fuse MITSUBISHI DIAMANTE 1900 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 266 of 408

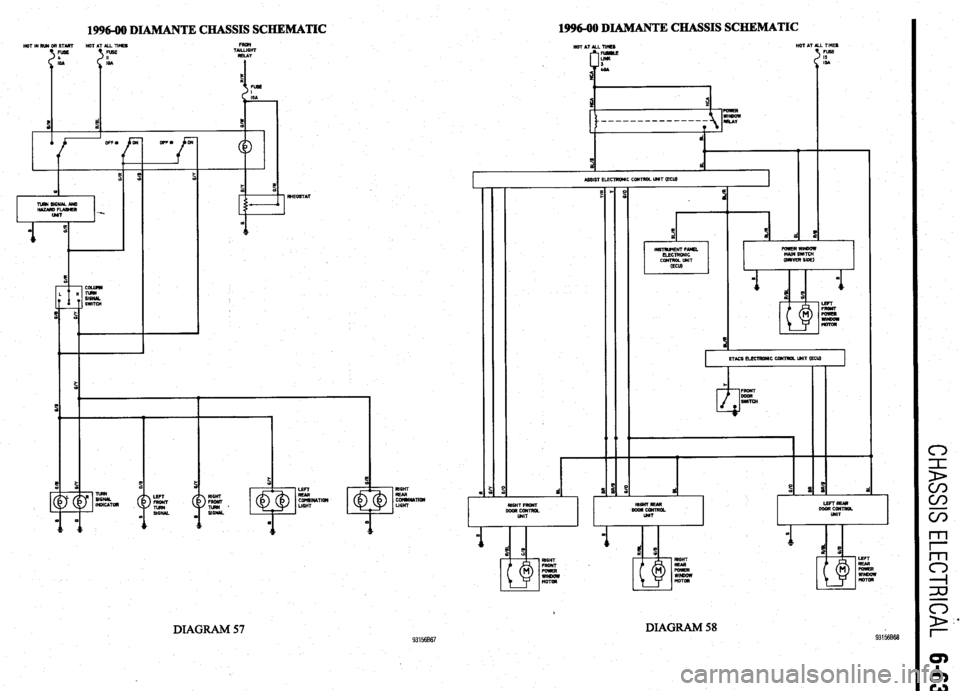

199640 DIAMANTE CHASSIS SCHEMATIC 199640 DIiUW.ANTE CHASSIS SCHEMATIC H6TINRlN6RSTM MT AT ML TIMES

FIB6 FUSE T AK&T

A II RELAY

WA WA

TlmNslcNuAm

-- -..- UNIT

ii

f ii:

r 1 L 1 RllmsTAl

I FHERWlW6W

MAIN SWITCH

CMIVER SIDE)

I

;

I RIGHT fMNT

I I Rl6H-r RUR

wcwc6NTna WORCDWTROL

WT WlT

P

DIAGRAM 58 93156868 DIAGRAM 57 93156B67

Page 268 of 408

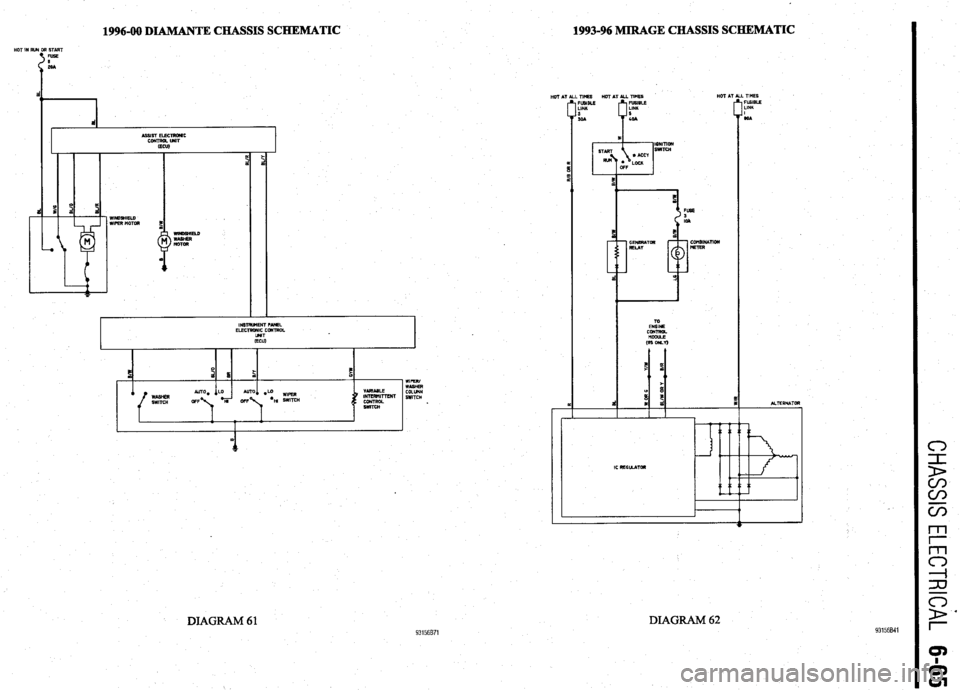

1996-00 DIAMANT E CHASSIS SCHEMATIC 1993-96 MIRAGE CHASSIS SCHEMATIC

ASSIST ELECTRONIC

CONTROL WIT

omJl

WINDEHIELO

WIRER MOTolr

:

INsTRunENT FANEL

ELECTRONIC CONlROL

UNIT

(ECU)

I I

h t

- WIPER/

WASHER

MO, &LO AmOb *LO mPER VARIASLE

COLUMN

INTERtllTTENT

CFF -H1 OfF %I SWITCH 3WlTCH

DIAGRAM 61 93156B71

HOT AT

[ TlnEs HOT AT ALL TIMES HOT Al

FUSlBLE

P FUSISLE

LINK LINU

:oA 5

MA

IGNITION

SWlTCH

,

FUSE

3

ID1

l

s

-- GENERATOR -- CWSlNATtffl

RELAY METER

I

TO

ENOINE

CONTROL TIMES

FUSISLE

LINK

I,

DIAGRAM 62 93156841

Page 271 of 408

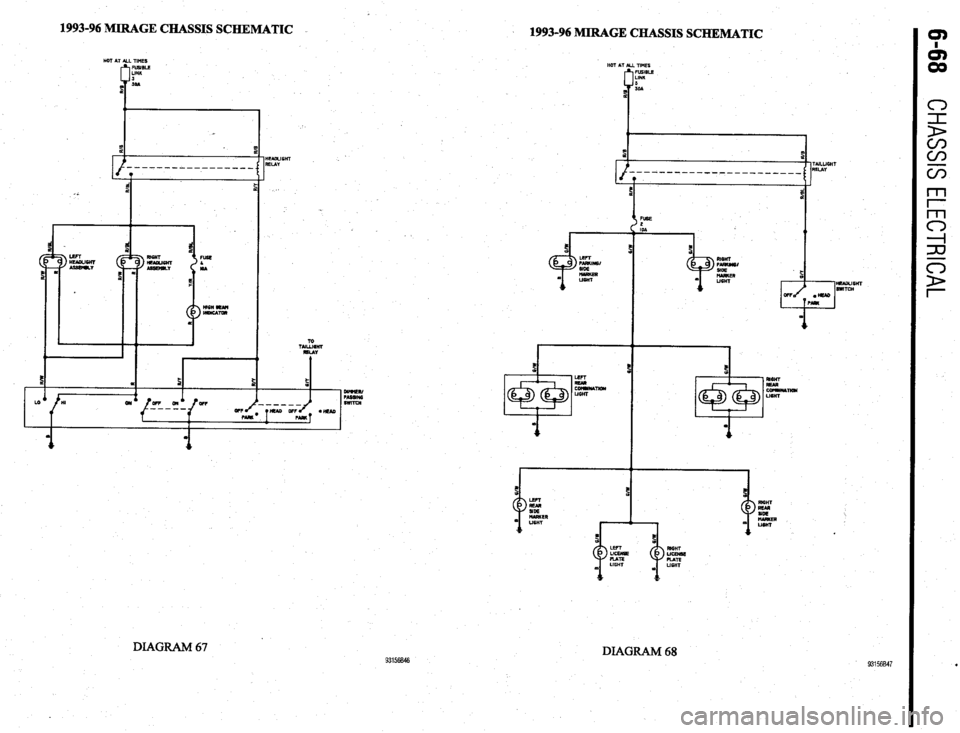

1993-96 MIRAGE CHASSIS SCHEMATIC

1993-96 MIRAGE CHASSIS SCHEMATIC

HOT AT ALL nm3

i-7 FUSIBLE

LINK HOT &T IIMES

lmsLE

INK

OA ALL’

:

3

E 3

F i

, -.

c

5

I

I

L

C 4 TAILUGHT

RELAY

---------~------------

FUSE

2

loA

5

7 m RIGNT

PMKWCI

SiIER

LIGHT

93156847

RIGHT

Eiz

NARKER

uGHT

1 MARKER

P

UGHT

DIAGlU’dM 67

DIAGRAM 68

Page 272 of 408

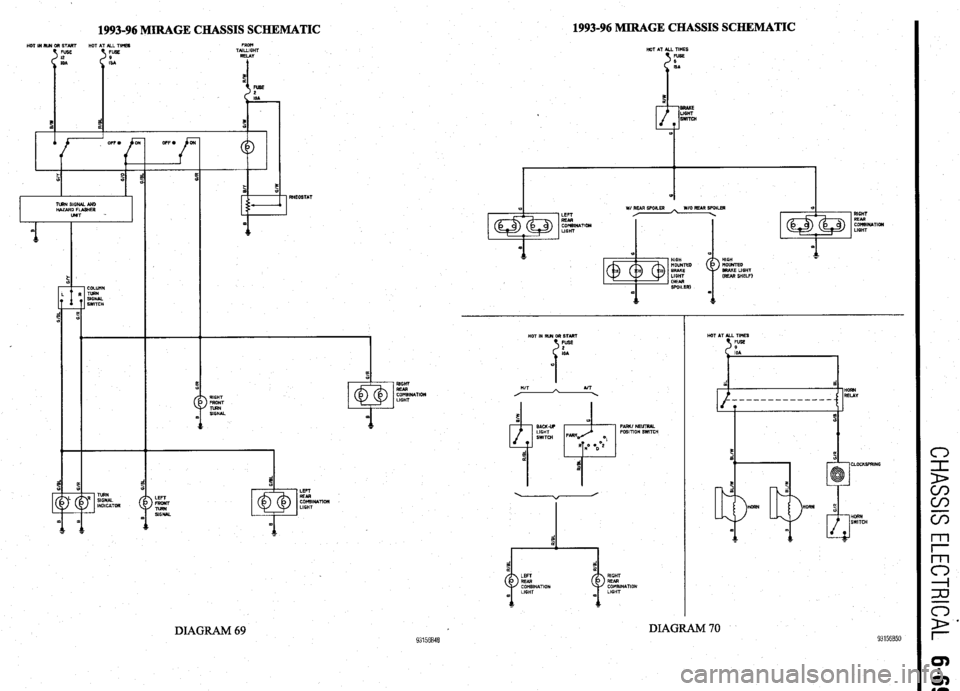

1993-96 MIRAGE CHASSIS SCHEMATIC 1993-96 MIRAGE CHASSIS SCHEMATIC

TURN SIGNAL AND

HAZARD FIASHER

WIT -

COLIJNN

TWN

SIGNAL

SWITCH OFF. 0

c

LEFT

REAR

CDMSINA

LIGHT

HIGH

NOWTED

BRAKE LIGHT

RBAR SHELF)

HOT IN Ruw OR START

FUSE

e

IQ*

> MGWT

FRONT

2LL

SIGNAL LEFT

REAR

COtlBINATlDN

LIGHT

DIAGRAM 69

RIGHT

Zh~T10t4

LIGHT

PARK/ NEUTRAL

POSITION SWITCH RIGHT

REAR

COtlBIKATlQN

UGHT

HOT AT Ml. TIMES

RIGHT

REAR

COHSINATION

LIGHT

DIAGRAM 70 93156850

CI)

72

D

cn

m

cn

Page 274 of 408

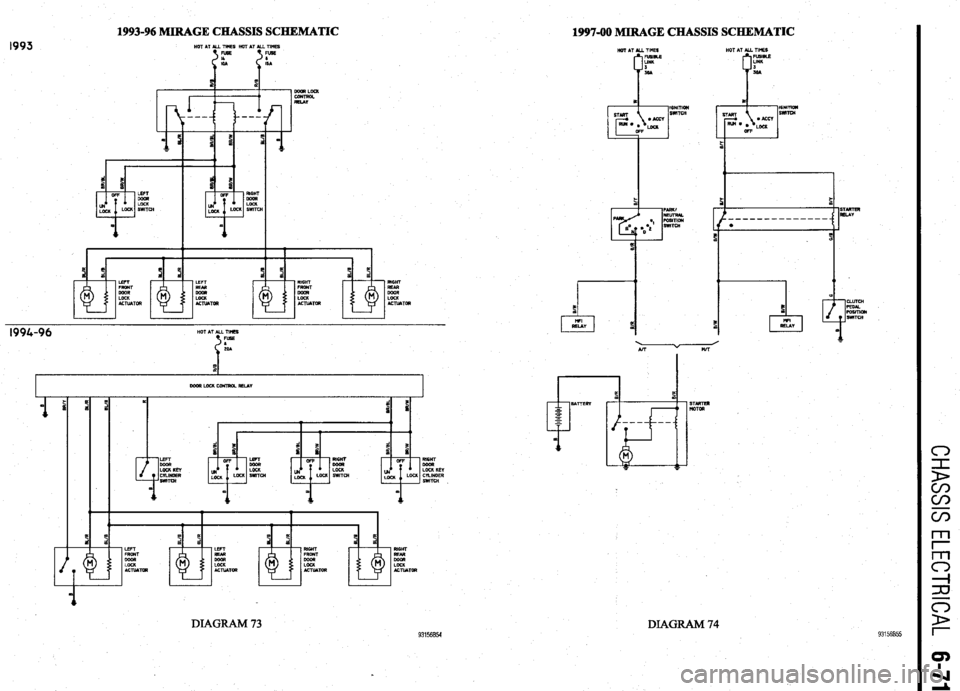

1993-96 MIRAGE CHASSIS SCHEMATIC

1997-00 MIRAGE CHASSIS SCHEMATIC HOT AT ALL TIHEE HOT AT ALL TIMES

LEFT - , RIGHT

FRONT

DOOR

LOCK

ACTUATOR

1994-96 HOT AT ALL TIMES

FUSE

1)

ZOA

1 1 I

r! c

d ii

-- LEFT LEFT ’ RIGHT I

FRW

OOUR Ez zr

kt%ATlm LOCK LOCK

ACTUATOR KTWTOR

DIAGRAM 73

HOT AT N.L TIMES HOT AT ALL TlIlES

FusmlE FUSIBLE

LIRK LINK

s

SOA LA

z 1

‘ISNITIQII ICNITIOW

SWITCH SWITCH

RIWT

iii%

LOCK

ACTUATOR

93156954 DIAGRAM 74 93156855

Page 277 of 408

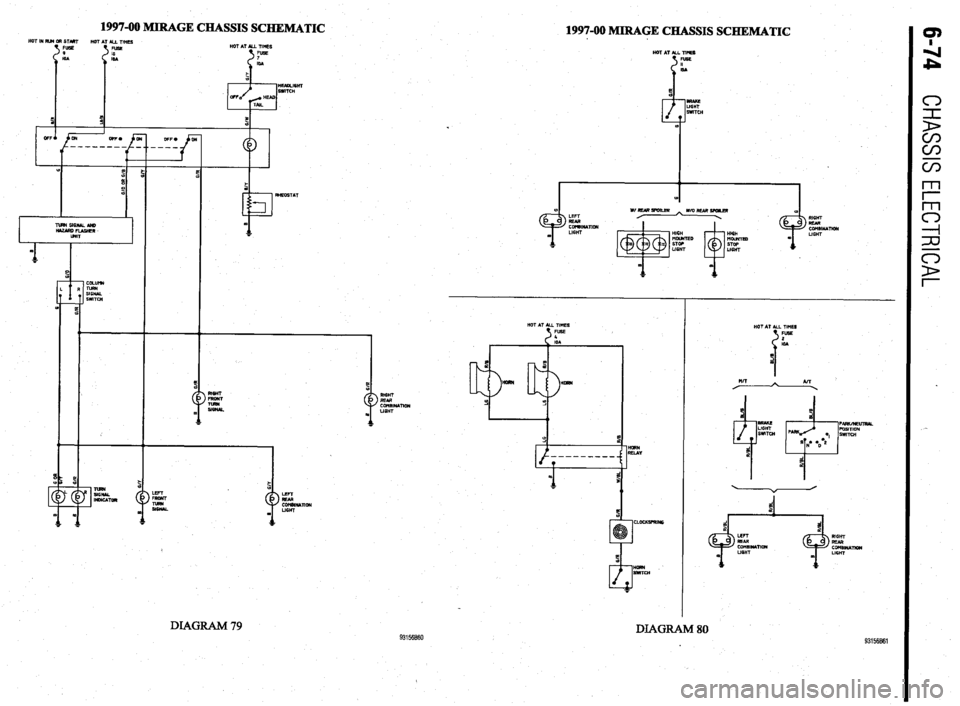

1997-00 MIRAGE CHASSIS SCHEMATIC

1997-00 MIRAGE CHASSIS SCIfEWTIC

$

RIGHT

FRONT RIGHT

EL IE&4ATllm

UGHT

)ET

TmN

SIGNAL

RIGHT

ZiilNAT,ON

LIGHT

HOT AT AU TMES

34 FUSE

RIGHT

REAR

CONEINATIQII

LIGHT

DIAGRAM 79

DIAGRAM 80

Page 278 of 408

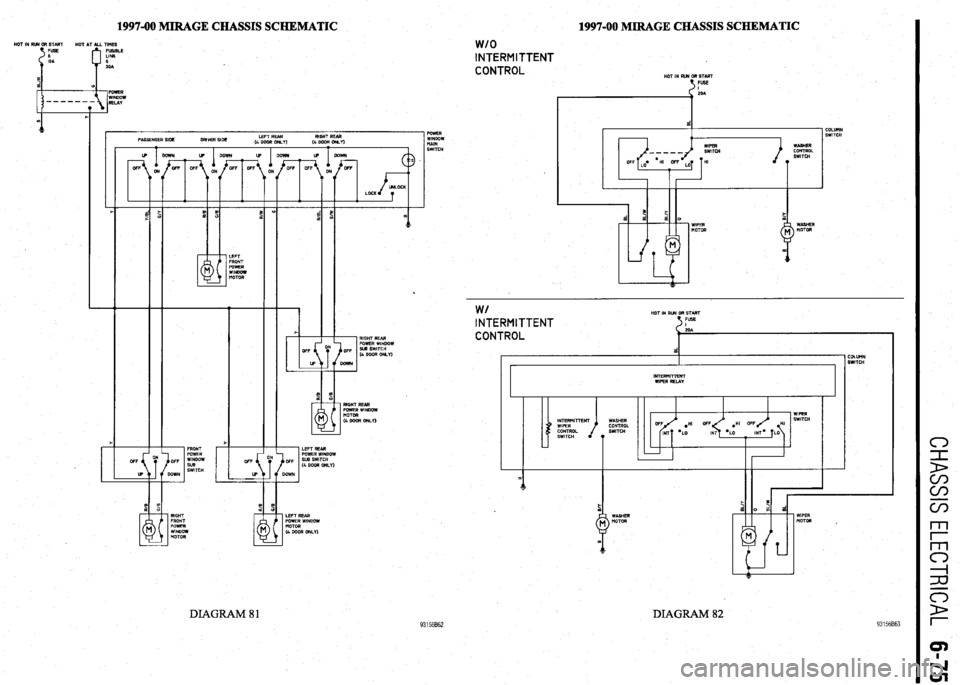

1997-00 MIRAGE CHASSIS SCHEMATIC HOT IN RR4 OR STMT

HOT AT ALL TIMES

FUSIBLE

LINK

6

SOA 1997-00 MIRAGE CHASSIS SCHEMATIC

1 POWER

WINDOW

tiAlN

SWITCH

w/o INTERMITTENT

CONTROL

HOT IN RUN OR START

t FUSE

COLUllN

SWITCH

LEFT REAR RIGHT REAR

4 DOOR or&Y)

(4WWOM.I)

I .

F ?E

d d a 0

WIPER WASHER

MOTOR MOTOR

.

93156862

W/ HOT IN RUN GR START INTERMITTENT FUSE 5

CONTROL

d COLUtlN

SWITCH

I r INTERMITTENT

WIPER RELAY

I I

WIPER

WASHER SWITCH

CONTROL .HI OFF HI

SWITCH

*LO MT= LO

T

1

LEFT REAR

POWER WINDOW

MOTOR

(4 GOOR ONLY) RIGHT

FRONT

POWER

WINDOW

MOTOR WIPER

MOTOR .

DIAGRAM 82 DIAGRAM 81

Page 279 of 408

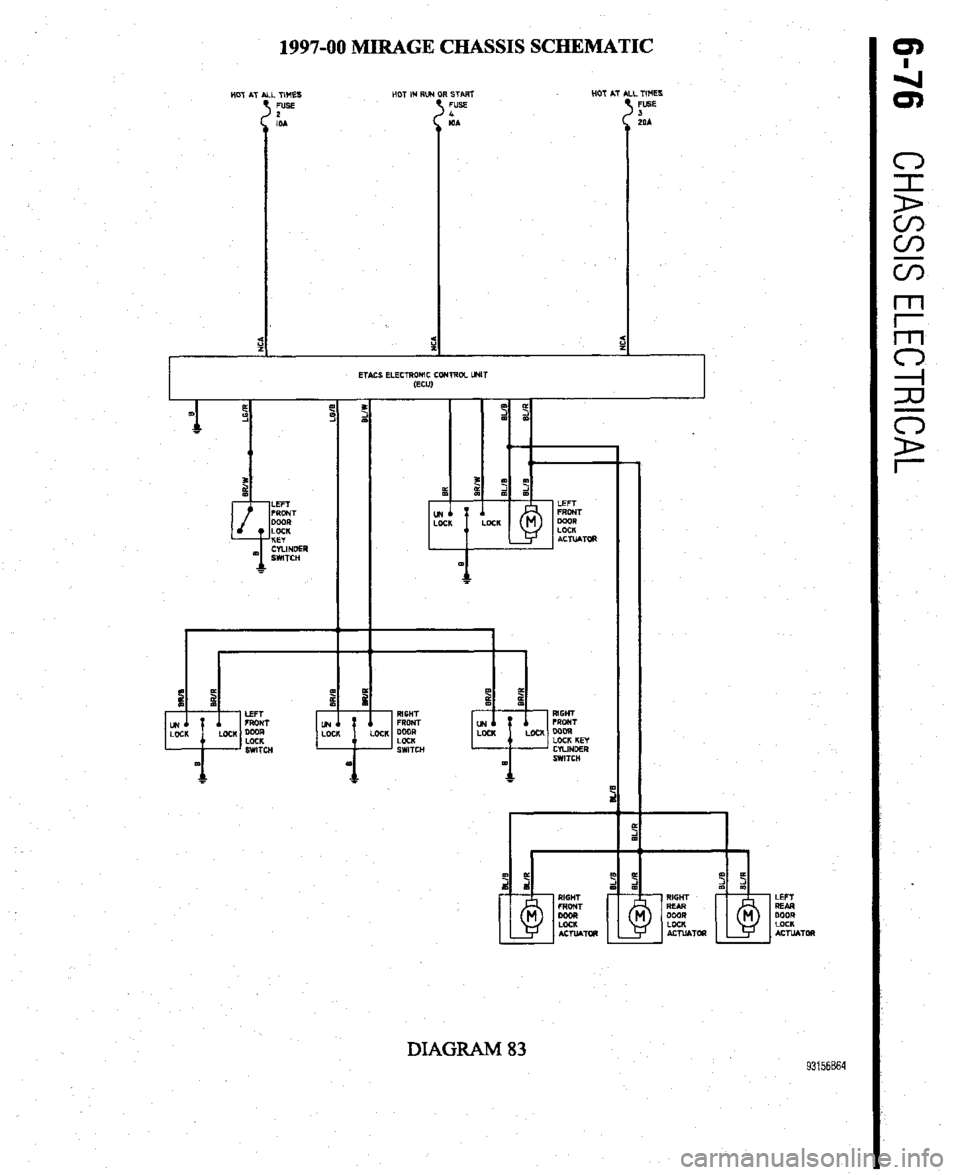

1997-00 MIRAGE CHASSIS SCHEMATIC

START HOT AT

FUSE

I

IOA

ETACS ELECTRONIC CCMROL

(ECU1 _ TIMES

FUSE

J

LOA

DIAGRAM 83 93156B64

Page 338 of 408

9-2 BRAKES

Hydraulic systems are used to actuate the brakes

of all modern automobiles. The system transports the

power required to force the frictional surfaces of the

braking system together from the pedal to the indi-

vidual brake units at each wheel. A hydraulic system

is used for two reasons.

First, fluid under pressure can be carried to all

parts of an automobile by small pipes and flexible

hoses without taking up a significant amount of room

or posing routing problems.

Second, a great mechanical advantage can be

given to the brake pedal end of the system, and the

foot pressure required to actuate the brakes can be

reduced by making the surface area of the master

cylinder pistons smaller than that of any of the pis-

tons in the wheel cylinders or calipers.

The master cylinder consists of a fluid reservoir

along with a double cylinder and piston assembly.

Double type master cylinders are designed to sepa-

rate the front and rear braking systems hydraulically

in case of a leak. The master cylinder converts me-

chanical motion from the pedal into hydraulic pres-

sure within the lines. This pressure is translated back

into mechanical motion at the wheels by either the

wheel cylinder (drum brakes) or the caliper (disc

brakes).

Steel lines carry the brake fluid to a point on the

vehicle’s frame near each of the vehicle’s wheels. The

fluid is then carried to the calipers and wheel cylin-

ders by flexible tubes in order to allow for suspen-

sion and steering movements.

In drum brake systems, each wheel cylinder con-

tains two pistons, one at either end, which push out-

ward in opposite directions and force the brake shoe

into contact with the drum.

In disc brake systems, the cylinders are part of the

calipers. At least one cylinder in each caliper is used

to force the brake pads against the disc.

All pistons employ some type of seal, usually

made of rubber, to minimize fluid leakage. A rubber

dust boot seals the outer end of the cylinder against

dust and dirt. The boot fits around the outer end of

the piston on disc brake calipers, and around the

brake actuating rod on wheel cylinders.

The hydraulic system operates as follows: When at

rest, the entire system, from the piston(s) in the mas-

ter cylinder to those in the wheel cylinders or

calipers, is full of brake fluid. Upon application of the

brake pedal, fluid trapped in front of the master cylin-

der piston(s) is forced through the lines to the wheel

cylinders. Here, it forces the pistons outward, in the

case of drum brakes, and inward toward the disc, in

the case of disc brakes. The motion of the pistons is

opposed by return springs mounted outside the

cylinders in drum brakes, and by spring seals, in disc

brakes.

Upon release of the brake pedal, a spring located

inside the master cylinder immediately returns the

master cylinder pistons to the normal position. The

pistons contain check valves and the master cylinder

I

has compensating ports drilled in it. These are un-

covered as the pistons reach their normal position.

The piston check valves allow fluid to flow toward the

wheel cylinders or calipers as the pistons withdraw.

Then, as the return springs force the brake pads or

shoes into the released position, the excess fluid

reservoir through the compensating ports. It is during the time the pedal is in the released position that any

fluid that has leaked out of the system will be re-

placed through the compensating ports.

Dual circuit master cylinders employ two pistons,

located one behind the other, in the same cylinder.

The primary piston is actuated directly by mechanical

linkage from the brake pedal through the power

booster. The secondary piston is actuated by fluid

trapped between the two pistons. If a leak develops in

front of the secondary piston, it moves forward until it

bottoms against the front of the master cylinder, and

the fluid trapped between the pistons will operate the

rear brakes. If the rear brakes develop a leak, the pri-

mary piston will move forward until direct contact

with the secondary piston takes place, and it will

force the secondary piston to actuate the front brakes.

In either case, the brake pedal moves farther when the

brakes are applied, and less braking power is avail-

able.

All dual circuit systems use a switch to warn the

driver when only half of the brake system is opera-

tional. This switch is usually located in a valve body

which is mounted on the firewall or the frame below

the master cylinder. A hydraulic piston receives pres-

sure from both circuits, each circuits pressure being

applied to one end of the piston. When the pressures

are in balance, the piston remains stationary. When

one circuit has a leak, however, the greater pressure

in that circuit during application of the brakes will

push the piston to one side, closing the switch and

activating the brake warning light.

In disc brake systems, this valve body also con-

tains a metering valve and, in some cases, a propor-

tioning valve. The metering valve keeps pressure

from traveling to the disc brakes on the front wheels

until the brake shoes on the rear wheels have con-

tacted the drums, ensuring that the front brakes will

never be used alone. The proportioning valve con-

trols the pressure to the rear brakes to lessen the

chance of rear wheel lock-up during very hard brak-

ing.

Warning lights may be tested by depressing the

brake pedal and holding it while opening one of the

wheel cylinder bleeder screws. If this does not cause

the light to go on, substitute a new lamp, make conti-

nuity checks, and, finally, replace the switch as nec-

essary.

The hydraulic system may

be checked for leaks by applying pressure to the pedal gradually and steadily.

If the pedal sinks very slowly to the floor, the system

has a leak. This is not to be confused with a springy

or spongy feel due to the compression of air within

the lines. If the system leaks, there will be a gradual

change in the position of the pedal with a constant

pressure.

Check for leaks along all lines and at wheel cylin-

ders. If no external leaks are apparent, the problem is

inside the master cylinder,

DISC BRAKES

Instead of the traditional expanding brakes that

press outward against a circular drum, disc brake

systems utilize a disc (rotor) with brake pads posi-

tioned on either side of it. An easily-seen analogy is

the hand brake arrangement on a bicycle. The pads

squeeze onto the rim of the bike wheel, slowing its

motion. Automobile disc brakes use the identical principle but apply the braking effort to a separate

disc instead of the wheel.

The disc (rotor) is a casting, usually equipped with

cooling fins between the two braking surfaces. This

enables air to circulate between the braking surfaces

making them less sensitive to heat buildup and more

resistant to fade. Dirt and water do not drastically af-

fect braking action since contaminants are thrown off

by the centrifugal action of the rotor or scraped off

the by the pads. Also, the equal clamping action of

the two brake pads tends to ensure uniform, straight

line stops. Disc brakes are inherently self-adjusting.

There are three general types of disc brake:

1. A fixed caliper.

2. A floating caliper.

3. A sliding caliper.

The fixed caliper design uses two pistons

mounted on either side of the rotor (in each side of

the caliper). The caliper is mounted rigidly and does

not move.

The sliding and floating designs are quite similar.

In fact, these two types are often lumped together. In

both designs, the pad on the inside of the rotor is

moved into contact with the rotor by hydraulic force.

The caliper, which is not held in a fixed position,

moves slightly, bringing the outside pad into contact

with the rotor. There are various methods of attaching

floating calipers. Some pivot at the bottom or top,

and some slide on mounting bolts. In any event, the

end result is the same.

DRUM BRAKES

Drum brakes employ two brake shoes mounted on

a stationary backing plate. These shoes are posi-

tioned inside a circular drum which rotates with the

wheel assembly. The shoes are held in place by

springs. This allows them to slide toward the drums

(when they are applied) while keeping the linings and

drums in alignment. The shoes are actuated by a

wheel cylinder which is mounted at the top of the

backing plate. When the brakes are applied, hydraulic

pressure forces the wheel cylinder’s actuating links

outward. Since these links bear directly against the

top of the brake shoes, the tops of the shoes are then

forced against the inner side of the drum. This action

forces the bottoms of the two shoes to contact the

brake drum by rotating the entire assembly slightly

(known as servo action). When pressure within the

wheel cylinder is relaxed, return springs pull the

shoes back away from the drum.

Most modern drum brakes are designed to self-

adjust themselves during application when the vehi-

cle is moving in reverse. This motion causes both

shoes to rotate very slightly with the drum, rocking

an adjusting lever, thereby causing rotation of the ad-

justing screw. Some drum brake systems are de-

signed to self-adjust during application whenever the

brakes are applied. This on-board adjustment system

reduces the need for maintenance adjustments and

keeps both the brake function and pedal feel satisfac-

tory.

POWER BOOSTERS

Virtually all modern vehicles use a vacuum as-

sisted power brake system to multiply the braking

force and reduce pedal effort. Since vacuum is always

available when the engine is operating, the system is

Page 387 of 408

.

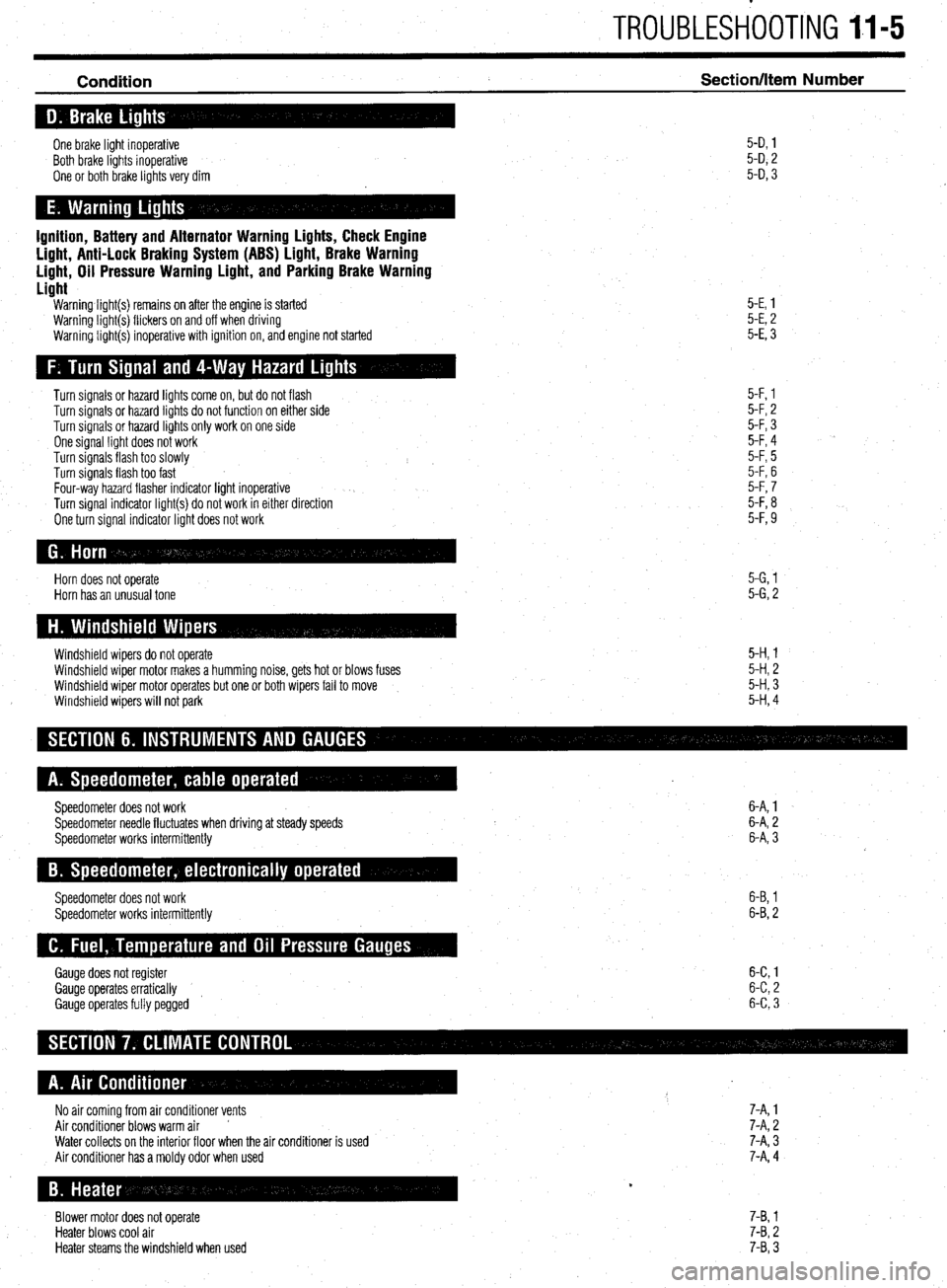

TROUBLESHOOTING II-5

Condition Section/Item Number

One brake light inoperative

Both brake lights inoperative

One or both brake lights very dim 5-D, 1

5-D, 2

5-D, 3

Ignition, Battery and Alternator Warning Lights, Check Engine

Light, Anti-Lock Braking System (ABS) Light, Brake Warning

Light, Oil Pressure Warning Light, and Parking Brake Warning

Light

Warning light(s) remains on after the engine is started

Warning light(s) flickers on and off when driving

Warning light(s) inoperative with ignition on, and engine not started 5-E, 1

5-E, 2

5-E, 3

Turn signals or hazard lights come on, but do not flash

Turn signals or hazard lights do not function on either side

Turn signals or hazard lights only work on one side

One signal light does not work

Turn signals flash too slowly

Turn signals flash too fast

Four-way hazard flasher indicator light inoperative

Turn signal indicator light(s) do not work in either direction

One turn signal indicator light does not work 5-F, 1

5-F, 2

5-F, 3

5-F, 4

5-F, 5

5-F, 6

5-F, 7

5-F, 8

5-F, 9

Horn does not operate

Horn has an unusual tone 5-G, 1

5-G, 2

Windshield wipers do not operate

Windshield wiper motor makes a humming noise, gets hot or blows fuses

Windshield wiper motor operates but one or both wipers fail to move

Windshield wipers will not park 5-H, 1

5-H, 2

5-H, 3

5-H, 4

Speedometer does not work

Speedometer needle fluctuates when driving at steady speeds

Speedometer works intermittently 6-A, 1

6-A, 2

6-A, 3

Speedometer does not work

Speedometer works intermittently 6-B, 1

6-B, 2

Gauge does not register 6-C 1

Gauge operates erratically 6-C 2

’

Gauge operates fully pegged 6-C 3

No air coming from air conditioner vents 7-A, 1

Air conditioner blows warm air ’ 7-A, 2

Water collects on the interior floor when the air conditioner is used

Air conditioner has a moldy odor when used 7-A, 3

7-A, 4

Blower motor does not operate

Heater blows cool air

Heater steams the windshield when used 7-B, 1

7-B, 2

7-B, 3