parts as necessary.

3. Exhaust system hangs too low

a. Check the exhaust hangers, brackets and mounts. Replace broken, missing or dam-

aged mounts.

b. Check the exhaust routing and alignment. Check and replace bent or damaged com-

ponents. If the exhaust is not routed properly, loosen and reposition the exhaust sys-

tern.

4. Exhaust sounds loud

a. Check the system for looseness and leaks. Check the exhaust pipes, clamps, flange

bolts and manifold fasteners for tightness. Check and replace any failed gaskets.

b. Check and replace exhaust silencers that have a loss of efficiency due to internally

broken baffles or worn packing material.

c. Check for missing mufflers and silencers that have been replaced with straight pipes

or with non-original equipment silencers.

NOTE: Exhaust system rattles, vibration and proper alignment should not

be overlooked. Excessive vibration caused by collapsed engine mounts,

damaged or missing exhaust hangers and misalignment may cause surface

cracks and broken welds, creating exhaust leaks or internal damage to ex-

haust components such as the catalytic converter, creating a restriction to

exhaust flow and loss of power.

1. Transmission shit& erratically

a. Check and if not within the recommended range, add or remove transmission fluid to

obtain the correct fluid level. Always use the recommended fluid type when adding

transmission fluid.

b. Check the fluid level condition. If the fluid has become contaminated, fatigued from

excessive heat or exhibits a burning odor, change the transmission fluid and filter us-

ing the recommended type and amount of fluid. A fluid which exhibits a burning odor

indicates that the transmission has been slipping internally and may require future re-

pairs.

c. Check for an improperly installed transmission filter, or missing filter gasket, and re-

pair as necessary.

d. Check for loose or leaking gaskets, pressure lines and fittings, and repair or replace as

necessary.

e. Check for loose or disconnected shift and throttle linkages or vacuum hoses, and re-

pair as necessary. ,

2. Transmission will not engage

a. Check the shift linkage for looseness, wear and proper adjustment, and repair as nec-

essary. b. Check for a loss of transmission fluid and top off as needed with the recommended

fluid.

c. If the transmission does not engage with the shift linkage correctly installed and the

proper fluid level, internal damage has likely occurred, requiring transmission removal

and disassembly.

3. Transmission will not downshift during heavy acceleration

a. On computer controlled transmissions, check for failed sensors or control units and

repair or replace defective components.

b. On vehicles with kickdown linkages or vacuum servos, check for proper linkage ad-

justment or leaking vacuum hoses or servo units.

NOTE: Mlany automatic transmissions use an electronic control module,

electrical sensors and solenoids to control transmission shifting. When

troubleshooting a vehicle with this type of system, be sure the electrical

connectors are fully connected, clean and not physically damaged. If nec-

essary, clean the electrical contacts using electrical contact cleaner. The

use of cleaning agents not specifically designed for electrical contacts

could leave a film or damage the insulation of the wiring.

Page 392 of 408

II-10 TROUBLESHOOTING

1. Transmission grinds going into forward gears while driving

a. Check the clutch release system. On clutches with a mechanical or cable linkage,

check the adjustment. Adjust the clutch pedal to have 1 inch (25mm) of free-play at

the pedal.

b. If the clutch release system is hydraulically operated, check the fluid level and, if low,

top off using the recommended type and amount of fluid. ,

c. Synchronizers worn. Remove transmission and replace synchronizers.

d. Synchronizer sliding sleeve worn. Remove transmission and replace sliding sleeve.

e. Gear engagement dogs worn or damaged. Remove transmission and replace gear.

2. Transmission jumps out of gear

a. Shift shaft detent springs worn. Replace shift detent springs.

b. Synchronizer sliding sleeve worn. Remove transmission and replace sliding sleeve.

c. Gear engagement dogs worn or damaged. Remove transmission and replace gear.

d. Crankshaft thrust bearings worn. Remove engine and crankshaft, and repair as neces-

sary.

3. Transmission difficult to shift

a. Verify the clutch adjustment and, if not properly adjusted, adjust to specification.

b. Synchronizers worn. Remove transmission and replace synchronizers.

c. Pilot bearing seized. Remove transmission and replace pilot bearing.

d. Shift linkage or bushing seized. Disassemble the shift linkage, replace worn or dam-

aged bushings, lubricate and reinstall.

4. Transmission leaks fluid

a. Check the fluid level for an overfilled condition. Adjust the fluid level to specification.

b. Check for a restricted transmission vent or breather tube. Clear the blockage as neces-

sary and check the fluid level. If necessary, top off with the recommended lubricant.

c. Check for a porous casting, leaking seal or gasket. Replace defective parts and top off

the fluid level with the recommended lubricant.

1. Clutch slips on hills or during sudden acceleration

a. Check for insufficient clutch pedal free-play. Adjust clutch linkage or cable to allow

about 1 inch (25mm) of pedal free-play.

b. Clutch disc worn or severely damaged. Remove engine or transmission and replace

clutch disc.

c. Clutch pressure plate is weak. Remove engine or transmission and replace the clutch

pressure plate and clutch disc.

d. Clutch pressure plate and/or flywheel incorrectly machined. If the clutch system has

been recently replaced and rebuilt, or refurbished parts have been used, it is possible

that the machined surfaces decreased the clutch clamping force. Replace defective

parts with new replacement parts.

2. Clutch will not disengage, difficult to shift

a. Check the clutch release mechanism. Check for stretched cables, worn linkages or

failed clutch hydraulics and replace defective parts. On hydraulically operated clutch

release mechanisms, check for air in the hydraulic system and bleed as necessary.

b. Check for a broken, cracked or fatigued clutch release arm or release arm pivot. Re-

place defective parts and properly lubricate upon assembly.

c. Check for a damaged clutch hub damper or damper spring. The broken parts tend to

become lodged between the clutch disc and the pressure plate. Disassemble clutch

system and replace failed parts.

d. Check for a seized clutch pilot bearing. Disassemble the clutch assembly and replace

the defective parts.

e. Check for a defective clutch disc. Check for warpage or liningthicknesses larger than

original equipment.

3. Clutch is noisy when the clutch pedal is pressed

a. Check the clutch pedal stop and pedal free-play adjustment for excessive movement

and adjust as necessary.

b. Check for a worn or damaged release bearing. If the noise ceases when the pedal is re-

leased, the release bearing should be replaced.

c. Check the engine crankshaft axial play. If the crankshaft thrust bearings are worn or

damaged, the crankshaft will move when pressing the clutch pedal. The engine must

be disassembled to replace the crankshaft thrust bearings.

4. Clutch pedal extremely difficult to press

a. Check the clutch pedal pivots and linkages for binding. Clean and lubricate linkages.

b. On cable actuated clutch systems, check the cable routing and condition. Replace

kinked, frayed, damaged or corroded cables and check cable routing to avoid sharp

bends. Check the engine ground strap for poor conductivity. If the ground strap is

marginal, the engine could try to ground itself via the clutch cable, causing premature

failure. c. On mechanical linkage clutches, check the linkage for binding or misalignment. Lubri-

cate pivots or linkages and repair as necessary.

d. Check the release bearing guide tube and release fork for a lack of lubrication. Install a

smooth coating of high temperature grease to allow smooth movement of the release

bearing over the guide tube.

5. Clutch pedal remains down when pressed

a, On mechanical linkage or cable actuated clutches, check for a loose or disconnected

link.

b. On hydraulically actuated clutches, check the fluid level and check for a hydraulic leak

at the clutch slave or master cylinder, or hydraulic line. Replace failed parts and bleed

clutch hydraulic system. If no leakage is noted, the clutch master cylinder may have

failed internally. Replace the clutch master cylinder and bleed the clutch hydraulic sys-

tem.

6. clutch chatters when engaging

a. Check the engine flywheel for warpage or surface variations and replace or repair as

necessary.

b. Check for a warped clutch disc or damaged clutch damper hub. Remove the clutch

disc and replace.

c. Check for a loose or damaged clutch pressure plate and replace defective components.

NOTE: The clutch is actuated either by a mechanical linkage, cable or a

clutch hydraulic system. The mechanical linkage and cable systems may

require the clutch pedal free-play to be adjusted as the clutch disc wears. A

hydraulic clutch system automatically adjusts as the clutch wears and, with

the exception of the clutch pedal height, no adjustment is possible.

1. Differential makes a low pitched rumbling noise

a. Check fluid level type and amount. Replace the fluid with the recommended type and

amount of lubricant.

b. Check the differential bearings for wear or damage. Remove the bearings, inspect the

drive and driven gears for wear or damage, and replace components as necessary.

2. Differential makes a howling noise

a. Check fluid level type and amount. Replace the fluid with the recommended type and

amount of lubricant.

b. Check the differential drive and driven gears for wear or damage, and replace compo-

nents as necessary.

All Wheel and Four Wheel Drive Vehicles

1. Leaks fluid from seals or vent after being driven

a. Fluid level overfilled. Check and adjust transfer case fluid level.

b. Check for a restricted breather or breather tube, clear and check the fluid level and top

off as needed.

c. Check seal condition and replace worn, damaged, or defective seals. Check the fluid

level and top off as necessary.

2. Makes excessive noise while driving

a. Check the fluid for the correct type of lubricant. Drain and refill using the recom-

mended type and amount of lubricant.

b. Check the fluid level. Top off the fluid using the recommended type and amount of lu-

bricant.

c. If the fluid level and type of lubricant meet specifications, check for internal wear or

damage. Remove assembly and disassemble to inspect for worn, damaged, or defec-

tive components.

3. Jumps out of gear

a. Stop vehicle and make sure the unit is fully engaged.

b. Check for worn, loose or an improperly adjusted linkage. Replace and/or adjust link-

age as necessary.

c. Check for internal wear or damage. Remove assembly and disassemble to inspect for

worn, damaged, or defective components.

Rear Wheel, All Wheel and Four Wheel Drive Vehicles

1. Clunking noise from center of Vehicle shifting from forward to reverse

a. Worn universal joint. Remove driveshaft and replace universal joint.

2. Excessive vibration from center of vehicle when accelerating

a. Worn universal joint. Remove driveshaft and replace universal joint.