boot MITSUBISHI DIAMANTE 1900 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 349 of 408

BRAKiS 9-13

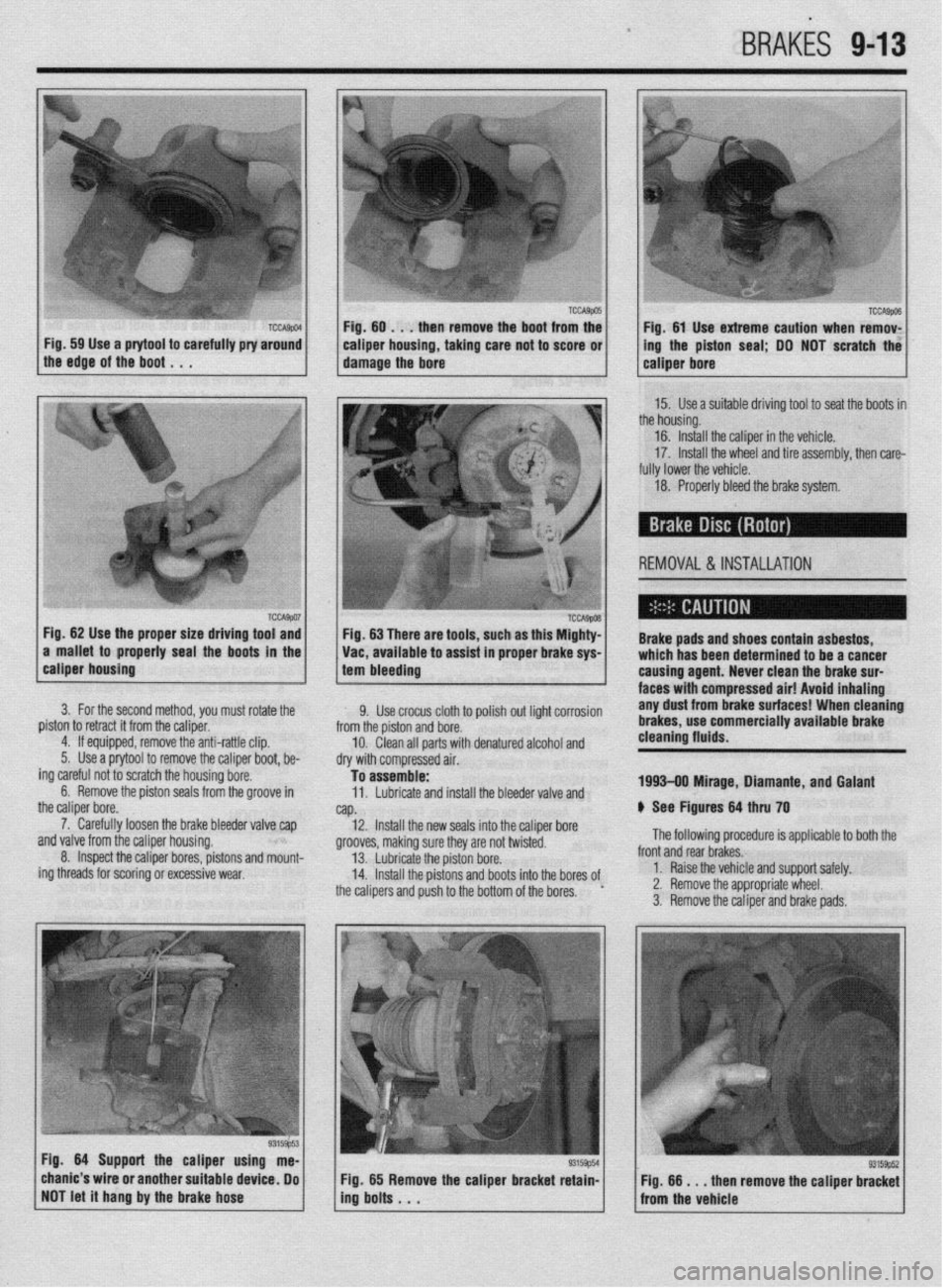

Fig. 59 Use a prytool to carefully pry around 1

the edge of the boot , , . caiper housing, taking care not to score or 1

damage the bore ing the piston seal; DO NOT scratch the

15. Use a suitable driving tool to seat the boots in

the housing.

16. Install the caliper in the vehicle.

17. Install the wheel and tire assembly, then care-

fully lower the vehicle.

18. Properly bleed the brake system.

REMOVAL &INSTALLATION

Fig. 62 Use the proper size driving tool and

a mallet to properly seal the boots in the Fig. 63 There are tools, such as this Mighty-

Vat, available to assist in proper brake sys- Brake pads and shoes contain asbestos,

which has been determined to be a cancer

calmer housino

1 tam hlasrlinn . --~-~~~v

3. For the second method, you must rotate the

piston to retract it from the caliper.

4. If equipped, remove the anti-rattle clip.

5. Use a prytool to remove the caliper boot, be-

ing careful not to scratch the housing bore.

6. Remove the piston seals from the groove in

the caliper bore.

7. Carefully loosen the brake bleeder valve cap

~nrl \I~IWJ frnm the r~linor hnlwinn

I causina aaent. LL.....” rlrr.. .I.,. l.uLr I..”

Yll” .UI”Y ll”lll LIIb rro,spl tI”“Jlly. 8. Inspect the caliper bores, pistons and mount-

ing threads for scoring or excessive wear,

--... -.---...= ’ I.twla lilci(lll Lllli uranl$ au,- faces with-compressed air! Avoid Inhaling

9. Use crocus cloth to polish out light corrosion any dust from brake surfaces! When cleaning

from the piston and bore. brakes, use commercially available brake

10. Clean all parts with denatured alcohol and cleaning fluids.

dry with compressed air.

To assemble:

11. Lubricate and install the bleeder valve and 1993-09 Mirage, Diamante, and Galant

NP. 6 See Figures 64 thru 70

12. Install the new seals into the caliper bore

nrnnlrhr m”lr;nn Clln-. M..-.., nrn n.4 h..‘“‘“~ The following procedure is applicable to both the ytvvvca, lllanllly 3”IC o,ey ale II”, IWI~LCL. 13. Lubricate the piston bore.

14. Install the pistons and boots into the bores of

the calipers and push to the bottom of the bores. ’ front and rear brakes.

1. Raise the vehicle and support safely.

2. Remove the appropriate wheel.

3. Remove the caliper and brake pads.

Fia. 64 Suoaarl the calmer usina me-

., -----= -..- chanic’s wire or another suitable device, Do

NOT let it hang by the brake hose Fig. 65 Remove the caliper bracket retain-

ing bolts . . . Fig. 66 m . . then remove the caliper bracket

from the vehicle

Page 355 of 408

BRAtiES 9-19

*Soecial flare nut wrenches shauld

REMOVAL&INSTALLATION

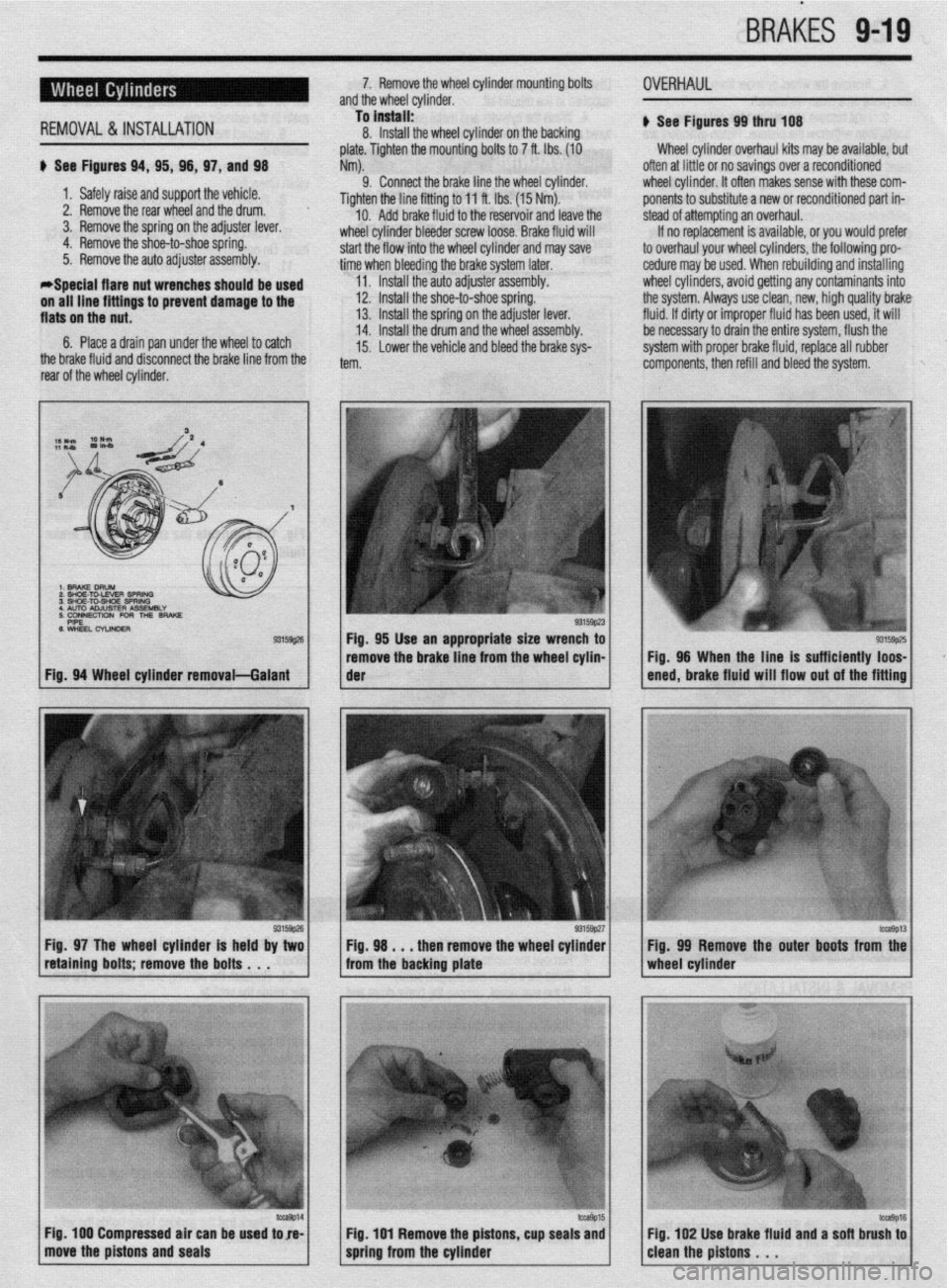

be used u See Figures 94, 95, 98, 97, and 98

1. Safely raise and support the vehicle.

2. Remove the rear wheel and the drum.

3. Remove the spring on the adjuster lever,

4. Remove the shoe-to-shoe spring.

5. Remove the auto adjuster assembly. 7. Remove the wheel cylinder mounting bolts

and the wheel cylinder.

To install:

11. Install the auto adjusterassembly. 8. Install the wheel cylinder on the backing

plate. Tighten the mounting bolts to 7 ft. Ibs. (10

Nm).

9. Connect the brake line the wheel cylinder.

Tighten the line fitting to 11 ft. Ibs. (15 Nm).

10. Add brake fluid to the reservoir and leave the

wheel cylinder bleeder screw loose. Brake fluid will

start the flow into the wheel cylinder and may save

time when bleeding the brake system later.

OVERHAUL

u See Figures 99 thru lD8

Wheel cylinder overhaul kits may be available, but

often at little or no savings over a reconditioned

wheel cvlinder. It often makes sense with these com-

ponents to substitute a new or reconditioned part in-

stead of attempting an overhaul.

If no replacement is available, or you would prefer

to overhaul your wheel cylinders, the following pro-

cedure may be used. When rebuilding and installing

wheel cylinders, avoid getting any contaminants into

the system. Always use clean, new, high quality brake

fluid. If dirty or improper fluid has been used, it will

be necessary to drain the entire system, flush the

system with proper brake fluid, replace all rubber

components, then refill and bleed the system.

Fig. 97 The wheel cylinder is held by two Fig. 98 . . . then remove the wheel cylinder

retaining bolts; remove the bolts . . . from the backing plate

/ move the pistons and seals ‘Tr 1 Fig 100 Compressed air can be used tore- Fig. 99 Remove the outer boots from the

/cleanthepistons. ‘. ‘*I6 Fig 102 Use brake fluid and a sofl brush to

Page 356 of 408

‘I

9-20 ,BRAKES

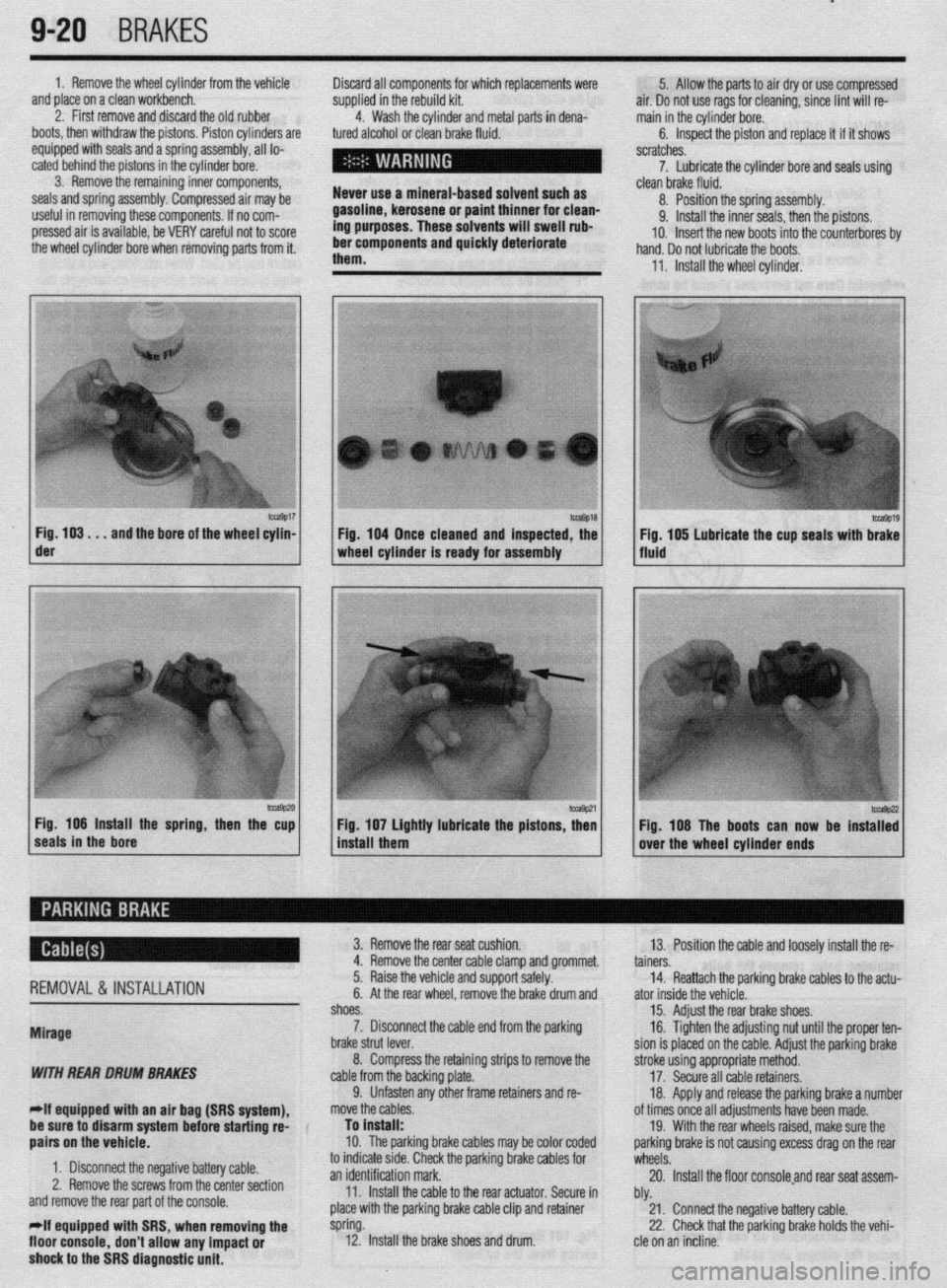

1. Remove the wheel cylinder from the vehicle

and place on a clean workbench.

2. First remove and discard the old rubber

boots, then withdraw the pistons. Piston cylinders are

equipped with seals and a spring assembly, all lo-

cated behind the pistons in the cylinder bore.

3. Remove the remaining inner components,

seals and spring assembly. Compressed air may be

useful in removing these components. If no com-

pressed air is available, be VERY careful not to score

the wheel cylinder bore when removing parts from it. Discard all components for which replacements were

supplied in the rebuild kit.

4. Wash the cylinder and metal parts in dena-

tured alcohol or clean brake fluid.

Never use a mineral-based solvent such as

gasoline, kerosene or paint thinner for clean-

ing purposes. These solvents will swell rub-

ber components and quickly deteriorate

them. 5. Allow the parts to air dry or use compressed

air. Do not use rags for cleaning, since lint will re-

main in the cylinder bore.

6. Inspect the piston and replace it if it shows

scratches.

7. Lubricate the cylinder bore and seals using

- clean brake fluid.

8. Position the spring assembly.

9. Install the inner seals, then the pistons.

IO. Insert the new boots into the counterbores bv

hand. Do not lubricate the boots,

11, Install the wheel cylinder,

m9017 Fig. 103. . .

and the bore of the wheel cylin- der

-9P20 Fig. 106 Install the spring, then the cup

seals in the bore 1 Fig. 104 Once cleaned and inspected, the

1 wheel cylinder Is ready for assembly

1 install them Fig 107 Lightly lubricate the pistons z

’ Fig. 108 The boots can now be instaT:

over the wheel cylinder ends

REMOVAL& INSTALLATION

Mirage

WITH REAR DRUM BRAKES

-If equipped witti an air bag (SRS system), 3. Remove the rear seat cushion.

13. Position the cable and loosely install the re-

4. Remove the center cable clamp and grommet.

tainers.

5. Raise the vehicle and support safely.

14. Reattach the parking brake cables to the actu-

6. At the rear wheel, remove the brake drum and

ator inside the vehicle.

shoes.

15. Adjust the rear brake shoes.

7. Disconnect the cable end from the parking

16. Tighten the adjusting nut until the proper ten-

brake strut lever.

sion is placed on the cable. Adjust the parking brake

8. Compress the retaining strips to remove the

stroke using appropriate method.

cable from the backing plate.

17. Secure all cable retainers,

9. Unfasten any other frame retainers and re-

18. Apply and release the parking brake a number

move the cables.

of times once all adjustments have been made.

be sure to disarm system

befok starting rd-

aairs on the vehicle. To install:

10. The parkinq brake cables mav be color coded 19. With the rear wheels raised, make sure the

oarkino brake is not causina excess draa on the rear

1. Disconnect the negative battery cable.

2. Remove the screws from the center section

and remove the rear part of the console.

*If equipped with SRS, when removing the

floor console,

don’t allow any impact or

shock to the SRS diagnostic unit. to indicate stde. Check the parking brake cables for

wheels: .A

an identification mark.

20. Install the floor consoleand rear seat assem-

11. Install the cable to the rear actuator. Secure in

bly.

place with the parking brake cable clip and retainer

21. Connect the negative battery cable.

spring.

22. Check that the parking brake holds the vehi-

12. Install the brake shoes and drum.

cle on an incline.

Page 372 of 408

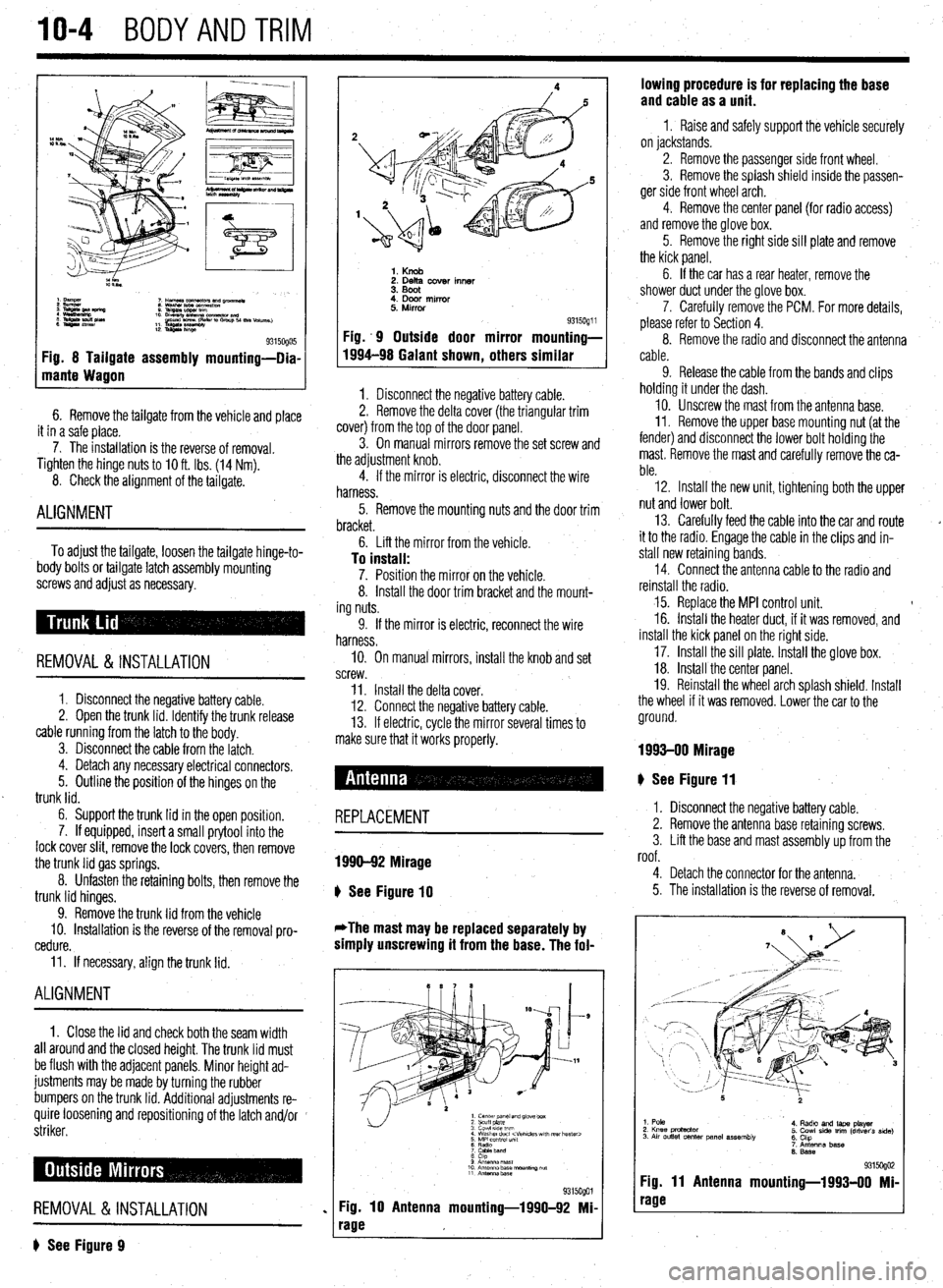

10-4 BODYANDTRIM

Fig. 8 Tailgate assembly mounting-Dia-

mante Wagon

6. Remove the tailgate from the vehicle and place

it in a safe place.

7. The installation is the reverse of removal.

Tighten the hinge

nuts to IO ft. Ibs. (14 Nm).

8. Check the alignment of the tailgate.

ALIGNMENT

To adjust the tailgate, loosen the tailgate hinge-to-

body bolts or tailgate latch assembly mounting

screws and adjust as necessary.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Open the trunk lid. Identify the trunk release

cable running from the latch to the body.

3. Disconnect the cable from the latch.

4. Detach any necessary electrical connectors.

5. Outline the position of the hinges on the

trunk lid.

6. Support the trunk lid in the open position.

7. If equipped, insert a small prytool into the

lock cover slit, remove the lock covers, then remove

the trunk lid gas springs.

8. Unfasten the retaining bolts, then remove the

trunk lid hinges.

9. Remove the trunk lid from the vehicle

10. Installation is the reverse of the removal pro-

cedure.

11. If necessary, align the trunk lid.

ALIGNMENT

1. Close the lid and check both the seam width

all around and the closed height. The trunk lid must

be flush with the adjacent panels. Minor height ad-

justments may be made by turning the rubber

bumpers on the trunk lid. Additional adjustments re-

quire loosening and repositioning of the latch and/or

striker.

REMOVAL &INSTALLATION

? See Figure 9

1. Knob 2. Delta cover inner

3. Boot

4. Door mirror

5. Mirror

Fig. .9 Outside door mirror

1994-98 Galant shown

, others 9315oQ1 i mounting-

similar

1. Disconnect the negative battery cable.

2. Remove the delta cover (the triangular trim

cover) from the top of the door panel.

3. On manual mirrors remove the set screw and

the adjustment knob.

4. If the mirror is electric, disconnect the wire

harness.

5. Remove the mounting nuts and the door trim

bracket.

6. Lift the mirror from the vehicle.

To install: 7. Position the mirror on the vehicle.

8. Install the door trim bracket and the mount-

ing nuts.

9. If the mirror is electric, reconnect the wire

harness.

IO. On manual mirrors, install the knob and set

screw.

11. Install the delta cover.

12. Connect the negative battery cable.

13. If electric, cycle the mirror several times to

make sure that it works properly.

# See Figure 11

REPLACEMENT

1990-92 Mirage

b

See Figure 10

*The mast may be replaced separately by

simply unscrewing it from the base. The fol-

1. center panel and glove box

2 scuff plate

3 cowl 51ae wm

4 Washer duct

7 CaMeband

8 cap

9 Anrsnna mast

10 Antenna base “ourmng ““f

11 Antennz.base

%i%Qol

Fig. 10 Antenna mounting-1990-92 Mi-

rage lowing procedure is for replacing the base

and cable as a unit.

1 I Raise and safely support the vehicle securely

on jackstands.

2. Remove the passenger side front wheel.

3. Remove the splash shield inside the passen-

ger side front wheel arch.

4. Remove the center panel {for radio access)

and remove the glove box.

5. Remove the right side sill plate and remove

the kick panel.

6. If the car has a rear heater, remove the

shower duct under the glove box.

7. Carefully remove the PCM. For more details,

please refer to Section 4.

8. Remove the radio and disconnect the antenna

cable.

9. Release the cable from the bands and clips

holding it under the dash.

10. Unscrew the mast from the antenna base.

II. Remove the upper base mounting nut (at the

fender) and disconnect the lower bolt holding the

mast. Remove the mast and carefully remove the ca-

ble.

12. Install the new unit, tightening both the upper

nut and lower bolt.

13. Carefully feed the cable into the car and route

it to the radio. Engage the cable in the clips and in-

stall new retaining bands.

14. Connect the antenna cable to the radio and

reinstall the radio.

15. Replace the MPI control unit. t

16. Install the heater duct, if it was removed, and

install the kick panel on the right side.

17. Install the sill plate. Install the glove box.

18. Install the center panel.

19. Reinstall the wheel arch splash shield. Install

the wheel if it was removed. Lower the car to the

ground.

1993-00 Mirage

I. Disconnect the negative battery cable.

2. Remove the antenna base retaining screws.

3. Lift the base and mast assembly up from the

roof.

4. Detach the connector for the antenna.

5. The installation is the reverse of removal.

1. Pole

2. Knee protactor

3. Air outlet center panel assembly 4. Radto and laps player

5. Cowl side trim (driver’s side)

6. Chp

7. Antenna base

6. Base

931 !iogo2 Fig. 11 Antenna mounting-1993-00 Mi-

rage

Page 395 of 408

TROUBLESHOOTING 11-13

NOTE: When one shock fails, ft is recommended to replace front or rear

units as pairs.

3. Vehicle leans excessively in turns

a. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

b. Check for missing, damaged, or worn stabilizer links or bushings, and replace or in-

stall as necessary.

4. Vehicle ride quality seems excessively ha&h

a. Check for seized shock absorbers or strut assemblies and replace as necessary.

b. Check for excessively high tire pressures and adjust pressures to vehicle recommen-

dations.

5. Vehicle seems low or leans to one side

a. Check for a damaged, broken or weak spring. Replace defective parts and check for a

needed alignment.

b. Check for seized shock absorbers or strut assemblies and replace as necessary.

c. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

Noises 1. Vehicle makes a clicking noises when driven

a. Check the noise to see if it varies with road speed. Verify if the noise is present when

coasting or with steering or throttle input. If the clicking noise frequency changes with

road speed and is not affected by steering or throttle input, check the tire treads for a

stone, piece of glass, nail or another hard object imbedded into the tire or tire tread.

Stones rarely cause a tire puncture and are easily removed. Other objects may create

an air leak when removed. Consider having these objects removed immediately at a

facility equipped to repair tire punctures.

b. If the clicking noise varies with throttle input and steering, check for a worn Constant

Velocity (CV-joint) joint, universal (U- joint) or flex joint.

2. Vehicle makes a clunking or knocking noise over bumps

a. A clunking noise over bumps is most often caused by excessive movement or clear-

ance in a suspension component. Check the suspension for soft, cracked, damaged or

worn bushings. Replace the bushings and check the vehicle’s alignment.

b. Check for loose suspension mounting bolts. Check the tightness on subframe bolts,

pivot bolts and suspension mounting bolts, and torque to specification.

c. Check the vehicle for a loose wheel bearing. Some wheel bearings can be adjusted for

looseness, while others must be replaced if loose. Adjust or replace the bearings as

recommended by the manufacturer.

d. Check the door latch adjustment. If the door is slightly loose, or the latch adjustment

is not centered, the door assembly may create noises over bumps and rough surfaces.

Properly adjust the door latches to secure the door. 3. Vehicle makes a low pitched rumbling noise when driven

a. A low pitched rumbling noise is usually caused by a drive train related bearing and is

most often associated with a wheel bearing which has been damaged or worn. The

damage can be caused by excessive brake temperatures or physical contact with a pot

hole or curb. Sometimes the noise will vary when turning. Left hand turns increase the

load on the vehicle’s right side, and right turns load the left side. A failed front wheel

bearing may also cause a slight steering wheel vibration when turning. A bearing

which exhibits noise must be replaced.

b. Check the tire condition and balance. An internally damaged tire may cause failure

symptoms similar to failed suspension parts. For diagnostic purposes, try a known

good set of tires and replace defective tires.

4. Vehicle makes a squeaking noise over bumps

a. Check the vehicle’s ball joints for wear, damaged or leaking boots. Replace a ball joint

if it is loose, the boot is damaged and leaking, or the ball joint is binding. When re-

placing suspension parts, check the vehicle for alignment.

b. Check for seized or deteriorated bushings. Replace bushings that are worn or dam-

aged and check the vehicle for alignment.

c. Check for the presence of sway bar or stabilizer bar bushings which wrap around the

bar. Inspect the condition of the bushings and replace if worn or damaged. Remove

the bushing bracket and apply a thin layer of suspension grease to the area where the

bushings wrap around the bar and reinstall the bushing brackets. ~

5. Vehicle vibrates when driven

a. Check the road surface. Roads which have rough or uneven surfaces may cause un-

usual vi brations.

b. Check the tire condition and balance. An internally damaged tire may cause failure

symptoms similar to failed suspension parts. For diagnostic purposes, try a known

good set of tires and replace defective tires immediately.

c. Check for a worn Constant Velocity (CV-joint) joint, universal (U- joint) or flex joint

and replace if loose, damaged or binding.

d. Check for a loose, bent, or out-of-balance axle or drive shaft. Replace damaged or

failed components.

NOTE: Diagnosing failures related to wheels, tires, steering and the sus-

pension system can often times be accomplished with a careful and thor-

ough test drive. Bearing noises are isolated by noting whether the noises

or symptoms vary when turning left or right, or occur while driving a

straight line. During a teft hand turn, the vehicle’s weight shifts to the

right, placing more force on the right side bearings, such that if a right side

wheel bearing is worn or damaged, the noise or vibration should increase

during light-to-heavy acceleration. Conversely, on right hand turns, the ve-

hicle tends to lean to the left, loading the left side bearings.

Knocking noises in the suspension when the vehicle is driven over rough roads, rail-

road tracks and speed bumps indicate worn suspension components such as bushings,

ball joints or tie rod ends, or a worn steering system.

1. One headlight only works on high or low beam

a. Check for battery voltage at headlight electrical connector. If battery voltage is present,

replace the headlight assembly or bulb if available separately. If battery voltage is not

present, refer to the headlight wiring diagram to troubleshoot.

2. Headlight does not work on high or low beam

a. Check for battery voltage and ground at headlight electrical connector. If battery volt-

age is present, check the headlight connector ground terminal for a proper ground. If

battery voltage and ground are present at the headlight connector, replace the head-

light assembly or bulb if available separately. If battery voltage or ground is not pre-

sent, refer to the headlight wiring diagram to troubleshoot.

b. Check the headlight switch operation. Replace the switch if the switch is defective or

ooerates intermittentlv. 1. Tail light, running light or side marker light inoperative

a. Check for battery voltage and ground at light’s electrical connector. If battery voltage is

present, check the bulb socket and electrical connector ground terminal for a proper

ground. If battery voltage and ground are present at the light connector, but not in the

socket, clean the socket and the ground terminal connector. If battery voltage and

ground are present in the bulb socket, replace the bulb. If battery voltage or ground is

not present, refer to the wiring diagram to troubleshoot for an open circuit.

b. Check the light switch operation and replace if necessary.

2. Tall light, running light or side marker light works intermittently

a. Check the bulb for a damaged filament, and replace if damaged.

b. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

w 3. Headlight(s) very dim

a. Check for battery voltage and ground at headlight electrical connector. If battery volt-

age is present, trace the ground circuit for the headlamp electrical connector, then

clean and repair as necessary. If the voltage at the headlight electrical connector is

significantly less than the voltage at the battery, refer to the headlight wiring diagram

to troubleshoot and locate the voltage drop. c. Check for loose, damaged or corroded wires and electrical terminals, and repair as

necessary.

d. Check the light switch operation and replace if necessary.

3. Tail light, running light or side marker light very dim

a. Check the bulb and bulb socket for corrosion and clean or replace the bulb and

socket.

Page 404 of 408

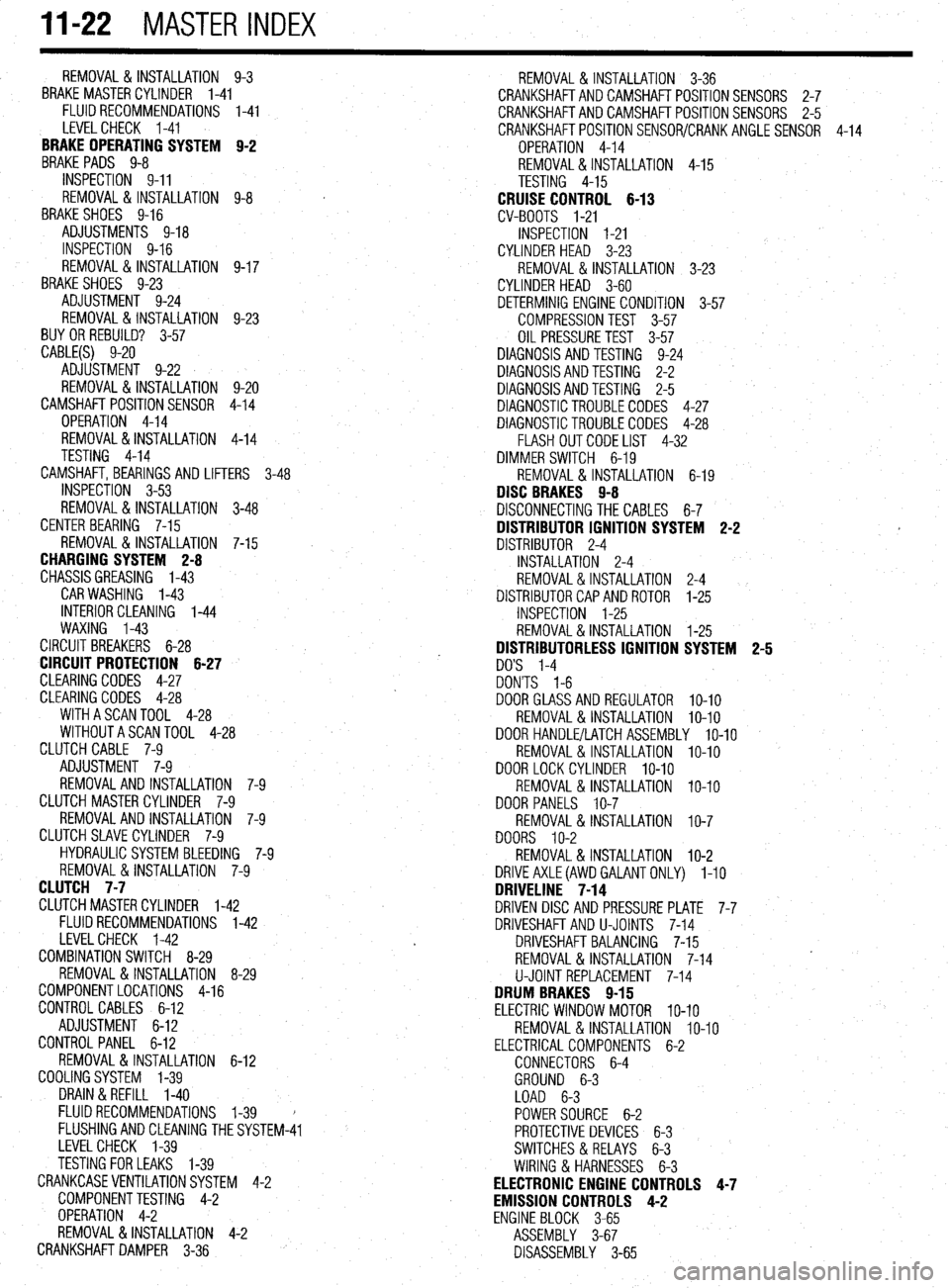

11-22 MASTER INDEX

REMOVAL&INSTALLATION 9-3

BRAKE MASTERCYLINDER I-41

FLUIDRECOMMENDATIONS 1-41

LEVELCHECK I-41

BRAKE OPERATING SYSTEM B-2

BRAKEPADS 9-8

INSPECTION 9-11

REMOVAL & INSTALLATION 9-8

'

BRAKESHOES 9-16

ADJUSTMENTS 9-18

INSPECTION 9-16

REMOVAL&INSTALLATION 9-17

BRAKESHOES 9-23

ADJUSTMENT 9-24

REMOVAL & INSTALLATION 9-23

BUY OR REBUILD? 3-57

CABLE(S) 9-20

ADJUSTMENT 9-22

REMOVAL & INSTALLATION 9-20

CAMSHAFT POSITIONSENSOR 4-14

OPERATION 4-14

REMOVAL &INSTALLATION 4-14

TESTING 4-14

CAMSHAFT, BEARINGSAND LIFTERS 3-48

INSPECTION 3-53

REMOVAL & INSTALLATION 3-48

CENTERBEARING 7-15

REMOVAL & INSTALLATION 7-15

CHARGING SYSTEM 2-8

CHASSISGREASING l-43

CAR WASHING 1-43

INTERIOR CLEANING l-44

WAXING l-43

CIRCUIT BREAKERS 6-28

CIRCUIT PROTECTION 6-27

CLEARING CODES 4-27

CLEARING CODES 4-28

WITHASCANTOOL 4-28

WITHOUTASCANTOOL 4-28

CLUTCH CABLE 7-9

ADJUSTMENT 7-9

REMOVAL AND INSTALLATION 7-9

CLUTCH MASTER CYLINDER 7-9

REMOVALANDINSTALLATION 7-9

CLUTCHSLAVECYLINDER 7-9

HYDRAULIC SYSTEM BLEEDING 7-9

REMOVAL &INSTALLATION 7-9

CLUTCH 7-7

CLUTCHMASTERCYLINDER l-42

FLUIDRECOMMENDATIONS l-42

LEVELCHECK l-42

COMBINATION SWITCH 8-29

REMOVAL &INSTALLATION 8-29

COMPONENTLOCATIONS 4-16

CONTROL CABLES 6-12

ADJUSTMENT 6-12

CONTROL PANEL 6-12

REMOVAL&INSTALLATION 6-12

COOLINGSYSTEM l-39

DRAIN &REFILL I-40

FLUIDRECOMMENDATIONS l-39

FLUSHINGANDCLEANING THESYST

EM-41

LEVELCHECK l-39

TESTING FOR LEAKS l-39

CRANKCASEVENTILATIONSYSTEM 4-2

COMPONENTTESTING 4-2

OPERATION 4-2

REMOVAL &INSTALLATION 4-2

CRANKSHAFTDAMPER 3-36 REMOVAL &INSTALLATION 3-36

CRANKSHAFTANDCAMSHAFTPOSITIONSENSORS 2-7

CRANKSHAFTANDCAMSHAFTPOSITIONSENSORS 2-5

CRANKSHAFTPOSlTlONSENSOR/CRANKANGLESENSOR 4-14

OPERATION 4-14

REMOVAL&INSTALLATION 4-15

TESTING 4-15

CRUISE CONTROL 6-13

CV-BOOTS I-21

INSPECTION I-21

CYLINDER HEAD 3-23

REMOVAL & INSTALLATION 3-23

CYLINDER HEAD 3-60

DETERMINIG ENGINE CONDITION 3-57

COMPRESSION TEST 3-57

OIL PRESSURETEST 3-57

DIAGNOSIS AND TESTING 9-24

DIAGNOSISANDTESTING 2-2

DIAGNOSISANDTESTING 2-5

DIAGNOSTICTROUBLECODES 4-27

DIAGNOSTICTROUBLECODES 4-28

FLASH OUTCODELIST 4-32

DIMMER SWITCH 6-19

REMOVAL &INSTALLATION 6-19

DISC BRAKES 9-8

DISCONNECTING THE CABLES 6-7

DISTRIBUTOR IGNITION SYSTEM 2-2 f

DISTRIBUTOR 2-4

INSTALLATION 2-4

REMOVAL&INSTALLATION 2-4

DISTRIBUTORCAPANDROTOR l-25

INSPECTION l-25

REMOVAL&INSTALLATION l-25

DISTRIBUTORLESS IGNITION SYSTEM 2-5

DO'S l-4

DON'TS l-6

DOORGLASSANDREGULATOR lo-10

REMOVAL &INSTALLATION IO-IO

DOOR HANDLE/LATCHASSEMBLY IO-IO

REMOVAL & INSTALLATION IO-IO

DOORLOCKCYLINDER IO-IO

REMOVAL & INSTALLATION IO-IO

DOOR PANELS IO-7

REMOVAL & INSTALLATION IO-7

DOORS IO-2

REMOVAL &INSTALLATION IO-2

DRlVEAXLE(AWD GALANTONLY) l-10

DRIVELINE 7-14

DRIVEN DISC AND PRESSURE PLATE 7-7

DRIVESHAFTAND U-JOINTS 7-14

DRIVESHAFT BALANCING 7-15

REMOVAL & INSTALLATION 7-14

U-JOINTREPLACEMENT 7-14

DRUM BRAKES 9-15

ELECTRIC WINDOW MOTOR IO-IO

REMOVAL &INSTALLATION IO-IO

ELECTRICALCOMPONENTS 6-2

CONNECTORS 6-4

GROUND 6-3

LOAD 6-3

POWERSOURCE 6-2

PROTECTIVE DEVICES 6-3

SWITCHES&RELAYS 6-3

WIRING & HARNESSES 6-3

ELECTRONIC ENGINE CONTROLS 4-7

EMISSION CONTROLS 4-2

ENGINE BLOCK 3-65

ASSEMBLY 3-67

DISASSEMBLY 3-65