boot MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 284 of 408

DRIVETRAIN 7-5

1, While the vehicle is still on the ground, re- IO. Insert the halfshaft into the tram&e. Be sure cle is being serviced could make a difference in joint

move the cotter pin, and loosen the axle nut. it is fully seated. type. Be sure to properly identify the joint before at-

2. Raise the vehicle and support it safely. 1 I. Pull the strut assembly out and install the tempting joint or boot replacement. Look for identifi-

3. If equipped with ABS, remove the front wheel other end to the hub. cation numbers at the large end of the boots and/or

speed sensor. 12. Install the center bearing bracket bolts and on the end of the metal retainer bands.

4. If equipped with Active Electronic Control tighten to 33 ft. Ibs. (45 Nm). The 3 types of joints used are the Birfield Joint,

Suspension (Active-ECS), perform the following: 13. Install the washer on the axle shaft so the (B.J.), the Tripod Joint (T.J.) and the Double Offset

a. Loosen the nut that secures the air line to chamfered edge faces outward. Install the axle nut, Joint (D.O.J.).

the to the top of the strut and discard the O-ring.

b. Remove the bolts that secure the actuator but do not tighten it fully at this time.

14. Connect the ball joint to the steering knuckle. *Do not disassemble a Birfield joint. Ser-

to.the top of the strut and remove the compo-

Torque the new retaining nut to 43-52 ft. Ibs. (68-72 vice with a new joint or clean and repack us-

nent. Disconnect the wiring harness.

Nm) and secure with a new cotter pin. ing a new boot kit.

5. Disconnect the lower ball joint and the tie rod

15. Connect the tie rod end to the steering

The distance between the large and small boot

end from the steering knuckle.

knuckle. Torque the retaining nut to 21 ft. Ibs. (29

bands is important and should be checked prior to

6. Remove the axle nut and the washer.

Nm) and secure with a new cotter pin.

and after boot service. This is so the boot will not be

7. If removing the left side axle with an inner 16. If equipped with ABS, install the front wheel

installed either too loose or too tight, which could

shaft, remove the center support bearing bracket speed sensor.

cause early wear and cracking, allowing the grease to

bolts and washers. Then, remove the halfshaft by set-

17. If equipped with Active-KS, perform the fol- get out and water and dirt in, leading to early joint

ting up a puller on the outside wheel hub and push-

lowing:

failure.

ing the halfshaft from the front hub. Tap the shaft a. Install the air line with a new O-ring.

union at the joint case with a plastic hammer to re- b. Install the actuator to the top of the strut. *The drfveshaft joints use special grease;

move the halfshaft and inner shaft from the transaxle. Connect the wiring harness. do not add any grease other than that sup-

8. If removing right side axle shafts without an 18. Install the wheel and lower the vehicle to the plied with the kit.

inner shaft, remove the halfshaft by setting up a floor.

puller on the outside wheel hub and pushing the half- 19. Tighten the axle nut to 145-188 ft. Ibs.

Double Offset Joint

shaft from the front hub. After pressing the outer (200-260 Nm) and secure with a new cotter pin.

shaft, insert a prybar between the transaxle case and The Double Offset Joint (D.O.J.) is bigger than

the halfshaft and pry the shaft from the transaxle.

CV-JOINTS OVERHAUL other joints and, in these applications, is normally

*Do not pull on the shaft; doing so damages used as an inboard joint.

the inboard joint. b See Figures 14 thru 27 1. Remove the halfshaft from the vehicle.

2. Side cutter pliers can be used to cut the metal

To install: These vehicles use several different types of joints. retaining bands. Remove the boot from the joint outer

9. Replace the circlips on the ends of the half- Engine size, transaxle type, whether the joint is an in- race.

shafts. board or outboard joint, even which side of the vehi-

TCCS7030 TCCS7031

I I TCCS7032 Fig. 15 Removing the outer band from the

Fig. 16 Removing the inner band from the

Fig. 14 Check the CV-boot for wear

W-boot

lho~sing IFi7~ / Fig 17 Removing the CV-boot from the joint 1 1 CV-boot

TCCS7035 Fig 18 Clean the CV-joint housing prior to

removing boot Tccs7W 1 1 sembiy Fig 19 Removing the CV-joint housing as-

Page 285 of 408

-

7-6 DRIVETRAIN

fig. 20 Removing the CV-joint Fig. 21 inspecting the M-joint housing

TCCS7042 1 Fig. 26 Removing the CV-joint inner

snapring Fig, 27 installing the CV-joint assembly Removing the CV-joint outer

Fig. 25 Removing the CV-joint assembly

11. Install the halfshaft to the vehicle.

Except Double Otfset Joint

1. Disconnect the neaative batterv cable. Remove

the halfshaft. - ’

2. Use side cutter oliers to remove the metal re-

taining bands from the boot(s) that will be removed.

Slide the boot from the T.J. case.

3. Remove the snapring and the tripod joint spi-

der assembly from the halfshaft. Do not disassemble

the spider and use care in handling.

4. If the boot is be reused, wrap vinyl tape around

the spline part of the shaft so the boot(s) will not be

I

3. Locate and remove the large circlip at the ’

base of the joint. Remove the outer race (the body of

the joint).

4. Remove the small snapring and take off the

inner race, cage and balls as an assembly. Clean the

inner race, cage and balls without disassembling.

5. If the boot is to be reused. wioe the arease

from the splines and wrap the splfnes in vin$ tape

before sliding the boot from the shaft.

6. Remove the inner (D.O.J.) boot from the

shaft. If the outer (B.J.) boot is to be replaced, re-

move the boot retainer rings and slide the boot down

and off of the shaft at this time.

To install:

7. Be sure to tape the shaft splines before in-

stalling the boots. Fill the inside of the boot with the (typiW

1

specified grease. Often the grease supplied in the re-

placement parts kit is meant to be divided in half,

with half being used to lubricate the joint and half be-

ing used inside the boot.

Install the cage onto the halfshaft so the small 8.

diameter side of the cage is installed first. With a

brass drift pin, tap lightly and e ’ ’ ‘* ’

nemy arouna me Inner

race to install the race until it comes into contact with

the rib of the shaft. Apply the specified grease to the

inner race and cage and fit them together. Insert the

balls into the cage.

9. Install the outer race (the body of the joint)

after filling with the specified grease. The outer race

should be filled with this greas e.

10. Tighten the boot bands

securely. Make sure

the distance between the boot t,, IuJ IJ ,,“I lGbl. \onrlo i.i *nrro”+ damaged when removed. Remove the dynamic

To install: damper, if used, and the boots from the shaft.

5. -

Double check that the correct replacement

parts are being installed. Wrap vinyl tape around the

splines to protect the boot and install the boots and

damper, if used, in the correct order,

6. Install the joint spider assembly to the shaft

and ipctdl the cnmrinn 7. Fill the inside ofthe boot with the specified

grease. Often the grease supplied in the replacement

parts kit is meant to be divided in half, with half being

used to lubricate the joint and half being used inside

the boot. Keep grease off the rubber part of the dy-

namic damper (if used).

8. Secure the boot bands with the halfshaft in a

horizontal position. Make sure distance between boot

bands is correct.

9. Install the halfshaft to the vehicle and recon-

nect

the negative battery cable.

Page 293 of 408

7-14 DRIVETRAIN

The only model covered by this manual equipped

with a transfer case is the 1990-93 AWD Galant. assembly. Place a drain pan under the rear of the

transfer assembly to catch any fluid that leaks out.

3. Usinq a flat-bladed prying tool, carefully re-

REMOVAL &INSTALLATION

move the ofi seal from the transfer dust seal guard

To install: 4. Using proper size seal driver tool, install the

seal into the dust seal quard and the transfer assem-

blv.

# See Figures 49 and 50

1. Raise and support the vehicle safely.

2. Remove the propeller shaft from the transfer ‘5. Install the rear propeller shaft.

6. Carefully lower the vehicle and inspect the

transfer assembly fluid level.

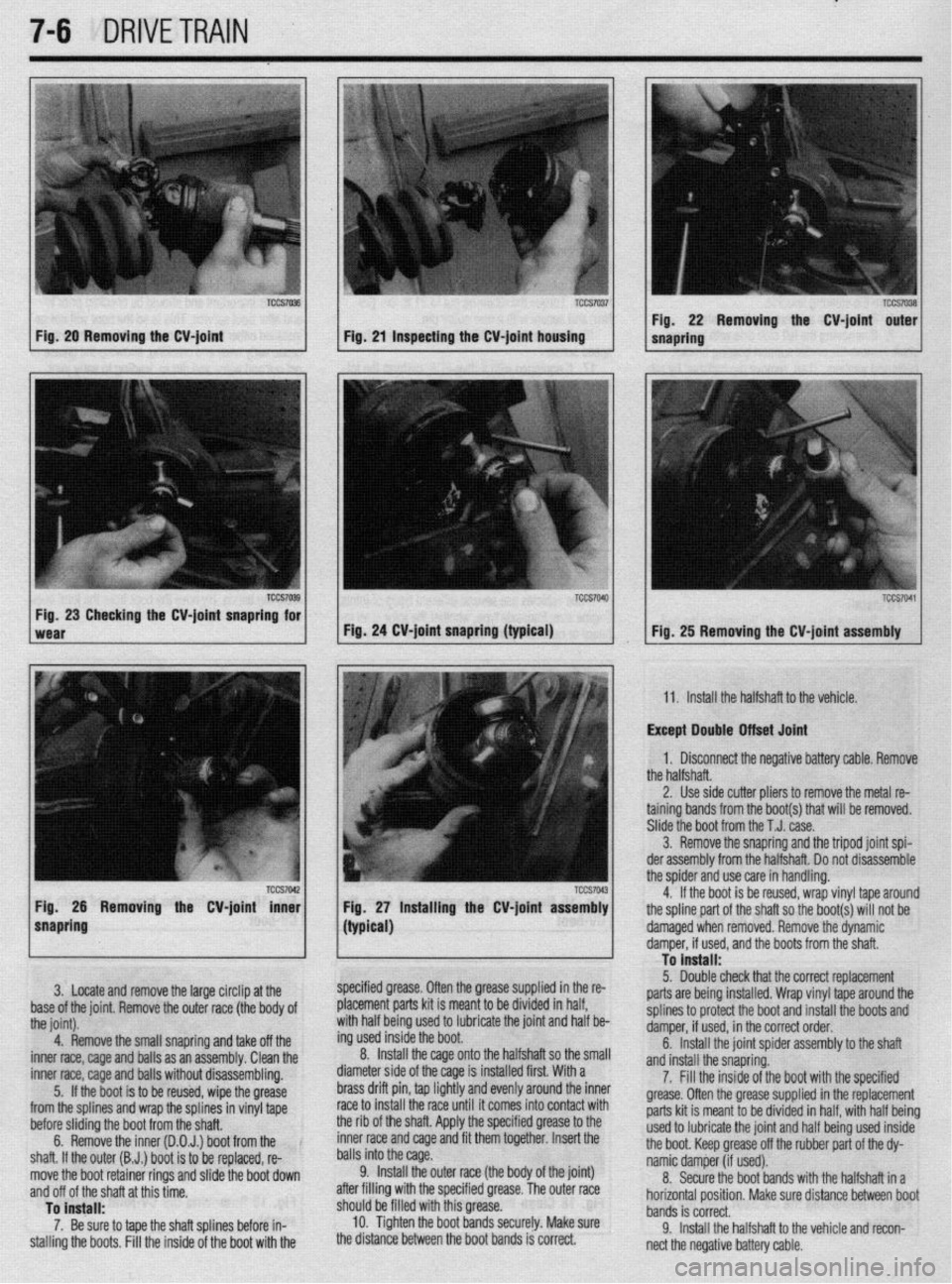

a9577g50 1 Fig. 49 Exploded view of the transfer case

1 extension housing and related components a9577g51 Fig. 50 Install the oil seal using the proper

sized driver and a hammer REMOVAL &INSTALLATION

1. Disconnect the battery negative cable.

2. Raise the vehicle and support safely. Drain the

transfer oil.

3. Disconnect the front exhaust pipe.

4. Unbolt the transfer case assembly and remove

by sliding it off the rear driveshaft. Be careful not to

damage the oil seal in the transfer case output hous-

ing. Do not let the rear driveshaft hang; suspend it

from a frame piece. Cover the opening in the

transaxle and transfer case to keep oil from dripping

and to keep dirt out.

5. Lubricate the driveshaft sleeve yoke and oil

seal lipan the transfer extension housing. Install the

transfer case assembly to the transaxle. Use care

when installing the rear driveshaft to the transfer case

output shaft.

6. Tighten the transfer case to transaxle bolts to

40-43 ft. Ibs. (55-60 Nm) with manual transaxle;

43-58 ft. Ibs. (60-80 Nm) with automatic transaxle.

7. Install the exhaust pipe using a new gasket. In-

stall removed bumper components.

8. Refill the transfer case and check oil levels in

transaxle and transfer case.

The only model covered by this manual equipped

with a driveshaft is the 1990-93 AWD Galant.

REMOVAL &INSTALLATION

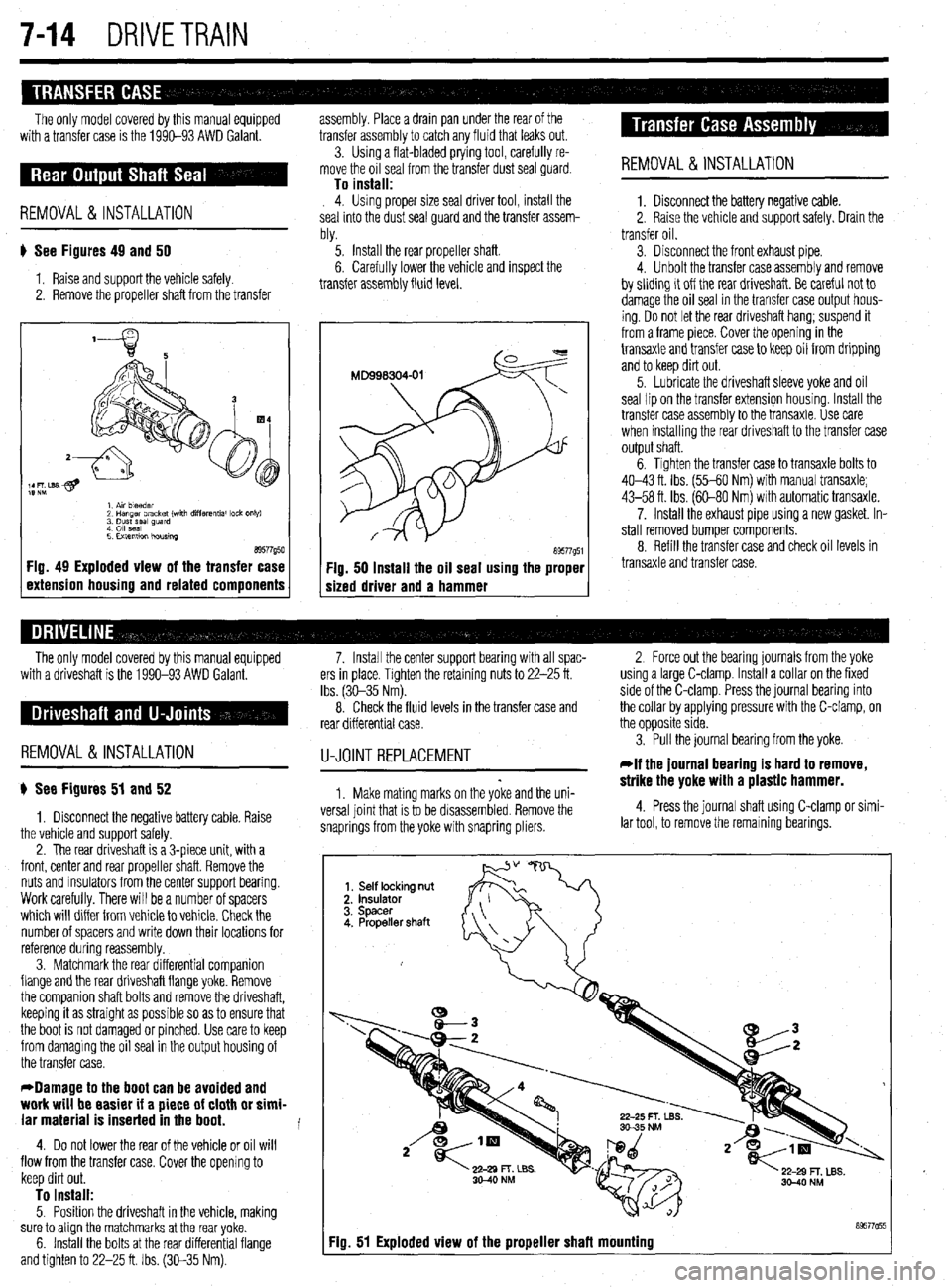

) See Figures 51 and 52

1. Disconnect the negative battery cable. Raise

the vehicle and support safely.

2. The rear driveshaft is a 3-piece unit, with a

front, center and rear propeller shaft. Remove the

nuts and msulators from the center support bearing.

Work carefully. There will be a number of spacers

which will differ from vehicle to vehicle. Check the

number of spacers and write down their locations for

reference during reassembly.

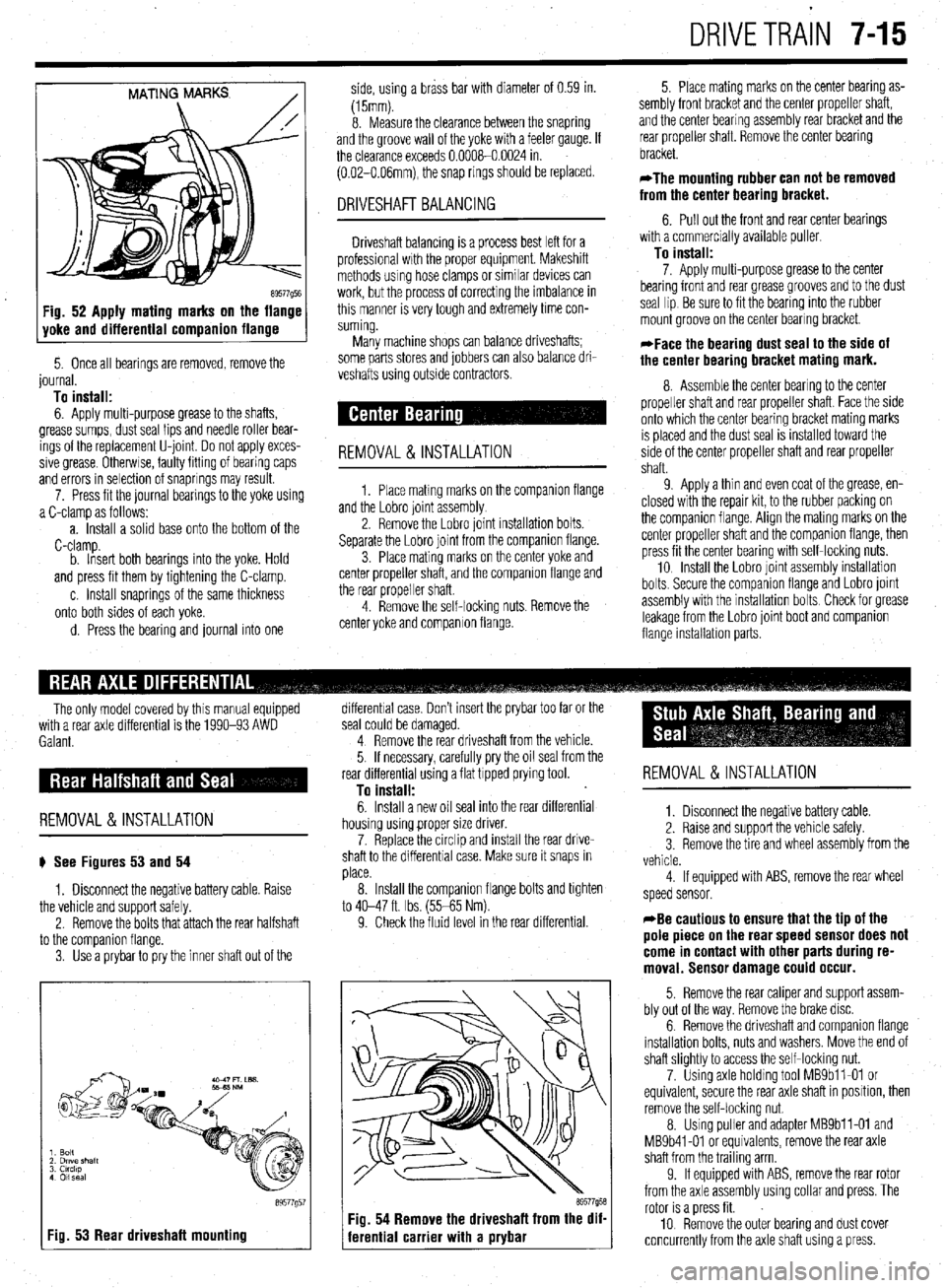

3. Matchmark the rear differential companion

flange and the rear driveshaft flange yoke. Remove

the companion shaft bolts and remove the driveshaft,

keeping it as straight as possible so as to ensure that

the boot is not damaged or pinched. Use care to keep

from damaging the oil seal in the output housing of

the transfer case.

*Damage to the boot can be avoided and

work will be easier if a piece of cloth or simi-

lar material is inserted in the boot.

4. Do not lower the rear of the vehicle or oil will

flow from the transfer case. Cover the opening to

keep dirt out.

To install: 5. Position the driveshaft in the vehicle, making

sure to align the matchmarks at the rear yoke.

6. Install the bolts at the rear differential flange

and tighten to 22-25 ft. Ibs. (30-35 Nm). 7. Install the center support bearing with all spac- 2 Force out the bearing journals from the yoke

ers in place. Tighten the retaining nuts to 22-25 ft. using a large C-clamp. Install a collar on the fixed

Ibs. (3C-35 Nm). side of the C-clamp. Press the journal bearing into

8. Check the fluid levels in the transfer case and the collar by applying pressure with the C-clamp, on

rear differential case. the opposite side.

U-JOINTREPLACEMENT

1. Make mating marks on the yoke and the uni-

versa1 joint that is to be disassembled. Remove the

snaprings from the yoke with snapring pliers. 3. Pull the journal bearing from the yoke.

rlf the journal bearing is hard to remove,

strike the yoke with a plastic hammer.

4. Press the journal shaft using C-clamp or simi-

lar tool, to remove the remaining bearings.

Fiu. 51 Exploded view of the proueller shafl mounting

Page 294 of 408

DRIVETRAiN 7-15

MATING MARKS

/

89577Q5E Fig. 52 Apply mating marks on the flange

yoke and differential companion flange

5. Once all bearings are removed, remove the

journal.

To install:

6. Apply multi-purpose grease to the shafts,

grease sumps, dust seal lips and needle roller bear-

ings of the replacement U-joint Do not apply exces-

sive grease Otherwse, faulty fitting of bearing caps

and errors in selection of snaprings may result.

7. Press fit the journal bearings to the yoke using

a C-clamp as follows:

a. Install a solid base onto the bottom of the

C-clamp.

b. Insert both bearings into the yoke. Hold

and press fit them by tightening the C-clamp.

c. Install snaprings of the same thickness

onto both sides of each yoke.

d. Press the bearing and journal into one side, using a brass bar with diameter of 0.59 in.

(15mm).

8. Measure the clearance between the snapring

and the groove wall of the yoke with a feeler gauge. If

the clearance exceeds 0.0008-0.0024 in.

(0.02-O.O6mm), the snap rings should be replaced.

DRIVESHAFT BALANCING

Driveshaft balancing is a process best left for a

professional wrth the proper equipment. Makeshift

methods using hose clamps or similar devices can

work, but the process of correcting the imbalance in

this manner is very tough and extremely time con-

suming.

Many machine shops can balance driveshafts;

some parts stores and jobbers can also balance dri-

veshafts using outside contractors.

REMOVAL&INSTALLATION

1. Place matmg marks on the companron flange

and the Lobro joint assembly

2. Remove the Lobro joint installation bolts.

Separate the Lobro joint from the companion flange.

3. Place mating marks on the center yoke and

center propeller shaft, and the companion flange and

the rear propeller shaft.

4. Remove the self-locking nuts. Remove the

center yoke and companion flange. 5. Place mating marks on the center bearing as-

sembly front bracket and the center propeller shaft,

and the center bearing assembly rear bracket and the

rear propeller shaft. Remove the center bearing

bracket.

*The mounting rubber can not be removed

from the center bearing bracket.

6. Pull out the front and rear center bearings

with a commercially available puller

To install:

7. Apply multi-purpose grease to the center

bearing front and rear grease grooves and to the dust

seal lip Be sure to fit the bearing into the rubber

mount groove on the center bearing bracket.

*Face the bearing dust seal to the side of

the center bearing bracket mating mark.

8. Assemble the center bearing to the center

propeller shaft and rear propeller shaft. Face the side

onto which the center bearing bracket mating marks

IS placed and the dust seal is installed toward the

side of the center propeller shaft and rear propeller

shaft.

9 Apply a thin and even coat of the grease, en-

closed with the repair kit, to the rubber packing on

the companion flange. Align the mating marks on the

center propeller shaft and the companion flange, then

press fit the center bearing with self-locking nuts.

10 Install the Lobro joint assembly installation

bolts. Secure the companron flange and Lobro joint

assembly with the installation bolts Check for grease

leakage from the Lobro joint boot and companion

flange installabon parts.

The only model covered by this manual equipped

with a rear axle differential is the 1990-93 AWD

Galant.

REMOVAL &INSTALLATION

# See Figures 53 and 54

1. Disconnect the negative battery cable. Raise

the vehicle and support safely.

2. Remove the bolts that attach the rear halfshaft

to the comoanion flanae.

3. Use’a prybar topry the inner shaft out of the

I Fig. 53 Rear driveshaft mounting

89577g5

differential case. Don’t insert the prybar too far or the

seal could be damaged.

4 Remove the rear driveshaft from the vehicle.

5. If necessary, carefully pry the oil seal from the

rear differential using a flat tipped prying tool.

To install:

6. Install a new oil seal into the rear differential

housing using proper size driver.

7. Replace the circlip and install the rear drive-

shaft to the differential case. Make sure it snaps in

place.

8. Install the companion flange bolts and tighten

to 40-47 ft. Ibs. (55-65 Nm).

9. Check the fluid level in the rear differential.

69577958 Fig. 54 Remove the driveshaft from the dif-

ferential carrier with a prybar

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Raise and support the vehicle safely.

3 Remove the tire and wheel assembly from the

vehicle.

4 If equipped with ABS, remove the rear wheel

speed sensor.

*Be cautious to ensure that the tip of the

pole piece on the rear speed sensor does not

come in contact with other parts during re-

moval. Sensor damage could occur.

5. Remove the rear caliper and support assem-

bly out of the way. Remove the brake disc.

6. Remove the driveshaft and companion flange

installation bolts, nuts and washers. Move the end of

shaft slightly to access the self-locking nut.

7. Using axle holding tool MBSbll-01 or

equivalent, secure the rear axle shaft in position, then

remove the self-locking nut.

8. Using puller and adapter MBSbll-01 and

MB9b41-01 or equivalents, remove the rear axle

shaft from the trailing arm

9. If equipped with ABS, remove the rear rotor

from the axle assembly using collar and press. The

rotor is a press fit.

10 Remove the outer bearing and dust cover

concurrently from the axle shaft using a press.

Page 328 of 408

.

8132 SUSPENSION AND STEERING

(42 Nm) on Mirage and 36-39 ft. tbs. (49-53 Nm)

on Galant and Diamante models.

19. Have the front end alignment checked, and

adjusted if necessary.

Inner Tie Rods

11. Loosen the inner tie rod end nut from the

steering gear and remove the inner tie rod end.

To install: 12. Using a new lock plate, install the tie rod end

and tighten the tie rod to 65 ft. Ibs. (90 Nm). REMOVAL &INSTALLATION 13. Bend the tabs of the new lock plate to secure

1. Raise the front of the vehicle and support it

on jackstands.

2. Remove the wheel.

3. Remove the cotter pin and the outer tie rod

ball joint stud nut. Note the position of the steering

linkage.

4. Wire brush the threads on the tie rod shaft

and lubricate with penetrating oil.

5. Using a suitable ball joint separator tool, re-

move the tie rod ball joint from the steering knuckle.

6. Loosen the locknut and remove the tie rod

end from the tie rod. Count the number of complete

turns it takes to completely remove it.

7. Remove the tie rod-to-steering gear locknut.

8. Remove the clamps that secure the flexible

boot to the steering gear.

9. Slide the boot from the inner tie rod and re-

move the boot.

IO. Bend the lock plate tabs from the inner tie rod

end nut. the inner tie rod end.

14. Slide the boot onto the steering gear and se-

cure it with new clamps.

15. Install the outer tie rod end to the steering

gear locknut.

16. Install the outer tie rod end, turning it in ex-

actly as many turns as it was to remove the old one.

Make sure it is correctly positioned in relationship to

the steering linkage.

22. Have a front end alignment performed. 17. Connect the outer tie rod end to the steering

knuckle and install the castle nut. Tighten the nut to

25 ft. Ibs. (34 Nm,) on the Mirage and 21 ft. Ibs. (29

Nm) on the Galant and Diamante models.

18. Install a new cotter pin to the castle nut.

19. Tighten the tie rod end locking nut to 30 ft.

Ibs. (42 Nm) on the Mirage and 36-39 ft. Ibs. (49-53

Nm) on the Galant and Diamante models.

20. Install the wheel and tire assembly.

21. Lower the vehicle.

Mirage

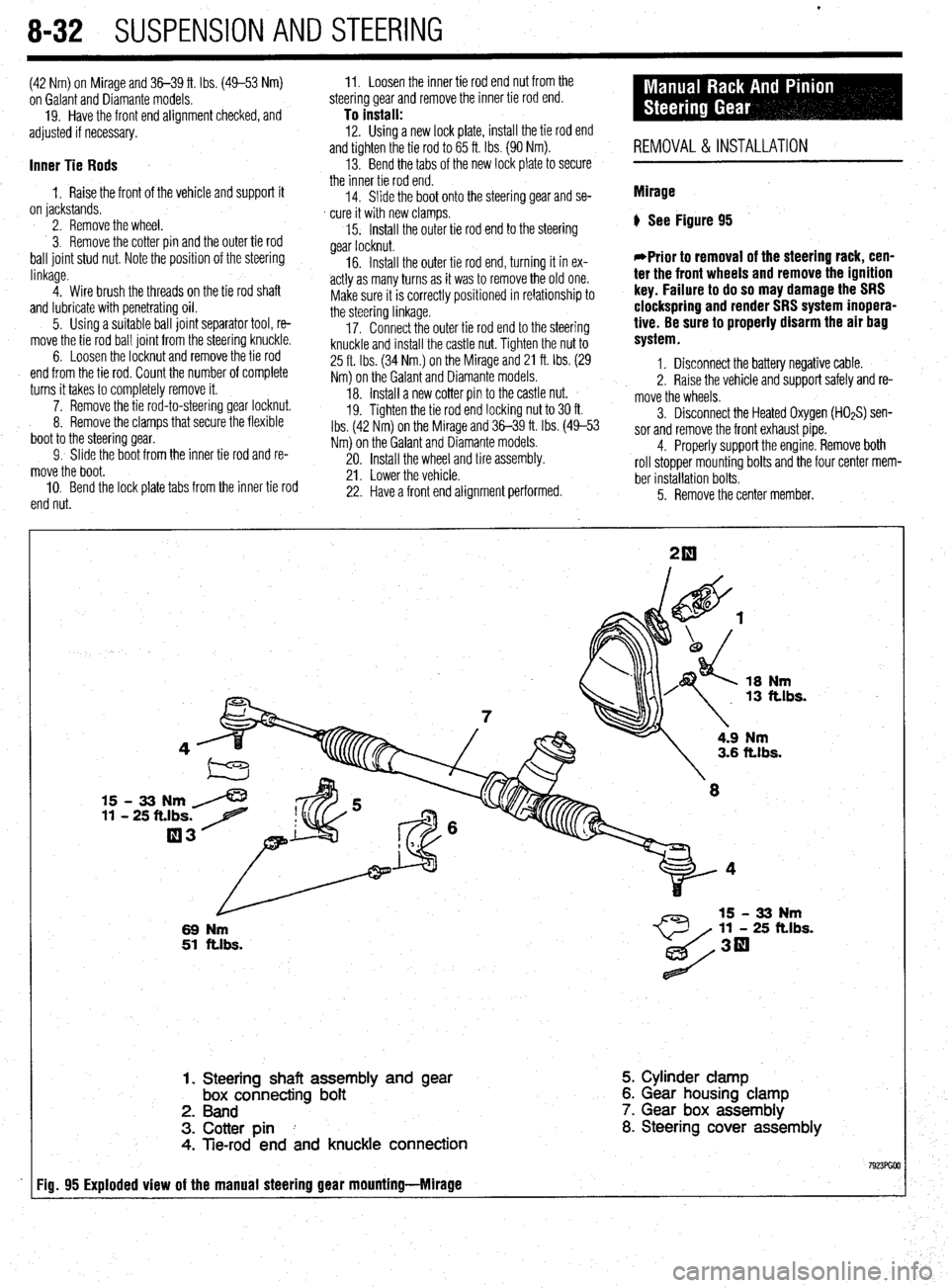

) See Figure 95

*Prior to removal of the steering rack, cen-

ter the front wheels and remove the ignition

key. Failure to do so may damage the SRS

clockspring and render SRS system inopera-

tive. Be sure to properly disarm the air bag

system.

1. Disconnect the battery negative cable.

2. Raise the vehicle and support safely and re-

move the wheels.

5. Remove the center member. 3. Disconnect the Heated Oxygen (HOzS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine. Remove both

roll stopper mounting bolts and the four center mem-

ber installation bolts.

18

Nm 13 ft.lbs.

15 - 33 Nm /

11 - 25 ft.lbs. 7

03

L

69 Nm

51 ftlbs.

4.9 Nm 3.6 ft.lbs.

11 - 25 ft.lbs.

1. Steering shaft assembly and

gear box connecting bolt

2. Band

3. Cotter pin I

4. Tie-rod end and knuckle connection 5. Cylinder clamp

6. Gear housing clamp

7. Gear box assembly

8. Steering cover assembly

Fig. 95 Exploded view of the manual steering gear mounting-Mlrage

Page 329 of 408

SUSPENSION AND STEERING 8-33

*Matchmark the pinion input shaft of the

rack to the lower steering column joint for in-

stallation purposes.

6. Remove the pinch bolt holding the lower

steering column joint to the rack and pinion input

shaft.

7. Remove the cotter pins and disconnect the tie

rod ends from the steering knuckle.

8. Remove the rack and pinion steering assem-

bly and its rubber mounts from the right side of the

vehicle.

To install: 9. Align the matchmarks of the input shaft and

install the rack to the vehicle.

10. Secure the rack using the retainer clamps and

bolts. Tighten the bolts to 51 ft. Ibs. (70 Nm).

11. Tighten the steering column pinch bolt to 13

ft. Ibs. (18 Nm).

12. Install the center member.

13. Install the front exhaust pipe.

14. Connect the HO$ sensor.

15. Connect the tie rod ends to the steering

knuckles and tighten the castle nuts to 25 ft. Ibs. (34

Nm). Install new cotter pins.

16. Install the wheels and connect the negative

battery cable.

17. Have a front end alignment performed.

REMOVAL &INSTALLATION

Diamante

FRONT

*Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clock spring and render SRS system in-

operative.

1. Disconnect the negative battery cable.

2. Disconnect the front exhaust pipe.

3. If equipped with AWD, remove the transfer

case assembly.

4. Remove the bolt holding the lower steering

column joint to the rack and pinion input shaft.

5. Remove the cotter pins and disconnect the tie

rod ends.

6. Remove the left and right frame members.

7. Remove the stabilizer bar bracket.

8. If equipped with four-wheel steering, discon-

nect the lines going to the rear pump.

9. Remove the rack and pinion steering assem-

bly and its rubber mounts. Move the rack to the right

to remove it from the crossmember.

To install: IO. Install the rack and mounting bolts. Tighten

the bolts to 51 ft. Ibs. (70 Nm). When installing the

rubber rack mounts, align the projection of the

mounting rubber with the indentation in the cross:

member. Install the pinch bolt.

11. Connect the pressure and return lines to the

rack and to the rear pump, if equipped.

12. Install the frame members and tighten the

bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Connect the tie rods and install new cotter

pins. 14. Install the transfer case and front exhaust

pipe.

15. Refill the reservoir and bleed the system.

16. Have a front end alignment performed.

REAR

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Drain the power steering fluid.

4. Remove the main muffler assembly.

5. Remove the rear shock absorber lower

mounting bolts.

6. Using the proper equipment, support the

weight of the rear differential. Remove the 2 small

crossmember brackets.

7. Remove the large self-locking crossmember

mounting nuts on the differential side.

8. Remove the oil line clamp bolts.

9. Remove the pressure tubes.

IO. Hold the tie rod ends stationary and remove

the tie rod end nuts. Remove the tie rod ends from

the trailing arms.

11. Remove the mounting bolts and remove the

rear steering gear.

To install: 12. Secure the unit to the crossmember. Move

the power cylinder piston rod over its full stroke to

determine its neutral position.

13. Align the tie rod ends with the holes in the

trailing arms and install the nuts. Adjust the length of

the tie rods with the nuts if necessary. The difference

in length between the 2 tie rod ends should not ex-

ceed 0.04 in. (1 mm). The nuts’ torque specification is

42 ft. Ibs. (58 Nm).

14. Replace the O-rings and install the pressure

tubes. Clamp in place.

15. Install the large self-locking crossmember

mounting nuts on the differential side. Tighten to

80-94 ft. Ibs. (110-130 Nm).

16. Remove the support equipment.

17. Install the 2 small crossmember brackets.

18. Install the shock mounting bolts.

19. Install the muffler assembly.

20. Refill the reservoir and bleed the system.

21. Have a front end alignment performed. _

Galant

1990-93 MODELS

1. Disconnect the negative battery cable.

2. Drain the power steering fluid.

3. Raise the vehicle and support safely.

4. Remove the bolt holding lower steering col-

umn joint to the rack and pinion input shaft.

5. Remove the transfer case, if equipped.

6. Remove the cotter pins and using the proper

tools, separate the tie rod ends from the steering

knuckle.

7. Locate the triangular brace near the stabilizer

bar brackets on the crossmember and remove both

the brace and the stabilizer bar bracket.

8. Support the center crossmember.

9. Remove the through-bolt from the round roll

stopper and remove the rear bolts from the center

crossmember.

10. Disconnect the front exhaust pipe, if

equipped with FWD.

11. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings. Plug the

fittings to prevent excess fluid leakage. 12. Lower the crossmember slightly.

13. Remove the rack and pinion steering assem-

bly and its rubber mounts. Move the rack to the right

to remove from the crossmember. Tilt the assembly

downward and remove from the left side of the vehi-

cle. Use caution to avoid damaging the boots.

To install: 14. Install the rack and install the mounting bolts. Tighten the mounting bolts to 43-58 ft. Ibs. (60-80

Nm). When installing the rubber rack mounts, align

the projection of the mounting rubber with the inden-

tation in the crossmember.

15. Connect the power steering fluid lines to the

rack.

16. Connect the exhaust pipe, if removed.

17. Raise the crossmember into position. Install

the center member mounting bolts and tighten to 72

ft. Ibs. (100 Nm). Install the roll stopper bolt and new

nut. Tighten nut to 47 ft. Ibs. (65 Nm).

18. Install the stabilizer bar brackets and brace.

19. Connect the tie rod ends and tighten nuts to

25 ft. Ibs. (34 Nm).

20. Install the transfer case, if removed. Check

and fill fluid.

21. Refill the reservoir with power steering fluid

and bleed the system.

22. Have a front end alignment performed.

1994-M MODELS

+ See Figure 96

Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clock spring and render SRS system in-

operative.

1. Disconnect the negative battery cable.

2. Raise and properly support the vehicle.

3. Remove both front wheel assemblies.

4. Remove the bolt holding lower steering col-

umn joint to the rack and pinion input shaft.

5. Remove the stabilizer bar.

6. Remove the cotter pins, and using joint sepa-

rator MB991 113 or equivalent, disconnect the tie rod

ends from the steering knuckle.

7. On vehicles equipped with Electronic Control

Power steering (EPS), detach the wiring harness from

the solenoid connector.

8. Locate the two triangular braces near the

crossmember and remove both.

9. Support the center crossmember. Remove the

through-bolt from the front round roll stopper and re-

move the bolts securing the center crossmember.

10. Remove the center crossmember. ,

Il. Properly support the engine and remove the

rear roll stopper through-bolt.

12. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings. Plug the

fittings to prevent excessive fluid leakage.

13. Remove the clamp bolts and the two bolts se-

curing the rack assembly to the chassis.

14. Remove the rack and pinion steering assem-

bly and its rubber mounts.

*When removing the rack and pinion as-

sembly, tilt the assembly to the vehicle side

of the compression lower arm and remove

from the left side of the vehicle.

Page 338 of 408

9-2 BRAKES

Hydraulic systems are used to actuate the brakes

of all modern automobiles. The system transports the

power required to force the frictional surfaces of the

braking system together from the pedal to the indi-

vidual brake units at each wheel. A hydraulic system

is used for two reasons.

First, fluid under pressure can be carried to all

parts of an automobile by small pipes and flexible

hoses without taking up a significant amount of room

or posing routing problems.

Second, a great mechanical advantage can be

given to the brake pedal end of the system, and the

foot pressure required to actuate the brakes can be

reduced by making the surface area of the master

cylinder pistons smaller than that of any of the pis-

tons in the wheel cylinders or calipers.

The master cylinder consists of a fluid reservoir

along with a double cylinder and piston assembly.

Double type master cylinders are designed to sepa-

rate the front and rear braking systems hydraulically

in case of a leak. The master cylinder converts me-

chanical motion from the pedal into hydraulic pres-

sure within the lines. This pressure is translated back

into mechanical motion at the wheels by either the

wheel cylinder (drum brakes) or the caliper (disc

brakes).

Steel lines carry the brake fluid to a point on the

vehicle’s frame near each of the vehicle’s wheels. The

fluid is then carried to the calipers and wheel cylin-

ders by flexible tubes in order to allow for suspen-

sion and steering movements.

In drum brake systems, each wheel cylinder con-

tains two pistons, one at either end, which push out-

ward in opposite directions and force the brake shoe

into contact with the drum.

In disc brake systems, the cylinders are part of the

calipers. At least one cylinder in each caliper is used

to force the brake pads against the disc.

All pistons employ some type of seal, usually

made of rubber, to minimize fluid leakage. A rubber

dust boot seals the outer end of the cylinder against

dust and dirt. The boot fits around the outer end of

the piston on disc brake calipers, and around the

brake actuating rod on wheel cylinders.

The hydraulic system operates as follows: When at

rest, the entire system, from the piston(s) in the mas-

ter cylinder to those in the wheel cylinders or

calipers, is full of brake fluid. Upon application of the

brake pedal, fluid trapped in front of the master cylin-

der piston(s) is forced through the lines to the wheel

cylinders. Here, it forces the pistons outward, in the

case of drum brakes, and inward toward the disc, in

the case of disc brakes. The motion of the pistons is

opposed by return springs mounted outside the

cylinders in drum brakes, and by spring seals, in disc

brakes.

Upon release of the brake pedal, a spring located

inside the master cylinder immediately returns the

master cylinder pistons to the normal position. The

pistons contain check valves and the master cylinder

I

has compensating ports drilled in it. These are un-

covered as the pistons reach their normal position.

The piston check valves allow fluid to flow toward the

wheel cylinders or calipers as the pistons withdraw.

Then, as the return springs force the brake pads or

shoes into the released position, the excess fluid

reservoir through the compensating ports. It is during the time the pedal is in the released position that any

fluid that has leaked out of the system will be re-

placed through the compensating ports.

Dual circuit master cylinders employ two pistons,

located one behind the other, in the same cylinder.

The primary piston is actuated directly by mechanical

linkage from the brake pedal through the power

booster. The secondary piston is actuated by fluid

trapped between the two pistons. If a leak develops in

front of the secondary piston, it moves forward until it

bottoms against the front of the master cylinder, and

the fluid trapped between the pistons will operate the

rear brakes. If the rear brakes develop a leak, the pri-

mary piston will move forward until direct contact

with the secondary piston takes place, and it will

force the secondary piston to actuate the front brakes.

In either case, the brake pedal moves farther when the

brakes are applied, and less braking power is avail-

able.

All dual circuit systems use a switch to warn the

driver when only half of the brake system is opera-

tional. This switch is usually located in a valve body

which is mounted on the firewall or the frame below

the master cylinder. A hydraulic piston receives pres-

sure from both circuits, each circuits pressure being

applied to one end of the piston. When the pressures

are in balance, the piston remains stationary. When

one circuit has a leak, however, the greater pressure

in that circuit during application of the brakes will

push the piston to one side, closing the switch and

activating the brake warning light.

In disc brake systems, this valve body also con-

tains a metering valve and, in some cases, a propor-

tioning valve. The metering valve keeps pressure

from traveling to the disc brakes on the front wheels

until the brake shoes on the rear wheels have con-

tacted the drums, ensuring that the front brakes will

never be used alone. The proportioning valve con-

trols the pressure to the rear brakes to lessen the

chance of rear wheel lock-up during very hard brak-

ing.

Warning lights may be tested by depressing the

brake pedal and holding it while opening one of the

wheel cylinder bleeder screws. If this does not cause

the light to go on, substitute a new lamp, make conti-

nuity checks, and, finally, replace the switch as nec-

essary.

The hydraulic system may

be checked for leaks by applying pressure to the pedal gradually and steadily.

If the pedal sinks very slowly to the floor, the system

has a leak. This is not to be confused with a springy

or spongy feel due to the compression of air within

the lines. If the system leaks, there will be a gradual

change in the position of the pedal with a constant

pressure.

Check for leaks along all lines and at wheel cylin-

ders. If no external leaks are apparent, the problem is

inside the master cylinder,

DISC BRAKES

Instead of the traditional expanding brakes that

press outward against a circular drum, disc brake

systems utilize a disc (rotor) with brake pads posi-

tioned on either side of it. An easily-seen analogy is

the hand brake arrangement on a bicycle. The pads

squeeze onto the rim of the bike wheel, slowing its

motion. Automobile disc brakes use the identical principle but apply the braking effort to a separate

disc instead of the wheel.

The disc (rotor) is a casting, usually equipped with

cooling fins between the two braking surfaces. This

enables air to circulate between the braking surfaces

making them less sensitive to heat buildup and more

resistant to fade. Dirt and water do not drastically af-

fect braking action since contaminants are thrown off

by the centrifugal action of the rotor or scraped off

the by the pads. Also, the equal clamping action of

the two brake pads tends to ensure uniform, straight

line stops. Disc brakes are inherently self-adjusting.

There are three general types of disc brake:

1. A fixed caliper.

2. A floating caliper.

3. A sliding caliper.

The fixed caliper design uses two pistons

mounted on either side of the rotor (in each side of

the caliper). The caliper is mounted rigidly and does

not move.

The sliding and floating designs are quite similar.

In fact, these two types are often lumped together. In

both designs, the pad on the inside of the rotor is

moved into contact with the rotor by hydraulic force.

The caliper, which is not held in a fixed position,

moves slightly, bringing the outside pad into contact

with the rotor. There are various methods of attaching

floating calipers. Some pivot at the bottom or top,

and some slide on mounting bolts. In any event, the

end result is the same.

DRUM BRAKES

Drum brakes employ two brake shoes mounted on

a stationary backing plate. These shoes are posi-

tioned inside a circular drum which rotates with the

wheel assembly. The shoes are held in place by

springs. This allows them to slide toward the drums

(when they are applied) while keeping the linings and

drums in alignment. The shoes are actuated by a

wheel cylinder which is mounted at the top of the

backing plate. When the brakes are applied, hydraulic

pressure forces the wheel cylinder’s actuating links

outward. Since these links bear directly against the

top of the brake shoes, the tops of the shoes are then

forced against the inner side of the drum. This action

forces the bottoms of the two shoes to contact the

brake drum by rotating the entire assembly slightly

(known as servo action). When pressure within the

wheel cylinder is relaxed, return springs pull the

shoes back away from the drum.

Most modern drum brakes are designed to self-

adjust themselves during application when the vehi-

cle is moving in reverse. This motion causes both

shoes to rotate very slightly with the drum, rocking

an adjusting lever, thereby causing rotation of the ad-

justing screw. Some drum brake systems are de-

signed to self-adjust during application whenever the

brakes are applied. This on-board adjustment system

reduces the need for maintenance adjustments and

keeps both the brake function and pedal feel satisfac-

tory.

POWER BOOSTERS

Virtually all modern vehicles use a vacuum as-

sisted power brake system to multiply the braking

force and reduce pedal effort. Since vacuum is always

available when the engine is operating, the system is

Page 345 of 408

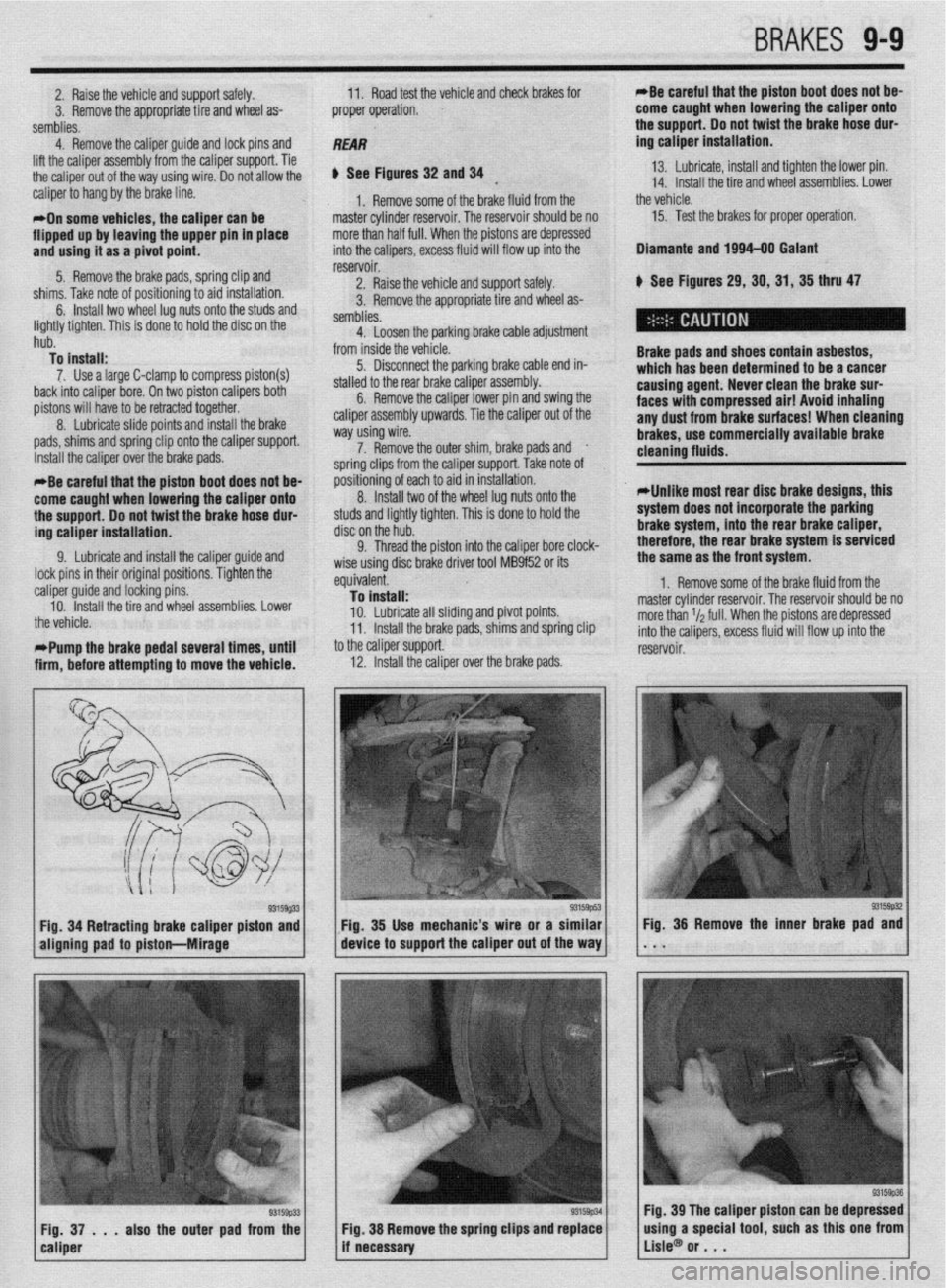

2. Raise the vehicle and support safely.

3. Remove the appropriate tire and wheel as-

semblies. 11. Road test the vehicle and check brakes for

proper operation. *Be careful that the piston boot does not be-

come caught when lowering the caliper onto

+ha n,.nnnr) lh nnt t&at thm hr&a hnra rlnr-

4. Remove the calmer auide and lock Dins and

REAR

lift the caliper assembly’from the caliper support. Tie

the caliper

out of the way using wire. 00 not allow the

caliper to hang by the brake line.

*On some vehicles, the caliper can be

flipped up by leaving the upper pin in place

and usinu it as a oivot ooint.

---- sa - . -.

5. Remove the brake pads, spring clip and

cl7knr T&n nn+n ,-A nrdtinninntn sir-4 inc+alhtinn

u See Figures 32 and 34 13. Lubricate, install and tighten the lower pin.

*

14. Install the tire and wheel assemblies. Lower

1, Remove some of the brake fluid from the the vehicle.

master cylinder reservoir. The reservoir should be no 15. Test the brakes for proper operation:

more than half full. When the p istons are depressed

into the calioers. excess fluid

3 111,113. ,(lhC ,,“LC “I p”3”‘““H’y I” a,u IIIaLcuIaLt”II. 6. Install two wheel lug nuts onto the studs and

:

lightly tighten. This is done to hold the disc on the

hub.

To install:

7. Use a large C-clamp to compress piston(s)

back into caliper bore. On two piston calipers both

pistons will have to be retracted together.

8. Lubricate slide points and install the brake

pads, shims and spring clip ont- +‘- --“n-* n**nnnA reservoir. /ill flow up into the

2. Raise the vehicle and support safely.

s tire and wheel as- 3. Remove the appropriate

semblies.

4. Loosen the parking bra

from inside the vehicle.

5. Disconnect the parking brake cable end in-

stalled to the rear brake caliper assembly.

6. Remove the caliper lower pin and swing the

caliper assembly upwards. Tie the caliper out of the

way using wire. Dlamante and 1994-00 Galant

k See Figures 29,30,31,35 thru 47

Brake pads and shoes contain asbestos,

which has been determined to be a cancer

causing agent. Never clean the brake sur-

faces with compressed air! Avoid inhaling

any dust from brake surfaces! When cleaning

brakes. use commerciallv avallable brake Ike cable adjustment

Install the caliper over the brake ,..uuG. 7. Remove the outer shim, brake pads and

.

ie caliper support. Take note of soring clips from tl

nositibning of eact

8

IndalI twn cleaning flutds. -

*Be careful that the piston boot does not be-

come caught when lowering the caliper onto

the support. Do not twist the brake hose dur-

ing caliper installation. I to aid in installation.

“. llluLull L..V of the wheel lug nuts onto the

studs and lightly tighten. This is done to hold the

disc on the hub.

Cl Thrm-l the nictnn into thP r!alinar hnre rlnrk-

*Unlike most rear disc brake designs, this

system does not incorporate the parking

brake system, into the rear brake caliper,

therefore, the rear brake system is serviced

9. Lubricate and install the caliper guide and

lock pins in their original positions. Tighten the

: caliper guide and locking pins.

10. Install the tire and wheel assemblies. Lower

the vehicle.

t *Pump the brake pedal several times, until

i

firm, before attempting to move the vehicle. V. ,,,lV”” ,,,V ~,“L”,’ III1” .IIV “..*.prv, ““I., “.“-a.

wise using disc brake driver tool MB9f52 or its

equivalent.

To install:

10. Lubricate all sliding and pivot points.

11. Install the brake pads, shims and spring clip

to the caliper support.

12. Install the caliper over ”

’ -’ ---I~ me oraxe paas. the same as the front system.

1. Remove some of the brake fluid from the

master cylinder reservoir. The reservoir should be no

more than r/a full. When the pistons are depressed

into the calipers, excess fluid will flow up into the

reservoir.

93159#2 Fig. 34 Retracting brake caliper piston and Fig. 35 Use mechanic’s wire or a similar

aligning pad to piston-hlirage device to support the caliper out of the way Fig. 36 Remove the inner brake pad and

. . .

93159p33 Fig, 37 . . . also the outer pad from the

caliper Fig. 39 The caliper piston can be depressed

Fig. 38 Remove the spring clips and replace

if necessary using a special tool, such as this one from

Lisle@ or . . .

Page 346 of 408

l

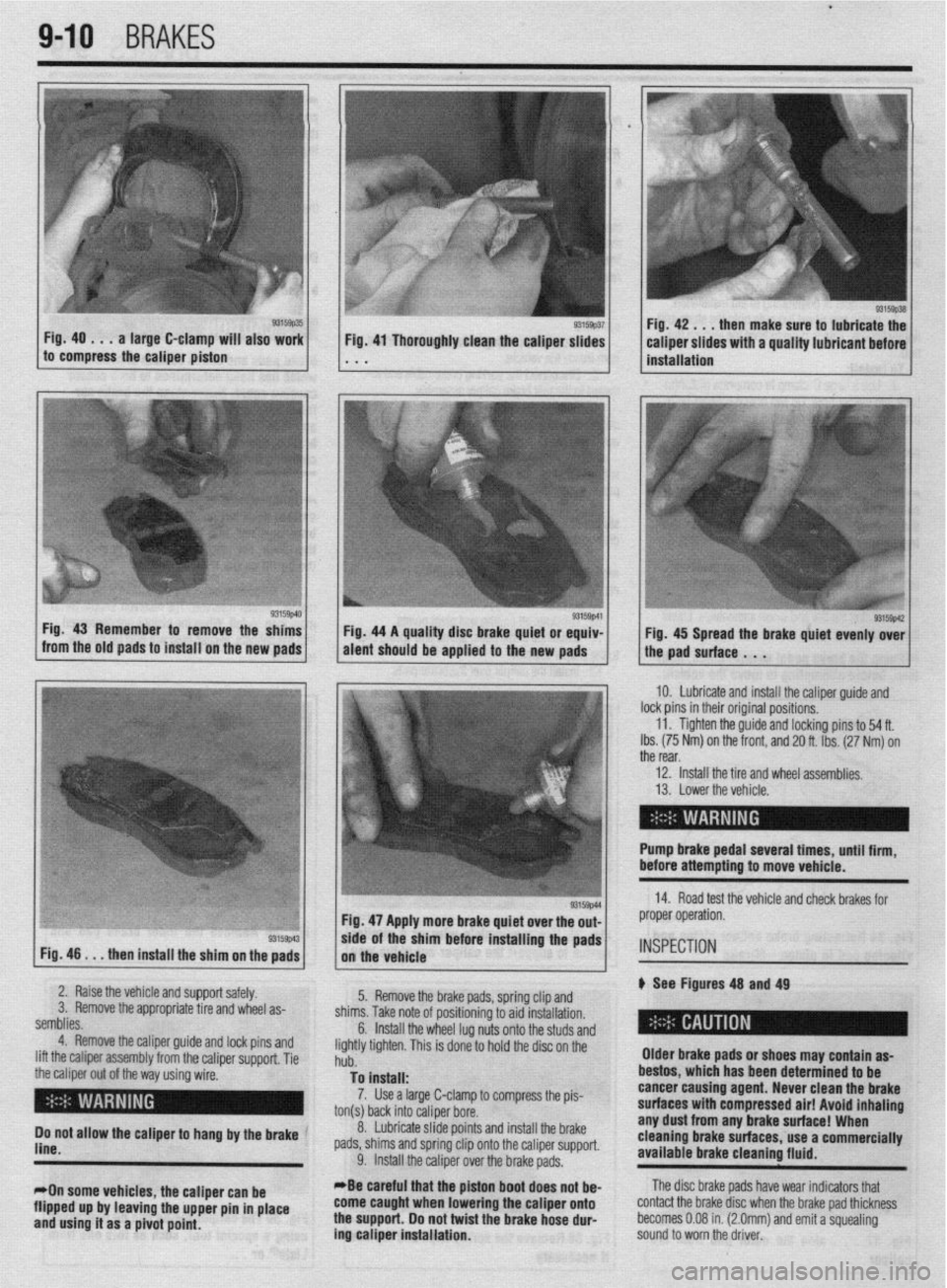

9-10 BRAKES

Fig. 40 . . . a large C-clamp will also work

to compress the caliper piston then make sure to lubricate the

Fig. 46

. . . then install the shim on the pads Fig. 47 Apply more brake quiet over the out-

/, the vehicle .Is/l*

wde of the sham before installing the pads

2. Raise the vehicle and support safely.

3. Remove the appropriate tire and wheel as-

semblies.

4. Remove the caliper guide and lock pins and

lift the caliper assembly from the caliper support. Tie

the caliper out of the way using wire.

( I ’ 5. Remove the brake pads, spring clip and

shims. Take note of positioning to aid installation.

6.

Do not allow the caliper to hang by the brake ’

line.

*On some vehicles, the caliper can be

flipped up by leaving the upper pin in place

and using it as a pivot point. Install the wheel lug nuts onto the studs and

lightly tighten. This is done to hold the disc on the

hub.

To install:

7. Use a large C-clamp to compress the pis-

ton(s) back into caliper bore.

_

8. Lubricate slide points and install the brake

pads, shims and spring clip onto the caliper support.

9. Install the caliper over the brake pads.

*Be careful that the piston boot

does not be- come caught when lowering the caliper onto

the support. Do not twist the brake hose dur-

ing caliper installation. Older brake pads or shoes may contain as-

bestos, which has been determined to be

cancer causing agent. Never clean the

brake

surfaces with compressed air! Avoid inhaling any dust from any brake surface! When

cleaning brake surfaces, use a commercially

available brake cleaning fluid. IO. Lubricate and install the caliper guide and

lock pins in their original positions.

11. Tighten the guide and locking pins to 54 ft.

Ibs. (75 Nm) on the front, and 20 ft. Ibs. (27 Nm) on

the rear,

12. install the tire and wheel assemblies.

13. Lower the vehicle.

Pump brake pedal several tlmes, until firm,

before attempting to move vehicle.

14. Road test the vehicle and check brakes for

proper operation.

INSPECTION

p See Figures 48 and 49

The disc brake pads have wear indicators that

contact the brake disc when the brake pad thickness

becomes 0.08 in. (2.0mm) and emit a squealing

sound to worn the driver.

Page 348 of 408

l

942 BRAKES

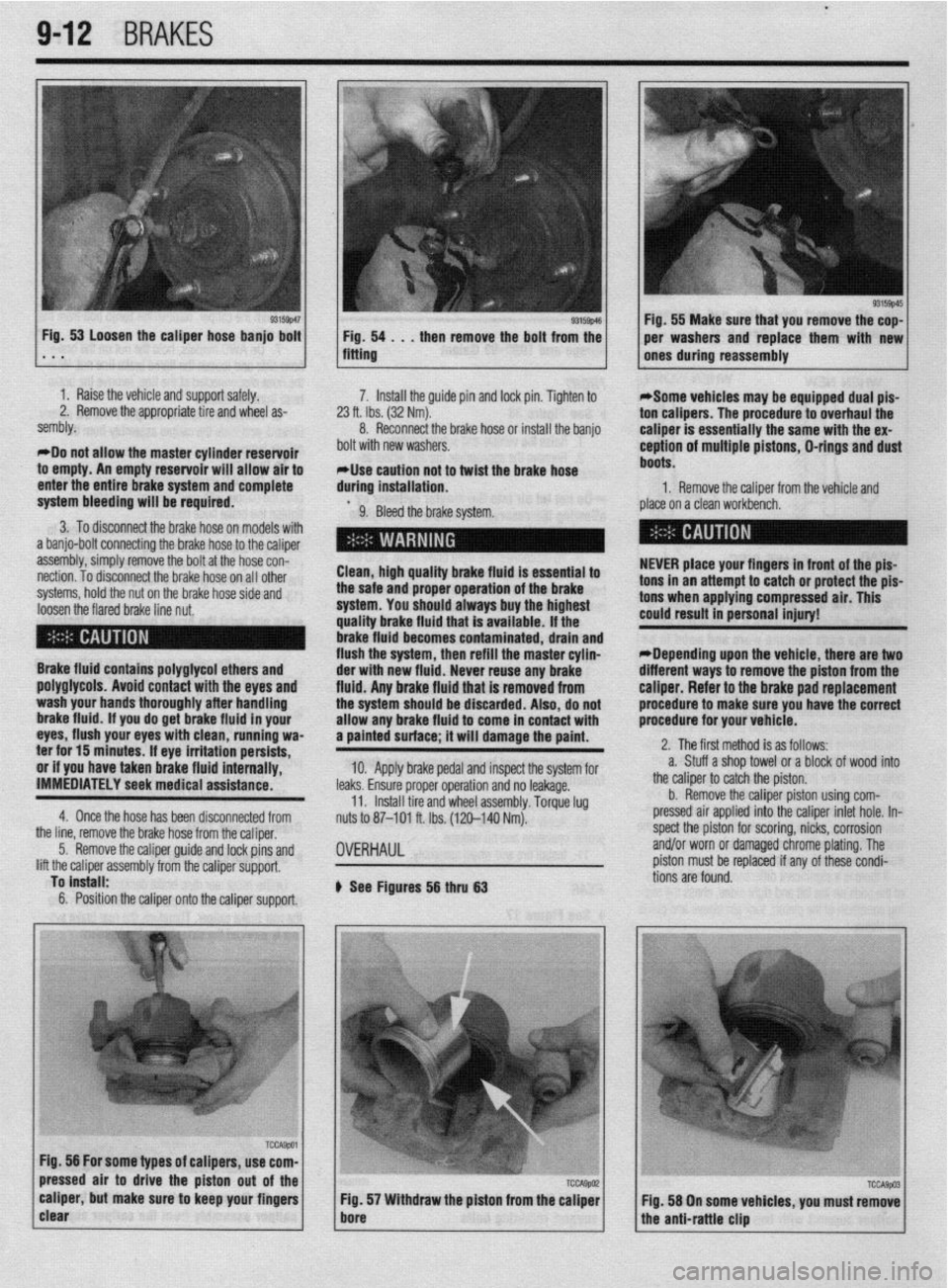

I 93155~46 Fig, 53 Loosen the caliper hose banjo bolt

1 Fig. 54 . . , then remove the bolt from the . * . fitting

1 I Raise the vehicle and support safely.

2. Remove the appropriate tire and wheel as-

sembly.

*Do not allow the master cylinder reservoir

to empty. An empty reservoir will allow air to

enter the entire brake system and complete 7. Install the guide pin and lock pin. Tighten to

23 ft. Ibs. (32 Nm).

8. Reconnect the brake hose of install the banjo

bolt with new washers.

*Use caution not to twist the brake hose

during installation.

system bleeding will be required.

9. Bleed the brake system.

3. To disconnect the brake hose on models with

a banjo-bolt connecting the brake hose to the caliper

assembly, simply remove the bolt at the hose con-

nection. To disconnect the brake hose on all other

systems, hold the nut on the brake hose side and

loosen the flared brake line nut. Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

Brake fluid contains polyglycol ethers and

poly~lycols. Avoid contact with the eves and

wash your hands thoroughly after handling

brake fluid. if you do get brake fluid In your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

4. Once the hose has been disconnected from der with new fluid. Never reuse any brake

fluid. Anv brake fluid that is removed from

the systum should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

10. Apply brake pedal and inspect the system for

leaks. Ensure proper operation and no leakage.

11. Install tire and wheel assembly. Torque lug

nuts to 87-101 ft. Ibs. (120-140 Nm).

the line, remove the brake hose from the caliper,

5. Remove the caliper guide and lock pins and

lift the caliper assembly from the caliper support,

To install:

6. Position the caliper onto the caliper support.

OVERHAUL

b See Figures 56 thru 63 1 Fig. 55 Make sure that you remove the cop-

per washers and replace them with new

ones during reassembly

*Some vehicles may be equipped dual pis-

ton calipers. The procedure to overhaul the

caliper is essentially the same with the ex-

ception of multiple pistons, D-rings and dust

boots.

1. Remove the caliper from the vehicle and

place on a clean workbench.

NEVER place your fingers in front of the pis-

tons in an attempt to catch or protect the pis-

tons when applying compressed air. This

could result in personal injury!

*Depending upon the vehicle, there are two

different ways to remove the piston from the

caliper. Refer to the brake pad replacement

procedure to make sure you have the correct

procedure for your vehicle.

2. The first method is as follows:

a. Stuff a shop towel or a block of wood into

the caliper to catch the piston.

b. Remove the caliper piston using com-

pressed air applied into the caliper inlet hole. In-

spect the piston for scoring, nicks, corrosion

and/or worn or damaged chrome plating. The

piston must be replaced if any of these condi-

tions are found.