lock MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 28 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-29

i

*Bug screens which are mounted in front of

the condenser (unless they are original

equipment) are regarded as obstructtons.

l The condensation drain tube expels any water

which accumulates on the bottom of the evaporator

housing into the engine compartment. If this tube is

obstructed, the air conditioning performance can be

restricted and condensation buildup can spill over

onto the vehicle’s floor.

l Make sure the air passage selection lever is

operating correctly. Start the engine and warm it to

normal operating temperature, then make sure the

temperature selection lever is operating correctly.

-w

~1 ELEMENT(REFILL)CARE& REPLACEMENT

SYSTEM INSPECTION

b See Figure 125 b See Figures 126 thru 135

For maximum effectiveness and longest element

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per-

formed to help maintain the efficiency of the vehicle’s

A/C system. For A/C system inspection, perform the

following:

The easiest and often most important check for the

air conditioning system consists of a visual inspec-

tion of the system components. Visually inspect the

air conditioning system for refrigerant leaks, dam-

aged compressor clutch, abnormal compressor drive

belt tension and/or condition, plugged evaporator

drain tube, blocked condenser fins, disconnected or

broken wires, blown fuses, corroded connections and

poor insulation.

A refrigerant leak will usually appear as an oily

residue at the leakage point in the system. The oily

residue soon picks up dust or dirt particles from the

surrounding air and appears greasy. Through time,

this will build up and appear to be a heavy dirt im-

pregnated grease.

For a thorough visual and operational inspection,

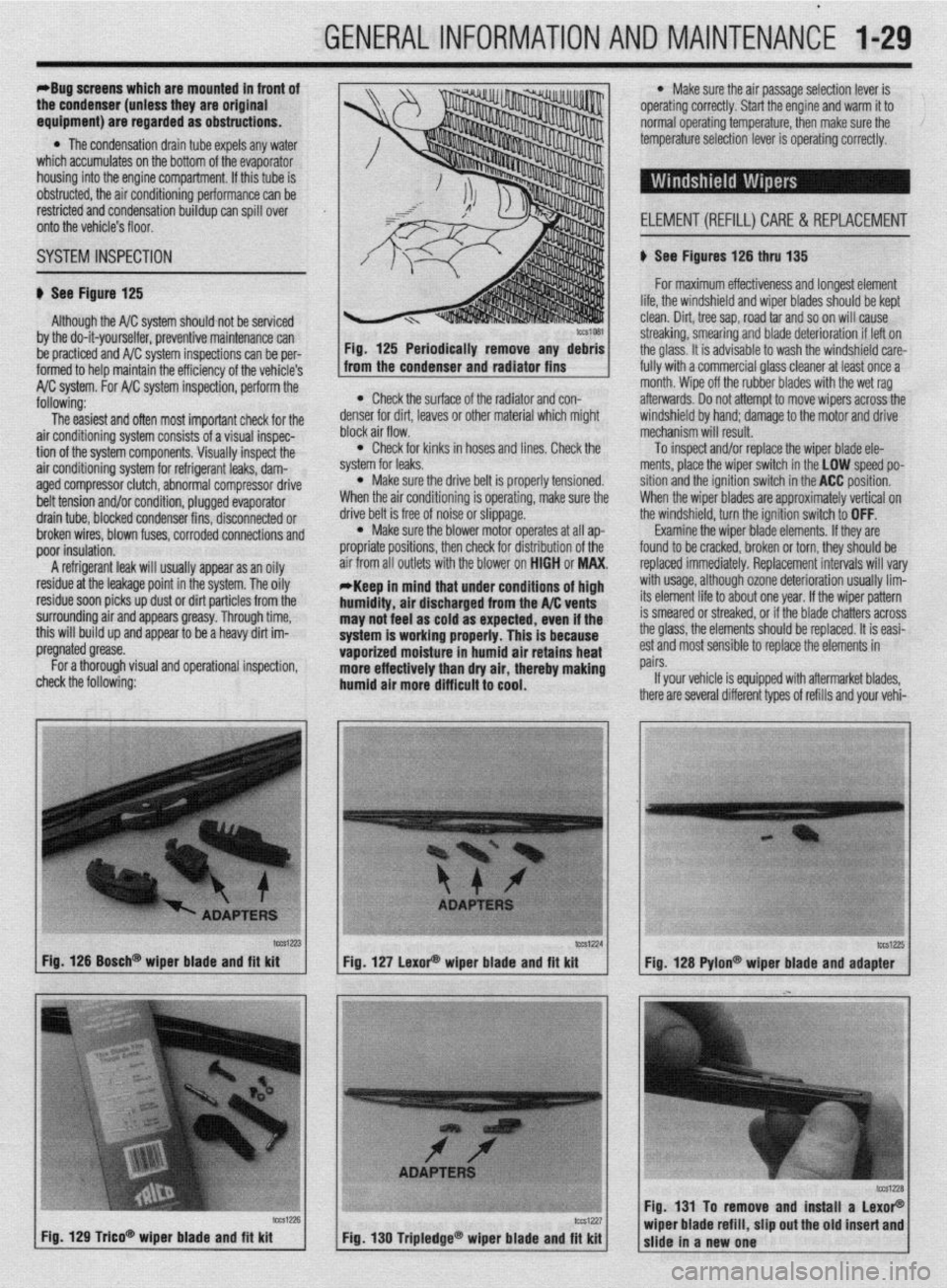

check the following: * Check the surface of the radiator and con-

denser for dirt, leaves or other material which might

block air flow.

l Check for kinks in hoses and lines. Check the

system for leaks.

l Make sure the drive belt is properly tensioned.

When the air conditioning is operating, make sure the

drive belt is free of noise or slippage.

l Make sure the blower motor operates at all ap-

propriate positions, then check for distribution of the

air from all outlets with the blower on HIGH or MAX.

*Keep in mind that under conditions of high

humidity, air discharged from the A/C vents

may not feel as cold as expected, even if the

system is working properly. This is because

vaporized moisture in humid air retains heat

more effectively than dry air, thereby making

humid air more difficult to cool.

lifp thp winrkhi&i nnri winor hlarlP~ shmM hP kmt . ..“. .I.” . . * ““I.. “.” I..” ...r”* “.“““” “, ,““,” “” ,~“r~ clean. Dirt, tree sap, road tar and so on will cause

streaking, smearing and blade deterioration if left on

the glass. It is advisable to wash the windshield care-

fully with a commercial glass cleaner at least once a

month. Wipe off the rubber blades with the wet rag

afterwards. Do not attempt to move wipers across the

windshield by hand; damage to the motor and drive

mechanism will result.

To inspect and/or replace the wiper blade ele-

ments, place the wiper switch in the LOW speed po-

sition and the ignition switch in the ACC position.

When the wiper blades are approximately vertical on

the windshield, turn the ignition switch to OFF.

Examine the wiper blade elements. If they are

found to be cracked, broken or torn, they should be

replaced immediately. Replacement intervals will vary

with usage, although ozone deterioration usually lim-

its element life to about one year. If the wiper pattern

is smeared or streaked, or if the blade chatters across

the glass, the elements should be replaced. It is easi-

est and most sensible to replace the elements in

pairs.

If your vehicle is equipped with aftermarket blades,

there are several different types of refills and your vehi-

tcca-23 Fig. 126 Bosch@ wiper blade and fft kit

Fig. 129 T&o* wioer blade and fit kit tCS1224

lW1Z?5 Fig. 127 LexoP wiper blade and fit kit

Fig. 128 Pylon@ wiper blade and adapter

Fig. 131 To remove and install a LexoP

Fig, 130 Tripledge@ wiper blade and fit kit wiper blade refill, slip out the old insert and

slide in a new one

Page 29 of 408

.

l-30 GENERAL'INFORMATIONAND MAINTENANCE

n Pylon@ inserts, the clip

be removed prior to siidi then the insert can be re

After installing the replacement

strip and pull up while twisting counterclockwise.

The backing strip will snap out of the retaining tab.

Do this for the remaining tabs until the refill is free of

the blade. The length of these refills is molded into

the end and they should be replaced with identical

types. cate the front end is out of alignment or that the tires

are out of balance.

TIRE ROTATION

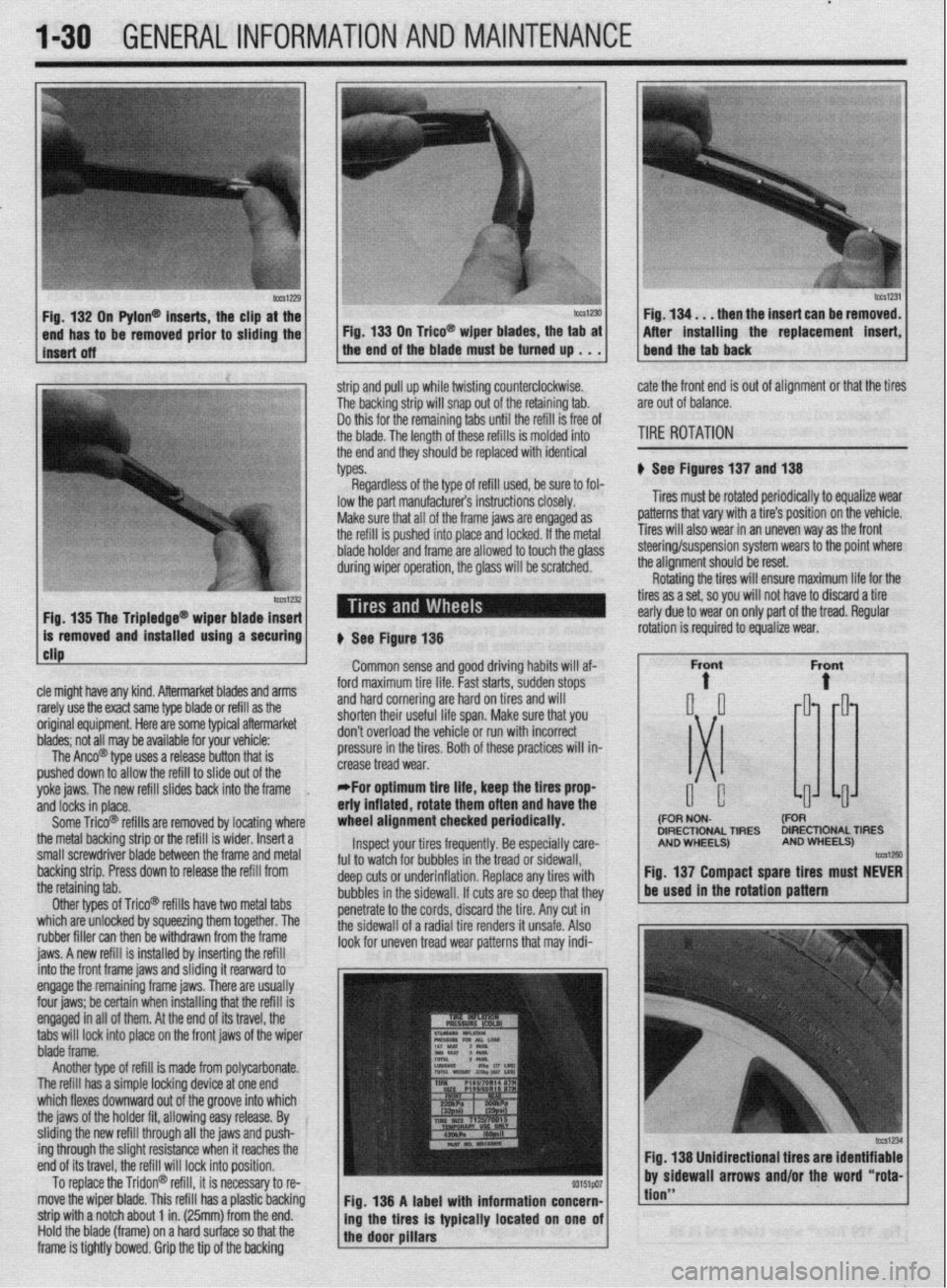

# See Figures 137 and 138

Tires must be rotated periodically to equalize wear

patterns that vary with a tire’s position on the vehicle.

Tires will also wear in an uneven way as the front

1 Fin 1% Tha Trinlarlna@

cle might have any kind. Aftermarket blades and arms

rarely use the exact same type blade or refill as the

original equipment. Here are some typiel aftermarket

blades; not all may be available for your vehicle:

The Anco@ type uses a release button that is

pushed down to allow the refill to slide out of the

yoke jaws. The new refill slides back into the frame

,

and locks in place.

Some Trico@ refills are removed by locating where

the metal backing strip or the refill is wider. Insert a

small screwdriver blade between the frame and metal

backing strip. Press down to release the refill from

the retaining tab.

Other types of Trico@’ refills have two metal tabs

which are unlocked by squeezing them together. The

rubber filler can then be withdrawn from the frame

iaws. A new refill is installed bv insertina the refill lowed to touch the olass steering/suspension system wears to the point where

the alianment should be reset.

# See Figure 138

Common sense and good driving habits will af-

ford maximum tire life. Fast starts, sudden stops

and hard cornering are hard on tires and will

shorten their useful life span. Make sure that you

don’t overload the vehicle or run with incorrect

pressure in the tires. Both of these practices will in-

crease tread wear.

*For optimum tire life, keep the fires prop

eriy inflated, rotate them often and have the

wheel alignment checked periodically.

Inspect your tires frequently. Be especially care-

ful to watch for bubbles in the tread or sidewall,

deep cuts or underinflation. Replace any tires with

bubbles in the sidewall. If cuts are so deep that they

penetrate to the cords, discard the tire. Any cut in

the sidewall of a radial tire renders it unsafe. Also

look for uneven tread wear patterns that may indi- Rotating the tires will ensure maximum life for the

tires as a set, so you will not have to discard a tire

early due to wear on only part of the tread. Regular

DIRECTIONAL TIRES DIRECTIONAL TIRES

jnto the front frame jaws and &ding it rearward to

engage the remaining frame jaws. There are usually

four jaws; be certain when installing that the refill is

engaged in all of them. At the end of its travel, the

tabs will lock into place on the front jaws of the wiper

blade frame.

Another type of refill is made from polycarbonate.

The refill has a simple locking device at one end

which flexes downward out of the groove into which

the jaws of the holder fit, allowing easy release. By

sliding the new refill through all the jaws and push-

ing through the slight resistance when it reaches the

end of its travel, the refill will lock into position.

To replace the Tridon@ refill, it is necessary to re-

move the wiper blade. This refill has a plastic backing

strip with a notch about 1 in. (25mm) from the end.

Hold the blade (frame) on a hard surface so that the

frame is tightly bowed. Grip the tip of the backing Fig. 138 A label with information concern-

ing the tires is typically located on one of

the door pillars

tion”

Page 37 of 408

t

1-38 GENERALINFORMATIONAND MAINTENANCE

11 I Add the recommended automatic transaxle

fluid to the transaxle through the dipstick tube. You

will need a long necked funnel, or a funnel and tube

to do this. A quick check of the capacities chart later

in this Section will reveal the capacity of the transaxle

in your vehicle. On a first fill after removing the pan

and filter, this number should be cut into a ‘hand

checked on the dipstick before refilling.

12. With the transaxle in P, put on the parking

brake, block the front wheels, start the engine and let

it idle. DO NOT RACE THE ENGINE. DO NOT MOVE

THE LEVER THROUGH ITS RANGES.

13. With the lever in Park, check the fluid level. If

it’s OK, take the car out for a short drive, park on a

level surface, and check the level again, as outlined

earlier in this section. Add more fluid if necessary. Be

careful not to overfill, which will cause foaming and

w fluid loss. n of the transfer case filler

3. Remove the filler and the drain plug and allow

the oil to drain into the drain pan.

4. After the fluid has drained completely, install

the drain plug and tighten to 24 ft. Ibs. (32 Nm).

5. Refill the transfer case to the proper level with

Fig. 184 . . .

the transaxle case before in-

stalling the gasket

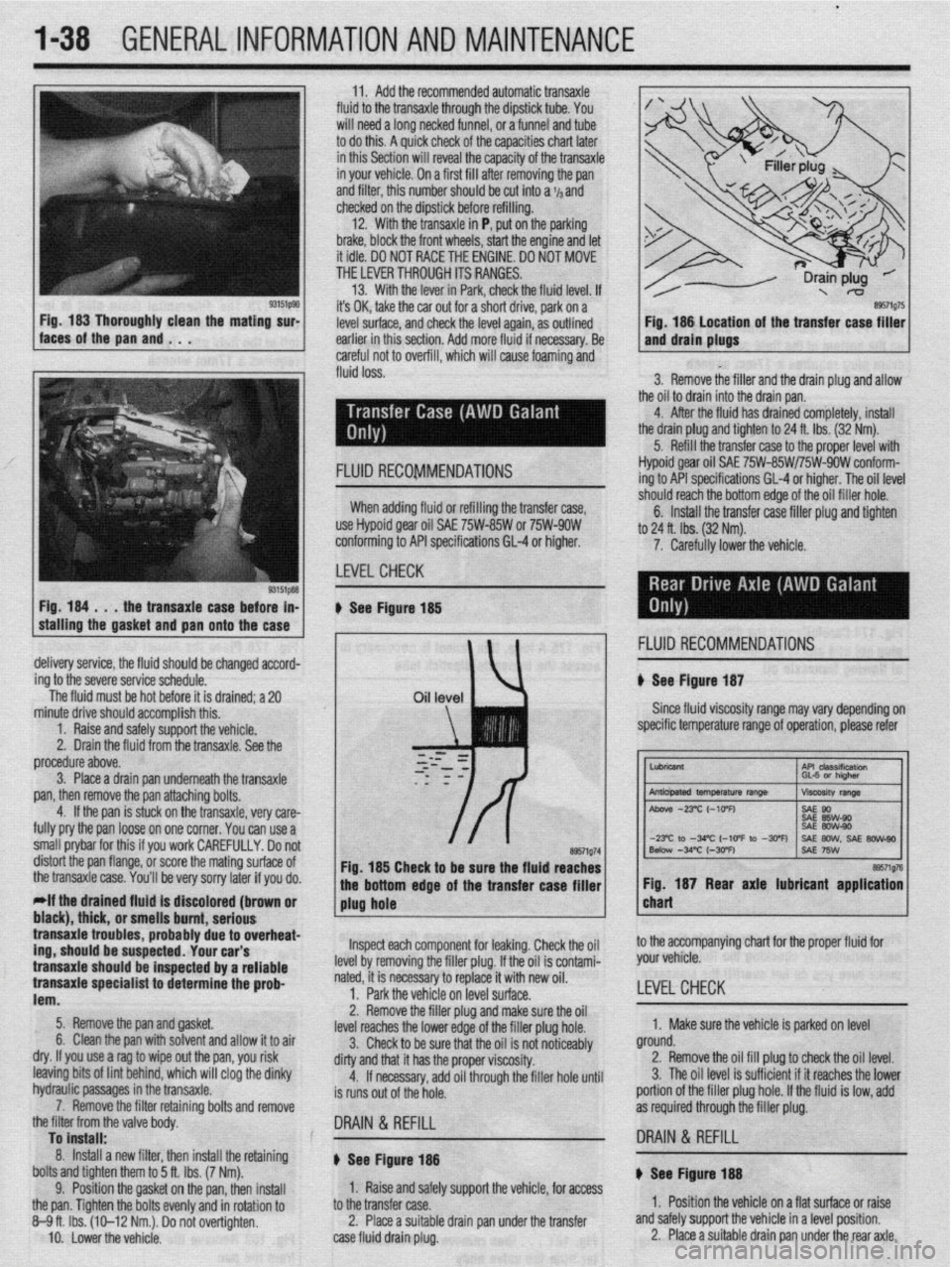

and pan onto the case FLUID RECOMMENDATIONS Hypoid gear oil SAE 75W-85W/75W-9OW conform-

ing to API specifications GL-4 or higher. The oil level

-‘-,*I’ -nnnh +‘* “%om edge of the oil filler hole.

nxfer raw filler nlm and tinhtm When adding fluid or refilling the transfer case,

use Hypoid gear oil SAE 75W-85W or 75W-9OW

conforming to API specifications 61-4 or higher.

LEVELCHECK 6. Install the tra .._._. ____ .._. T.-J _.._ .lJ . .._..

to 24 ft. lbs. (32 Nm).

7. Carefully lower the vehicle.

u See Figure 185

, 1 FLUID RECOMMENDATIONS

delivery service, the fluid should be changed accord-

ing to the severe service schedule.

The fluid must be hot before it is drained; a 20 u See Figure 187

Since fluid viscosity range may

vary depending on

specific temperature range of operation, please refer

~~

tne transaxle case.

You’ll be very sorry later if you do. bottom edge of the transfer case filler 1 1 Fig. 187 Rear axle lubricant application I

*If the drained fluld is discolored (brown or

1 plug hole chart black), thick, or pmmll~ hmmt nnrinmm I transaxle trouble .llln3llU ““III., url,““P s, probably due to overheat-

,r..rr,rA “#.a.- rrdr

trig, should be susp~~lr;u. lvUl vLlr J

transaxle should be inspected by a reliable

transaxle specialist to determine the prob-

lem.

5. Remove the pan and gasket.

6. Clean the pan with solvent and allow it to air

dry. If you use a rag to wipe out the pan, you risk

leaving bits of lint behind, which will clog the dinky

hydraulic passages in the bansaxle.

7. Remove the filter retaining bolts and remove

the filter from the valve bodv. lnsoect each component for leaking. Check the oil

he filler plug. If the oil is contami-

ry to replace it with new oil.

if% nn IPVPI z11rf2r~

level by removing t

nated, it is necessa

1. Park the vehi,., -.. ,-.“, __. ,“-_.

2. Remove the filler plug and make sure the oil

level reaches the lower edge of the filler plug hole.

3. Check to be sure that the oil is not noticeably

dirty and that it has the proper viscosity.

4. If necessary, add oil through the filler hole until

is runs out of the hole. to the accompanying chart for the proper fluid for

your vehicle.

LEVEL CHECK

1. Make sure the vehicle is parked on level

ground.

2. Remove the oil fill plug to check the oil level.

3. The oil level is sufficient if it reaches the lower

portion of the filler plug hole. If the fluid is low, add

as required through the filler plug.

To install: .

8. Install a new filter, then install the retaining

bolts and tighten them to 5 ft. Ibs. (7 Nm).

9. Position the gasket on the pan, then install

the pan. Tighten the bolts evenly and in rotation to

8-9ft. Ibs. (10-12 Nm.). Do not overtighten.

IO. Lower the vehicle. DRAIN & REFILL

I8 DRAIN & REFILL

u See Figure 188 ) See Figure- 14

1. Raise and safely support the vehicle, for access

to the transfer case.

2. Place a suitable drain pan under the transfer

case fluid drain plug. 1. Position the vehicle on a flat surface or raise

and safely support the vehicle in a level position.

2. Place a suitable drain pan under the rear axle.

Page 39 of 408

l-40 GENERALINFORMATIONAND MAINTENANCE

aiffiip98 Fig. 194 Pump the cooling system with pres-

sure, making sure not to overpressurize the

1 system or damage can occur

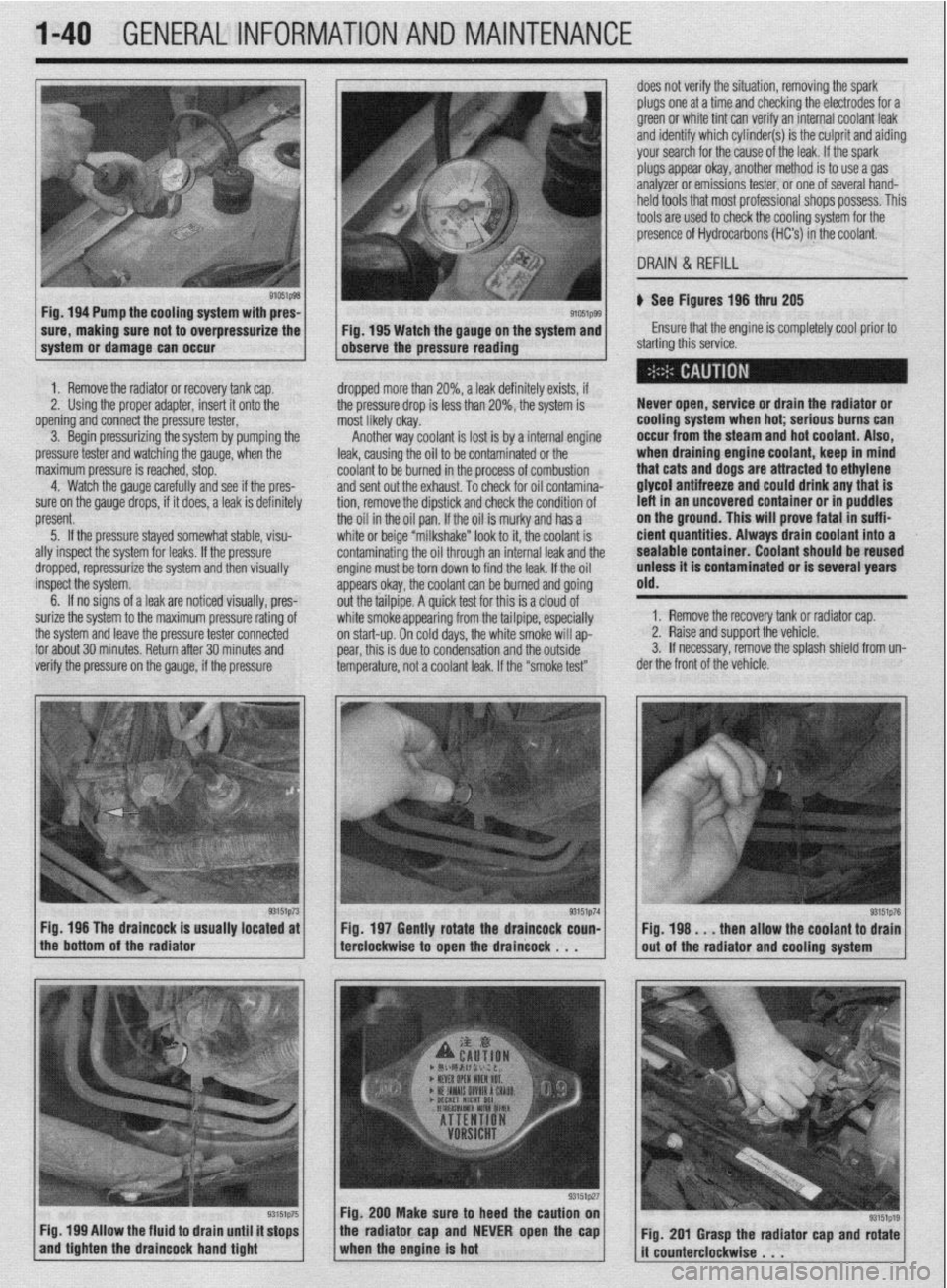

1. Remove the radiator or recovery tank cap.

2. Using the proper adapter, insert it onto the

opening and connect the pressure tester,

3. Begin pressurizing the system by pumping the

pressure tester and watching the gauge, when the

maximum pressure is reached, stop.

4. Watch the gauge carefully and see if the pres-

sure on the gauge drops, if it does, a leak is definitely

present.

5. If the pressure stayed somewhat stable, visu-

ally inspect the system for leaks, If the pressure

dropped, repressurize the system and then visually

inspect the system.

,

/ observe the pressure reading “@‘p~ 1 Fig 195 Watch the gauge on the system and

dropped more than 20%, a leak definitely exists, if

the oressure droo is less than 20%. the svstem is

most likely okay:

, cooling system when hot; serious burns can

Another way coolant is lost is by a internal engine occur from the steam and hot coolant. Also,

leak, causing the oil to be contaminated or the when draining engine coolant, keep in mind

coolant to be burned in the process of combustion that cats and dogs are attracted to ethylene

and sent out the exhaust. To check for oil contamina- glyeol antifreeze and could drink any that is

tion, remove the dipstick and check the condition of left in an uncovered container or in puddles

the oil in the oil pan. If the oil is murky and has a on the ground. This will prove fatal in suffi-

white or beige “milkshake” look to it, the coolant is cient quantities. Always drain coolant into a

contaminating the oil through an internal leak and the sealable container. Coolant should be reuser

enqine must be torn down to find the leak. If the oil mless it is contaminated or is several years

6. If no signs of a leak are noticed visually, pres-

surize the system to the maximum pressure rating of

the system and leave the uressure tester connected

fl sr about 30 minutes. Return after 30 minutes and

V erify the pressure on the gauge, if the pressure does not verify the situation, removing the spark

plugs one at a time and checking the electrodes for a

green or white tint can verify an internal coolant leak

and identify which cylinder(s) is the culprit and aiding

your search for the cause of the leak. If the spark

plugs appear okay, another method is to use a gas

analyzer or emissions tester, or one of several hand-

held tools that most professional shops possess. This

tools are used to check the cooling system for the

presence of Hydrocarbons (HC’s) in the coolant.

DRAIN & REFILL

p See figures 196 thru 205

Ensure that the engine is completely cool prior to

starting this service.

Never open, service or drain the radiator or

Ippears okay, the coolant can be burned and going

jut the tailpipe. A quick test for this is a cloud of

Nhite smoke appearing from the tailpipe, especially

In start-up. On cold days, the white smoke will ap-

Iear, this is due to condensation and the outside

emperature, not a coolant leak. If the “smoke test”

Fig. 196 The draincock is usually located at

Fig. 197 Gently rotate the draincock coun-

the bottom of the radiator

terclockwise to open the draincock . . .

Fig. 199 Allow the fluid to drain until it stops

and tighten the draineock hand tight

93151p27

1. Remove the recovery tank or radiator cap.

2, Raise and support the vehicle.

3. If necessary, remove the splash shield from un

ler the front of the vehicle.

93im76 Fig, 198 . _ . then allow the coolant to drain

out of the radiator and cooling system

Fig. 200 Make sure to heed the caution on

the radiator cap and NEVER open the cap

1 when the engine is hot ,, Fig. 201 Grasp the radiator cap and rotate

it counterclockwise . . .

Page 42 of 408

GENERALINFORMATIONAND MAINTENANCE l-43

l Special car washing detergent is the best to

use. Liquid dishwashing detergent can remove wax

and leave the car’s paint unprotected and in addition

some liquid detergents contains abrasives which can

scratch the paint.

l Bird droppings should be removed from the

paintwork as soon as possible, otherwise the finish

may be permanently stained.

When the car is driven immediately after be-

ing washed, apply the brakes several times

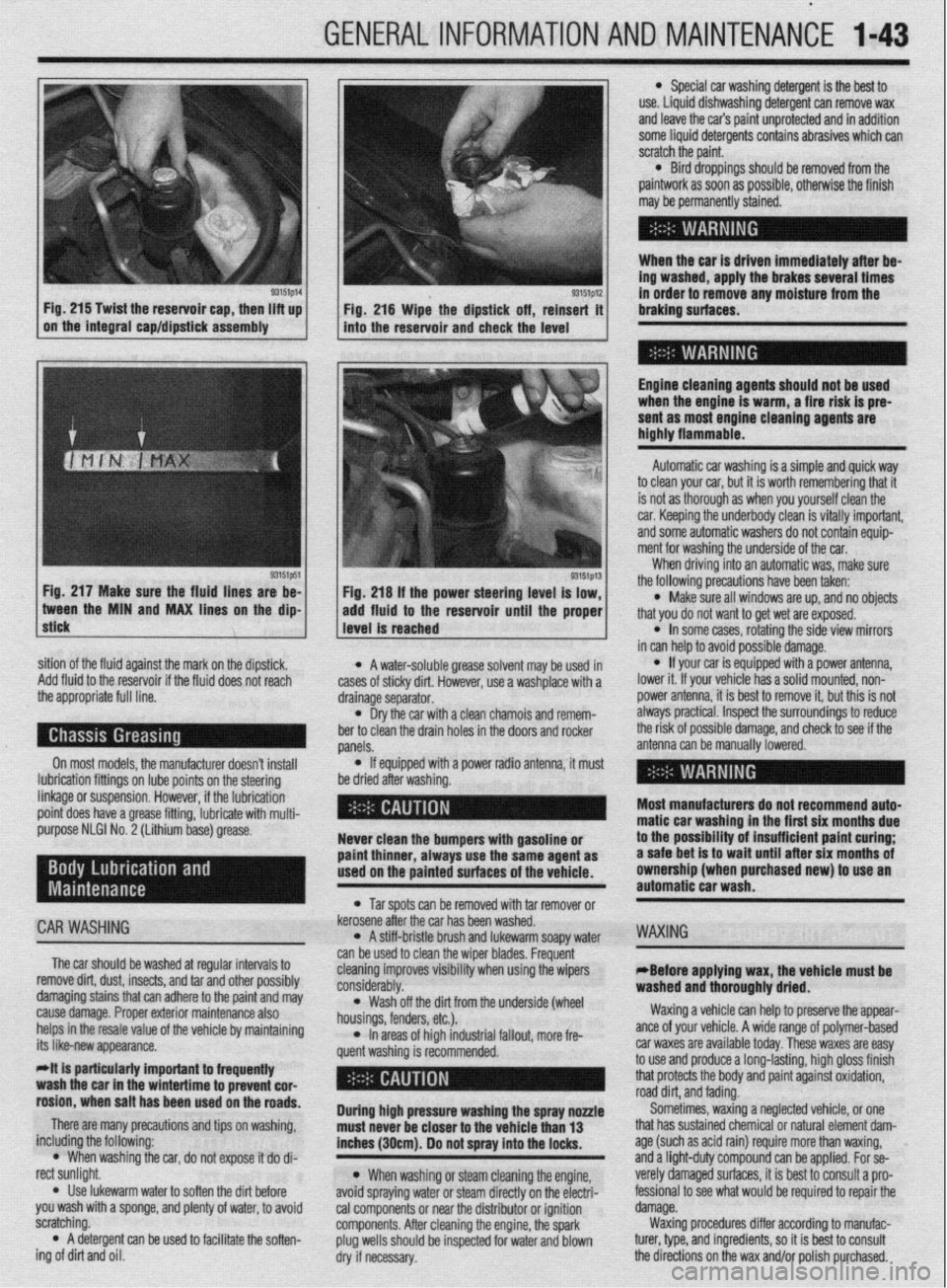

93151p14 93151p12 Fig. 215 Twist the reservoir cap, then lift up

I I

in order to remove any moisture from the

Fig. 216 Wipe the dipstick off, reinsert it braking surfaces.

on the integral cap/dipstick assembly

into the reservoir and check the level

I

Engine cleaning agents should not be used

when the engine is warm, a fire risk is pre-

sent as most engine cleaning agents are

highly flammable.

sition of the fluid against the mark on the dipstick,

Add fluid to the reservoir if the fluid does not reach

the appropriate full line.

On most models, the manufacturer doesn’t install

lubrication fittings on lube points on the steering

linkage or suspension. However, if the lubrication

point does have a grease fitting, lubricate with multi-

purpose NLGI No. 2 (Lithium base) grease.

CAR WASHING

The car should be washed at regular intervals to

remove dirt, dust, insects, and tar and other possibly

damaging stains that can adhere to the paint and may

cause damage. Proper exterior maintenance also

helps in the resale value of the vehicle by maintaining

its like-new appearance.

Mt is particularly important ta frequentiy

wash the car in the wintertime to prevent cor-

rosion, when salt has been used on the roads.

There are many precautions and tips on washing,

including the following:

l When washing the car, do not expose it do di-

rect sunlight.

. Use lukewarm water to soften the dirt before

you wash with a sponge, and plenty of water, to avoid

scratching.

l A detergent can be used to facilitate the soften-

ing of dirt and oil. * A water-soluble grease solvent may be used in

cases of sticky dirt. However, use a washplace with a

drainage separator.

l Dry the car with a clean chamois and remem-

ber to clean the drain holes in the doors and rocker

panels.

l If equipped with a power radio antenna, it must

be dried after washing.

Never clean the bumpers with gasoline or

paint thinner, always use the same agent as

used on the painted surfaces of the vehicle.

l Tar spots can be removed with tar remover or

kerosene after the car has been washed.

l A stiff-bristle brush and lukewarm soapy water

can be used to clean the wiper blades. Frequent

cleaning improves visibility when using the wipers

considerably.

l Wash off the did from the underside (wheel

housings, fenders, etc.).

l In areas of high industrial fallout, more fre-

quent washing is recommended.

During high pressure washing the spray nonle

must never be closer to the vehicle than 13

inches (30cm). Do not spray into the locks.

l When washing or steam cleaning the engine,

avoid spraying water or steam directly on the electri-

cal components or near the distributor or ignition

components. After cleaning the engine, the spark

plug wells should be inspected for water and blown

dry if necessary. Automatic car washing is a simple and quick way

to clean your car, but it is worth remembering that it

is not as thorough as when you yourself clean the

car. Keeping the underbody clean is vitally important,

and some automatic washers do not contain equip-

ment for washing the underside of the car.

When driving into an automatic was, make sure

the following precautions have been taken:

l Make sure all windows are up, and no objects

that you do not want to get wet are exposed.

l In some cases, rotating the side view mirrors

in can help to avoid possible damage.

l If your car is equipped with a power antenna,

lower it. If your vehicle has a solid mounted, non-

power antenna, it is best to remove it, but this is not

always practical. Inspect the surroundings to reduce

the risk of possible damage, and check to see if the

antenna can be manually lowered.

Most manufacturers do not recommend auto-

matic car washing in the first six months due

to the possibility of insufficient paint curing;

a safe bet is to wait until after six months of

ownership (when purchased new) to use an

automatic car wash.

WAXING

eBefore applying wax, the vehicle must be

washed and thoroughly dried.

Waxing a vehicle can help to preserve the appear-

ante of your vehicle. A wide range of polymer-based

car waxes are available today. These waxes are easy

to use and produce a long-lasting, high gloss finish

that protects the body and paint against oxidation,

road dirt, and fading.

Sometimes, waxing a neglected vehicle, or one

that has sustained chemical or natural element dam-

age (such as acid rain) require more than waxing,

and a light-duty compound can be applied. For se-

verely damaged surfaces, it is best to consult a pro-

fessional to see what would be required to repair the

damage.

Waxing procedures differ according to manufac-

turer, type, and ingredients, so it is best to consult

the directions on the wax and/or polish purchased.

Page 43 of 408

1-44 GENERALINFORMATIONAND MAINTENANCE

INTERIOR CLEANING

Upholstery

Fabric can usually be cleaned with soapy water or

a proper detergent. For more difficult spots caused by

oil, ice cream, soda, etc., use a fabric cleaner avail-

able at most parts stores. Be sure when purchasing

the cleaner to read the label to ensure it is safe to use

on your type of fabric. A safe method of testing the

cleaner is to apply a small amount to an area usually

unseen, such as under a seat, or other areas. Wart a

while, perhaps even a day to check the spot for fad-

ing, discoloring, etc., as some cleaners will only

cause these problems after they have dried

Leather upholstery requrres special care, it can be

cleaned with a mild soap and a soft cloth. It is recom-

mended that a special leather cleaner be used to

clean but also treat the leather surfaces in your vehi-

cle. Leather surfaces can age quickly and can crack if

not properly taken care of, so it is vital that the leather

surfaces be maintained.

Floor Mats and Carpet

The floor mats and carpet should be vacuumed or

brushed regularly. They can be cleaned with a mild

soap and water. Special cleaners are available to

clean the carpeted surfaces of your vehicle, but take

care in choosing them, and again it is best to test

them in a usually unseen spot.

Dashboard, Console, Door Panels, Etc.

The dashboard, console, door panels, and other

plastic, vinyl, or wood surfaces can be cleaned using

a mild soap and water. Caution must be taken to keep

water out of electronic accessories and controls to

avoid shorts or ruining the components Again spe-

cial cleaners are available to clean these surfaces, as

with other cleaners care must taken in purchasmg

and using such cleaners.

There are protectants available which can treat the

various surfaces in your car giving them a “shiny new

look”, however some of these protectants can cause

more harm than good in the long run. The shine that

is placed on your dashboard attracts sunlight accel-

erating the aging, fading and possibly even cracking

the surfaces. These protectants also attract more dust

to stick to the surfaces they treat, Increasing the cleaning you must do to maintain the appearance of

your vehicle. Personal discretion is advised here.

On most models covered by this manual, the

wheel bearmgs used are sealed units and do not re-

quire routine maintenance. However on some Galant

and Mirage models, the rear wheel bearing do require

periodic repacking. For removal and installation in-

structions, please refer to Section 7 (for rear bear-

ings) or Section 8 (for front bearings).

REPACKING

*Sodium based grease is not compatible

with lithium based grease. Read the package

labels and be careful not to mix the two

types. If there is any doubt as to the type of

grease used, completely clean the old

grease from the bearing and hub before re-

placing.

Before handling the bearings, there are a few

things that you should remember to do and not to do.

DO the following: l Remove all outside dirt from the housing be-

fore exposing the bearing.

l Treat a used bearing as gently as you would a

new one.

l Work with clean tools in clean surroundings. l Use clean, dry gloves, or at least clean, dry

hands.

l Clean solvents and flushing fluids are a must. l Use clean paper when laying out the bearings

to dry.

l Protect drsassembled bearings from rust and

dirt. Cover them up.

l Use clean, lint-free rags to wipe the bearings. l Keep the bearings in oil-proof paper when they

are to be stored or are not in use.

l Clean the inside of the housing before replac-

ing the bearin

Do NOT do he followino: El, l Do not work in dirty sirroundings. l Do not use dirty, chipped or damaged tools. l Do not work on wooden work benches or use

wooden mallets.

l Do not handle bearings with dirty or moist

hands.

l Do not use gasoline for cleaning. Use a safe

solvent.

l Do not spin dry bearings with compressed air.

They will be damaged.

l Do not use cotton waste or dirty cloths to wipe

bearings.

l Do not scratch or nick bearing surfaces. l Do not allow the bearina to come in contact

” with dirt or rust at any time.

The rear wheel bearinas on some Galant and Mi-

rage models require periodic maintenance. A pre-

mium high melting point grease meeting Grade

Multipurpose Grease NLGI Grade #2 or equivalent

must be used. Long fiber type greases must not be

used. This service is recommended every 30,000

miles (48,000 km).

*For information on Wheel Bearing removal

and installation, refer to Section 7 of this

manual.

1. Remove the wheel bearing.

2. Clean all parts in a non-flammable solvent and

let them air dry.

*Only use lint-free rags to dry the bearings.

Never spin-dry a bearing with compressed

air, as this will damage the rollers.

3. Check for excessive wear and damage. Replace

the bearing as necessary.

*Packina wheel bearinos with arease is

best accomplished by u&g a wheel bearing

packer (available at most automotive parts

stores).

4. If a wheel bearing packer is not available, the

bearings may be packed by hand.

a. Place a “healthy’ glob of grease in the

palm of one hand.

b. Force the edge of the bearing into the

grease so that the grease fills the space between

the rollers and the bearing cage.

c. Keep rotating the bearing while continuing

to push the grease through.

d. Continue until the grease is forced out the

other side of the bearing.

5. Place the packed bearing on a clean surface

and cover it until it is time for installation.

6. Install the wheel bearing.

# See Figures 219 and 220

To prevent the bumper from deforming, these vehi-

cles cannot be towed by a wrecker using sling-type

equipment. If these vehicles require towing, use a

wheel lift or flat bed equipment. It is recommended

that the vehicle be towed from the front If a flat bed is

not available.

Manual transaxle vehicles may be towed from the

rear provided that the transaxle is in Neutral and the

driveline has not been damaged. The steering wheel

must be clamped in the straight-ahead positron with a

steering wheel clamping device designed for towing

service use.

Do not use the steering column lock to secure

the front wheel uosition for towina.

Automatic transaxle vehicles may be towed on the

front wheels at speeds not to exceed 30 mph (50

km/h) for a distance not to exceed 18 miles (30 km).

If these limits can not be met, then the front wheels

must be placed on a tow dolly.

# See Figure 221

All Wheel Drive (AWD) vehicles should only be

towed with all 4 wheels on the ground or lifted from

the road surface. This means that the vehicle is to be

towed either with flatbed equipment, with all wheels

on dollies or flat towed. Damage to the viscous cou-

pling may result if the vehicle is towed with only 2

wheels on the ground.

p See Figure 222

Whenever a vehicle is jump started, precautions

must be followed In order to prevent the possibility of

Page 45 of 408

.

I-46 GENERALINFORMATIONAND MAINTENANCE

2. Pull the jumping vehicle (with the good bat-

tery) into a position so the jumper cables can reach

the dead battery and that vehicle’s engine. Make sure

that the vehicles do NOT touch.

3. Place the transmissions/transaxles of both ve-

hicles in Neutral (MT) or P (AT), as applicable, then

firmly set their parking brakes.

*ff necessary for safety reasons, the hazard

lights on both vehicles may be operated

throughout the entire procedure without sig-

nificantiy increasing the diff icuity of jumping

the dead battery.

4. Turn all lights and accessories OFF on both

vehicles. Make sure the ignition switches on both ve-

hicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do

not cover the terminals.

6. Make sure the terminals on both batteries are

clean and free of corrosion or proper electrical con-

nection will be impeded. If necessary, clean the bat-

tery terminals before proceeding.

7. Identify the positive (+) and negative (-) termi-

nals on both batteries.

8. Connect the first jumper cable to the positive

(t) terminal of the dead battery, then connect the

other end of that cable to the positive (t) terminal of

the booster (good) battery.

9. Connect one end of the other jumper cable to

the negative (−) terminal on the booster bat-

tery and the final cable clamp to an engine bolt head,

alternator bracket or other solid, metallic point on the

engine with the dead battery. Try to pick a ground on

the engine that is positioned away from the battery in

order to minimize the possibility of the 2 clamps

touching should one loosen during the procedure.

DO NOT connect this clamp to the negative (-) termi-

nal of the bad battery. cable on the donor battery. Disconnect the positive

cable from the donor battery and finally, disconnect

the positive cable from the formerly dead battery. Be

careful when disconnecting the cables from the posi-

tive terminals not to allow the alligator clips to touch

any metal on either vehicle or a short and sparks will

occur.

I

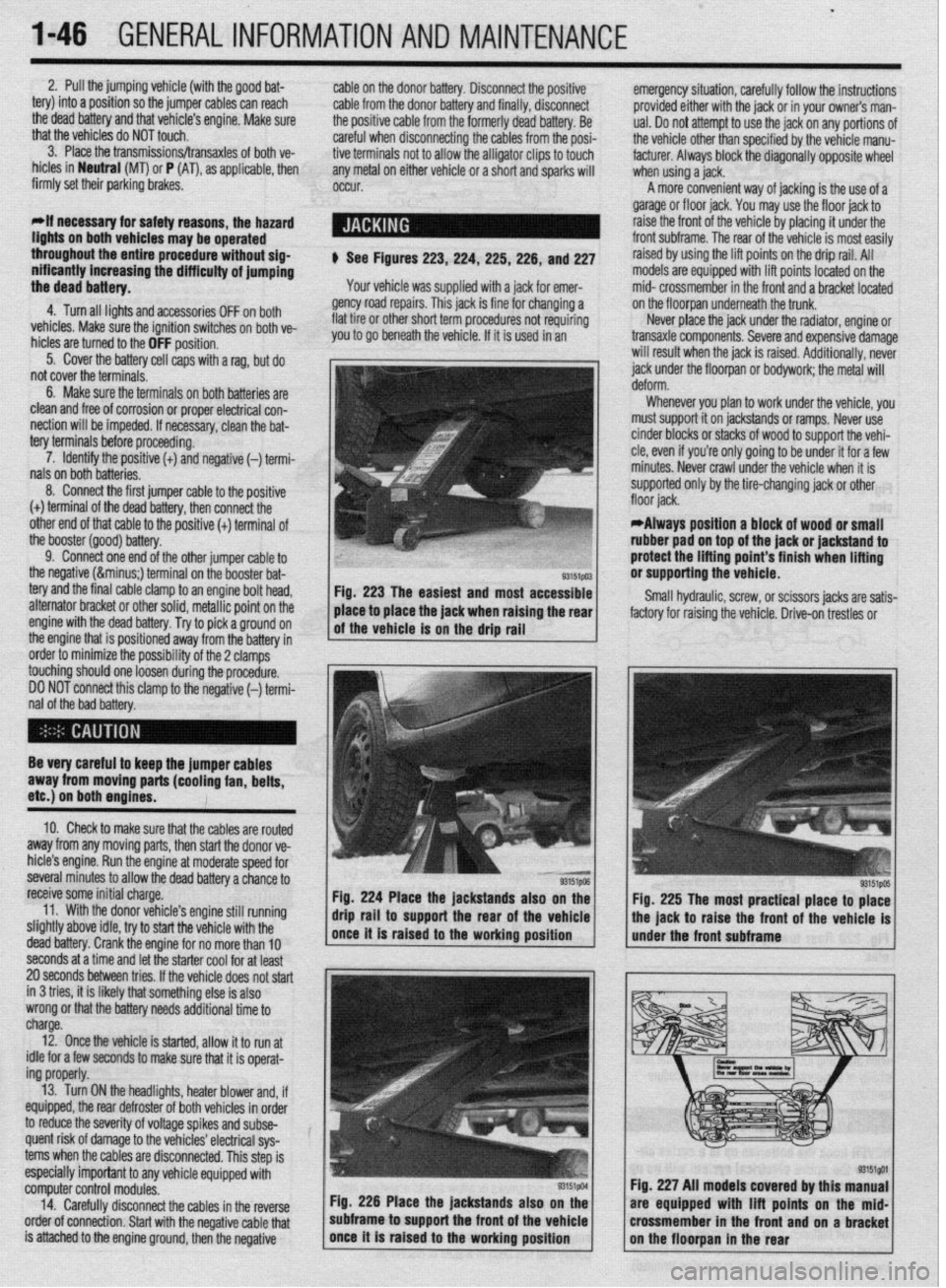

$ See Figures 223,224, 225,226, and 227

Your vehicle was supplied with a jack for emer-

gency road repairs. This jack is fine for changing a

flat tire or other short term procedures not requiring

you to go beneath the vehicle. If it is used in an emergency situation, carefully follow the instructions

provided either with the jack or in your owners man-

ual. Do not attempt to use the jack on any portions of

the vehicle other than specified by the vehicle manu-

facturer. Always block the diagonally opposite wheel

when using a jack.

A more convenient way of jacking is the use of a

garage or floor jack. You may use the floor jack to

raise the front of the vehicle by placing it under the

front subframe. The rear of the vehicle is most easily

raised by using the lift points on the drip rail. All

models are equipped with lift points located on the

mid- crossmember in the front and a bracket located

on the floorpan underneath the trunk.

Never place the jack under the radiator, engine or

transaxle components. Severe and expensive damage

will result when the jack is raised. Additionally, never

jack under the floorpan or

bodywork; the

metal will

Whenever you plan to work under the vehicle, you

must support it on jackstands or ramps. Never use

cinder blocks or stacks of wood to support the vehi-

cle, even if you’re only going to be under it for a few

minutes. Never crawl under the vehicle when it is

supported only by the tire-changing jack or other

*Always position a block of wood or small

rubber pad on top of the jack or jackstand to

protect the lifting point’s finish when lifting

or supporting the vehicle.

Small hydraulic, screw, or scissors jacks are satis-

factory for raising the vehicle. Drive-on trestles or

Be very careful to keep the jumper cables

away from moving parts (cooling fan, belts,

etc.) on both engines.

10. Check to make sure that the cables are routed

away from any moving parts, then start the donor ve-

hicle’s engine. Run the engine at moderate speed for

several minutes to allow the dead battery a chance to

receive some initial charge.

11. With the donor vehicle’s engine still running

slightly above idle, try to start the vehicle with the

dead battery. Crank the engine for no more than 10 &stands also on the

Fig. 225 The most practical place to place

front of the vehicle is

seconds at a time and let the starter cool for at least

20 seconds between tries. If the vehicle does not start

in 3 tries, it is likely thatsomething else is also

wrong or that the battery needs additional time to

charge.

12. Once the vehicle is started, allow it to run at

idle for a few seconds to make sure that it is operat-

ing properly.

13. Turn ON the headlights, heater blower and, if

equipped, the rear defroster of both vehicles in order

to reduce the severity of voltage spikes and subse-

quent risk of damage to the vehicles’ electrical sys-

tems when the cables are disconnected. This step is

especially important to any vehicle equipped with

computer control modules.

14. Carefully disconnect the cables in the’reverse

order of connection. Start with the negative cable that

is attached to the engine ground, then the negative Fig. 226 Place the jackstands also

subframe to support the front of the Fig. 227 All models covered by this

are equipped with lift points on t

crossmember in the front and on a

Page 46 of 408

GENERAL INFORMATION AND MAINTENANCE 1-47

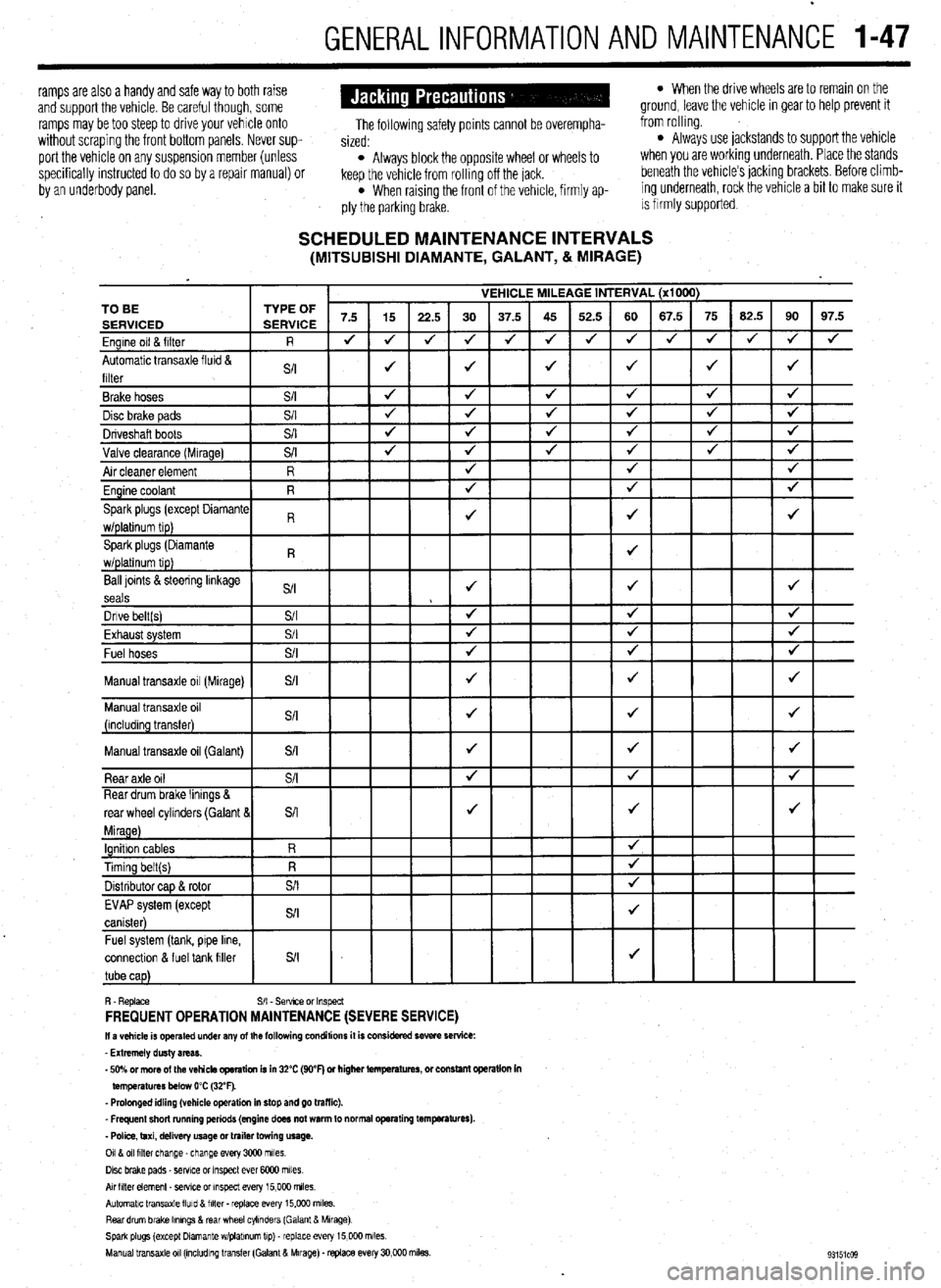

ramps are also a handy and safe way to both raise l When the drive wheels are to remain on the

and support the vehicle. Be careful though, some ground, leave the vehicle in gear to help prevent it

ramps may be too steep to drive your vehicle onto

The following safety points cannot be overempha- from rolling.

without scraping the front bottom panels. Never sup-

sized:

l Always use jackstands to support the vehicle

port the vehicle on any suspension member (unless l Always block the opposite wheel or wheels to when you are working underneath. Place the stands

specifically instructed to do so by a repair manual) or

keep the vehicle from rolling off the jack. beneath the vehrcle’s jacking brackets Before climb-

by an underbody panel.

l When raising the front of the vehicle, firmly ap- ing underneath, rock the vehicle a bit to make sure it

ply the parking brake. is firmly supported.

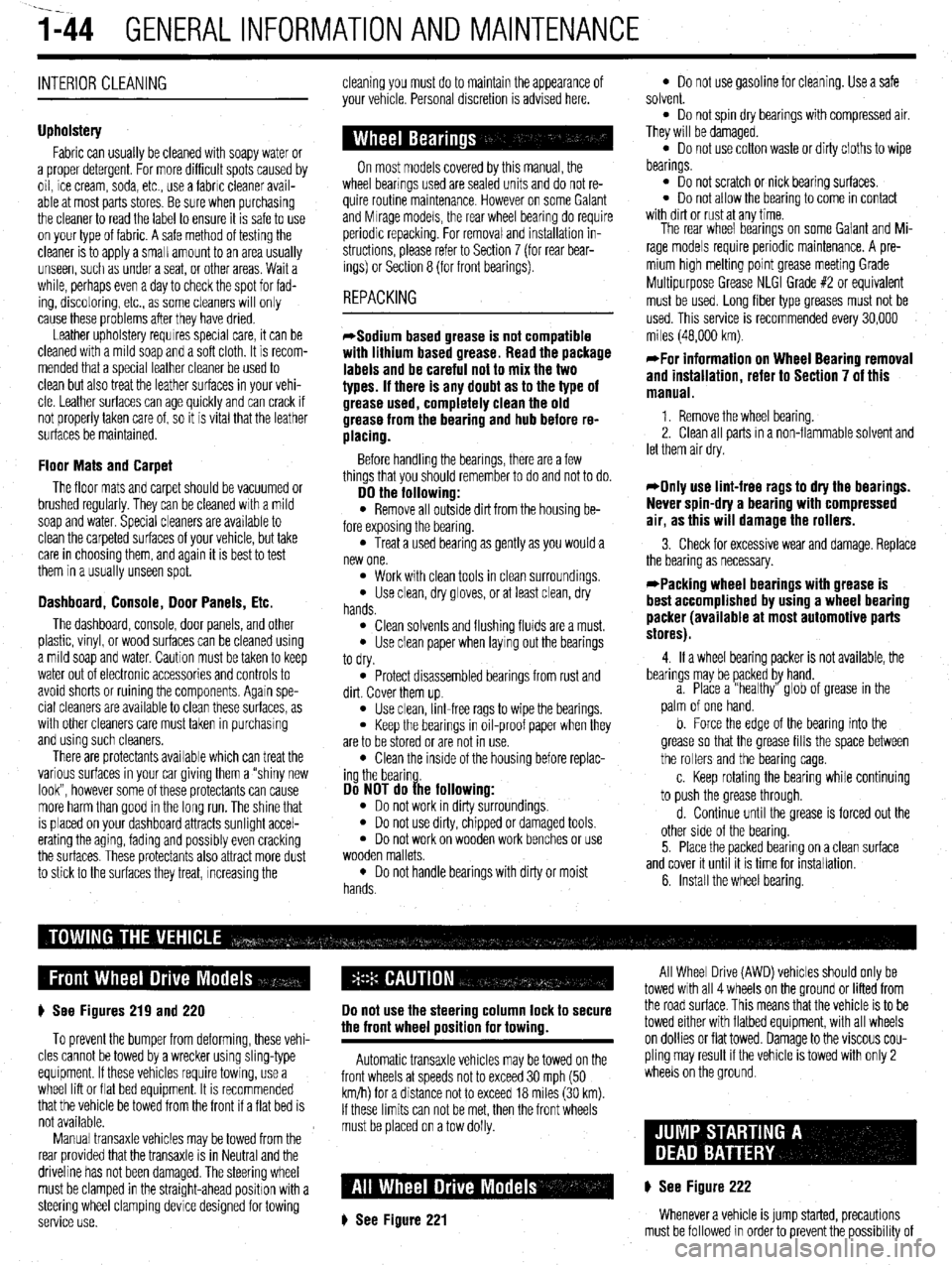

SCHEDULED MAINTENANCE INTERVALS (MITSUBISHI DIAMANTE, GALANT, & MIRAGE)

VEHICLE MILEAGE INTERVAL (x1000)

7.5 15

22.5 30 37.5 45 52.5 60 67.5 75 62.5 90 97.5

J J

J 4 J J 4 4 4 J J

J 4

4

J J J J 4 TO BE

Ball loints &steering linkage

S/I J J J

seals

Dnve belt(s) S/I 4 4 J

Fvha,,rt cvctom $/I

J J J LmI,..“w. “,YL”,‘. Fuel hoses

+

Manual transaxle oil (Galant)

connectlon & fuel tank filler

R. Replace S/I - Sefwce or Inspect FREQUENT OPERATION MAINTENANCE (SEVERE SERVICE) II a vehicle is operated under any of the following conditions it is considered severe service:

- Extremely dusty areas.

- 50% or more of the vehicle operation is in 32% (WF) or higher temperatures, or constant opsralion in

temperatures below 0% (32°F).

- Prolonged idling (vehicle operation in stop and go traffic).

_ Frequent short running periods (engine does not warm to normal operating temfwatures).

- Police, taxi, delivery usage or trailer towing usage.

0118 011 filter change-change every 3CQO miles.

Disc brake pads - sewce or Inspect ever 6COO miles

AN hlter element _ setwe or inspect every 15,000 miles.

Automatic transaxle lluld 8 filter . replace every 15,COO m&s.

Rear drum brake Ikmngs & rear wheel cylinders (Galant & Mirage)

Spark plugs (except Dlamante wlplabnum tip) - replace every 15,COO miles.

Manual transaxle 011 (mcludlng transfer (Galant & Mirage). replace every 30,000 miles.

Page 51 of 408

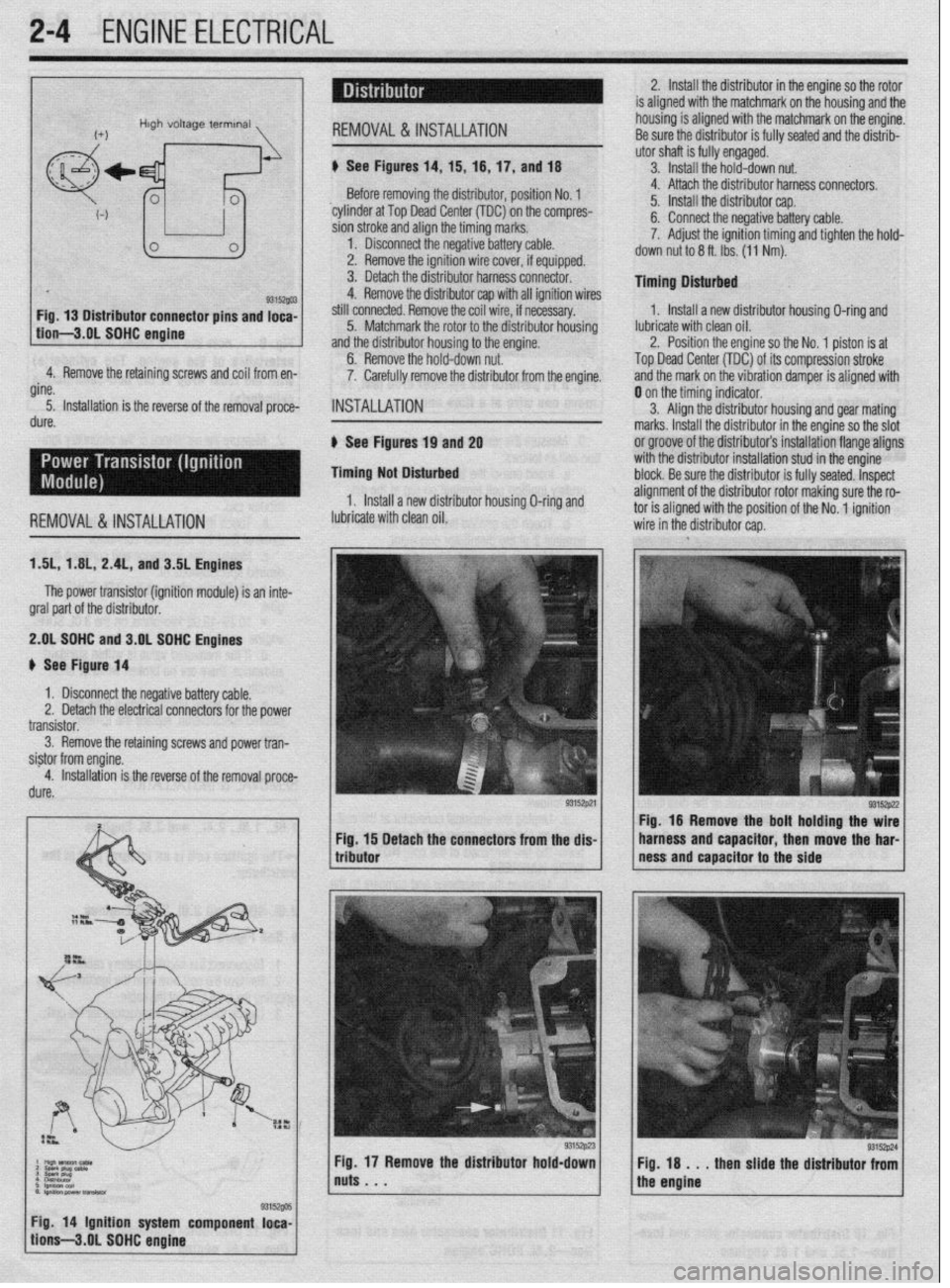

2-4 ENGINEELECTRICAL

2. Install the distributor in the engine so the rotor

is aligned with the matchmark on the housing and the

housing is aligned with the matchmark on the engine.

4.‘ Remove the retaining screws and coil from en-

gine.

5. Installation is the reverse of the removal proce-

dure. Before removing the distributor, position No. 1

‘cylinder at Top Dead Center (TDC) on the compres-

sion stroke and align the timing marks.

1. Disconnect the negative battery cable.

2. Remove the ignition wire cover, if equipped.

3. Detach the distributor harness connector.

4. Remove the distributor cap with all ignition wires

still connected. Remove the coil wire, if necessary.

5. Matchmark the rotor to the distributor housing

and the distributor housing to the engine.

6. Remove the hold-down nut.

7. Carefully remove the distributor from the engine.

INSTALLATION

6 See Figures 19 and 2g

Timing Not Disturbed

1, Install a new distributor housing O-ring and 4. Attach the distributor harness connectors.

5. Install the distributor cap.

6. Connect the negative battery cable.

7. Adjust the ignition timing and tighten the hold-

down nut to 6 ft. Ibs. (11 Nm).

Timing Dlsturbed

1. Install a new distributor housing O-ring and

lubricate with clean oil.

2. Position the engine so the No. 1 piston is at

Top Dead Center (TDC) of its compression stroke

and the mark on the vibration damper is aligned with

REMOVALS& INSTALLATION lubricate with clean oil. 0 on the timing indicator.

3. Align the distributor housing and gear mating

marks. Install the distributor in the engine so the slot

or groove of the distributor’s installation flange aligns

with the distributor installation stud in the engine

block. Be sure the distributor is fully seated. Inspect

alignment of the distributor rotor making sure the ro- tnr ic dinnnd with thn qn,c$nn of the Nn innitinn

ISL, 1 AIL, 2.4L, and 3.5L Engines

The power transistor (ignition module) is an inte-

gral part of the distributor.

2.gL SDHC and 3.OL SOHC Engines

# See Figure 14

1 x Disconnect the negative battery cable.

Remove the retaining screws and power tran-

Detach the connectors from the dis- Fig. 16 Remove the bolt holding the wire

harness and capacitor, then move the har-

ness and capacitor to the side

Fig. 18 . . . then slide the distributor from

the engine

/ tion’s-3.gL SOHC engine g3is~@ 1 Fig 14 Ignition system component loca-

Page 54 of 408

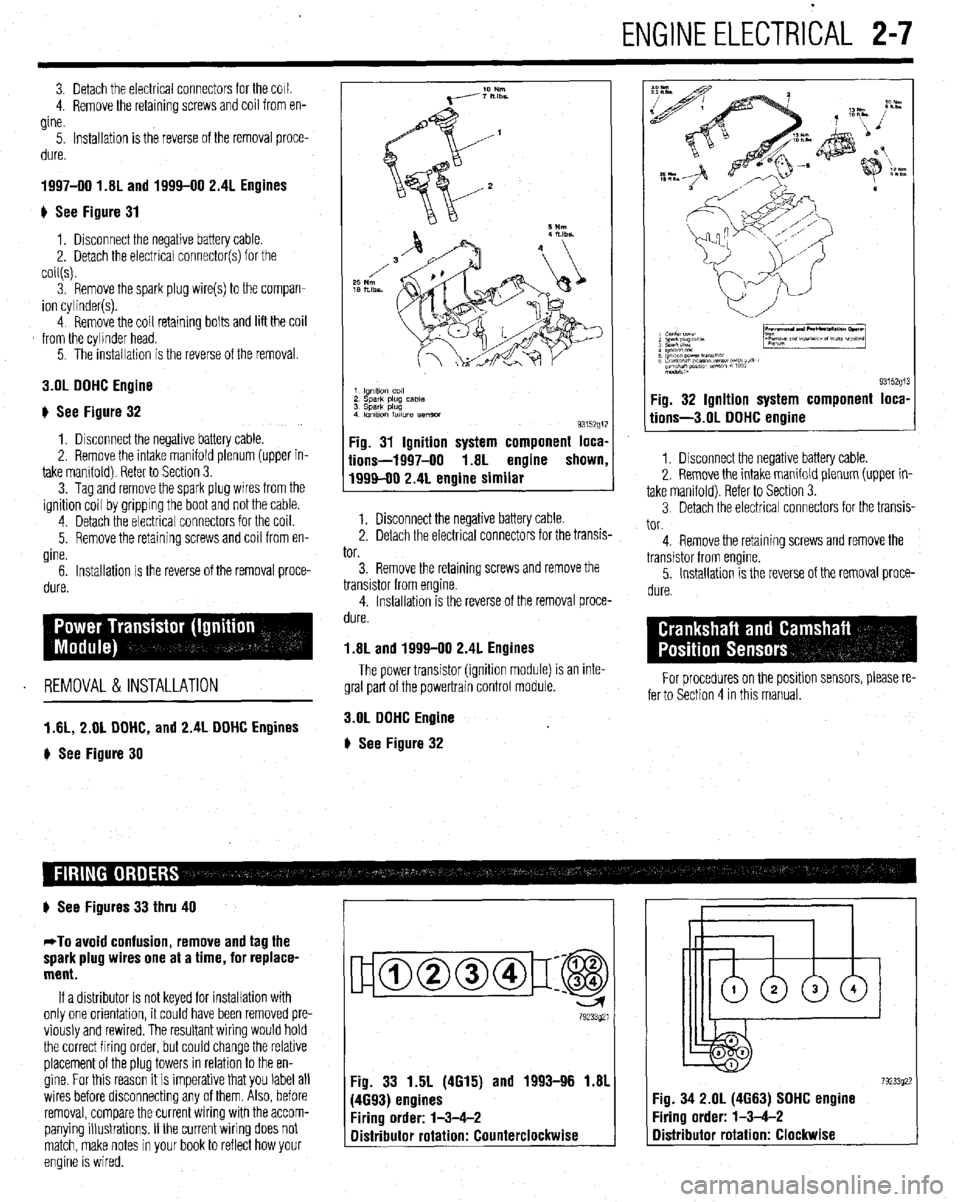

ENGINEELECTRICAL 2-7

3. Detach the electrical connectors for the COIL

4. Remove the retaining screws and coil from en-

gine.

5. Installation is the reverse of the removal proce-

dure.

1997-00 1.81 and 1994-00 2.4L Engines

) See Figure 31

1, Disconnect the negative battery cable.

2. Detach the electrical connector(s) for the

coil(s).

3. Remove the spark plug wire(s) to the compan-

ion cylinder(s).

4 Remove the coil retaining bolts and lift the coil

from the cylinder head.

5. The installation is the reverse of the removal.

3.OL DOHC Engine

# See Figure 32

1, Disconnect the negative battery cable.

2. Remove the intake manifold plenum (upper in-

take mamfold) Refer to Section 3.

3. Tag and remove the spark plug wires from the

ignition coil by gripping the boot and not the cable.

4 Detach the electrical connectors for the coil.

5. Remove the retaining screws and coil from en-

gine.

6. Installation is the reverse of the removal proce-

dure.

REMOVAL &INSTALLATION

1 AL, 2.01 DOHC, and 2.4L DOHC Engines

) See Figure 30

1 lgnltlo” co,,

2 sparlt plug case

3 Spark plug

4 Imltlon fatlure semm

93152g1:

Fig. 31 Ignition system component loca,

iions-1997-00 1.8L engine shown

1999-00 2.4L engine similar

1. Disconnect the negative battery cable.

2. Detach the electrical connectors for the transis-

tor.

3. Remove the retaining screws and remove the

transistor from engine.

4. Installation is the reverse of the removal proce-

dure.

1.8L and 1999-00 2.4L Engines

The power transistor (ignition module) is an inte-

gral part of the powertrain control module.

3.OL DOHC Engine

# See Figure 32

9315291 Fig. 32 Ignition system component loca,

tions-3.01 DOHC engine

1. Disconnect the negative battery cable.

2. Remove the intake manifold plenum (upper in-

take manifold). Refer to Section 3.

3 Detach the electrical connectors for the transis-

tor.

4. Remove the retaining screws and remove the

transistor from engine.

5. Installation is the reverse of the removal proce-

dure.

For procedures on the positlon sensors, please re-

fer to Section 4 in this manual.

# See Figures 33 thru 40

*To avoid confusion, remove and tag the

spark plug wires one at a time, for replace-

ment.

If a distributor is not keyed for installation with

only one orientation, it could have been removed pre-

viously and rewired. The resultant wiring would hold

the correct firing order, but could change the relative

placement of the plug towers in relation to the en-

gine. For this reason it is imperative that you label all

wires before disconnecting any of them. Also, before

removal, compare the current wiring with the accom-

panying illustrations. If the current wiring does not

match, make notes in your book to reflect how your

engine is wired.

ujamm-p:@

79233921

Fig. 33 1.5L (4615) and 1993-96 1.81

(4693) engines

Firing order: l-3-4-2

Distributor rotation: Counterclockwise 7923392: :ig. 34 2.OL (4663) SOHC engine

‘iring order: l-3-4-2

Distributor rotation: Clockwise