fuse MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 208 of 408

CHASSIS ELECTRiCAL 6-5

them. It is used for voltage and ground tests. To use voltmeter has a positive and a negative lead. To avoid

a 12 volt test light, connect the ground clip to a good damage to the meter, always connect the negative

ground and probe wherever necessary with the pick. lead to the negative (-) side of the circuit (to ground

The test light will illuminate when voltage is detected. or nearest the ground side of the circuit) and connect

This

does not necessarily mean that 12 volts (or any the positive lead to the positive(t) side of the circuit When diagnosing a specific problem, organized

troubleshooting is a must. The complexity of a mod-

particular amount of voltage) is present; it only (to the power source or the nearest power source).

means that some voltage is present. It is advisable Note that the negative voltmeter lead will always be ern automotive vehicle demands that you approach

before using the test light to touch its ground clip black and that the positive voltmeter will always be any problem in a logical, organized manner. There

and probe across the battery posts or terminals to some color other than black (usually red). are certain troubleshooting techniques, however,

which are standard:

make sure the light is operating properly.

l Ohmmeter-the ohmmeter is designed to read l Establish when the problem occurs. Does the

resistance (measured in ohms) in a circuit or compo-

nent. Most ohmmeters will have a selector switch problem appear only under certain conditions? Were

there any noises, odors or other unusual symptoms?

Do not use a test light to probe electronic ig- which permits the measurement of different ranges of

Isolate the problem area. To do this, make some sim-

nition, spark plug or coil wires. Never use a resistance (usually the selector switch allows the

multiplication of the meter reading by 10,100,1,000 ple tests and observations, then eliminate the sys-

pick-type test light to probe wiring on com- terns that are working properly. Check for obvious

puter controlled systems unless specifically and 10,000). Some ohmmeters are “auto-ranging”

which means the meter itself will determine which problems, such as broken wires and loose or dirty

instructed to do so. Any wire insulation that

scale to use. Since the meters are powered by an in- connections. Always check the obvious before as-

is pierced by the test light probe should be

ternal battery, the ohmmeter can be used like a self- suming something complicated is the cause.

taped and sealed with silicone after testing.

l Test for problems systematically to determine

powered test light. When the ohmmeter is connected,

the cause once the problem area is isolated. Are all

Like the jumper wire, the 12 volt test light is used current from the ohmmeter flows through the circuit

the components functioning properly? Is there power

to isolate opens in circuits. But, whereas the jumper or component being tested. Since the ohmmeter’s in-

ternal resistance and voltage are known values, the going to electrical switches and motors. Performing

wire is used to bypass the open to operate the load,

amount of current flow through the meter depends on careful, systematic checks will often turn up most

the 12 volt test light is used to locate the presence of

the resistance of the circuit or component being causes on the first inspection, without wasting time

voltage in a circuit. If the test light illuminates, there

tested. The ohmmeter can also be used to perform a checking components that have little or no relation-

is power up to that point in the circuit; if the test light ship to the problem.

does not illuminate, there is an open circuit (no continuity test for suspected open circuits. In using

the meter for making continuity checks, do not be

l Test all repairs after the work is done to make

power). Move the test light in successive steps back

concerned with the

actual resistance readings. Zero sure that the problem is fixed. Some causes can be

toward the power source until the light in the handle traced to more than one component, so a careful veri-

illuminates. The open is between the probe and a resistance, or any ohm reading, indicates continuity

fication of repair work is important in order to pick up

point which was previously probed. in the circuit, Infinite resistance indicates an opening

in the circuit. A high resistance reading where there additional malfunctions that may cause a problem to

The self-powered test light is similar in design to

should be none indicates a problem in the circuit. reappear or a different problem to arise. A blown

the 12 volt test light, but contains a 1.5 volt penlight

Checks for short circuits are made in the same man- fuse, for example, is a simple problem that may re-

battery in the handle. It is most often used in place of

ner as checks for open circuits, except that the circuit quire more than another fuse to repair. If you don’t

a multimeter to check for open or short circuits when look for a problem that caused a fuse to blow, a

power is isolated from the circuit (continuity test). must be isolated from both power and normal

ground. Infinite resistance indicates no continuity, shorted wire (for example) may go undetected.

The battery in a self-powered test light does not Experience has shown that most problems tend

provide much current. A weak battery may not pro- while zero resistance indicates a dead short.

to be the result of a fairly simple and obvious

vide enough power to illuminate the test light even I ’ cause, such as loose or corroded connectors, bad

when a complete circuit is made (especially if there is grounds or damaged wire insulation which causes a

high resistance in the circuit). Always make sure that Never use an ohmmeter to check the resis- short. This makes careful visual inspection of com-

the test battery is strong. To check the battery, briefly tance of a component or wire while there is ponents during testing essential to quick and accu-

touch the ground clip to the probe; if the light glows voltage applied to the circuit. rate troubleshooting.

brightly, the battery is strong enough for testing.

*A self-powered test light should not be

l Ammeter-an ammeter measures the amount

- I

used on any computer controlled system or of current flowing through a circuit in units called

component. The small amount of electricity amperes or amps. At normal operating voltage, most

circuits have a characteristic amount of amperes, OPEN CIRCUITS

transmitted by the test light is enough to

damage many electronic automotive compo- called “current draw” which can be measured using

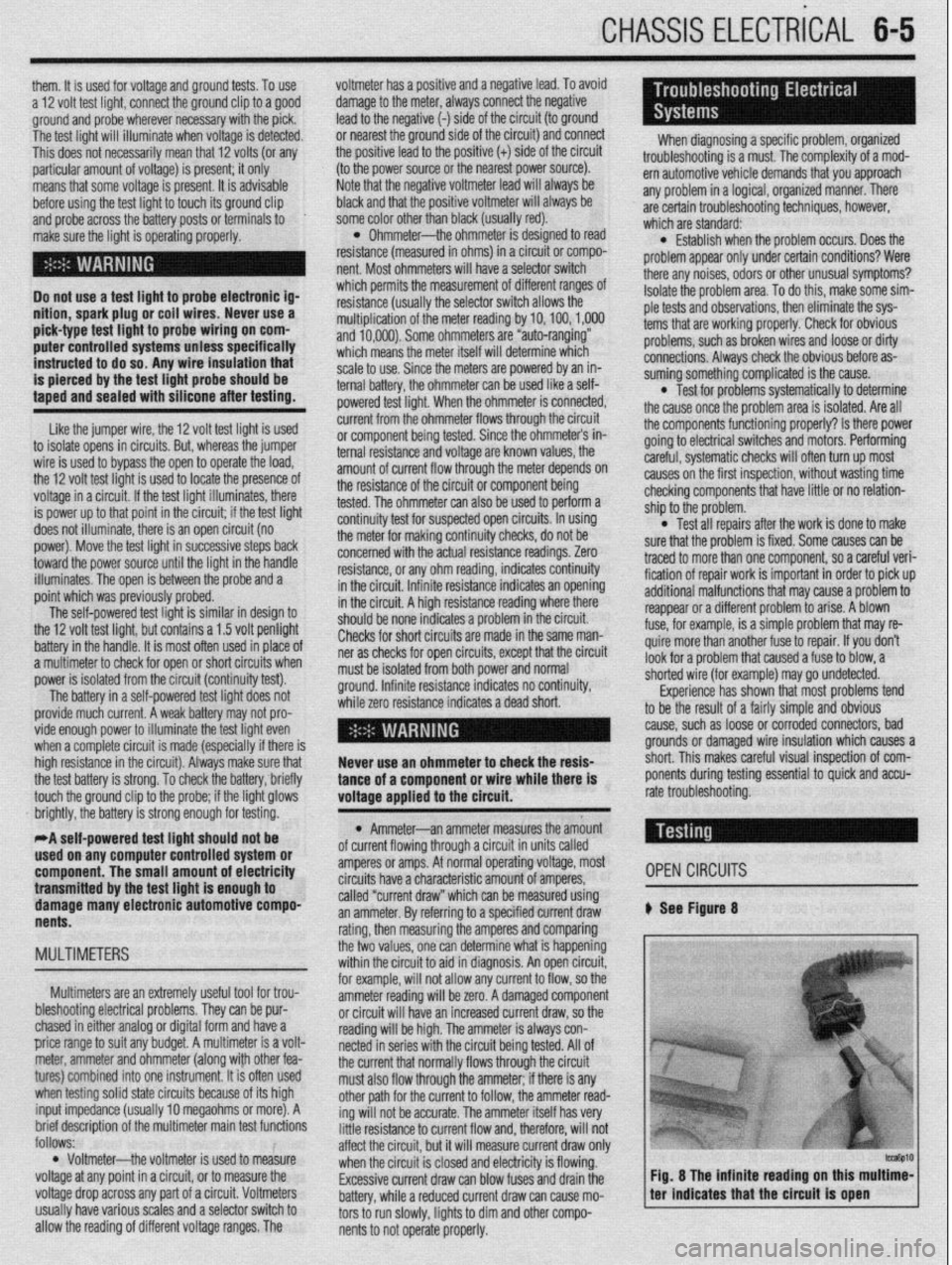

an ammeter. By referring to a specified current draw # See Figure 8

nents.

rating, then measuring the amperes and comparing

MULTIMETERS the two values, one can determine what is happening

within the circuit to aid in diagnosis. An open circuit,

for example, will not allow any current to flow, so the

Multimeters are an extremely useful tool for trou-

bleshooting electrical problems. They can be pur- ammeter reading will be zero. A damaged component

or circuit will have an increased current draw, so the

chased in either analog or digital form and have a

reading will be high. The ammeter is always con-

price range to suit any budget. A multimeter is a volt-

netted in series with the circuit being tested. All of

meter, ammeter and ohmmeter (along with other fea-

the current that normally flows through the circuit

tures) combined into one instrument. It is often used

must also flow through the ammeter; if there is any

when testing solid state circuits because of its high

other path for the current to follow, the ammeter read-

input impedance (usually 10 megaohms or more). A

ing will not be accurate. The ammeter itself has very

brief description of the multiieter main test functions

follows: little resistance to current flow and, therefore, will not

affect the circuit, but it will measure current draw only

l Voltmeter--the voltmeter is used to measure

when the circuit is closed and electricity is flowing.

voltage at any point in a circuit, or to measure the

Excessive current draw can blow fuses and drain the

voltage drop across any part of a circuit. Voltmeters

battery, while a reduced current draw can cause mo-

usually have various scales and a selector switch to

tors to run slowly, lights to dim and other compo-

allow the reading of different voltage ranges. The

nents to not operate properly.

Page 213 of 408

640 CHASSIS ELECTRICAL

careful not to allow anything to come in contact with

the air bag unit.

16. Remove the glove box lamp assembly.

17. Remove the remaining instrument panel

mounting screws and remove the instrument panel

from the vehicle.

18. Remove the left side foot shower ductwork,

lap cooler duct and center duct.

19. Remove the front and center reinforcements

and center stay assembly.

20. Remove the air distribution duct assembly.

21. Detach all connectors from heater-box-

mounted items.

22. Remove the heater box mounting screws and

nut, then remove the unit from the vehicle.

23. Disassemble on a workbench. Remove the

heater core from the heater case.

To install:

24. Thoroughly clean and dry the inside of the

case and install the heater core and all related parts.

25. Install the heater unit to the vehicle and install

the mounting screws and nut. Be sure the evaporator

case and heater case are fitted together properly. At-

tach all connectors to heater-box-mounted items.

26. Install the air distribution duct assembly. In-

stall the front and center reinforcements and center

stay assembly.

27. Install the center duct, lap cooler duct and left

side foot shower duct.

28. Install the instrument panel and mounting

screws.

29. Install the glove box lamp assembly.

30. Secure the steering column and attach all

steering column connectors.

31. Install the speedometer cable adapter to the

instrument panel.

32. Install the instrument cluster and the instru-

ment cluster bezel.

33. Install the speakers to the top of the instru-

ment panel.

34. Install the cup holder.

35. Install the climate control system control

head.

36. Install the stereo entertainment system and

bezel.

37. Install the screw below the glove box assem-

bly, and the entire glove box unit.

38. Install the steering column covers.

39. Install the knee protector support bracket, the

protector and the decorative plugs.

40. Install the console and the ashtray. 41. Install the right side foot shower duct.

42. Install the passenger side undercover.

43. Connect the heater hoses to the core tubes.

44. Fill the cooling system.

45. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Galant

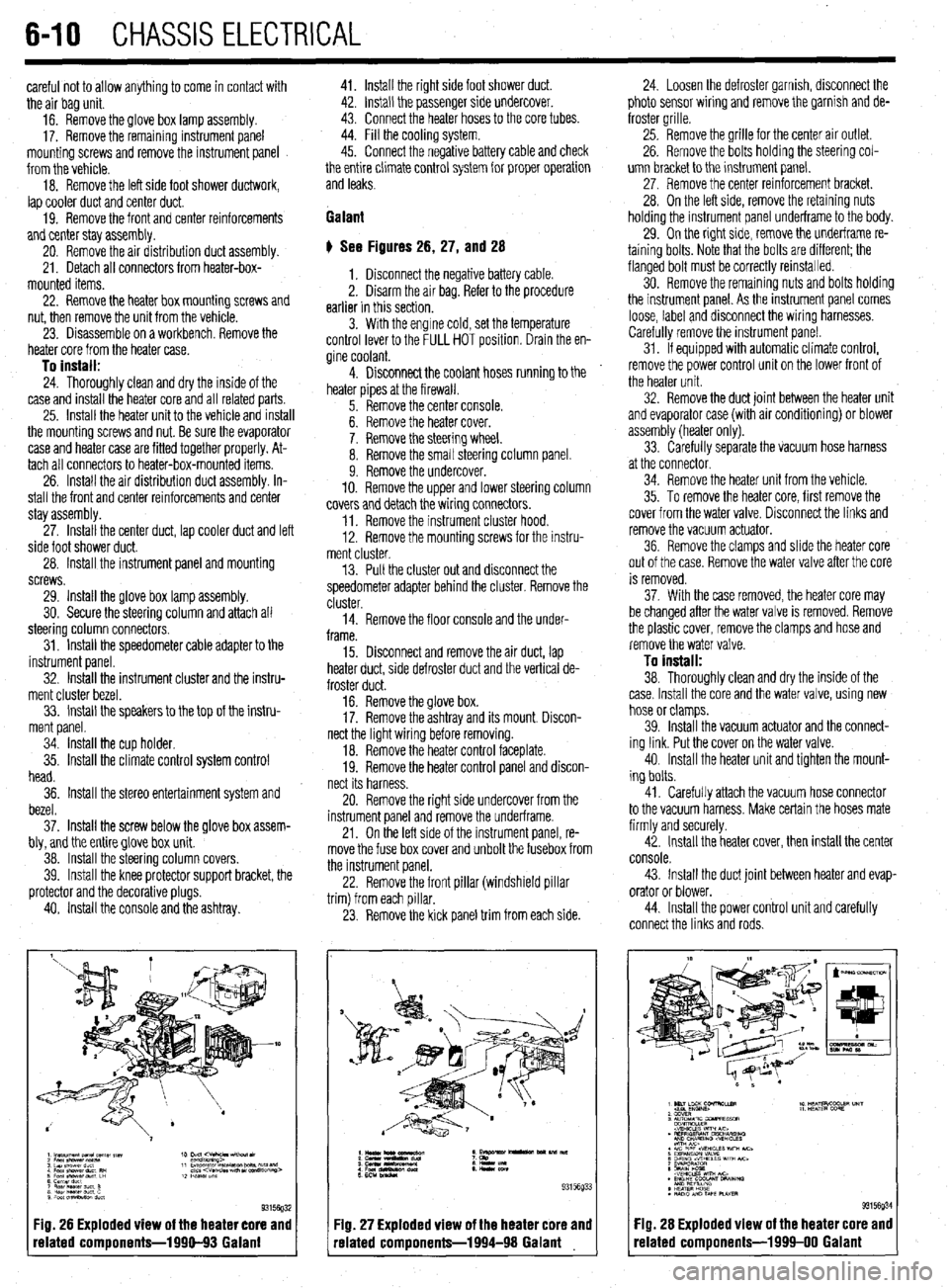

# See Figures 26, 27, and 28

1. Disconnect the negative battery cable.

2. Disarm the air bag. Refer to the procedure

earlier in this section.

3. With the engine cold, set the temperature

control lever to the FULL HOT position. Drain the en-

gine coolant.

4. Disconnect the coolant hoses running to the

heater pipes at the firewall.

5. Remove the center console.

6. Remove the heater cover.

7. Remove the steering wheel.

8. Remove the small steering column panel.

9. Remove the undercover.

10. Remove the upper and lower steering column

covers and detach the wiring connectors.

11. Remove the instrument cluster hood.

12. Remove the mounting screws for the instru-

ment cluster.

13. Pull the cluster out and disconnect the

speedometer adapter behind the cluster. Remove the

cluster.

14. Remove the floor console and the under-

frame.

15. Disconnect and remove the air duct, lap

heater duct, side defroster duct and the vertical de-

froster duct.

16. Remove the glove box.

17. Remove the ashtray and its mount. Discon-

nect the light wiring before removing.

18. Remove the heater control faceplate.

19. Remove the heater control panel and discon-

nect its harness.

20. Remove the right side undercover from the

instrument panel and remove the underframe.

21. On the left side of the instrument panel, re-

move the fuse box cover and unbolt the fusebox from

the instrument panel.

22. Remove the front pillar (windshield pillar

trim) from each pillar.

23. Remove the kick panel trim from each side.

Fig. 26 Exploded view of the heater core and

related components-1990-93 Galant

:IQ. 27 Exploded view of the heater core and

-elated components-1994-98 Galant 24. Loosen the defroster garnish, disconnect the

photo sensor wiring and remove the garnish and de-

froster grille.

25. Remove the grille for the center air outlet.

26. Remove the bolts holding the steering col-

umn bracket to the instrument panel.

27, Remove the center reinforcement bracket.

28. On the left side, remove the retaining nuts

holding the instrument panel underframe to the body.

29. On the right side, remove the underframe re-

taining bolts. Note that the bolts are different; the

flanged bolt must be correctly reinstalled.

30. Remove the remaining nuts and bolts holding

the instrument panel. As the instrument panel comes

loose, label and disconnect the wiring harnesses.

Carefully remove the instrument panel.

31. If equipped with automatic climate control,

remove the power control unit on the lower front of

the heater unit.

32. Remove the duct joint between the heater unit

and evaporator case (with air conditioning) or blower

assembly (heater only).

33. Carefully separate the vacuum hose harness

at the connector.

34. Remove the heater unit from the vehicle.

35. To remove the heater core, first remove the

cover from the water valve. Disconnect the links and

remove the vacuum actuator.

36. Remove the clamps and slide the heater core

out of the case. Remove the water valve after the core

is removed.

37. With the case removed, the heater core may

be changed after the water valve is removed. Remove

the plastic cover, remove the clamps and hose and

remove the water valve.

To install:

38. Thoroughly clean and dry the inside of the

case. Install the core and the water valve, using new

hose or clamps.

39. Install the vacuum actuator and the connect-

ing link. Put the cover on the water valve.

40. Install the heater unit and tighten the mount-

ing bolts.

41. Carefully attach the vacuum hose connector

to the vacuum harness. Make certain the hoses mate

firmly and securely.

42. Install the heater cover, then install the center

console.

43. Install the duct joint between heater and evap-

orator or blower.

44. Install the power control unit and carefully

connect the links and rods.

Fig. 28 Exploded view of the heater core and

related components-1999-00 Galant

Page 230 of 408

CHASSIS ELECTRICAL 6-27

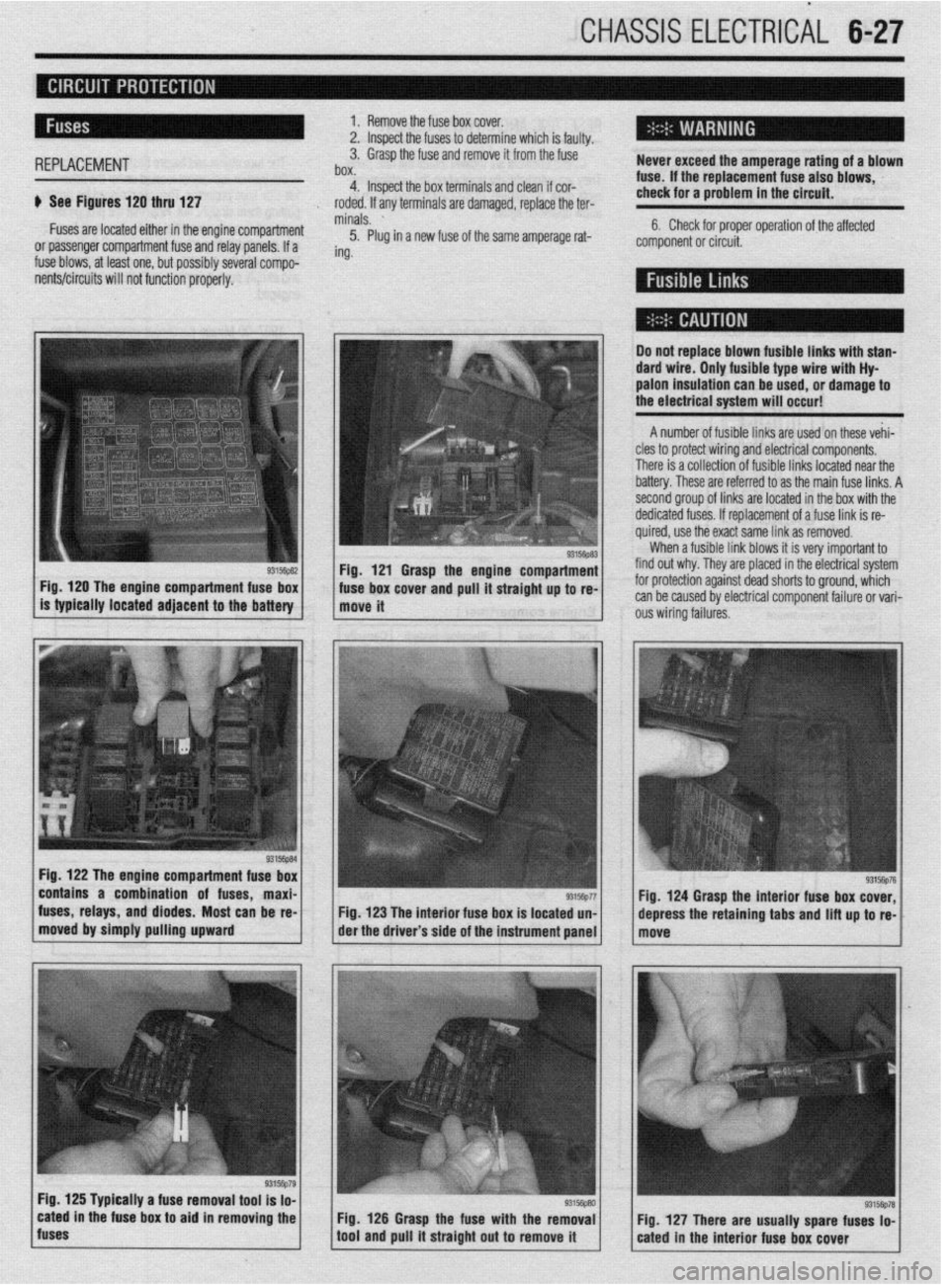

1. Remove the fuse box cover.

2. lnsoect the fuses to determine which is faulty.

REPLACEMENT 3. Grasp the fuse and remove it from the fuse

box. Never exceed the amperage rating of a blown

4. Inspect the box terminals and clean if cor- fuse. If the replacement fuse also blows,

It See Figures 120 thru 127 check for a problem in the circuit.

roded. If any terminals are damaged, replace the ter-

Fuses are located either in the engine Compartment minals. ’

5. Plug in a new fuse of the same amperage rat- 6. Check for proper operation of the affected

or passenger compartment fuse and relay panels. If a component or circuit.

fuse blows, at least one, but possibly several compo- ing.

ients/circuits will not function properly.

Fig, 120 The engine compartment fuse box

is typically located adjacent to the

battery

Fig. 122 The engine compartment fuse box

contains a combination of fuses, maxi-

fuses, relays, and diodes. Most can be re-

moved by simply pulling upward

I Do not replace blown fusible links with stan-

dard wire. Only fusible type wire with Hy

palon insulation can be

used, or damage to

the electrical system will occur!

A number of fusible links are used on these vehi-

cles to protect wiring and electrical components.

There is a collection of fusible links located near the

battery. These are referred to as the main fuse links. A

second group of links are located in the box with the

dedicated fuses. If replacement of a fuse link is re-

quired, use the exact same link as removed.

When a fusible link blows it is very important to

Fig. 121 Grasp the engine compartment find out why. They are placed in the electrical system

. ’ ‘“‘,+“” 1 ous wiring failures. fuse box cover and pull It straight up to re- for protection against dead shorts to ground, which

move it can be caused by electrical component failure or vari-

Fig. 123 The interior fuse box is located un-

der the driver’s side of the instrument panel

Fig. 125 Typically a fuse removal tool is lo-

cated in the fuse box to aid in removing the

fuses Fig. 126 Grasp the fuse with the removal

tool and pull it straight out to remove it Fig. 124 Grasp the interior fuse box cover,

depress the retaining

tabs and lift up to re-

Page 231 of 408

.

6-28 CHASSIS ELECTRICAL

Do not just replace the fosible link to correct

a problem! RESETTlNGAND/OR REPLACEMENT REPLACEMENT

When replacing all fusible links, they are to be re-

placed with the same type of prefabricated link avail-

able from your vehicle manufacturer. Circuit breakers are located inside the fuse panel.

They are automatically reset when the problem cor-

rects itself, is repaired, or the circuit cools down to

allow operation again. The turn signal and hazard flasher unit is located

in the interior fuse panel located under the driver’s

left side knee protector. They are replaced by simply

pulling them straight out. Note that the prongs are

arranged in such a way that the flasher must be prop-

erly oriented before attempting to install it. Turn the

flasher until the orientation of the prongs is correct

and simply push it firmly in until the prongs are fully

engaged.

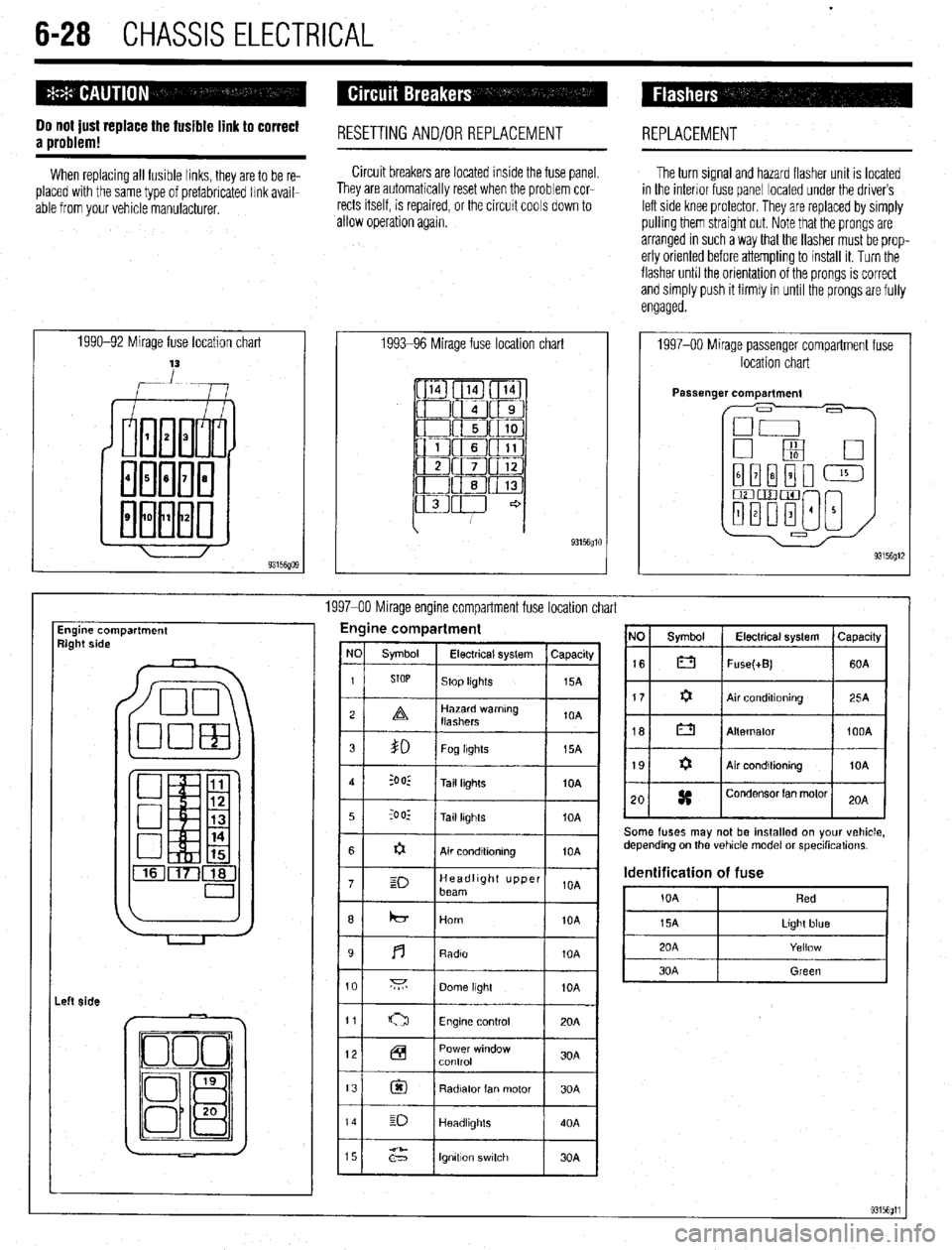

1990-92 Mirage fuse location chart

,-Lw 1993-96 Mirage fuse location chart

93156glO

1997-00 Mirage passenger compartment fuse

location chart

1997-00 Mirage engine compartment fuse location chart

Engine compartment

9ight side Engine compartment

I

I I 12 Power window

Control 30A

13

@I Radiator fan motor 30A

14 E-J

Headllghls 40A

15

;2” lgnttlon switch 30A NO Symbol Electrical system Capacrty

16 0 Fuse(+B) 60A

Some fuses may not be installed on your vehicle,

depending on the vehicle model or specihcations.

Identification of fuse

i0A Red

Page 232 of 408

CHASSIS ELECTRlCiL 6-29

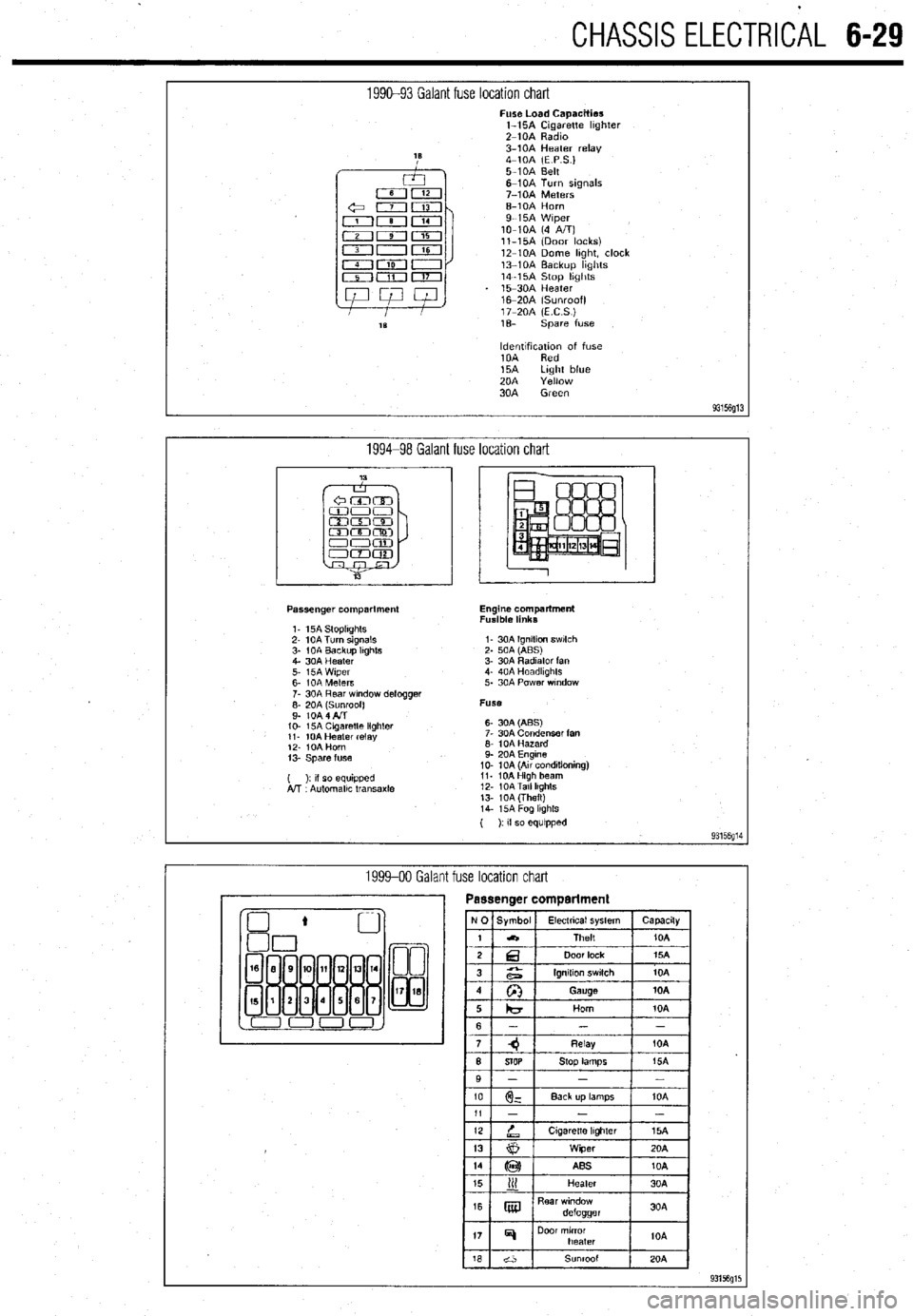

1990-93 Galant fuse location chart Fuse Load Capacities

l-15A Cigarette hghter

Z-10A Radm

3-10A Heater relay

4-10A (E P S.)

5-10A Belt

6-10A Turn signals

7-10A Meters

6-10A Horn

9-15A Wiper

lo-10A (4 A/T)

ll-15A (Door locks)

12-10A Dome hght, clock

13-10A Backup hghts

14-15A Stop hghts

15-30A Heater

16m20A (Sunroof)

17-20A (ECS)

1% spare fuse

ldentlfxation of fuse

10A Red

15A Light blue

20A Yellow

30A Green

93156g13

1994-98 Galant fuse location chart

Passenger compartment

1. 15A StoplIghts

2- 10A Turn signals

3- 1 OA Backup Itghts

4. 30A Heater

5. i5A Wiper

6- IOA Meters

7. 30A Rear wndow defogger

;: fo& fl$oof)

IO- 15A Cagaretle lighler

11. 10A Heater relay

12. IOA Horn

13. Spare fuse

( ): II so equipped

A!T Automallc transaxle Engine compartment

Fusible links

I- 30A Ignition swlch

2. 50A (ABS)

3. 30A Radiator fan

4. 40A Headkghts

5. 30A Power wndow

Fuse

6- 30A (ABS)

7. 30A Condenser fan

6. 10A Hazard

9. 20A Engine

10. 10A (Au conditioning)

11. 10AHigh beam

12. 10ATall lkghts

13. 10A (Theft)

14. i5A Fog lkghls

( ): If so equipped

93156g14

1999-00 Galant fuse location chart

Page 233 of 408

6-30 CHASSIS ELECTRICAL

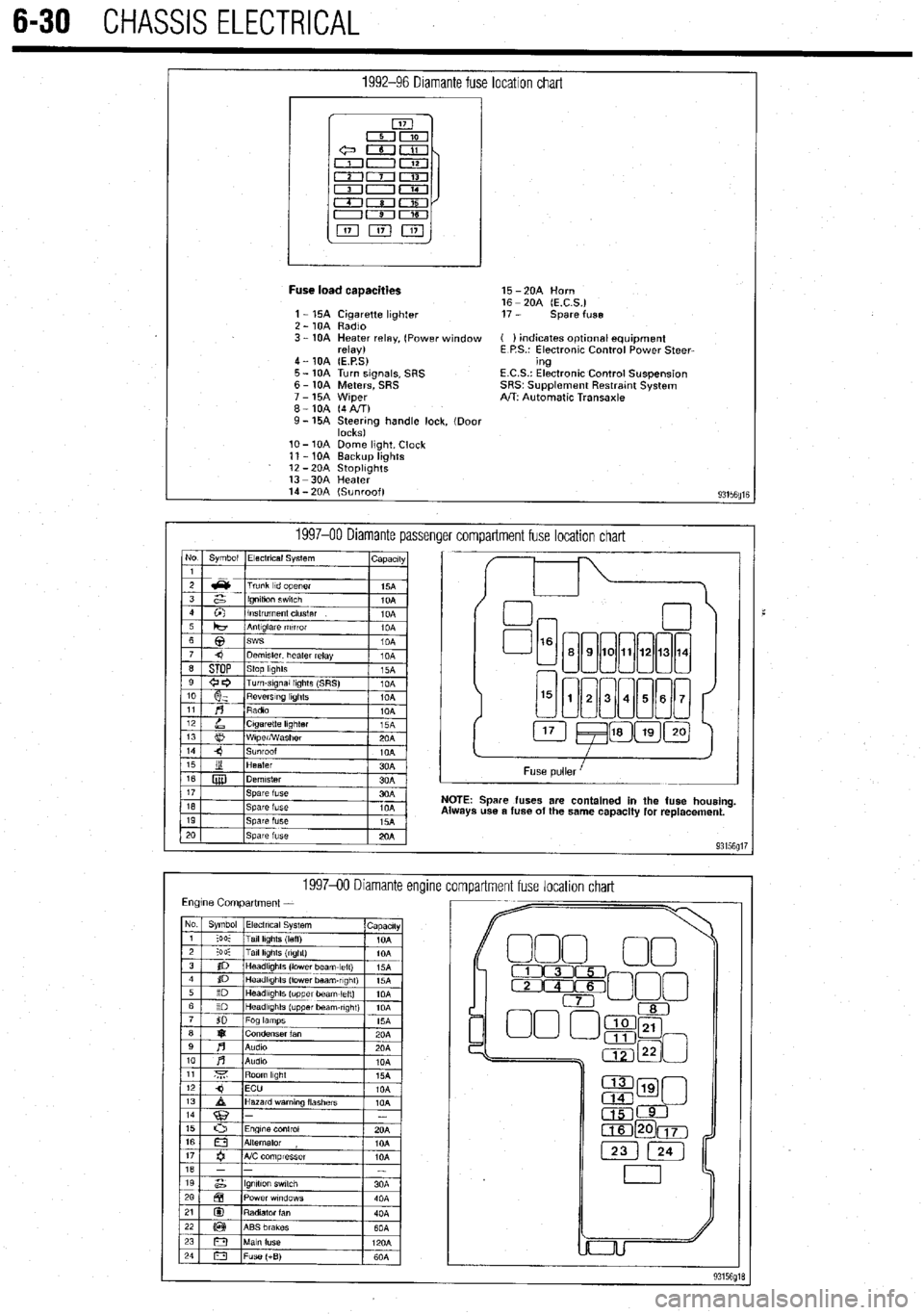

1992-96 Diamante fuse location chart

I

Fuse load caaacities 15 -2OA Horn

16 - 20A (E.C.S.)

1 - 15A Cigarette lighter 17 - spare fuse

2 - 10A Radio

3 - 10A Heater relay, (Power window ( ) indicates optlonal equipment

relay) E P.S.: Electronic Control Power Steer-

4 - 10A (E.P.S) ing

5 - 10A Turn signals, SRS E.C.S.: Electronic Control Suspension

6 - 10A Meters, SRS SRS~ Supplement Restratnt System

7 - 15A Wiper A/T: Automatic Transaxle

8-10A (4AIT)

9- 15A Steering handle lock, (Door

locks)

lo- 10A Dome light, Clock

11 - 10A Backup lights

12 -2OA StoplIghts

13 -3OA Heater

14 - 20A (Sunroof)

93156fllE

1997-00 Diamante passenger compartment fuse location chart No Symbol Electrical System

I capactty

I

Spare fuses are contained in the fuse housing

use a fuse of the same capacity for replacement.

199740 Diamante encline

compartment fuse location chart

Page 238 of 408

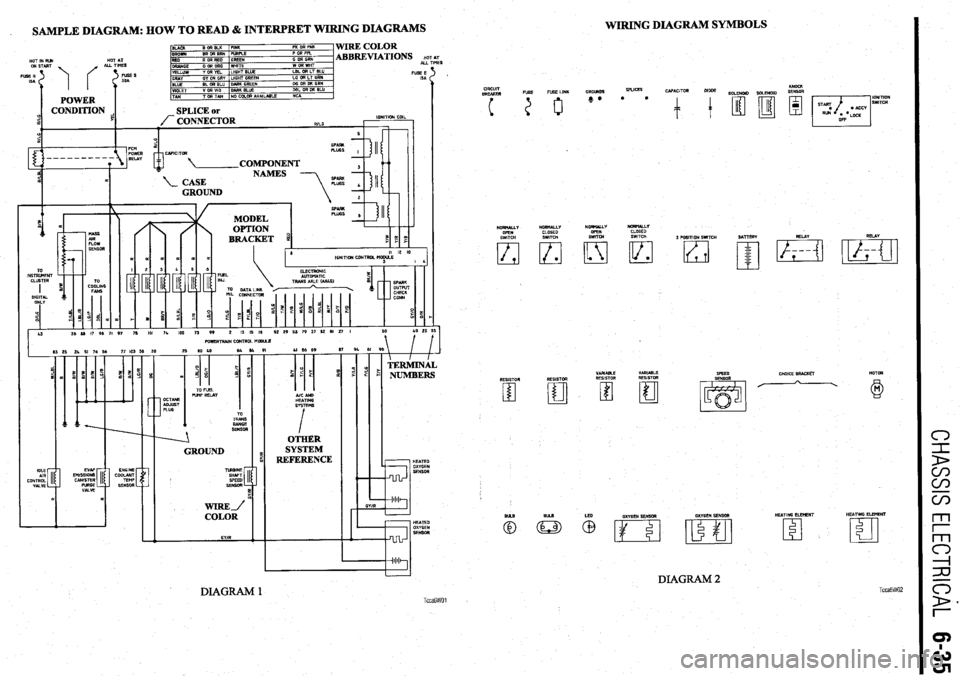

WIRING DIAGRAM SYMBOLS

. SAMPLE DIAGRAM: HOW TO READ & INTERPRET WIRING DIAGRAMS

c-l

1

D

m

m

WIRE COLOR

ABBREVIATIONS HO ALL TI’

TIM

FUSEE

ISA HOT IN RIM HOT AT r

ES

CIRCUIT

BREAKER

1 i ‘=iT KNOCK

SOLENOID SOLENOID SENSOR

3 POSITION SWITCH NORNALLY NORMALLY

NORHbUY

OPEN

SWITCH

El

RESISTOR

m NORMALLY

CLOSED

SWITCH

lzl l

RESISTOR

El SATTERY REIAY RELAY

WIWIZRTIWN CONTROL HODUsE

AICAND

HEATING

SYSTEMS

I

OTHER

SYSTEM

REFERENCE

CHOKE RRACKh MOTOR

VARIABLE VARIABLE

RESISTOR RESISTOR WEED

SENSOR

A

/

GROUND HEATED

IdI1

GYlR

m OXYGEN SENSOR HEATING ELEHENT HEATING ELEMENT

‘m

c3

DIAGRAM 2 TccaGW02 DIAGRAM 1 TccaGWOl

Page 239 of 408

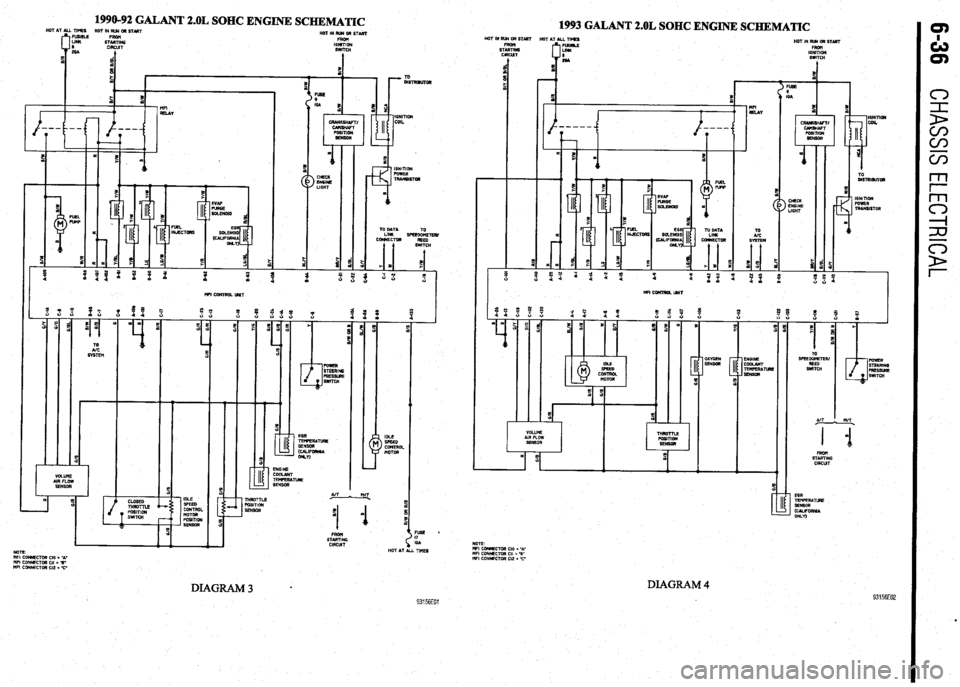

1990-92 GALANT 2.OL SOHC ENGINE SCHEMATIC

1993 GALANT 2.OL SOHC ENGINE SCHEMATIC HOT IN RIB aR START

STEki

CIRCUT HOTINRWORSTART

FROH

16NlTlON

SWITCH

t HOT IN RUR OR STlRT

HOT AT ALL TIMES

HOT IN RU4 DR START

FRDtl

IGNITION

SWITCH

I EEE LIGHT

! a

s ;

--

T m

> CHECK

EN6lNE

LIGHT

%

i E IGNITION

PDWER

4 ’

TRANSISTOR

D

4

&Rl,DR

s

ICNlTlOK

FUWER

TRARSlSTOR

m

TO OATA

LINK SPEED&TEfl/

CONRECTM

REED

( !iWlTCH TO

UC

WI CWJTROL UNIT

IDLE

> SFEED

CONTROL

MOTOR AIT

! n/T.

I 1 0

1

STEK

ClRCUT EGR

TEnFERA~

SENSOR

mLIFoRRlA

WLn

VOLUME

AIR FLOW

SENSOR

I

5

E

! %

FUSE *

I7

IOA

HOT AT ALL TIMES EGR

TEMFERATLRE

SERSDR

, (~~IFORR~A

ONLV) An L MT

.

B m

11

STARTING

CIRCUT NOTE

I’IFI CORRECTOR Cl0 = -A-

WI coRNEcmR CII - 3’

“FI CONNECTOR Cl2 I 77

DIAGRAM 4 93156E02

NOlE

MFI CCMECTOR Cl0 = ‘A-

WI CONNECTOR Cl, = %’

WI CDNNECTOR Cl2 = C

DIAGRAM3 l 93156EOl

Page 241 of 408

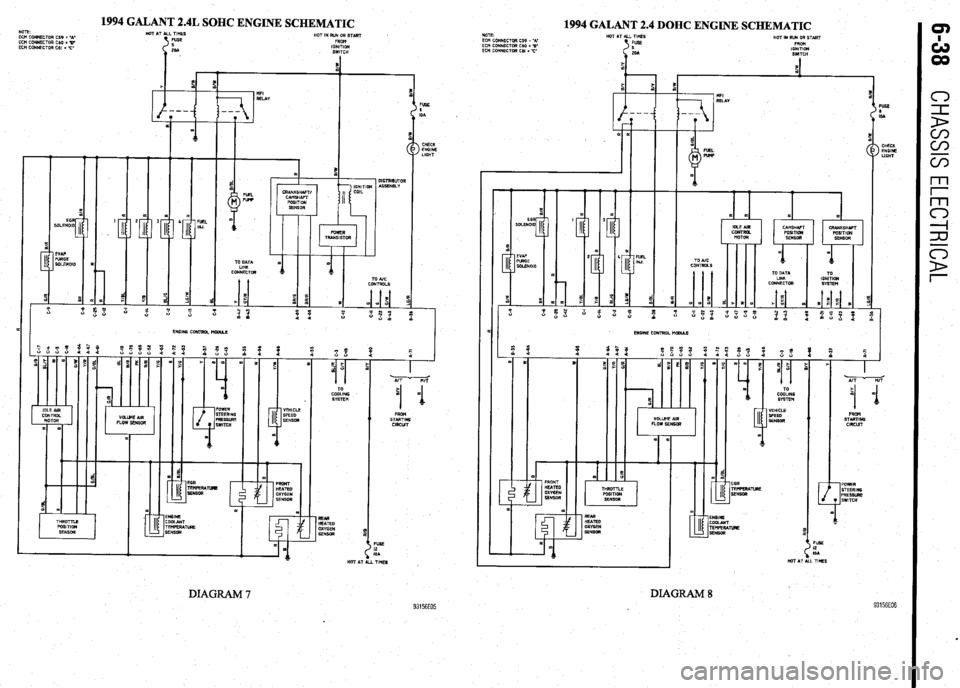

1994 GALANT 2.4L SOHC ENGINE SCHEMATIC

1994 GALANT 2.4 DOHC ENGINE SCHEMATIC NOTE

ECM CONNECTOR CS9 = ‘A’

ECH CONNECTOR C60 = B

ECH CONNECTOR Cti, = -I’ NOTE

ECH CONNECTOR C59 = ‘A-

ECH CONNECTOR C60 = ‘B

ECH CONNECTOR CM = -17 HOT AT ALL Tl?lES

FUSE

s

20A

s HQt IN RUN OR START

FRQ+l

IGNITION

SWITCH *

ON

:li IGI

SI

FVSE

0

IOA

> CHECK

ENGINE

LIGHT CHECU

/ ENOM

LIGHT

-T-T FUEL Pup

TO DATA

LINU

CONNECTOR I

CRANKSHAFT/

CAMSHAFT

POSITION

SENSOR

PQW2R

TRANSISTOR

m

(D

A

a

=

TO AK

CONTROLS

ENGINE CONTROL WCCU.2

m FRONT

H2AT2D

OXYGEN

SENSOR TO

CDDLING

SYSTEM

VEHICLE

SPEED

SENSOR

f FROM

START1116

CIRCWT

EGR

TEllPERATuRE

SENSOR

93156E05

HOT AT !NSlNE

3OLANT

rEMPERATu3E

ENSOR REAR

HEATED

OXYGEN

SENSOR REAR

HUTED

OXYGEN

SENSOA

TIM!3 vJ* HOT AT ALL TlblES

DIAGRAM 7

. DIAGRAM 8

Page 244 of 408

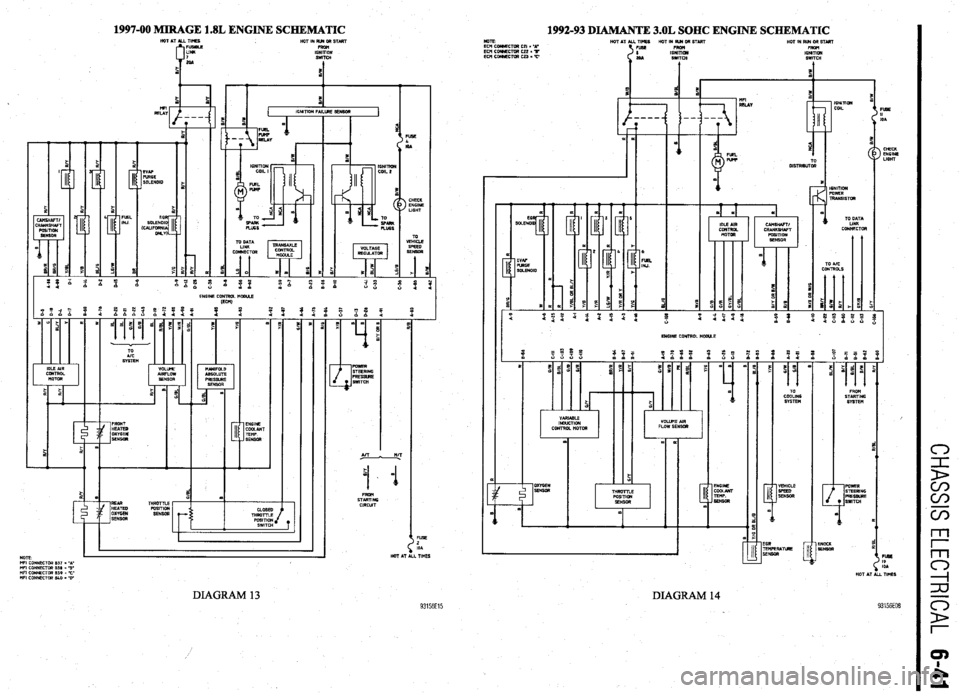

1997-00 MIRAGE 1.8L ENGINE SCHEMATIC

1992-93 DIAMANTE 3.OL SOHC ENGINE SCHEMATIC NOTE

HOT AT ML TIHGS

HOT IN R&S4 OR STbRT

HOT IM RUN OR START

ECM CGNNECTOR CZI = ‘4.

FUSS FROn

ECM COmECTOR CL2 = w

I IGNITIW

Et24 COtWECTOR CZ3 = ‘IT

zG4 SWITCH FROM

IGNlnON

SWITCH

4 HOT AT UL TIMES

HOT IN RiN GR START

FUSIRLE

FRW

LINK

IGNITION

:04 SWITCH

5

1

IGHlnON FAiLUlE SENSOR

FUSE

b

IO4

CHECK

ENGINE

LIGHT

TO

VEHICLG

ENGINE CONTROL MO4M.E

IECH)

II

ENGINE CONTROL MWUE

, 1 TO

COOLING

SYSTlw4

EGR

TEHFRR4TLtGE

SENSOR 1 POWER

STEERIMG

cI>

72

D

cn

c&n

.-

CD NT A NIT

.

5 (I)

I 4 FROM

STARTING

CIRCUT

HOT AT F!u3swE SWITCH

KNOCK

SENM

FLsC

I9

104 POSITION 6

SWITCH

FL&G

2

IOA

TIMES

hl

c3

-i

zu MFI CONNECTOR 8.37 = ‘4.

MFI CONNECTOR 811 - 3’

Hfl CONNECTOR 6.59 = ‘C’

WI CONNECTOR Sk0 g ‘D-

93156E15 DIAGRAM 13

DIAGRAM 14